Solid composite rudder blade high in rigidity and low in weight

A composite material and high-rigidity technology, applied in rudder steering and other directions, can solve the problems of low bending and torsion resistance, corrosion of internal skeleton structure, and high buoyancy of occupied reserves, etc., and achieve the effect of solving the problem of easy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

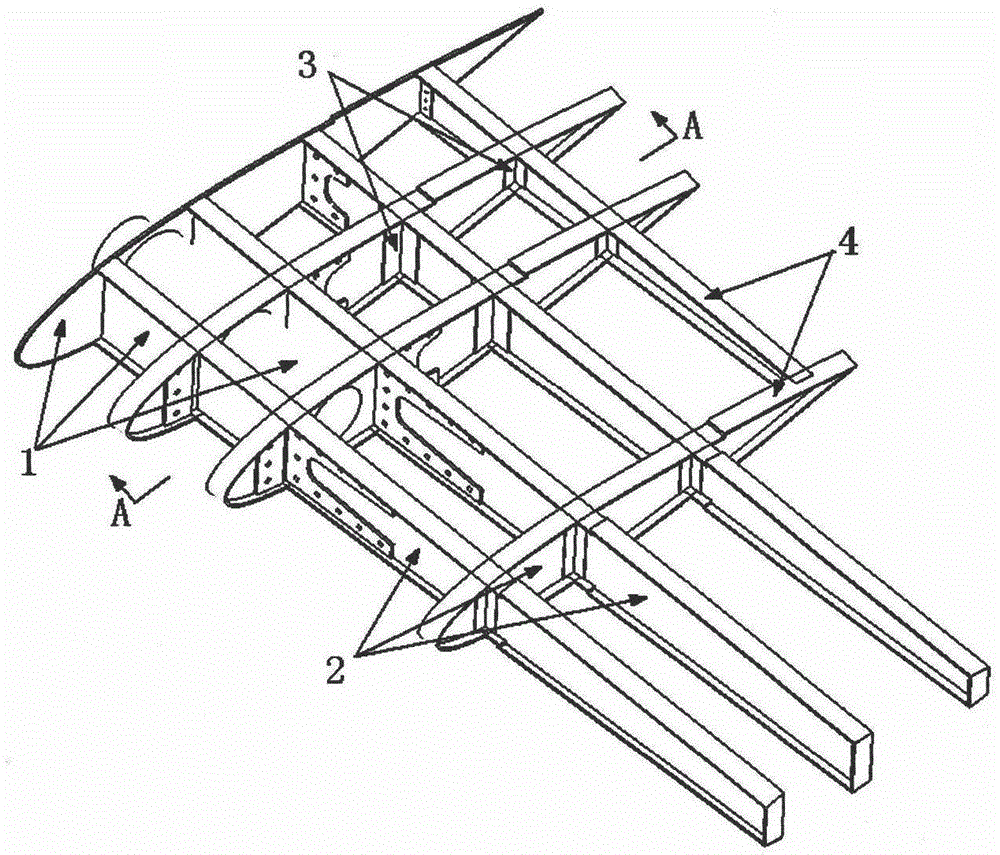

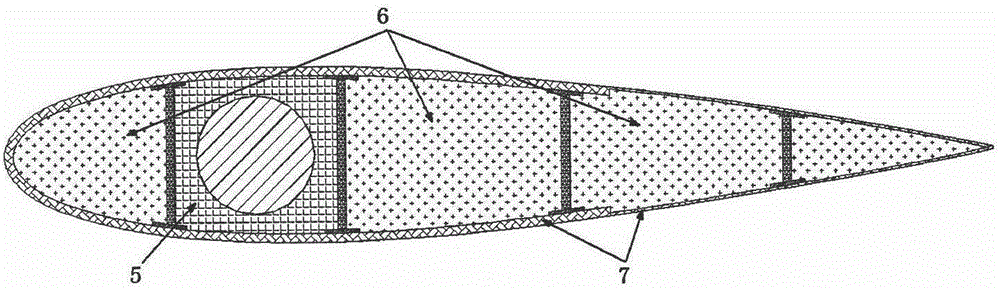

[0025] see figure 1 , figure 2 , image 3 with Figure 4 , the present embodiment is composed of a steel frame 1 in the rudder stock area, a skeleton 2 of composite material, a reinforcement angle 3 , a wing plate of composite material 4 , a damping and / or sound-absorbing material 5 , a buoyancy filling core material 6 and a skin 7 of composite material.

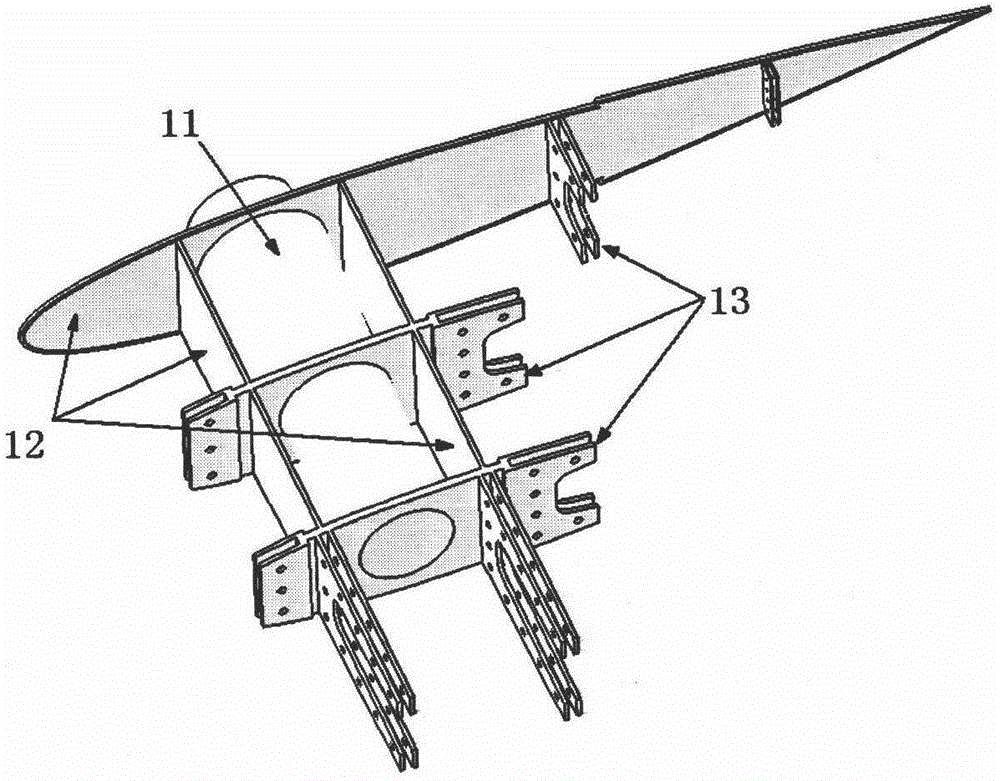

[0026] The steel frame 1 in the rudder stock area is made of No. 45 high-strength steel. The end of the rudder stock is welded with a whole piece of steel end plate, and the composite material skin 7 is terminated at the outer edge of the end plate, which can be connected watertight by screws or embedded The watertight connection structure is terminated; the steel frame 1 in the rudder stock area is composed of a rudder stock 11, a steel skeleton 12 and steel connectors 13, and the number of steel connectors 13 is 4 in the chord direction and 4 in the span direction; the rudder stock The surrounding is filled with dampin...

Embodiment 2

[0033] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0034] Such as Figure 5 As shown, blind holes 15 are provided at the end of the rudder stock 11 of the steel frame 1 in the rudder stock area, lightening holes 14 are provided on the steel frame 12, and lightweight foam materials are filled around the rudder stock 11 and in the blind holes at the ends to To further reduce the structural weight, the number of steel connectors 13 is 6 in the chord direction and 3 in the span direction. For the specific structure, see Figure 4 .

[0035] Such as Image 6As shown, the composite material skeleton 2 is composed of three cross ribs 22 and four chord ribs 21. The numbering of the ribs 22 from the leading edge to the trailing edge is sequentially numbered 1 to 3, and their thicknesses are sequentially 20mm, 20mm, 20mm, the chord ribs 21 are numbered successively from the rudder stock to the rudder shed as chord 1 to chord 4, and their ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com