Integral aluminum alloy spinning hub and manufacturing method thereof

A technology of an aluminum alloy wheel hub and a manufacturing method, which is applied in the directions of rims, transportation and packaging, vehicle parts, etc., can solve the problems of complex process, long processing cycle, high cost, etc., and achieves low raw material cost, low processing cost, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

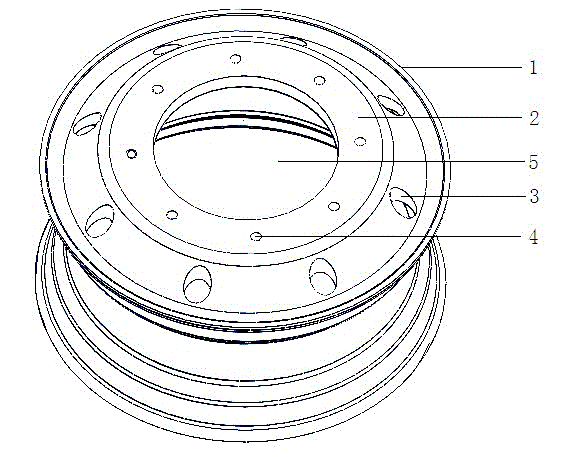

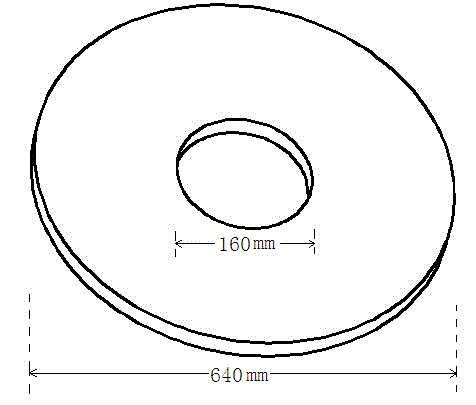

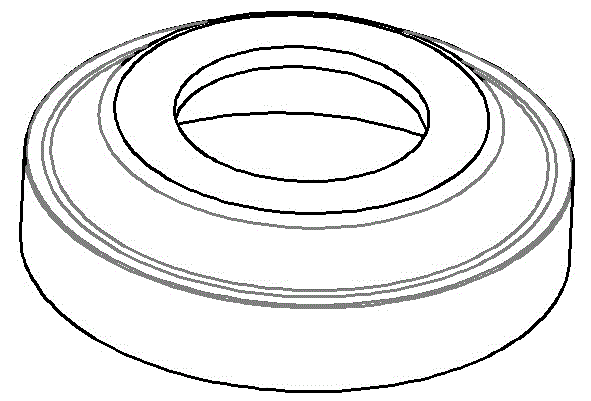

[0029] Such as figure 1 As shown, the present invention provides an integral aluminum alloy wheel hub for automobiles, including a rim 1 and a spoke 2, the rim 1 and the spoke 2 are formed by spinning from the same aluminum alloy plate; the axis of the spoke 2 There is a central hole 5, and the spoke 2 is provided with a number of bolt holes 4, the bolt holes 4 are evenly distributed around the central hole 5, and the side wall of the spoke 2 is provided with a number of evenly distributed ventilation holes 3, the The ventilation holes 3 are evenly distributed around the positioning hole 5, and the distance from the ventilation hole 3 to the center of the center hole 5 is greater than the distance from the bolt hole 4 to the center of the center hole 5; the rim 1 includes a rim front piece and a rim rear sheet, the outer sides of the front rim sheet and the rear rim sheet are stepped.

[0030] The present invention also provides a method for manufacturing an aluminum alloy wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Side wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com