Speed bump power generation device based on hydraulic system

A hydraulic system and power generation device technology, applied to machines/engines, mechanisms that generate mechanical power, roads, etc., can solve problems such as low power generation efficiency, complex and heavy power generation systems, etc., and achieve simple structure, convenient design and manufacture, and energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

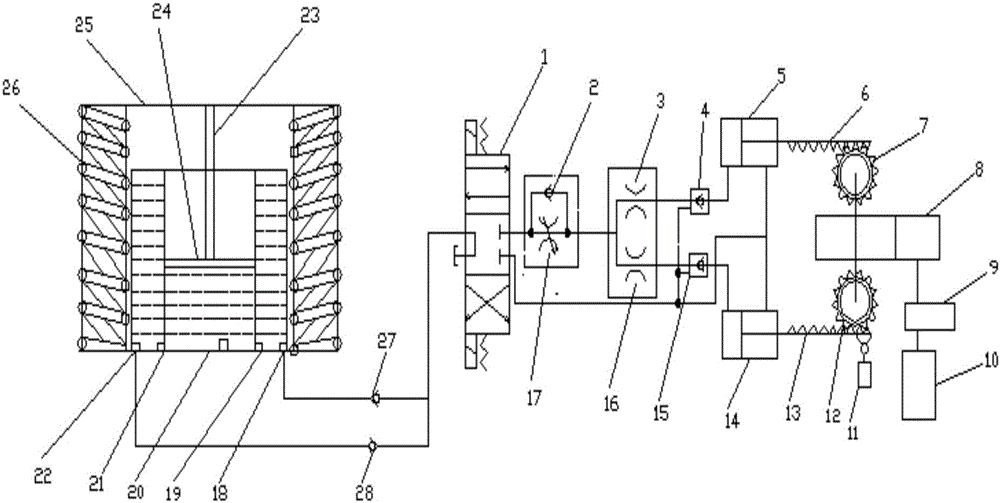

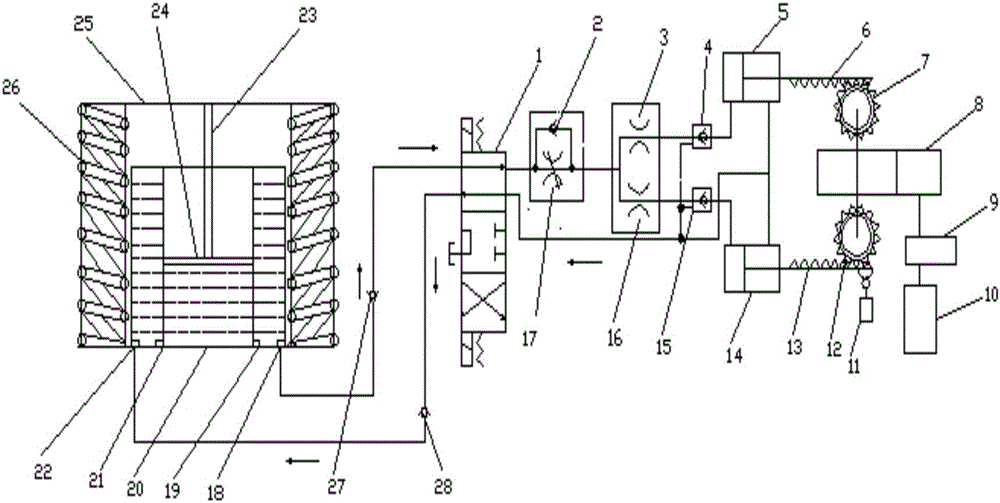

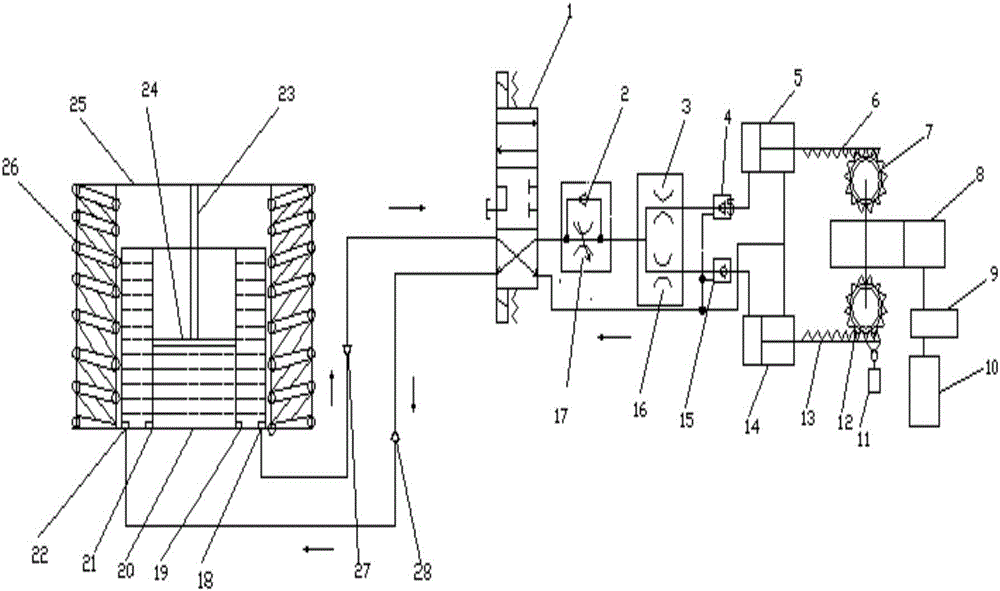

[0026] see figure 1 As shown, a kind of deceleration belt power generation device based on hydraulic system of the present invention comprises: three-position four-way solenoid valve 1; one-way throttle valve 2; diverter valve 3; hydraulic control one-way valve 4; first hydraulic cylinder 5; The first rack ejector 6; the first ratchet 7; the speed increaser 8; the counterweight wheel 9; the generator 10; the travel switch 11; the second ratchet 12; the second rack ejector 13; the second hydraulic cylinder 14; Hydraulic control check valve 15; diverter valve 16; throttle valve 17; external oil outlet 18; first built-in oil port 19; lower pressure bearing plate 20; second built-in oil port 21; external oil inlet 22; Cylinder push rod 23; piston 24; upper pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com