Patents

Literature

62results about How to "Reduce manufacturing risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

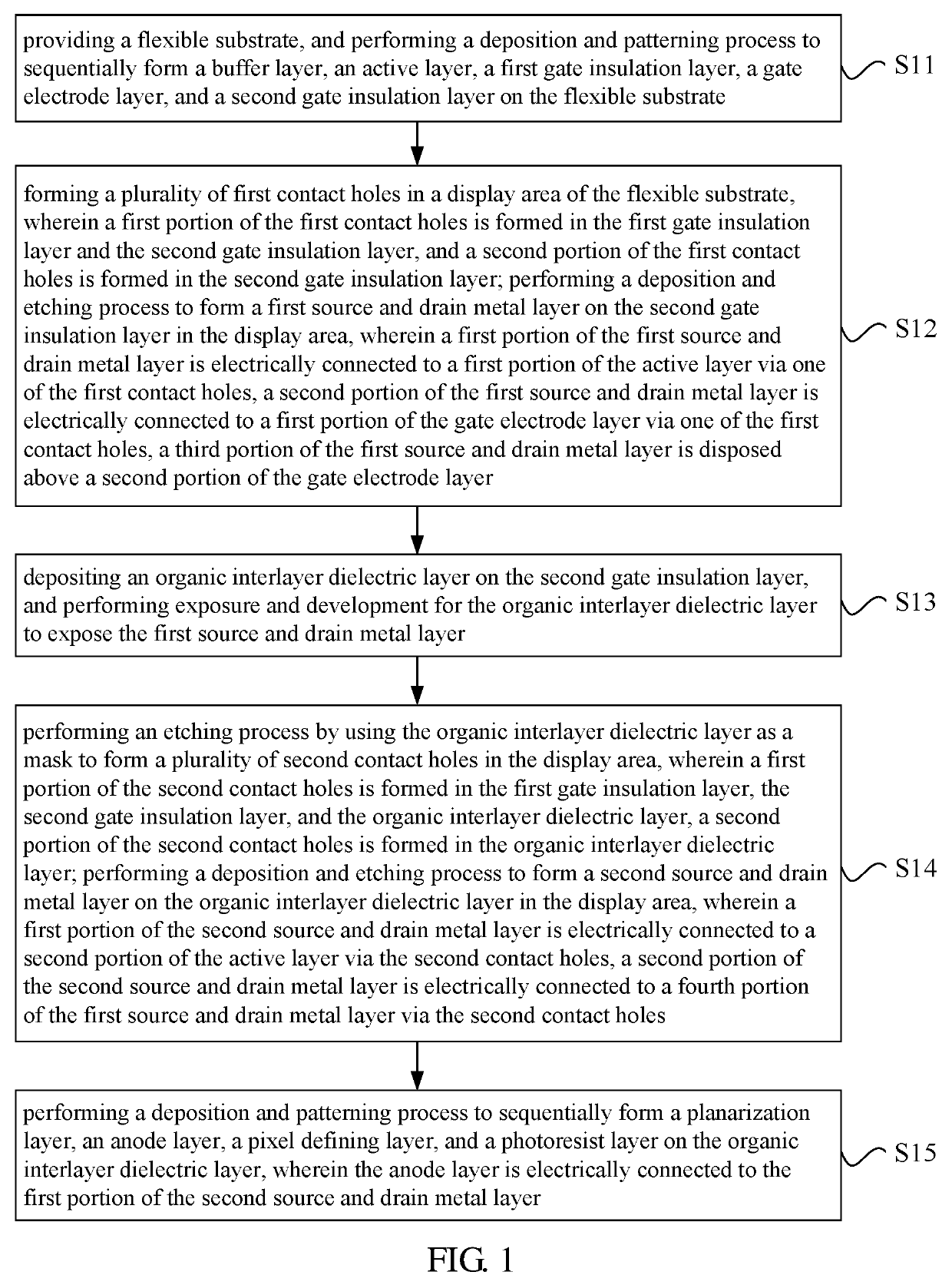

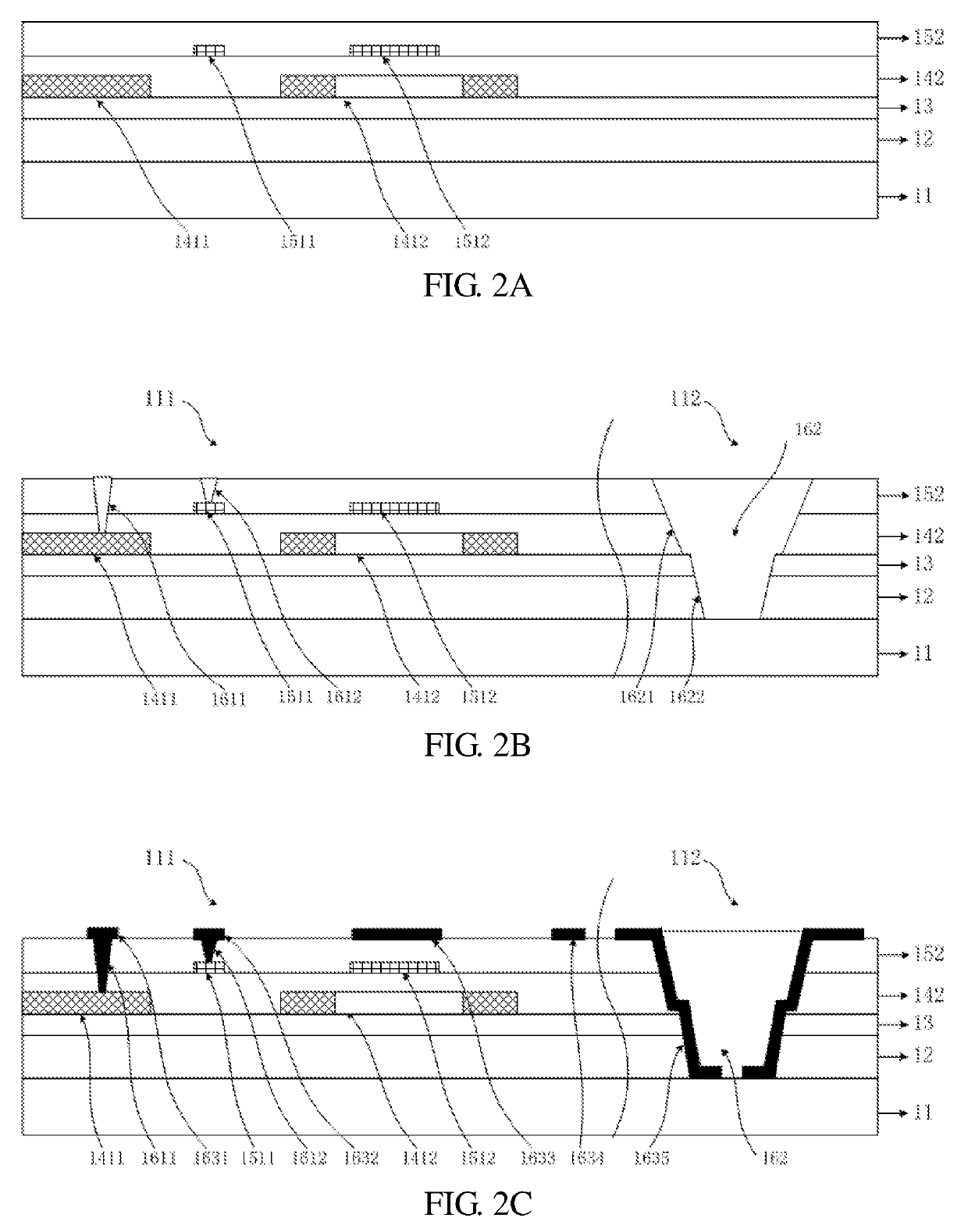

Flexible display panel and method for manufacturing same

ActiveUS20190259967A1Low hole densityGood bending propertiesStatic indicating devicesDigital data processing detailsEngineeringFlexible display

The present disclosure provides a flexible display panel and a method for manufacturing same. The present disclosure not only ensures improvement of bending characteristics of display panels but also ensures high pixels per inch (PPI) of the display panels. Moreover, IR-drop is lowered and display uniformity of the panels is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

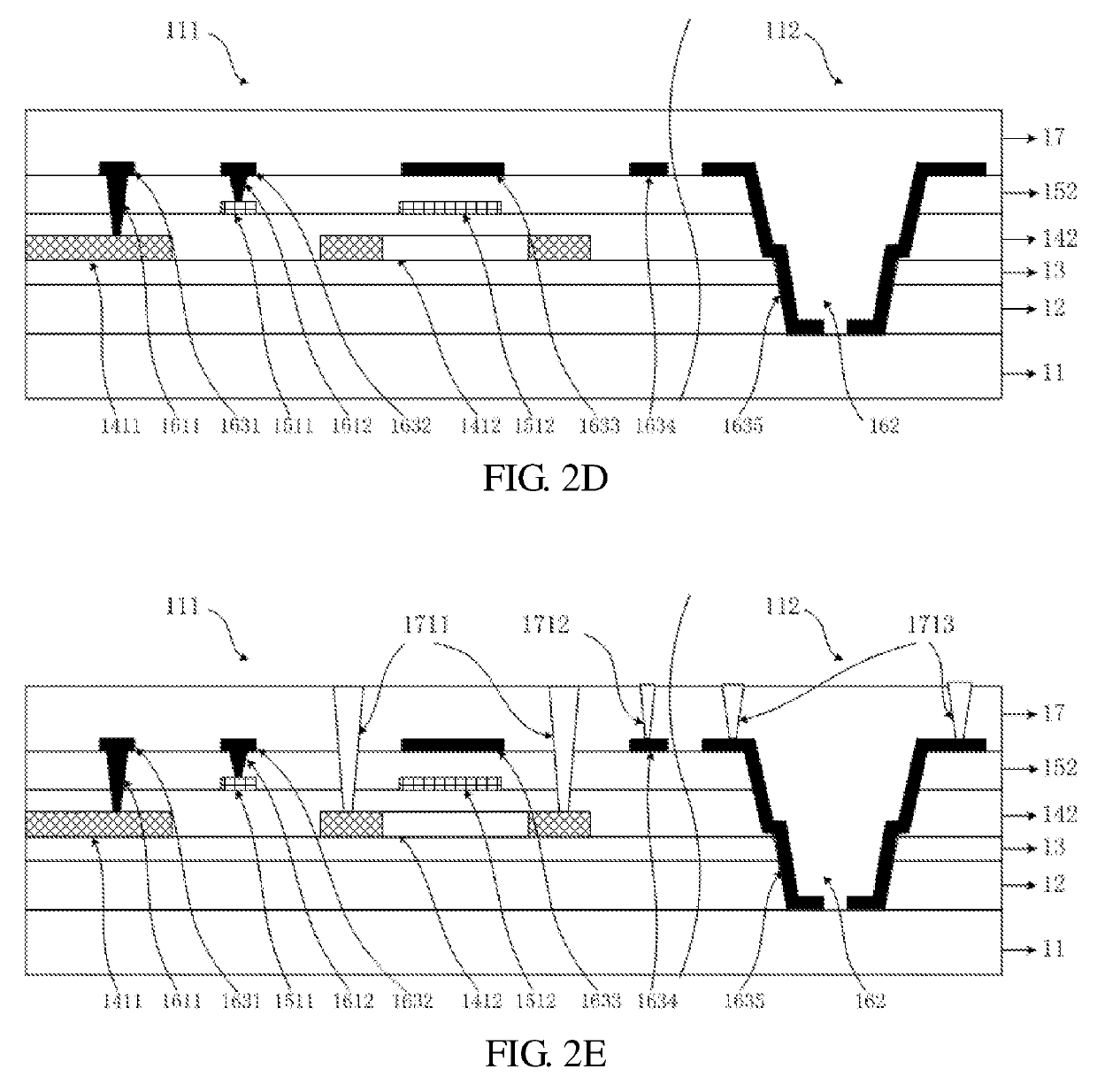

Flow controllable epoxy resin prepreg and preparation method thereof

A flow controllable epoxy resin prepreg and a preparation method thereof are disclosed. The preparation method comprises the following steps: individually preparing an epoxy resin component, a flow control component, and a curing component, adding the epoxy resin component and the curing component into the flow control component to prepare a flow controllable epoxy resin system with a viscosity more than 4 Pa.s, and finally compounding the system with an enhancing material so as to obtain the flow controllable expoxy resin prepreg; wherein the epoxy resin component can be single epoxy resin or a composition of multiple epoxy resins and accounts for 10 to 90% of the total weight of the system; the flow control component is a prepolymer or mixer of an epoxy resin modifier and epoxy resin and accounts for 5 to 60% of the total weight of the system, and the curing component is composed a single curing agent or a mixture of multiple curing agents or curing agents and promoters, and accounts for 2 to 30% of the total weight of the system. Through the provided flow controllable epoxy resin prepreg, the control modes of feeding pressurization and zero rubber absorption in the autoclave moulding engineering can be achieved, and thus the product quality is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

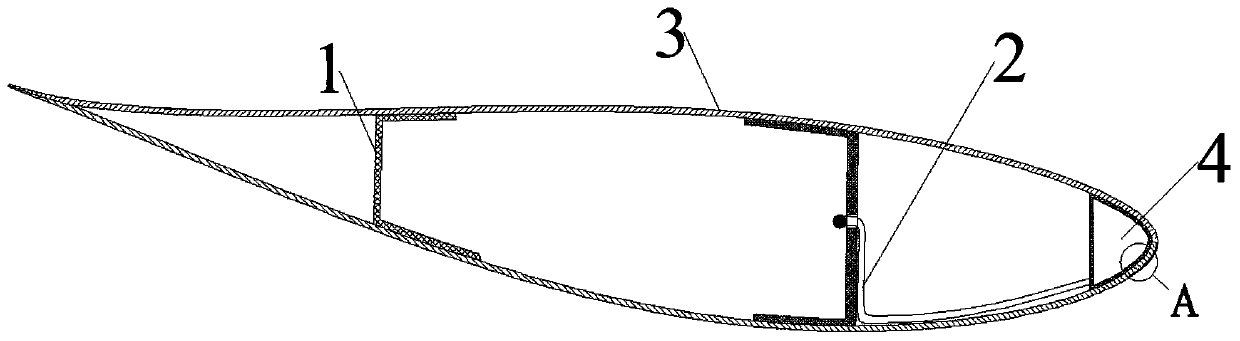

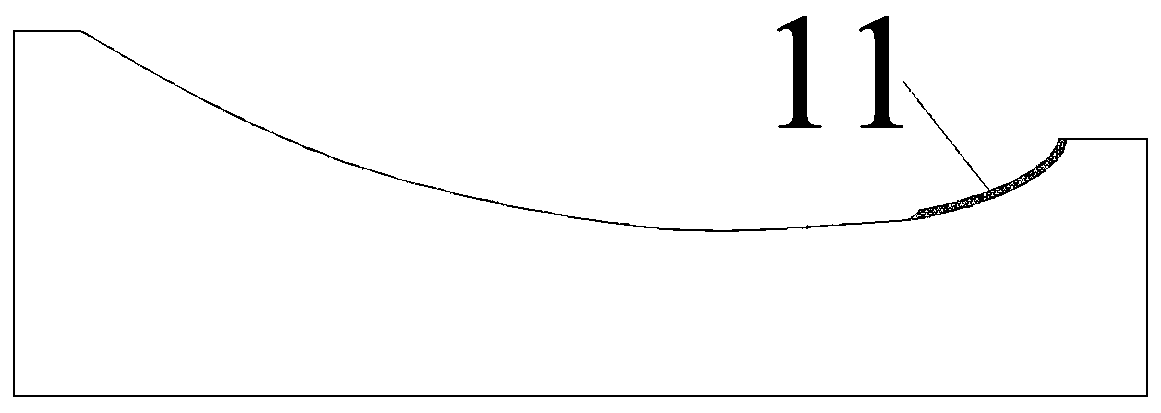

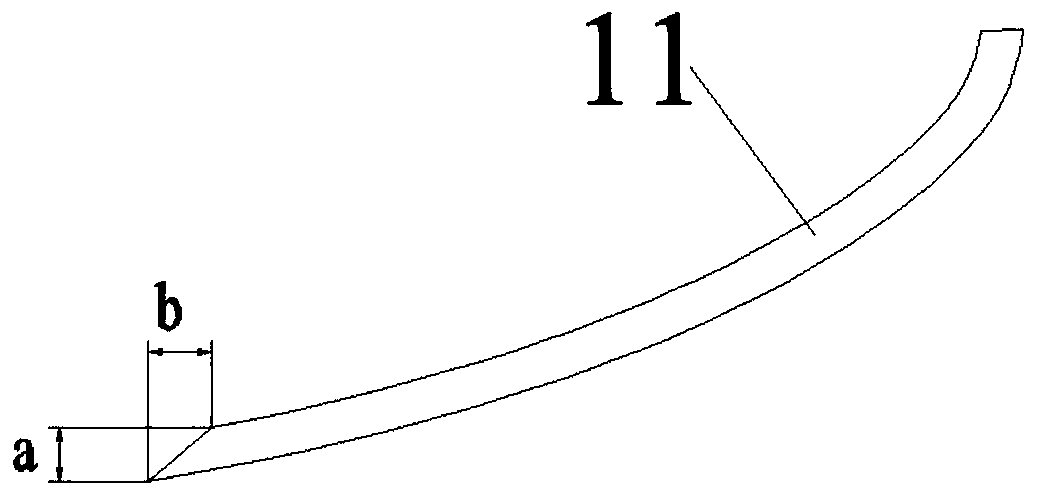

Making method of heavy gauge composite material main beam cap for fan blades

ActiveCN104325658ASolve efficiency problemsSolve the quality of workmanshipFinal product manufactureDomestic articlesState of artProcess quality

The invention discloses a making method of a heavy gauge composite material main beam cap for fan blades. The heavy gauge composite material main beam cap is made through a double-channel glue injection double face diversion improved vacuum adsorption technology. The problems of the making process efficiency and the process quality of the heavy gauge composite material main beam cap are effectively solved by controlling the paving dimensions of upper and lower diversion nets, and the resin glue injection sequences and other process parameters of corresponding glue injection tubes. Compared with the prior art, the method is in favor of realizing the process control of the making process of the heavy length and / or heavy thickness composite material main beam cap and reducing the making risk. The method can effectively reduce the requirements of the main beam cap making process on a matching resin system and a fabric structure form by designing the initial time and speed of resin perfusion of a fabric reinforced material layer in all directions, and is especially suitable for making heavy gauge carbon fiber fabric reinforced resin-based composite material main beam caps.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

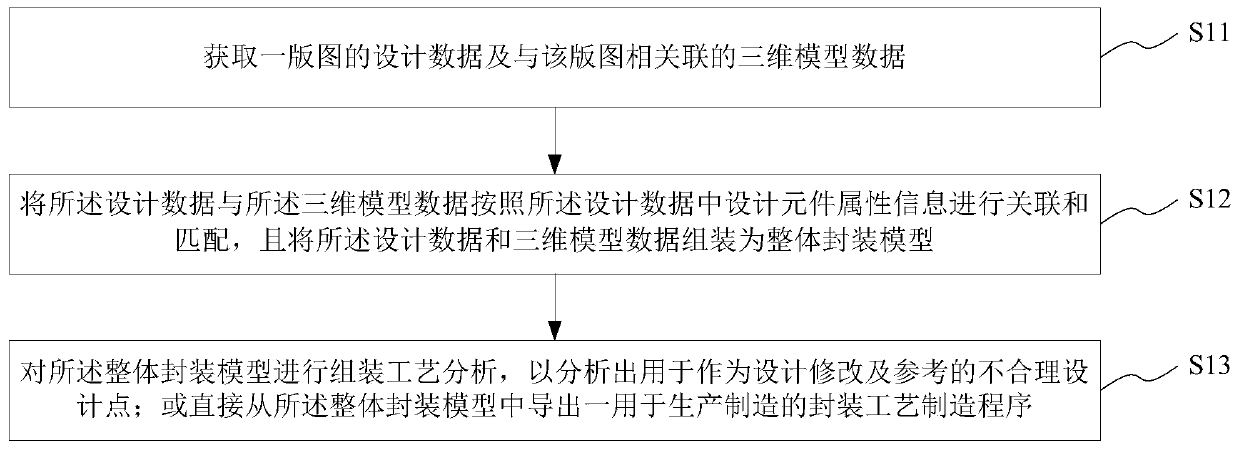

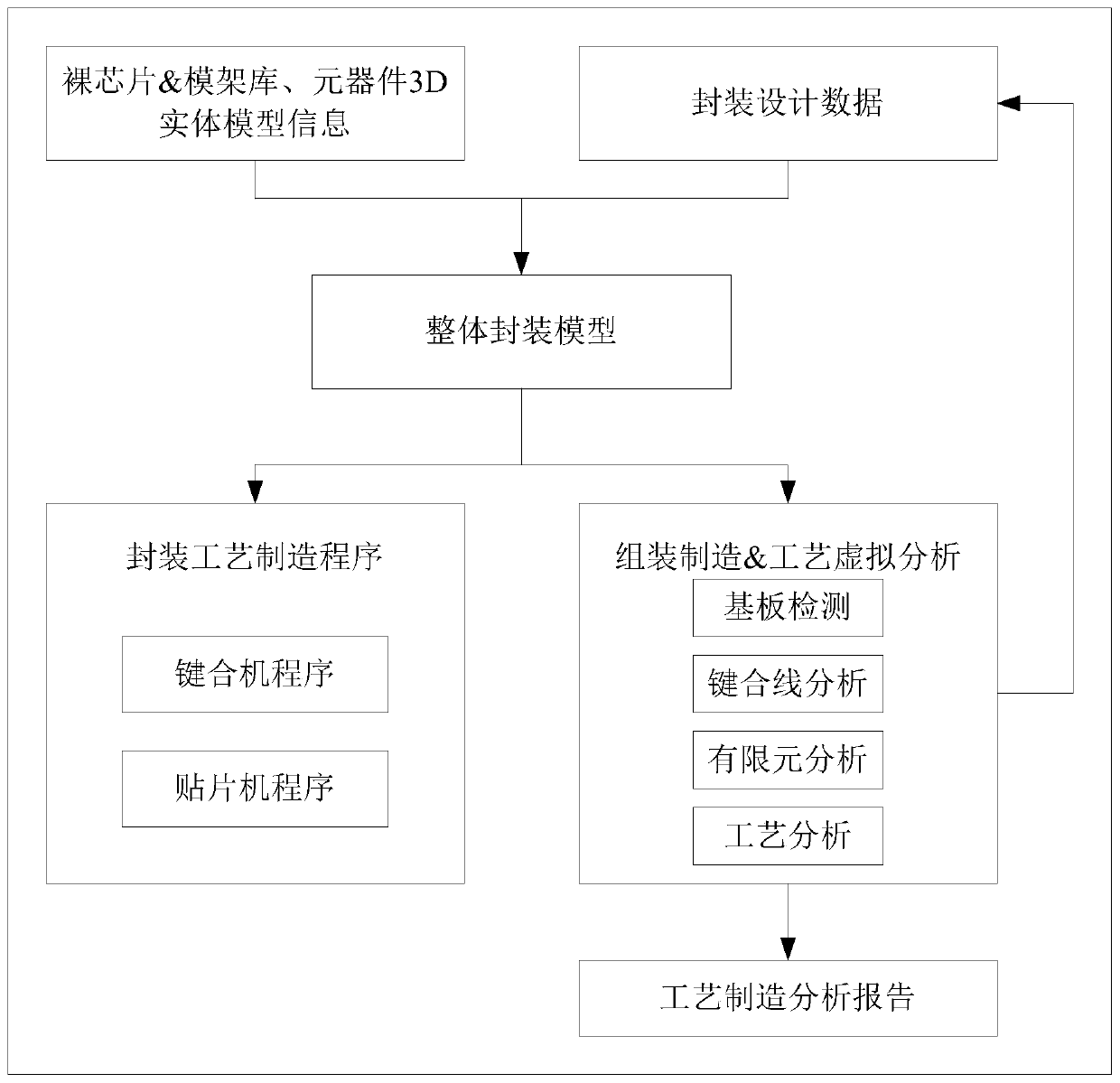

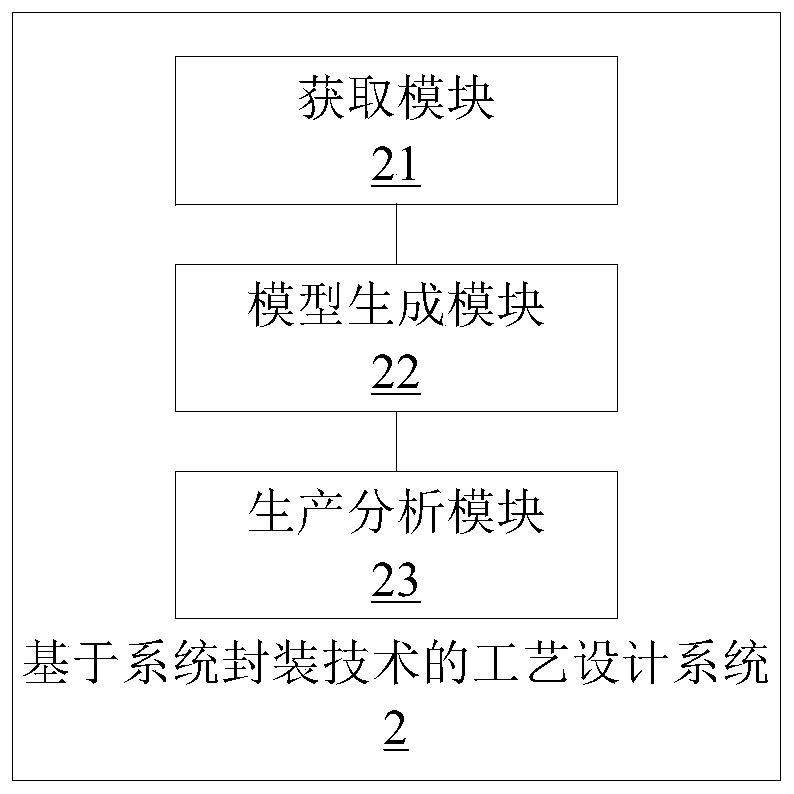

Process design method and system based on system packaging technology, medium and apparatus

ActiveCN110197019AShorten the timeEase of workConfiguration CADSpecial data processing applicationsProcess manufacturingProcess design

The invention provides a process design method and system based on a system packaging technology, a medium and an apparatus. The process design method based on the system packaging technology comprises the following steps of acquiring the design data of a layout and the three-dimensional model data associated with the layout; associating and matching the design data and the three-dimensional modeldata according to the design element attribute information in the design data, and assembling the design data and the three-dimensional model data into an integral packaging model; performing assembly process analysis on the integral packaging model to analyze unreasonable design points used as design modification and reference; or directly exporting a packaging process manufacturing procedure for production and manufacturing from the integral packaging model. According to the method, more repeated work can be removed, the manual work is replaced with automation, and compared with an originalmethod, the method saves 60%-80% of the time, and meanwhile, the working difficulty is reduced, and the process from design to simulation and production manufacturing is simplified, so that the competitiveness of an electronic product is greatly improved.

Owner:VAYO SHANGHAI TECH

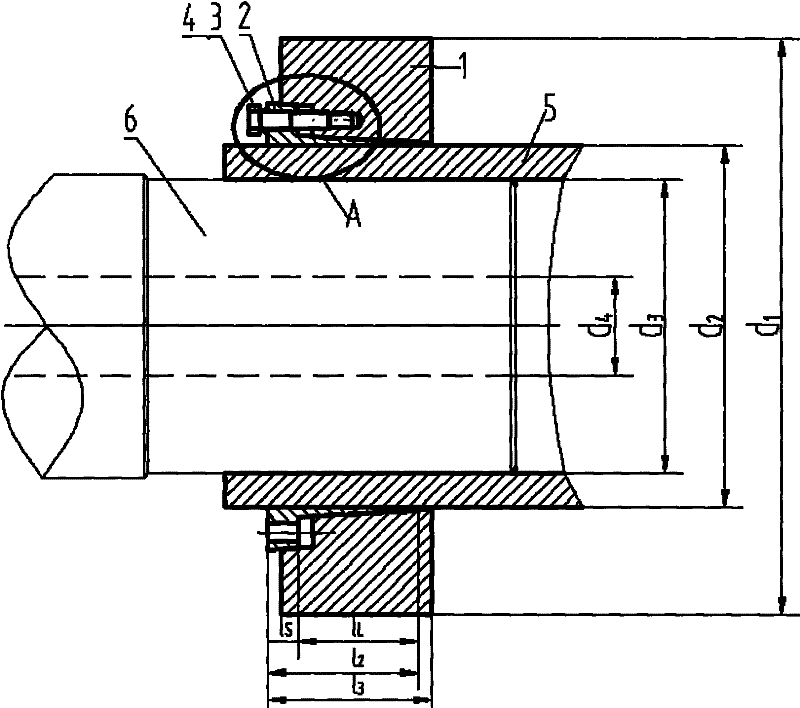

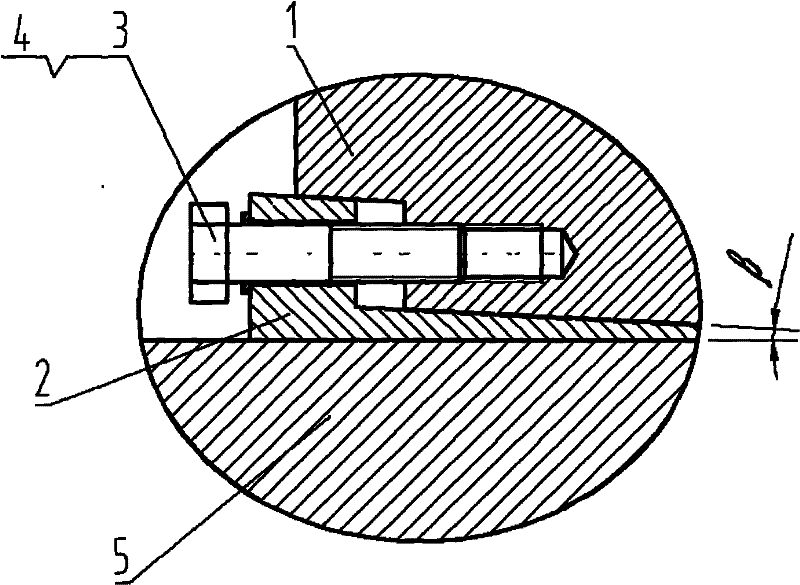

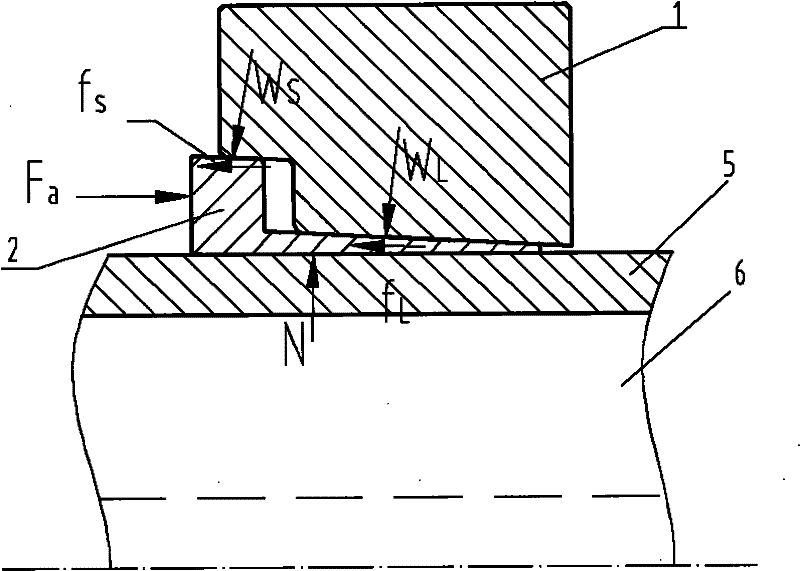

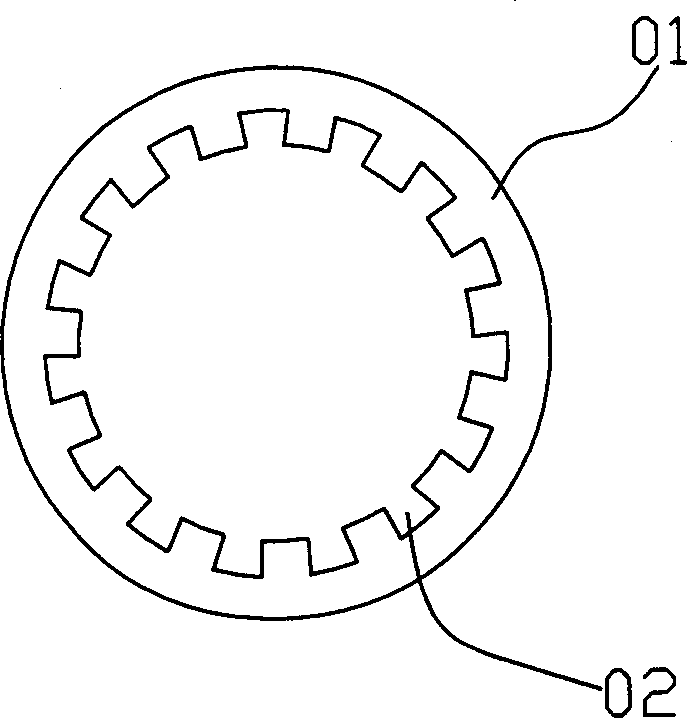

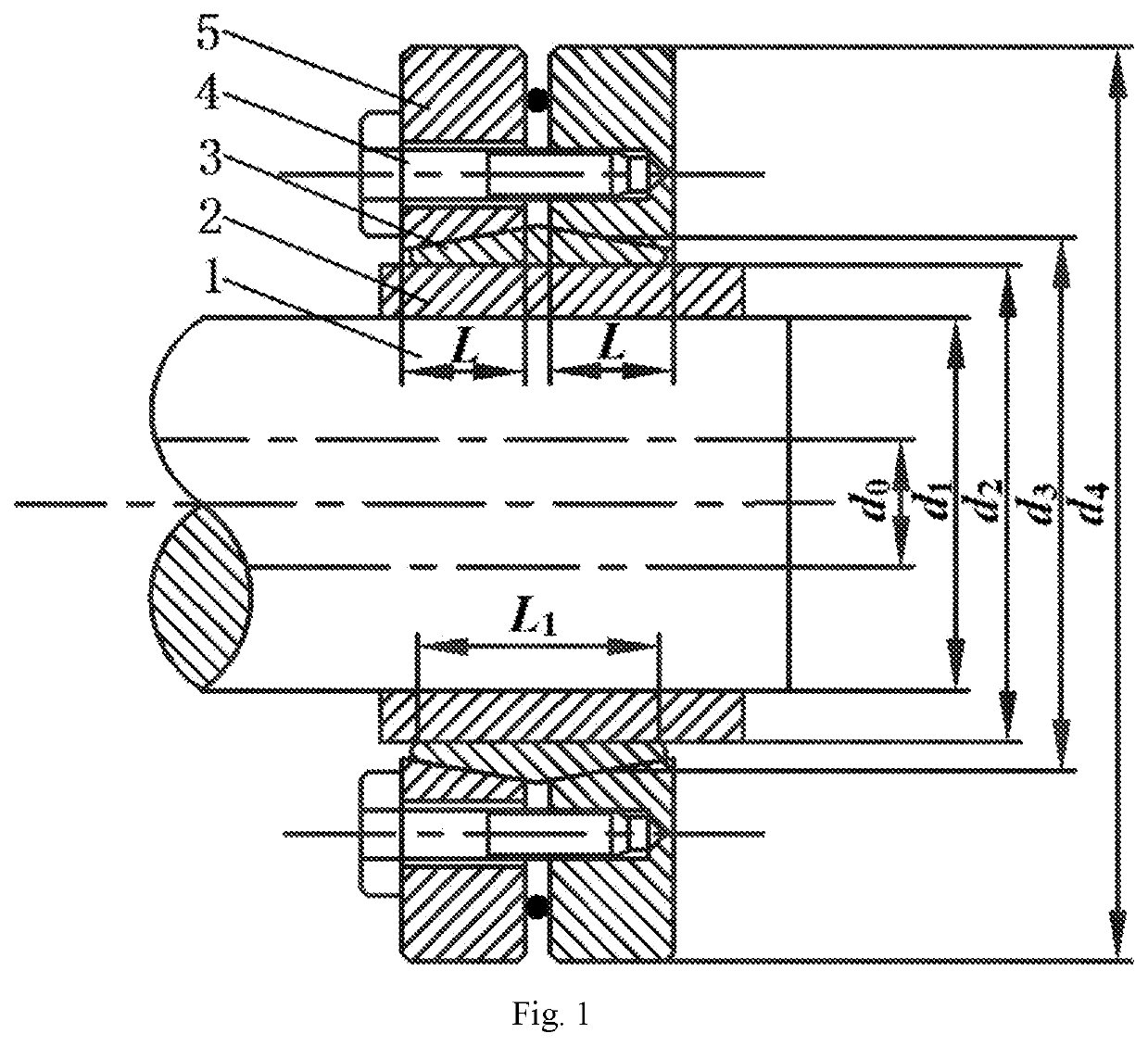

Method for checking intensity of wind power locking disk

InactiveCN102298656AVerify rationalityReduce manufacturing riskSpecial data processing applicationsElectricityMaximum torque

The invention discloses a method for checking the intensity of a wind power locking disk, belonging to the field of design of wind power generating equipment. The method comprises the following checking steps of: (1) computing the positive pressure of each conical contact surface between an outer sleeve and an inner ring; (2) computing the pressure intensity and interference magnitude of each conical contact surface between the outer sleeve and the inner ring after a bolt is screwed and ensuring the maximum pressure intensity and interference magnitude on the premise of ensuring that each component is not deformed plastically; (3) computing the pressure intensity and interference magnitude of a contact surface between the inner ring and a shaft sleeve after a bolt is screwed and ensuring the maximum pressure intensity and interference magnitude on the premise of ensuring that each component is not deformed plastically; (4) computing the pressure intensity and interference magnitude ofa contact surface between a shaft sleeve and a main shaft after a bolt is screwed and ensuring the maximum pressure intensity and interference magnitude on the premise of ensuring that each componentis not deformed plastically; and (5) computing the maximum torque which can be transferred by the contact surface between the main shaft and the shaft sleeve. According to the method, plastic deformation of each component material and the capabilities of the shaft sleeve and the main shaft for transferring a rated torque after the wind power locking disk is locked can be verified, the rationalityof the design size of the locking disk can be verified effectively, the manufacturing risk is lowered, and the product yield is increased.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

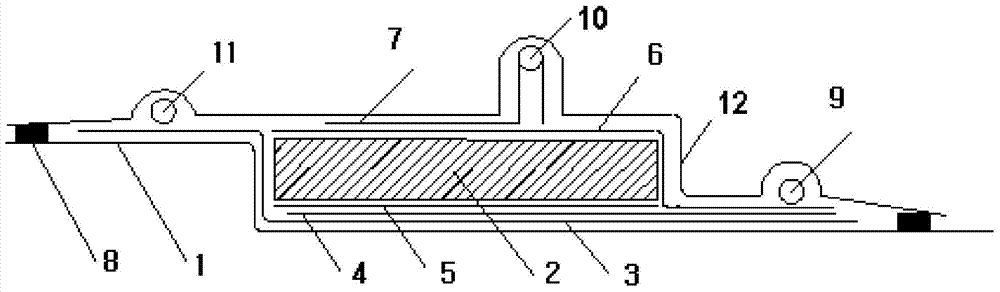

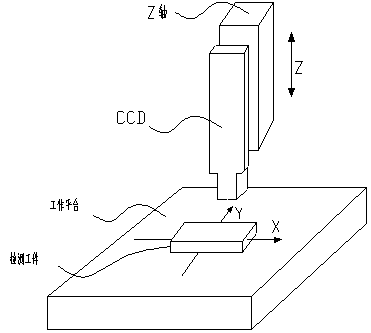

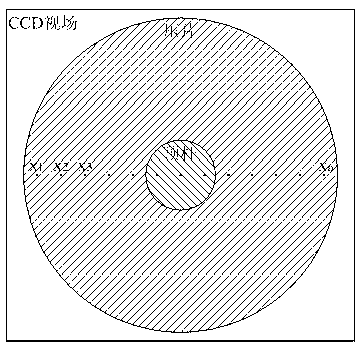

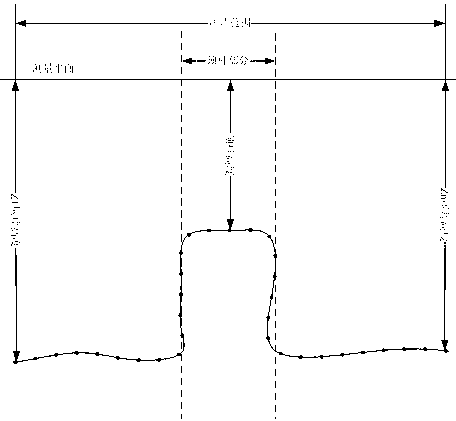

Visual detection device for press fitting sheet of engine cylinder locking plate

InactiveCN103217103AEasy to identifyAvoid negligenceUsing optical meansMetal working apparatusEngineeringEngine valve

The invention discloses a visual detection device for a press fitting sheet of an engine cylinder locking plate. The visual detection device for the press fitting sheet of the engine cylinder locking plate comprises a movable working platform, a detection head component and a controlling detecting system, wherein the movable working platform is used for containing installation components of engine valves to be detected, the platform can move horizontally on an X-axis and a Y-axis, the detection head component comprises a high-precision charge coupled device (CCD) and a prime lens, and the controlling detecting system comprises an X-axis, Y-axis and Z-axis movement control system and an identification system. The visual detection device for the press fitting sheet of the engine cylinder locking plate detects problems that a locking plate leaks pressure and press fitting is not in place after an automatic press fitting device of a cylinder cover split-assembling line locking plate is used, can avoid negligence and omissions caused by human factors, improves identification capability of press fitting defects, and reduces manufacturing risks. Meanwhile detection with equipment can quantify detection standards, solidify detection means, and guarantee stability and reliability of quality of products.

Owner:KUNSHAN THETA MICRO

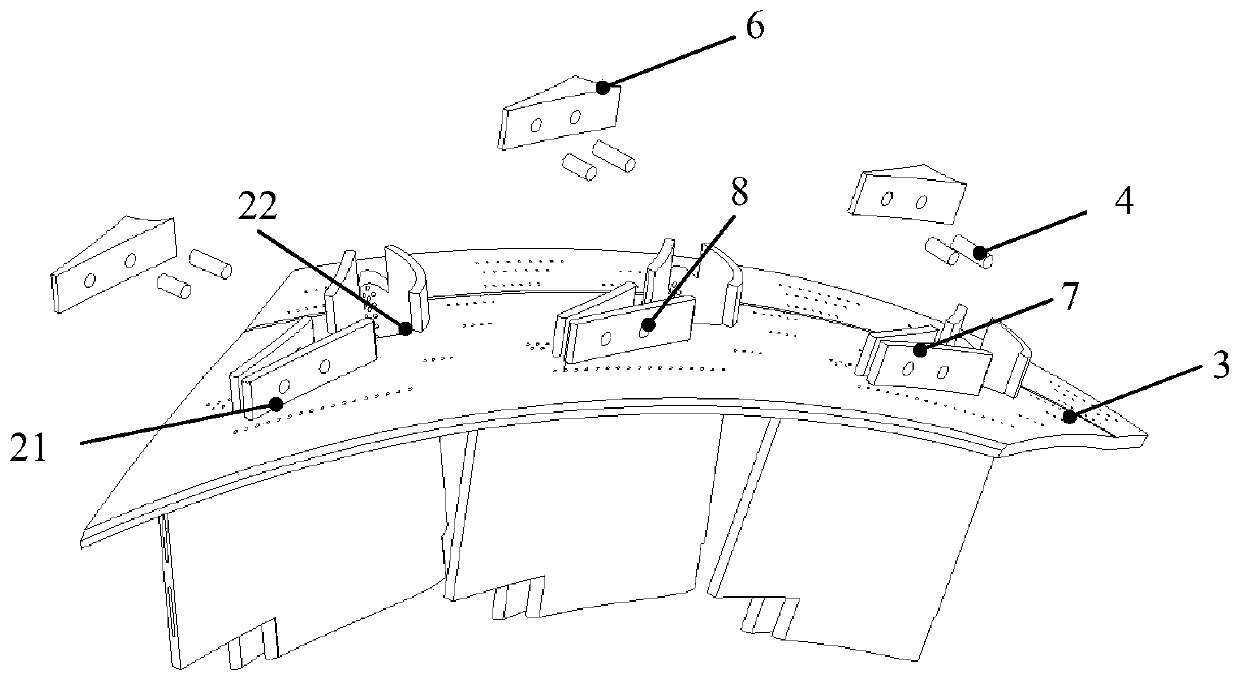

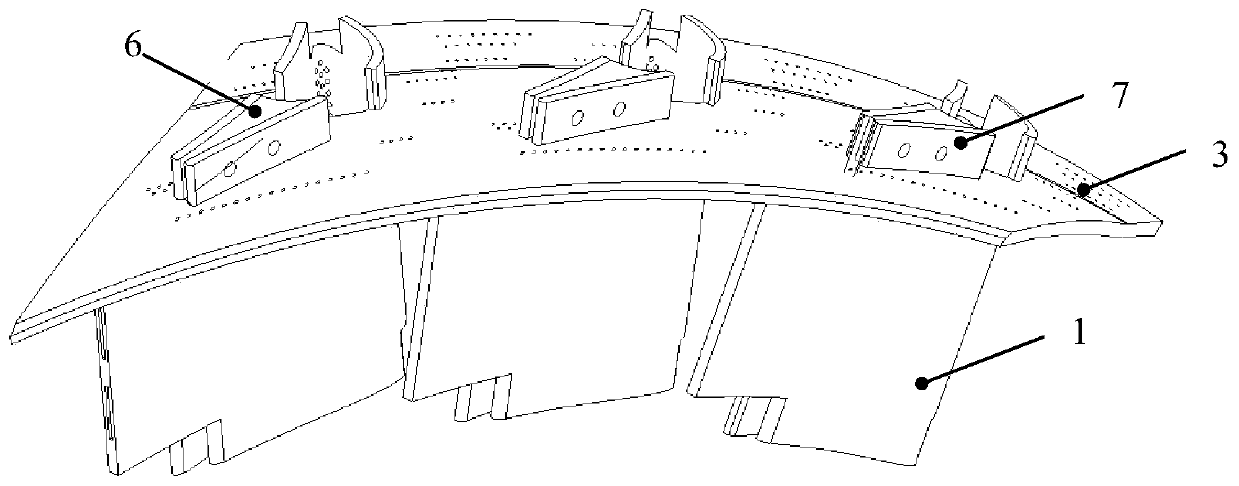

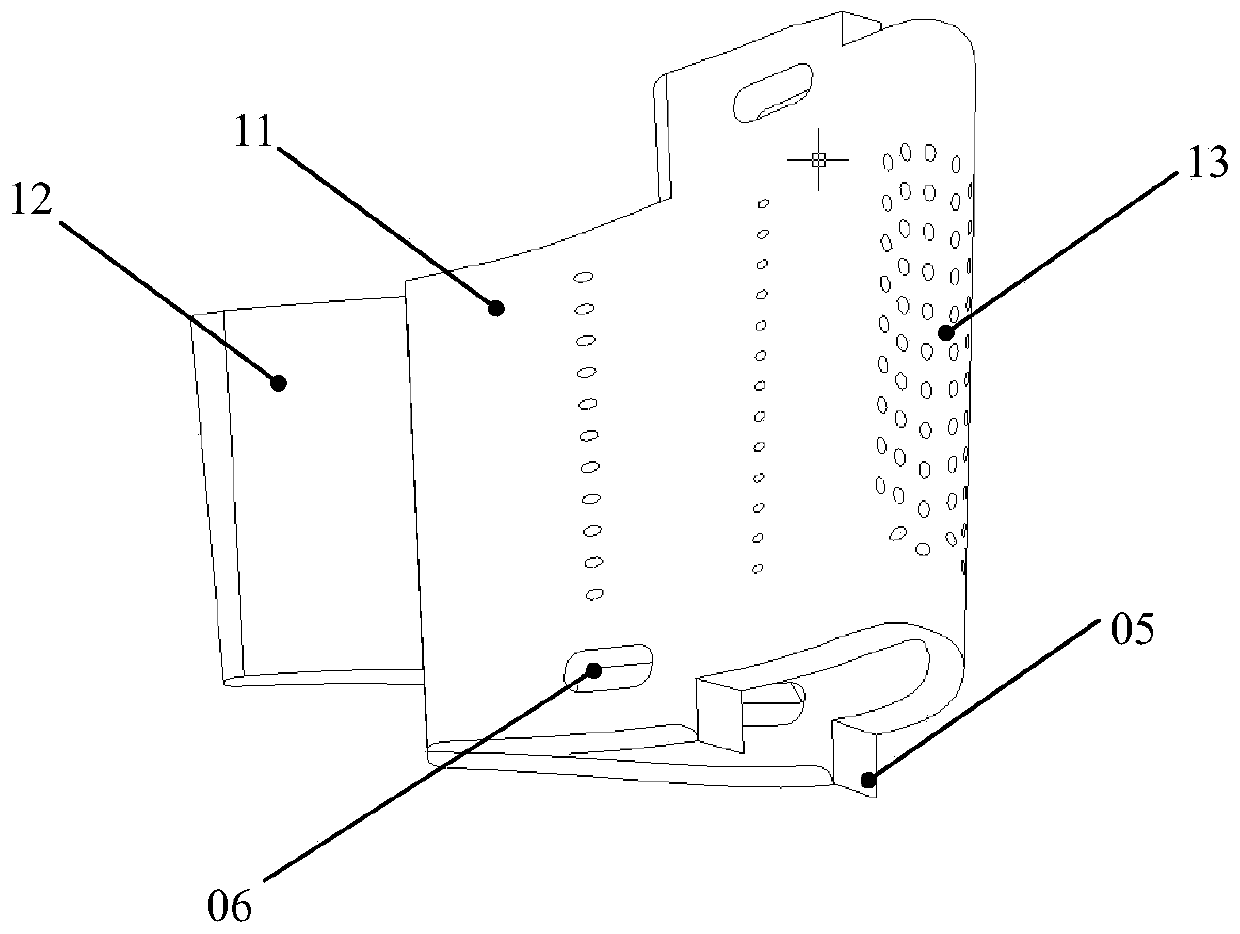

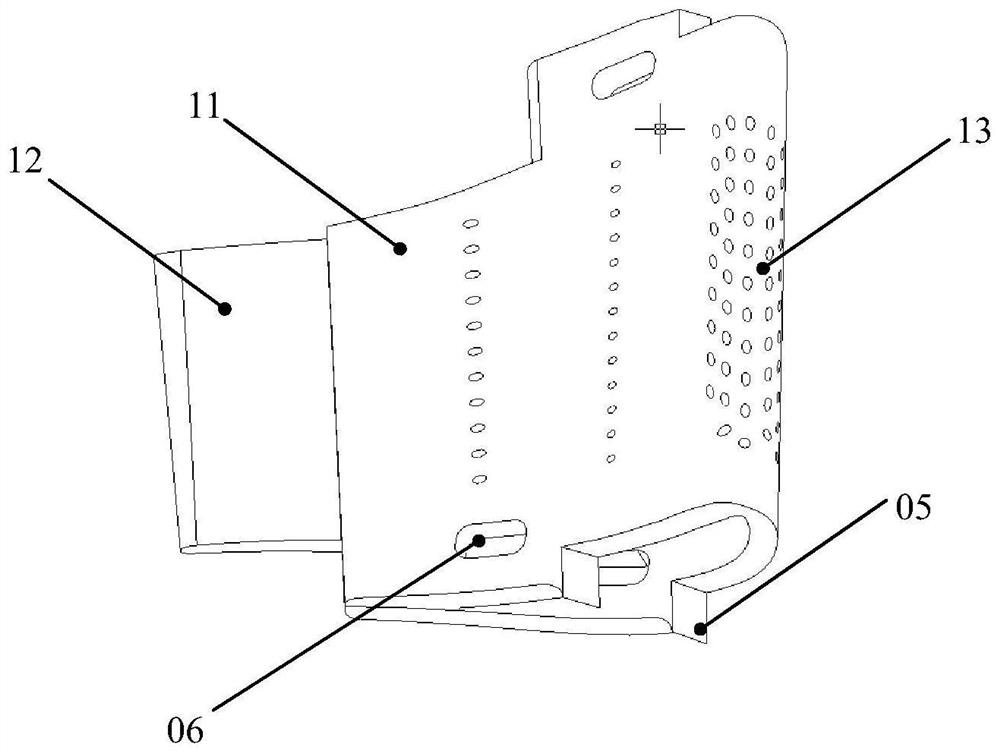

Aero-engine ceramic matrix composite fixation guider blade structure and molding method thereof

ActiveCN110966049AAvoid the defects of insufficient strengthGood workmanshipStatorsMachines/enginesEngineeringTurbine

The invention belongs to the technical field of preparation of an aero-engine fixation guider, relates to an aero-engine ceramic matrix composite fixation guider blade structure and a molding method thereof, and is to overcome the structural defects that an existing CMC guider blade prefabricated body is unreasonable in design and poor in blade root strength. A turbine guider blade manufactured in an integrated assembly mode comprises multiple stages of guide blades, parts are integrally assembled in a riveting mode, and an assembly structure adopts a SiC ceramic matrix to achieve welding; aneffective space between an upper edge plate and an outer casing is fully utilized, the blade body and the upper edge plate are installed and positioned through limiting rivets and a limiting table, the SiC ceramic matrix is deposited on the whole product through the CVI technology, and integrated preparation is completed; by means of the structure, the complex SiC / SiC multi-connected high-pressure guide blade has good manufacturability, the edge plate and the blade are easier to manufacture and more reliable to install, and the dimensional precision of a final product is easier to guarantee;and the structure can be fully applied to medium-sized and large-sized engines and five-generation engines.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

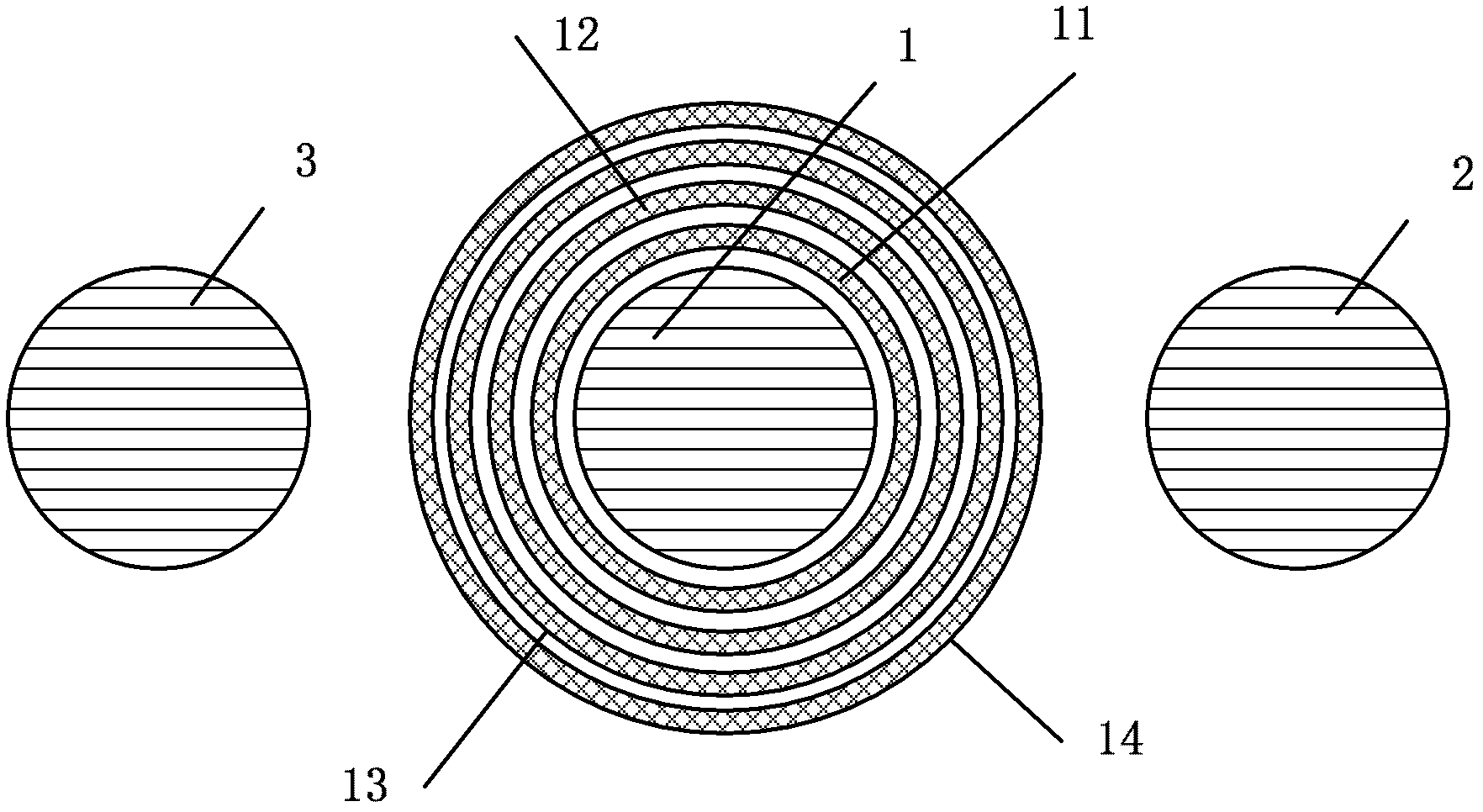

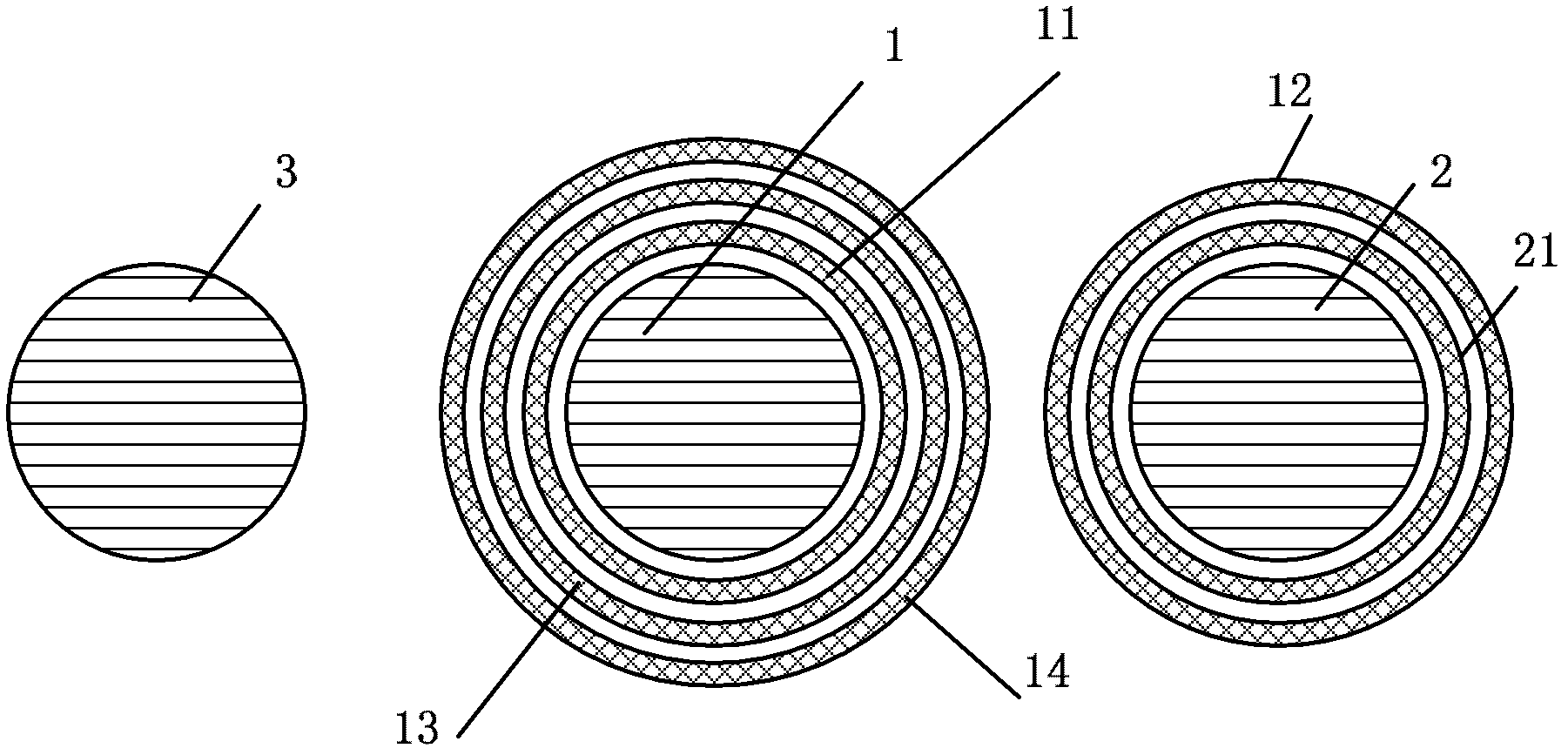

Single-phase transformer

ActiveCN102403106AEasy to windImprove operational reliabilityTransformers/inductances coils/windings/connectionsFixed transformersTransformerLow voltage

The invention discloses a single-phase transformer. The single-phase transformer comprises an iron core main column, a first iron core side column and a second iron core side column, wherein a low-voltage coil, a medium-voltage coil and a high-voltage coil are sleeved on the iron core main column from the inside to the outside in turn; an excitation coil and a voltage regulation coil are sleeved on the first iron core side column from the inside to the outside in turn; and the excitation coil is connected with the medium-voltage coil sleeved on the iron core main column in parallel in order to regulate the voltage of the voltage regulation coil. By sleeving the voltage regulation coil on the first iron core side column, the coil is convenient to wind, manufacturing risks are reduced, the operation reliability of the transformer is improved, and the overall width of the transformer is effectively reduced.

Owner:STATE GRID CORP OF CHINA

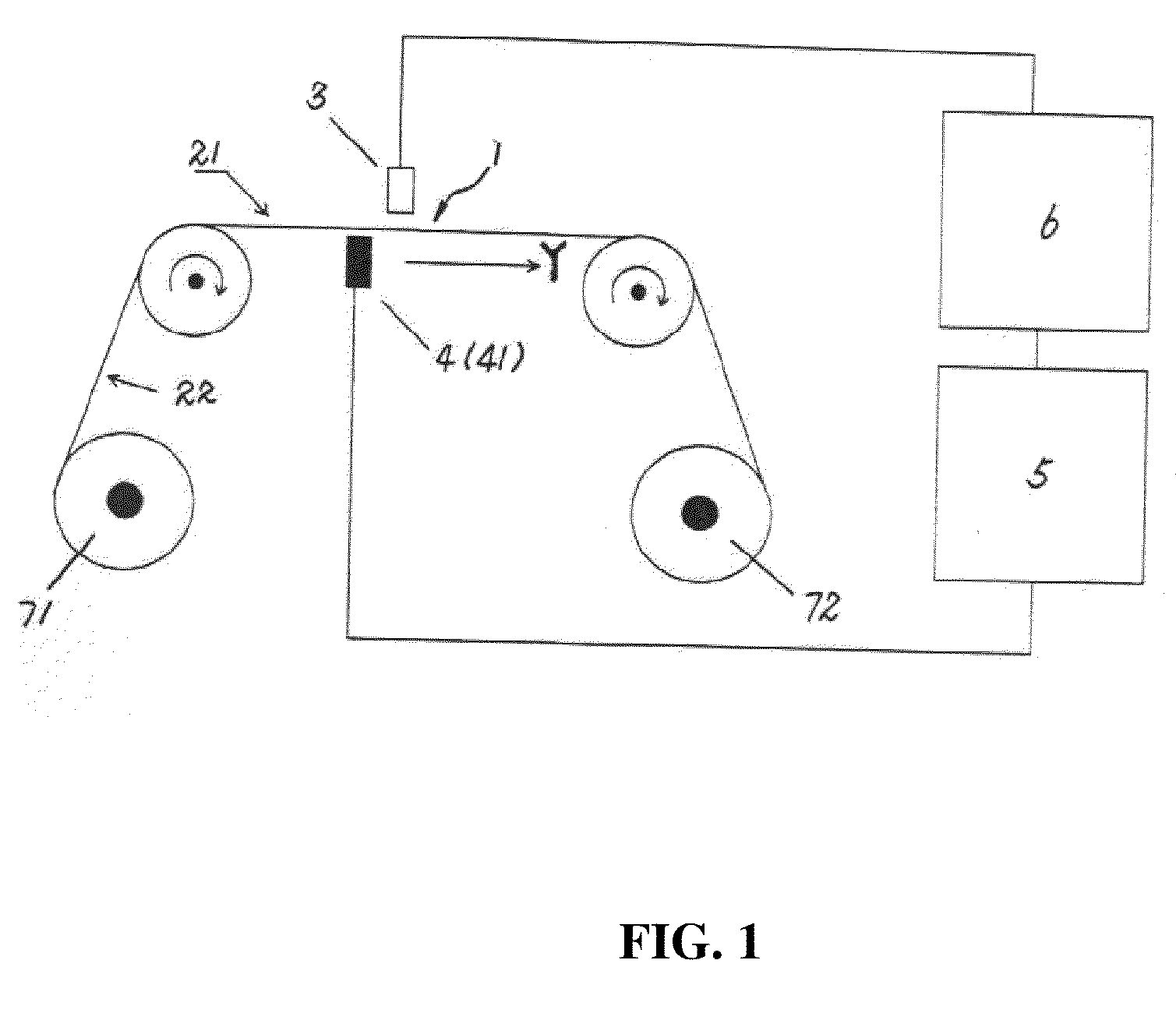

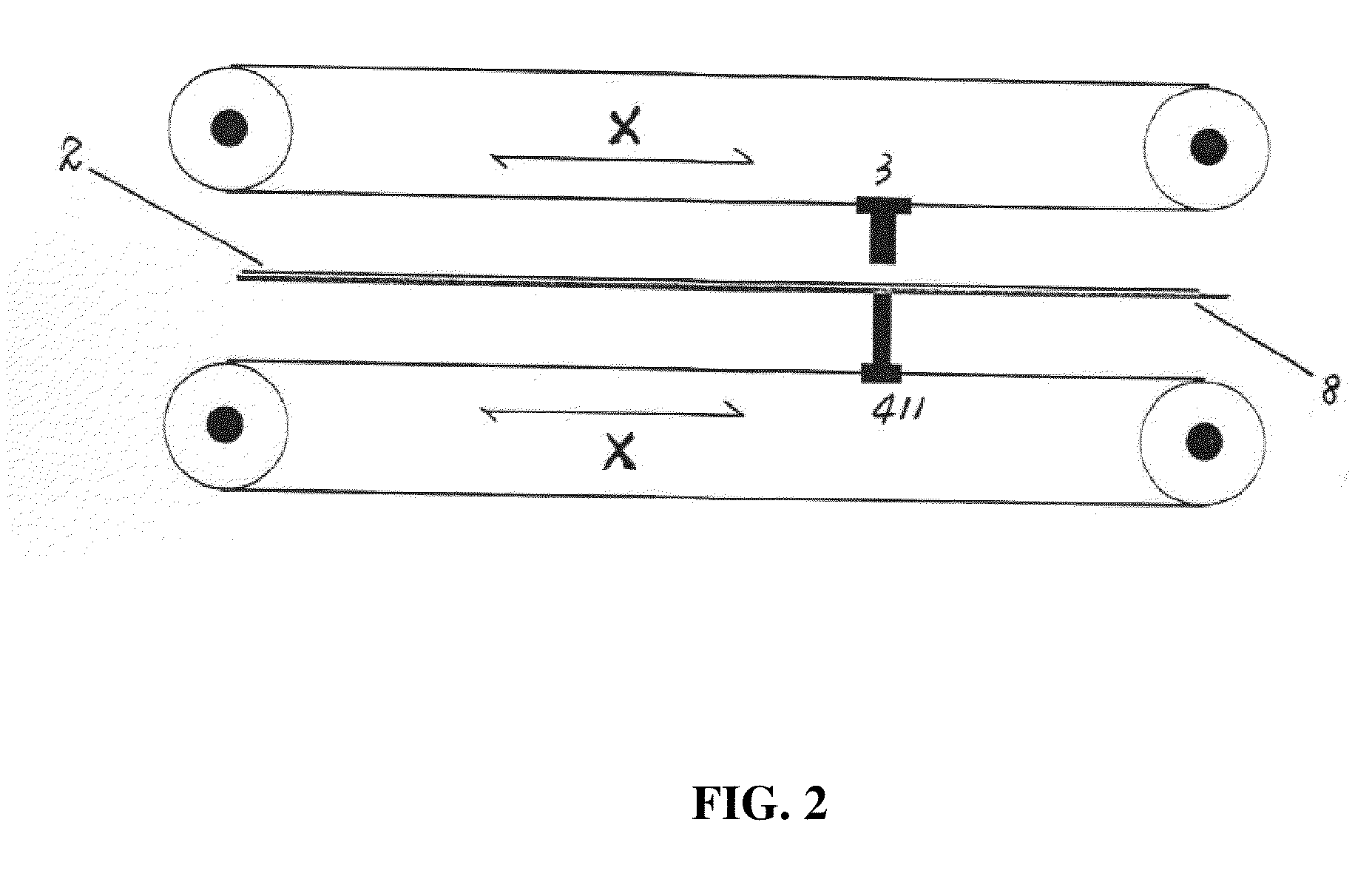

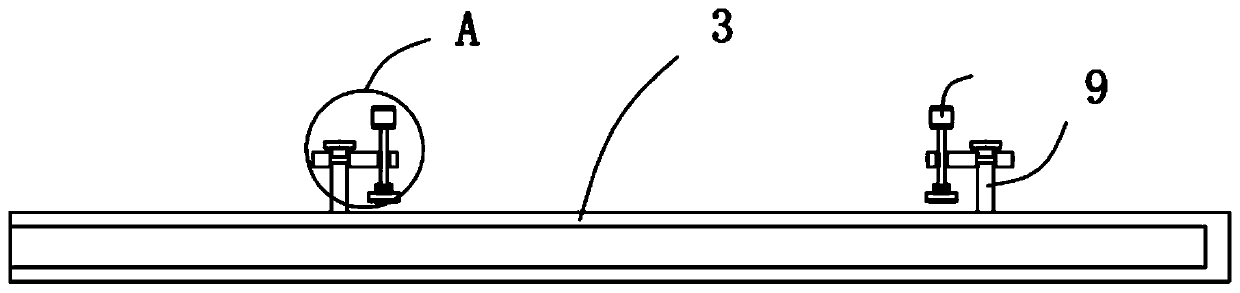

Process and apparatus for double-face ink-printing canvases for advertising light boxes

InactiveUS20090284776A1Easy maintenanceLow costDigitally marking record carriersDigital computer detailsEngineeringTime series processing

The present invention provides a process and apparatus for double-face ink-printing canvases for advertising light boxes. The process includes: disposing a print head at a side of an ink print workbench, an unprinted face of a reverse side of the canvas facing to the print head; disposing an inductor at the other side of the ink print workbench, a printed face of an obverse side of the canvas facing to the inductor; collecting image data of the printed face by the inductor during conveying the canvas and transmitting the image data to a signal processing device to process, and after time sequence processing, determining print positions on the unprinted face depending on results of the processing; and driving the print head to print on the determined print positions on the unprinted face by a print driving device, for achieving the double-faced ink print on the canvas for the advertising light boxes.

Owner:SHI GANG

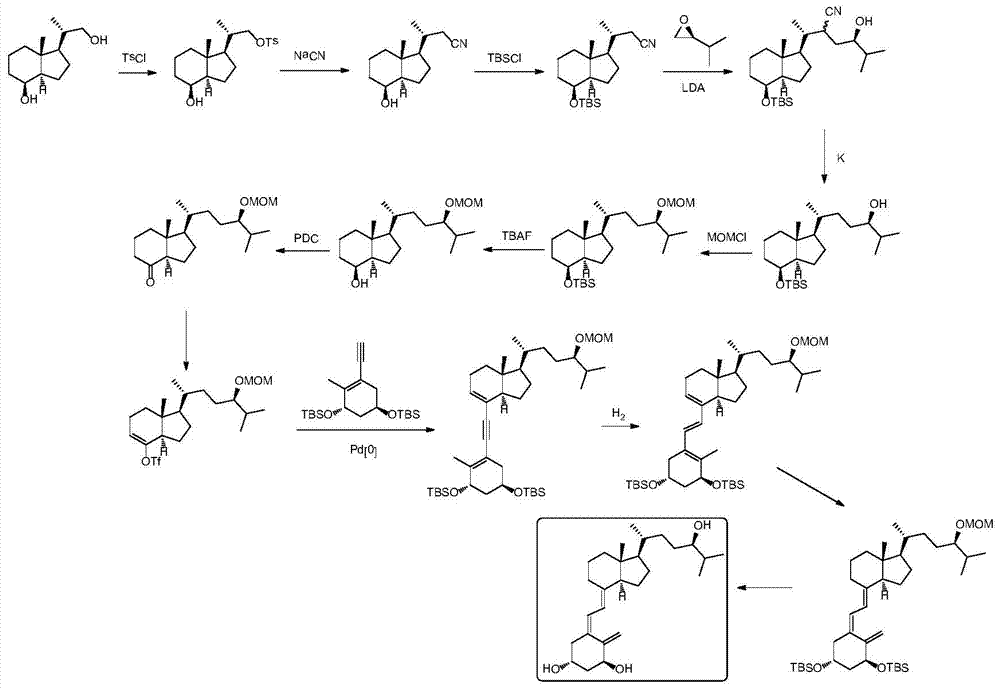

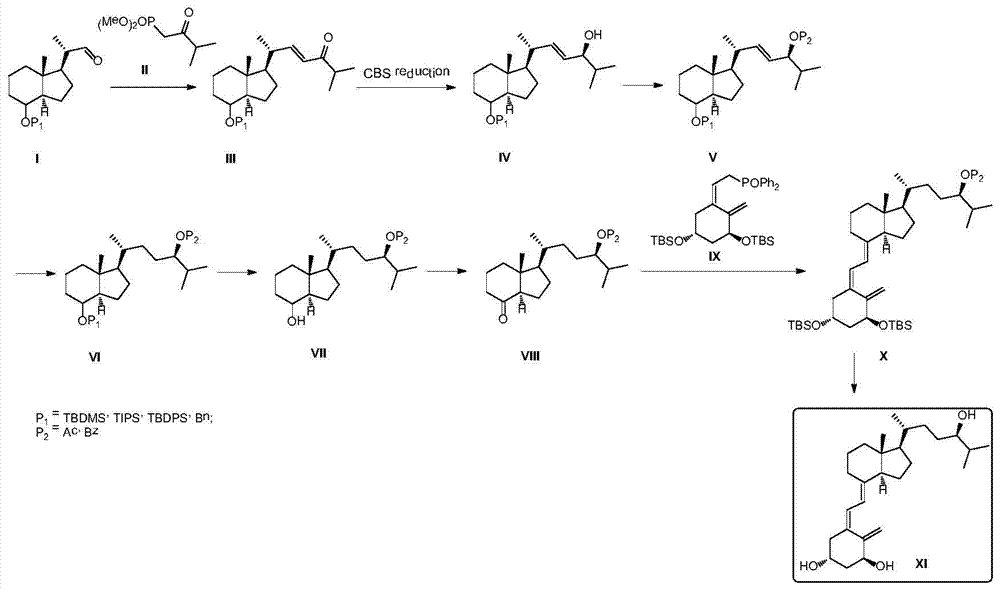

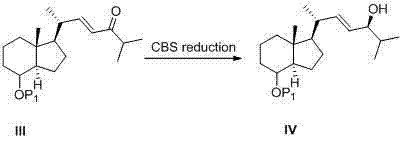

Method for preparing tacalcitol

ActiveCN104496871AEasy to scale up and scale up preparationEasy to scale upOrganic chemistryBulk chemical productionWittig reactionEther

The invention discloses a method for preparing tacalcitol. The method comprises the following steps: with a compound I as a starting raw material, carrying out Wittig reaction, CBS catalytic asymmetric reduction, hydroxy protection, hydrogenation reduction, desilication ether protection and oxidation reaction to prepare a compound VIII, carrying out Wittig Horner reaction on the compound VIII and a known compound IX for coupling, and carrying out dehydroxylation protection to obtain the target compound, namely tacalcitol. With cheap raw materials as the starting point, the method disclosed by the invention is simple, convenient and safe, steps unfavorable to amplification, such as illumination reaction and sodium amalgam reduction reaction, are avoided, and industrial production is facilitated.

Owner:SHANGHAI HAOYUAN MEDCHEMEXPRESS CO LTD +1

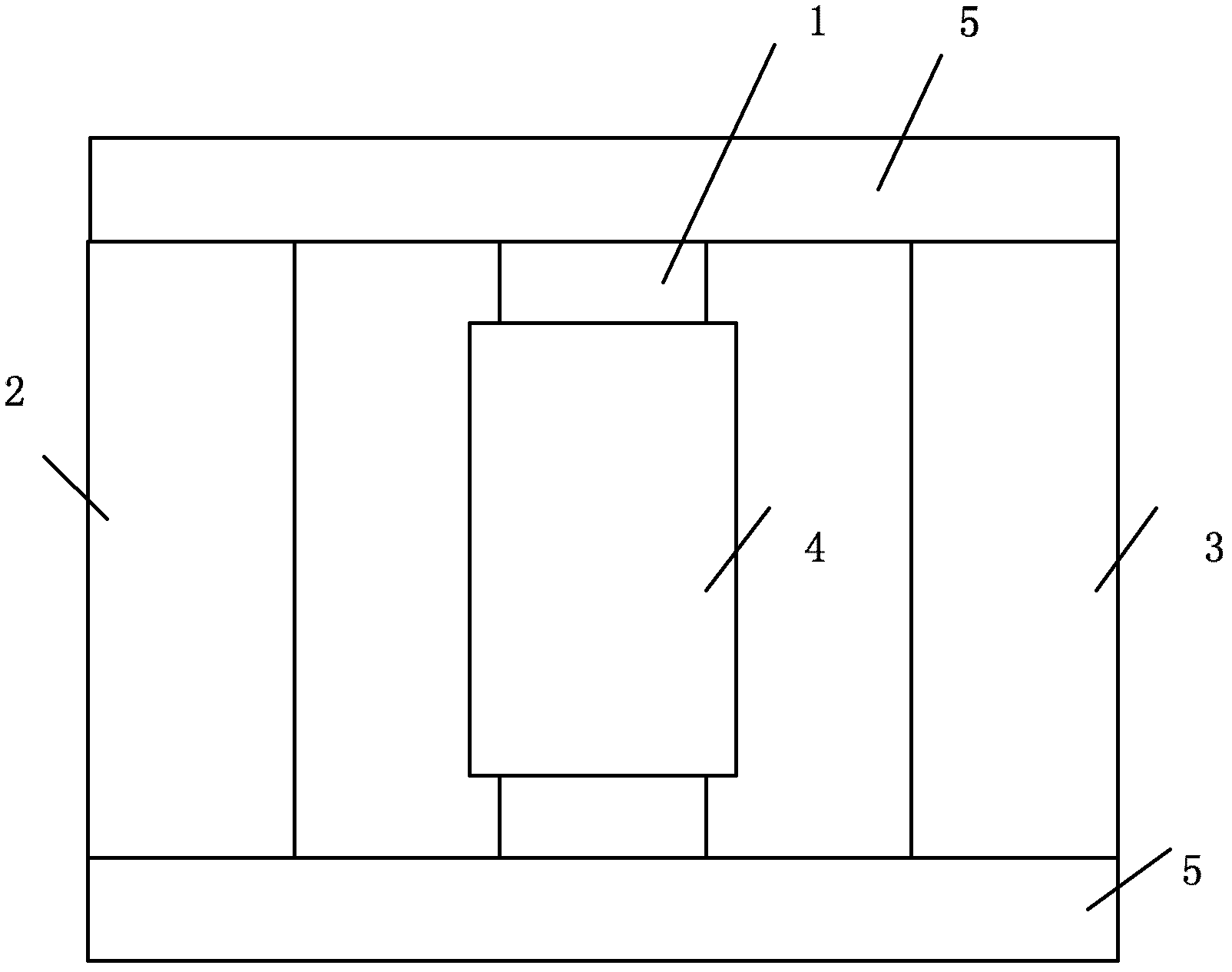

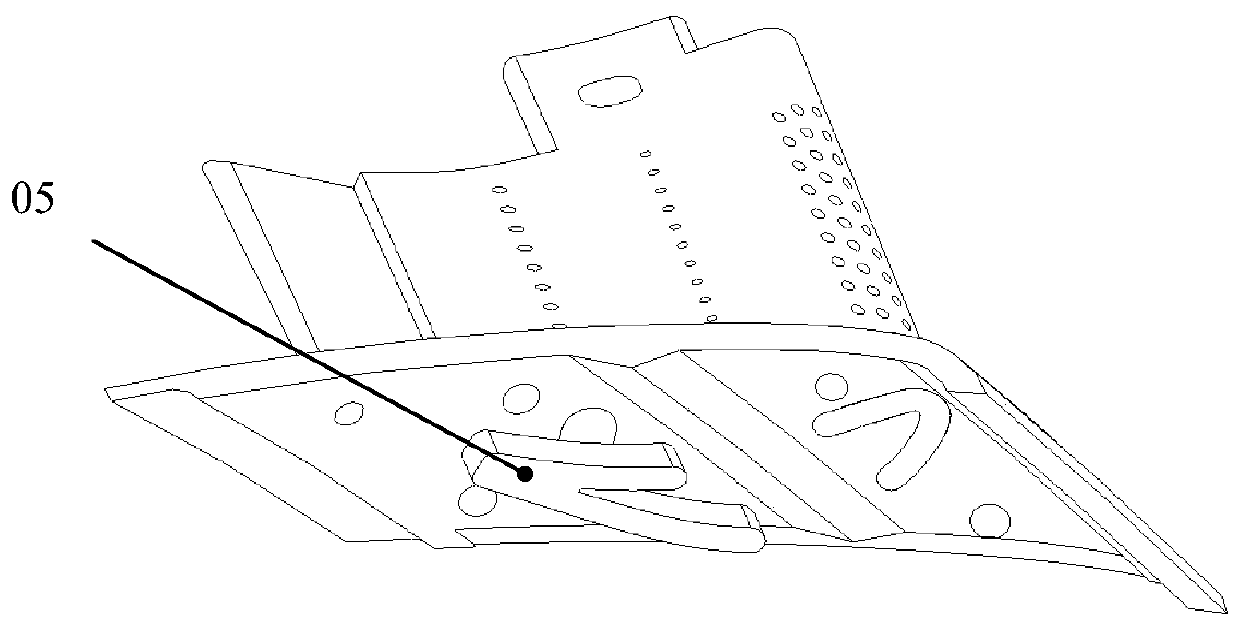

Conductor configuration system of wind power blade, wind power blade and preparing method thereof

ActiveCN109927318AResolve connectionSave operating spaceMachines/enginesWind energy generationElectricityShell molding

The invention discloses a conductor configuration system of a wind power blade. The system comprises a conductor containing fixing element and a conductor connected with a pre-embedded element on theouter surface of the wind power blade, the conductor containing fixing element and the conductor are arranged in a blade shell, the conductor is connected with the pre-embedded element through a through hole formed in the blade shell, the conductor containing fixing element is fixedly arranged in the through hole, and is provided with a penetrating-in hole used for allowing the conductor to penetrate in and a penetrating-out hole used for allowing the conductor to penetrate out, and the penetrating-out hole directly communicates with the through hole. The invention further provides the wind power blade and a preparing method of the wind power blade. According to the integral forming characteristics of a wind power blade vacuum guide-in molding forming process, the conductor configuration system is arranged in the wind power blade, and on the premise of ensuring the blade appearance, the connection problem of conductors inside and outside the shell can be solved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

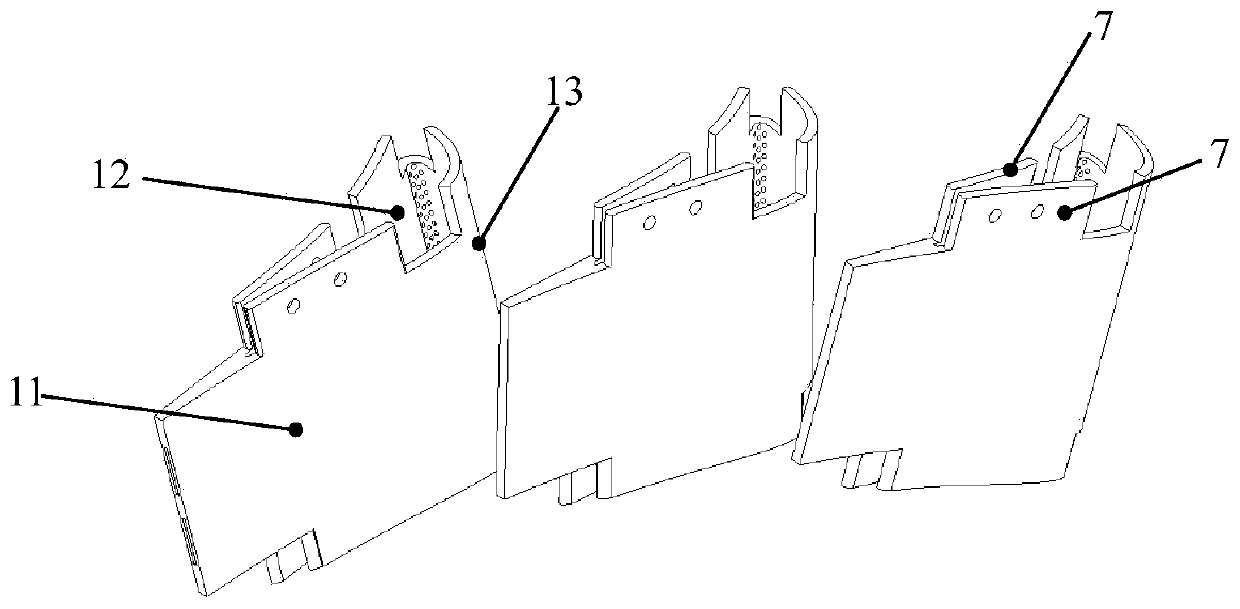

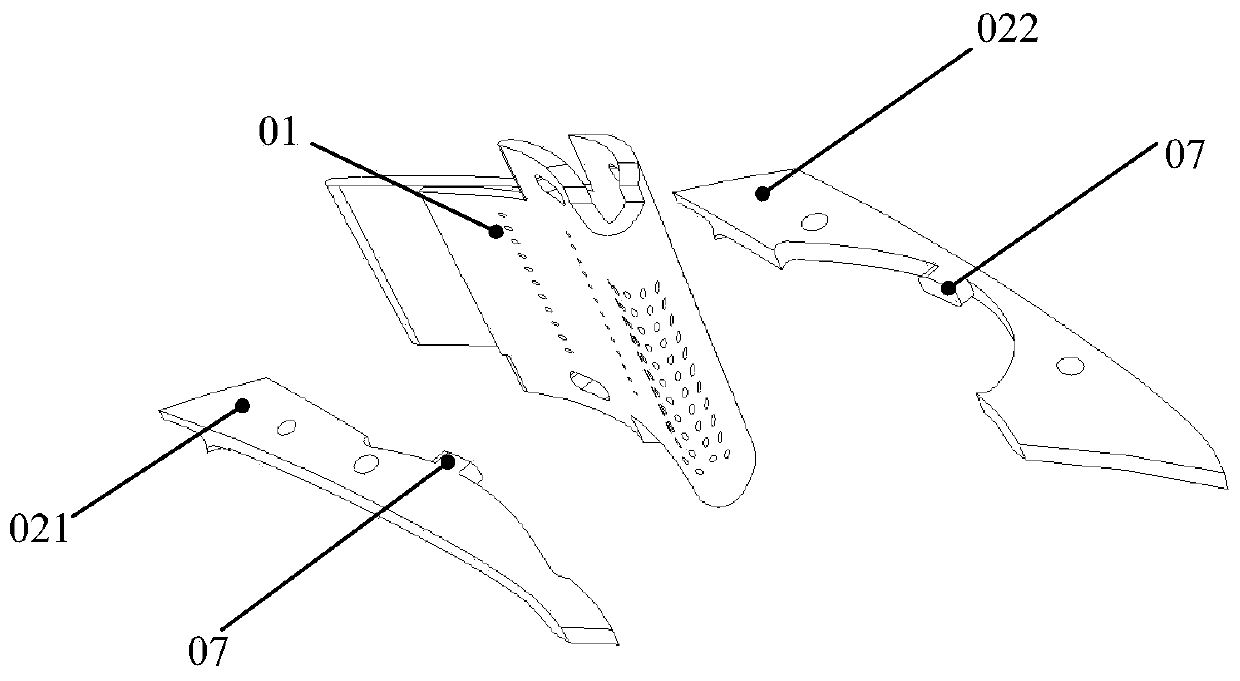

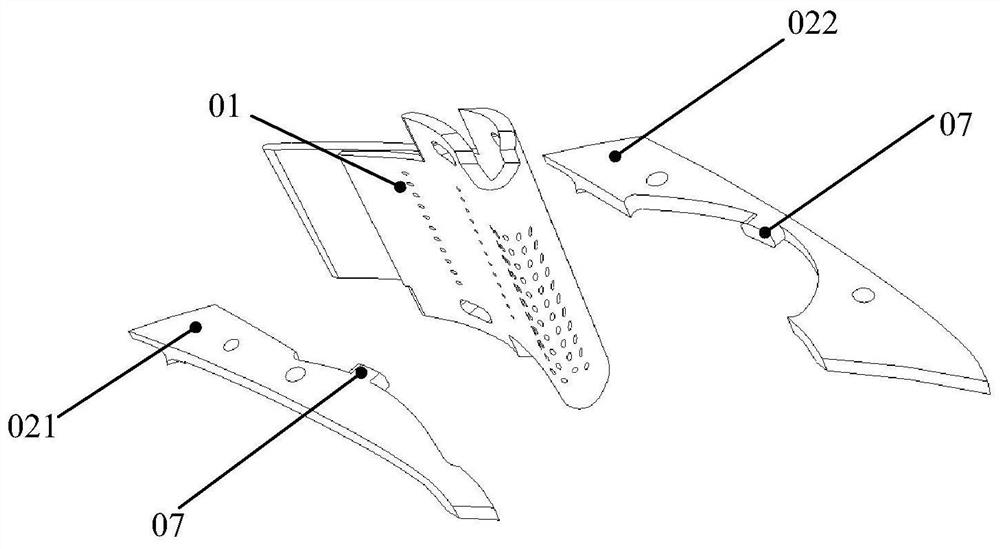

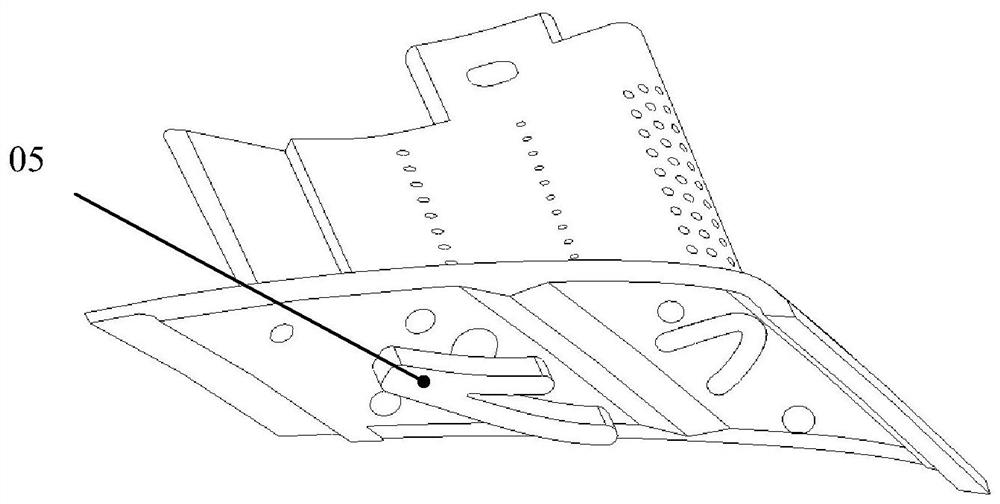

Aero-engine ceramic matrix composite fixed guider blade structure and forming method thereof

ActiveCN111102017AGood workmanshipEasy to prepareEfficient propulsion technologiesStatorsSmall engineEngineering

The invention relates to a fixed guider blade structure and forming, in particular to an aero-engine ceramic matrix composite fixed guider blade structure and a forming method thereof, and belongs tothe technical field of aero-engine fixed guider preparation. According to the aero-engine ceramic matrix composite fixed guider blade structure and the forming method thereof, a turbine guider blade is prepared in an integrated assembly mode, parts are integrally assembled in a riveting mode, an assembly structure adopts a SiC ceramic matrix to achieve welding, and therefore the defect that the strength of a blade root is insufficient due to a conventionally sewed and formed prefabricated body can be overcome; protrusions on a first lower edge plate and a second lower edge plate are directly riveted with the blade in a limiting mode and then riveted with a third lower edge plate and a fourth lower edge plate through riveting rivets, a SiC ceramic matrix is deposited on a whole product through a CVI technology, and therefore integrated preparation is completed; and in this way, the SiC / SiC high-pressure guide blade has good manufacturability, a margin plate and the blade are simpler toprepare and more reliable to install, and the structure can be fully applied to small engines such as civil turboshaft engines and turbojet engines.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

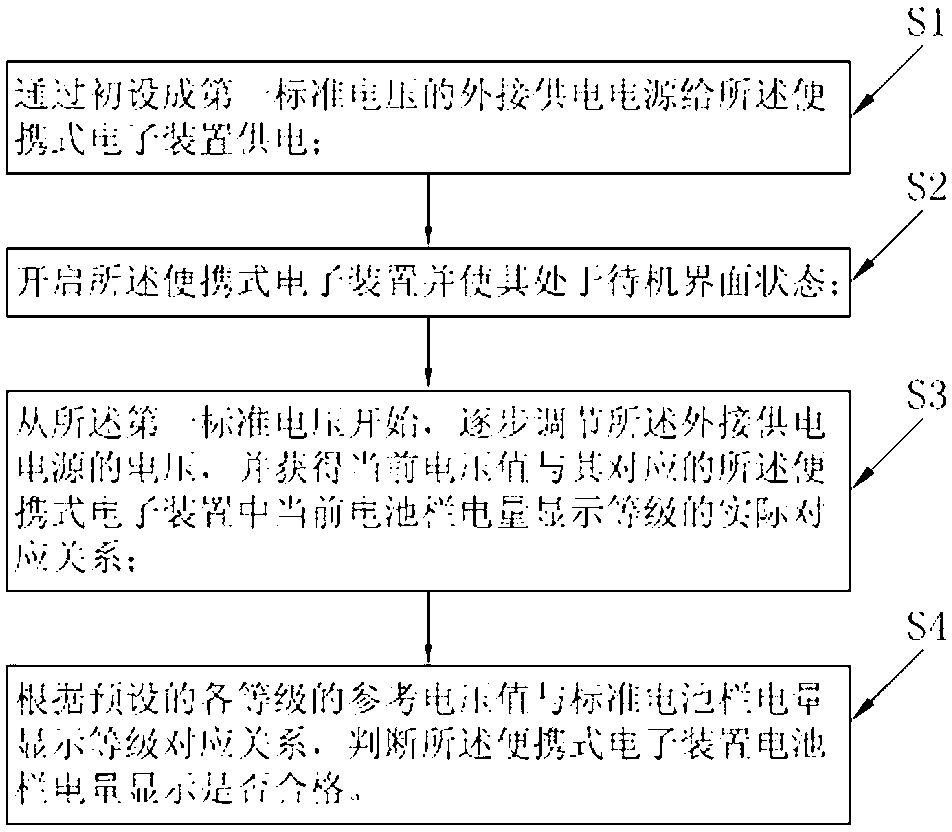

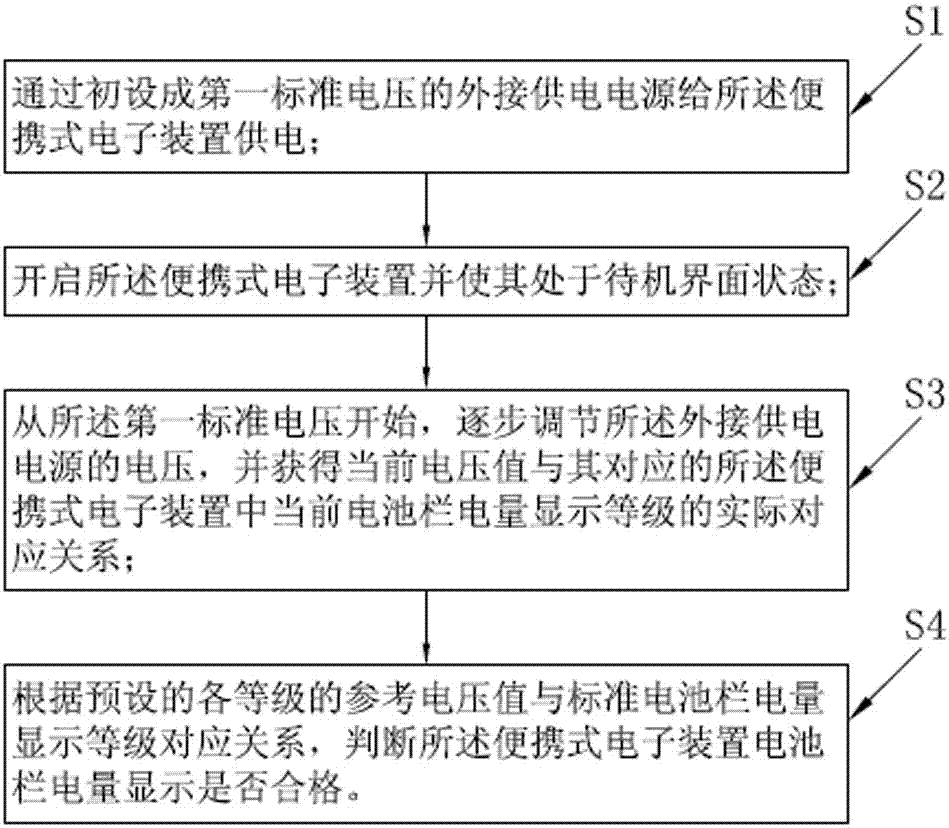

Testing method for electric quantity display in battery column in portable electronic device

ActiveCN102890244AEasy to operateQuality assuranceElectrical testingCurrent electricElectrical battery

The invention provides a testing method for electric quantity display in a battery column in a portable electronic device. The method comprises the following steps of: S1: supplying power to the portable electronic device through an external power supply which is initially set to be first standard voltage; S2: opening the portable electronic device and enabling the portable electronic device to be in a standby interface state; S3: starting from the first standard voltage, gradually regulating the voltage of the external power supply, and obtaining the actual corresponding relation between the current voltage value and the corresponding current electric quantity display level in the battery column in the portable electronic device; and S4: judging whether the electric quantity display in the battery column in the portable electronic device is qualified or not according to the corresponding relation between the preset reference voltage value of each level and the standard electric quantity display level in the battery column. According to the testing method disclosed by the invention, whether the electric quantity of the battery is correctly displayed on the portable electronic device can be quickly judged, so that the risk during the project manufacturing process is reduced, the quality of software and hardware of the portable electronic device is ensured, and the operation is simple and convenient.

Owner:BYD CO LTD

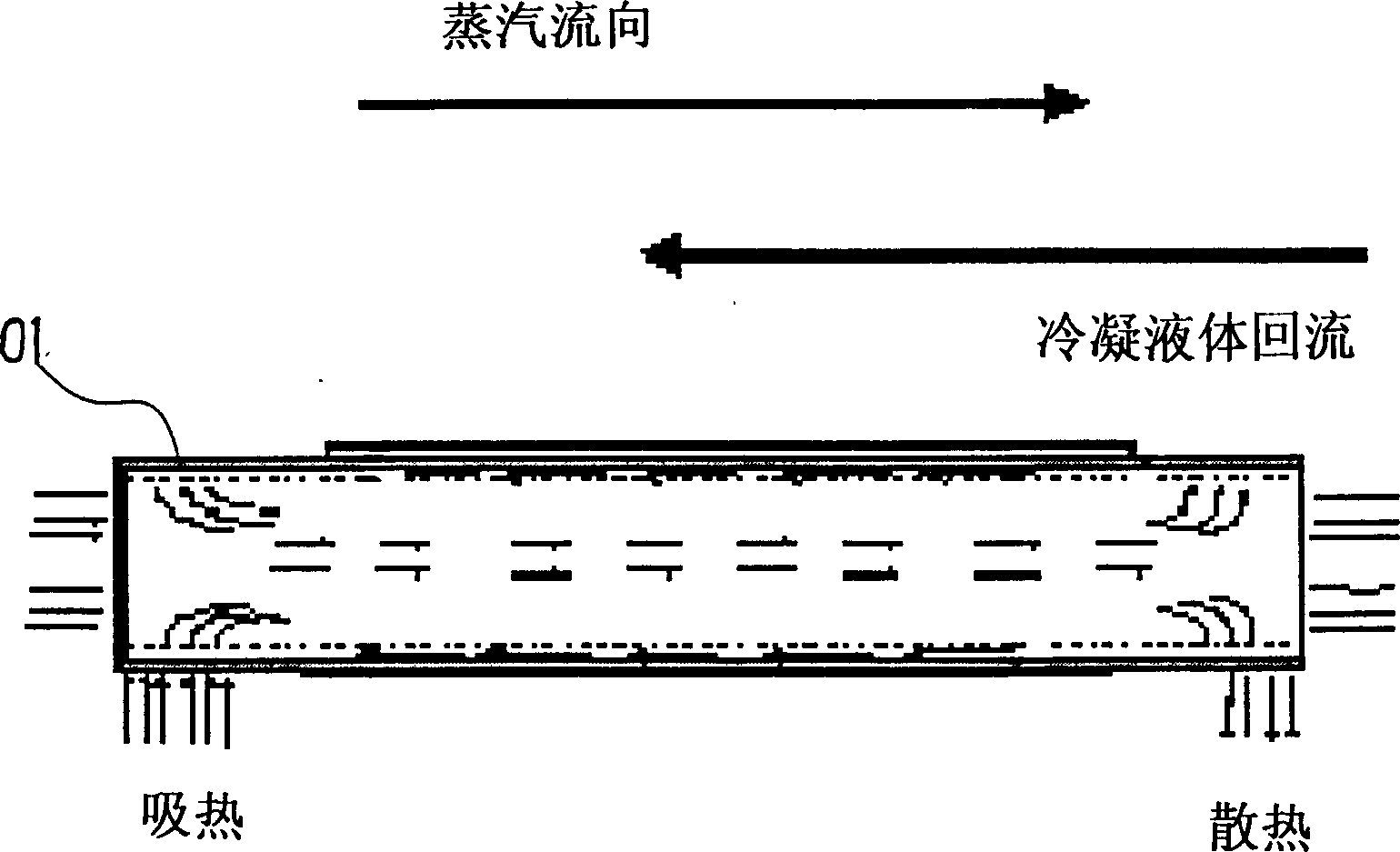

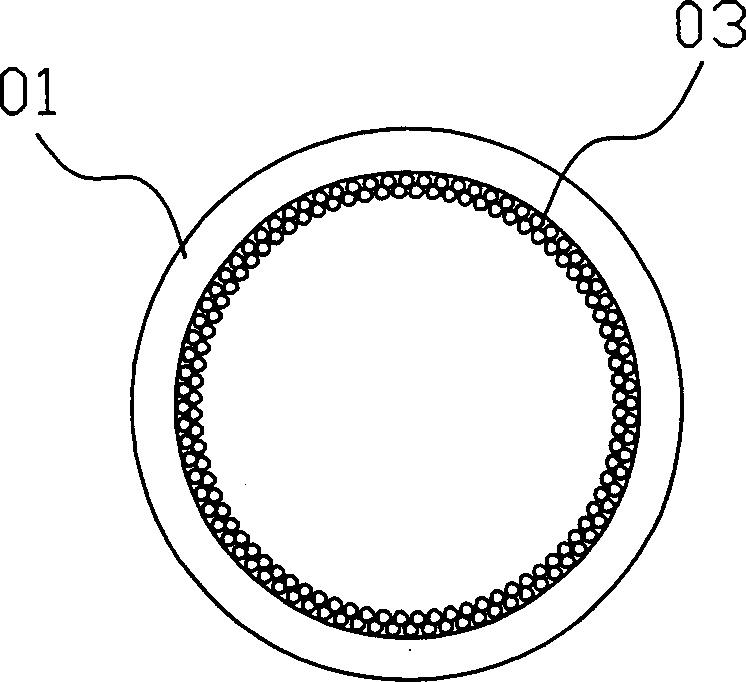

Heat pipe

InactiveCN1815127AIncrease attractivenessLess attractiveDigital data processing detailsIndirect heat exchangersWater storageInorganic salts

Present invention relates to computer fittings technology field, in particular referring to inner thermal pipe of computer radiator. Said thermal pipe has a hollow copper tube with sintered copper ball powder layer, which contains different kinds of easy hydroscopic inorganic salt ball and has different adding proportion in different section of copper tube. Said copper tube has obstruct layer in inner wall without generating sintering reaction with copper at lower 800 degree centigrade, which makes copper ball powder layer not sintering with copper tube. Due to copper tube inner wall having obstruct layer, copper ball powder layer can form a thin layer gap which forms the water duct to increase water storage, to make water flow unhindered, and reducing knee bend or stress for avoiding fracture.

Owner:杨开艳

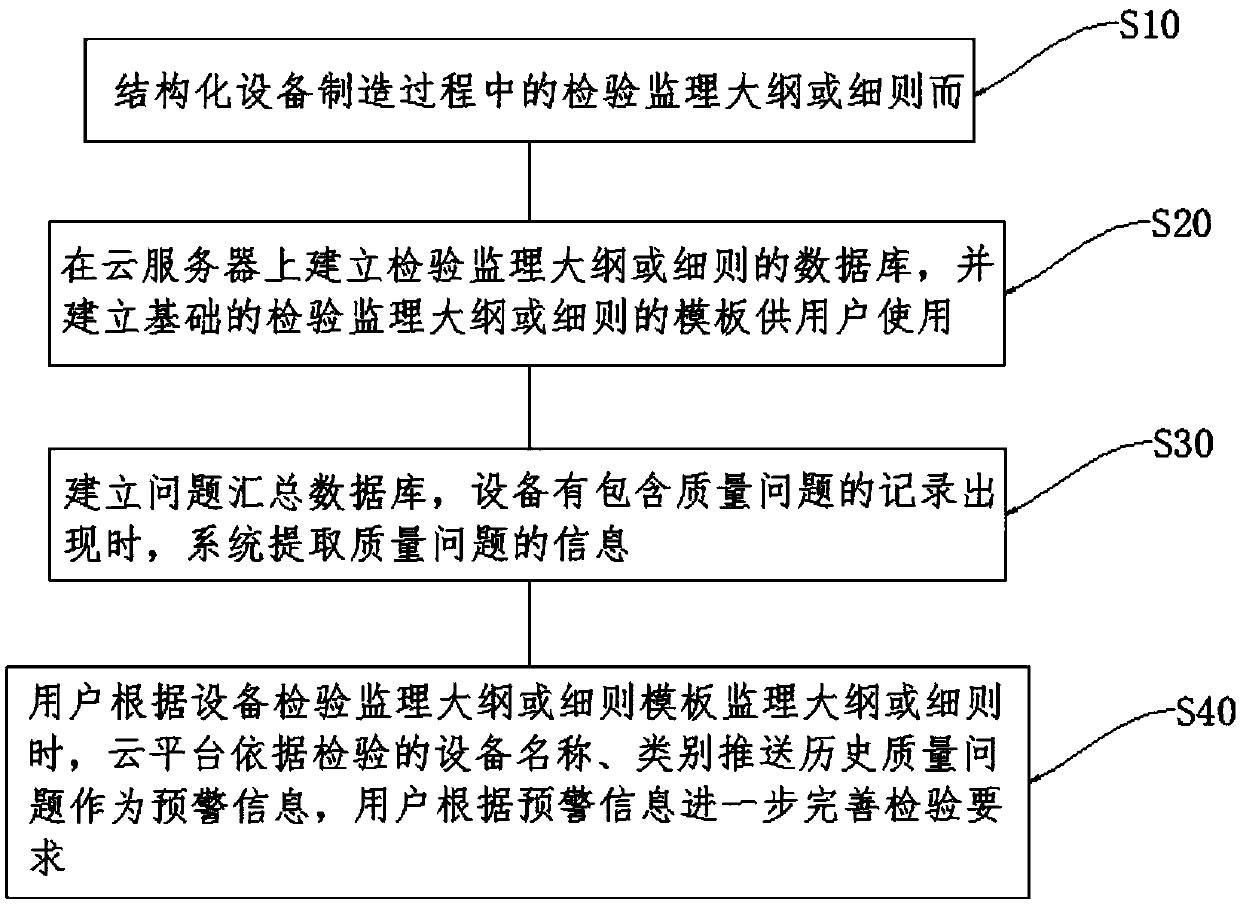

An early warning method for equipment manufacturing quality problems

InactiveCN109542880AIncrease credibilityIncrease authenticityDatabase design/maintainanceComputer scienceManufacturing quality

The invention discloses an early warning method for equipment manufacturing quality problems, which comprises the following steps: inspecting supervision outline or detailed rules in the manufacturingprocess of structured equipment; Establishing the database of inspection supervision outline or detailed rules on the cloud server, and establishing the template of basic inspection supervision outline or detailed rules for users to use; Establishing the problem summary database, wherein when the equipment has the record containing the quality problem, the system extracts the information of the quality problem; When the user inspects the supervision outline or detailed rules of the template supervision outline or detailed rules according to the equipment, Based on the name of the verified device, Category, the cloud platform pushes historical quality issues as alert information, and the user further perfects the inspection requirements according to the warning information.The invention provides a cloud database for effectively recording quality problems based on the cloud platform. The quality problems originate from the daily inspection work of all users. The invention has extremelyhigh reliability, effectively reduces the manufacturing risk and saves the cost..

Owner:上海众深科技股份有限公司

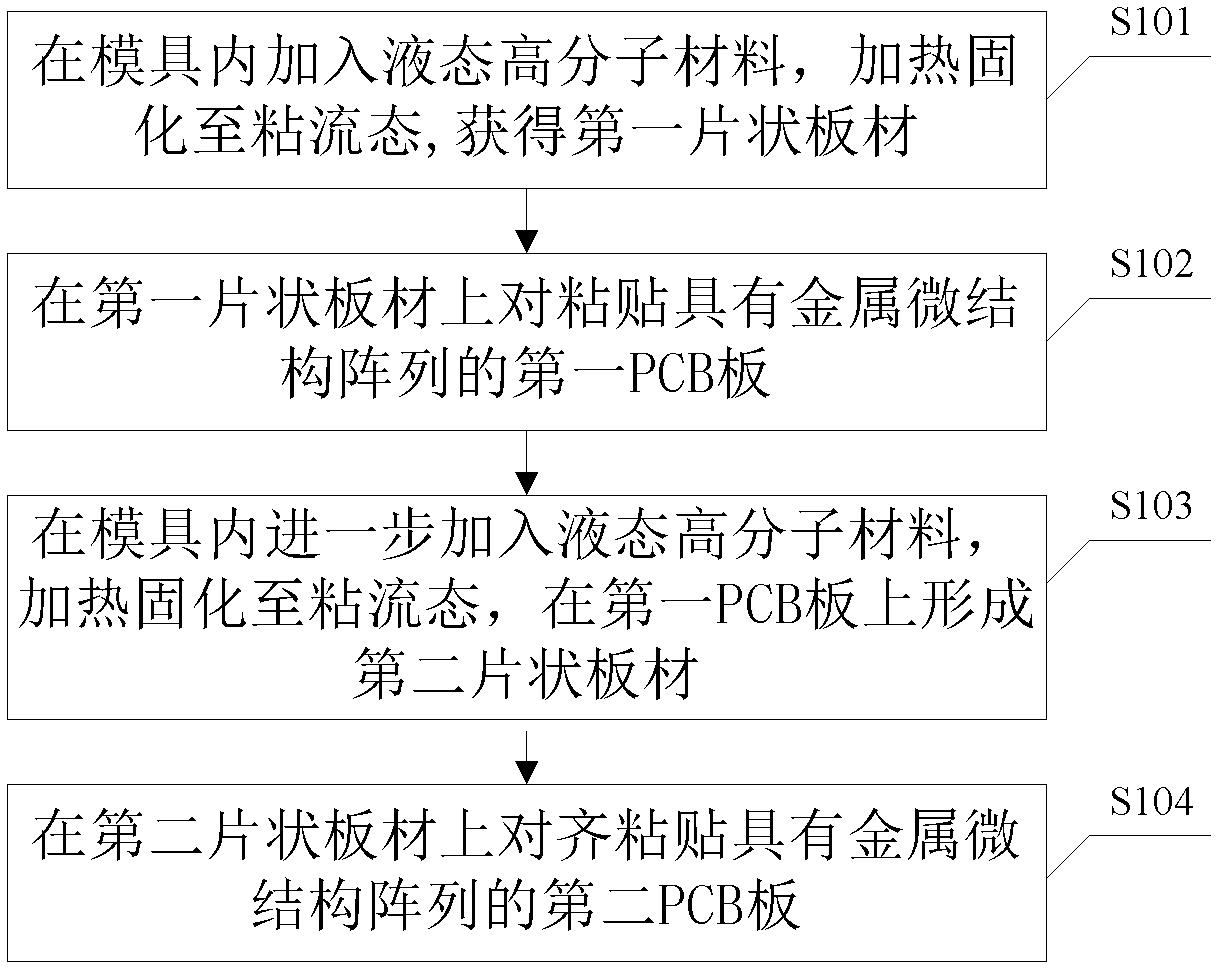

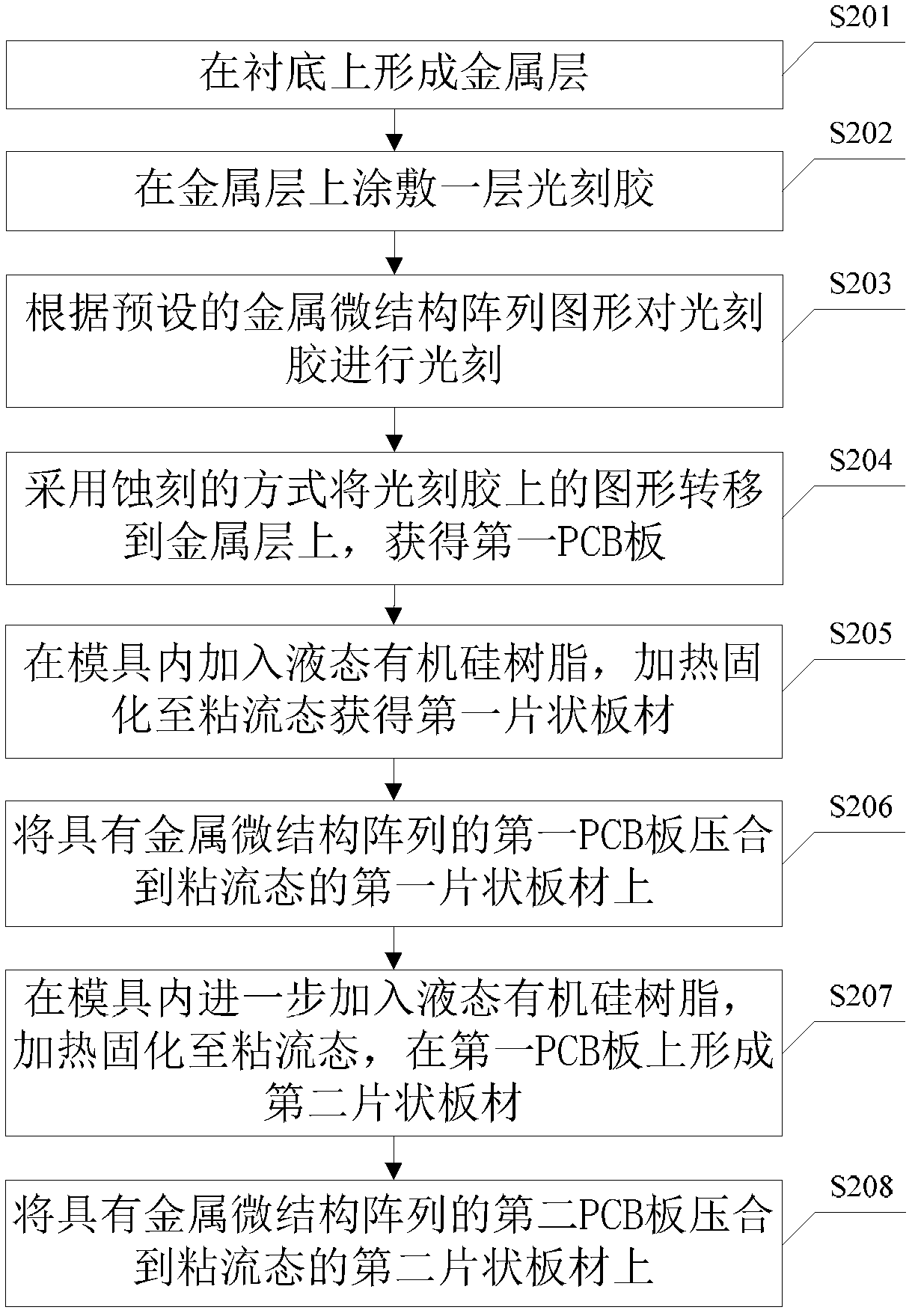

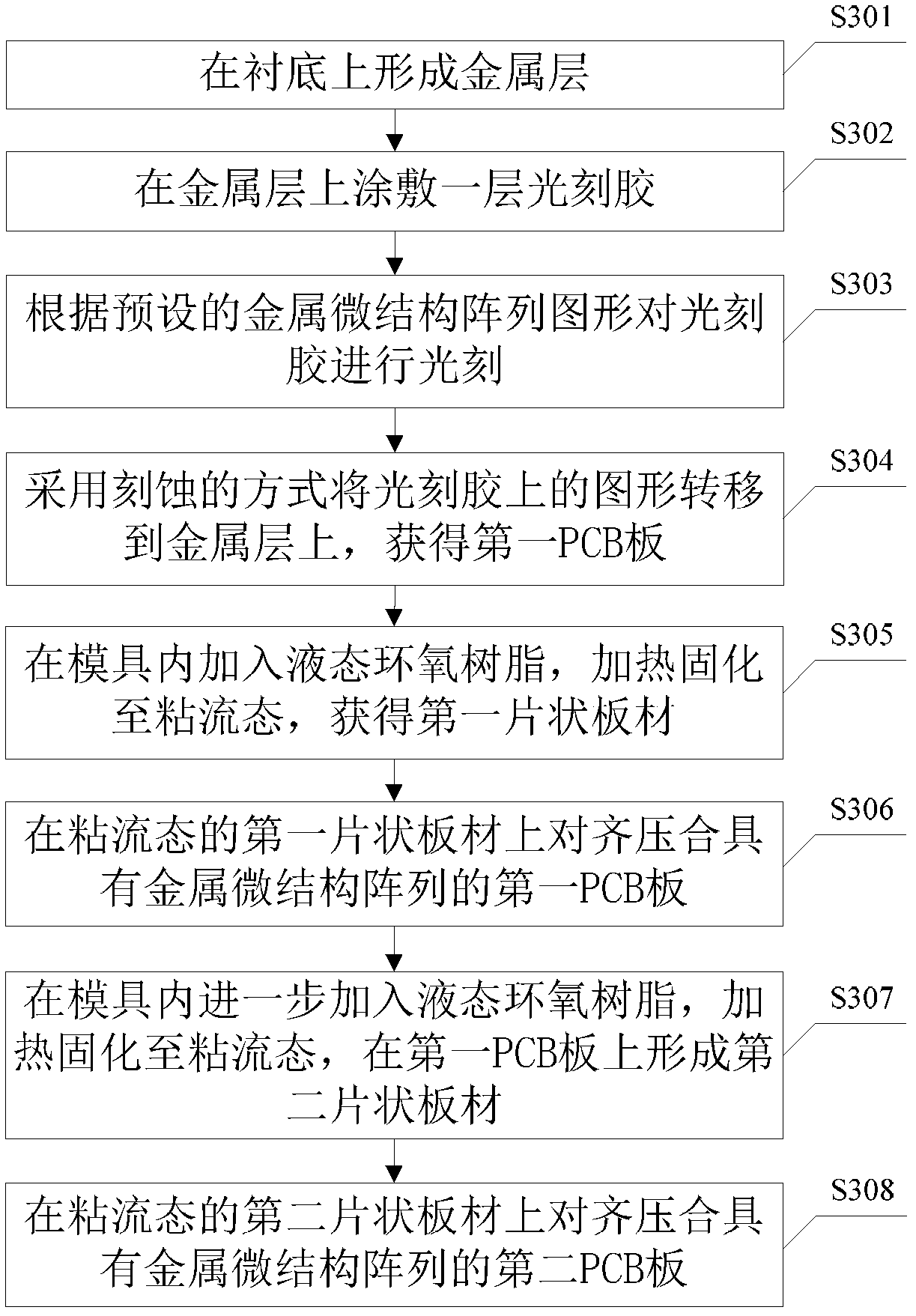

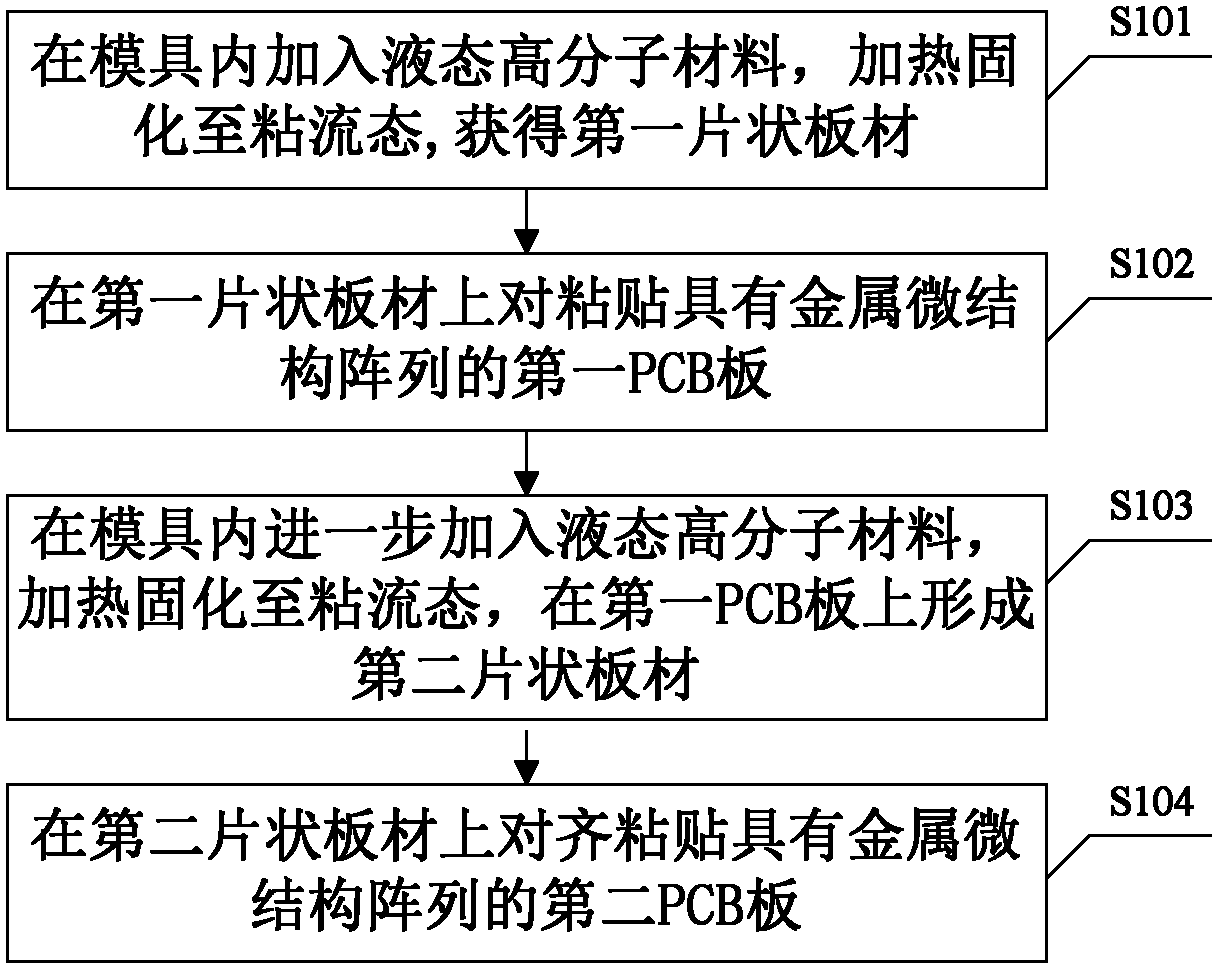

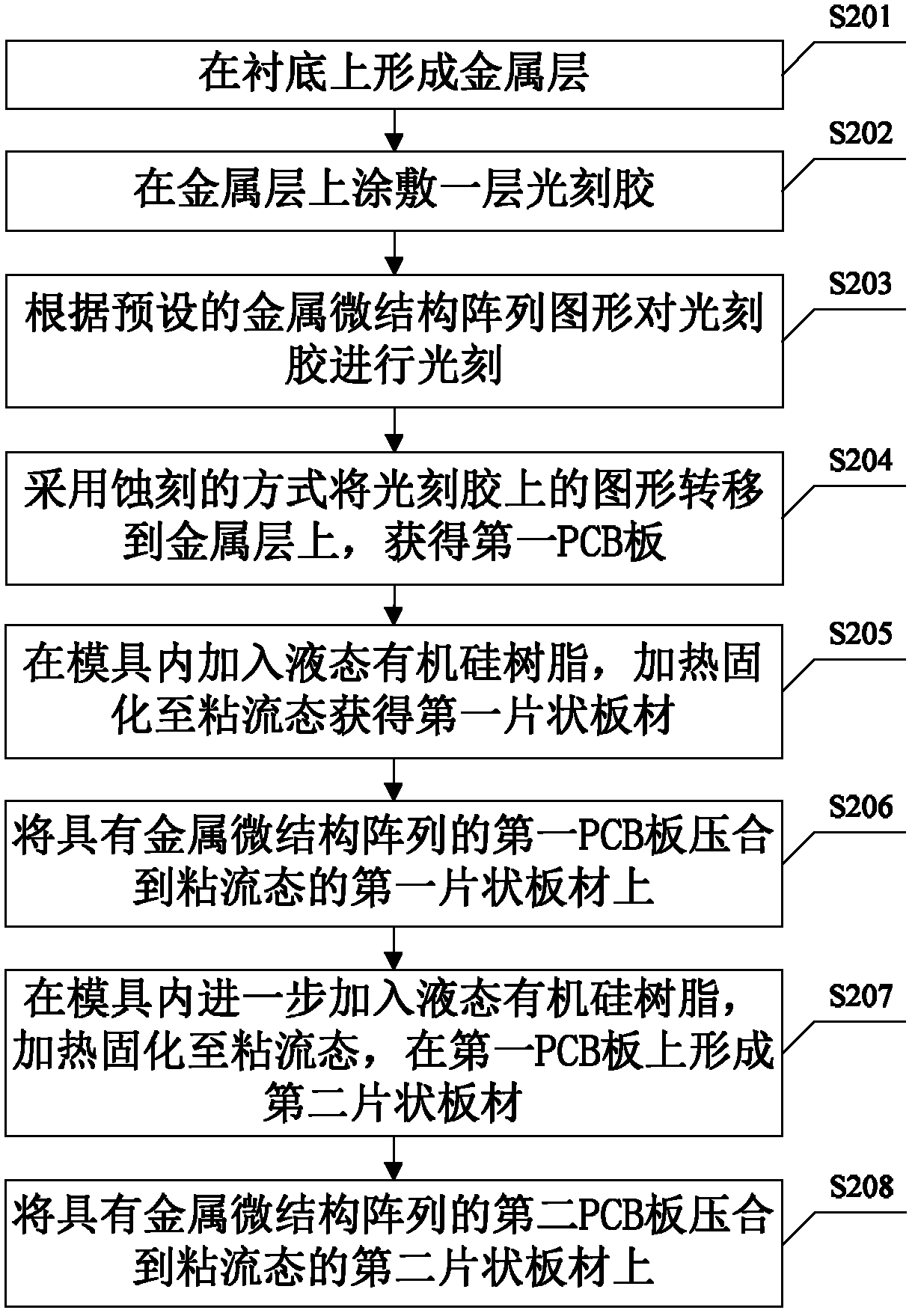

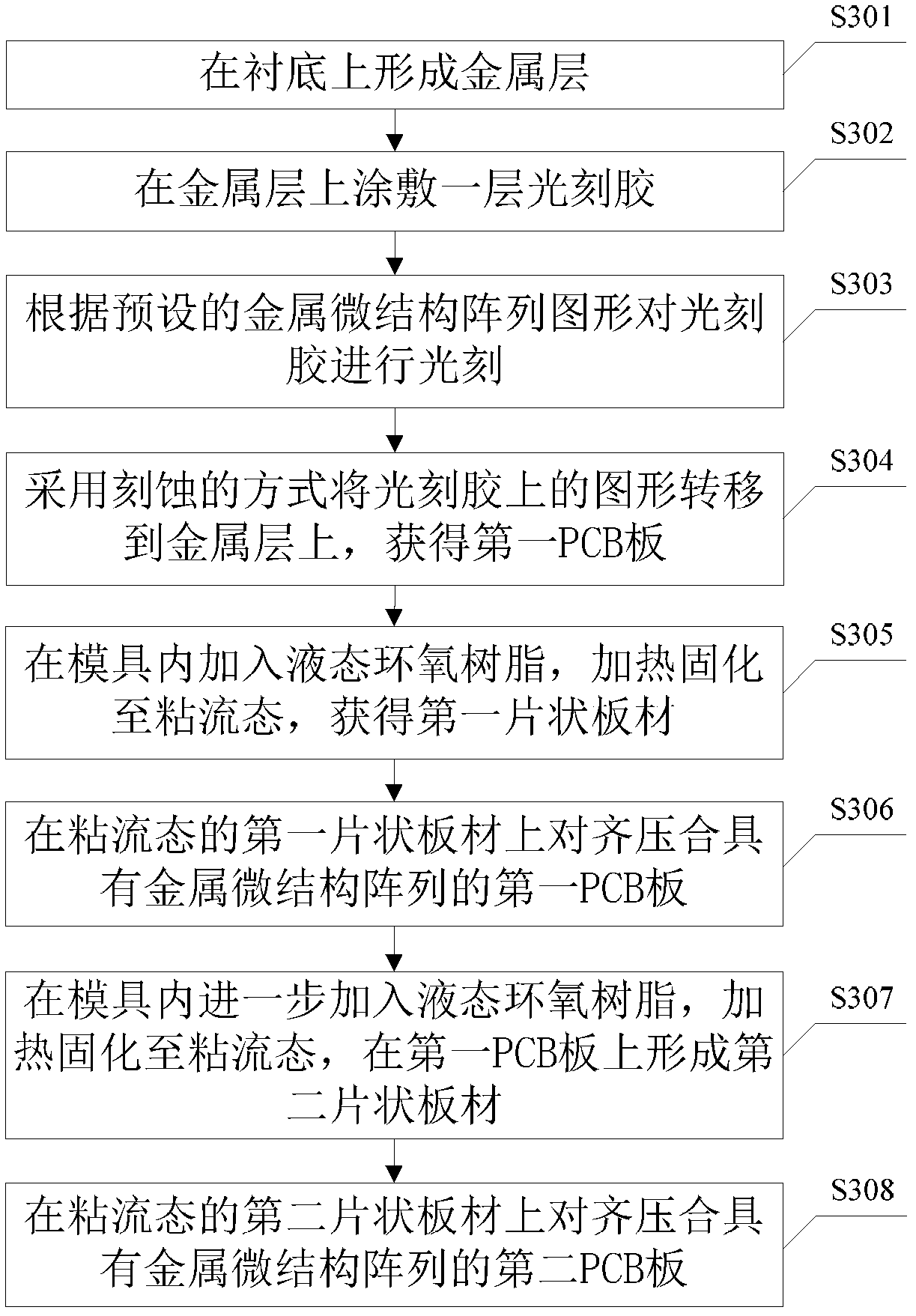

Preparation method of metamaterial and the same

ActiveCN102487579AReduce preparation riskQuality assuranceMultilayer circuit manufactureViscous flowMaterials science

Embodiments of the invention provide a preparation method of a metamaterial. The method comprises the following steps: adding a liquid-state high-molecular material in a mold and heating and curing to a viscous flow state so as to obtain a first flaky sheet material; aligning and pasting a first PCB possessing a metal microstructure array on the first flaky sheet material; further adding the liquid-state high-molecular material in the mold and heating and curing to the viscous flow state, and forming a second flaky sheet material on the first PCB; aligning and pasting a second PCB possessing the metal microstructure array on the second flaky sheet material. The embodiments of the invention also provide the metamaterial prepared by using the above preparation method. By using the method ofthe invention, malposition of the metal microstructure array on the PCB can be modified. Therefore, a preparation risk can be reduced and metamaterial quality can be guaranteed.

Owner:KUANG CHI INST OF ADVANCED TECH +1

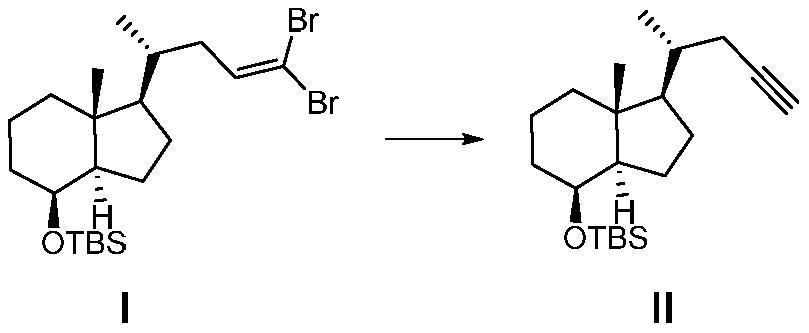

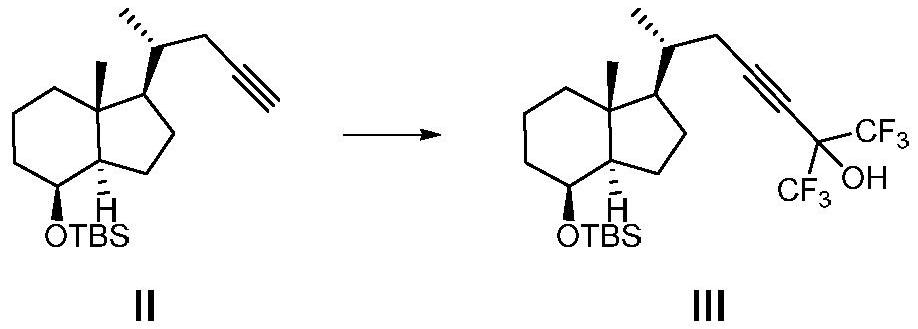

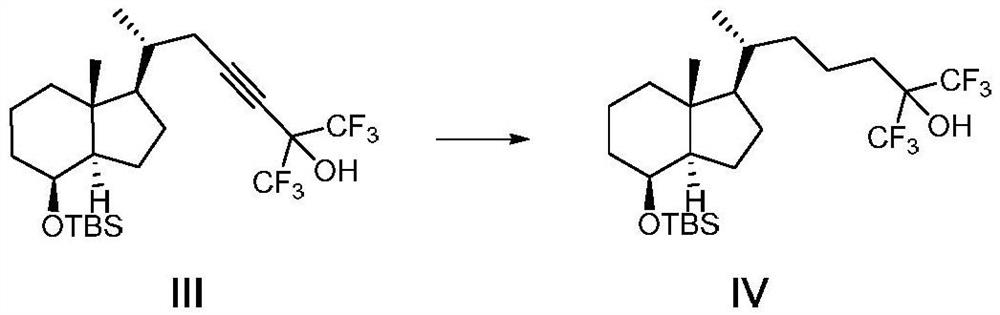

Preparation method and application of fluorocalciferol CD ring

PendingCN114044788AThe reaction steps are simpleShort synthesis cycleGroup 4/14 element organic compoundsOrganic compound preparationChemical compoundCombinatorial chemistry

The invention discloses a preparation method and application of a fluorocalciferol CD ring, and relates to the field of synthesis of medical intermediates. The invention discloses a preparation method of a compound VII with the following structure, and further the compound VII is used for preparing fluorocalciferol. According to the method, a convergence method is used for synthesis, so that the synthesis period is shortened, and the preparation cost is reduced; wherein the reaction yield is high, and the product quality is easy to control; in addition, the use of dangerous reagents is avoided, the preparation risk is reduced, and large-scale preparation is easy to realize.

Owner:甘肃皓天医药科技有限责任公司

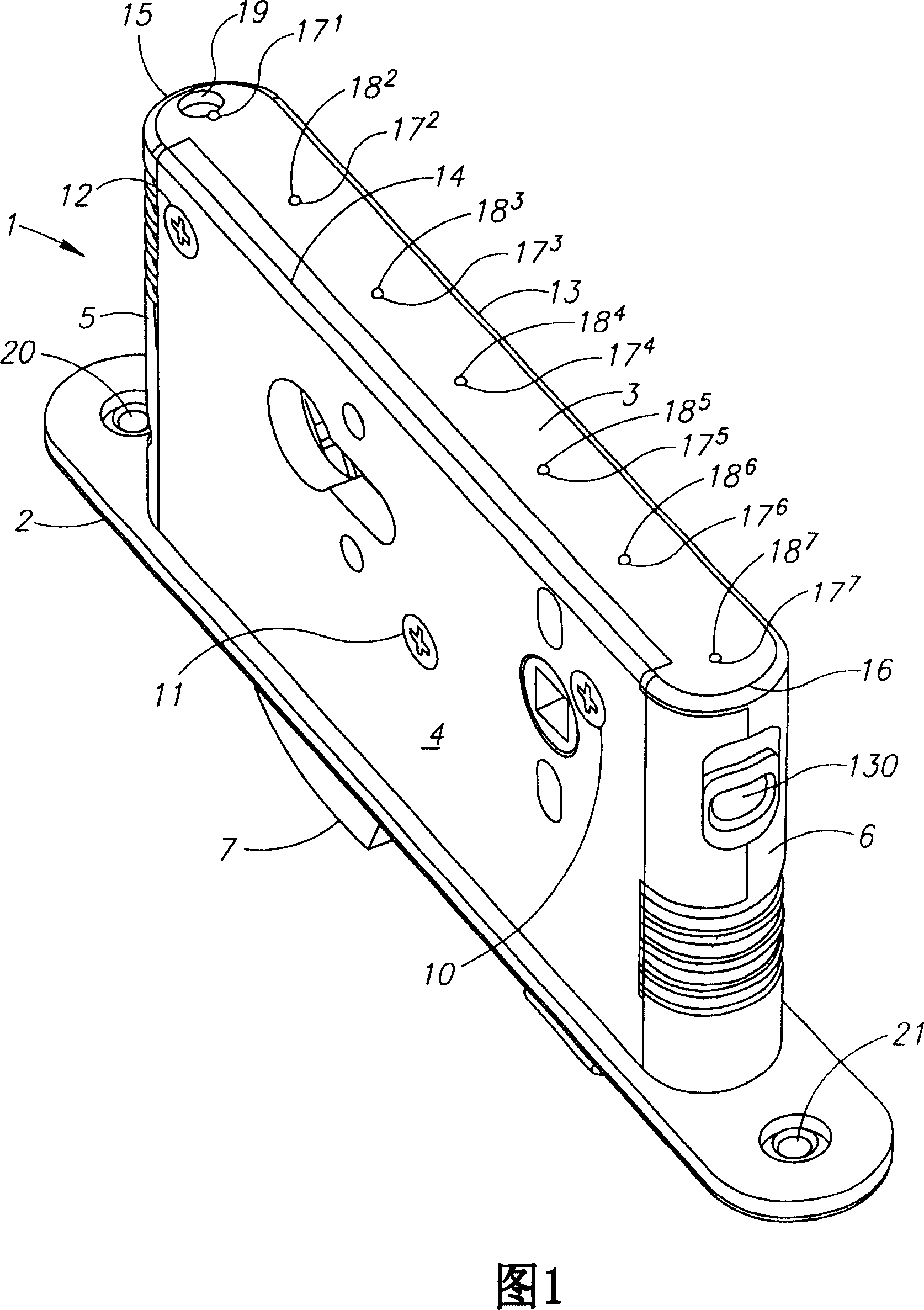

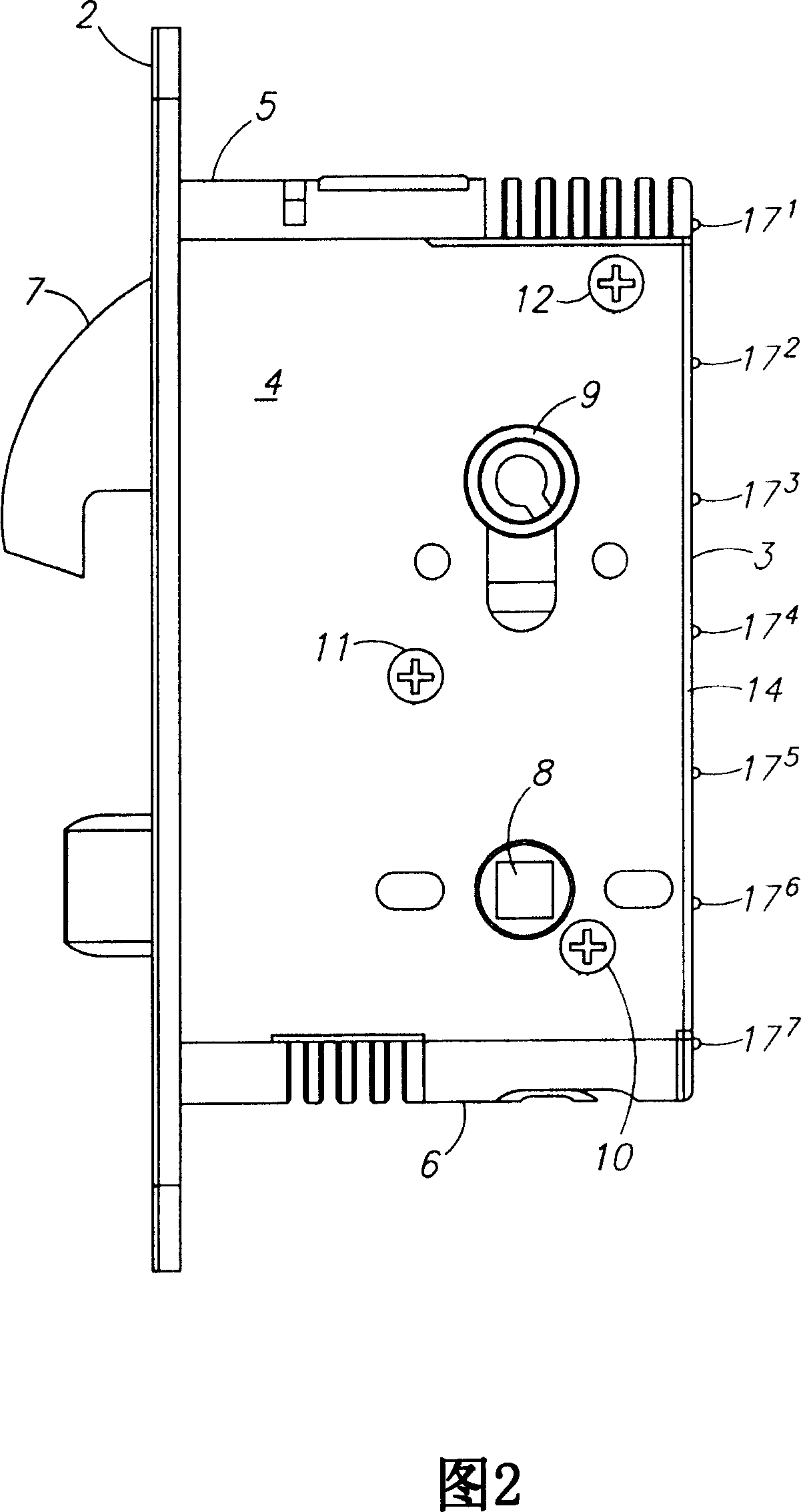

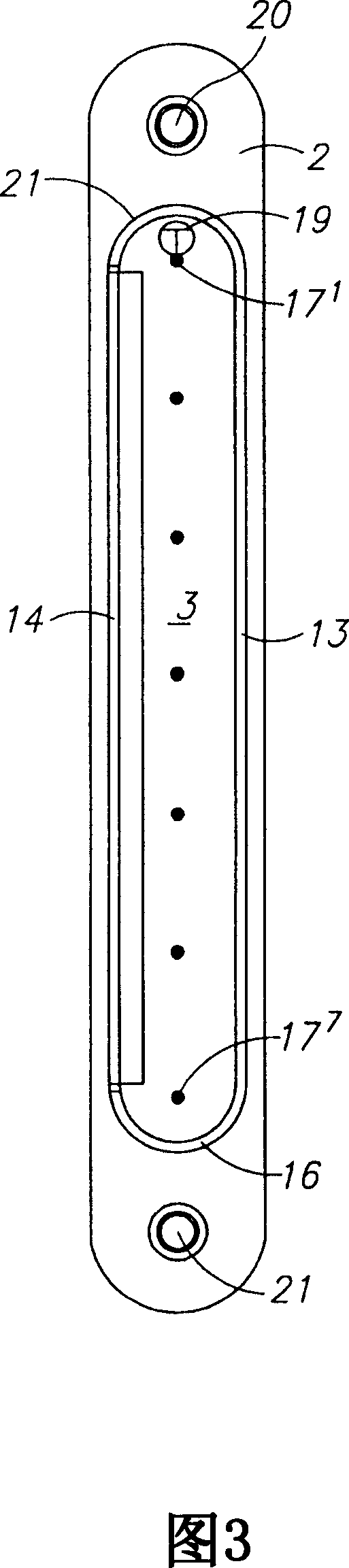

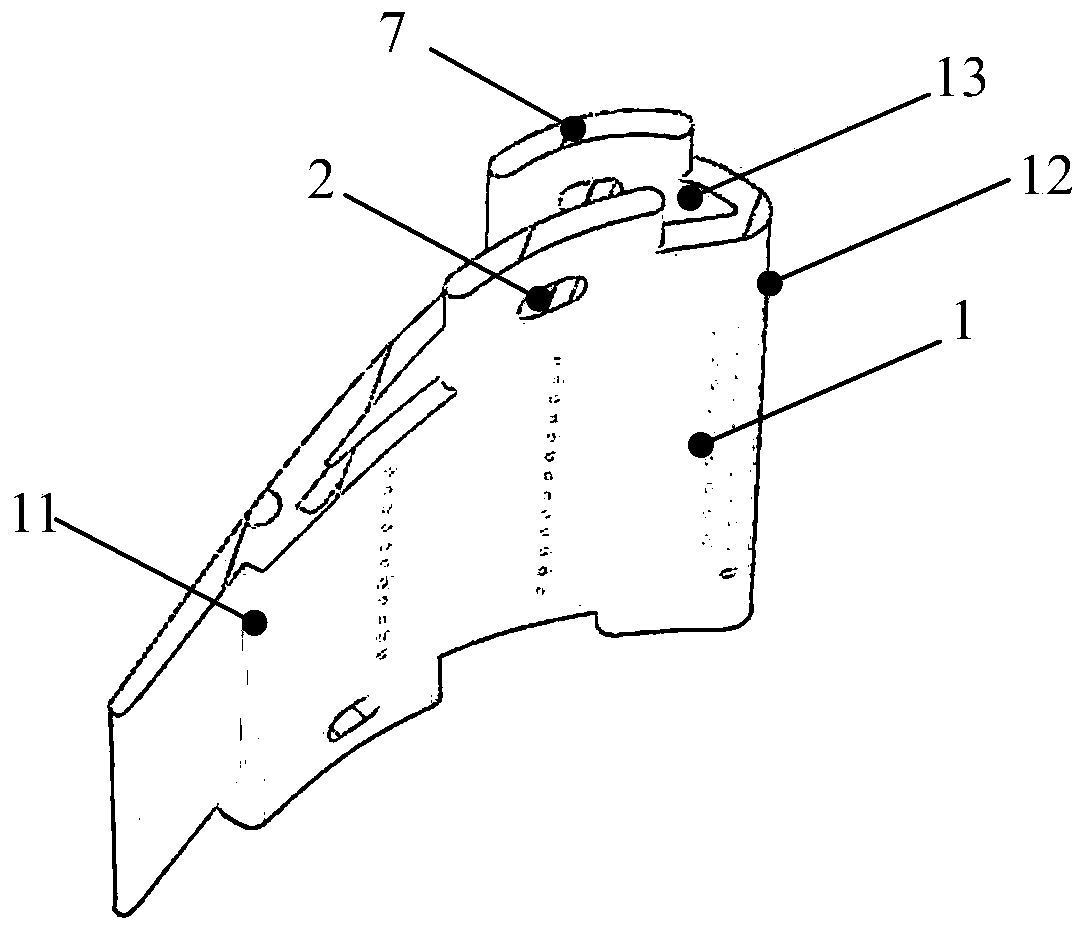

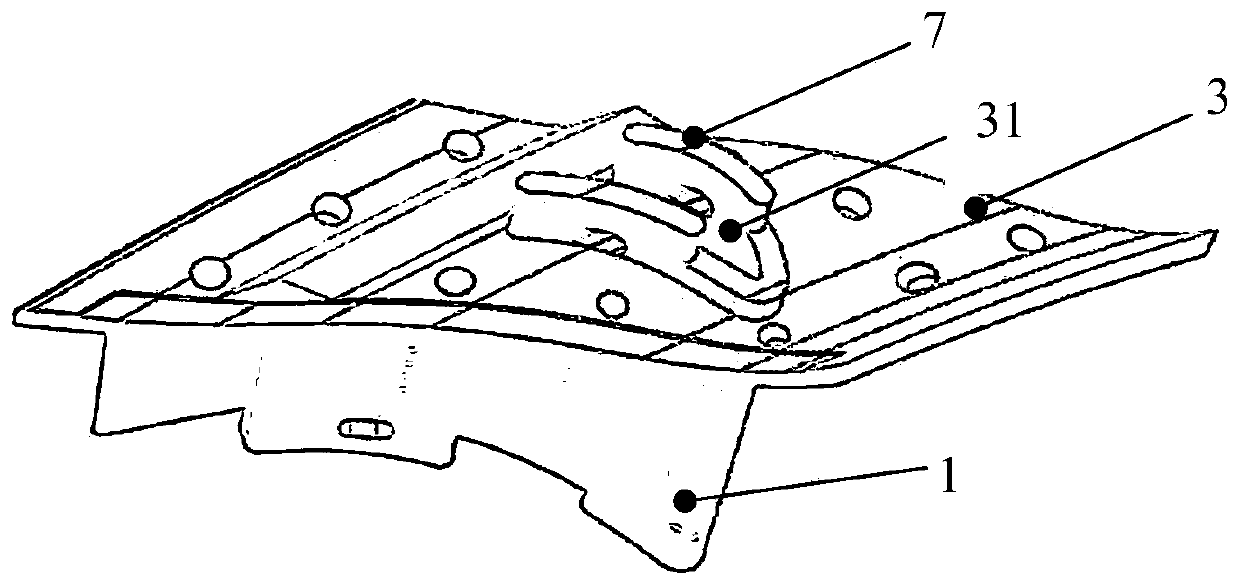

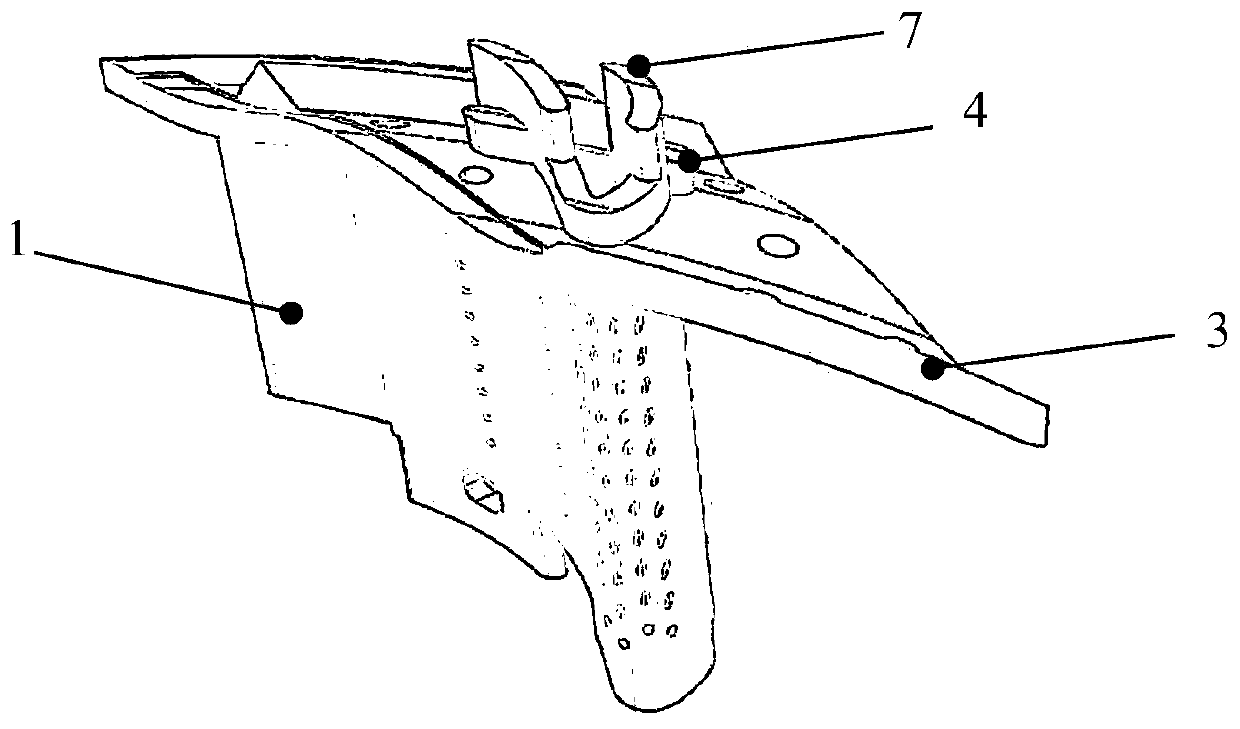

Features for convenient mortise lock installation

InactiveCN1932222AImprove installation accuracyReduce manufacturing riskNon-mechanical controlsLock casingsLocking mechanismSpring force

A mortise lock assembly for a door, including a casing, a locking mechanism arranged at least partly within the casing, and a plurality of location elements extending from the rear wall, for indicating a position for forming a recess in the door for receiving the lock assembly. Other non-limiting features allow the lock installer to decide what spring strength to give the handle of the mortise lock without having to carry two different locks in stock. Another non-limiting feature is an external sensor module that permits adding a microswitch or other sensor without having to provide it inside the lock.

Owner:阿萨阿布洛有限公司

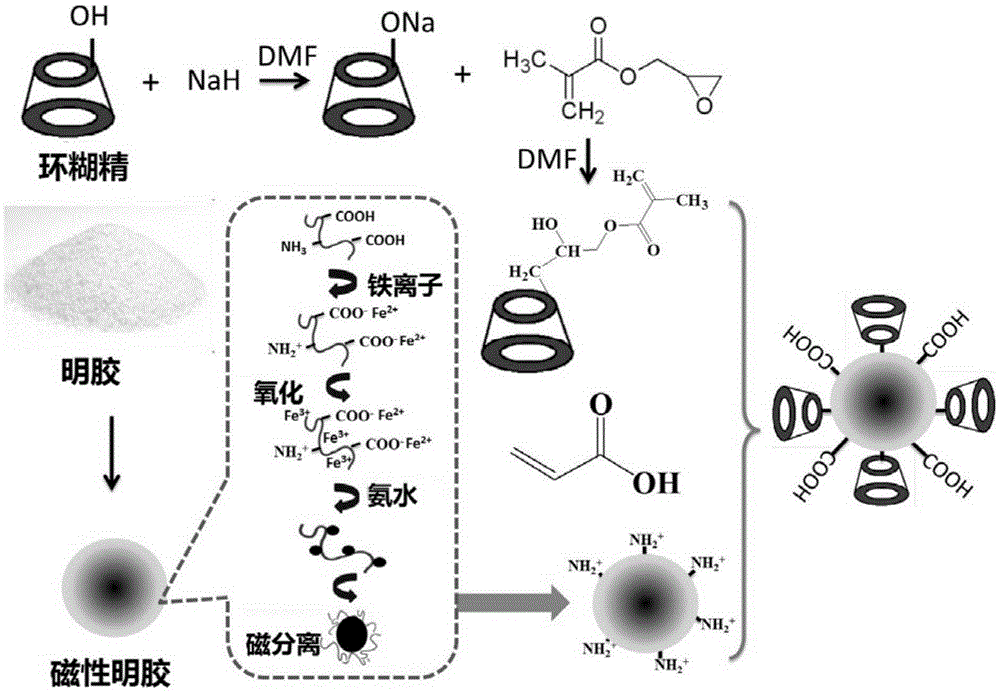

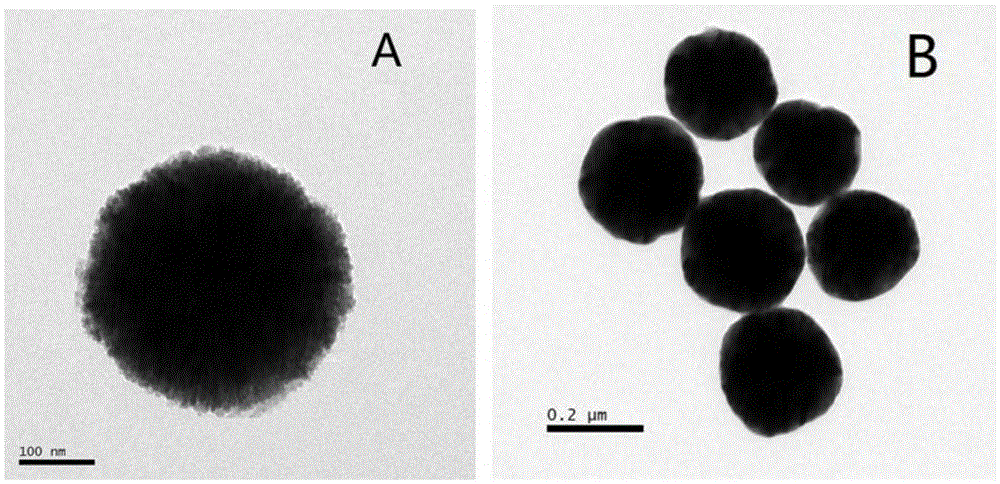

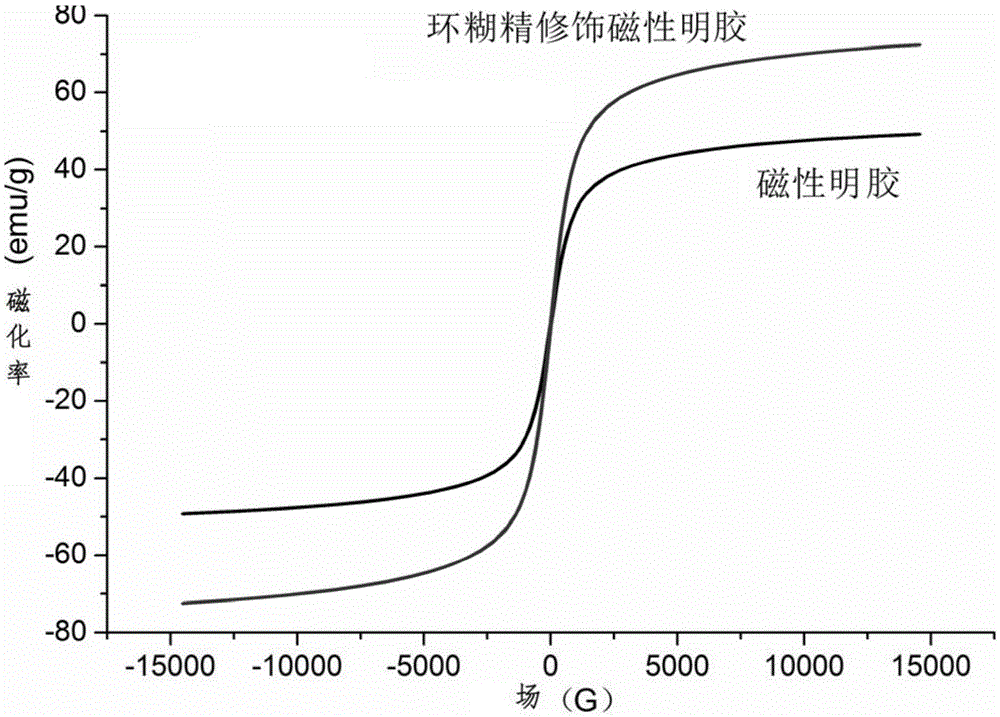

Cyclodextrin modified magnetic gelatin for efficient adsorption of moxidectin and preparation method of cyclodextrin modified magnetic gelatin

The invention provides a cyclodextrin modified magnetic gelatin for efficient adsorption of moxidectin and a preparation method of the cyclodextrin modified magnetic gelatin. The method comprises the following steps: firstly, preparing a magnetic gelatin; secondly, preparing vinyl modified cyclodextrin; and finally, performing reaction between the magnetic gelatin and the vinyl modified cyclodextrin to obtain the cyclodextrin modified magnetic gelatin. The cyclodextrin modified magnetic gelatin is prepared for the first time by the method provided by the invention, the efficient adsorption of moxidectin can be realized, the magnetic separation property can realize quick recovery of materials, and the operation is simple. Used materials are low in toxicity, the preparation cost is low, the safety is high, and the after-treatment is simple. Therefore, the method provided by the invention is far superior to an existing preparation method either safety of preparation or easy operability of the preparation process.

Owner:武汉鸿漫源检测技术科技有限公司

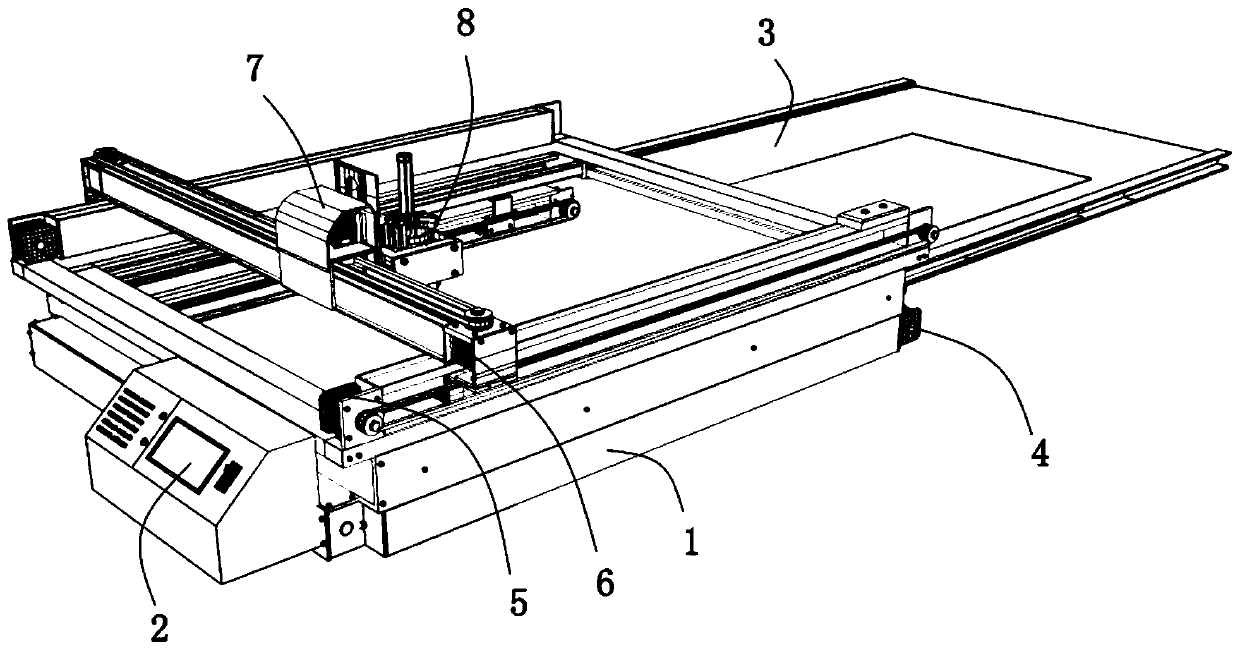

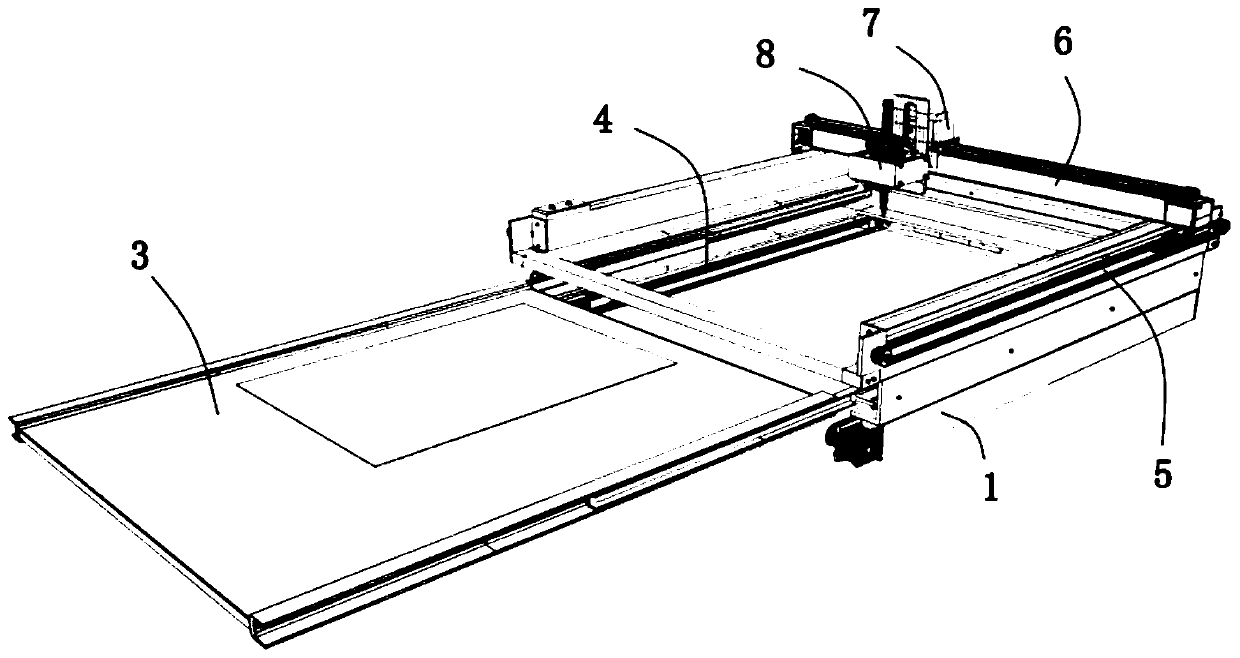

3D-to-2D animation hand-drawing-simulated line drawing instrument

PendingCN110744965AImprove production efficiencySolve the high labor costOther artistic work equipmentsLine drawingsEngineering

The invention provides a 3D-to-2D animation hand-drawing-simulated line drawing instrument. The 3D-to-2D animation hand-drawing-simulated line drawing instrument comprises a main body support, a control module, a positioning plate, an automatic paper-feeding positioning module, an X-axis guide module and a Y-axis guide module, wherein the control module is fixedly installed on the main body support; the positioning plate is installed on the main body support in a slide manner; the automatic paper-feeding positioning module is fixedly installed on the main body support and connected to the positioning plate; the X-axis guide module is fixedly installed on the main body support; and the Y-axis guide module is fixedly installed on the X-axis guide module. The 3D-to-2D animation hand-drawing-simulated line drawing instrument provided by the invention has the beneficial effects that existing animation production processes can be integrated; production efficiency of animation line drafts canbe optimized; requirements for technical qualities of operators are low; the number of the operations is small; duration is short; and later-stage amendment and adjustment can be conducted easily.

Owner:孙典

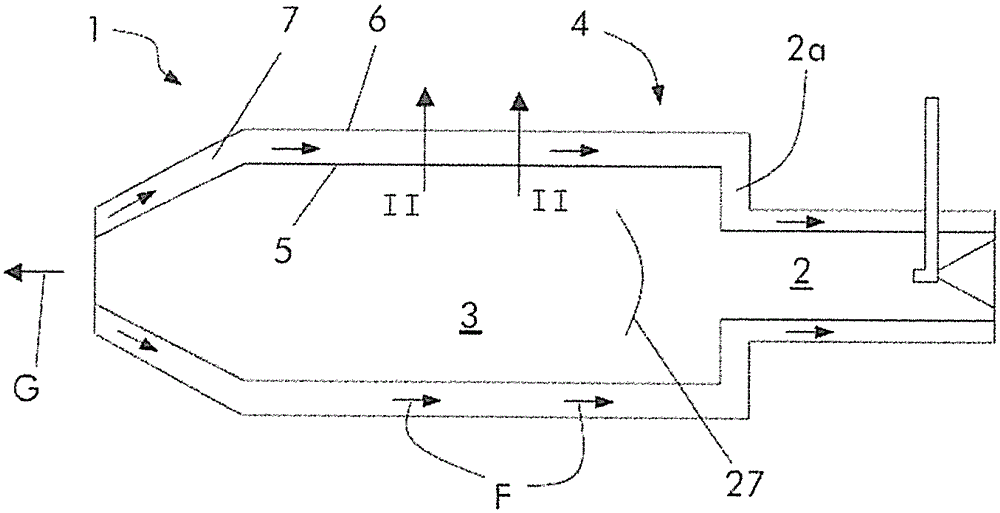

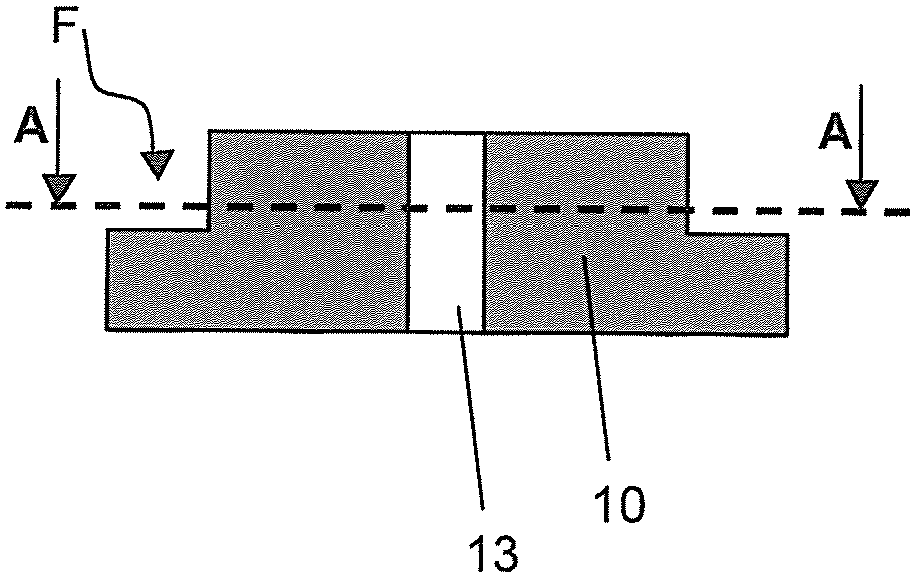

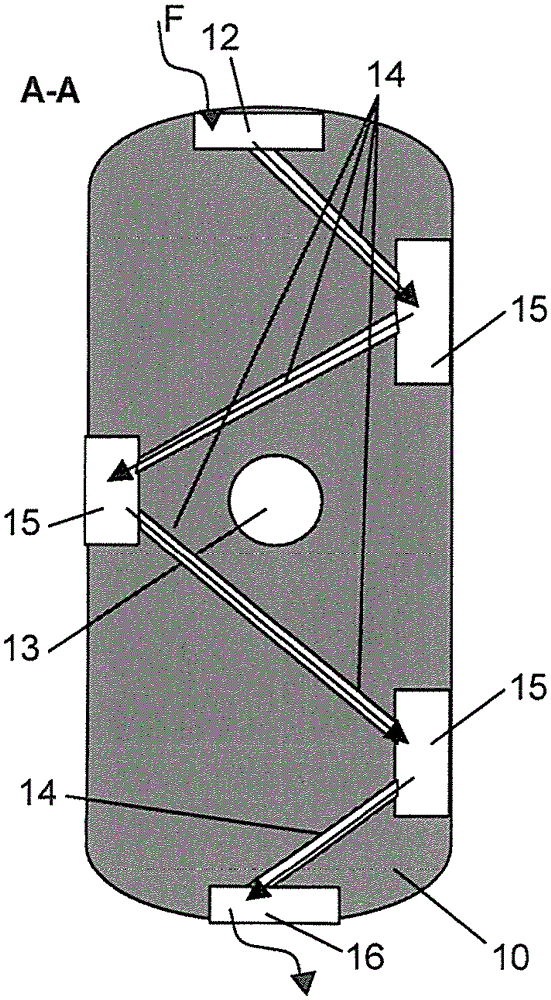

Damping devices for gas turbine combustors

ActiveCN103851645BImprove cooling effectImprove overall lifespanContinuous combustion chamberEngine fuctionsCombustorCombustion chamber

The present invention relates to damping arrangements for gas turbine combustors. It comprises: a wall having a first inner wall and a second outer wall arranged at a distance from each other; a plurality of cooling channels extending substantially parallel between the first inner wall and the second outer wall; and at least one damping space composed of The cooling channel delimits, further comprising a first passage for supplying cooling medium from the cooling channel into the damping space and a second passage for connecting the damping space to the combustion chamber, characterized in that the end plate fixed to the inner wall will The damping space is separated from the combustion chamber, said end plate is provided with a neck passage and additionally at least one supply plenum for a cooling medium, at least one outlet plenum for a cooling medium and at least one cooling passage, said At least one cooling passage enables a cooling medium to flow from at least one supply plenum to another supply plenum or to at least one outlet plenum.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Method for checking the design of locking assemblies

ActiveUS20200249108A1Easy to operateImprove applicabilityMeasurement of torque/twisting force while tighteningCouplings for rigid shaftsComputed torqueUltimate tensile strength

The present invention discloses a method for checking the design of locking assemblies, comprising: calculating a pressure on each contact surface and a torque that can be transferred by a spindle and a bushing after locking assemblies are locked, and comparing the calculated torque with the designed maximum transferable torque to calculate a torque safety coefficient; with a minimum fit clearance, calculating a resultant stress of components, and comparing the resultant stress with a yield strength of the material of the components to calculate a strength safety coefficient of the components; and obtaining a pre-tightening force of the bolts according to a given pre-tightening moment of the bolts, calculating a maximum equivalent stress of the bolts, and obtaining a safety coefficient of the bolts. This method in the present invention can effectively verify the rationality of design of locking assemblies, reduce the manufacture risk and increase the yield of products.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-invasive production method for double-edged eyelids

InactiveCN107811659AThe production procedure is simple and convenientQuick resultsSurgeryEyelidState of art

The invention discloses a method for making double eyelids, which solves the problem of complex double eyelid production procedures in the prior art, high production costs, long production time, large damage to the eyelids, resulting in unpredictable recovery period, and difficult adjustment after production, resulting in final production failure. high rate problem. The main steps of the present invention are: cleaning and disinfecting the four-layer eyelids and tools; then drawing lines on the four-layer eyelids to design the shape of the double eyelids, and marking six embedding points sequentially along the positions of the double eyelids; and then Use a polypropylene monofilament thread with barbs to pass through six embedding points in the same direction in order to fit the first eyelid and the fourth eyelid; finally use scissors to cut the excess polypropylene monofilament thread left on the eyelid Just cut it off and clean the tool. The invention has the advantages of simple production procedure, quick effect, short production time, low production risk, almost no damage to eyelids, no swelling and pain, very short recovery time or no recovery period, and low double eyelid production failure rate.

Owner:谭霞

Ceramic matrix composite material fixing guider blade structure of aircraft engine and molding thereof

ActiveCN110985134AAvoid the defects of insufficient strengthAvoid the risk of obsolescenceStatorsMachines/enginesAviationStructural engineering

The invention relates to a fixing guider blade structure and molding thereof, in particular to a ceramic matrix composite material fixing guider blade structure of an aircraft engine and molding thereof, and belongs to the technical field of preparation of fixing guiders of aircraft engines. According to the fixing guider blade structure and the molding thereof, the structural defects of unreasonable design and poor root strength of an existing CMC guider blade prefabricated body are overcome, a turbine guider blade is prepared by adopting an integrated assembly mode, parts are integrally assembled by adopting a riveting mode, the assembly structure adopts a SiC ceramic matrix to realize welding, and then the defect of insufficient root strength caused by conventional sewing the molded prefabricated body is avoided; and multi-part backup and assembly optimization can be realized, the risk of whole component scrapping caused by single part scrapping can be avoided, the preparation riskis reduced, the cost is reduced, and the component quality is improved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

A test method for battery bar power display in a portable electronic device

ActiveCN102890244BEasy to operateQuality assuranceElectrical testingCurrent electricElectrical battery

The invention provides a testing method for electric quantity display in a battery column in a portable electronic device. The method comprises the following steps of: S1: supplying power to the portable electronic device through an external power supply which is initially set to be first standard voltage; S2: opening the portable electronic device and enabling the portable electronic device to be in a standby interface state; S3: starting from the first standard voltage, gradually regulating the voltage of the external power supply, and obtaining the actual corresponding relation between the current voltage value and the corresponding current electric quantity display level in the battery column in the portable electronic device; and S4: judging whether the electric quantity display in the battery column in the portable electronic device is qualified or not according to the corresponding relation between the preset reference voltage value of each level and the standard electric quantity display level in the battery column. According to the testing method disclosed by the invention, whether the electric quantity of the battery is correctly displayed on the portable electronic device can be quickly judged, so that the risk during the project manufacturing process is reduced, the quality of software and hardware of the portable electronic device is ensured, and the operation is simple and convenient.

Owner:BYD CO LTD

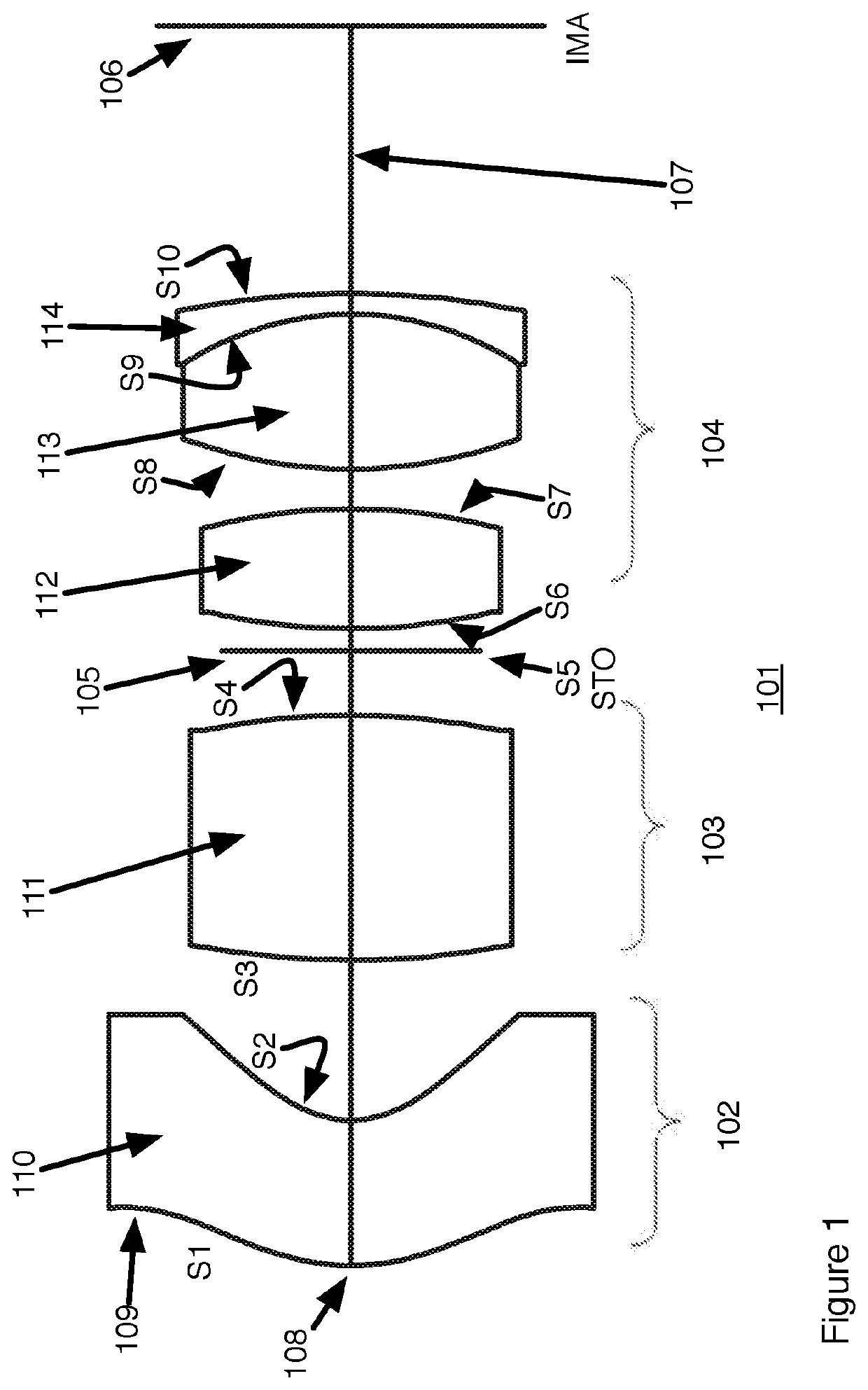

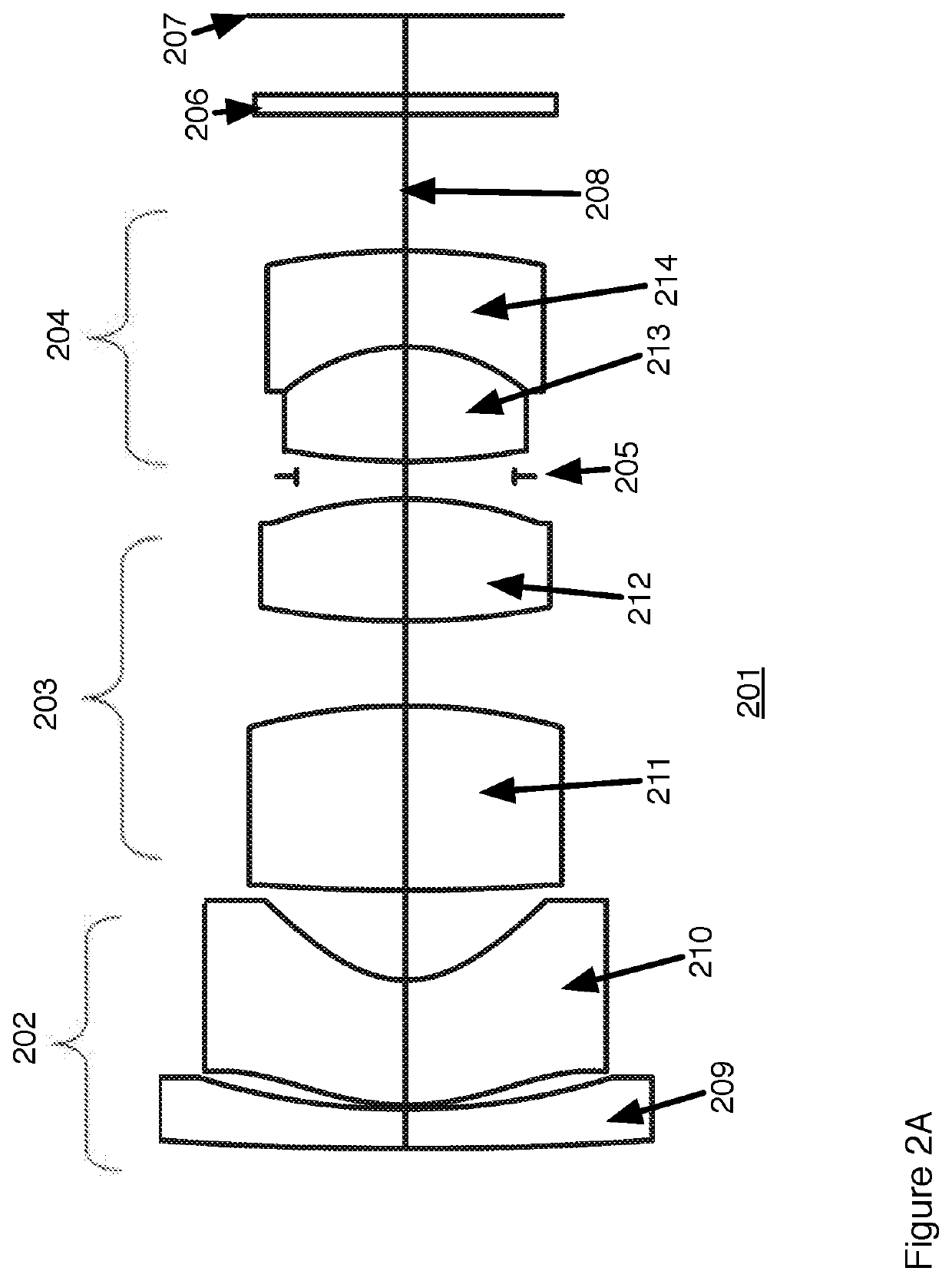

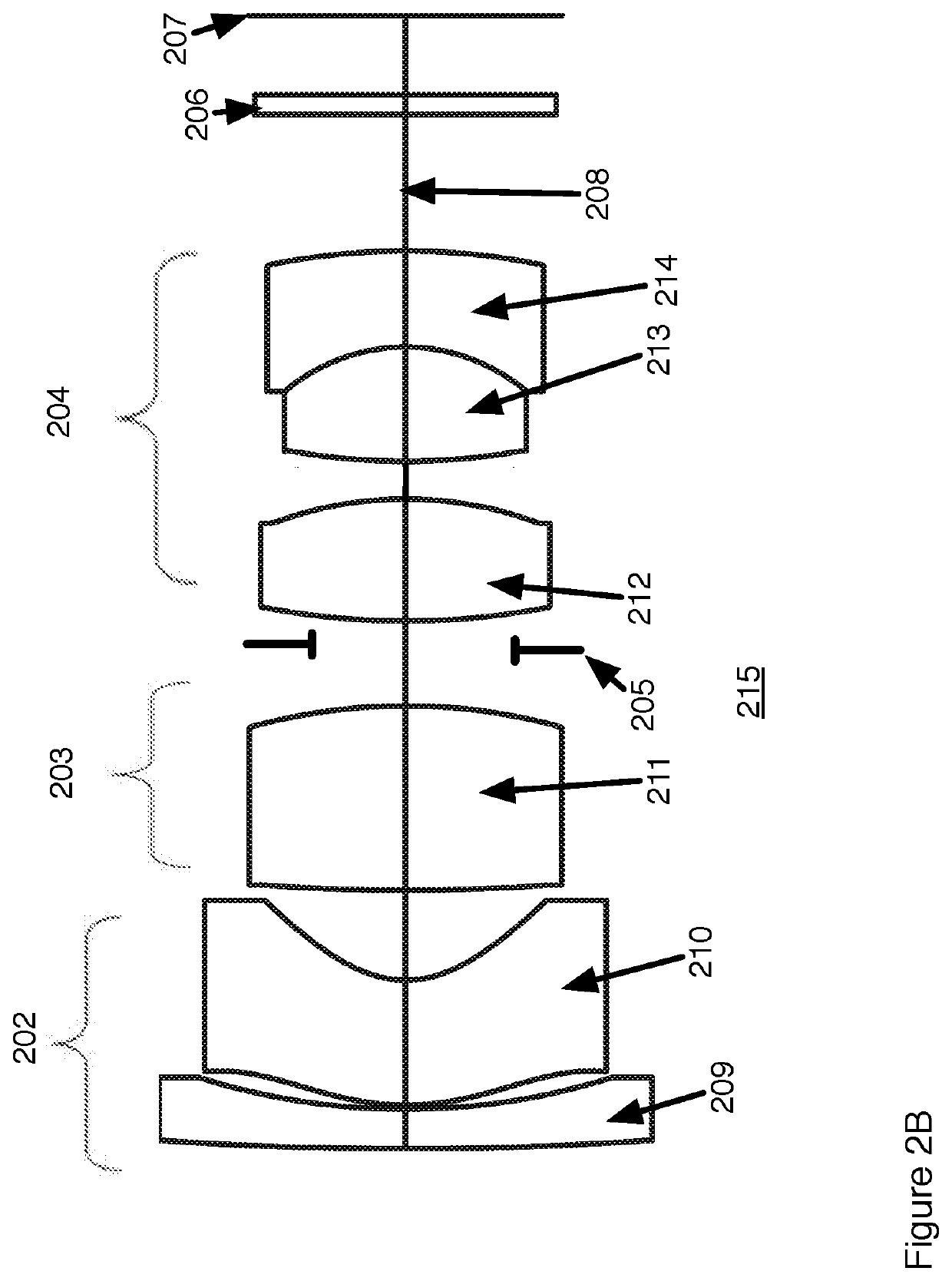

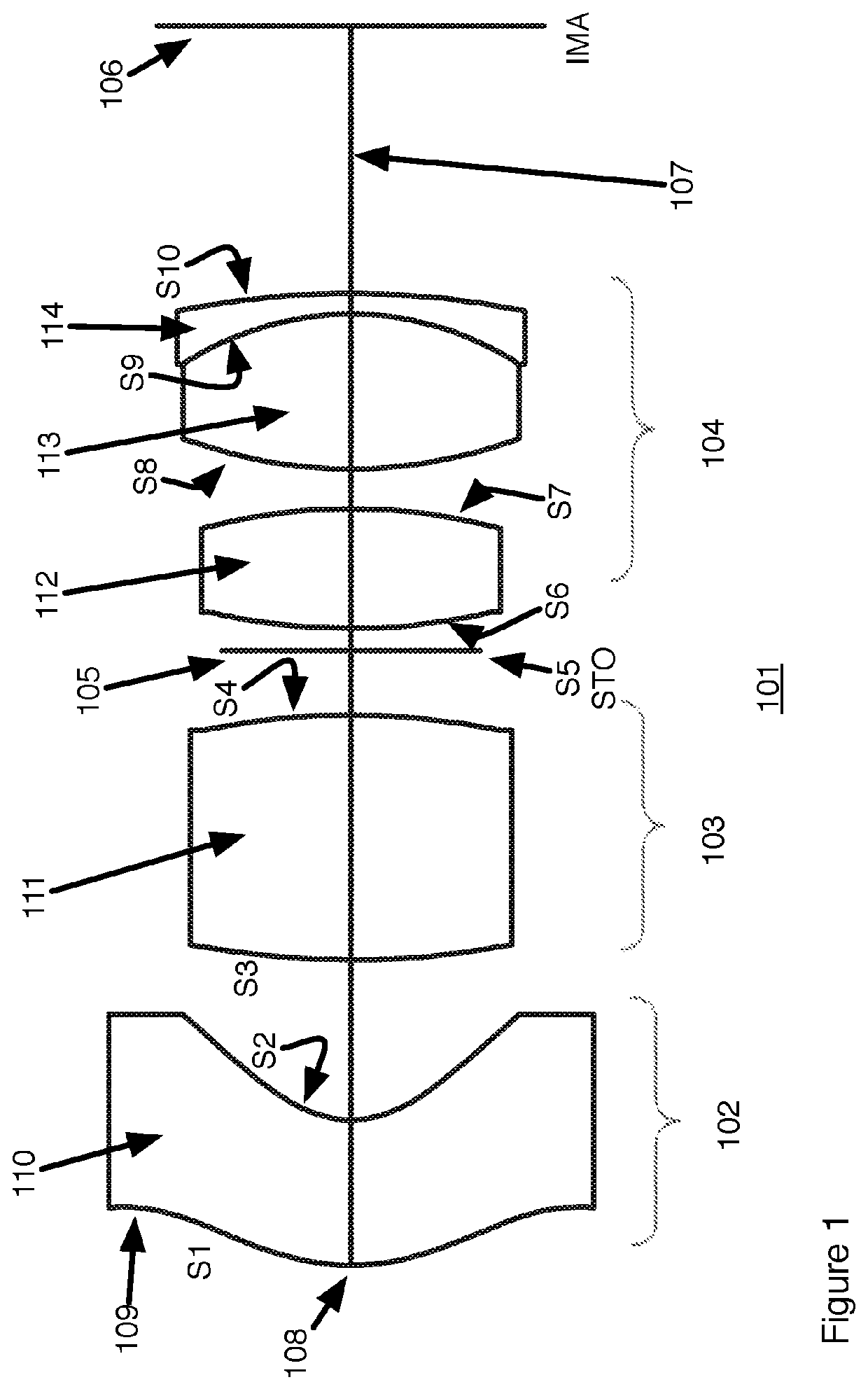

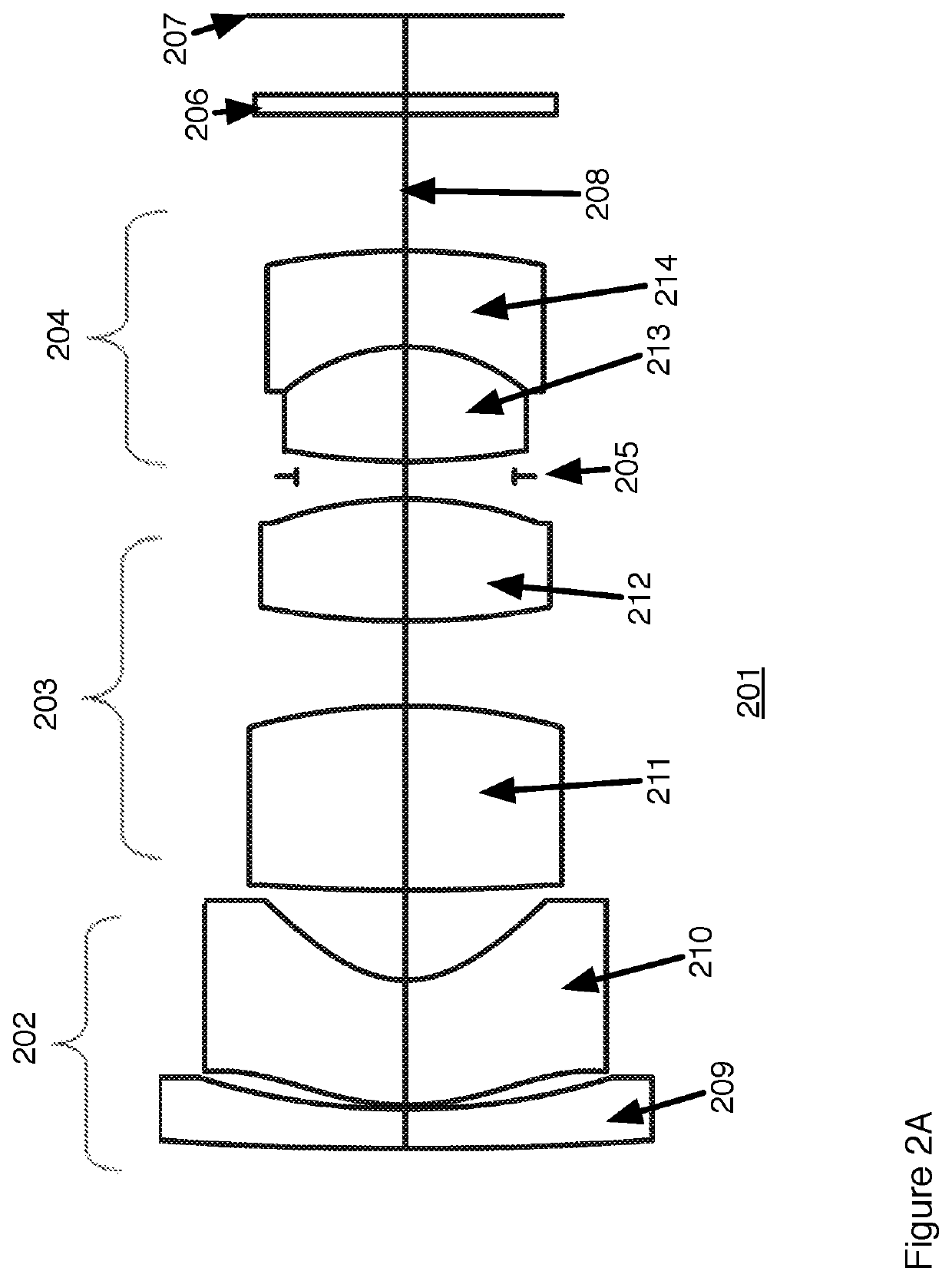

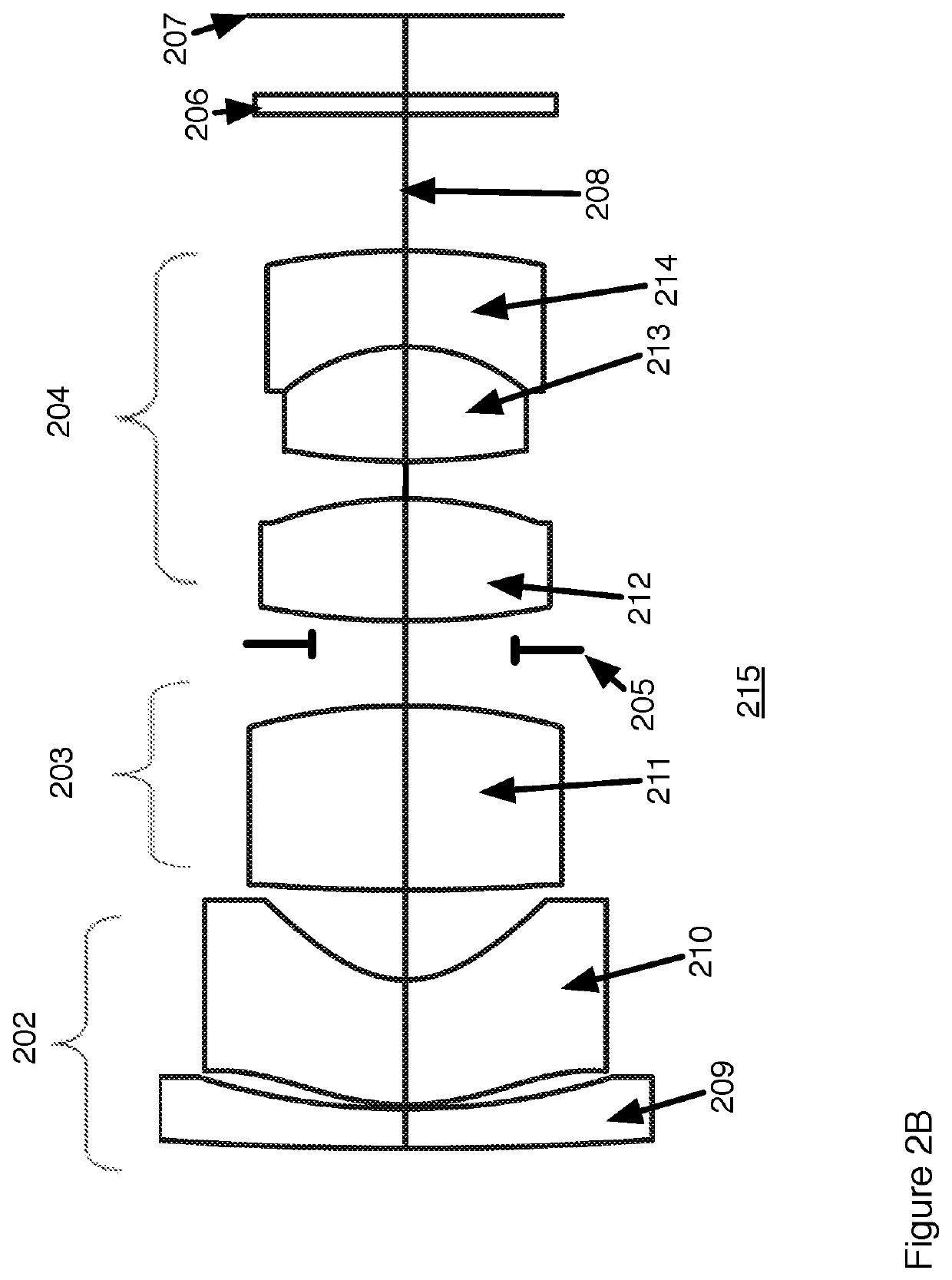

Fovea Lens

Wide angle fovea lens and a camera design using the lens are described. The lens has three lens groups and includes a single aspherical lens element. The lenses have higher magnification on the optical axis than at angles off the optical axis.

Owner:NING ALEX

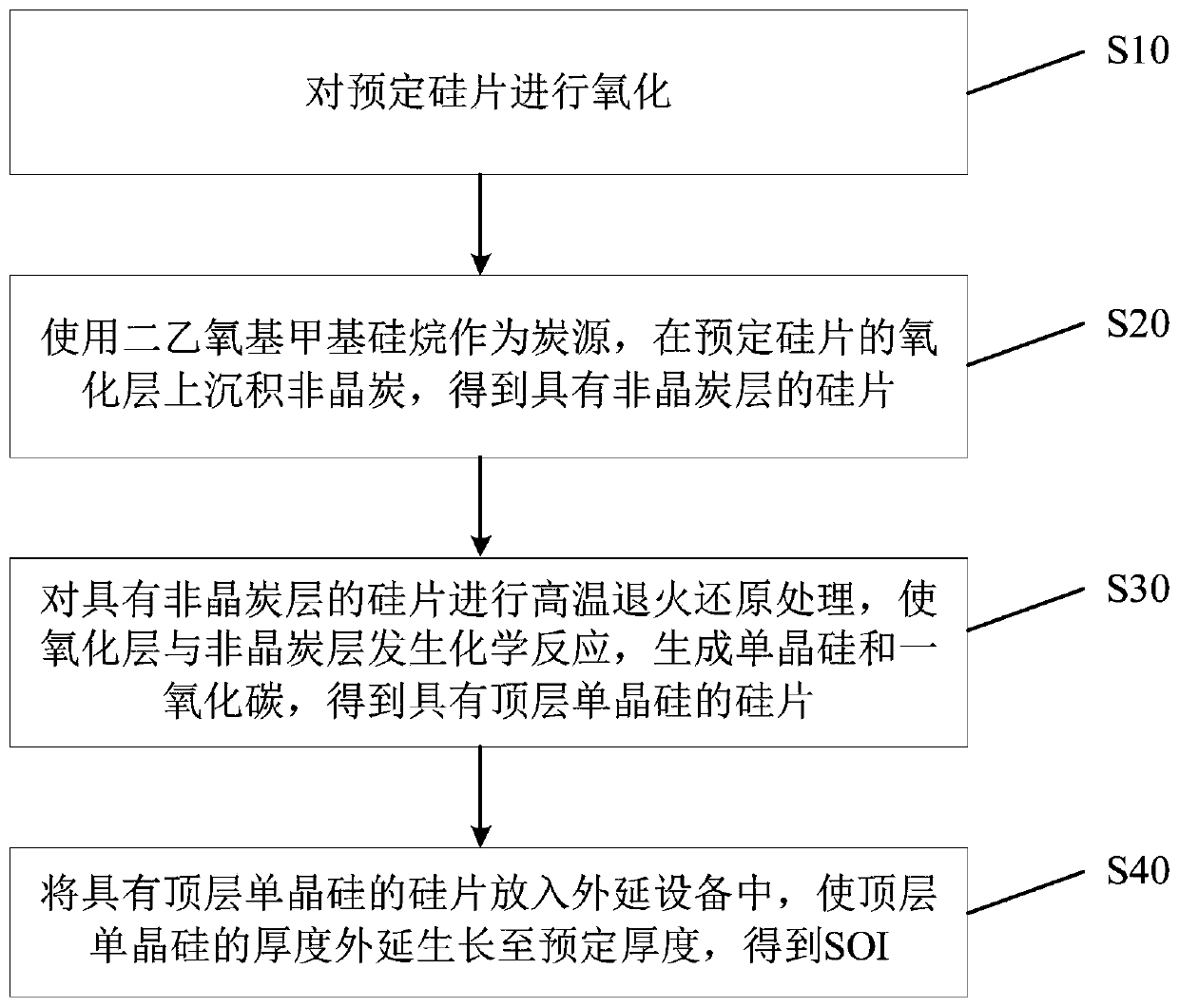

Method for direct growth of SOI

PendingCN110739262AReduce manufacturing riskImprove reliabilitySemiconductor/solid-state device manufacturingReduction treatmentChemical reaction

The invention provides a method for direct growth of SOI. The method comprises the following steps: oxidizing a predetermined silicon wafer; depositing amorphous carbon on an oxide layer of the predetermined silicon wafer by using diethoxymethylsilane as a carbon source so as to obtain a silicon wafer having an amorphous carbon layer; performing high-temperature annealing reduction treatment on the silicon wafer with the amorphous carbon layer to enable the oxide layer and the amorphous carbon layer to have chemical reaction so as to generate monocrystalline silicon and carbon monoxide and obtain the silicon wafer with the top monocrystalline silicon, wherein the treatment process is protected by inert gas; and putting the silicon wafer with the top monocrystalline silicon into epitaxial equipment and the thickness of the top monocrystalline silicon is epitaxially grown to a predetermined thickness so as to obtain the SOI. According to the method of direct growth of the SOI, the preparation process flow can be simplified, the production cost is low and the production capacity is high.

Owner:SHENYANG SILICON TECH

Aeroengine ceramic matrix composite fixed guide vane structure and its molding

ActiveCN111102017BAvoid the defects of insufficient strengthGood workmanshipEfficient propulsion technologiesStatorsEngineeringTurbojet engine

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Preparation method of metamaterial and the same

ActiveCN102487579BQuality assuranceReduce manufacturing riskMultilayer circuit manufactureLiquid stateViscous flow

Embodiments of the invention provide a preparation method of a metamaterial. The method comprises the following steps: adding a liquid-state high-molecular material in a mold and heating and curing to a viscous flow state so as to obtain a first flaky sheet material; aligning and pasting a first PCB possessing a metal microstructure array on the first flaky sheet material; further adding the liquid-state high-molecular material in the mold and heating and curing to the viscous flow state, and forming a second flaky sheet material on the first PCB; aligning and pasting a second PCB possessing the metal microstructure array on the second flaky sheet material. The embodiments of the invention also provide the metamaterial prepared by using the above preparation method. By using the method of the invention, malposition of the metal microstructure array on the PCB can be modified. Therefore, a preparation risk can be reduced and metamaterial quality can be guaranteed.

Owner:KUANG CHI INST OF ADVANCED TECH +1

Fovea lens

ActiveUS10901177B2Reduce manufacturing riskDifficult to manufactureOptical elementsOphthalmologyOptical axis

Wide angle fovea lens and a camera design using the lens are described. The lens has three lens groups and includes a single aspherical lens element. The lenses have higher magnification on the optical axis than at angles off the optical axis.

Owner:NING ALEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com