Patents

Literature

128results about How to "Guaranteed rotational stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

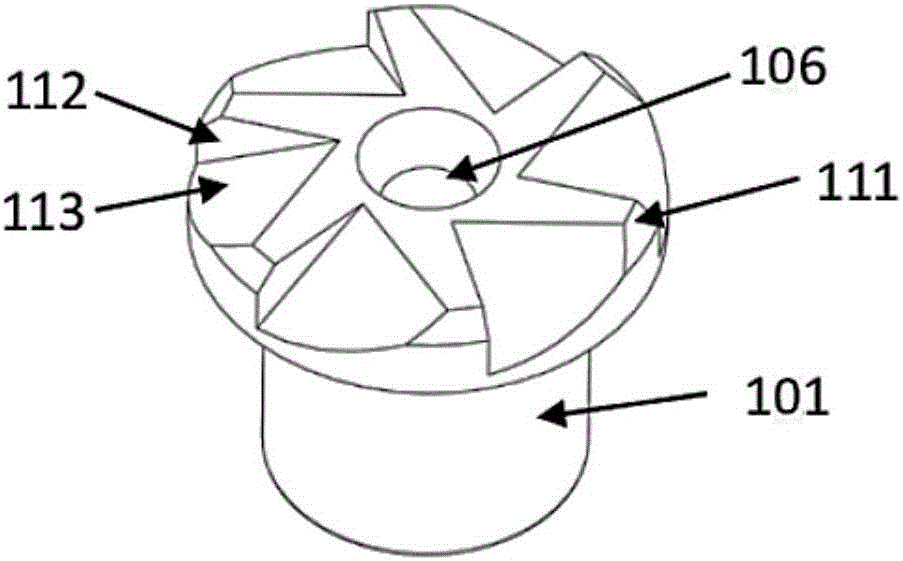

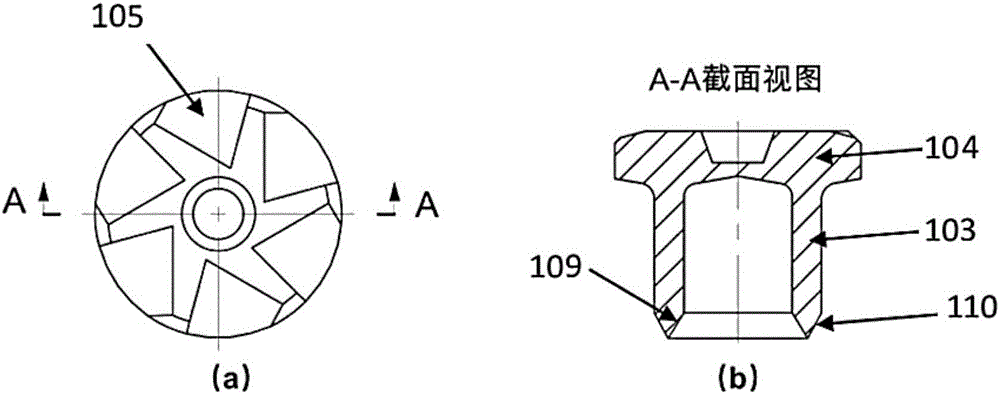

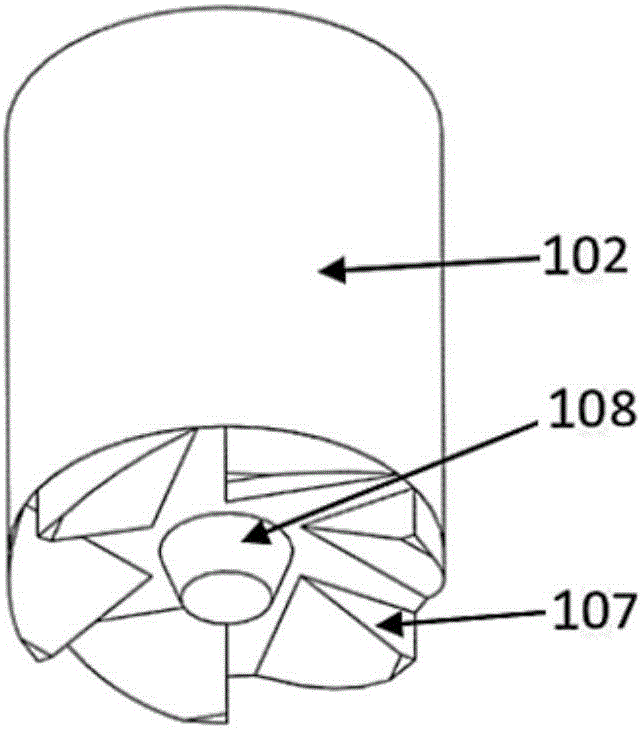

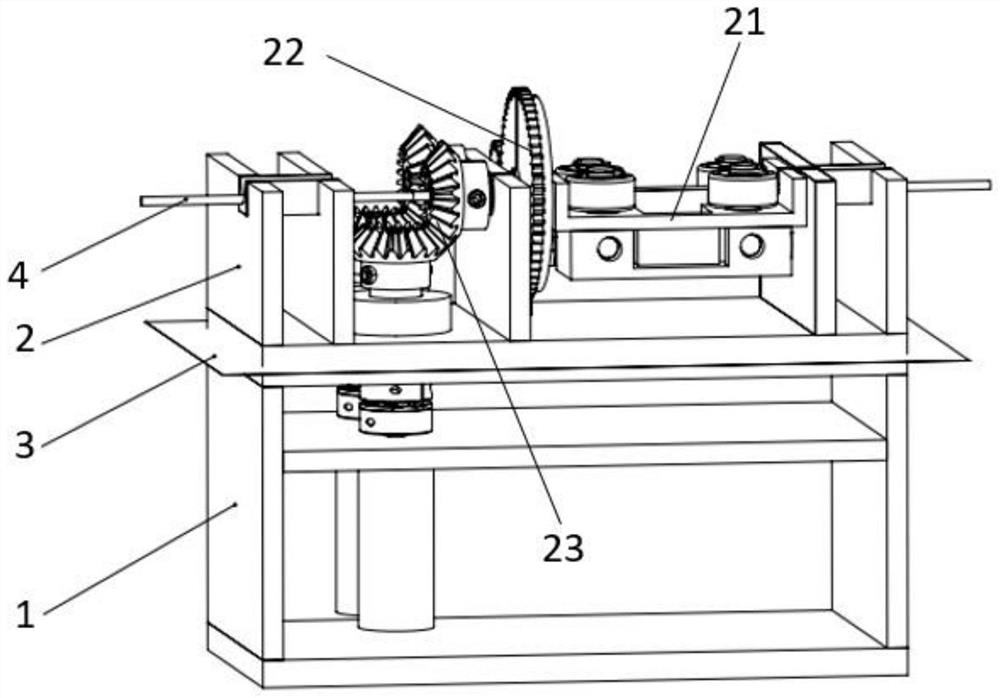

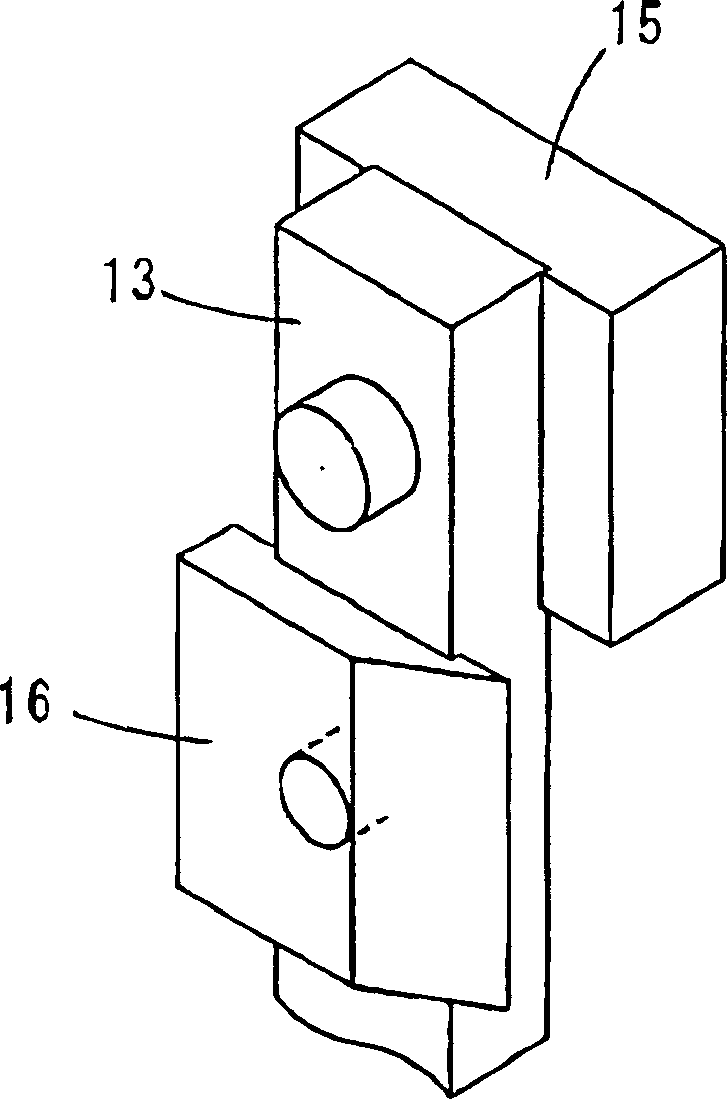

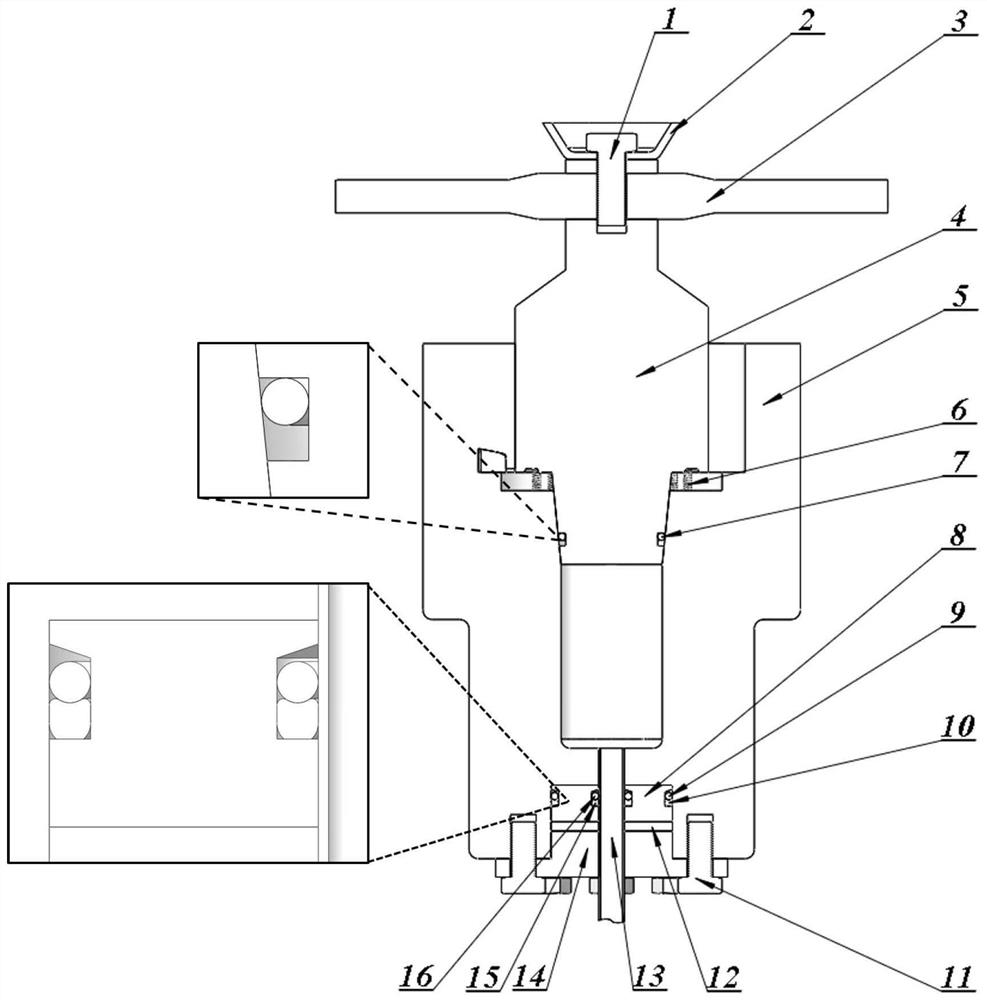

Rivet for friction-self piercing riveting (F-SPR) and F-SPR connecting system thereof

ActiveCN106112543AQuick clampingReduce weightScrewsOther manufacturing equipments/toolsEngineeringRivet

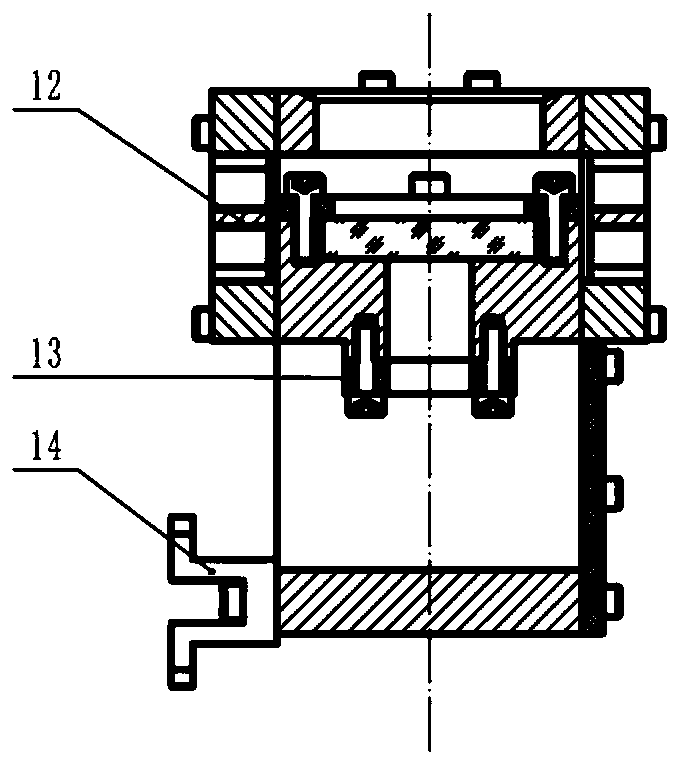

The invention discloses a rivet for friction-self piercing riveting (F-SPR) and an F-SPR connecting system thereof. The rivet comprises a semi-hollow rivet body and a rivet cap, wherein the lower surface of the rivet cap is connected with the semi-hollow rivet body; a wedge-shaped taper corner is arranged at the bottom end of the semi-hollow rivet body; chamfers for assembly and disassembly and a rotating driving structure are arranged on the edge of the upper end of the rivet cap; a locating structure is arranged in the center of the rivet cap; the rotating driving structure is a directed concave surface or a directed convex surface in central symmetry; and the locating structure is a convex surface or a concave surface in central symmetry and mirror symmetry. When the rivet is matched with a driving system for utilization, the driving rigidity and locating accuracy of the rivet during the F-SPR process can be improved, the problems that during the high-speed rotation process of the semi-hollow rivet, the stability is poor and the rivet axis and the rotation axis do not overlap are solved, the probability that a connector loses efficacy is reduced, the problem that a clearance is formed between the rivet and a panel is avoided, and the technological reliability of an F-SPR technology when connecting steel, aluminum, magnesium materials, composites and heterogeneous materials is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

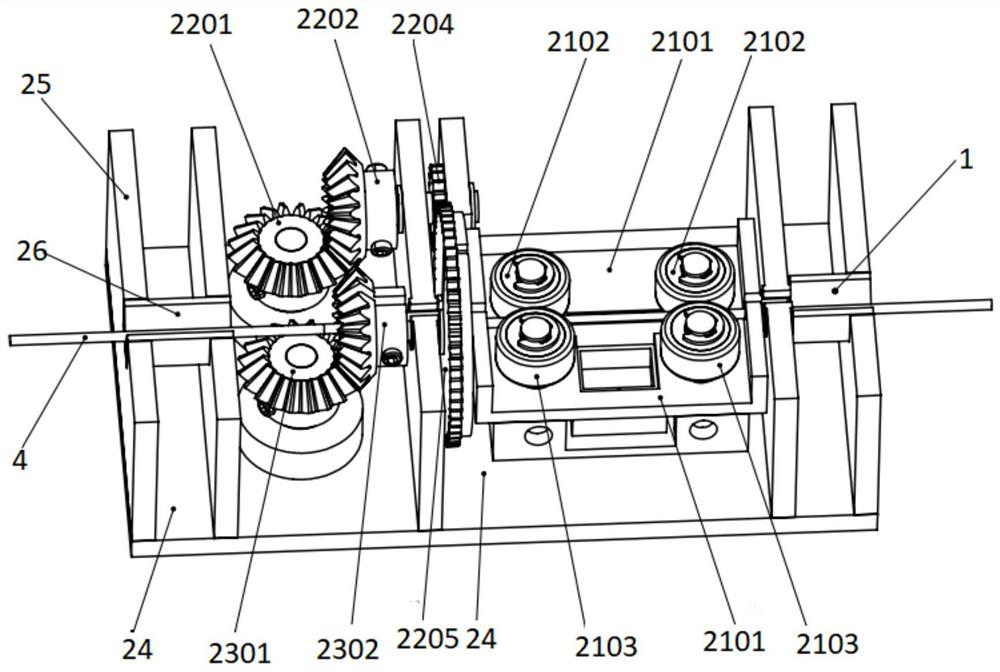

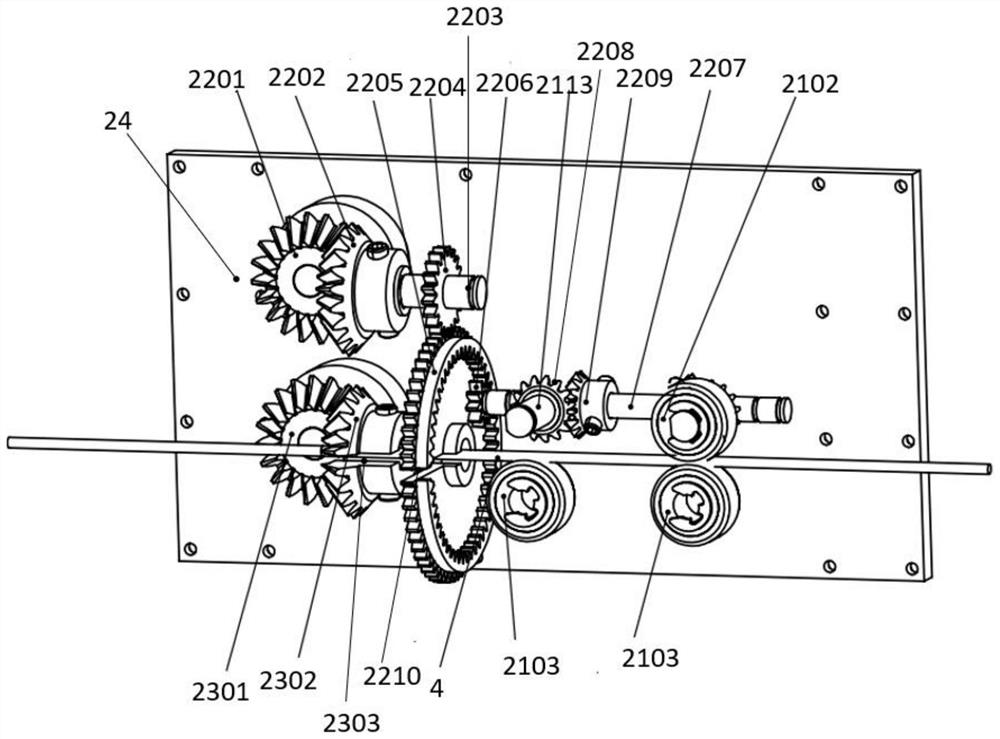

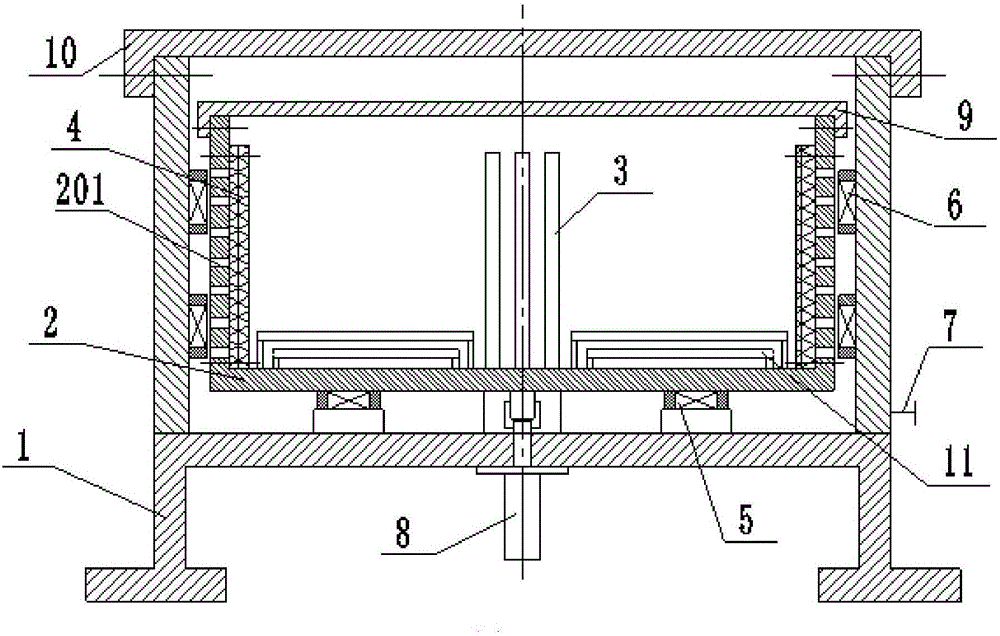

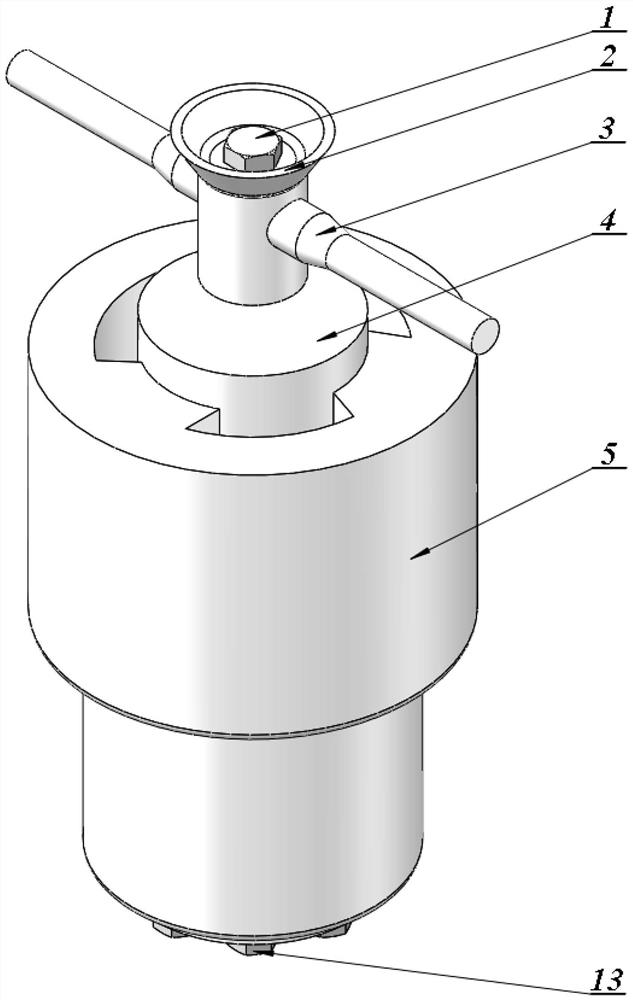

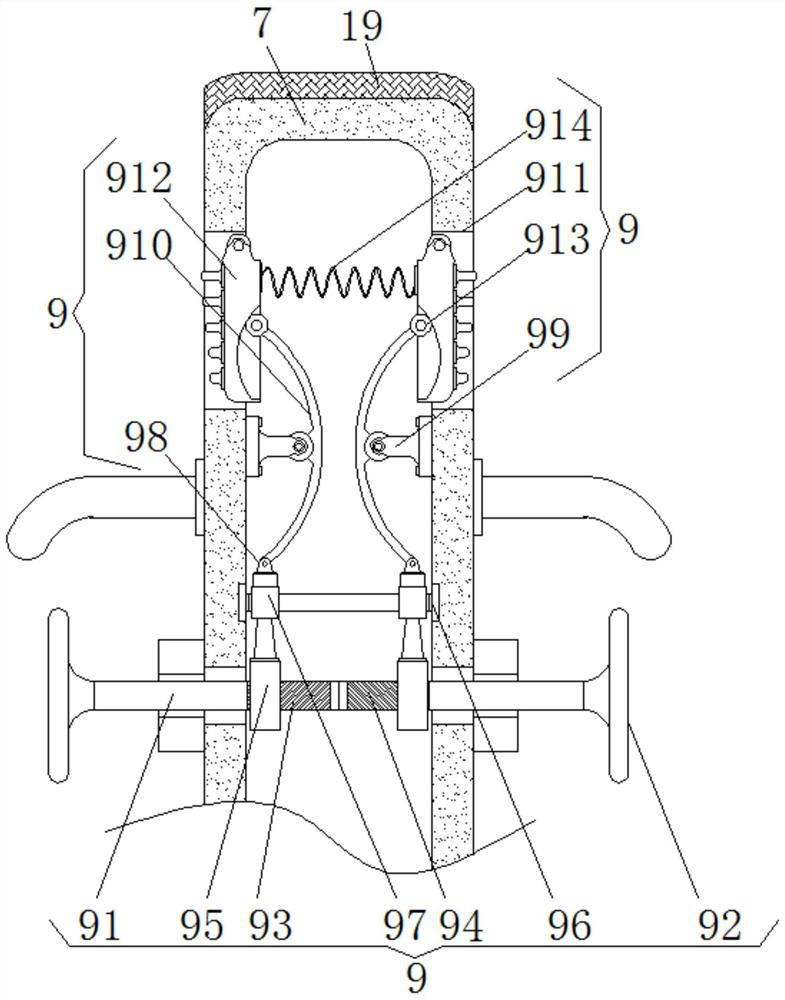

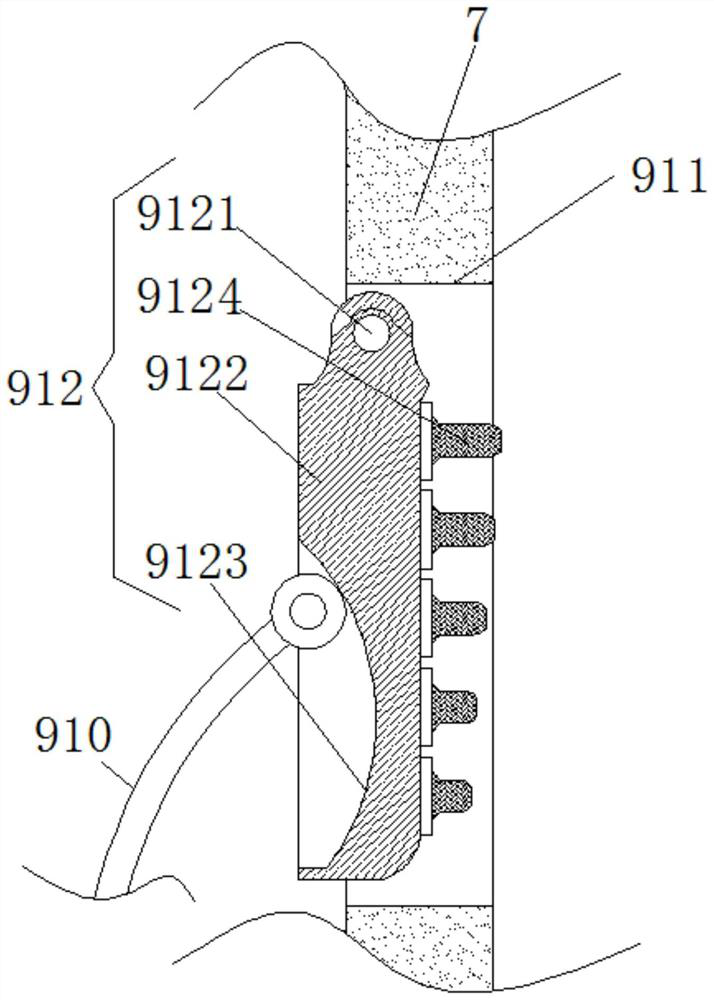

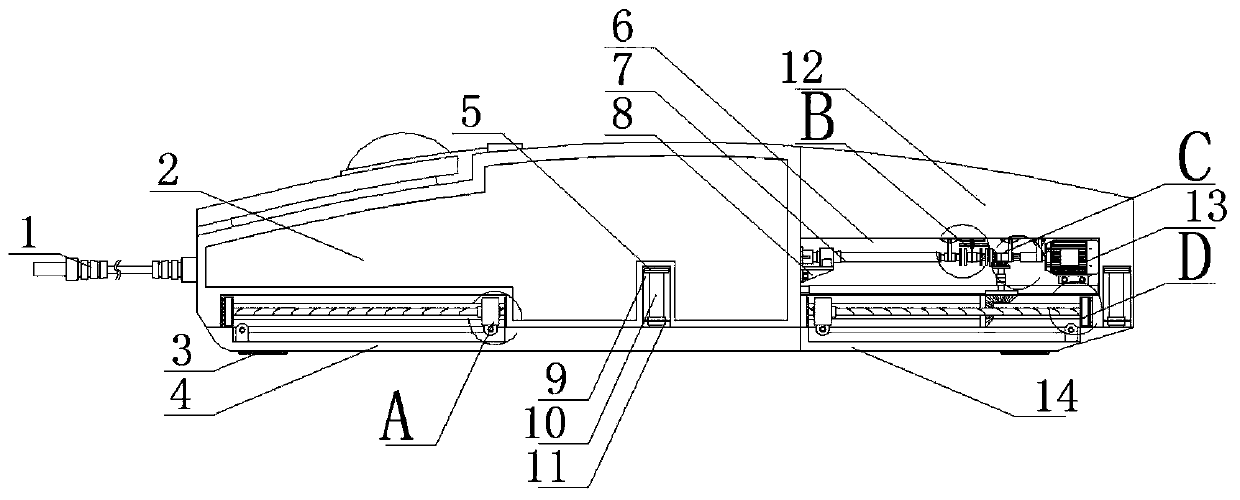

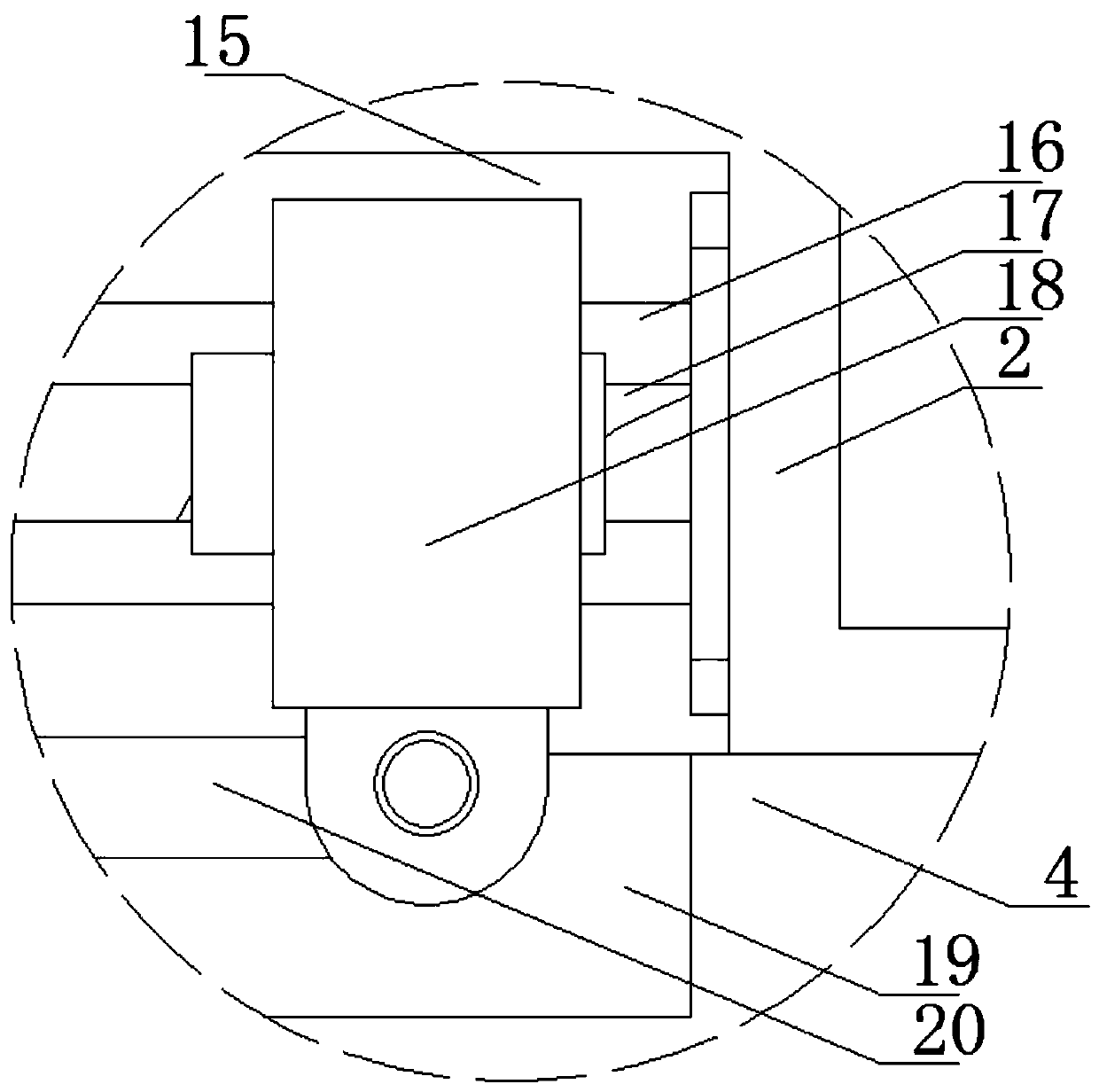

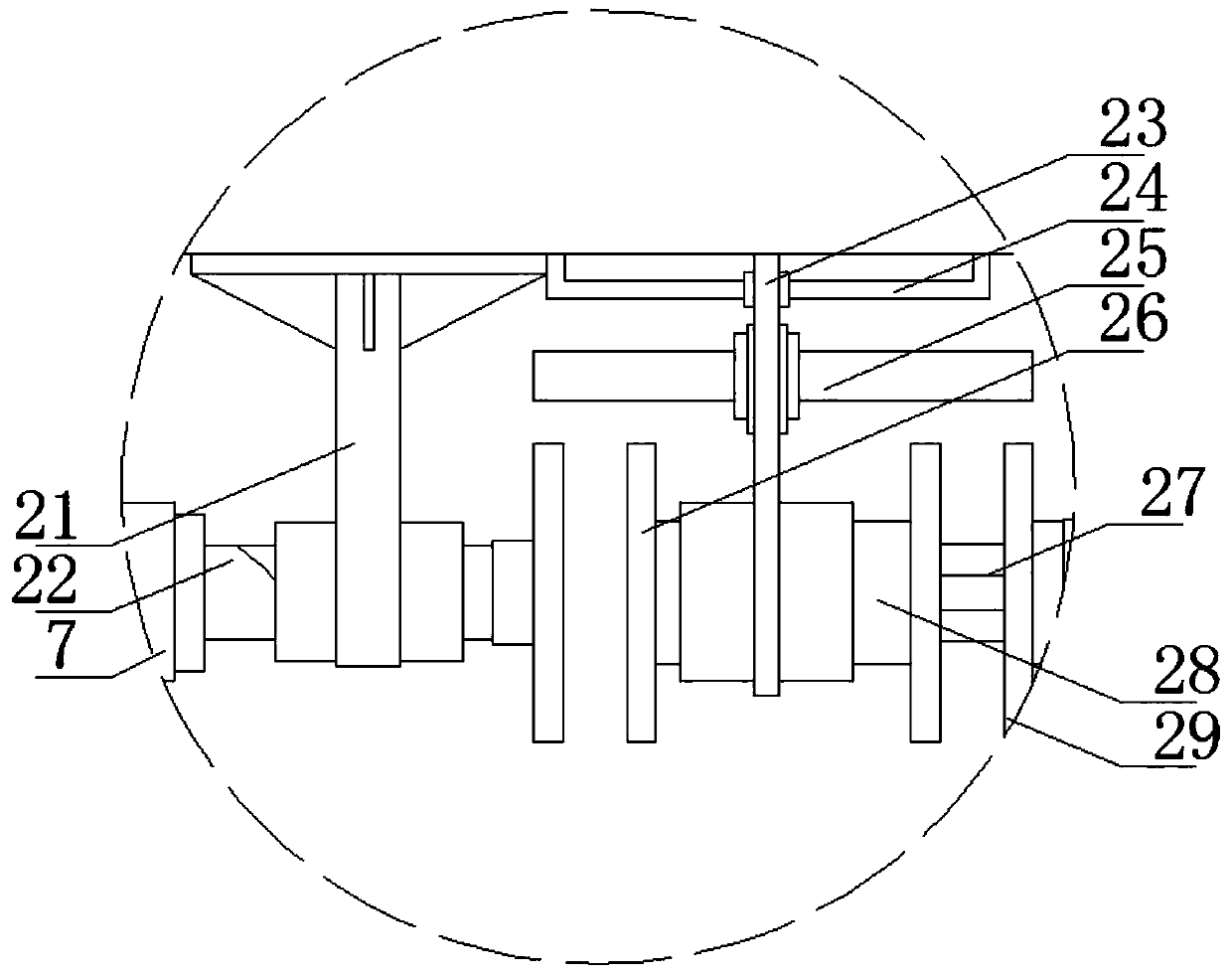

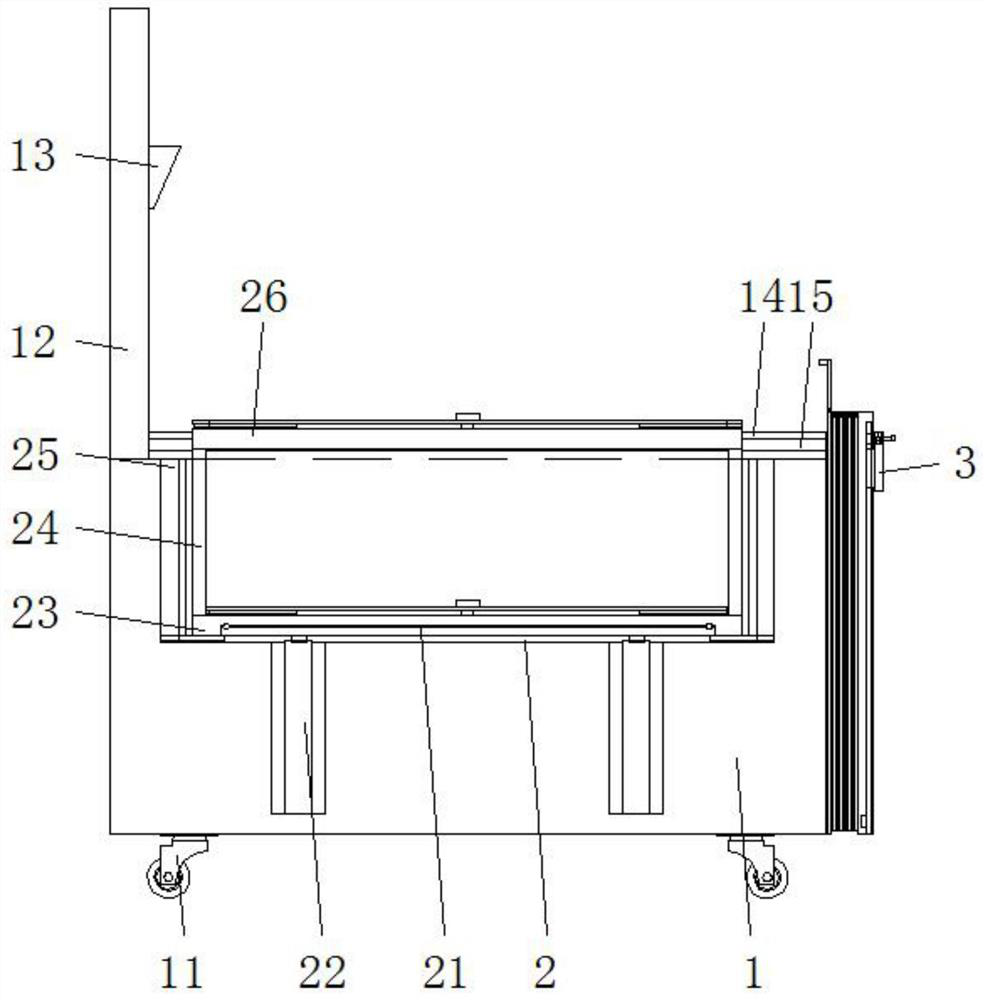

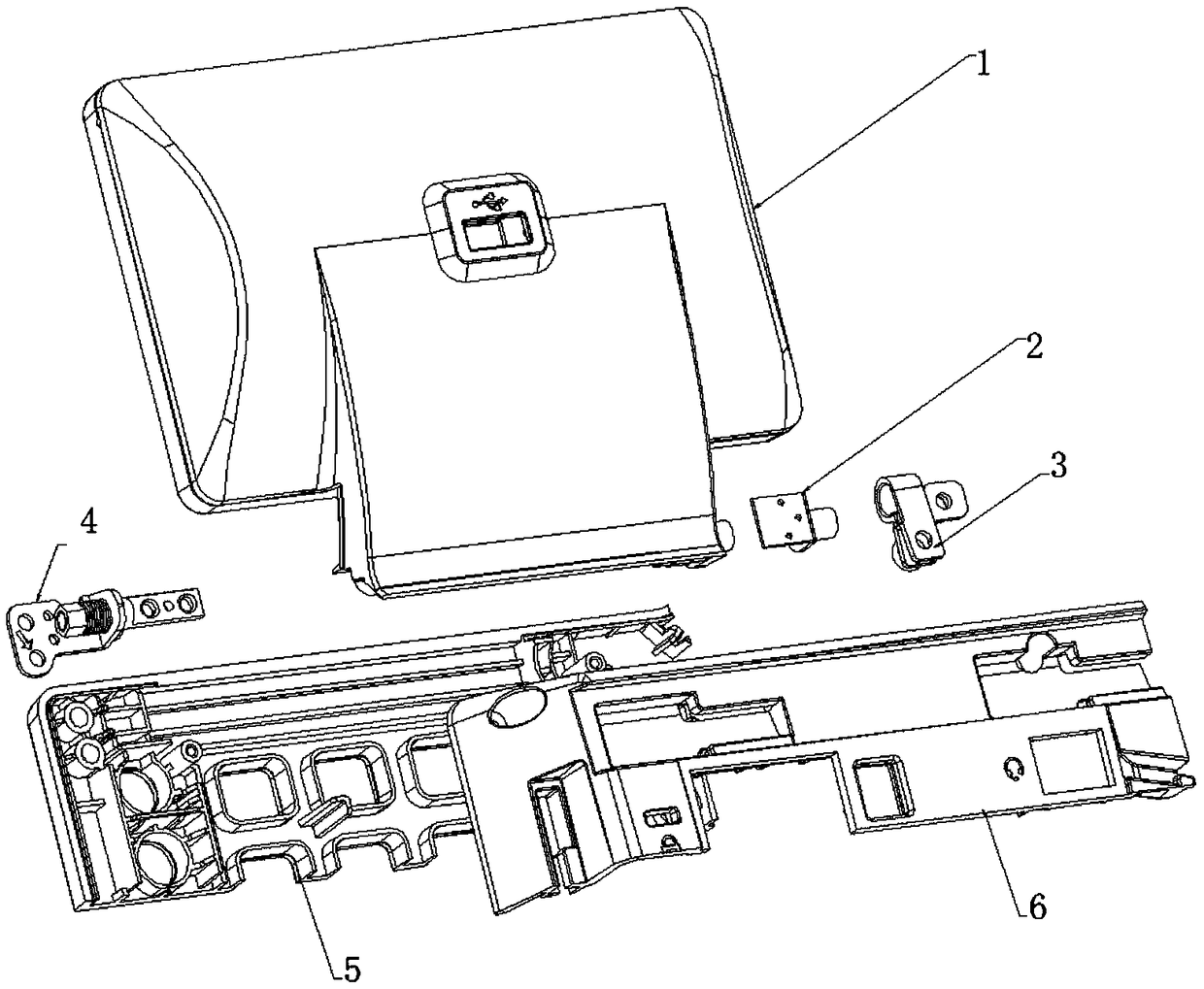

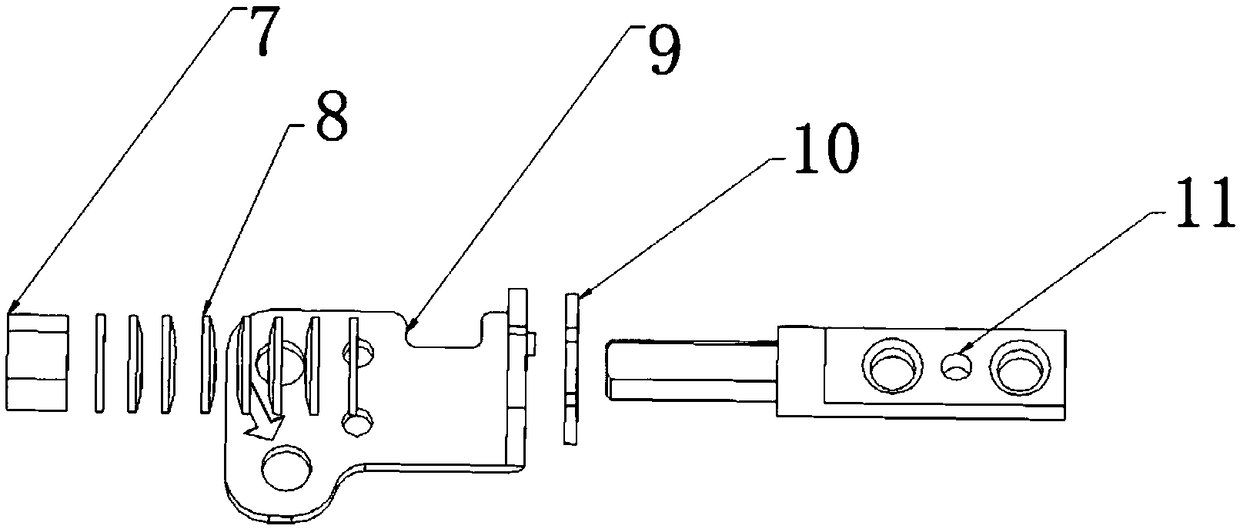

Guide wire/catheter delivery device for vascular intervention, use method of guide wire/catheter delivery device and vascular intervention surgical robot

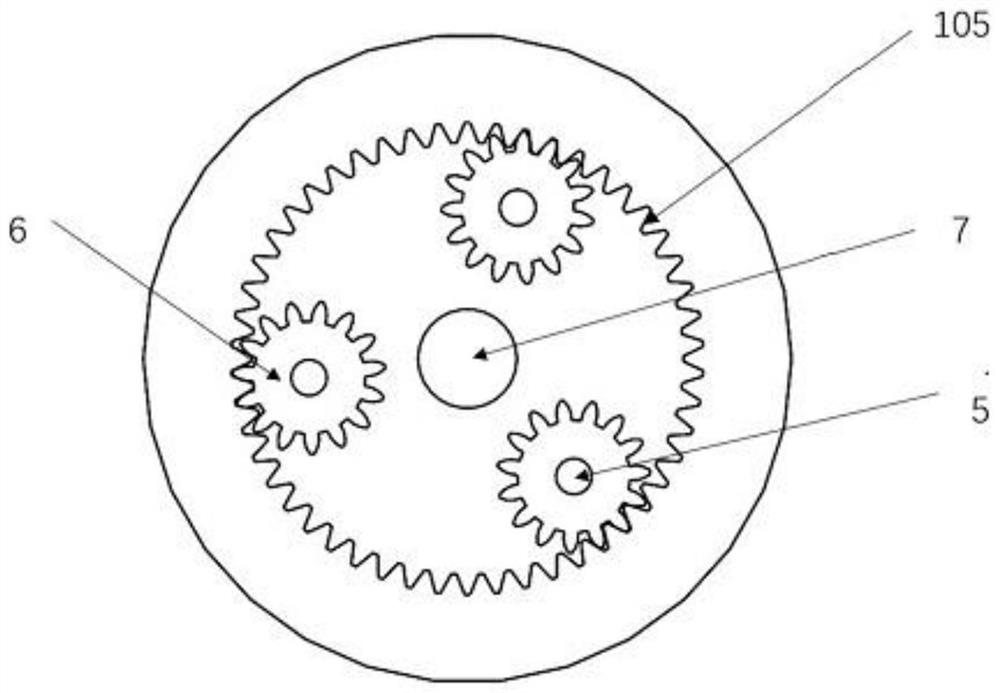

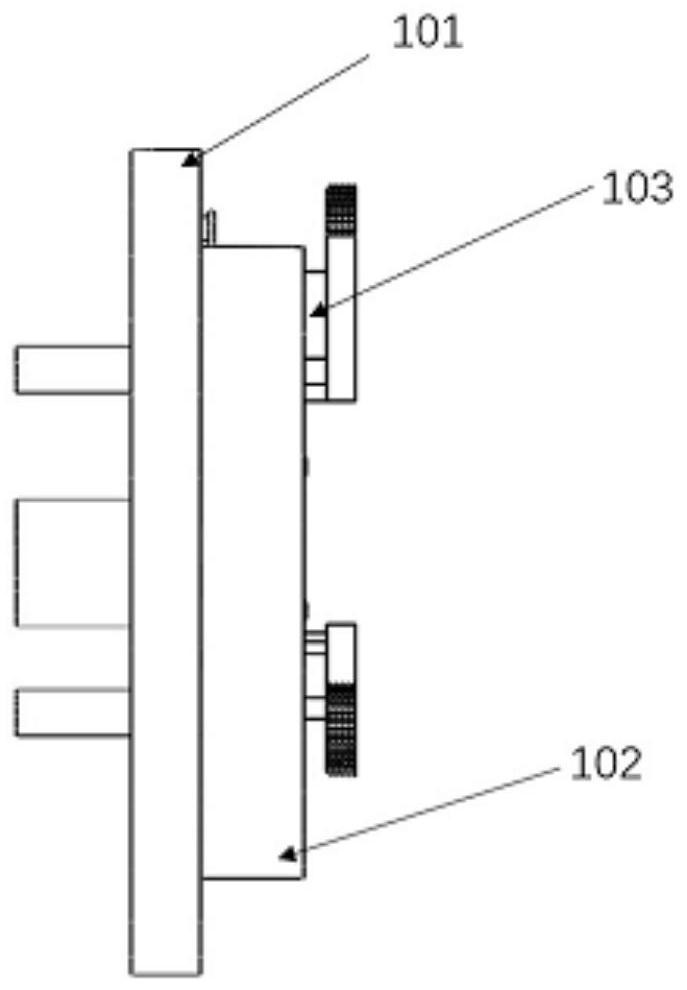

PendingCN113633383AGuaranteed stabilitySmall sizeCatheterSurgical robotsBiomedical engineeringSurgical robotics

The invention discloses a guide wire / catheter delivery device for vascular intervention and a using method of the guide wire / catheter delivery device and a vascular intervention surgical robot. The delivery device comprises a clamping assembly used for clamping a guide wire / catheter, and a driving part, wherein the clamping assembly comprises a clamping base, one or more driving wheels and one or more driven wheels, the driving wheels and the driven wheels are rotationally mounted on the clamping base, and are symmetrically arranged on the two sides of the guide wire / catheter; the driving part comprises a wire feeding and retreating driving unit and a wire rotating driving unit, the wire feeding and retreating driving unit is connected with the driving wheels and drives the driving wheels to rotate, and the driving wheels rotate to drive the guide wire / catheter to move in the axial direction; and the wire rotating driving unit is connected with the clamping base and drives the clamping base to rotate in the axial direction of the guide wire / catheter, and then the guide wire / catheter is driven to rotate. The guide wire / catheter rotates around a shaft and axially moves independently or rotates around the shaft and axially moves synchronously in an automatic mode, guide wire propelling accuracy and precision are improved, and therefore the operation safety is greatly improved.

Owner:SHANGHAI DROIDSURG MEDICAL CO LTD

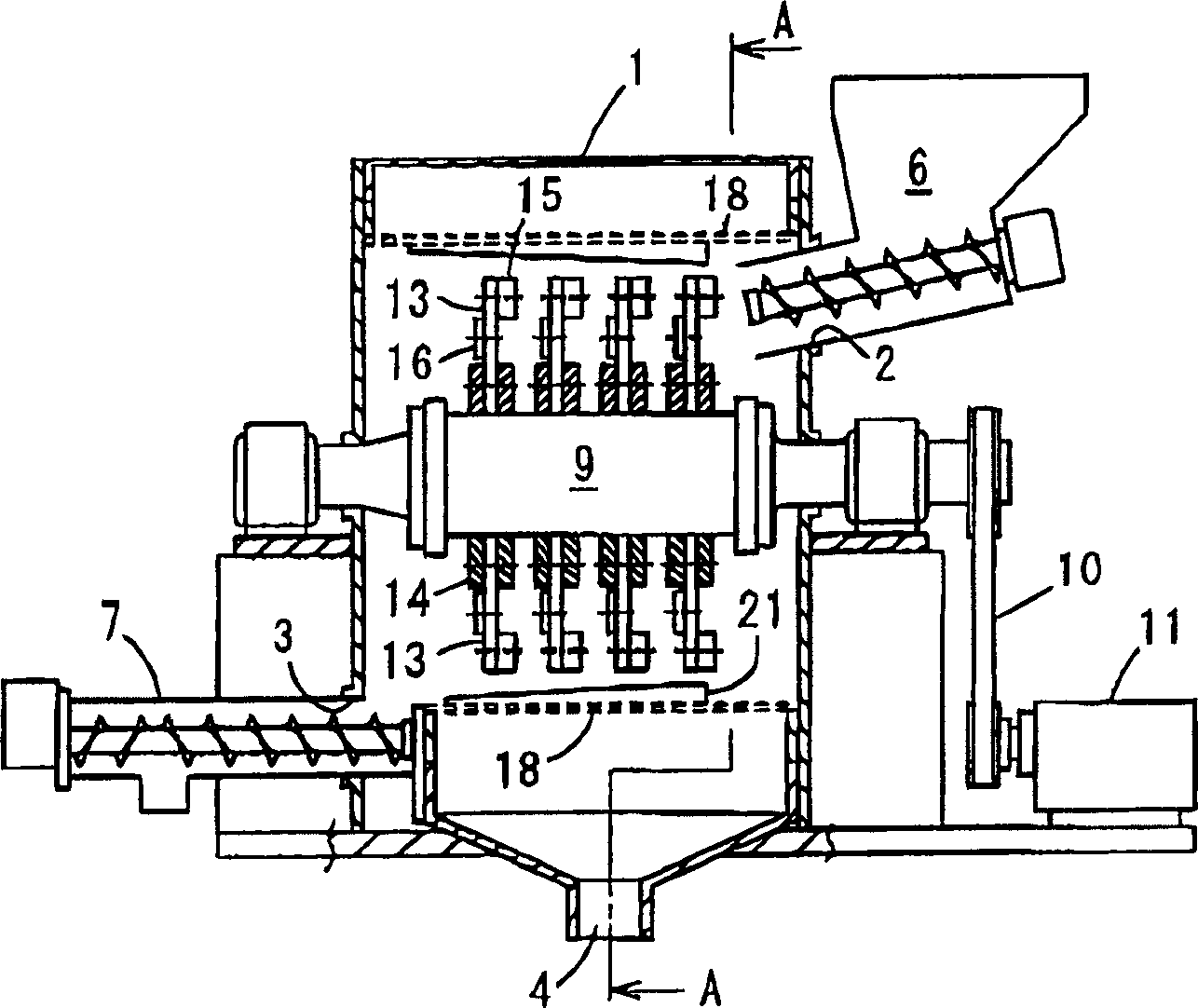

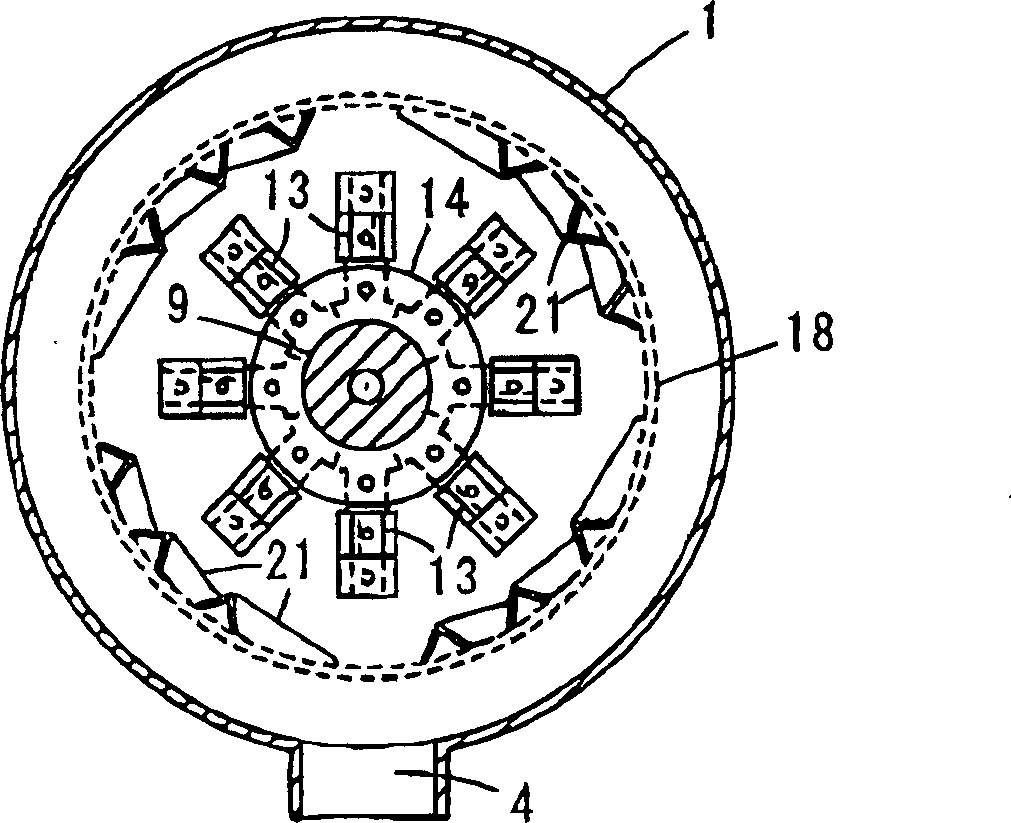

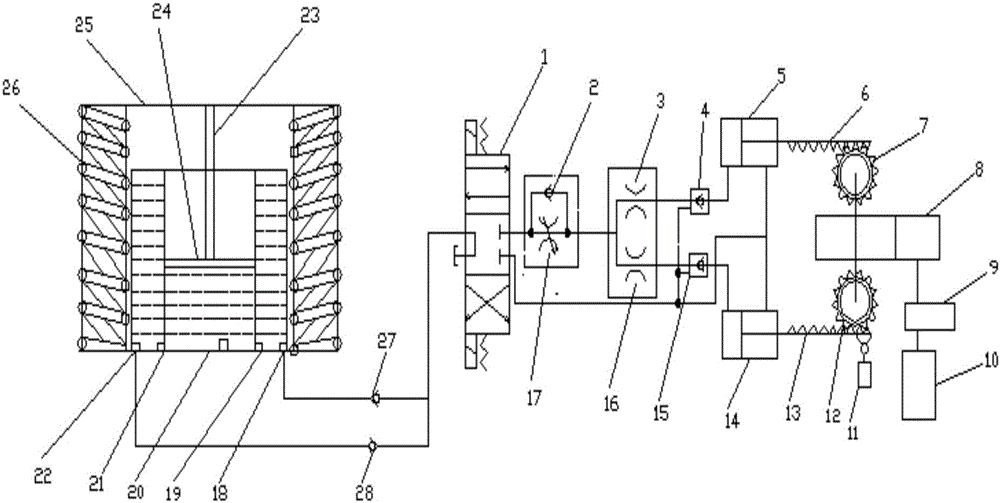

Plastic wastes dry type cleaning apparatus

InactiveCN1608818APowerful cleaning actionGuaranteed rotational stabilityRotary stirring mixersSolid waste disposalWaste materialPlastic waste

To provide a dry washing apparatus capable of removing an adherent from a plastic waste material simply and efficiently without performing pretreatment. This dry washing apparatus is equipped with a stirring casing having not only a waste material discharge port formed to one end part thereof but also a washing material discharge port for discharging the plastic waste material after washing formed to the other end part thereof and also having an adherent discharge port for discharging the adherent formed thereto, the rotary shaft provided in the stirring casing in a freely rotatable manner and a plurality of stirring arms provided to the rotary shaft in a protruded state within the stirring casing and provided with impact blocks for hitting the plastic waste material to crush the same.

Owner:日本阿尔斯泰克

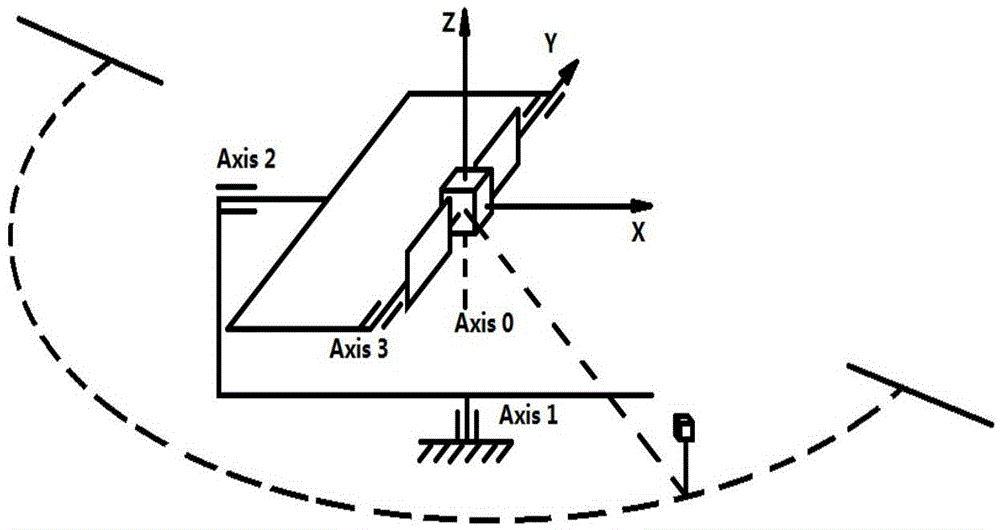

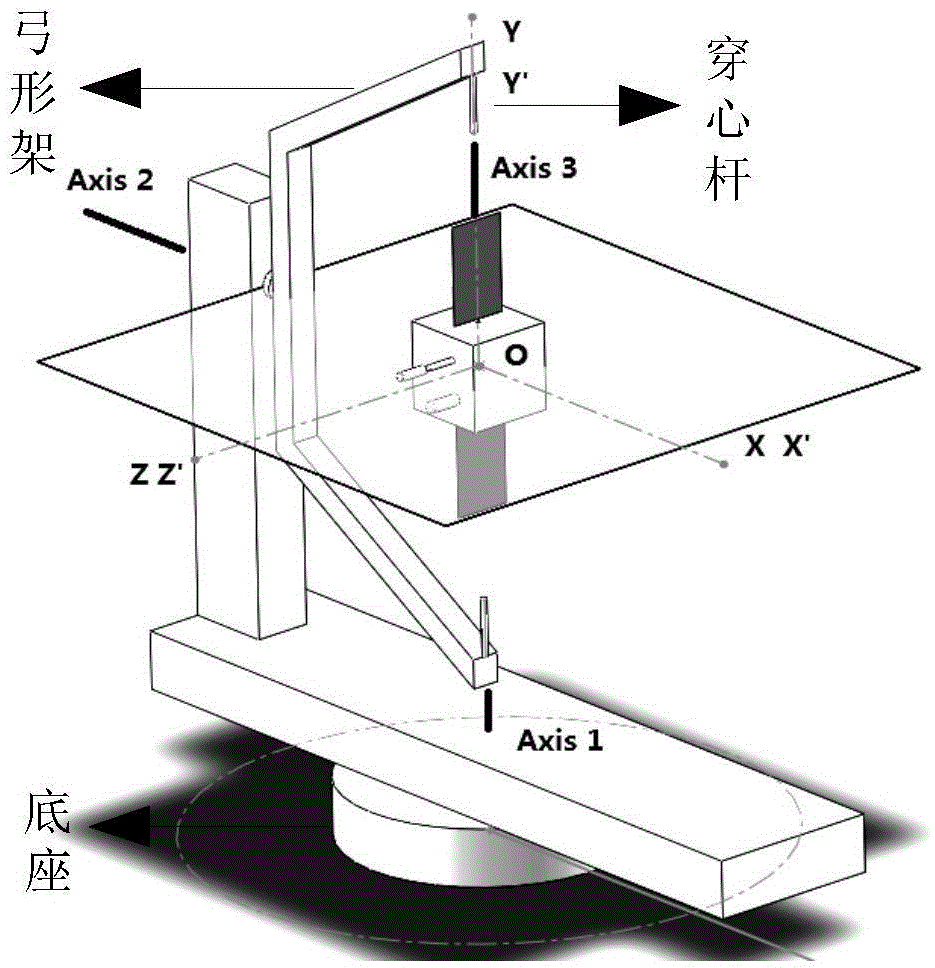

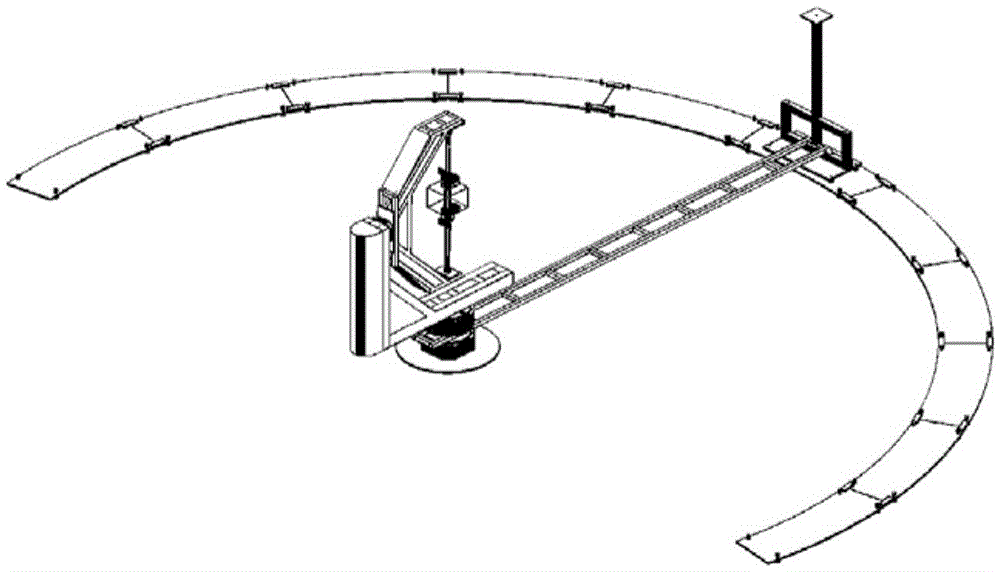

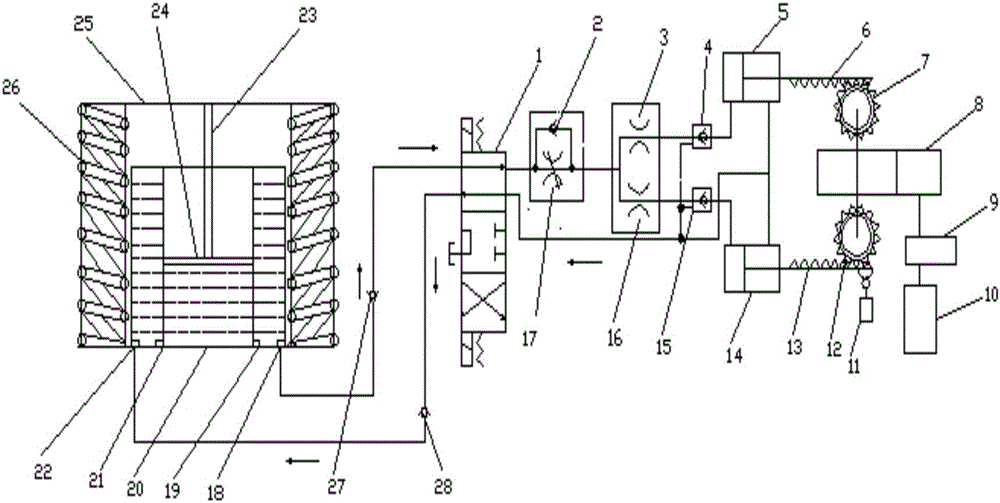

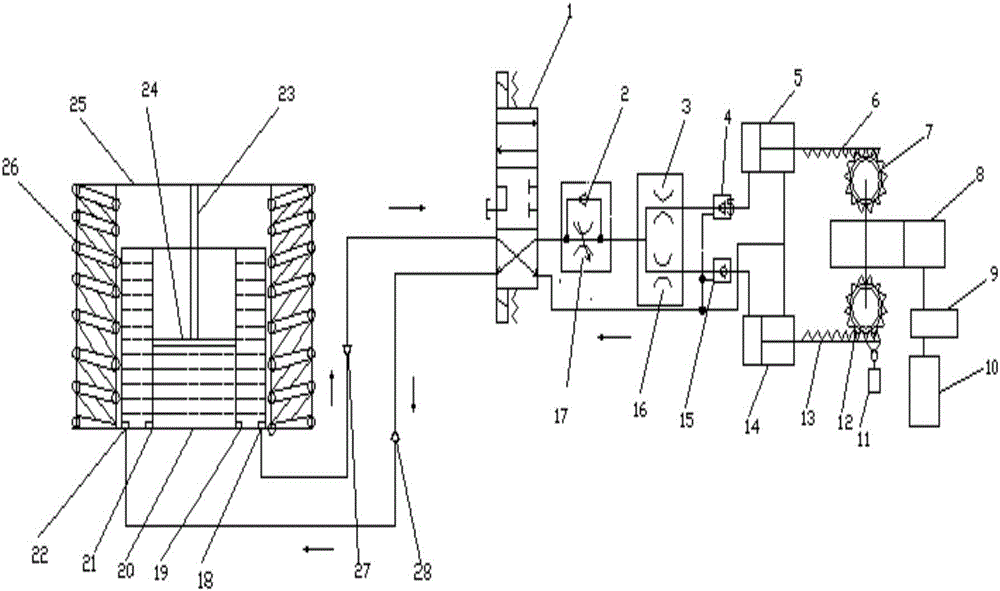

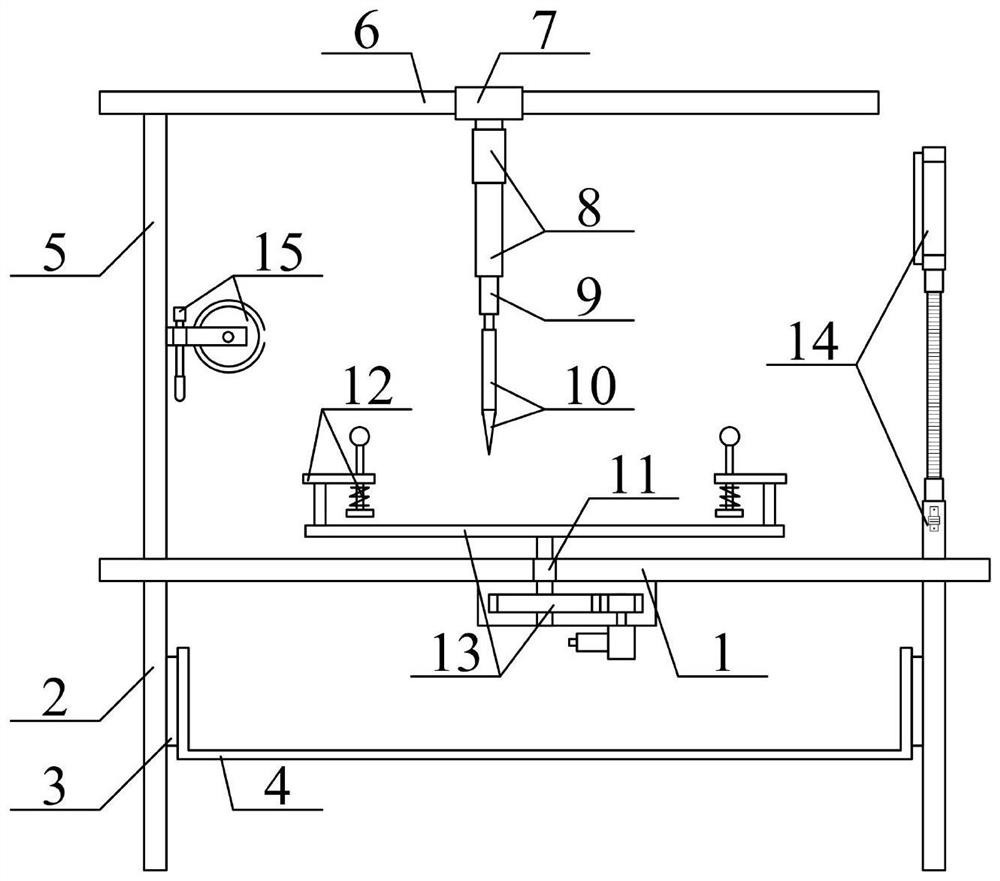

Laboratory measurement method for optical properties of satellites

InactiveCN105466476AGuaranteed rotation accuracyGuaranteed rotational stabilityTesting optical propertiesOptical propertyRelative motion

The invention discloses a laboratory measurement method for the optical properties of satellites, comprising the following steps: step 1, simulating the attitude motion of a satellite and establishing a satellite attitude motion model; step 2, establishing a light source model projected to a satellite model based on the satellite attitude motion model, and simulating the illumination of the sun to the satellite; and step 3, establishing a detector model simulating the detection angle of a detector based on the satellite attitude motion model and the light source model, wherein the direction of the detector in the detector model faces the satellite model in the satellite attitude motion model. Through equivalent treatment of the process of space optical observation, optical observation of a satellite is simulated in the laboratory; through satellite attitude control turntable scheme design, turntable rotation shafts clamping a target model are designed to simulate satellite attitude control; an around-center rotating part controlling the rotation of the detector is designed to simulate the relative motion of the optical detector; and a three-axis turntable and a detector are designed in a combined manner to simulate omni-directional observation based on a semicircular detection slide rail.

Owner:张雅声

Electrochemical polishing method for bearing retainer

ActiveCN102995099AGood self-lubricating performanceEliminate chromatic aberrationElectrolysisSquare decimeter

The invention relates to an electrochemical polishing method for a bearing retainer. The electrochemical polishing method for the bearing retainer comprises the steps of: preparing, electrochemical polishing, electrolyte mixing, cleaning by using cold water, passivating, cleaning by using hot water, drying and rust preventing; the electrolyte is prepared from phosphoric acid, water and chromic anhydride in a volume ratio of 8:4:1; the temperature of the electrolyte is controlled to be below 40 DEG C; in the electrochemical polishing step, the current density is 35A / square decimeter, the working voltage is 8-10V, the distance between the negative pole of an electrochemical polishing machine and a processed workpiece is 5-10mm, and the electrochemical polishing time is 90s; the preparing step comprises the sub-steps of: preparing the electrolyte, adding the electrolyte in an electrolytic vessel, placing a lead plate in the electrolytic vessel, connecting the lead plate and the negative pole of the electrochemical polishing machine, and preparing the processed workpiece; and the step of preparing the processed workpiece comprises the following sub-steps of: performing oil removing and cleaning on the processed workpiece, cleaning by using hot water, cleaning by using cold water, hanging on a hanger, and connecting the processed workpiece with the positive pole of the electrochemical polishing machine. According to the electrochemical polishing method, the clamping as well as the material charging and discharging are convenient, the occupying area is small, the cost is low, the burr removing effect is good, the labor intensity is obviously reduced, and the time and the labor are saved.

Owner:DEQING TIANMA BEARING CO LTD

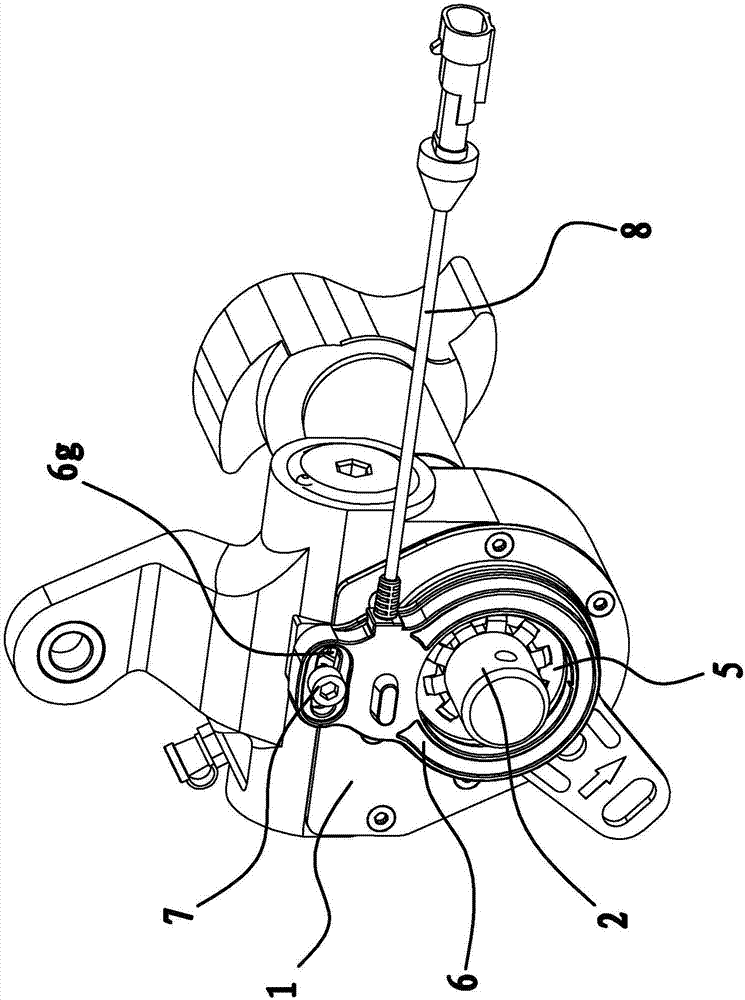

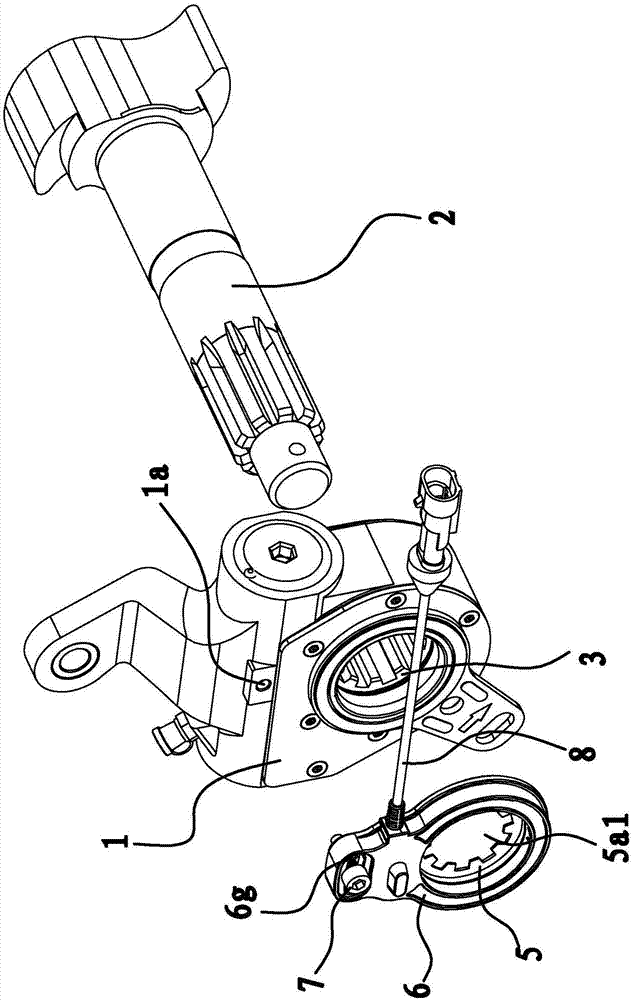

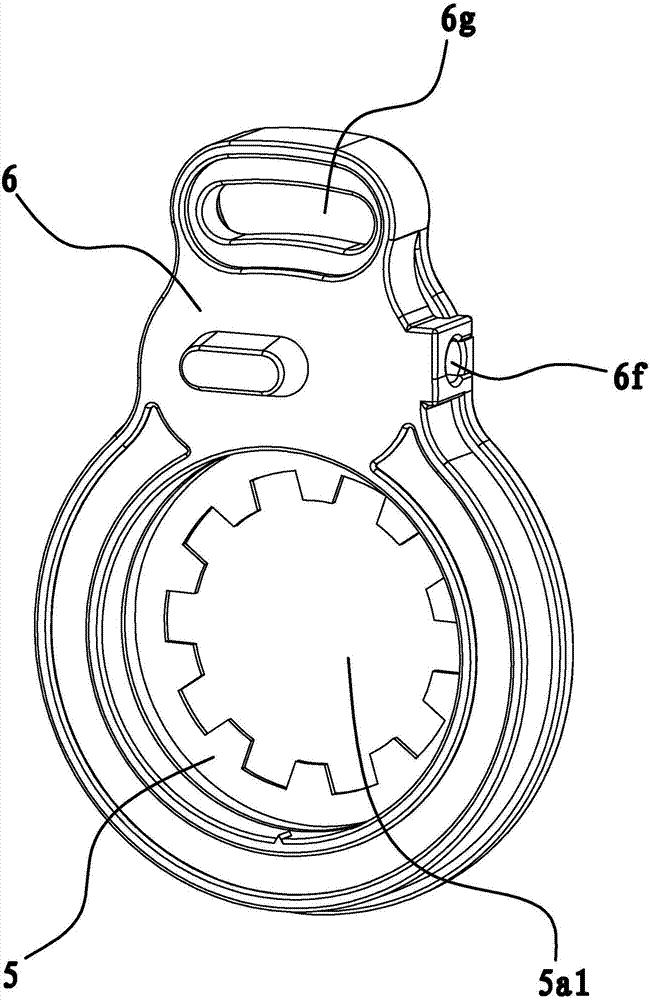

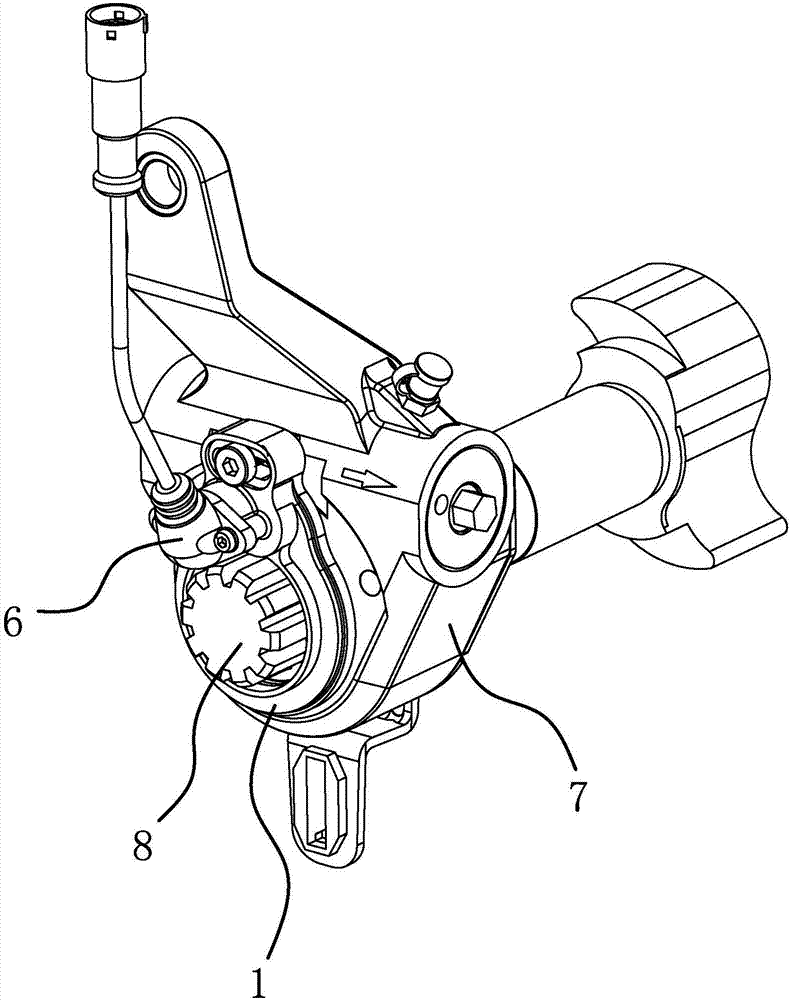

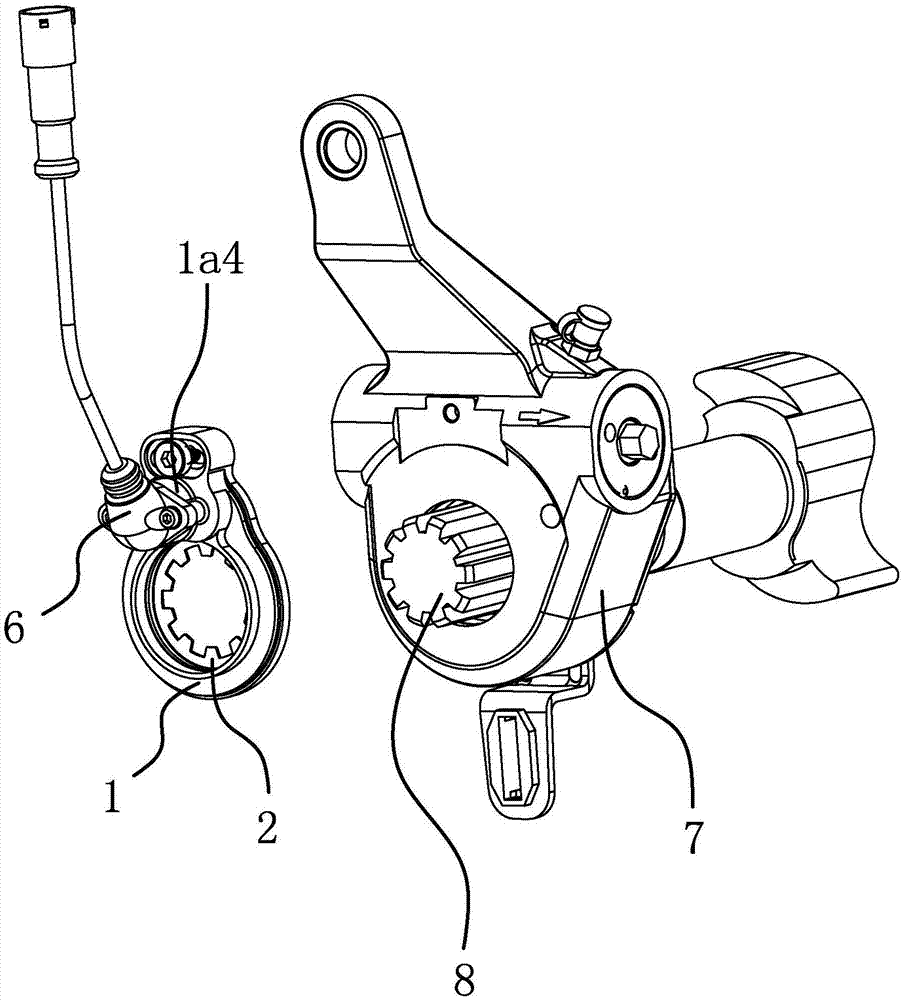

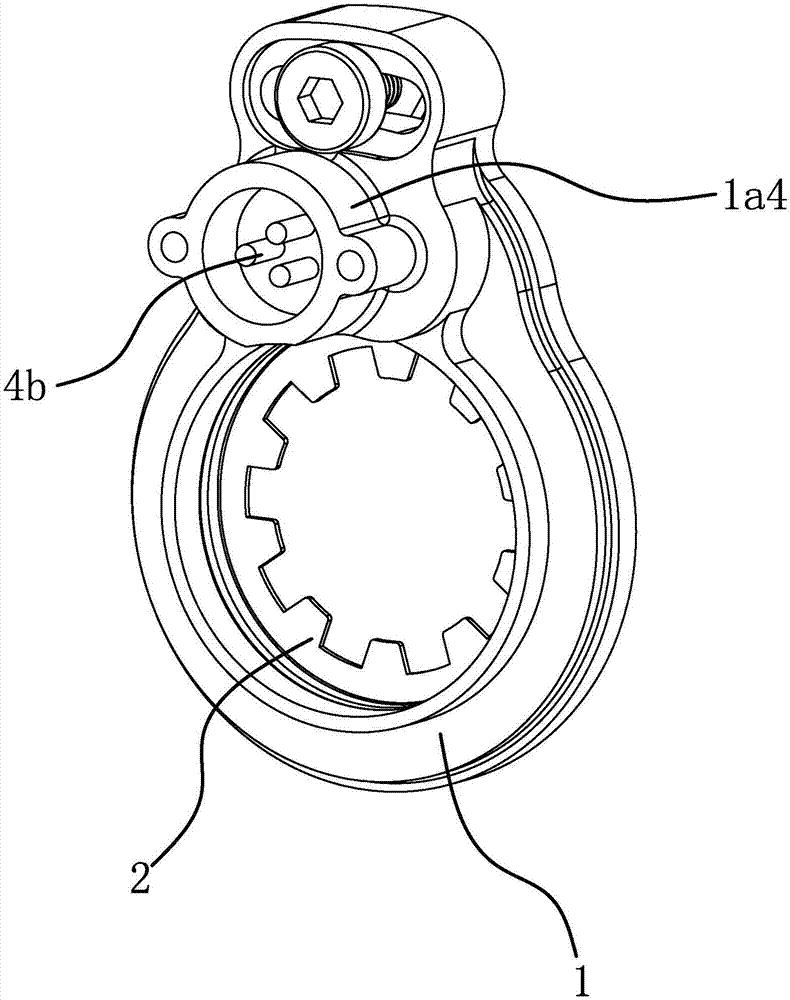

Wear indicator for adjusting arm and brake clearance adjusting arm

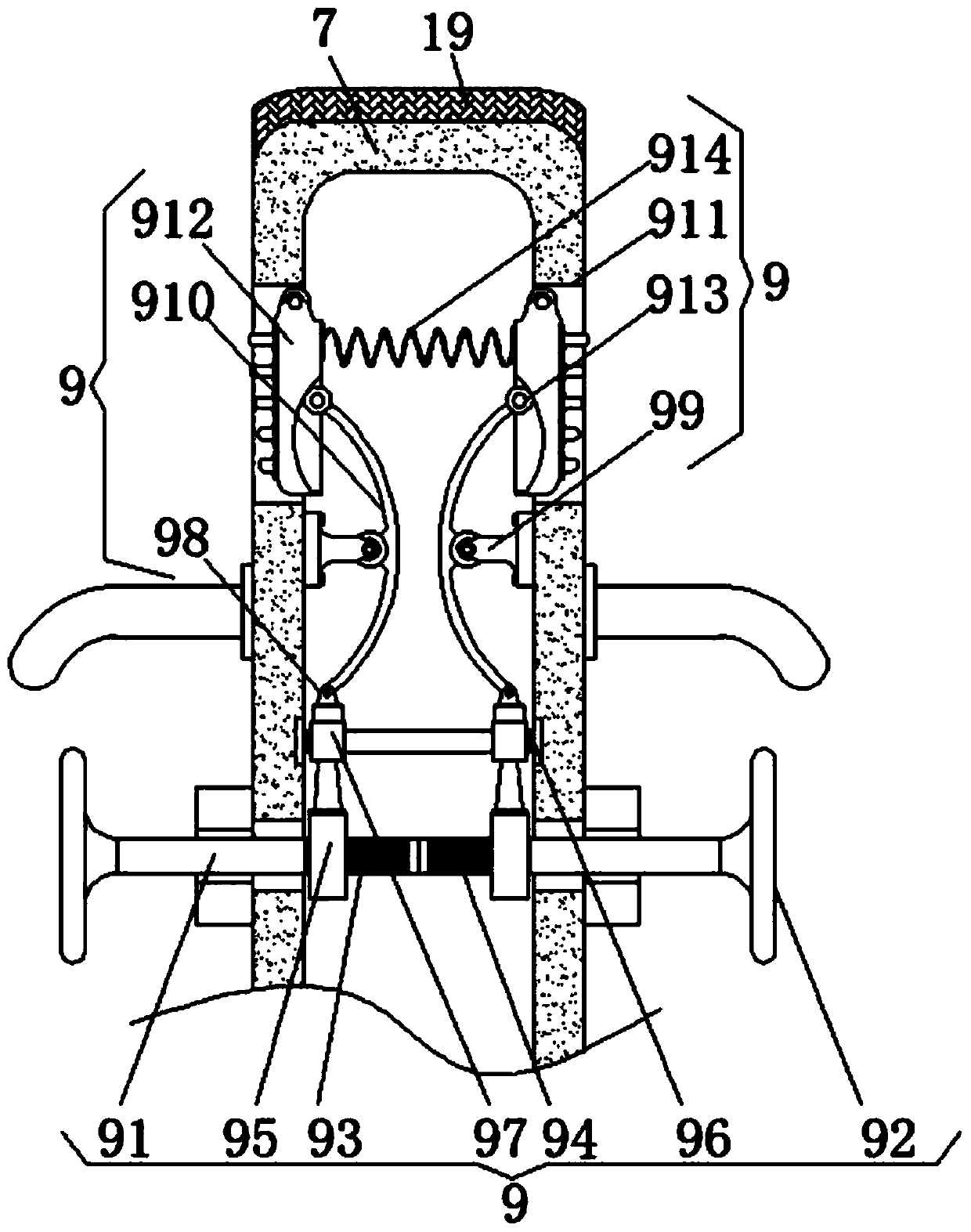

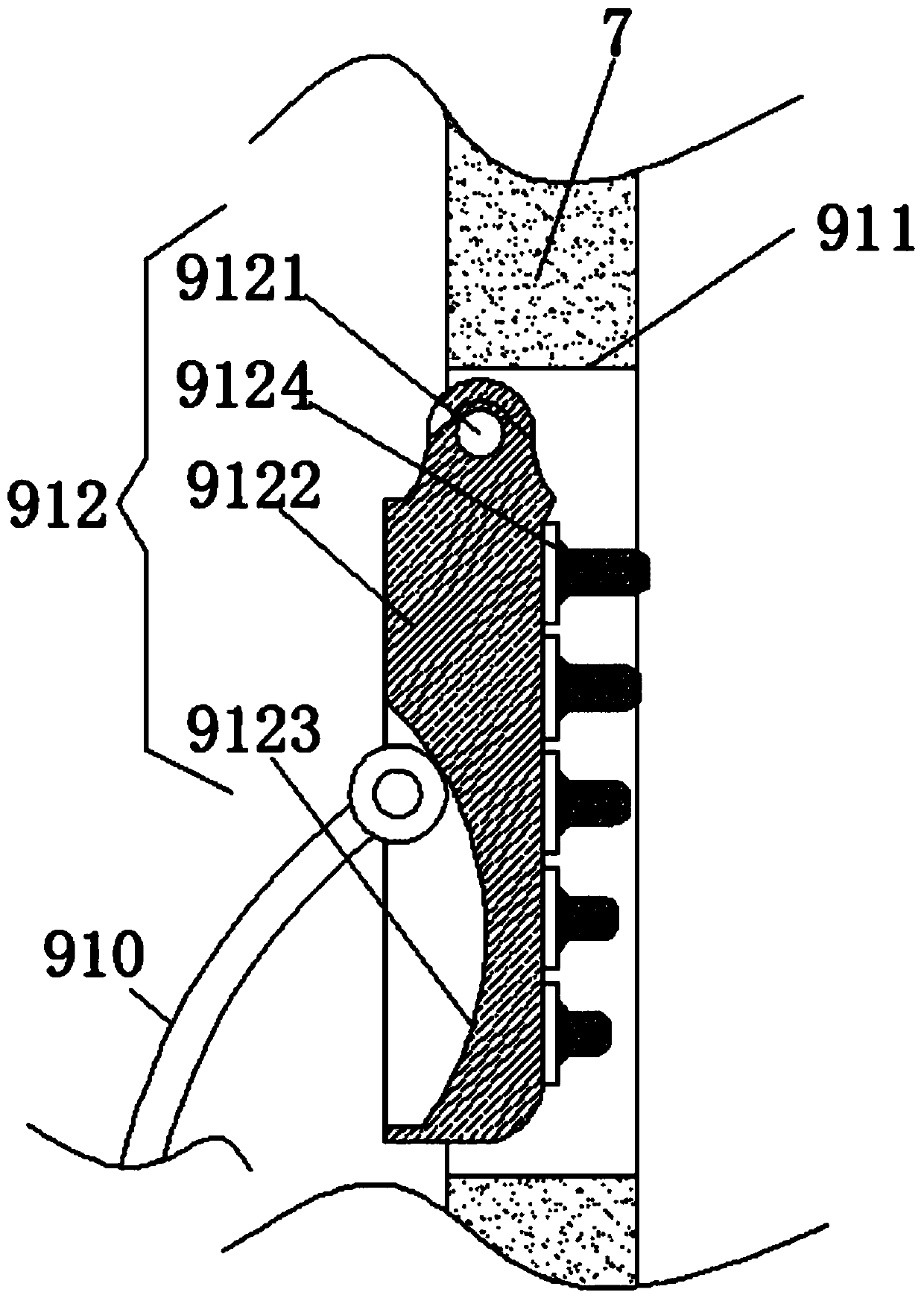

PendingCN107366698AGuaranteed rotational stabilityHigh matching precisionSlack adjustersRotating discEngineering

The invention provides a wear indicator for an adjusting arm and a brake clearance adjusting arm and belongs to the technical field of machinery. The problems that the conventional wear indicator is easily interfered and accurate alarm cannot be ensured are solved. The wear indicator for the adjusting arm comprises an on-off type switch, a mounting box and a rotating disc, wherein the on-off type switch is arranged in the mounting box; the mounting box comprises a limiting hole; the rotating disc is positioned in the limiting hole, and radial limiting is formed between the rotating disc and the limiting hole; circular grooves are formed in inner walls of the limiting hole; the outer edge of the rotating disc is positioned in the circular grooves, and the rotating disc is limited between groove walls on two sides of the circular grooves; the circular grooves are partially or completely penetrated, and the rotating disc can rotate relative to the mounting box; a protrusion part capable of triggering the on-off type switch is arranged on a part, which penetrates through the circular groove, of the rotating disc. The wear indicator for the adjusting arm and the brake clearance adjusting arm disclosed by the invention have the advantages of high working accuracy, difficulty in interference and the like.

Owner:LONGZHONG HLDG GRP

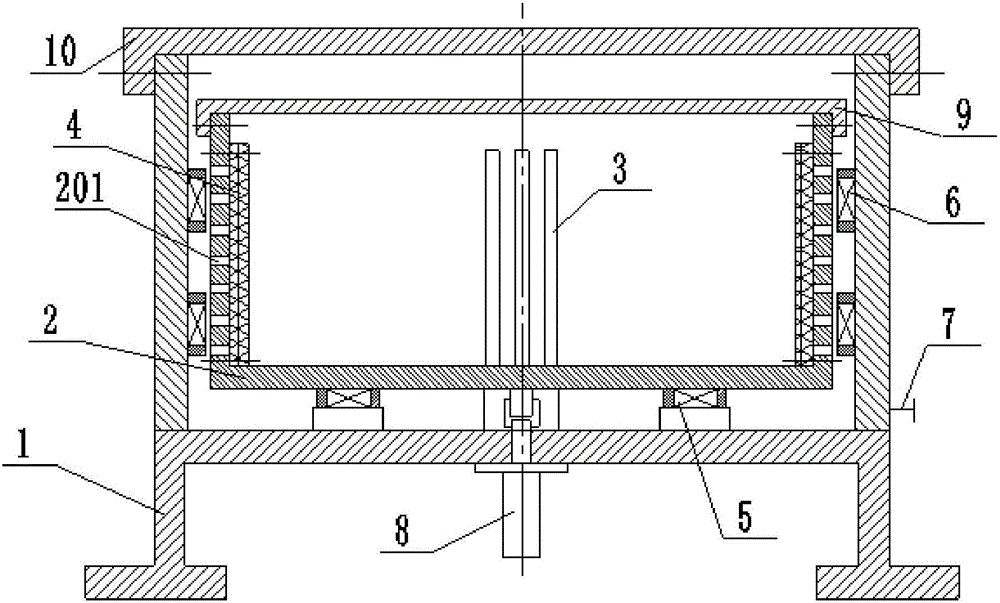

Magnetorheological fluid recovery device and method based on centrifugal separation effect

InactiveCN106082520AAvoid easy cloggingNot easy to settleWater/sewage treatment by centrifugal separationMagnetic liquidsDual effectDual action

The invention discloses a magnetorheological fluid recovery device and method based on a centrifugal separation effect, belonging to the field of magnetic waste liquid recovery equipment. The recovery device comprises an outer barrel, an inner barrel, an adsorption pipe and a filter net, wherein the inner barrel is installed in the outer barrel in a rotating manner by virtue of a bearing and is driven by a motor, and a filter hole communicating the inside and outside of the inner barrel is formed in the side wall of the inner barrel; the adsorption pipe is arranged in the middle of the inner barrel, and a coil is arranged in the adsorption pipe; the filter net is arranged on the inner side wall of the inner barrel and covers the filter hole; and the outer wall of the outer barrel is provided with a recovery check valve. The method utilizes the recovery device to allow carrier liquid and magnetic substances to make reverse motion under the dual effect of a centrifugal force and a magnetic field, so that the carrier liquid and the magnetic substances can be separated and recovered. By adopting the magnetorheological fluid recovery device and method, the magnetic substances of magnetorheological fluid can be separated and recovered from the carrier liquid. The magnetorheological fluid recovery device is simple in structure, easy to operate, high in recovery efficiency of the magnetic substances and also capable of reducing the subsequent treatment difficulty of the carrier liquid.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

Angle sensor for adjusting arm

The invention provides an angle sensor for an adjusting arm and belongs to the technical field of machinery. By means of the angle sensor for the adjusting arm, the problem that the detection precision of an existing angle sensor is low is solved. The angle sensor comprises an installation box capable of being connected to the side wall of the adjusting arm and a rotating disc capable of being fixed on a cam shaft of the adjusting arm in the circumferential direction, the rotating disc is located inside the installation box and can rotate relative to the installation box, the installation boxis further internally provided with a rotating wheel which can rotate, the external diameter of the rotating disc is larger than that of the rotating wheel and the rotating disc drives the rotating wheel to rotate through a driving belt or teeth, a rotating center of the rotating wheel is fixedly provided with a magnetic body, the installation box is internally and fixedly provided with a sensingelement which is arranged to be opposite to the magnetic body, and the sensing element can perform real-time sensing on rotating of the magnetic body and perform signal conversion. The angle sensor for the adjusting arm has the advantages of being high in detection precision, good in working stability and the like.

Owner:LONGZHONG HLDG GRP +1

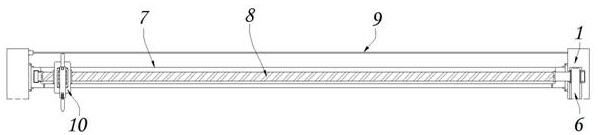

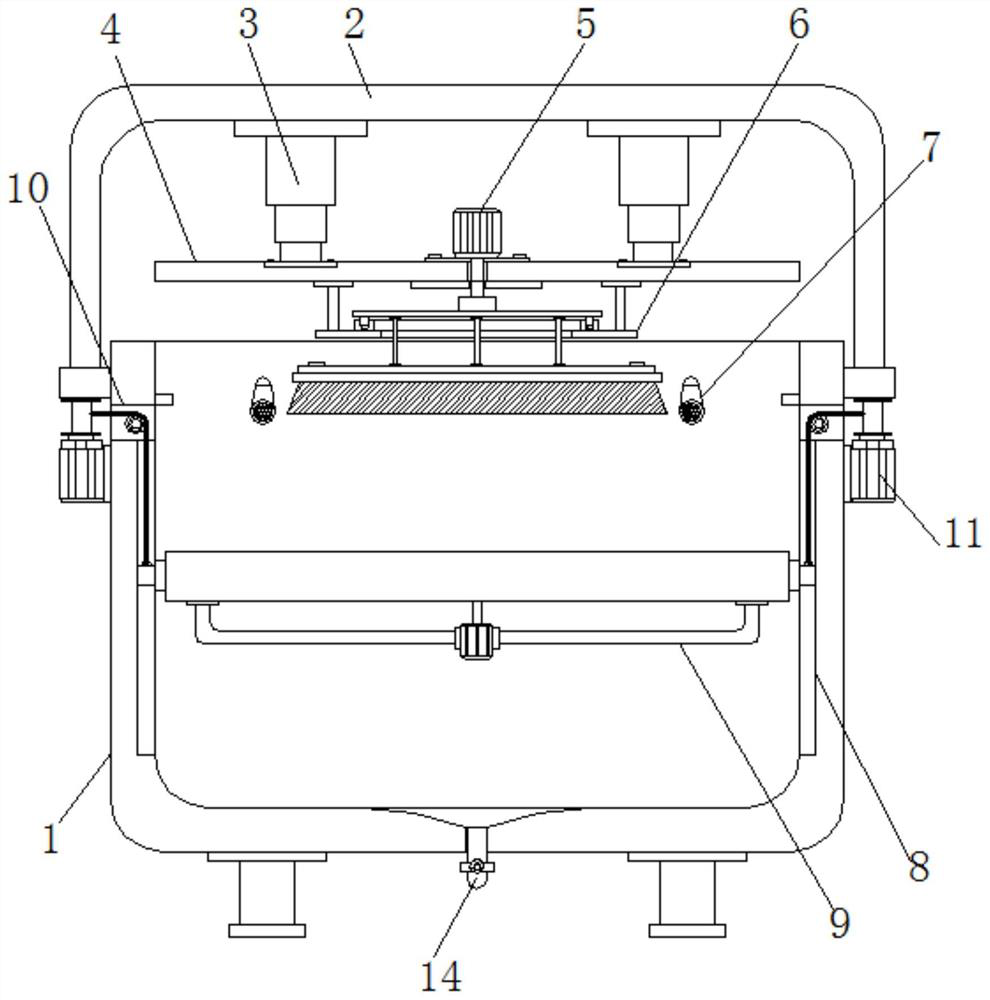

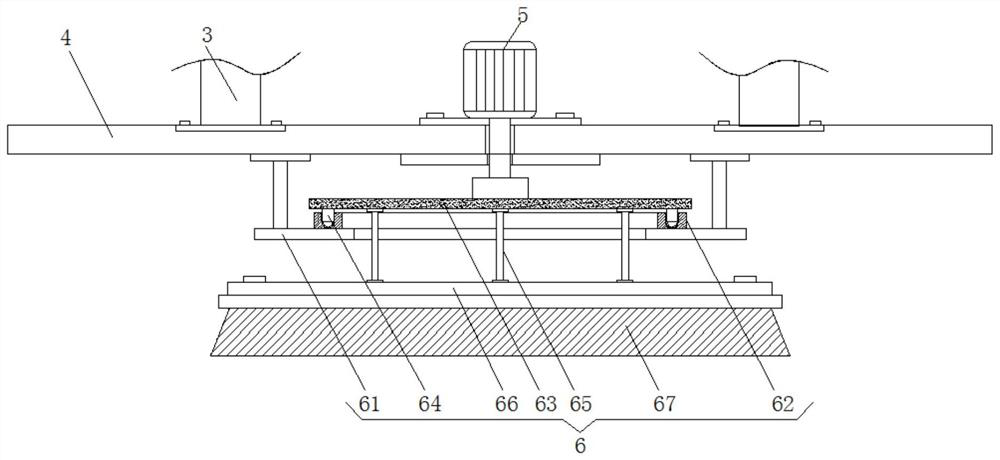

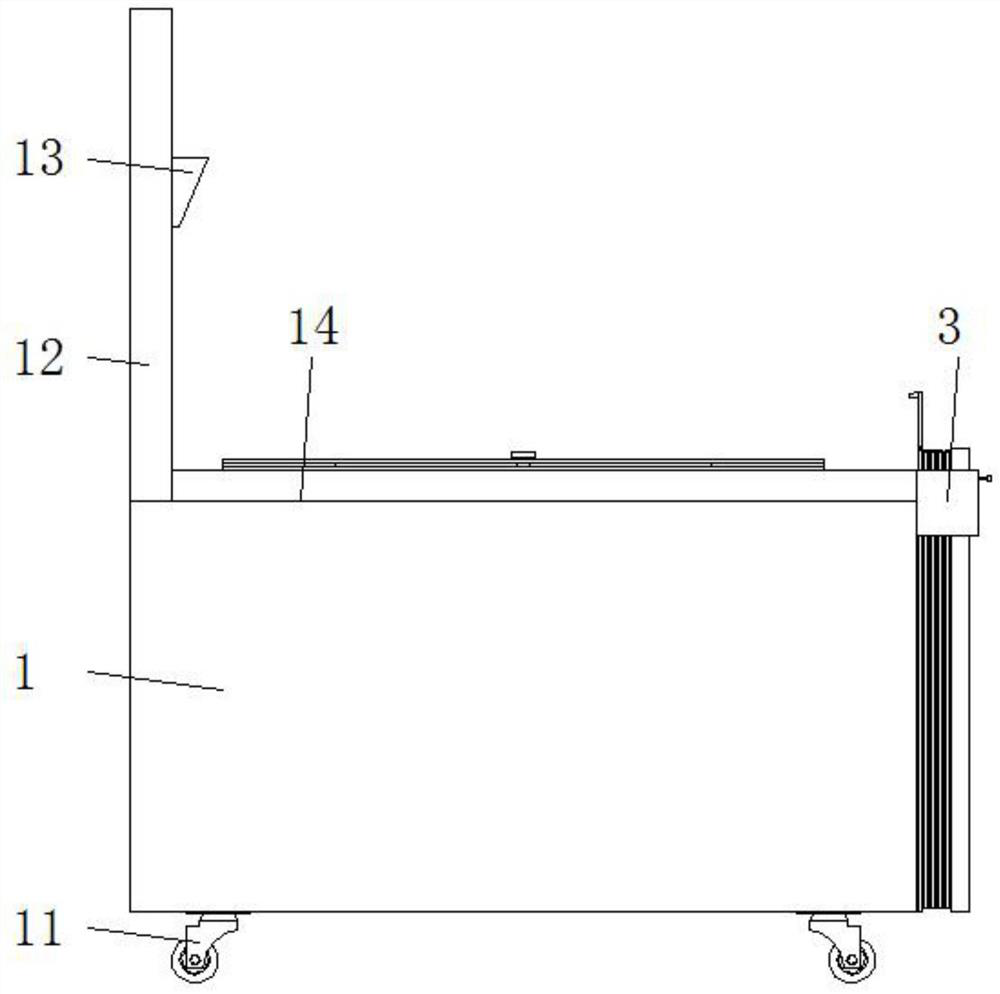

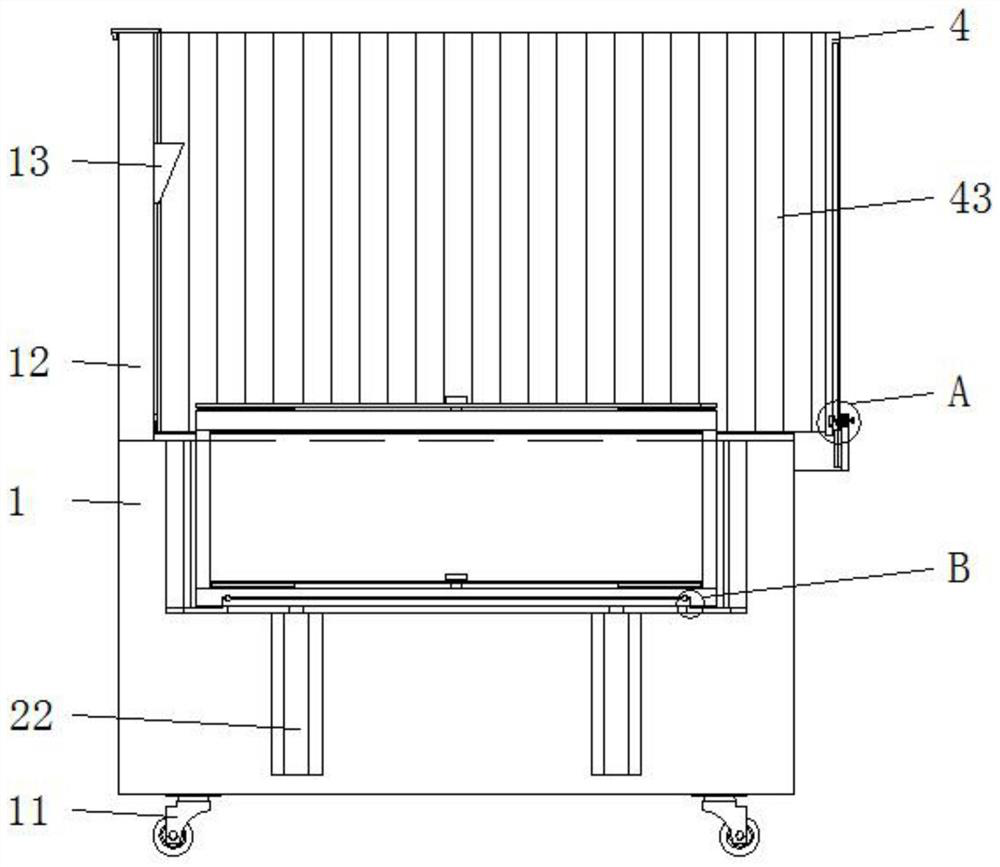

Large-caliber fruit glass can bottle body flushing equipment and method

ActiveCN111570455AIncrease the cleaning areaFast cleaningHollow article cleaningRotary stageElectric machine

Owner:绍兴博弈机械设备研发有限公司

Ionization/centrifugation-based magnetorheological fluid recovery device and treatment method thereof

InactiveCN106007162AEvenly dispersedNot easy to settleWater/sewage treatment by centrifugal separationTreatment involving filtrationCentrifugationMagnetorheological fluid

The invention discloses a magnetorheological fluid recovery device and a treatment method based on ionization and centrifugation, and belongs to the technical field of magnetic waste liquid recovery and treatment. The device includes an outer barrel, an inner barrel, an adsorption tube, and a filter screen. The inner barrel is rotatably mounted in the outer barrel through a bearing and driven by a motor. The sidewall of the inner barrel is provided with filter holes that communicate with the inside and the outside, and the adsorption tube is arranged in the inner barrel. In the middle of the body, a coil is arranged in the adsorption tube, an electrode plate is arranged in the inner barrel, a filter screen is arranged on the inner side wall of the inner barrel and covers the filter hole, and a recovery stop valve is arranged on the outer wall of the outer barrel. The method of the invention realizes the separation and recovery treatment of the magnetorheological fluid through ionization treatment, centrifugal breaking treatment and centrifugal separation treatment. The present invention processes the magnetorheological fluid, separates and recovers the main dispersed particles and the carrier liquid, does not need any treatment agent for preliminary treatment in the early stage, and has high recovery efficiency, and the recovered carrier liquid can be used as a new carrier liquid after a little treatment.

Owner:MAANSHAN FULAIYI ENVIRONMENT PROTECTION TECH CO LTD

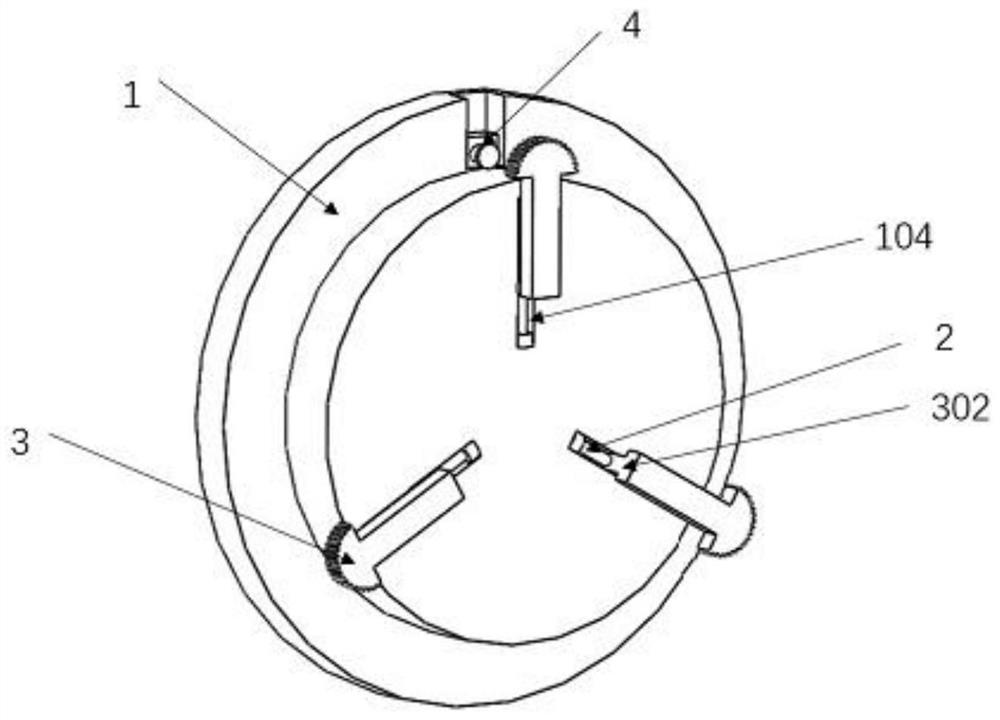

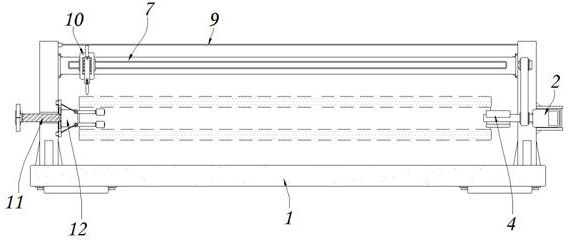

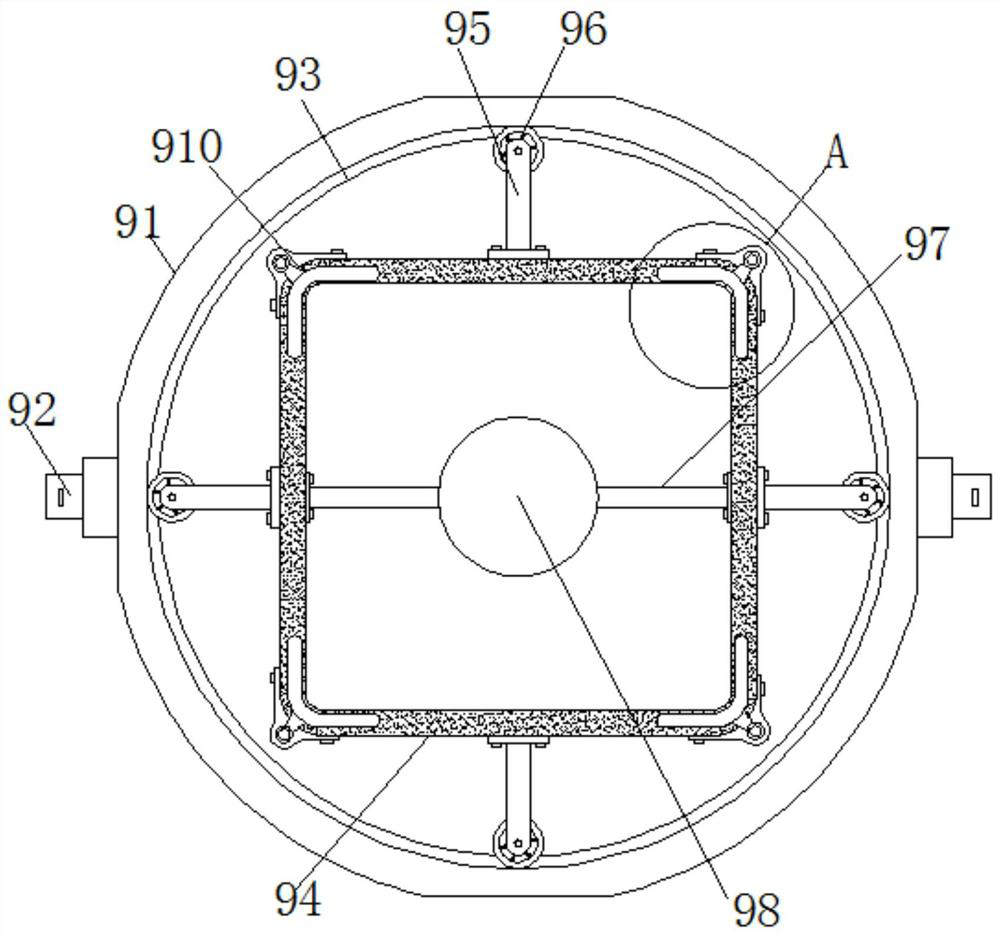

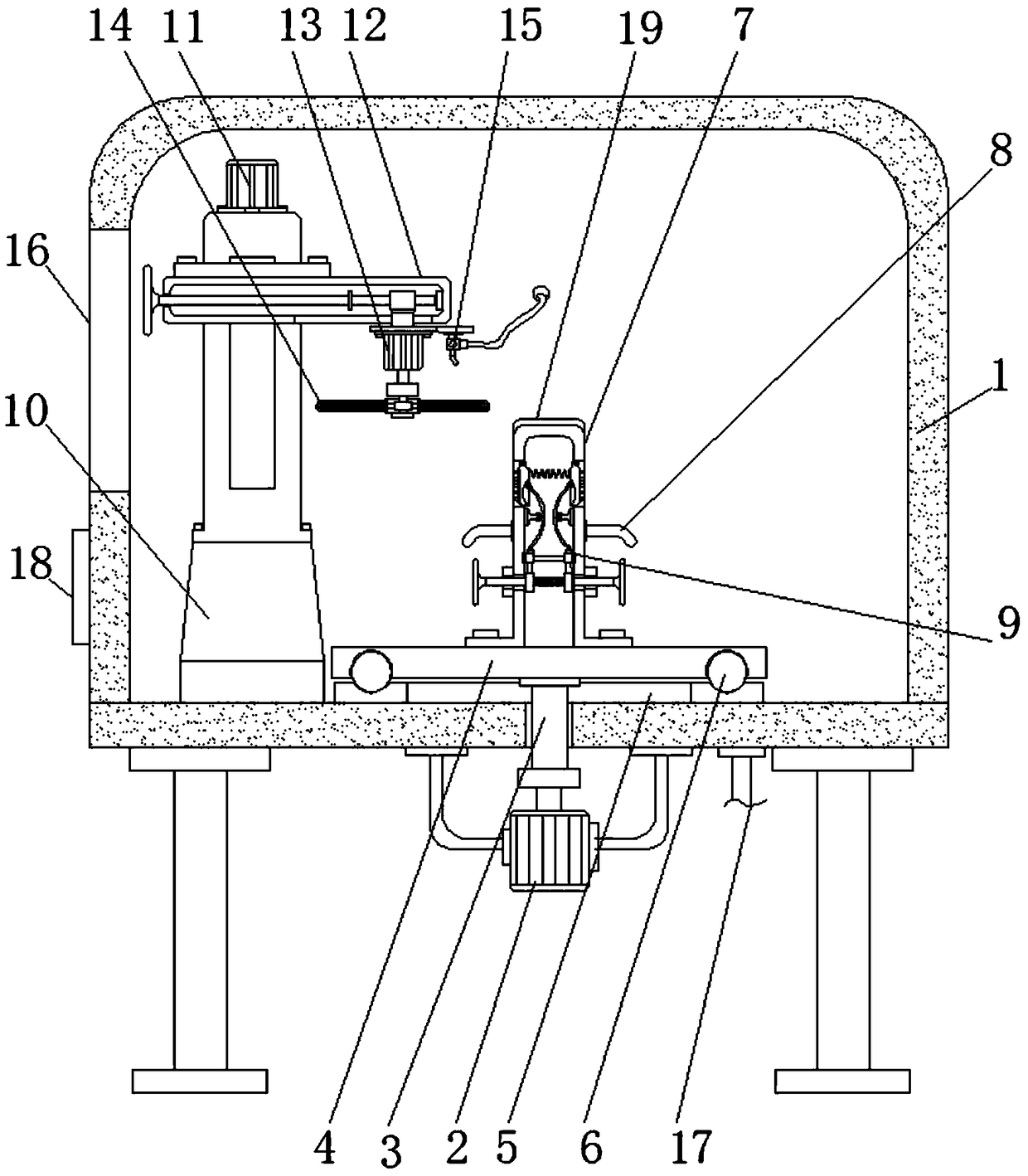

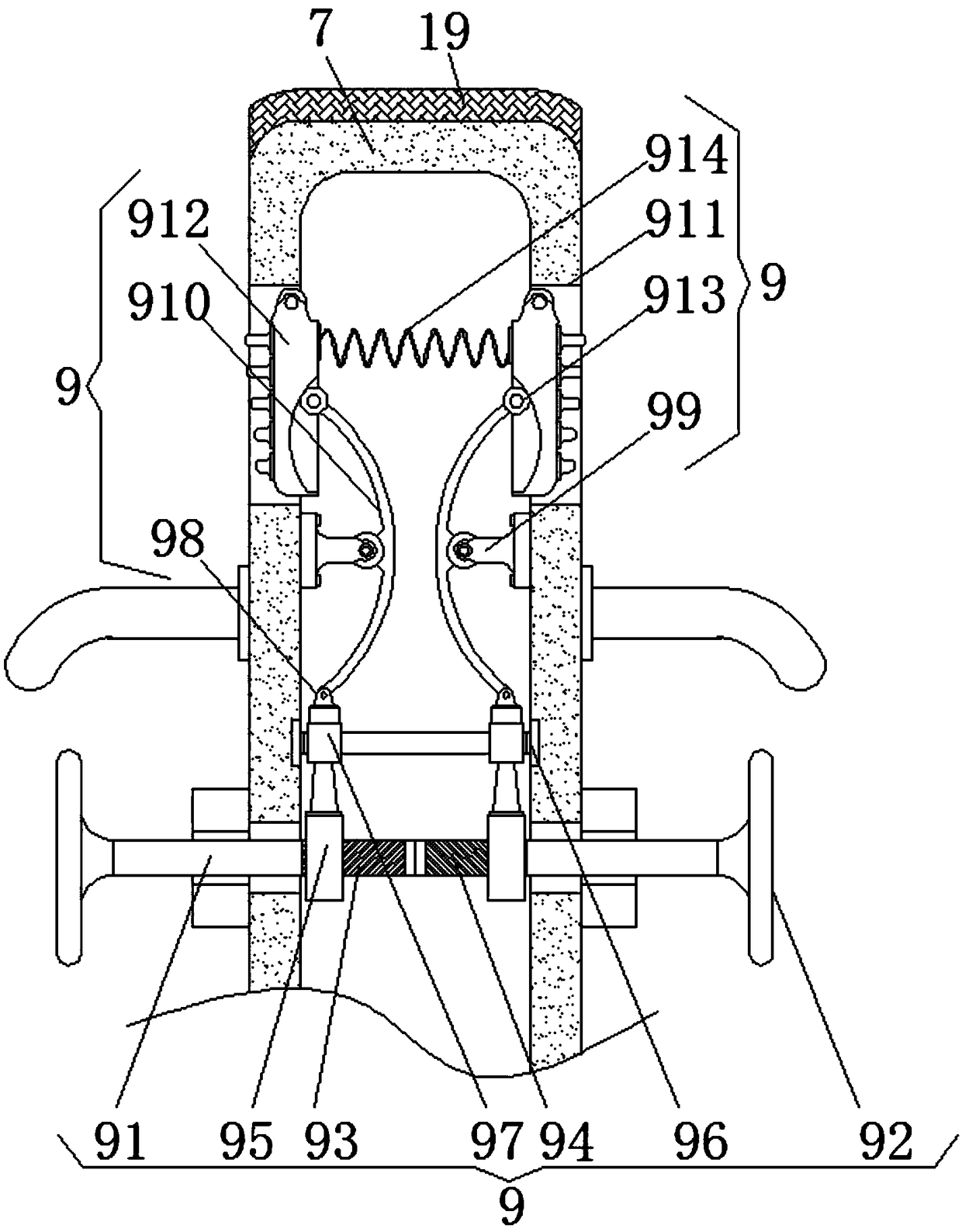

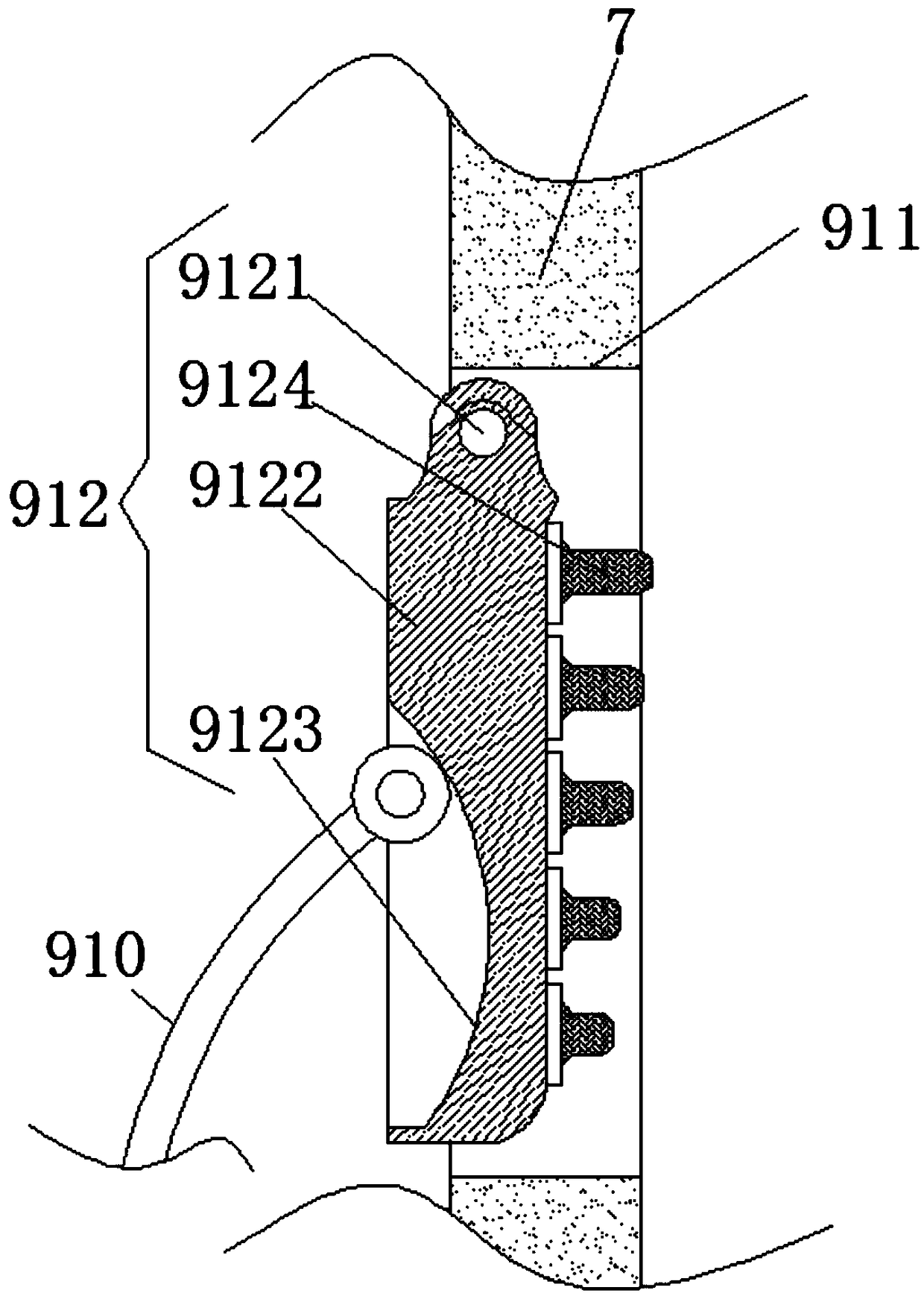

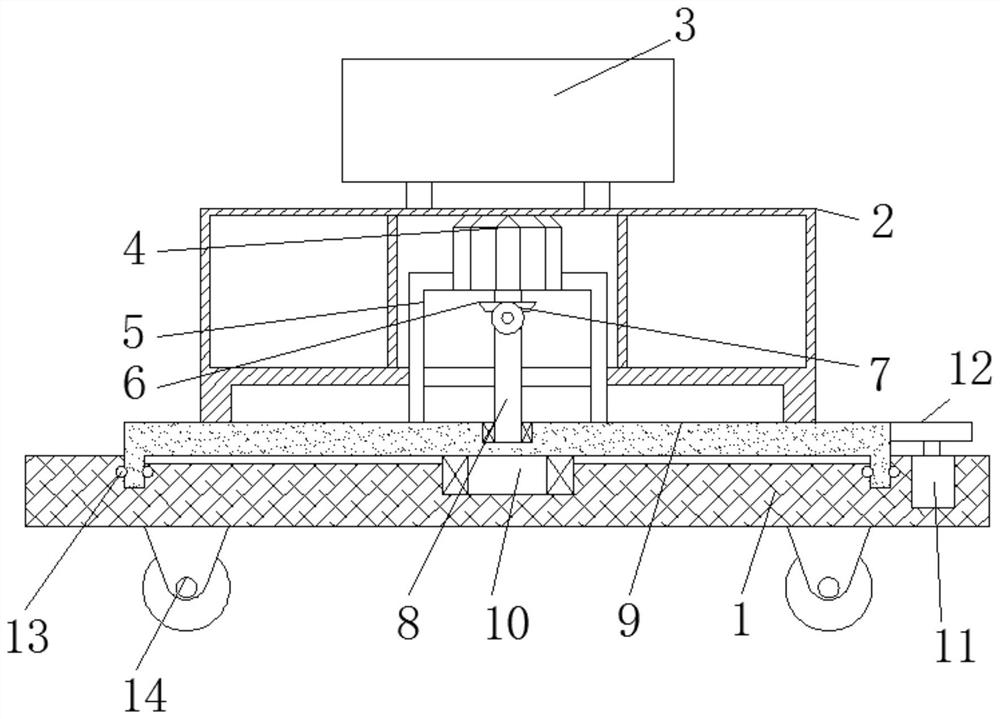

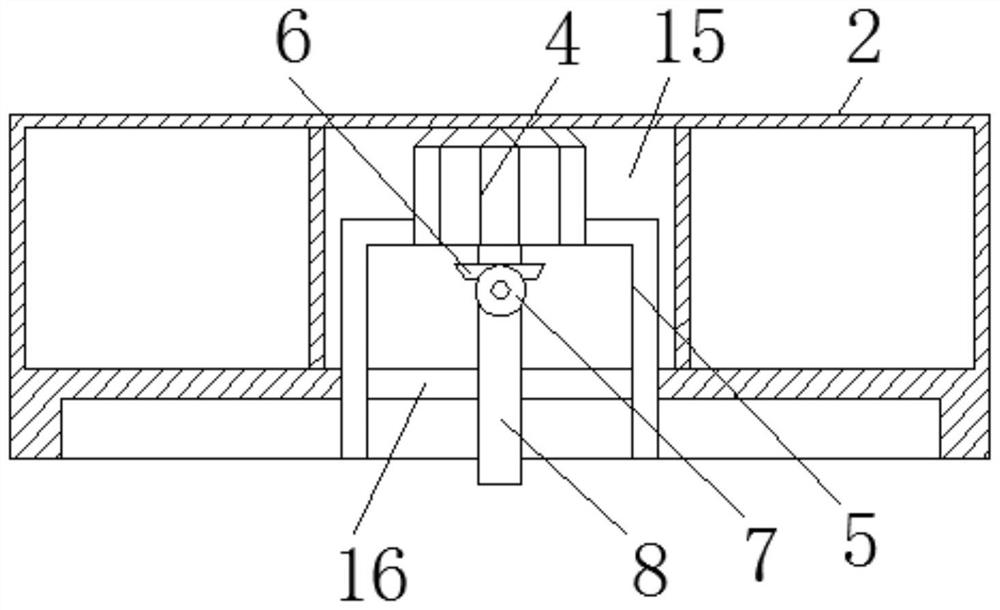

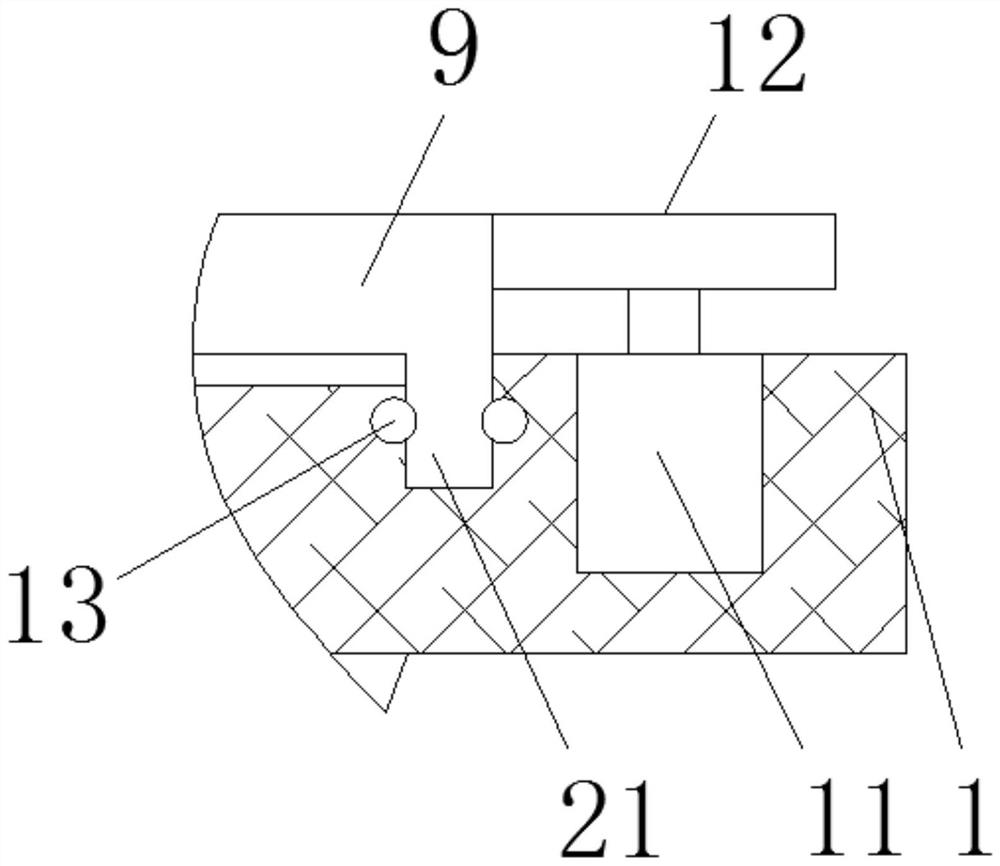

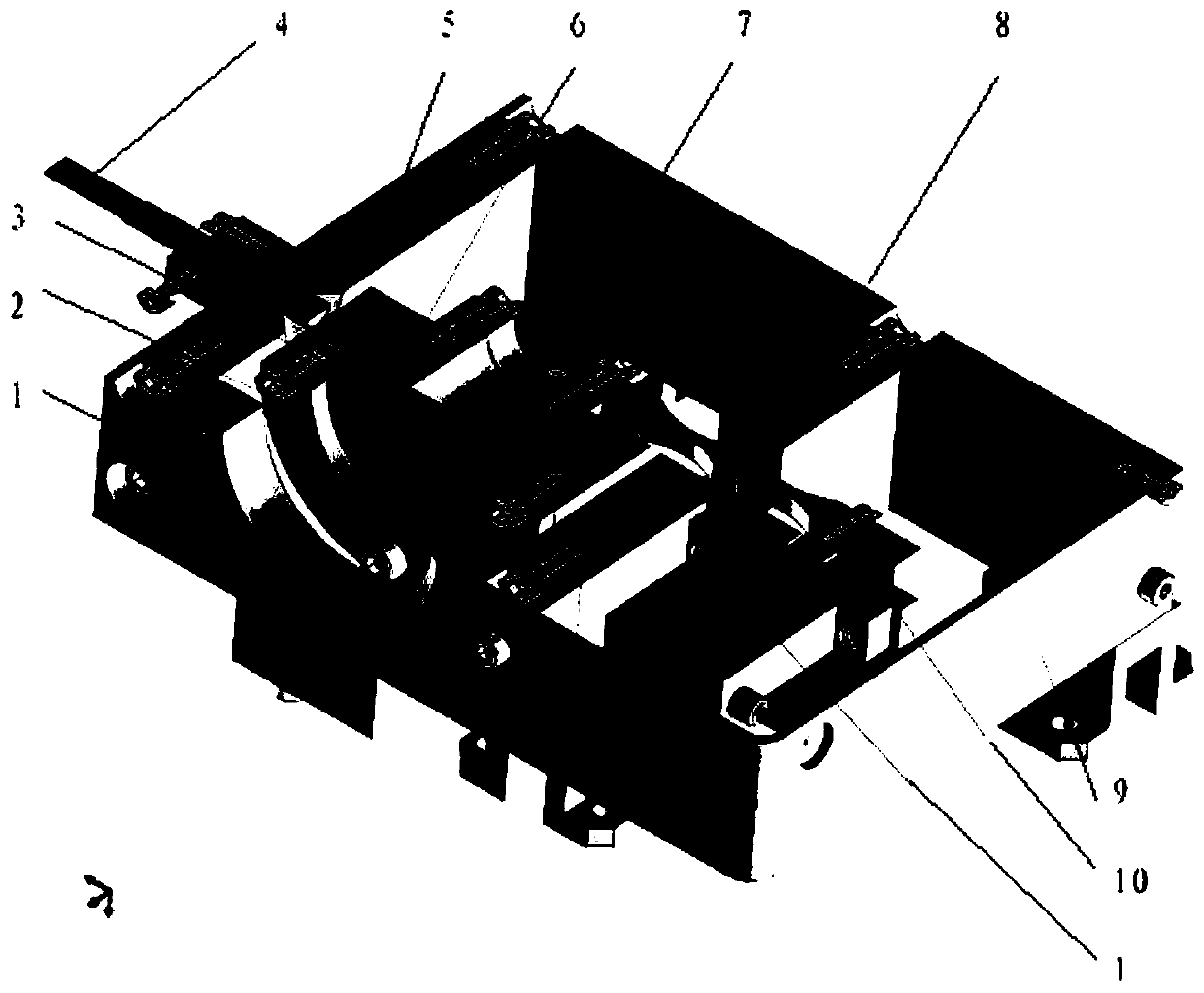

Clamp for repairing shield tunneling machine sealing runway through laser cladding and using method

ActiveCN112008264AReduce stressSave work spaceMetallic material coating processesLaser beam welding apparatusLight spotStatic friction

The invention discloses a clamp for repairing a shield tunneling machine sealing runway through laser cladding and a using method thereof. The clamp comprises a chassis, hydraulic oil cylinders, pushing pieces and an adjusting mechanism, wherein three flange guide rails forming 120-degree included angles are arranged at the position, close to the outer circle, of the front face of the chassis; anda slide groove is formed in the position close to the circle center above each flange guide rail; a hydraulic oil cylinder and a pushing piece are arranged at the bottom of each slide groove. In theclamp repairing shield tunneling machine sealing runway through laser cladding, a vertical clamping mode is adopted, so that the working space is reduced, the cladding head is vertically opposite to apart to be repaired, a light spot can keep constant in the shape and size, and the improvement of the energy utilization rate and the repairing efficiency are facilitated; a pushing device is drivenby the hydraulic oil cylinders, so that the rotation stability is ensured; the adjusting mechanism is adopted to adjust a contact position of each pushing piece and the inner ring of the sealing runway, elastic protruding materials are adopted at the contact position of each pushing piece to increase static friction force, and synchronous rotation of a pushing rod and a workpiece is achieved.

Owner:济南重工集团有限公司

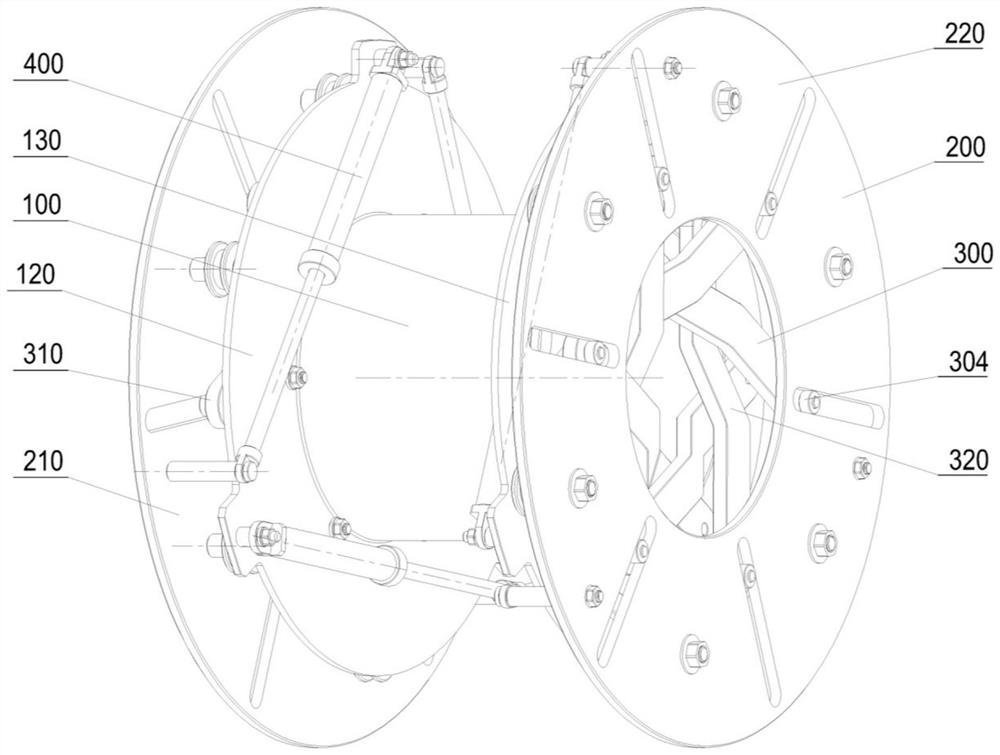

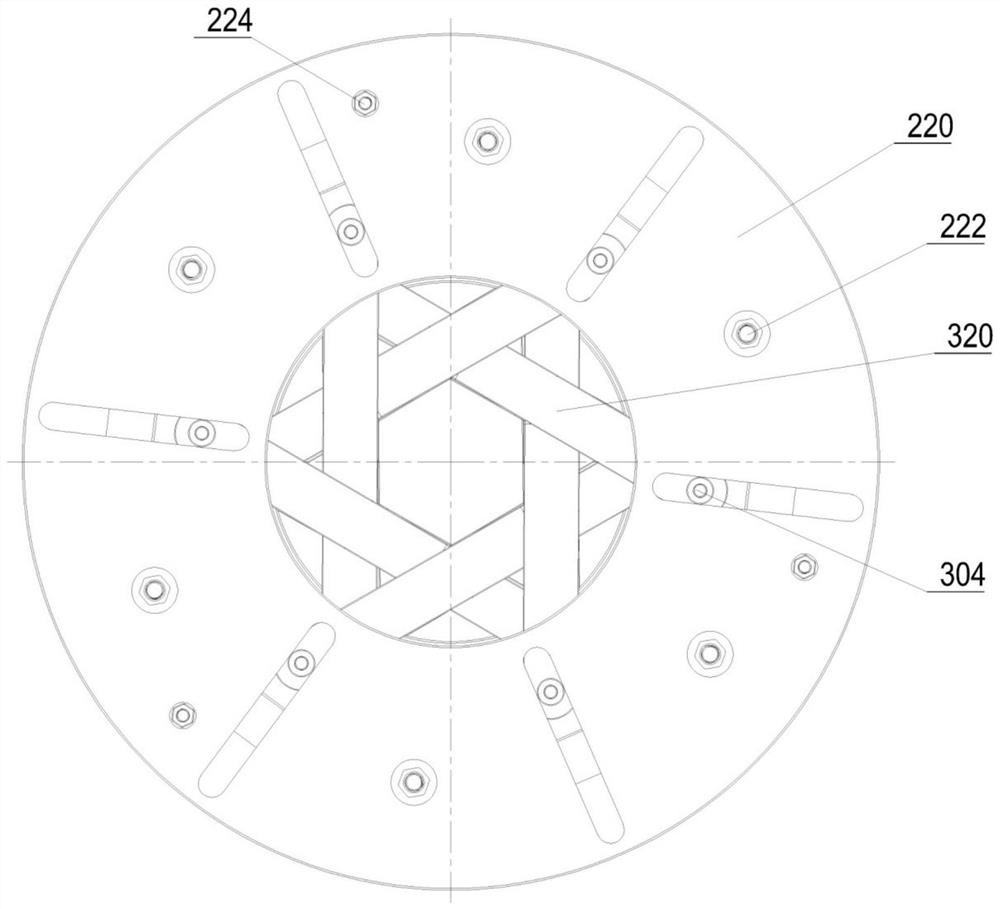

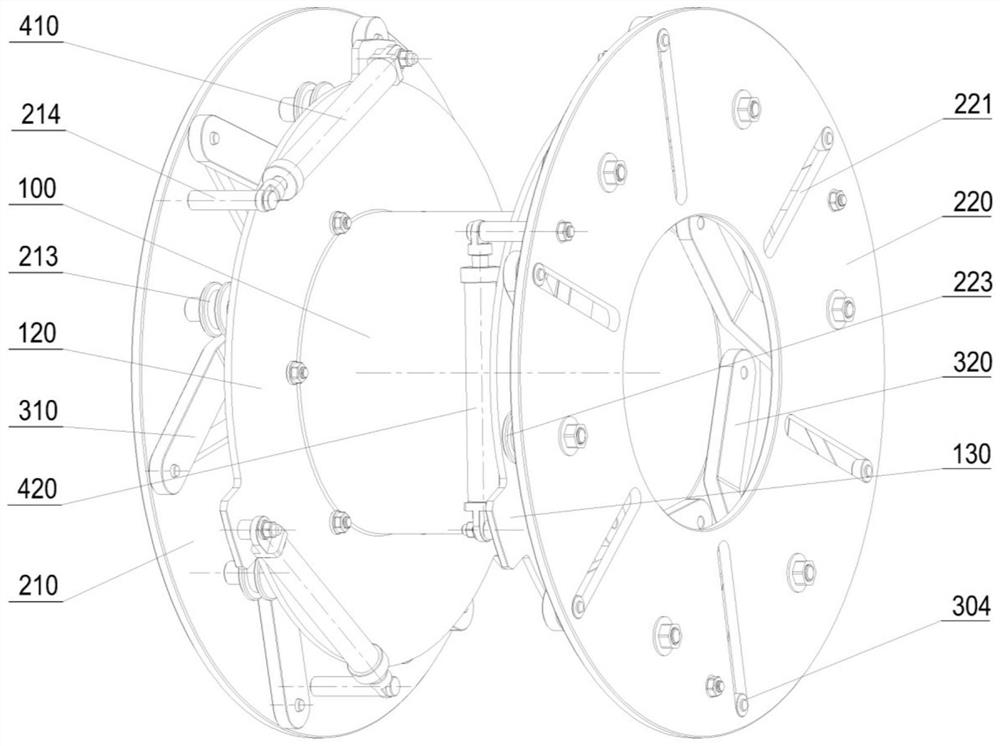

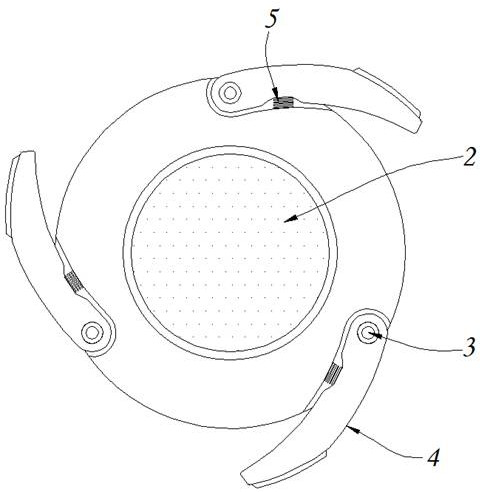

Diameter-adjustable barrel machining auxiliary tool

ActiveCN112171168AAchieve clampingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a diameter-adjustable barrel machining auxiliary tool. The diameter-adjustable barrel machining auxiliary tool comprises a tool main body and a telescopic cylinder set. The tool main body comprises a main barrel and protruding rings symmetrically arranged at two ends of the main barrel. The outer side face of each protruding ring is connected with a guide ring. The outer side face of each guide ring is rotationally connected with a reducing control ring. The reducing control rings, the protruding rings, the guide rings and the main barrel are coaxially arranged. The telescopic cylinder set comprises a left telescopic cylinder set body and a right telescopic cylinder set body which are connected to the main barrel. The left telescopic cylinder set body is used for controlling the reducing control ring at one end to rotate, and the right telescopic cylinder set body is used for controlling the reducing control ring at the other end to rotate. At least three reducing rod sets are evenly distributed between the reducing control ring at each end and the corresponding protruding ring. The first ends of the reducing rod sets are connected with the reducing controlrings, the second ends of the reducing rod sets are hinged to the outer side faces of the protruding rings, and the side faces of the reducing rod sets are used for clamping workpieces penetrating through the main barrel. According to the tool, the reducing control rings rotate to drive the reducing rod sets to rotate, and barrels with different diameters are clamped.

Owner:NANJING COLLEGE OF INFORMATION TECH

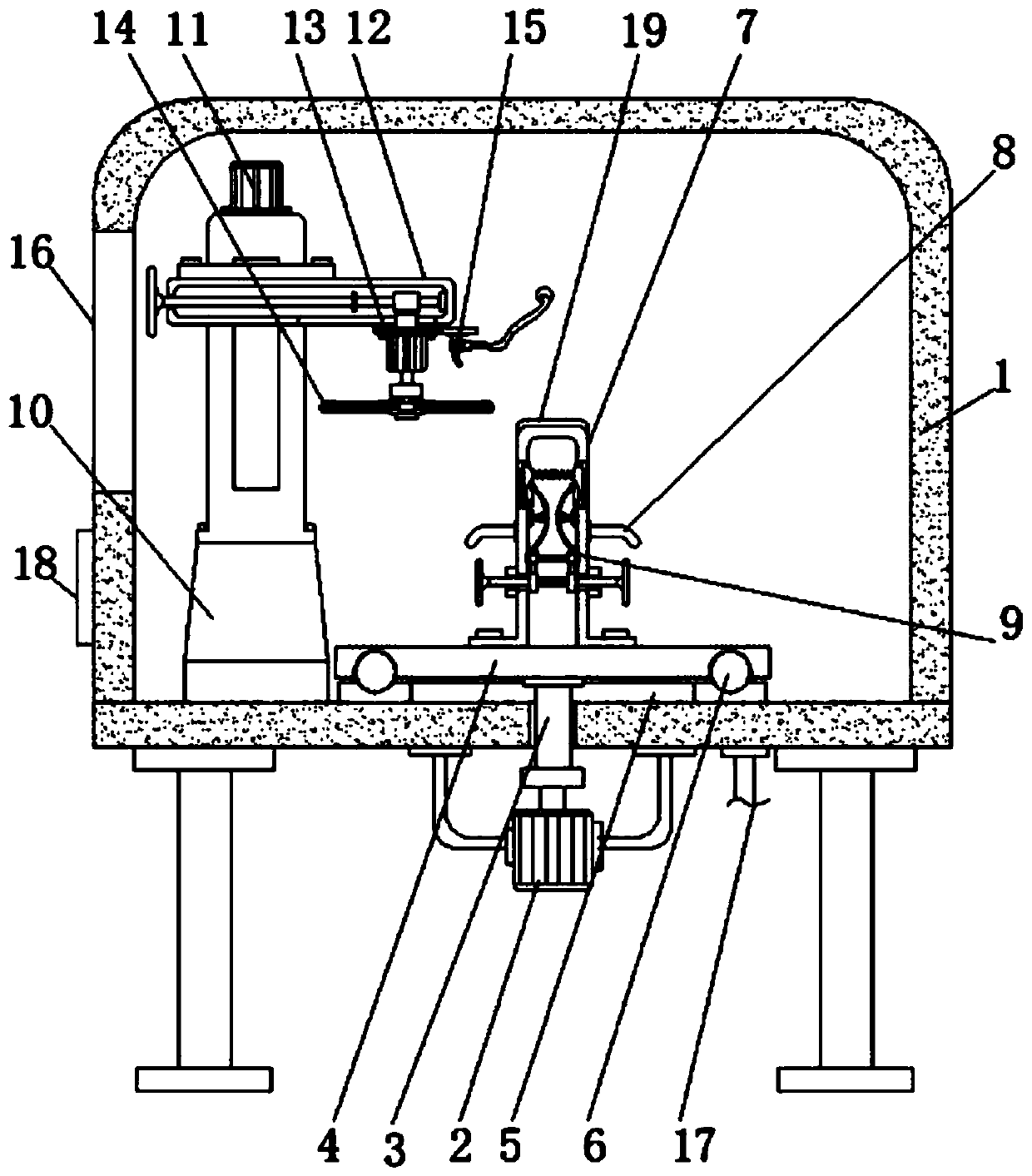

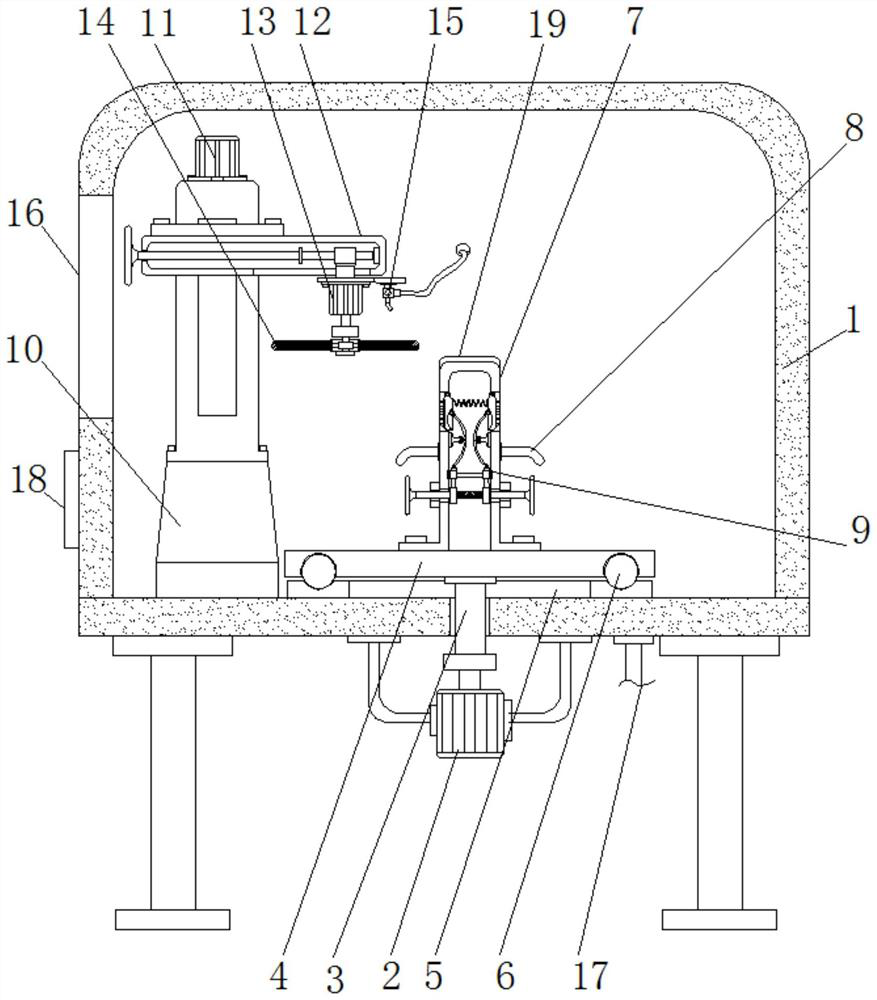

Multi-station drilling machine capable of conveniently drilling two ends of column simultaneously

ActiveCN112338226AImprove continuityImprove drilling efficiencyMetal working apparatusBoring/drilling machinesControl engineeringElectric machinery

The invention discloses a multi-station drilling machine capable of conveniently drilling the two ends of column simultaneously. The multi-station drilling machine comprises a supporting table plate,a first supporting table is fixedly connected to the side, close to the front left portion, of the middle of the upper end of the supporting table plate, and a transposition motor is fixedly connectedto the rear portion of the upper end of the first supporting table; the output end of the transposition motor is fixedly connected with a material bearing mechanism in a penetrating and inserting mode, and the upper portion of the material bearing mechanism is movably connected with an L-shaped positioning mechanism; the lower end of the positioning mechanism is fixedly connected with the front side of the middle of the upper end of the supporting table plate, and a chip groove is formed in the middle of the upper end of the supporting table plate; and the chip groove is formed under the material bearing mechanism. According to the multi-station drilling machine capable of conveniently drilling the two ends of the column simultaneously, through rotation of a supporting disc, the five charging barrels are arranged on the supporting disc, drilling operation can be continuously conducted on the five columns, through drilling cutters on the left side and the right side of the material bearing barrel, the two end faces of the columns can be drilled at the same time, and the drilling efficiency is high.

Owner:中山开通塑胶五金有限公司

Speed bump power generation device based on hydraulic system

InactiveCN106523312ASimple structureEasy to design and manufactureMachines/enginesTraffic signalsSpeed bumpEconomic benefits

The invention discloses a speed bump power generation device based on a hydraulic system. The speed bump power generation device comprises a speed bump system, the hydraulic system and a mechanical system. The speed bump system comprises an upper pressure bearing plate, a lower pressure bearing plate, a spring, a cylinder barrel ejector rod and a piston. The spring is supported between the upper pressure bearing plate and the lower pressure bearing plate and internally provided with a cylinder barrel. The cylinder barrel comprises an outer cylinder barrel body. An inner cylinder barrel body is formed in the outer cylinder barrel body in a surrounding mode. The piston is located in the inner cylinder barrel body. The upper pressure bearing plate is connected with the piston through the cylinder barrel ejector rod. The bottom of the outer cylinder barrel body is provided with an external oil outlet and an external oil inlet. The upper pressure bearing plate is arranged below a speed bump. The speed bump system is connected with the mechanical system used for power generation through the hydraulic system. According to the speed bump power generation device based on the hydraulic system, expressway pavement vibration energy is fully recycled, energy conversion is achieved, the power consumption cost is reduced, and the economic benefit is improved.

Owner:CHANGAN UNIV

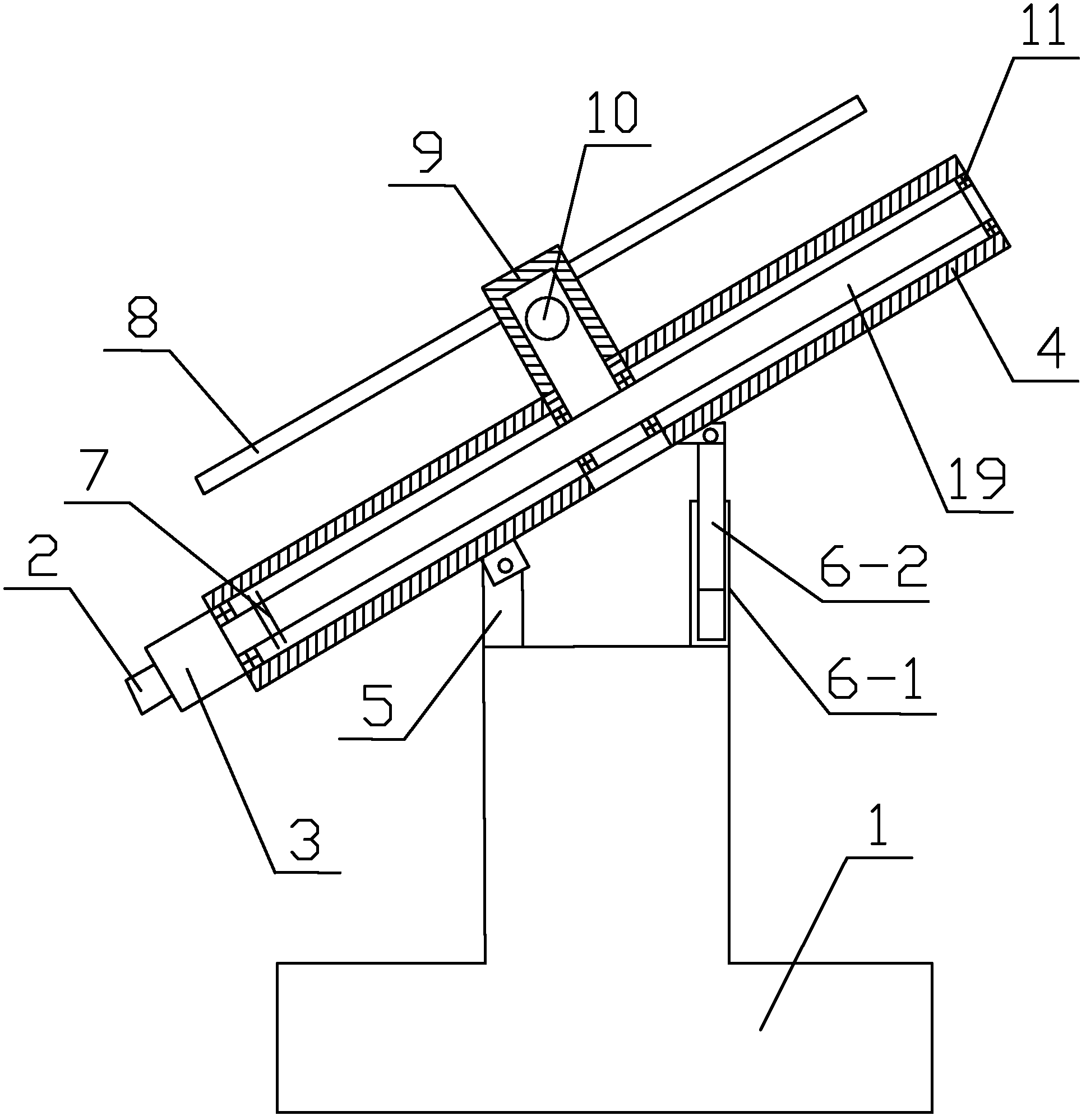

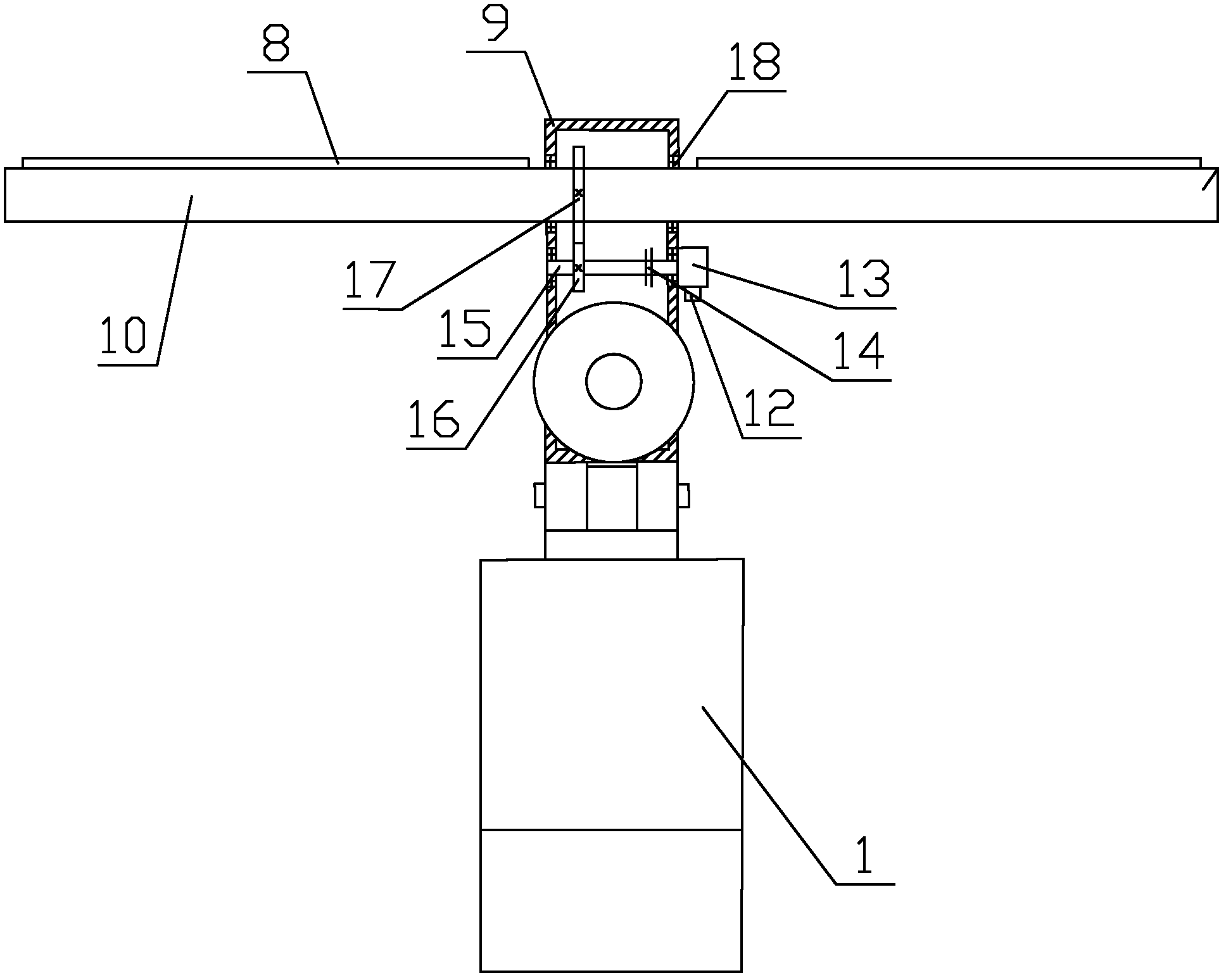

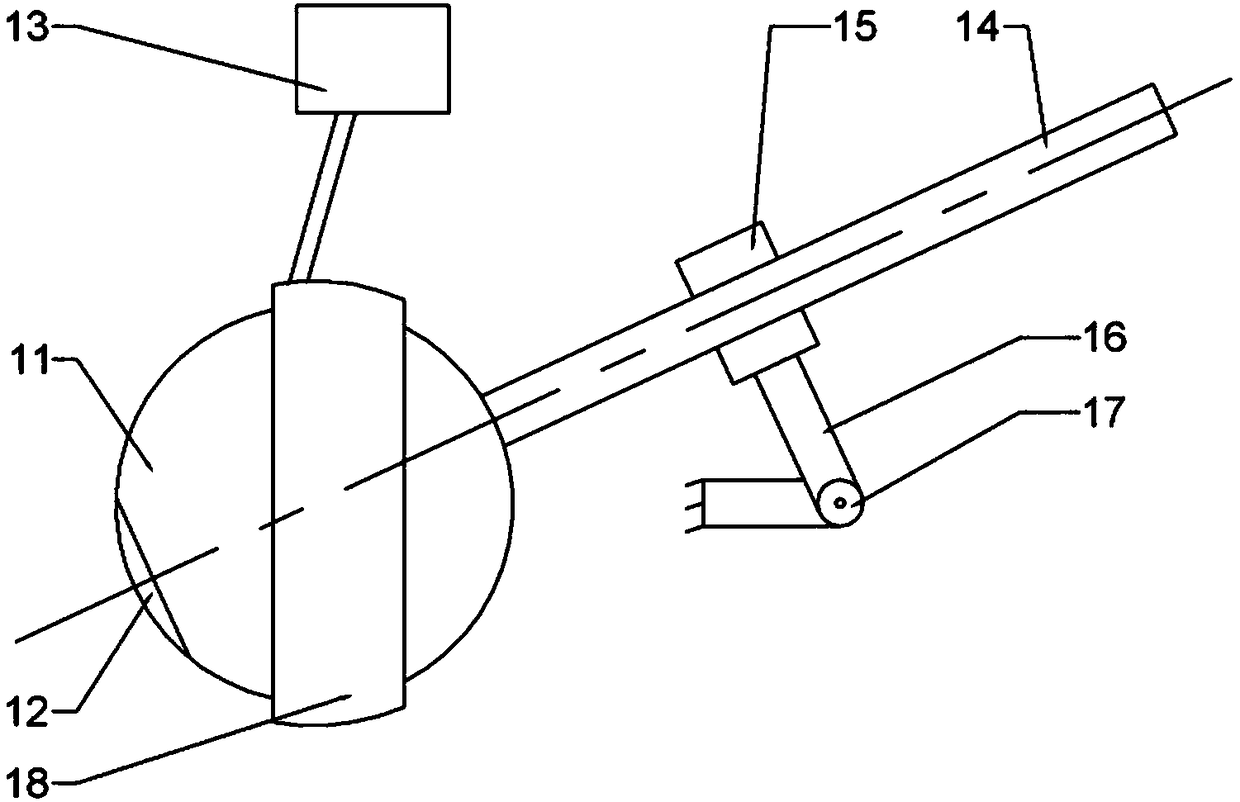

Two-dimensional sunlight automatically tracking device

InactiveCN103135561ACompact structureReasonable designPosition/direction controlRotational stabilityEngineering

The invention discloses a two-dimensional sunlight automatically tracking device which comprises a bearing frame, a first supporting column and a second supporting column which are arranged at the top end of the supporting frame and an inclined rotation mechanism housing and a horizontal rotation mechanism housing which are cradled at the top end of the first supporting column and the second supporting column. An inclined rotation shaft which is connected with an inclined rotation power mechanism is arranged in the inclined rotation mechanism housing; a small gear shaft which is provided with a small gear is arranged in the horizontal rotation mechanism housing; the horizontal rotation mechanism housing which is arranged above the small gear shaft is provided with a horizontal rotation shaft; the horizontal rotation shaft is provided with a big gear which is meshed with the small gear; the end portion of one end of the small gear shaft is connected with a horizontal rotation power mechanism; and two ends of the horizontal rotation shaft are respectively provided with a solar cell panel. The two-dimensional sunlight automatically tracking device has the advantages of being compact in structure, reasonable in design, convenient to install, convenient and rapid to use, high in rotating stability and tracking precision, low in achievement cost, power consumption and operating cost, good in using effect and convenient to popularize and utilize.

Owner:XIAN DAYU PHOTOELECTRIC TECH

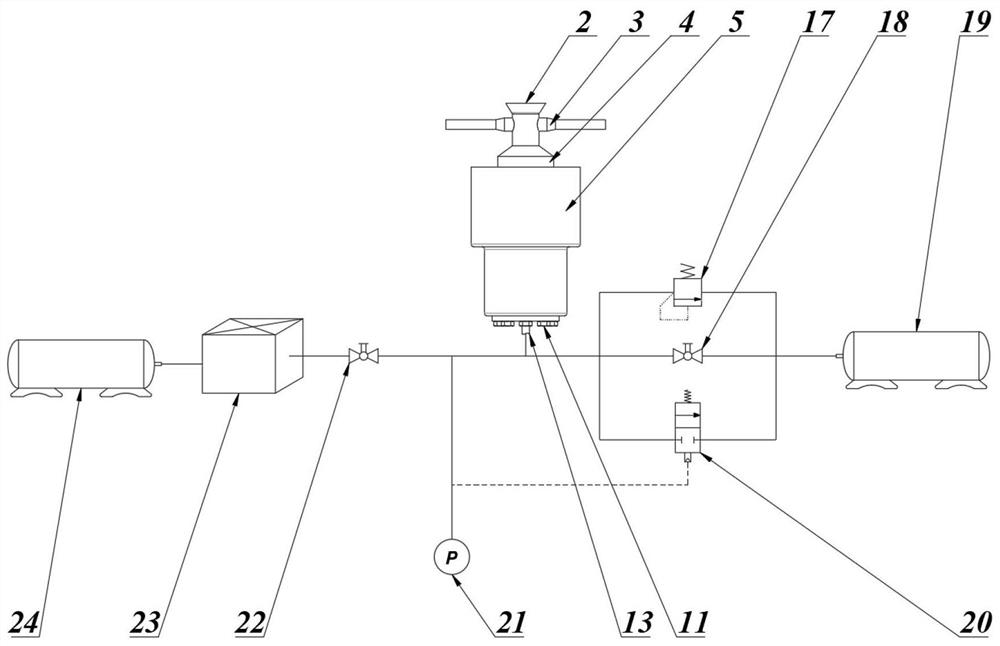

Internal inclination angle testing device capable of analyzing influence of section diameter of O-shaped ring on high-pressure sealing performance

ActiveCN112304530AAfter solving the installation test O-ring 7Solve the centering problem of cylinder 5 cone surface fitMeasurement of fluid loss/gain rateMachine sealing rings testingEngineeringVALVE PORT

An internal inclination angle testing device capable of analyzing the influence of the section diameter of an O-shaped ring on the high-pressure sealing performance comprises a cylinder, the middle lower portion of a movable cover extends into the cylinder to be connected with the cylinder, the lower portion of the movable cover is of a conical structure, and the O-shaped ring for testing is arranged in an annular sealing groove in the outer side wall of the conical structure. The movable cover is matched with a spiral groove in the inner side wall of the barrel through a protruding spiral block on the outer side wall of the middle to achieve rotation, the bottom of the barrel is communicated with an air inlet pipeline and an air outlet pipeline, an annular protrusion is arranged in the middle of the movable cover, the spiral block is arranged on the bottom side outside the annular protrusion, and the spiral face is provided with an inner inclination angle, correspondingly, spiral grooves are uniformly distributed in the cylinder body, and the characteristic angle of the spiral groove is matched with the related characteristic angle of the spiral block. The section diameter of theO-shaped ring for testing is controlled by changing the fit clearance between the sealing groove in the bottom of the movable cover and the conical surface of the barrel, and gas recovery, overpressure overflow and unloading under pressure fluctuation of the testing device are achieved through cooperation of the pressure detection meter and the valve.

Owner:TSINGHUA UNIV +1

High-precision surface flatness detection equipment for bearing processing

PendingCN113983922AGuaranteed detection accuracyGuaranteed rotation stabilityElectric/magnetic roughness/irregularity measurementsElectric machineTransmission belt

The invention discloses high-precision surface flatness detection equipment for bearing processing. The equipment comprises a base, a butt joint lead screw and an embedded part; a driving motor is mounted on the outer side of the edge end of the base, a conveying belt is mounted at the output end of the driving motor in a nested manner, the conveying belt is connected with the inner side of the base, and a nested frame is mounted at the upper end of the base through bolts; the butt joint lead screw is installed at the inner end of the nested frame in a nested mode, the side end of the butt joint lead screw is in nested butt joint with the upper end of the conveying belt, and a reserved electric wire connected with a power source is installed at the upper end of the base; and the embedded part is in threaded butt joint with the outer side of the butt joint lead screw. According to the high-precision surface flatness detection equipment for bearing processing, the driving motor stably drives three groups of contact pieces on the outer side of the output end to perform centrifugal movement in the working process, and friction blocks at the edge ends of the driving motor are attached to the inner side of a bearing piece to make contact with the inner side of the bearing piece, so that the bearing piece to be detected is synchronously driven to perform circumferential movement through the rotating centrifugal force of the driving motor, and all-around multi-area detection work is carried out on an object in cooperation with a self-displacement nested piece.

Owner:宁波纽兰得轴承有限公司

A large-diameter fruit glass can bottle body washing equipment

ActiveCN109047231BIncrease the cleaning areaFast cleaningHollow article cleaningRotary stageElectric machine

The invention relates to the technical field of fruit glass can cleaning, and discloses a large-caliber fruit glass can bottle body washing device, which includes a body, the bottom of the body is fixedly connected with a low-speed motor through a fixing frame, and the output shaft of the low-speed motor is fixed through a coupling It is connected with a torque shaft. The torque shaft runs through the bottom of the body at the end away from the low-speed motor and is fixedly connected with the rotary table. The inner bottom of the body is fixed with a ring chute matching the outer diameter of the rotary table through bolts. The rotary table The bottom of the bottom is movably connected with movable balls, and the bottom of the movable balls is positioned at the inner side of the ring chute. The present invention solves the problems of glass by arranging the machine body, low-speed motor, torque shaft, rotary table, positioning support cylinder, adjusting and positioning mechanism, vertical circulation mechanism, lateral positioning mechanism, rotating motor, disc cleaning brush, spray head and control panel to cooperate with each other. The labor intensity and cost of cleaning the body of the canned food are relatively large.

Owner:CHONGQING YANQUAN FOOD CO LTD

A household square mat rotary cleaning equipment

ActiveCN108888201BReduce labor intensityAchieve the purpose of removingCarpet cleanersFloor cleanersElectric machineAgricultural engineering

The invention relates to the technical field of household daily necessities, and discloses a household square mat rotary cleaning device, which includes a cylinder body, a support frame, an electric lifting rod and a sealing cylinder cover, and the left and right sides of the cylinder body pass through a fixed block The support frame is fixedly connected, and the two sides of the inner top of the support frame are fixedly connected with electric lifting rods. The ends of the two electric lifting rods are fixedly connected with a sealing cylinder cover that matches the size and shape of the top of the cylinder. The sealing cylinder cover The upper surface of the sealing cylinder is fixedly connected with a vertical rotating motor, and the output shaft of the vertical rotating motor runs through the upper surface of the sealing cylinder cover and is connected with a load-bearing connection auxiliary mechanism. The present invention cooperates with each other by arranging cylinder body, load-bearing connection auxiliary mechanism, flushing nozzle, rotary positioning adjustment mechanism and winding mechanism, so as to achieve the purpose of removing soil impurities adhering to the square floor mat, and greatly reduces the traditional impact on square floor mats. Pads are labor intensive to clean.

Owner:乐清市梦依轩居室用品有限公司

Large-caliber fruit glass canned bottle body washing equipment

ActiveCN109047231AIncrease the cleaning areaFast cleaningHollow article cleaningRotary stageLow speed

The invention relates to the technical field of fruit glass can washing and discloses large-caliber fruit glass canned bottle body washing equipment comprising a machine body. A low speed motor is fixedly connected to the bottom of the machine body through a fixing frame. A torque rotary shaft is fixedly connected to an output shaft of the low speed motor through a coupling. The end, away from thelow speed motor, of the torque rotary shaft penetrates through the bottom of the machine body and is fixedly connected with a rotary table. A circular ring chute matched with the size of the outer diameter of the rotary table is fixedly connected to the bottom of the inner side of the machine body through a bolt. A movable ball is movably connected to the bottom of the rotary table. The bottom ofthe movable ball is located on the inner side of the circular ring chute. The machine body, the low speed motor, the torque rotary shaft, the rotary table, a locating support barrel, an adjusting locating mechanism, a vertical circulation mechanism, a transverse locating mechanism, a rotary motor, a disc type cleaning brush, a spraying head and a control panel are arranged and matched, so that the problems of high labor intensity and cost of cleaning of glass canned bottle bodies are solved.

Owner:重庆岩泉食品有限公司

Mouse with high applicability

InactiveCN111290639ASmooth rotationGuaranteed stabilityInput/output processes for data processingEngineeringStructural engineering

The invention discloses a mouse with high applicability that comprisesa first body; one side of the first body abuts against a second body; a mounting groove is provided on one side of the second body; bearing grooves are provided at the lower end of the first body and the lower end of the second body; the upper end of one of the bearing grooves is communicated with the mounting groove; the mounting groove corresponds to the first body; a power mechanism is arranged on the side wall of one end in the mounting groove; and a connecting pipe and a first shaft sleeve are arranged on the power mechanism. The distance between the two bodies can be adjusted, and the distance between the bodies and the U-shaped plate can also be adjusted, therefore, the application range of the mouse can be well expanded; the adjustable mouse is simple in structure and convenient to use, can be well suitable for different users, can guarantee the stability of the adjusted mouse, improves the use comfort of theusers, can well avoid the situation that the palm and the arm of some users are prone to fatigue when the existing mouse is used due to the fact that the mouse cannot be adjusted, and facilitates prolonging of the use time of the users.

Owner:长沙凯泽工程设计有限公司

Traditional village building exhibition stand and display method thereof

ActiveCN112089274AAvoid Dust ProblemsAvoid affecting the display effectEducational modelsShow shelvesSupport plane

Owner:HENAN UNIV OF URBAN CONSTR

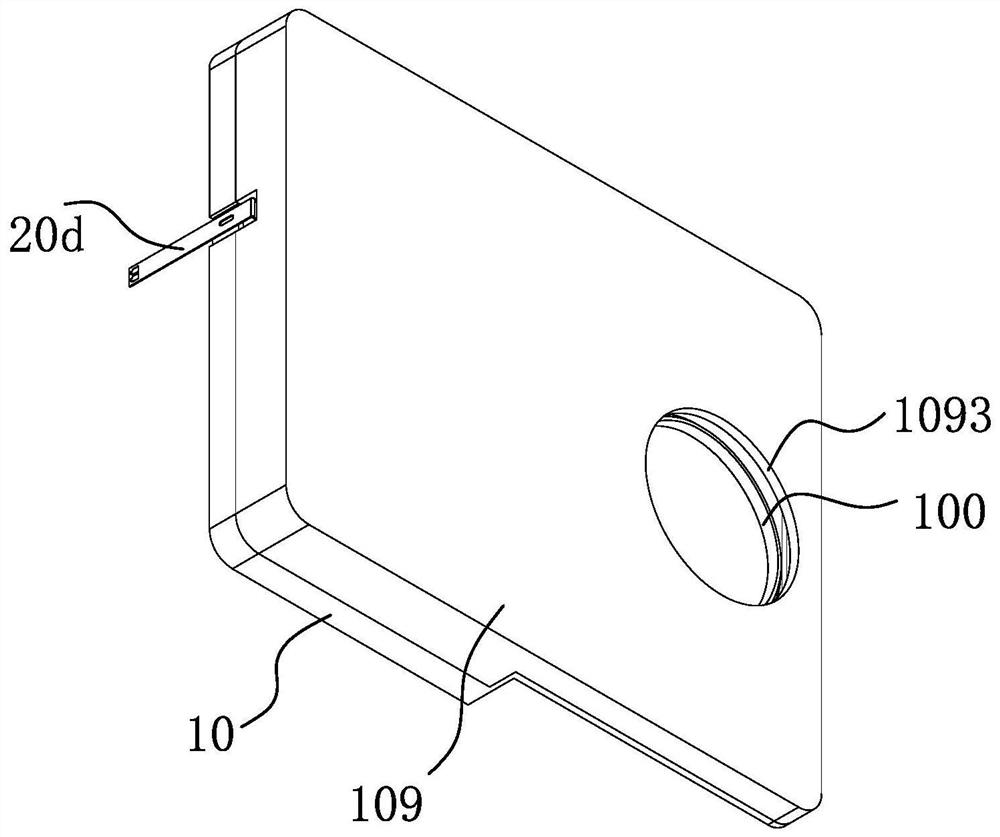

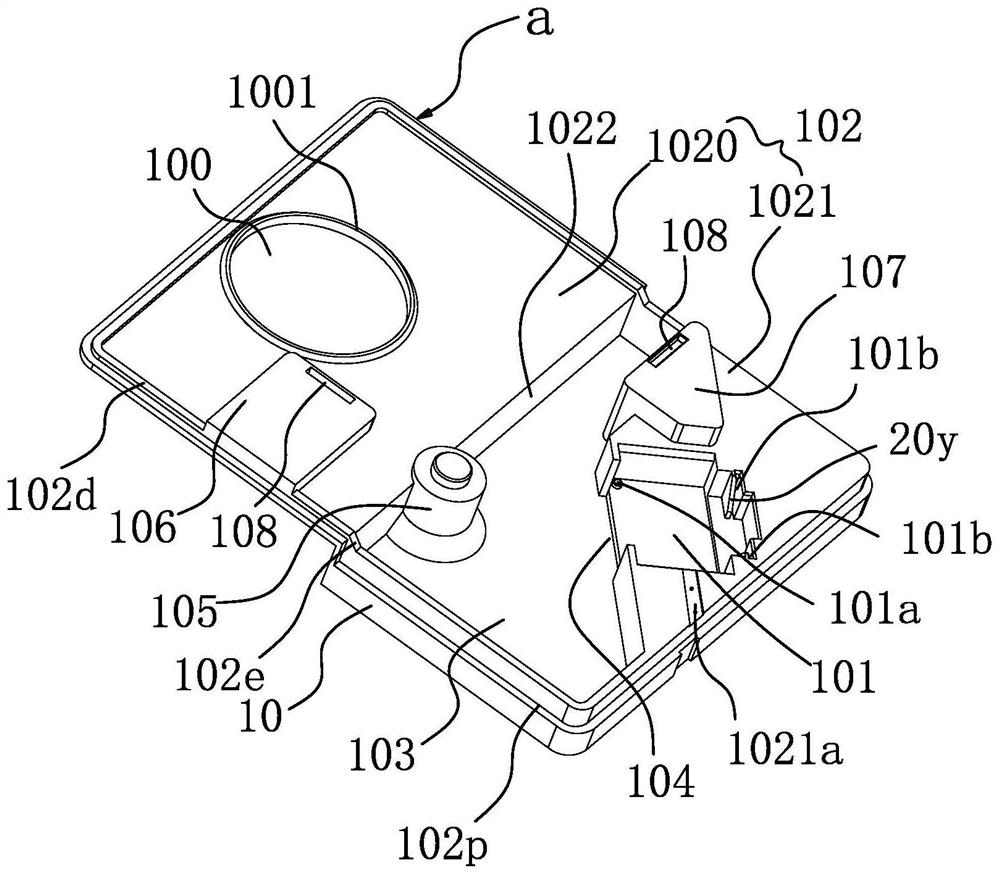

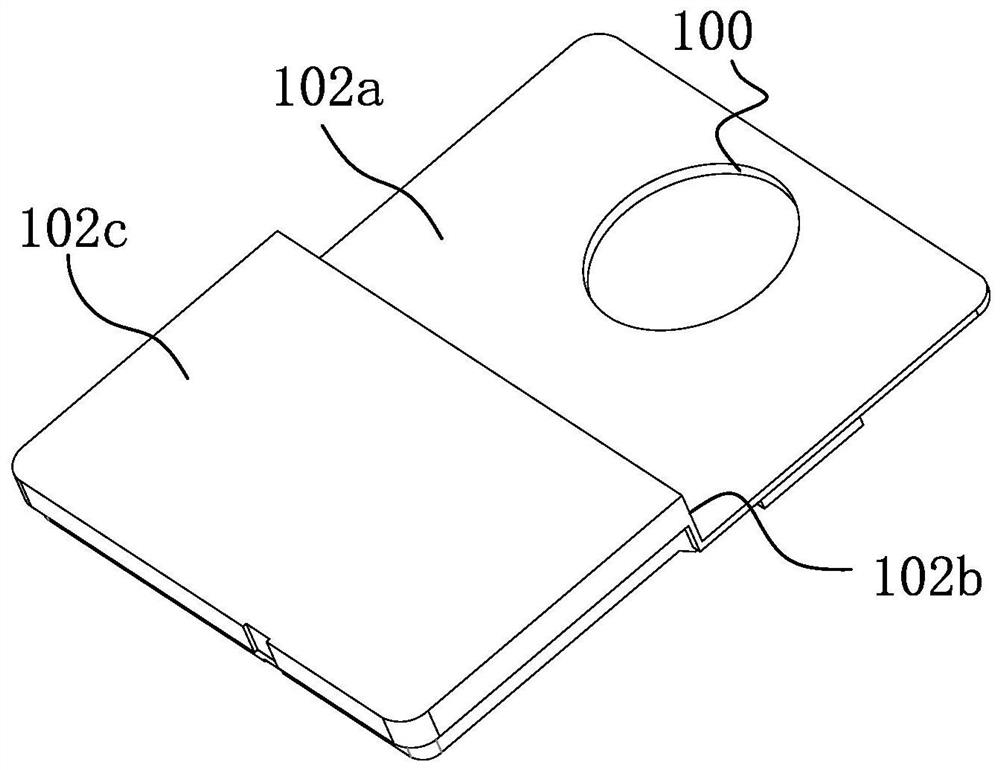

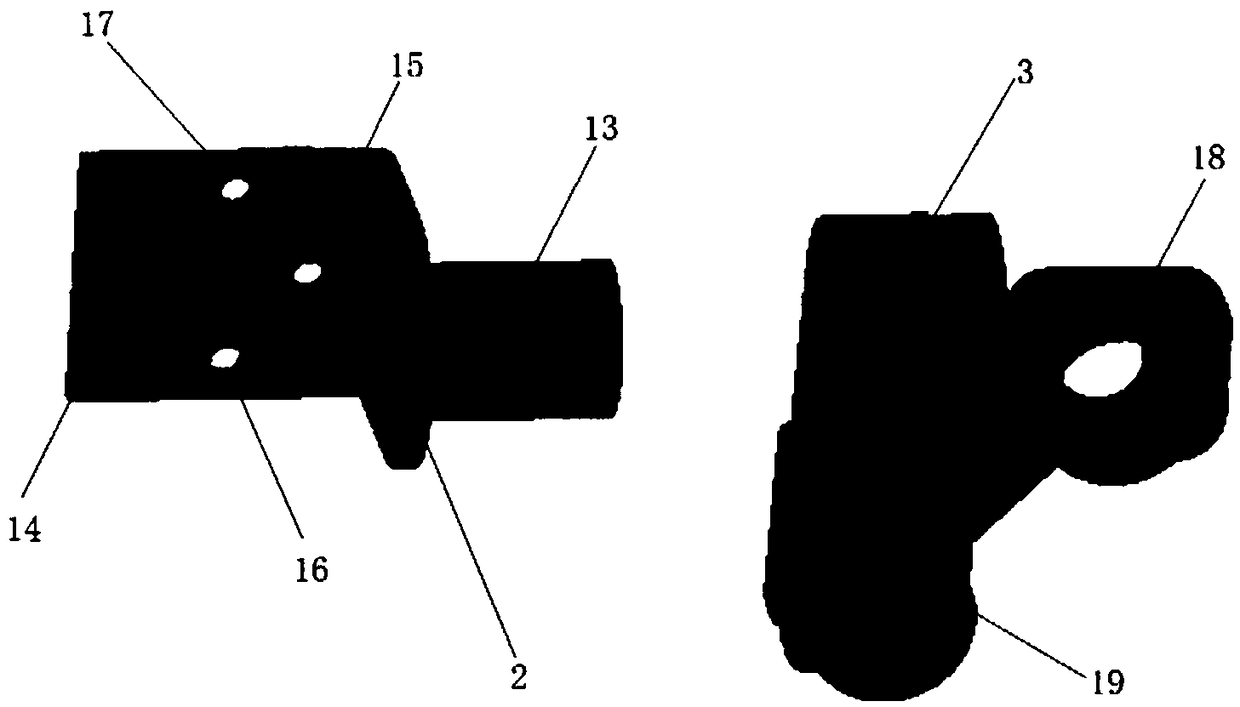

Stabilizing mechanism of driving device, aperture assembly, camera device and electronic equipment.

The invention belongs to the technical field of electronic equipment, and particularly relates to a stabilizing mechanism of a driving device, an aperture assembly, a camera device and electronic equipment. The defects that an existing driving device is unstable in movement and the like are overcome. According to the stabilizing mechanism of the driving device, the driving device comprises a frame body installed on a variable aperture base, a rotating block arranged in the frame body and rotationally connected with the frame body, a swing cantilever connected to the front end of the rotating block, and a driving magnet installed on the rotating block, and the stabilizing mechanism comprises stabilizing magnetic conductive sheets. The stable magnetic conductive sheets and the end face, away from the swing cantilever, of the driving magnet are distributed at intervals and used for providing continuous adsorption force for the driving magnet. The stable magnetic conductive sheets provide continuous adsorption force for the driving magnet, so that the movement stability of the driving device is ensured, and finally, the shielding aperture stably moves.

Owner:NEW SHICOH MOTOR CO LTD

A network big data analysis device

ActiveCN113093887BImprove operational efficiencyAchieve circulationDigital processing power distributionHousing of computer displaysElectric machineMechanical engineering

The invention discloses a network big data analysis device in the technical field of big data analysis, comprising a base, a rotating plate is arranged on the upper end of the base, a frame is arranged on the upper end surface of the rotating plate, and rollers are arranged on corners of the lower end surface of the base, The upper end surface of the frame is fixedly connected with a display screen, the inside of the frame is provided with a groove, the inside of the groove is provided with a motor, the two ends of the motor are fixedly connected with slide bars, the output shaft of the motor is fixedly connected with a screw rod, and the screw rod The lower end of the sliding rod is inserted into the inside of the rotating plate, and a connecting bearing is provided between the screw rod and the rotating plate, and the lower end surface of the sliding rod is fixedly connected with the rotating plate, which can dissipate heat from the inside of the frame and has a good Usability, it can effectively dissipate the heat of the device independently in the process of high commission, has a good adjustment effect and can also ensure the stability of the adjustment process, and can greatly improve the operating efficiency of the staff, which is more practical.

Owner:DEZHOU UNIV

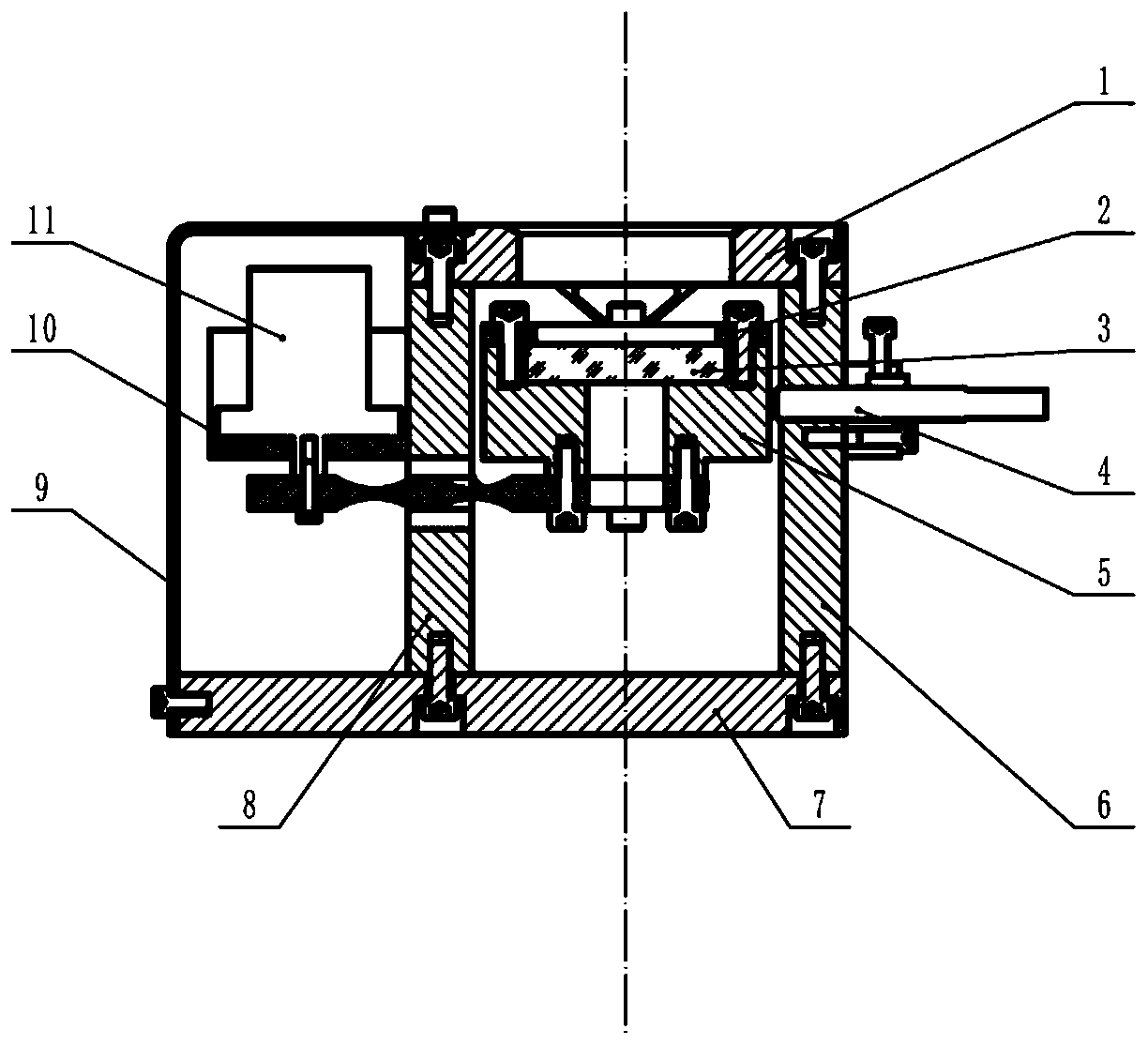

Composite rotating shaft mechanism

PendingCN109253155AAchieve rotationLimit reachedStands/trestlesPivotal connectionsEngineeringMechanical engineering

The invention discloses a composite rotating shaft mechanism. The composite rotating shaft mechanism comprises a face shell, a bottom shell, a liquid crystal assembly, a limit rotating shaft, a fixedsupport, a reinforced shaft, and screws; according to one end of the novel composite rotating shaft mechanism, a routine rotating shaft is fixedly arranged on the liquid crystal assembly and the faceshell, and the other end is provided with a composite rotating shaft structure; the reinforced shaft is adopted for cooperation with the fixed support, so that double-shaft stability and reliability are achieved. The composite rotating shaft mechanism is low in cost, is capable of solving a problem in the prior art that cost is relatively high because of adoption of double rotating shafts in a conventional rotating shaft assembling method; different display angles can be achieved through rotating of the liquid crystal assembly by users; the assembling mode is simple; complex assembling requirements of routine rotating shafts are avoided; and product comprehensive competition advantages are improved greatly.

Owner:XIAMEN YEALINK NETWORK TECH

High-precision and high-stability pendulum mirror device suitable for space environment and working method thereof

ActiveCN110082904AReduce volumeOvercome precision requirementsOptical elementsSpace environmentLoop control

The invention provides a high-precision and high-stability pendulum mirror device suitable for space environment and a working method thereof. A pendulum mirror is arranged in a pendulum mirror chamber. The front section of the pendulum mirror chamber is mounted on a fixed front panel through two flexible structures in an up-down symmetry manner, and no impact force guarantees adjustment stability; the back end of the pendulum mirror chamber is provided with an adjusting rod, and the other end of the adjusting rod is equipped with an adjustment actuator, so that the position of the pendulum mirror can be adjusted precisely; the side surface of the pendulum mirror chamber is equipped with a high-precision sensor; and the high-precision sensor and a sensor connection plate, together with thetwo flexible structure members, the pendulum mirror chamber, the adjustment actuator and the adjustment lever, form real time closed-loop control. The device can ensure coincidence of the adjusting centers of the flexible structures and ensure direction adjusting accuracy and stability to the maximum extent; the high-precision sensor can detect the position information of the pendulum mirror in real time; the position of the pendulum mirror drifts a little bit due to load excitation of temperature and vibration and the like during working; and through the high-precision sensor, position information is fed back and through the adjustment actuator, the position of the pendulum mirror is corrected, thereby ensuring position precision of the pendulum mirror.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

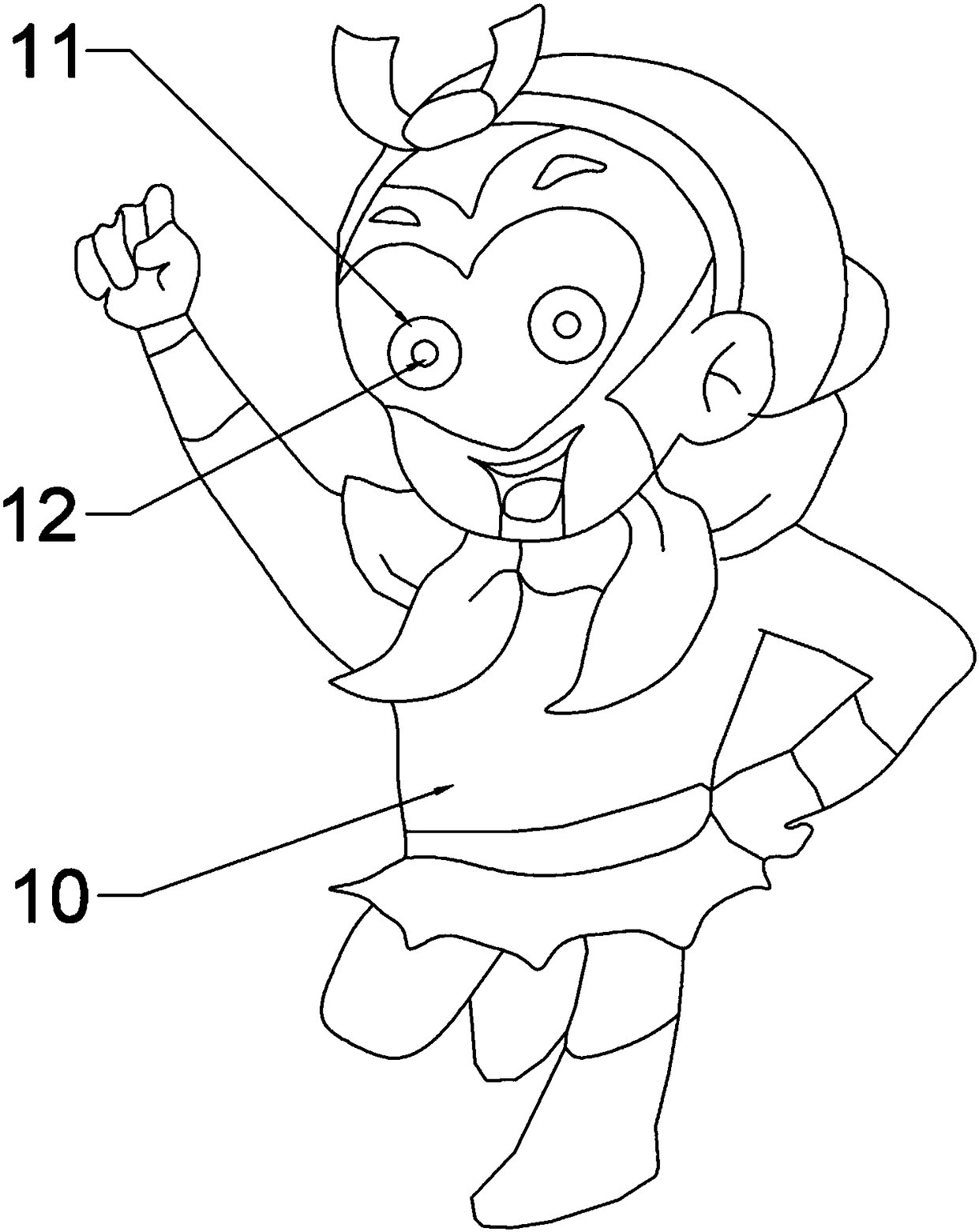

Multifunctional interactive robot

The invention discloses a multifunctional interactive robot. The multifunctional interactive robot comprises a robot body and two projection mechanisms located at the eye parts of the robot body. Eachprojection mechanism is mounted at the corresponding eye part of the robot, and the projection angle is controlled by a servo steering machine, so that the rich projection combination is achieved, for example, two images are spliced together to form an ultra-wide picture, or the two images are projected separately to form different pictures, more information is fed back to a user, enjoyment is high, and playability is high.

Owner:重庆门罗机器人科技有限公司

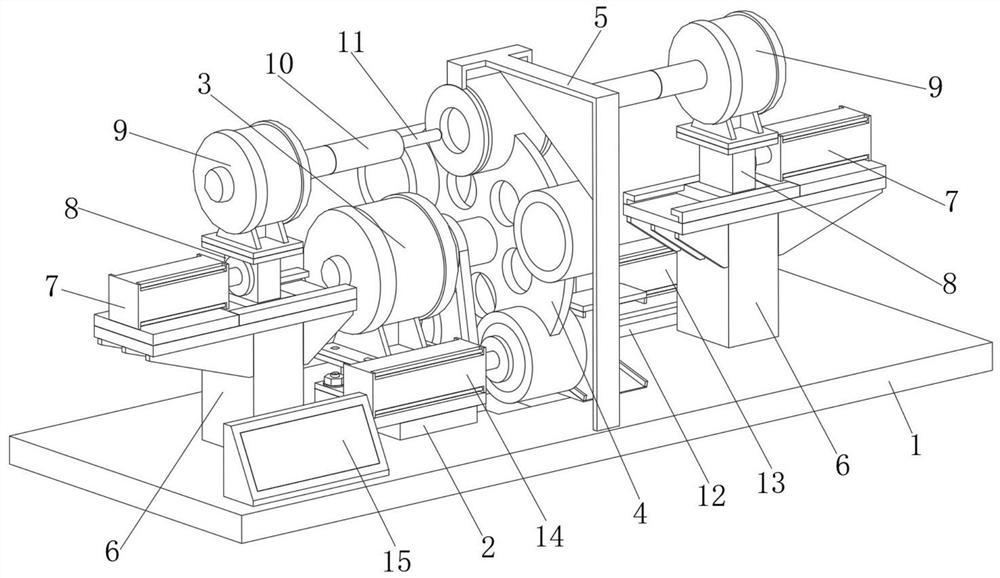

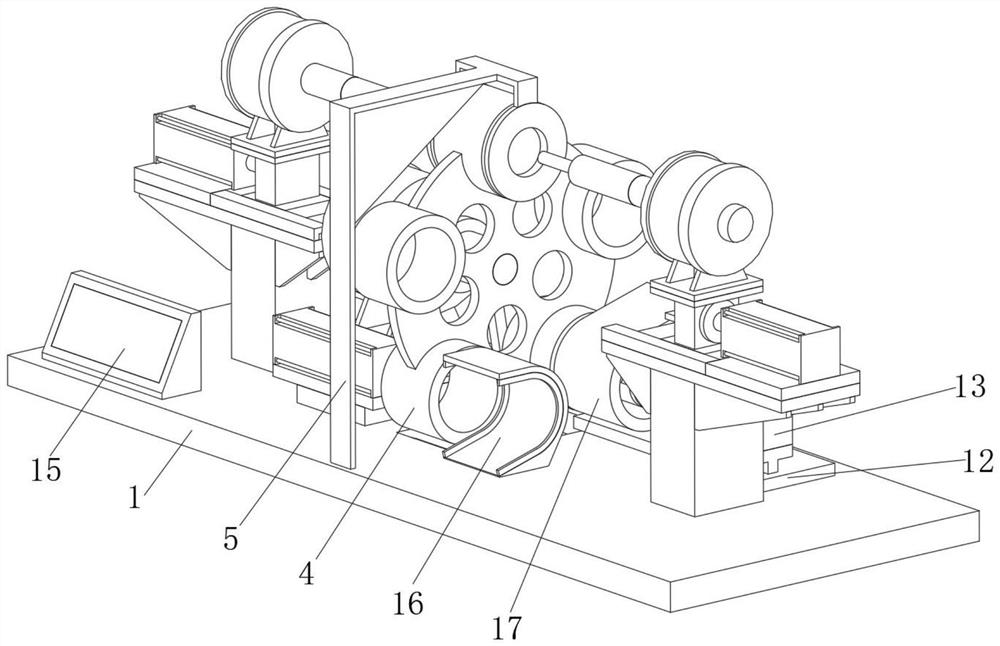

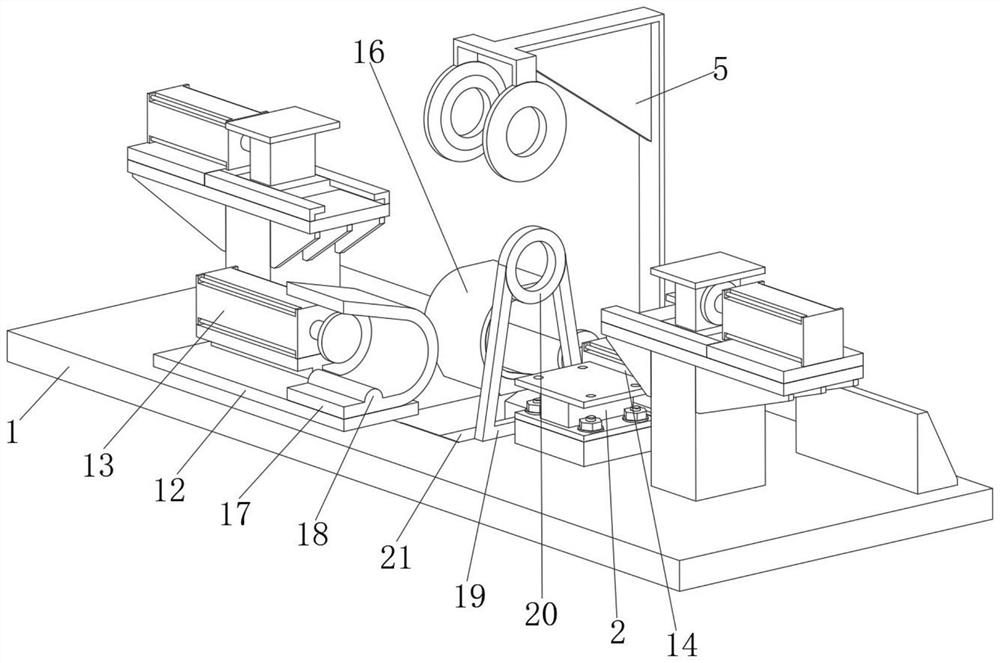

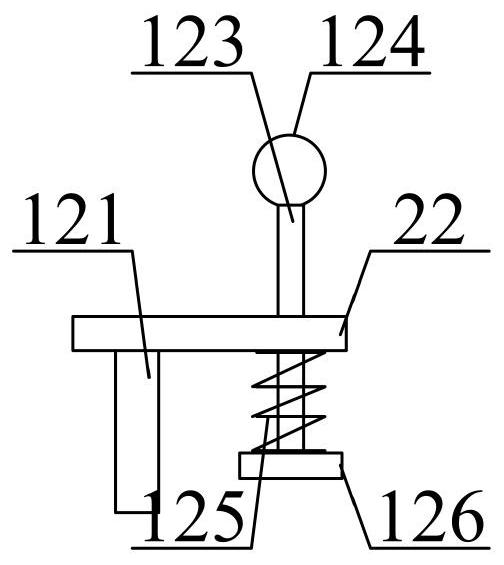

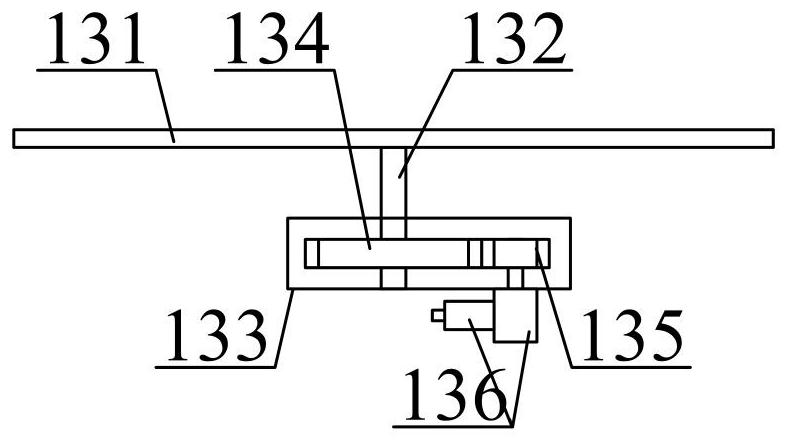

Vertical adjustment mechanism for serving channel in tennis ball serving machine

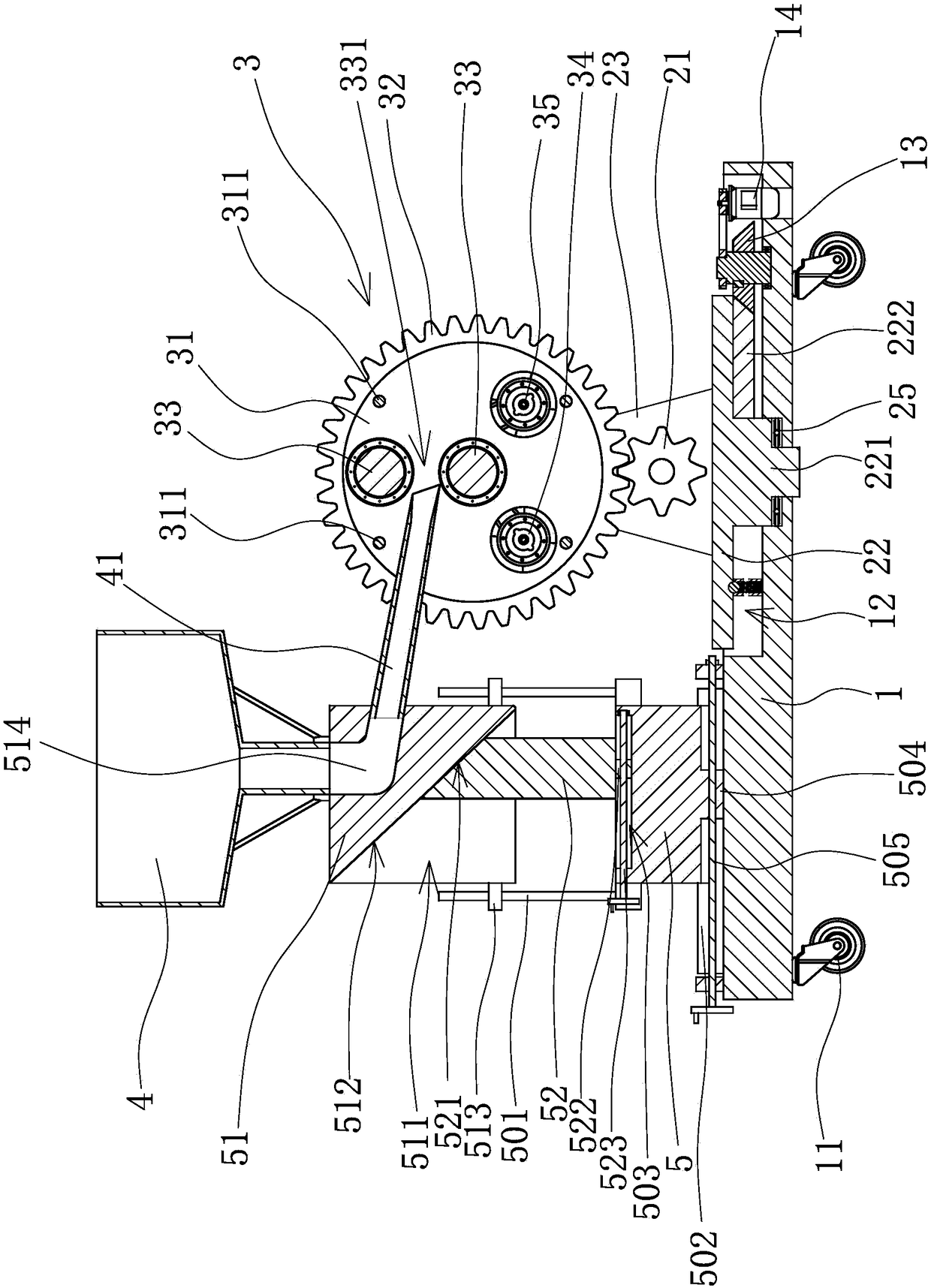

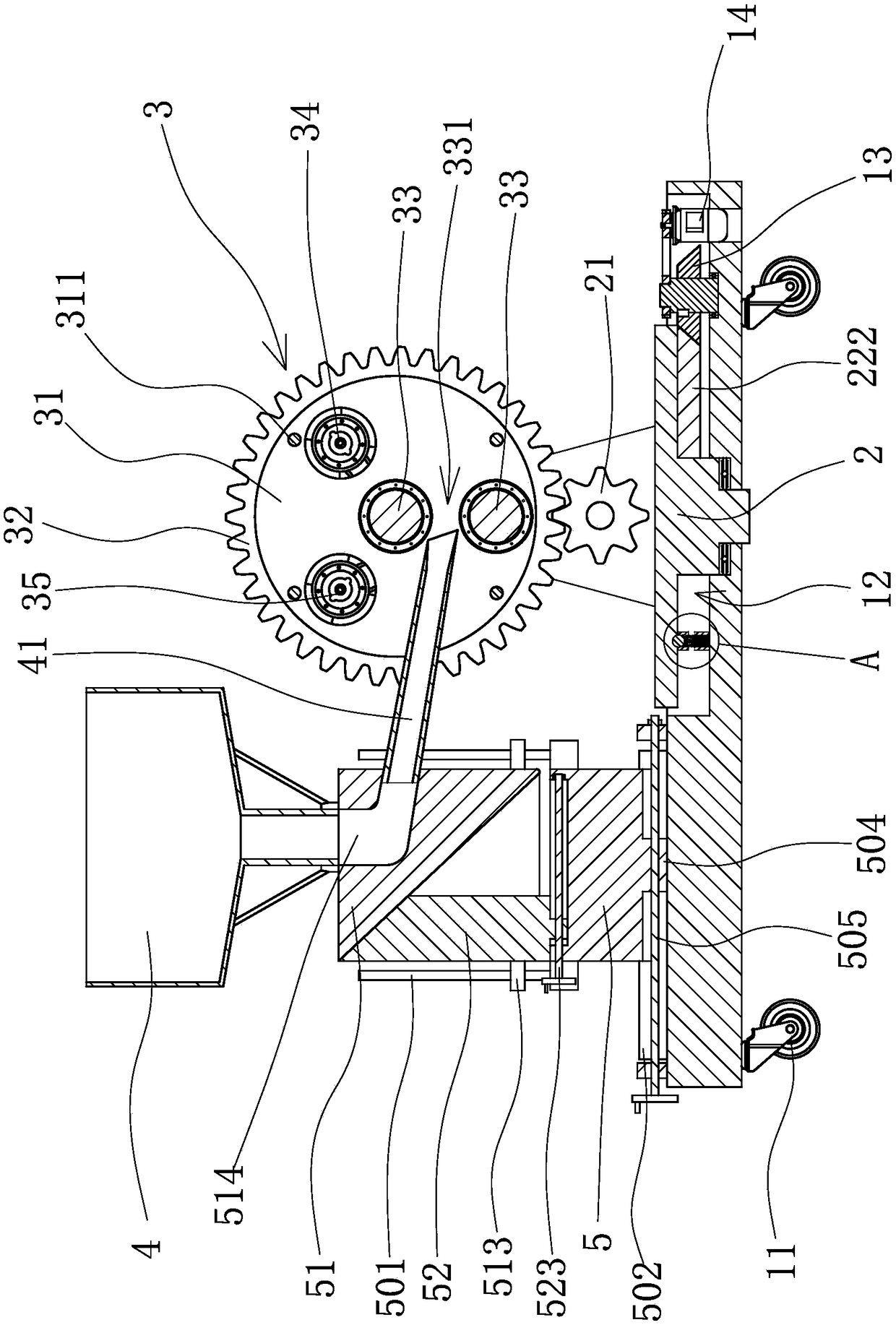

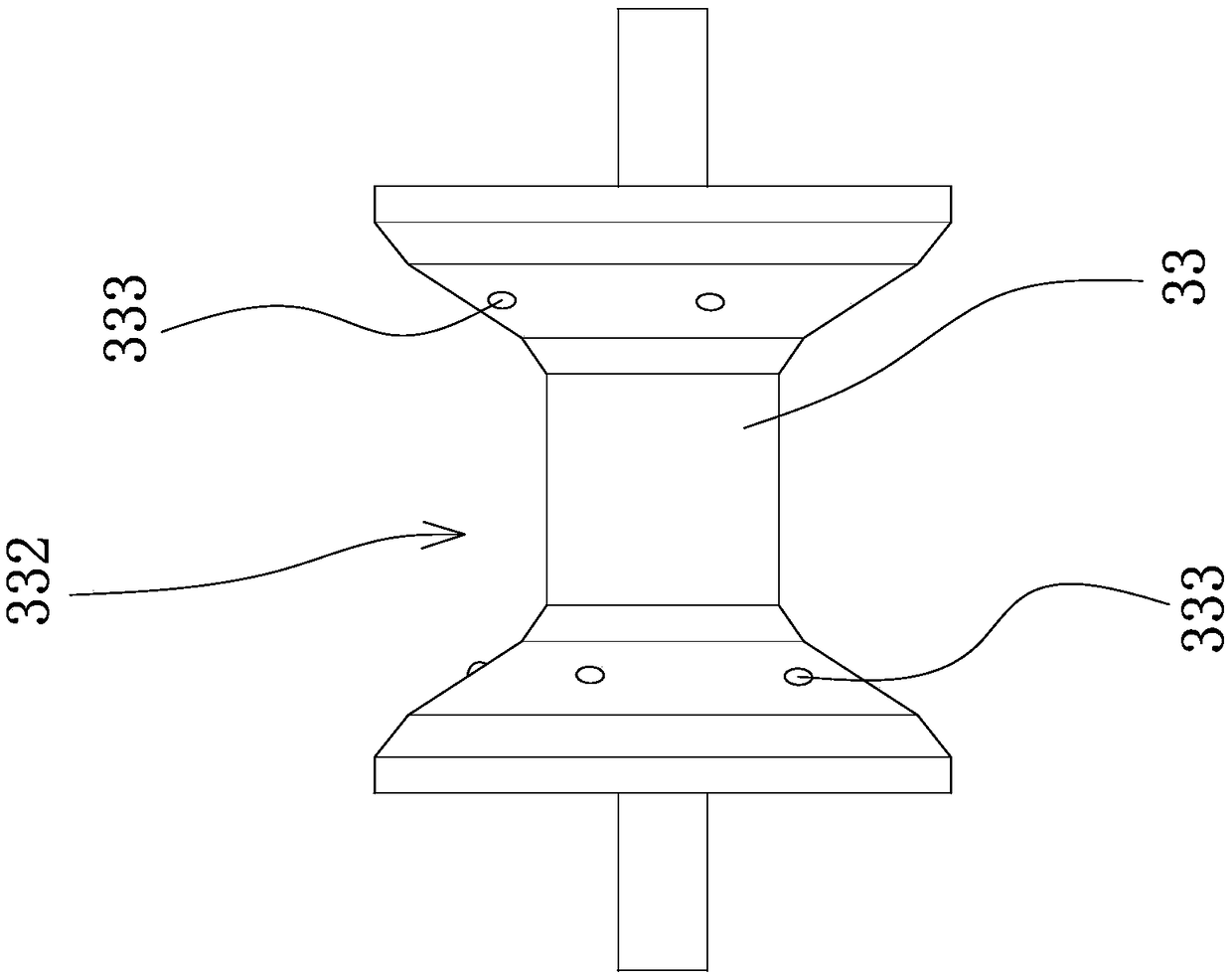

PendingCN108371804AGuaranteed rotational stabilityEasy to practiceSport apparatusAgricultural engineeringSports equipment

The invention provides a vertical adjustment mechanism for a serving channel in a tennis ball serving machine, which belongs to the technical field of sports equipment. The vertical adjustment mechanism solves the technical problems of conventional tennis ball serving machines, such as fewer ball routes. The tennis ball serving machine comprises a base with universal wheels, and two pinch rollers,wherein the serving channel is formed by the two pinch rollers, and a serving base is arranged at the front end of the base. The vertical adjustment mechanism for the serving channel comprises a mounting base which is shaped like a disk and vertically arranged on the serving base, wherein the mounting base comprises two mounting disks which are arranged in parallel and separately, the two mounting disks are fixedly connected with each other through a plurality of connecting rods, the center of the outer side of each of the two mounting disks is provided with a rotating sleeve, a shaft sleeveis rotatably connected to the serving base, and the two pinch rollers are both rotatably connected between the two mounting disks. The vertical adjustment mechanism has the advantage of enabling the serving machine to serve balls in more different routes.

Owner:平湖市酷风文体用品有限公司

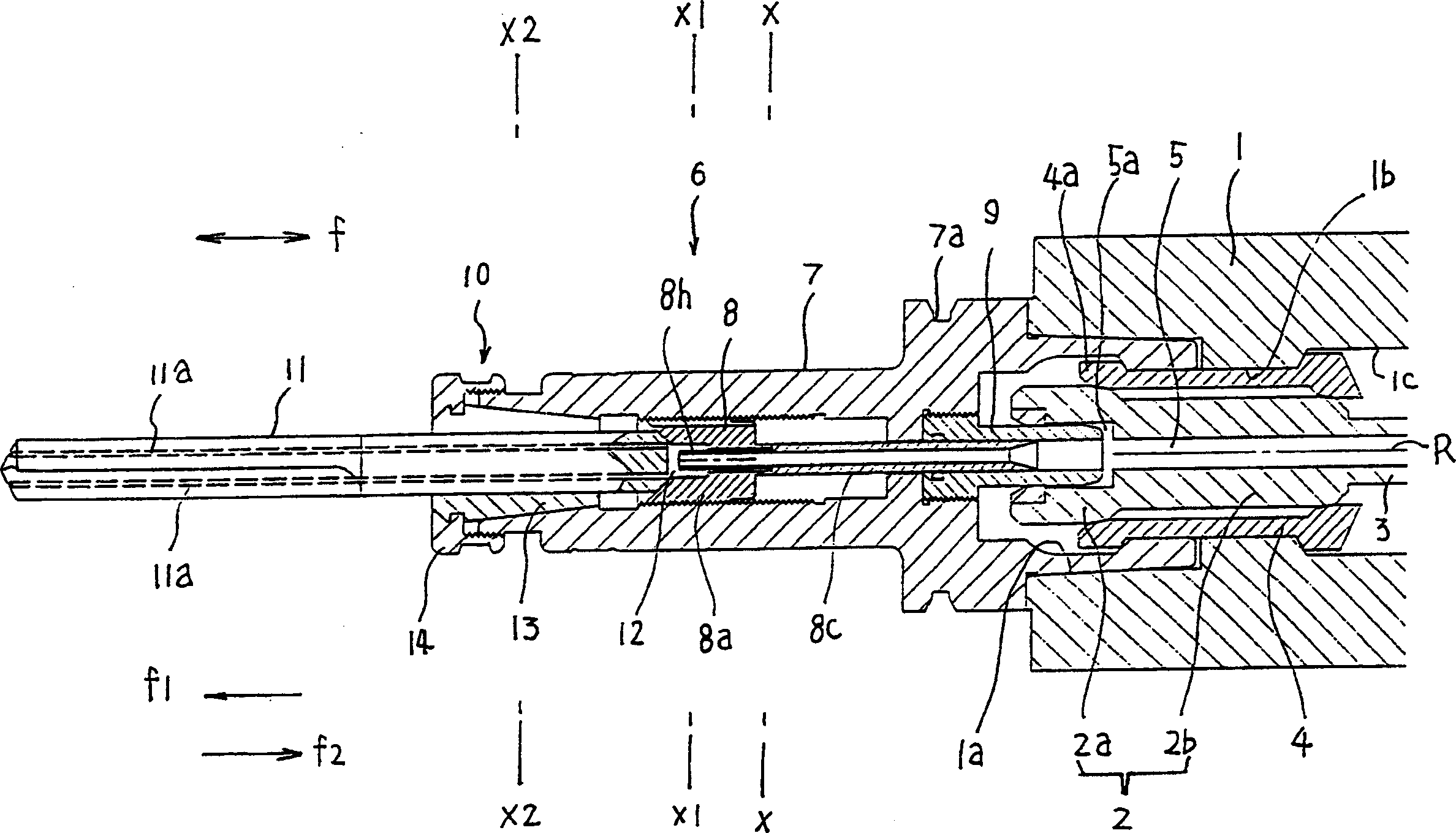

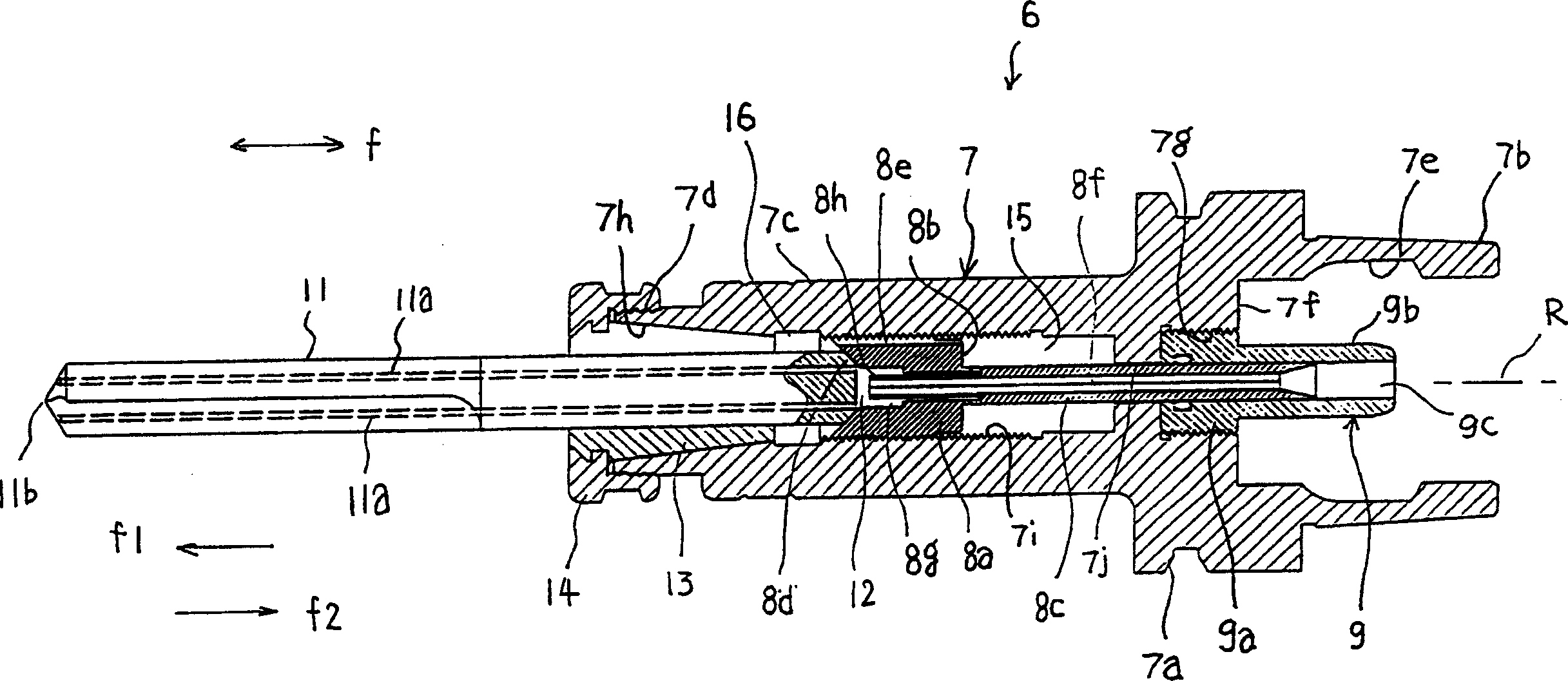

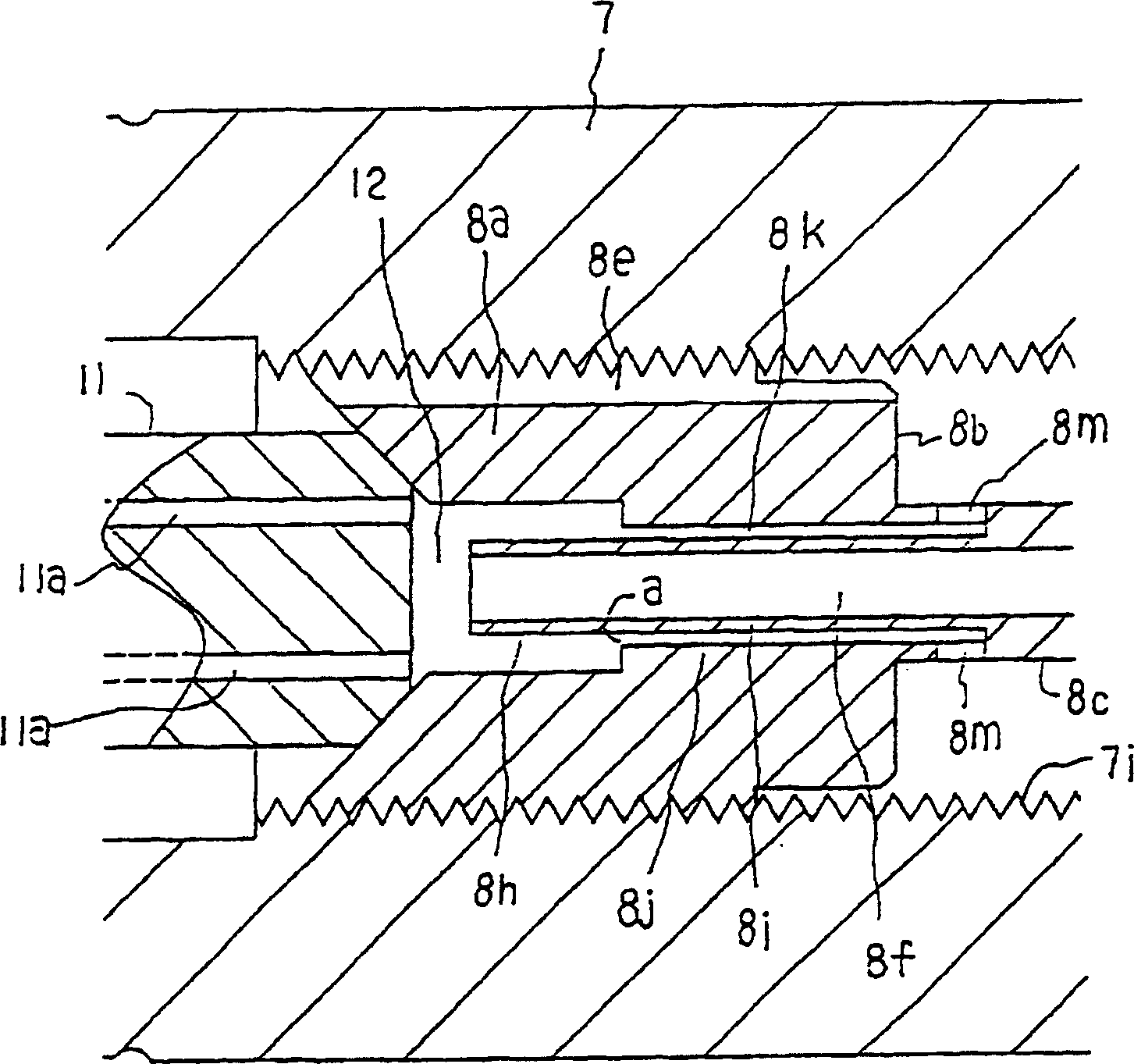

Tool holder of machine tool

InactiveCN1668420AGood symmetryGuaranteed rotational stabilityLarge fixed membersMaintainance and safety accessoriesMachine toolAtmosphere

A tool holder of a machine tool, wherein a holder rear end part is fixed to the front end part of the spindle of the machine tool, a tool receiving surface part (8d) for receiving the rear end face of a shaft-like tool (11) fixed to a holder front end part so that a closed space (12) in contact with the rear end face can be formed and fog cutting fluid passages (8f, 9c) for leading fog cutting fluid fed from the front end part of the spindle to the closed space (12) are formed in a holder body (7) on a rotating center (R), and exhaust passages (8k, 8m, 8e) are formed for opening a part of the tool receiving surface part (8d) in contact with the closed space (12) to the atmosphere, whereby even when the shaft-like tool (11) is small in diameter and the amount of the fog cutting fluid flowing out to the atmosphere through a passage hole (11a) in the shaft-like tool (11) is small, the liquefied cutting fluid can be prevented from being accumulated in the fog cutting fluid passages (8f, 9c) by maintaining the flow velocity of the fog cutting fluid in the fog cutting fluid passages (8f, 9c) at proper levels.

Owner:HORKOS

Multifunctional computer accessory machining device

InactiveCN112974905AEasy drilling operationGuaranteed operational stabilityMeasurement/indication equipmentsMetal working apparatusBall bearingElectric machinery

The invention provides a multifunctional computer accessory machining device. The multifunctional computer accessory machining device comprises a rack, supporting legs, magnet blocks, impurity collecting boxes, supporting columns, a cross beam, a concentric-square-shaped sliding block, a telescopic push rod, a drilling motor, a drill bit and a deep groove ball bearing; the supporting legs are connected to the four corners of the bottom of the rack through bolts; the magnet blocks are connected to the upper middle portions of the inner sides of the supporting legs through bolts; and the impurity collecting boxes are arranged on the inner sides between the magnet blocks in an attracted manner. According to the multifunctional computer accessory machining device, by means of the arrangement of the stand columns, a fixing base, a clamping rod, a pull ring, a compressed spring and an anti-damage pressing base, various accessories can be better pressed and clamped, and drilling operation is facilitated; after the accessories are in place, the anti-damage pressing base can be used for conducting pressing and clamping operation, the pull ring is held by hand to pull the clamping rod, the anti-damage pressing base is lifted, and the accessories can be taken and placed; and the pull ring is loosened, due to the fact that the compressed spring releases energy, the anti-damage pressing base can rebound, the accessories are pressed, then drilling operation can be conducted, and operation stability is guaranteed.

Owner:青岛自主可控工业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com