Clamp for repairing shield tunneling machine sealing runway through laser cladding and using method

A laser cladding and shield machine technology, applied in laser welding equipment, manufacturing tools, coatings, etc., can solve the problem that the controllable rotation of parts cannot be achieved, it is not suitable for stable clamping of large parts, and the range of workpiece size changes is limited, etc. problem, to ensure that the shape and size of the spot remain unchanged, improve energy utilization, and improve repair efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

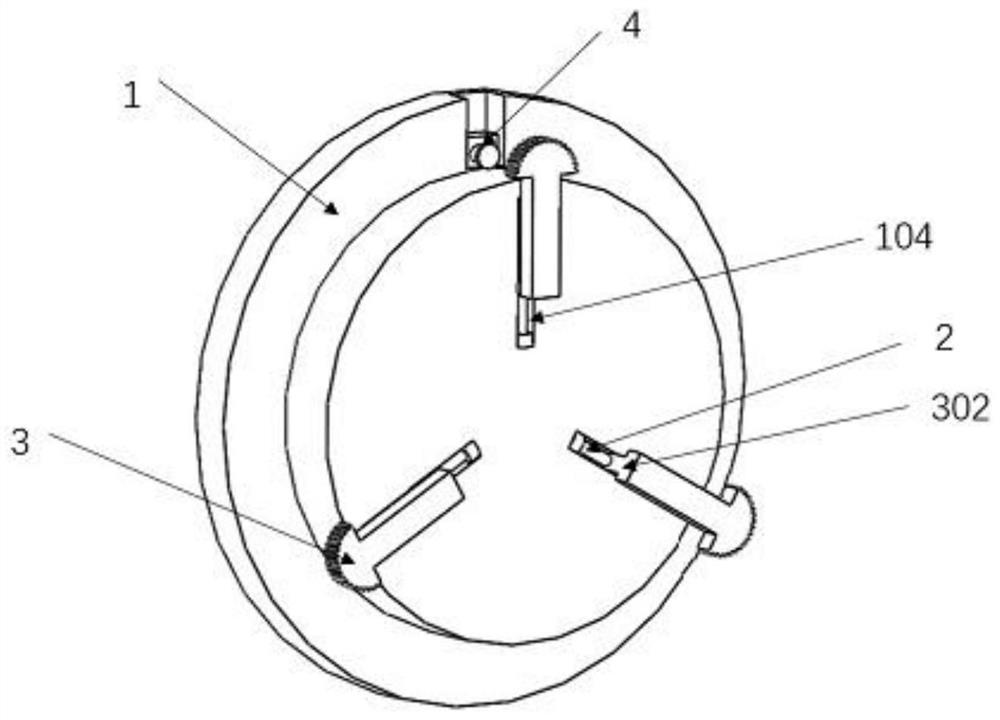

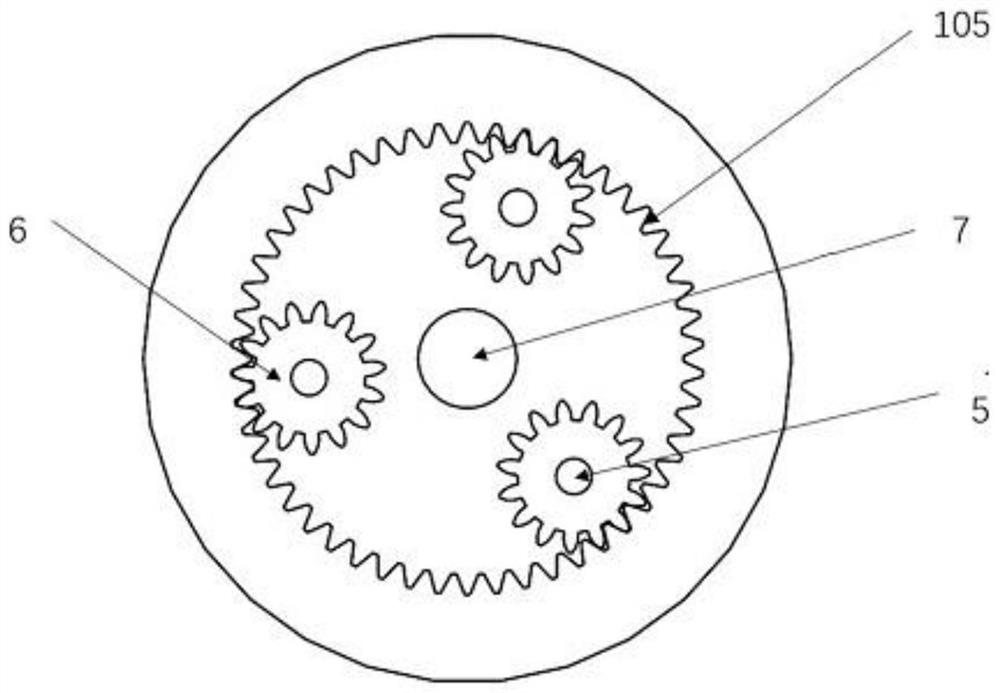

[0027] figure 1 Shown is a schematic diagram of the overall structure of the present invention.

[0028] figure 2 Shown is a schematic rear view of the overall structure of the present invention.

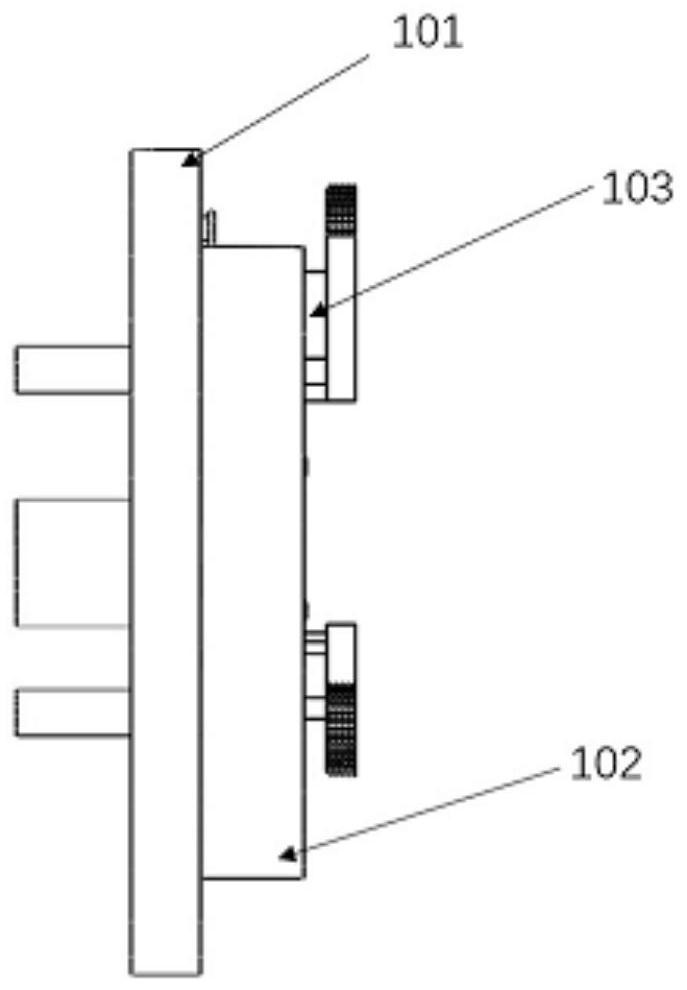

[0029] image 3 Shown is a schematic side view of the overall structure of the present invention.

[0030] The present invention provides a jig for laser cladding and repairing the sealed runway of a shield machine, which includes a chassis 1, a hydraulic cylinder 2, a pusher 3 and an adjustment mechanism 4, and the front of the chassis 1 near the outer circle is provided with three 120 ° flange guide rails 103, each flange guide rail 103 top is provided with a chute 104 near the center of the circle; the bottom of the chute 104 is provided with a hydraulic cylinder 2 and a push piece 3; the push piece 3 includes a movement bar 302 and The push pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com