Single-phase transformer

A single-phase transformer and voltage regulating coil technology, applied in the field of transformers, can solve problems such as transportation difficulties, waste of resources, and increase the overall width of the transformer, and achieve the effects of improving operational reliability, facilitating coil winding, and reducing manufacturing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

[0024] The following is an example of a self-coupling oil-immersed 500KV single-phase transformer. Those skilled in the art can understand that the various embodiments of the present invention are also applicable to other types of single-phase transformers.

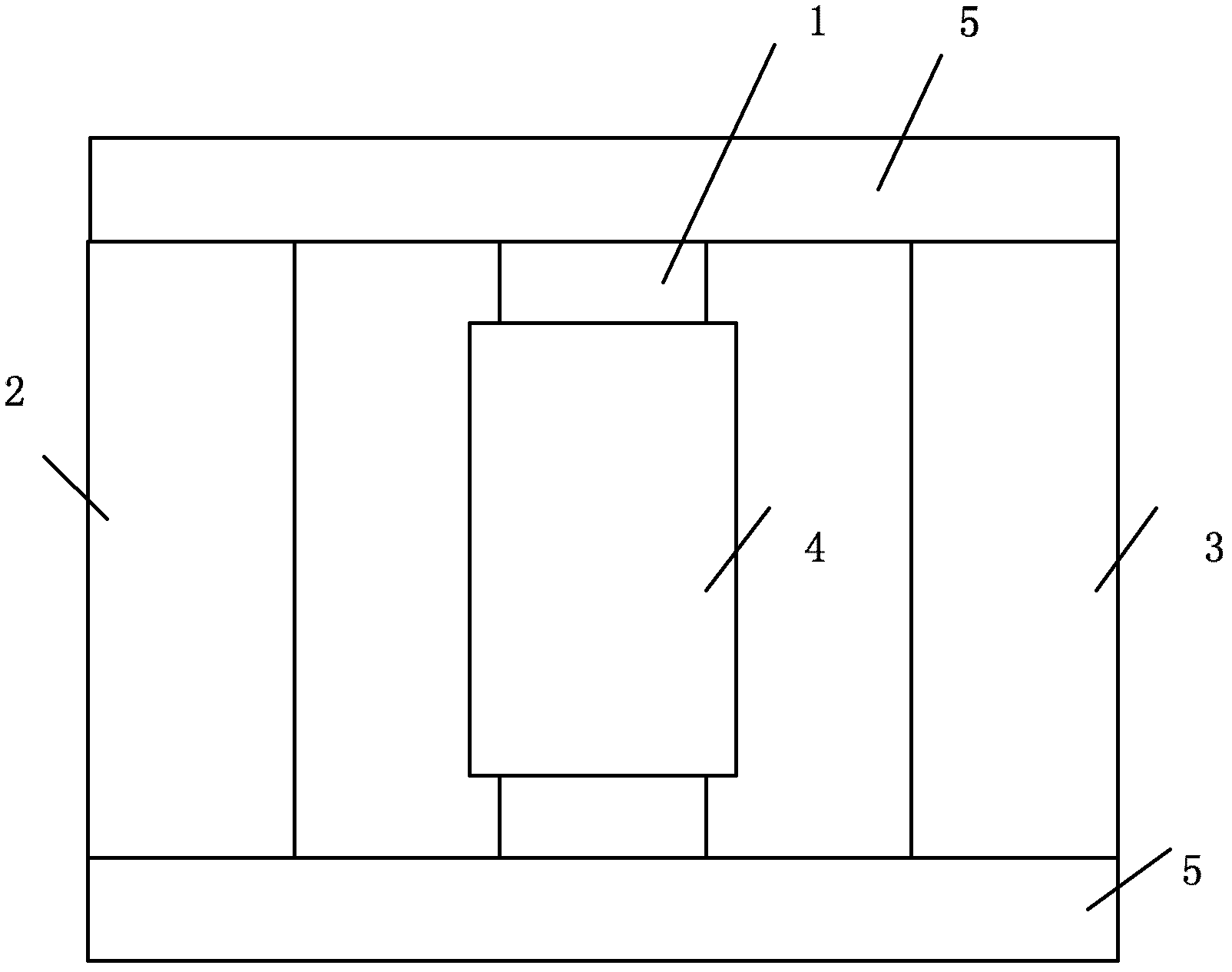

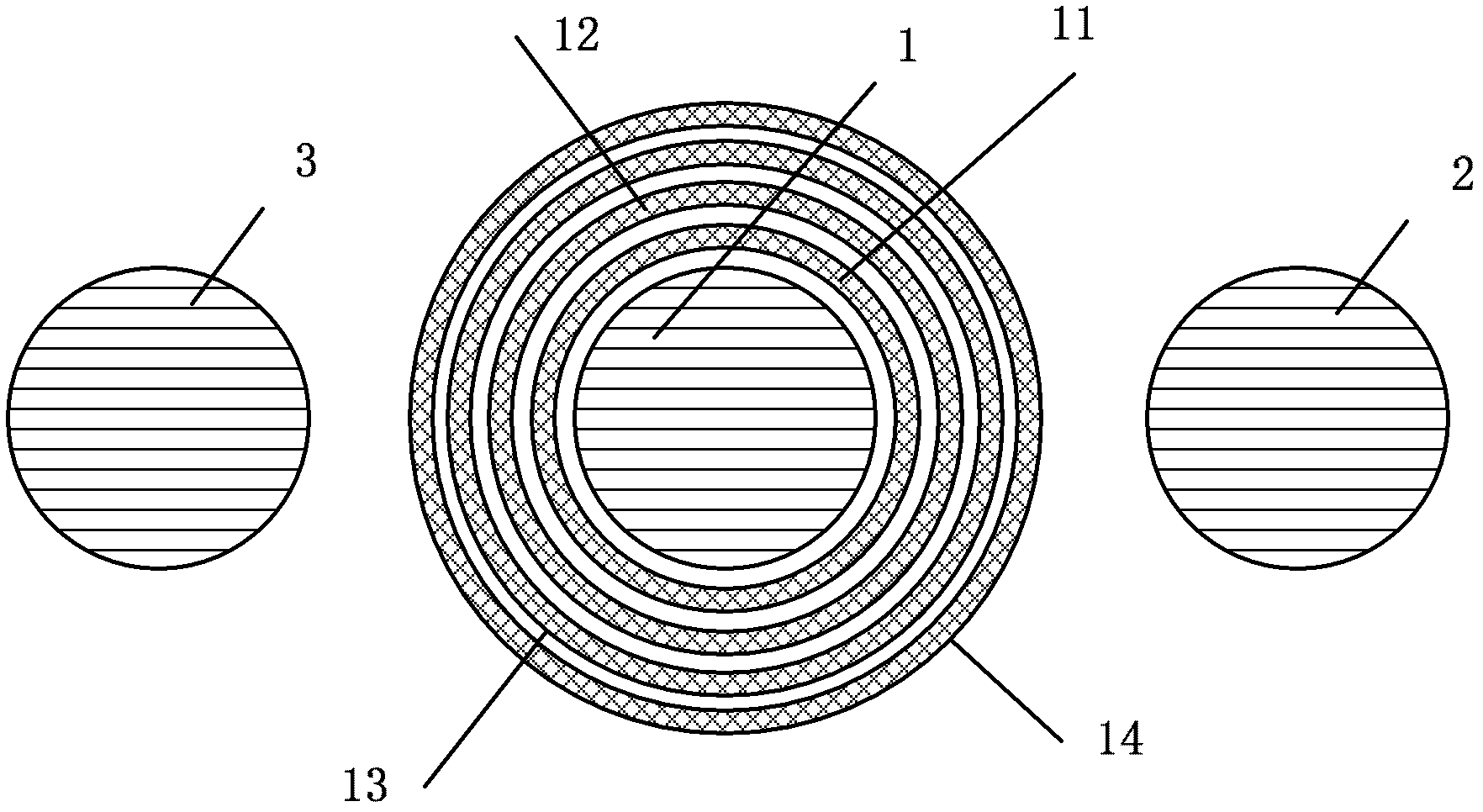

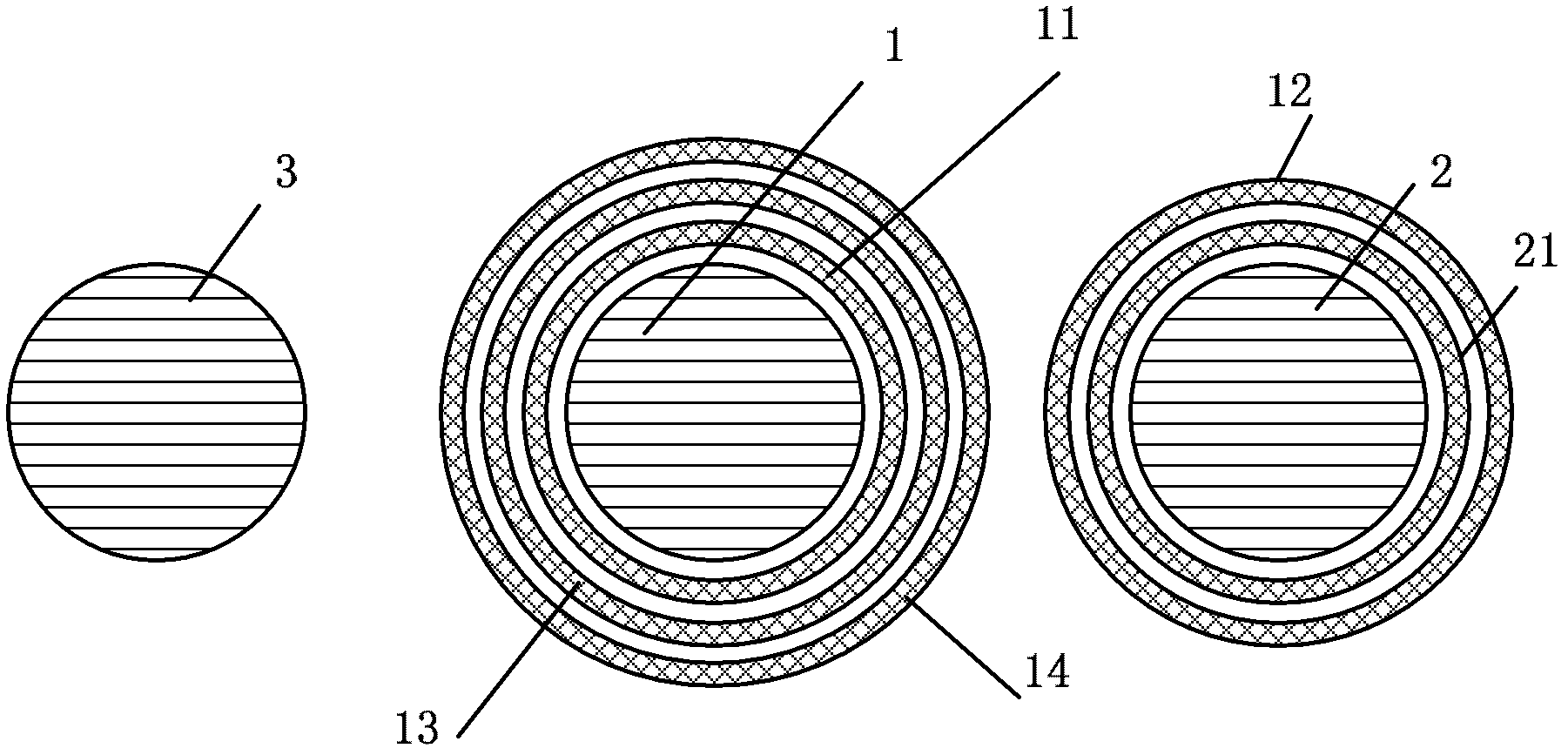

[0025] image 3 It is a top view of an embodiment of the single-phase transformer of the present invention. like image 3 shown, and figure 2 Compared with the prior art shown, the voltage regulating coil 12 is moved from the main column 1 of the iron core to the side column 2 of the iron core, and the excitation coil 21 is placed inside the voltage regulating coil 12 . The excitation coil 21 is connected in parallel with the medium-voltage coil 13 set on the main column 1 of the iron core, so as to achieve the purpose of locking the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com