Angle sensor for adjusting arm

A technology of angle sensor and adjusting arm, which is applied in the field of angle sensor and angle sensor of adjusting arm, which can solve the problems of small rotation angle of camshaft and low detection accuracy of friction pad wear, so as to improve detection accuracy and ensure rotation stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

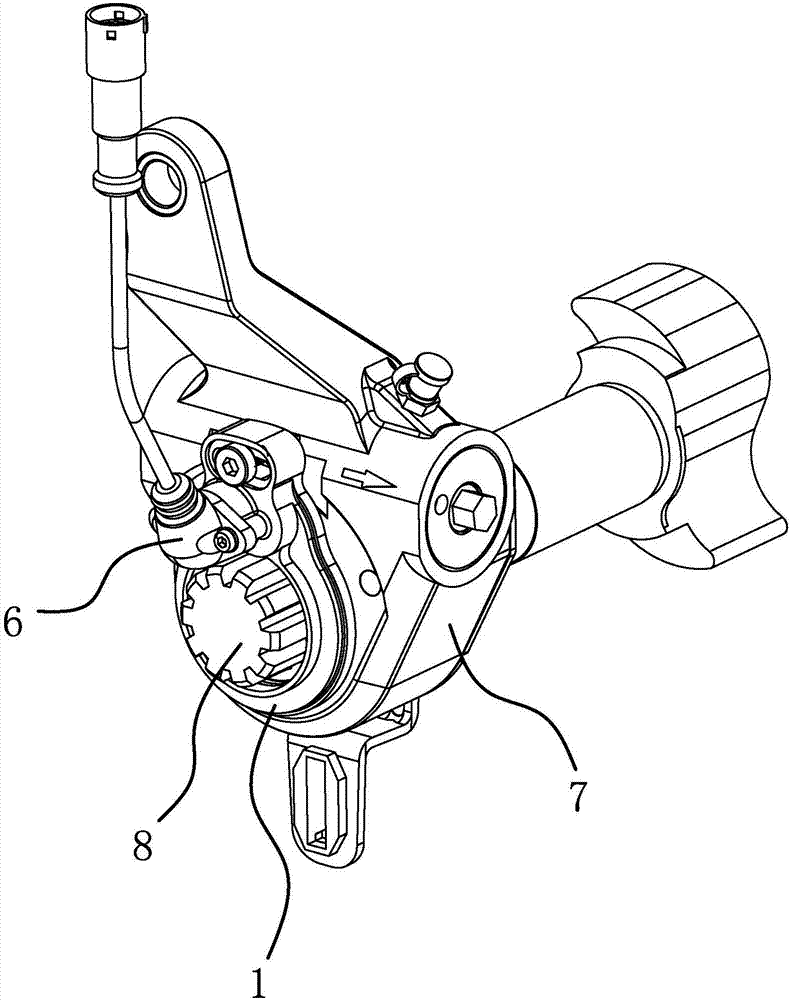

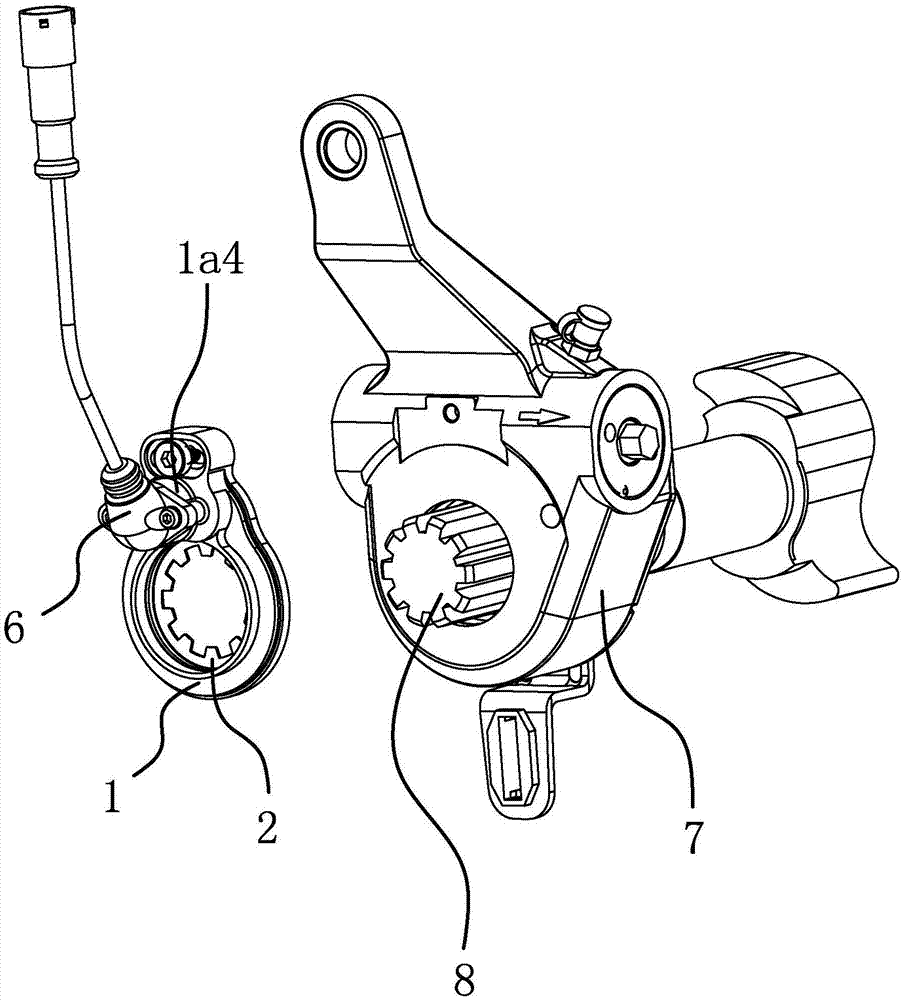

[0051] Such as figure 1 and figure 2 As shown, an angle sensor for adjusting the arm, the adjusting arm includes a housing 7, a worm wheel and a camshaft 8, the worm gear is arranged in the housing 7 and can rotate relative to the housing 7, and one end of the camshaft 8 is inserted into the housing 7, the worm gear is sleeved on the camshaft 8 and fits with the camshaft 8 through a spline. The specific structure of the adjustment arm in this embodiment can refer to a kind of automobile brake gap with the application number 201611140721.8 proposed by the applicant. Automatically adjust the arm.

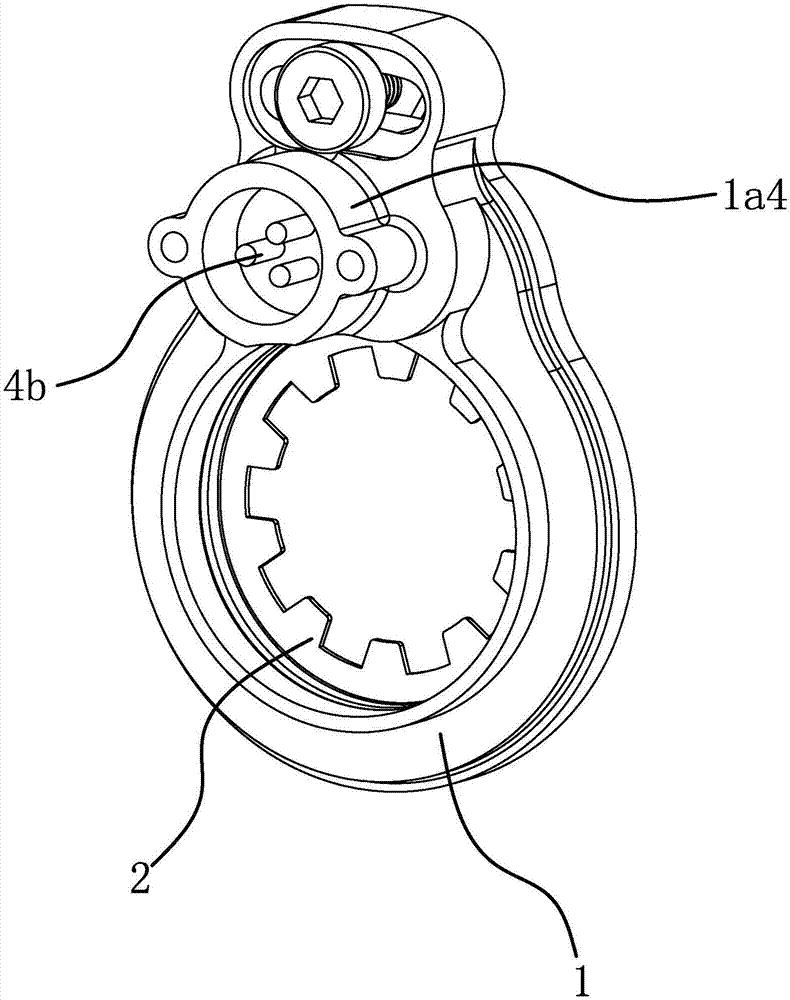

[0052] Such as image 3 , Figure 4 and Figure 5 As shown, the angle sensor includes an installation box 1 connected to one side of the housing 7 and a turntable 2 that is arranged in the installation box 1 and can rotate. 2 The turntable 2 is driven to rotate through the spline fit, and the turntable 2 is axially limited and radially limited in the installation box 1 . The an...

Embodiment 2

[0061] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, a transmission belt is set between the outer peripheral side of the limiting part 3b2 and the outer peripheral side of the turntable 2, and the turntable 2 is driven by the transmission belt. The rotating wheel 3 rotates, thereby utilizing the rotation of the rotating wheel 3 and combining the outer diameters of the rotating wheel 3 and the rotating disk 2 to amplify the rotation angle of the rotating disk 2, so as to improve the detection accuracy of the angle sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com