High molecular waste pyrolysis catalysis conical rotary reaction kettle

A technology of pyrolysis catalysis and reactor, applied in chemical/physical/physical chemical mobile reactors, plastic recycling, recycling technology, etc., can solve the problems of large investment, instability, high energy consumption, etc., and achieve increased heating area, increase the overall stiffness, and eliminate the effect of coking environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

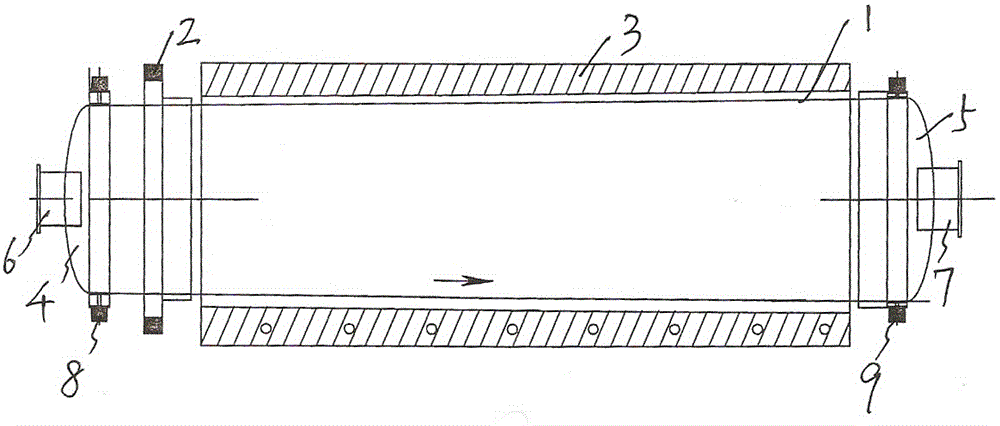

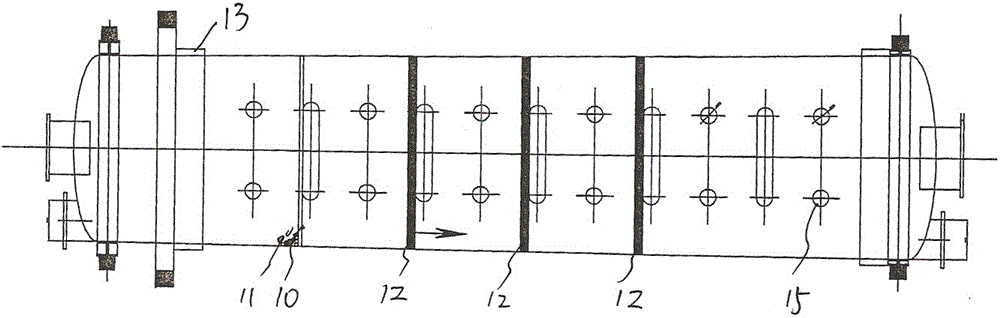

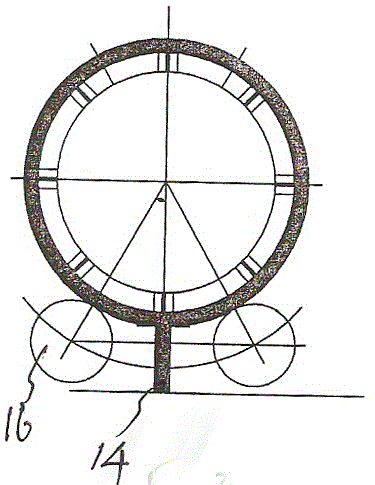

[0026] A pyrolysis catalyzed cone rotary reaction kettle for polymer waste, comprising a rotary reaction kettle barrel 1, a rotary reaction kettle power large gear ring 2, the barrel is in a cone shape, and the small head is located at the inlet end and the big head is located at the outlet end; The heating furnace body 3 is sheathed outside the body, and there is a gap between the heating furnace body and the cylinder; the two ends of the cylinder are provided with spherical cap heads 4 and 5, and the two ends of the spherical cap are provided with an inlet pipe 6 and an outlet pipe 7 respectively; The two ends of the body are respectively provided with an entrance support roller 8 and an exit support roller 9 which are matched with the corresponding support rollers 16, and a radial grid 10 is provided in the front of the cylinder. A steel ball 11 with a diameter for ball milling is placed in front of the grid. , A plurality of catalyst discs 12 are arranged behind the grille, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com