Conductor configuration system of wind power blade, wind power blade and preparing method thereof

A technology of wind power blades and wires, which is applied to wind power generation, wind engines consistent with the wind direction, and mechanical equipment. The effect of creating risks and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

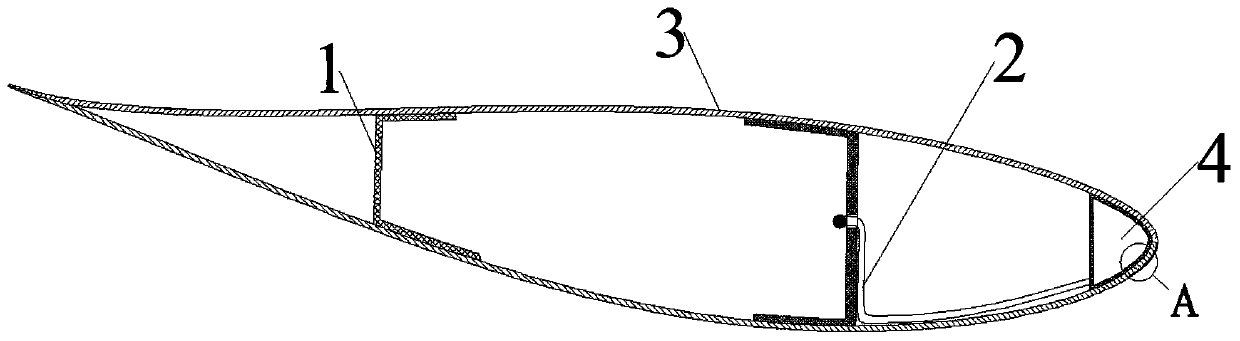

[0041] Such as Figure 1-5 As shown, the wire arrangement system of the wind power blade in this embodiment includes a wire receiving and fixing element 4 and a component 6 for pre-embedding with the outer surface of the wind power blade (which can be a temperature sensor, a heating element, a lightning protection device, a strain gauge, etc.) Connected wire 2. The wire holding and fixing element 4 and the wire 2 are both arranged in the blade shell 3. The wire 2 is laid along the inner web 1 of the wind power blade. The accommodating and fixing element 4 is fixedly arranged at the through hole 5 . The wire receiving and fixing element 4 is provided with a penetration hole 7 for the wire 2 to pass through and a penetration hole 8 for the wire 2 to pass through, and the penetration hole 8 coincides with the through hole 5 . In this embodiment, the web 1 and the wire 2 can be integrally molded for pouring, or bonded by hand lay-up.

[0042] In this embodiment, the wire accomm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com