Patents

Literature

143results about How to "Achieve the purpose of removing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

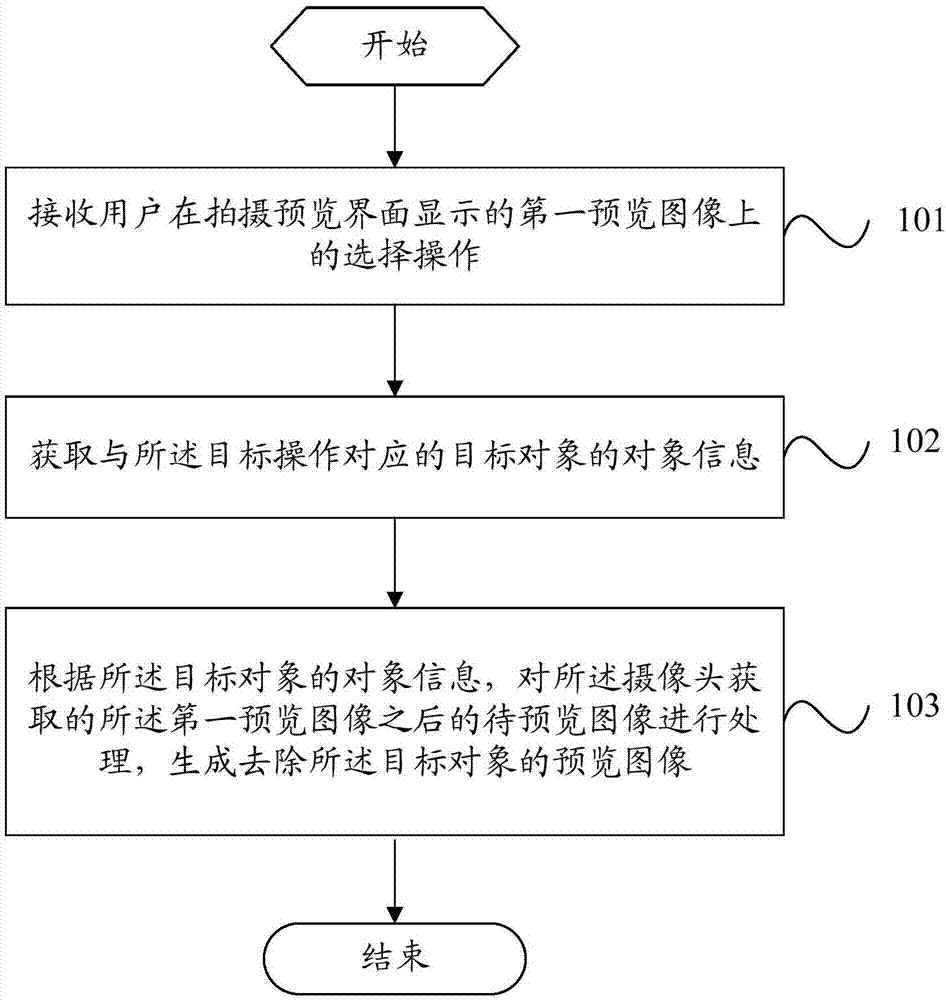

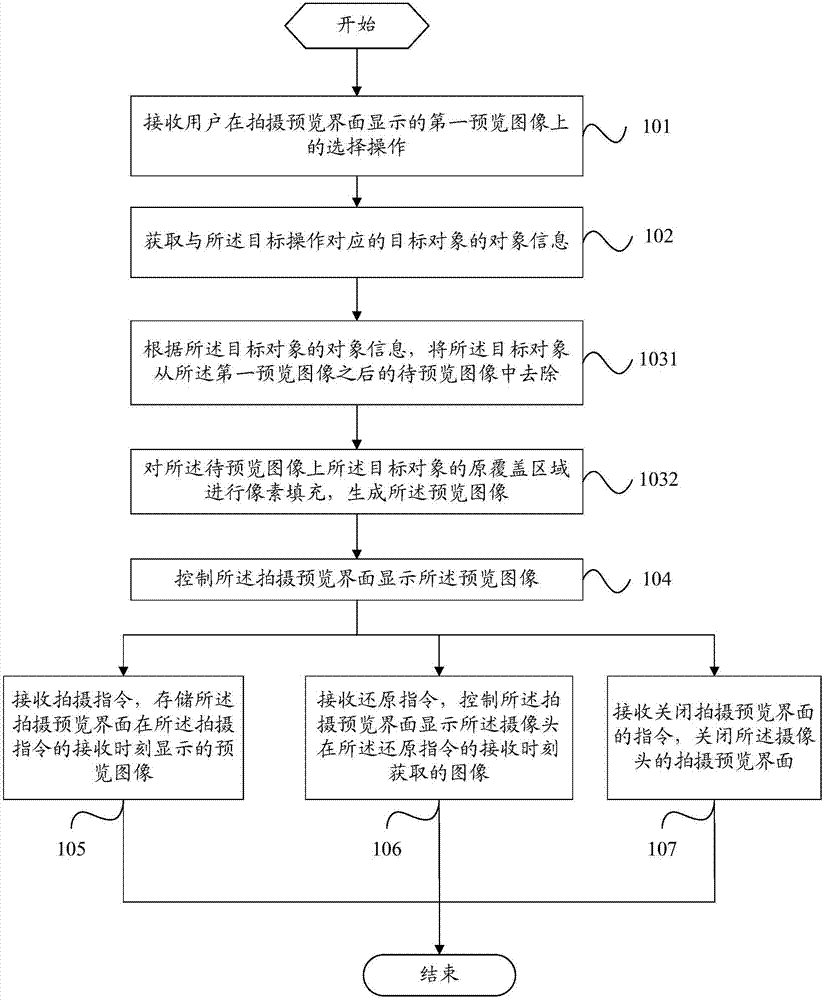

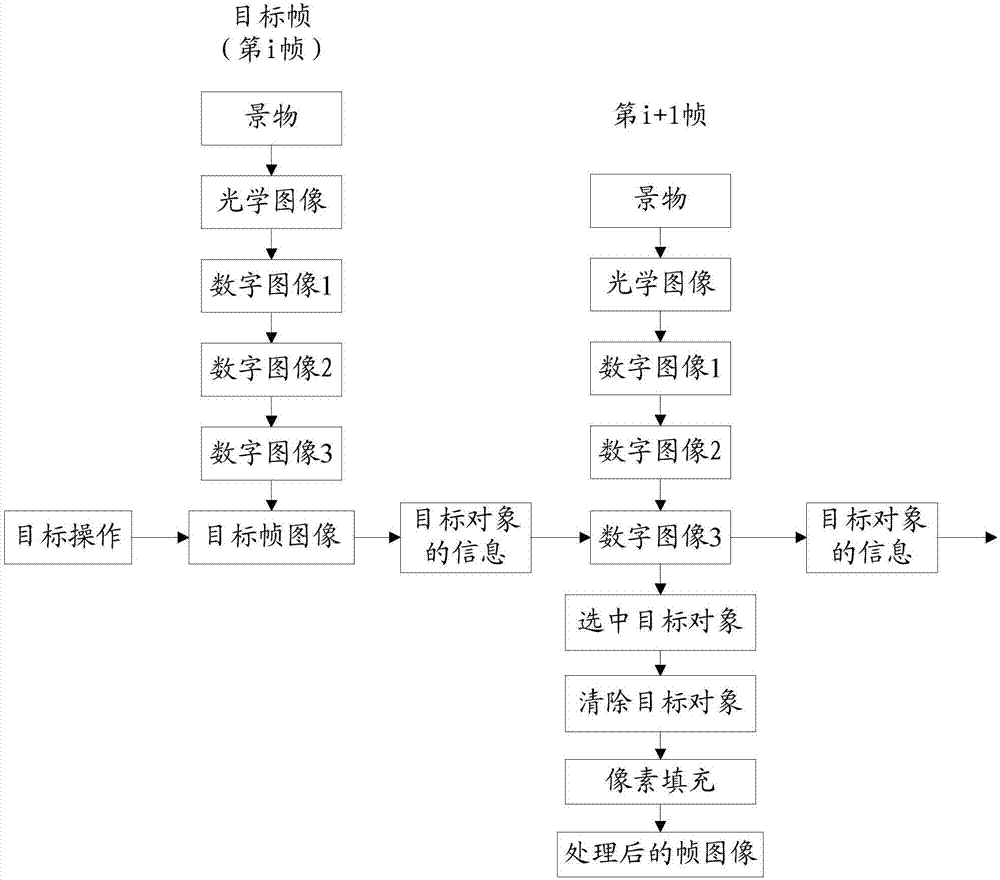

Image processing method and mobile terminal

InactiveCN106937055AIntegrity guaranteedAchieve the purpose of removingTelevision system detailsColor television detailsImaging processingComputer terminal

The invention provides an image processing method and a mobile terminal. The method comprises the following steps: receiving a selecting operation on a first preview image displayed by a user on a photographing preview interface; acquiring the object information of a target object corresponding to the selecting operation; and processing images to be previewed after the first preview image acquired by a camera according to the object information of the target object, and generating the preview image of which the target object is removed. According to the embodiment of the invention, the purpose of removing shelters can be achieved, and the integrity and harmony feeling of the subsequent preview images can also be guaranteed.

Owner:VIVO MOBILE COMM CO LTD +1

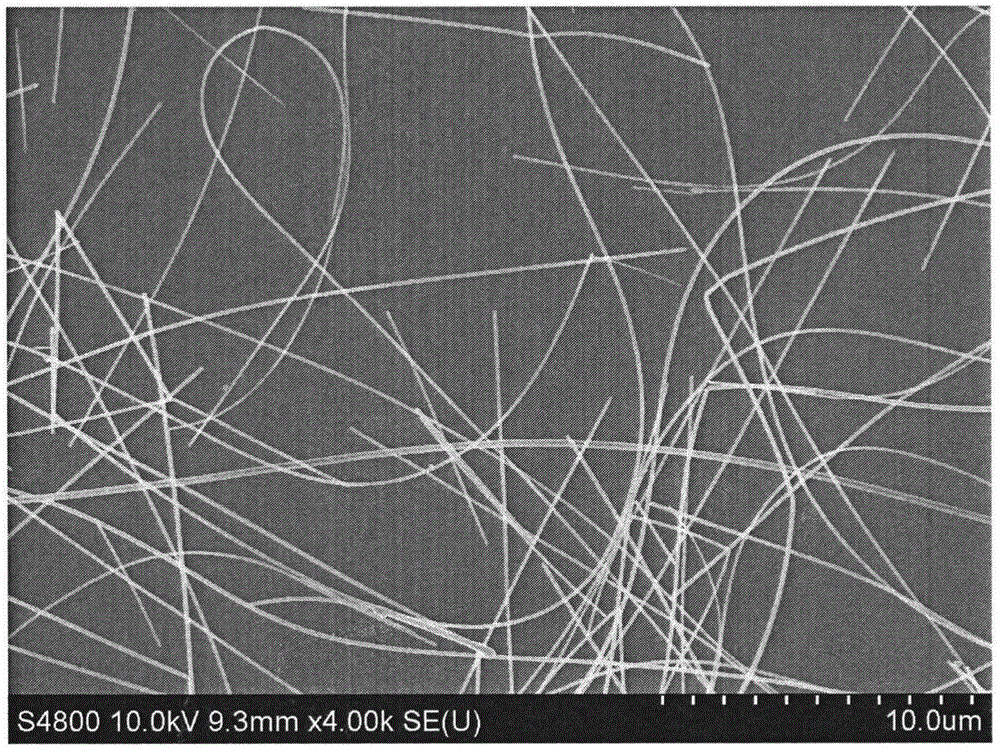

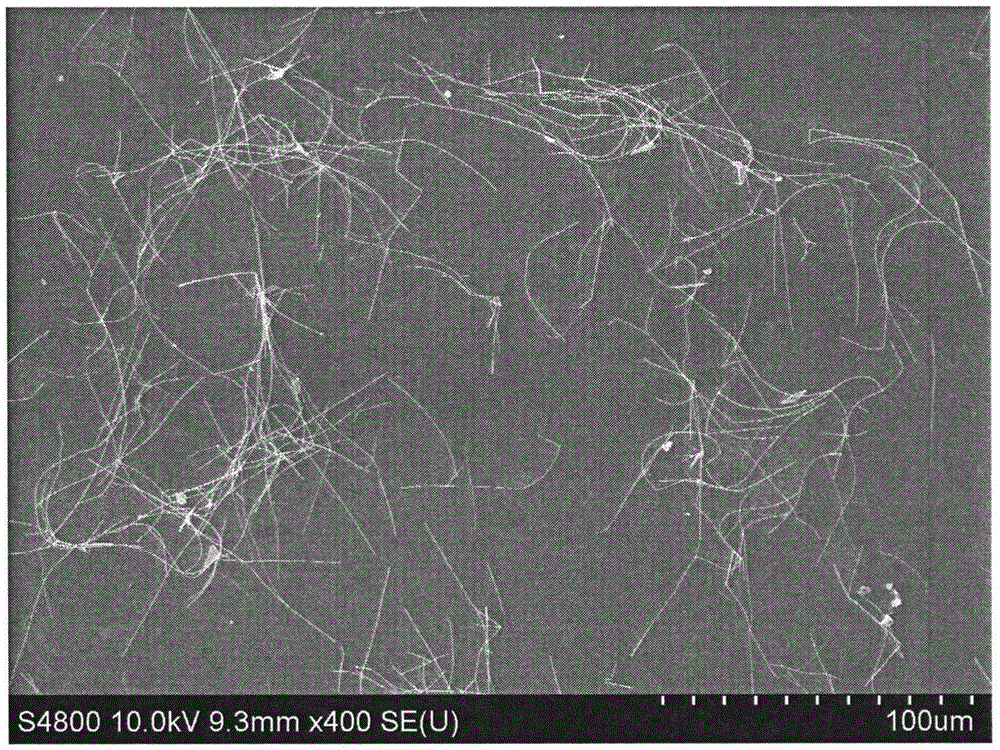

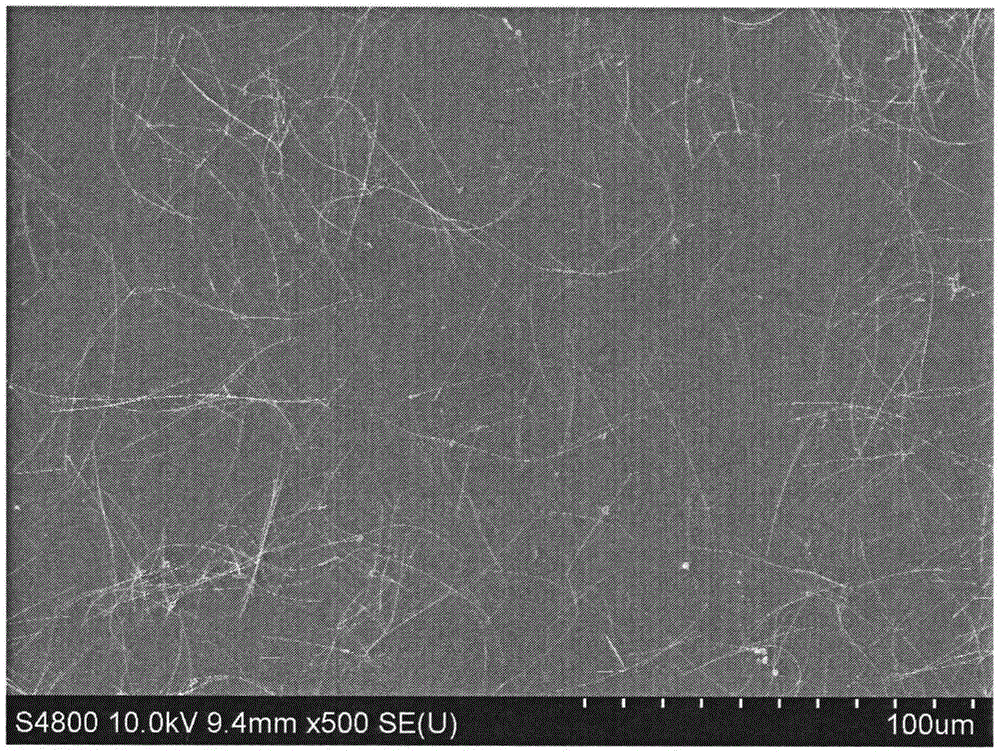

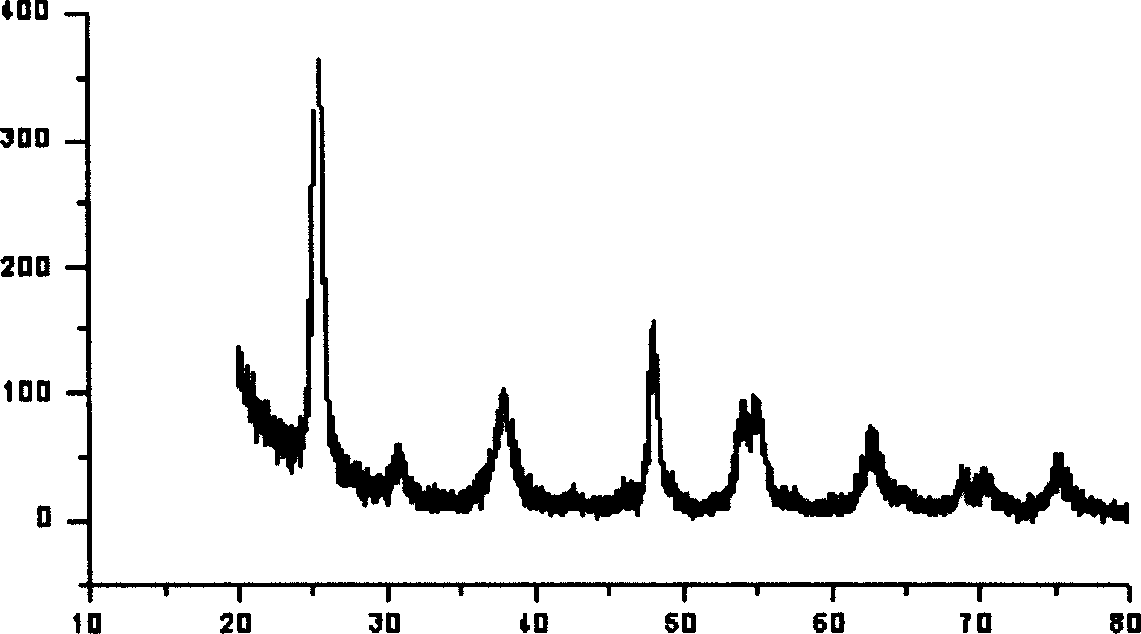

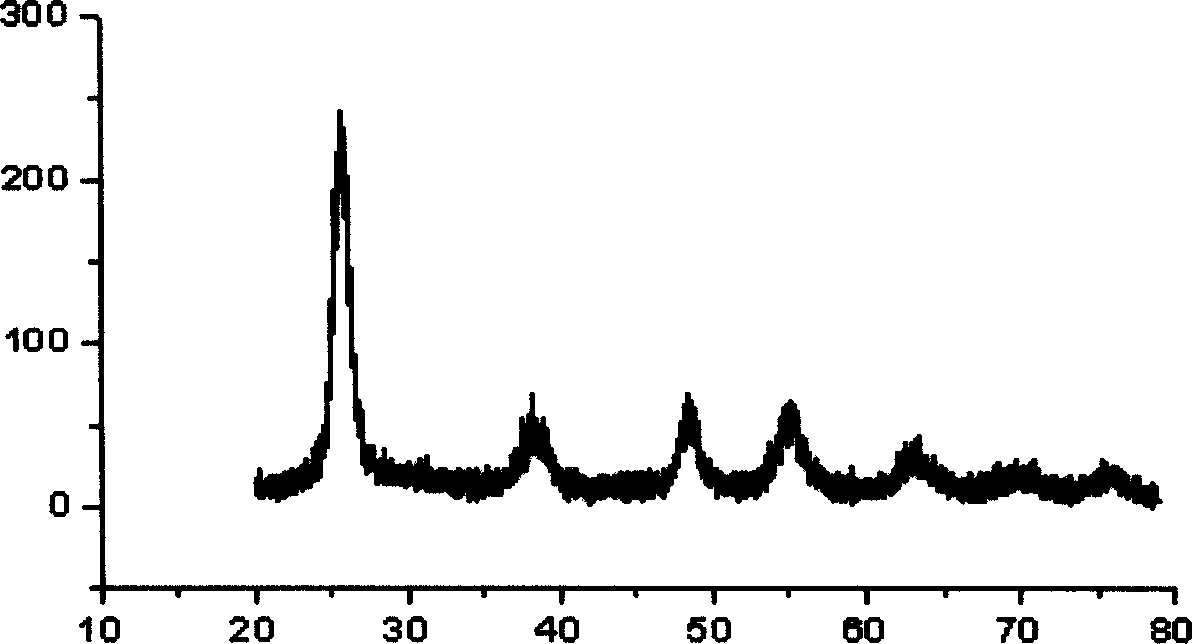

Method for preparing silver nanowires

InactiveCN105537622AEasy to operateAvoid the effects of reactionsNanotechnologyPolymerPhotochemistry

The invention discloses a method for preparing silver nanowires. Under protection of inert gas, a polymer polyhydric alcohol solution and a silver salt and halide polyhydric alcohol solution are sequentially added into a premixing container and are stirred to be completely dissolved, and mixed liquor is transferred to a reaction device which is preheated to 100-180 DEG C to react for 2-5 h; acetone with the volume being 5-9 times that of prepared silver nanowire mother liquor is added into the prepared silver nanowire mother liquor, natural settling is conducted for 10-30 min after acute vibration, supernatant is moved away, sediment is reserved, and the process is repeated 2-3 times; ethyl alcohol with the volume being 5-9 times that of the mother liquor is added into the sediment, centrifugal separation is carried out, supernatant is moved away, sediment is reserved, and the process is repeated 2-3 times; and obtained silver nanowires are stored in the ethyl alcohol in a scattered mode. The preparation method is one-pot, operation is simple, and stability and repeatability are good; stirring is not needed in the reaction process during preparation, and silver wire particles are few; the material adding speed does not need to be strictly controlled in the preparing process, and large-scale production is facilitated; separation and purification are carried out through natural settling of the acetone and then centrifugal sedimentation of the ethyl alcohol, so that the separation efficiency is higher.

Owner:嘉兴禾浦光电科技有限公司

SiO2/TiO2 composite nanometer photocatalysis membrane for treating indoor light pollution air and preparing method thereof

InactiveCN1583248AIncrease surface areaIncrease contactPhysical/chemical process catalystsDispersed particle separationGlass fiberNano sio2

A composite nano-SiO2 / TiO2 membrane as photocatalyst for treating the slightly polluted indoor air is prepared by sol-gel method, which includes such steps as preparing sol, immersing the treated glass fibres in it, pulling up, drying and calcining.

Owner:鞍山市环境保护研究所 +1

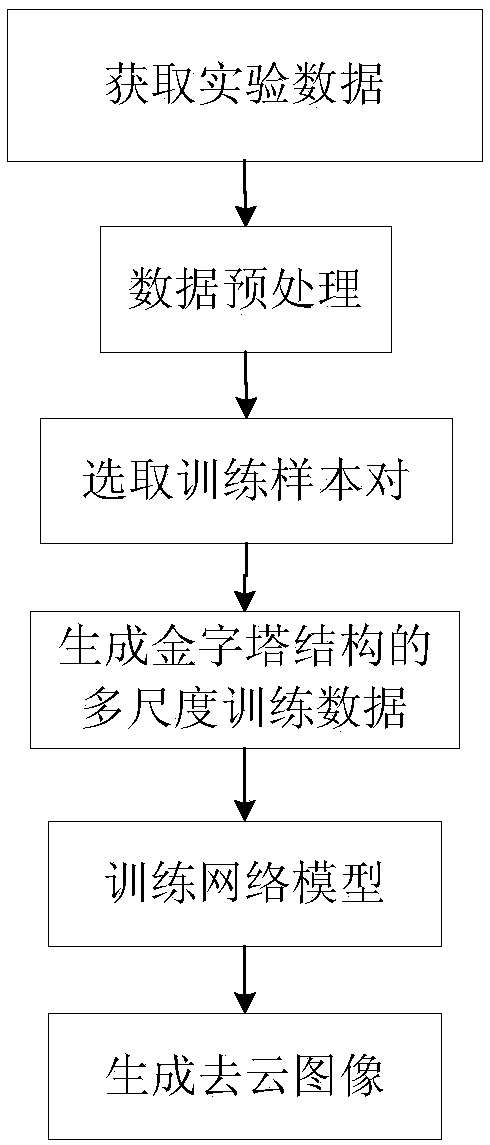

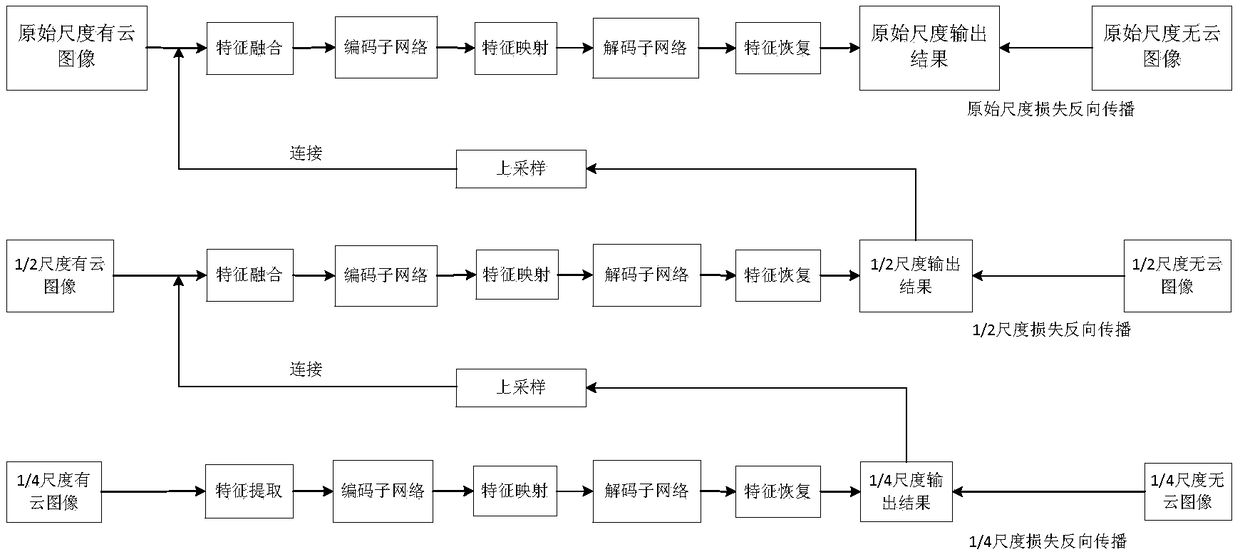

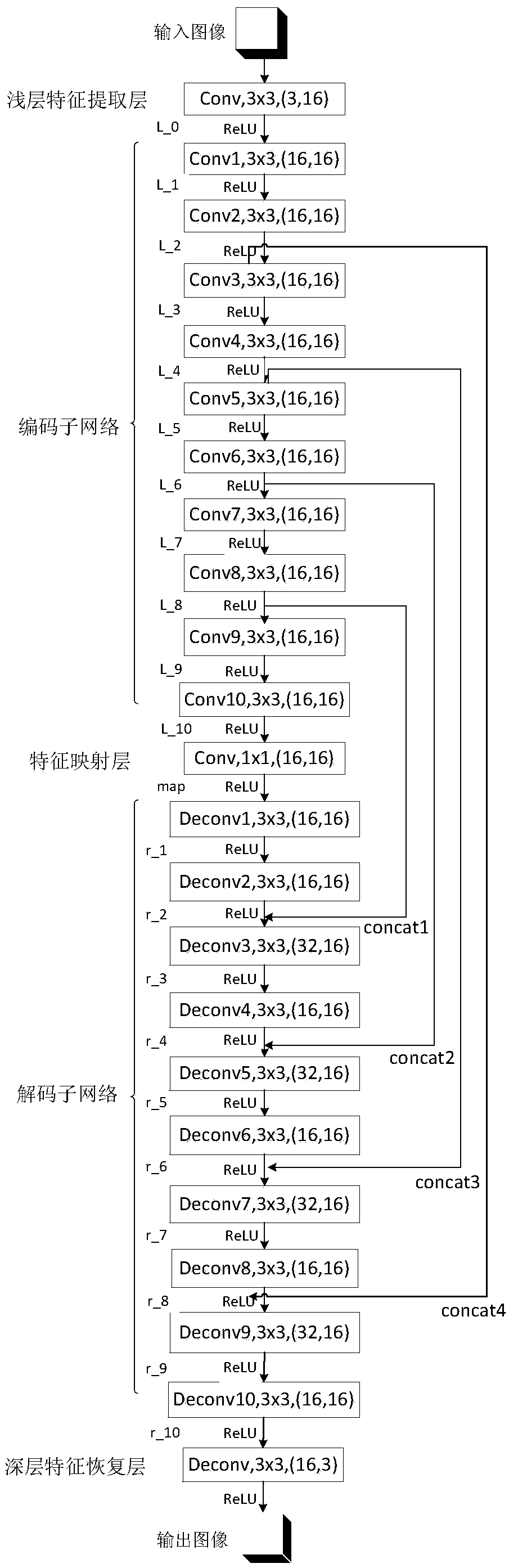

Remote sensing image thin cloud removal method based on multi-scale collaborative learning convolutional neural network

ActiveCN108921799AGood removal effectAchieve the purpose of removingImage enhancementImage analysisScale transformationNetwork structure

The invention relates to a remote sensing image thin cloud removal method based on a multi-scale collaborative learning convolutional neural network. According to the method, training data is input into network structures with different scales after being subjected to scale transformation; features under different scales are extracted level by level from coarse granularity to fine granularity sequentially for fusion, so that coarse-to-fine multi-scale learning is realized; and last, a mapping relation between cloudy data and cloudless data is obtained, cloud components are effectively removed,image details are restored, and the purpose of thin cloud removal is achieved. An experiment result indicates that compared with a traditional thin cloud removal method, the method can eliminate a manual trace brought by the traditional method, information of a cloudy region in an image can be accurately restored, the fidelity of a cloudless region can be maintained, the thin cloud removal effectis better, and thin cloud removal precision is higher.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

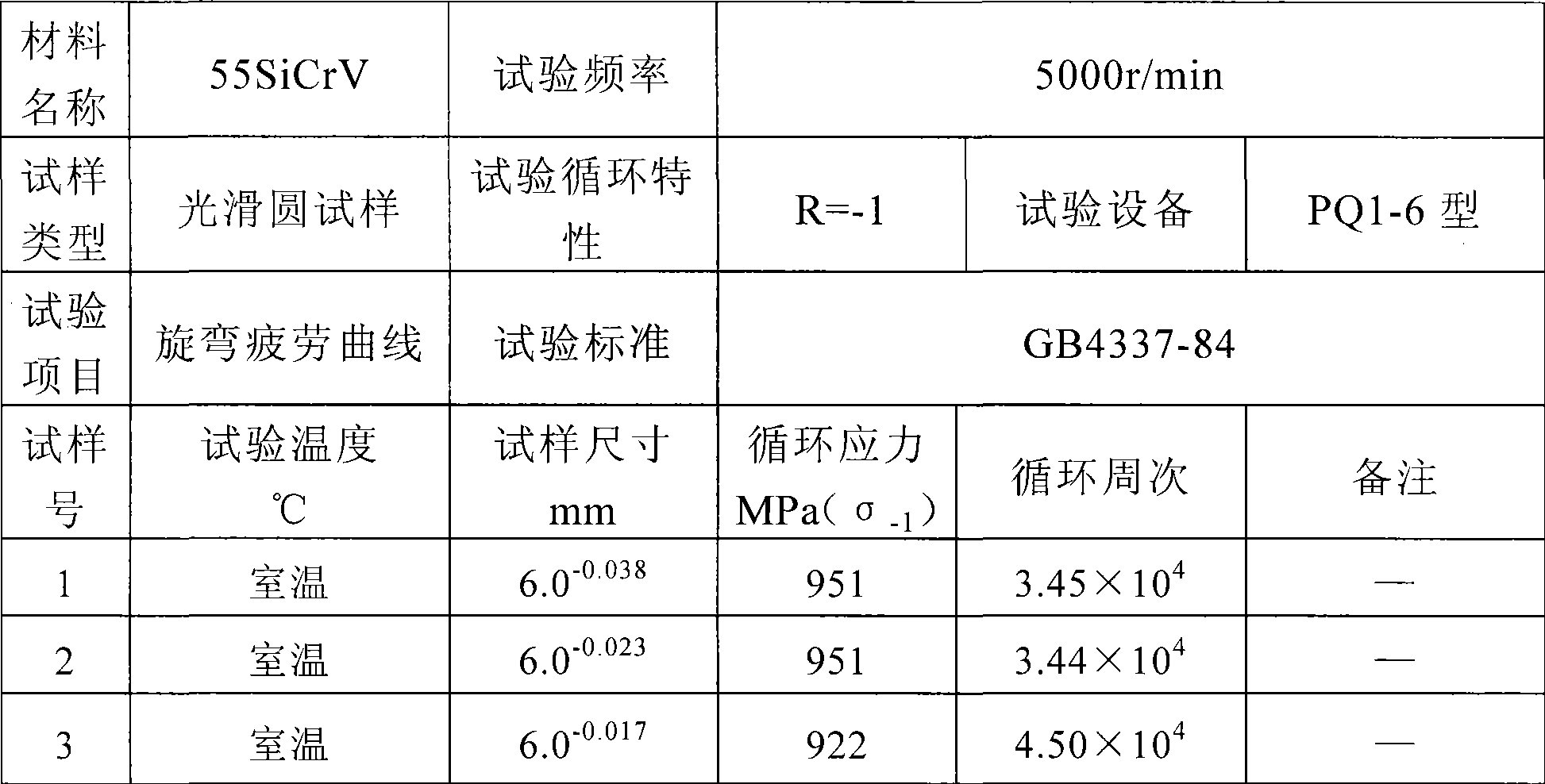

Method for controlling non-metallic impurities in structural alloy steel

ActiveCN101519710AAvoid it happening againFully float to removeProcess efficiency improvementFatigue loadingNon-metallic inclusions

A method for controlling non-metallic impurities in structural alloy steel includes the following steps of: step one: pre-smelting molten steel: (1) batching; (2) slagging in advance in the melting stage; (3) tapping, tapping conditions: (P) is less than or equal to 0.005 percent; (S) is less than or equal to 0.005 percent; and tapping temperature is 1640 DEG C to 1660 DEG C; step two: external refining: at the time of one third of the tapping of a primary smelting furnace, fluxing medium is added into ladles; the heating station of an external refining furnace adopts Si-Fe powder and SiC powder to conduct diffusive deoxidation; oxygen is determined before the ladles enter vacuum degassing, and deoxidizing agent is added; step three: vacuum refining: the vacuum process is kept for longer than or equal to 20min under less than or equal to 66.7Pa; the post-vacuum soft argon blowing time is longer than or equal to 15min; the soft argon blowing intensity is less than or equal to 0.10Mpa; and the post-vacuum crane ladle temperature is 1530 DEG C to 1540 DEG C; and step four: continuous casting. The method improves the purity of steel by improving the composition and size of the non-metallic impurities in steel so as to further meet the requirement on pure steel under high dynamic stress and high cycle fatigue loading.

Owner:宝武特种冶金有限公司

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

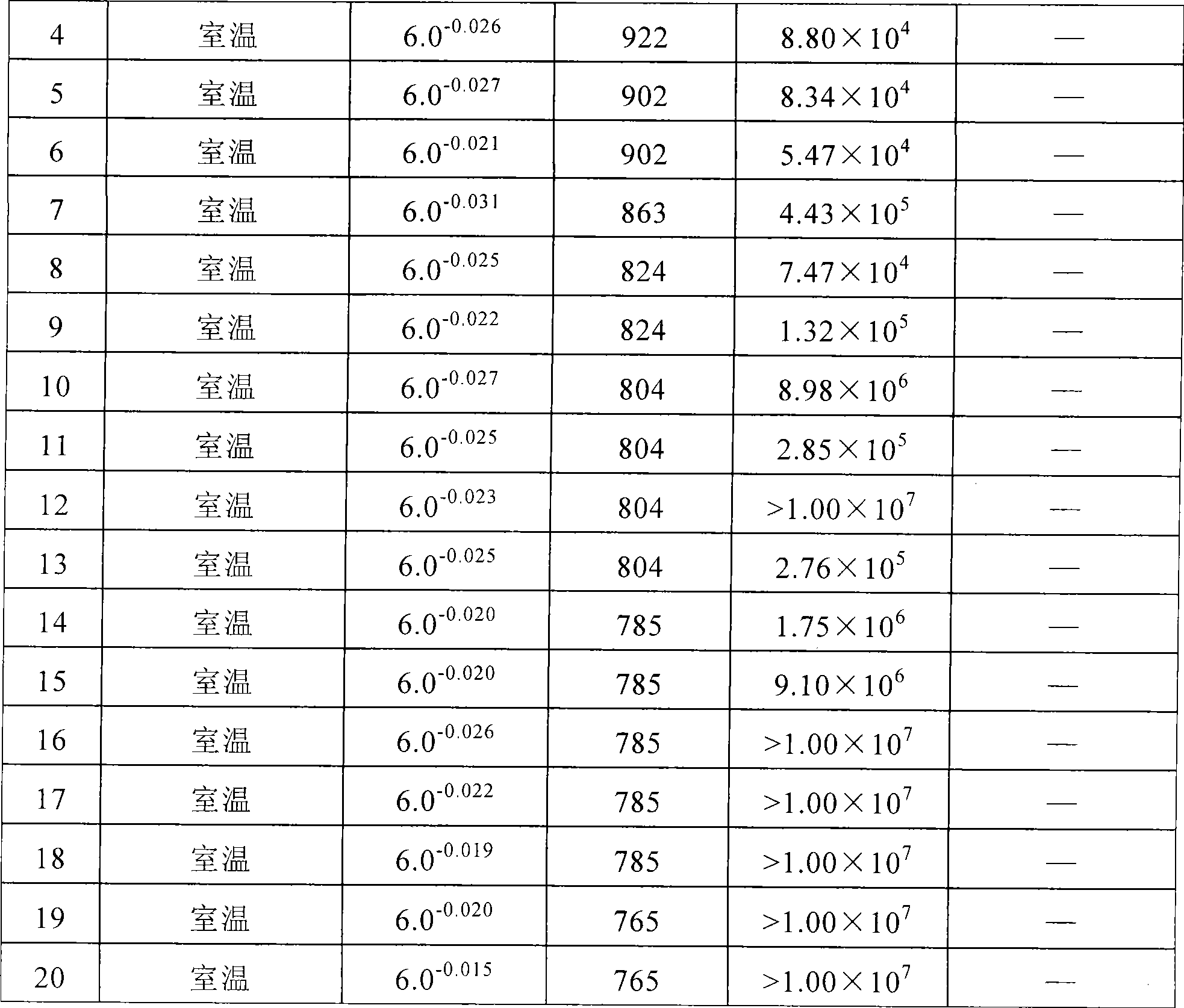

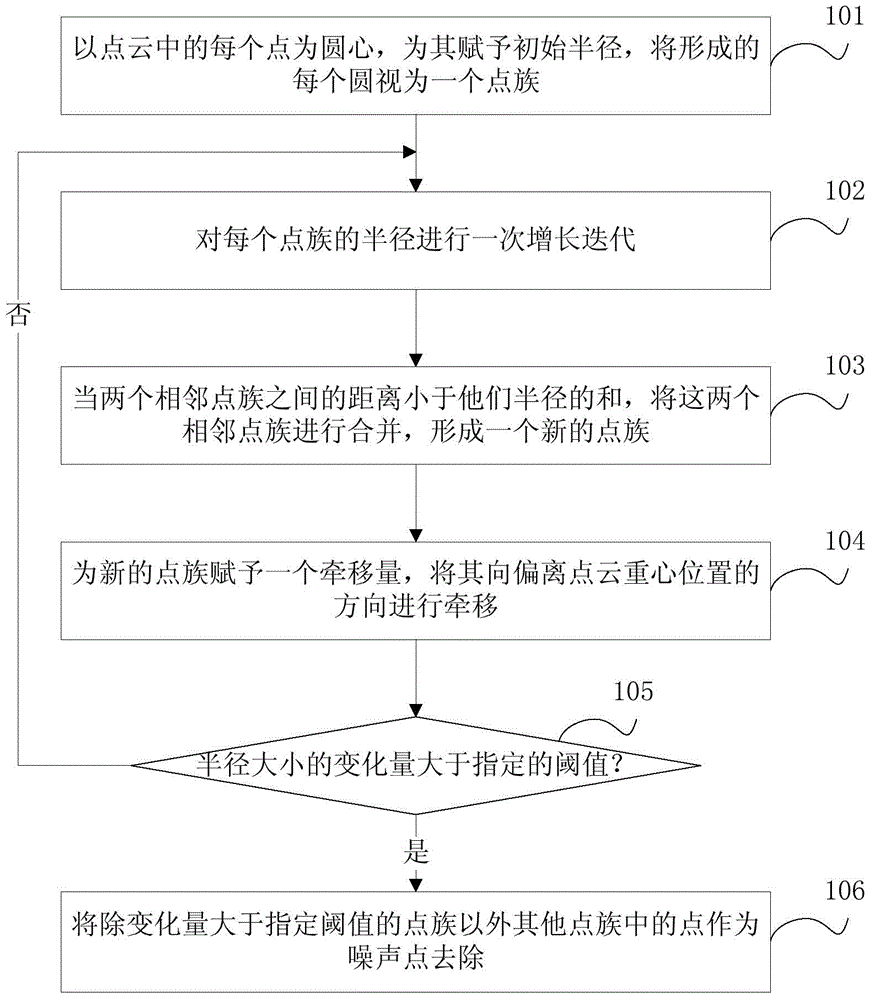

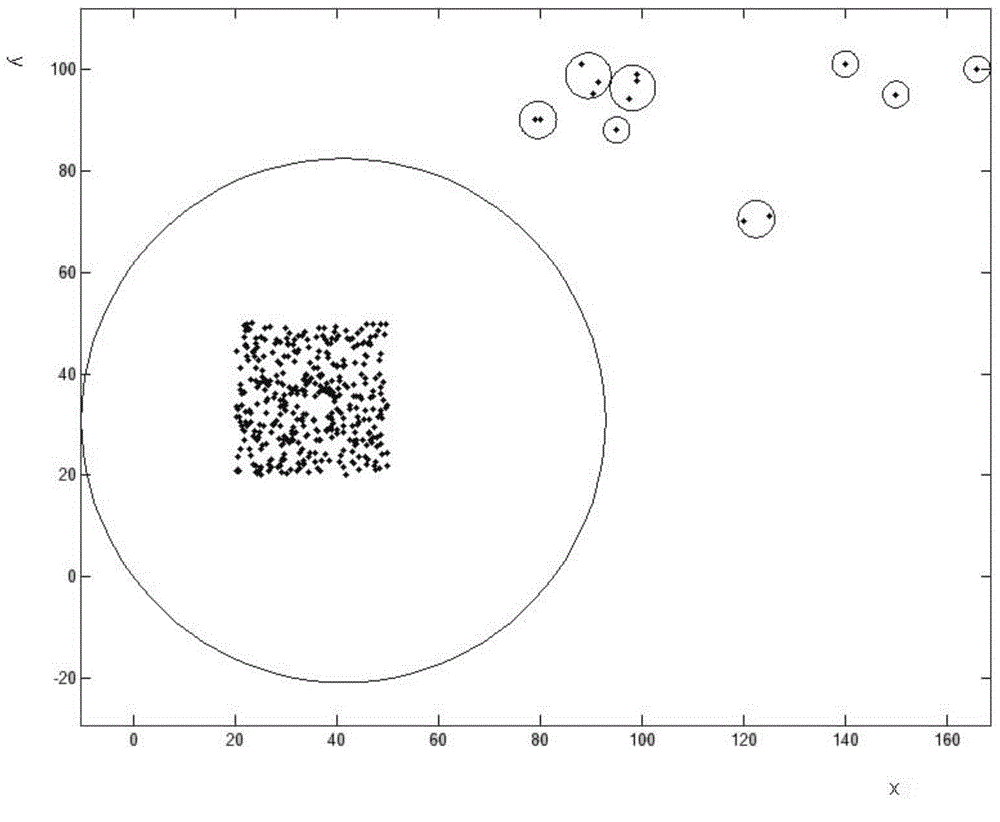

Removal method for point cloud noise points

The invention discloses a removal method for point cloud noise points. The method is used for removing the noise point in a point cloud. The removal method comprises the steps that the initial radius is given to the point cloud with each point in the point cloud as the circle center or the ball center, and each formed circle or ball is regarded as a point group; the radius of each point group is increased and iterated for one time; when the distance between two adjacent point groups is smaller than the sum of the radiuses of the two adjacent point groups, the adjacent point groups are merged and form a new point group; pulling amount is given to the new point group, and the point group is pulled towards the direction deviating from the gravity center position of the point cloud; when all the current point groups are sorted according to the radiuses of the point groups, the change amount of the radius corresponding to each point group is calculated, if the change amount is larger than the specified threshold value, iteration is finished, and otherwise, returning to iteration of next time is carried out; finally, the points in the other point groups except for the point groups with the change amount larger than the specified threshold value are regarded as the noise points and removed. The removal method effectively improves the removal efficiency of the point cloud noise points.

Owner:ZHEJIANG UNIV OF TECH

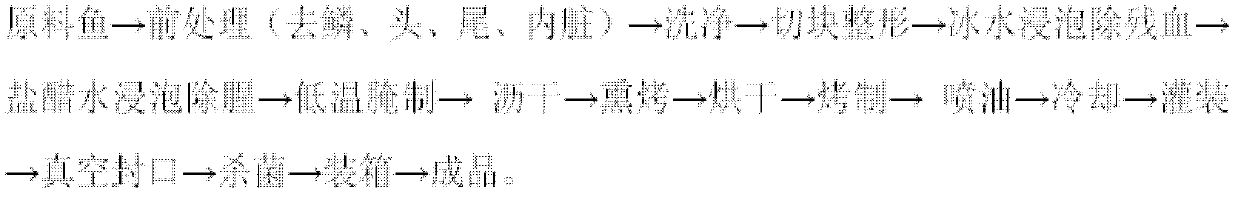

Method for preparing non-fried instant freshwater fish

The invention provides a method for preparing a non-fried instant freshwater fish, comprising the concrete steps of preparing a raw material fish, carrying out pretreatment (scale, head, tail and innards removing), washing clearly, cutting and shaping, soaking in ice water, soaking in water containing salt and vinegar, curing at a low temperature, draining, performing roast smoking, stoving, baking, spouting oil, filling, carrying out vacuum seal and microwave sterilization, boxing up to obtain the finished product. The fish prepared by adopting the method for preparing the non-fried instant freshwater fish has the advantages of no fishy smell, good taste, no poisonous or harmful substance of fried foods, little oil content and capability of guaranteeing the product quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

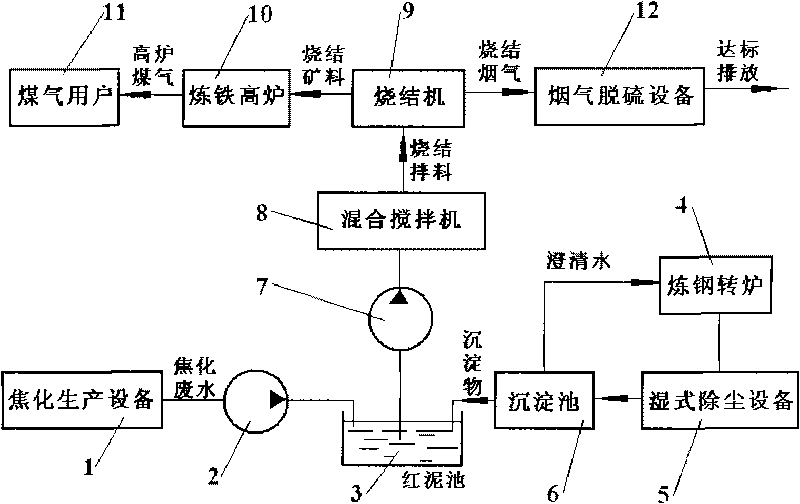

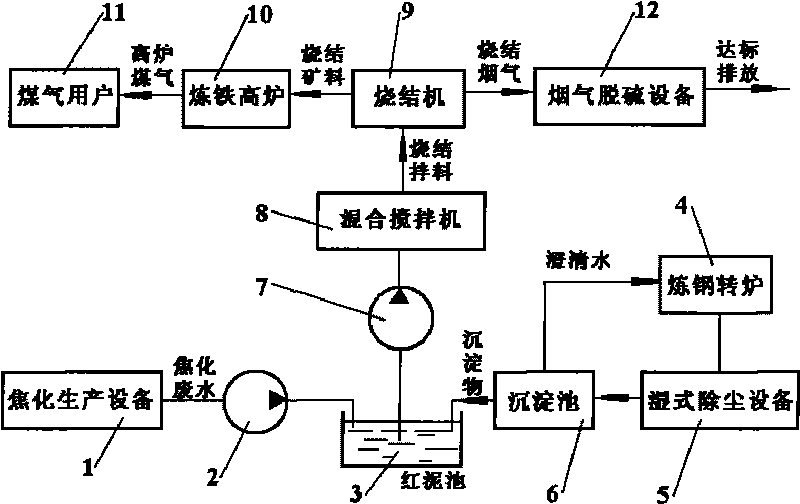

Method for processing and utilizing wastewater and waste material in steel production and processing system thereof

ActiveCN101734776AReduce pollutionReduce fresh water consumptionSludge treatmentWaste water treatment from metallurgical processSlurry pumpToxic material

The invention discloses a method for processing and utilizing wastewater and waste materials in steel production, which comprises the following steps: pumping the coked wastewater from a waste liquid pump into a red mud pool; generating waste materials in the shape of red mud by wet dust removal and enabling the red mud shape precipitate of the waste materials to enter the red mud pool after precipitating by a settling tank; adopting a residue slurry pump, pumping the mixture of the red mud shape precipitate in the red mud pool and the coked wastewater into a mixed stirrer and mixing and stirring together with sintering raw materials to form a sintering stirring material; and delivering the sintering stirring material to a sintering machine for sintering to form a sintering mineral aggregate. The invention also discloses a processing system executing the above method. By adopting the technical scheme, toxic substances contained in phenol-cyanogen wastewater generated by the coking process are completely recycled, wastes are comprehensively utilized, the pollution to the environment is reduced, and the aim of final removing is achieved; the use quantity of new water is reduced; and the entire process has very small occupied area, simple and reasonable process and little investment.

Owner:WUHU XINXING DUCTILE IRON PIPES

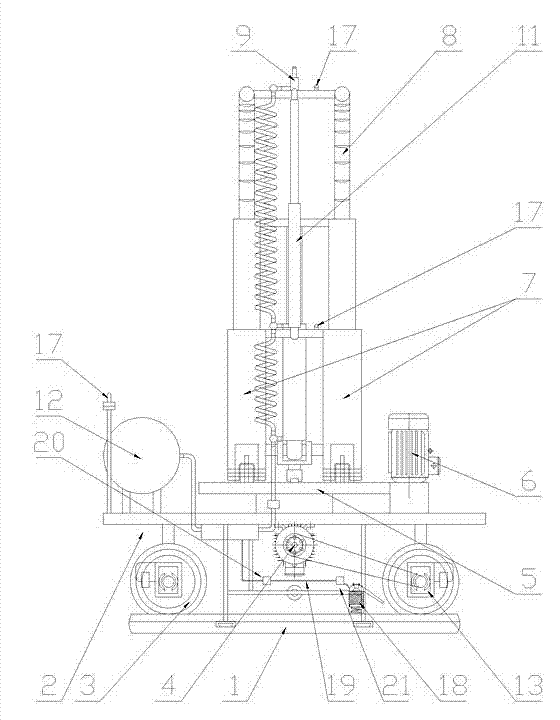

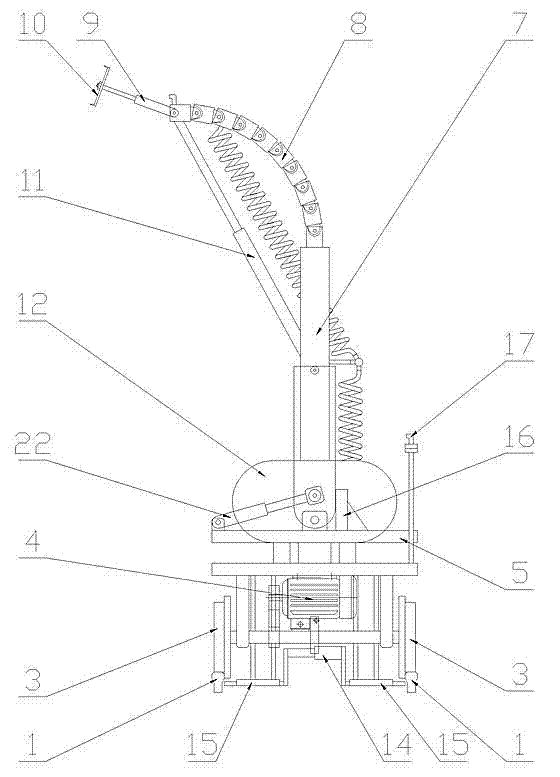

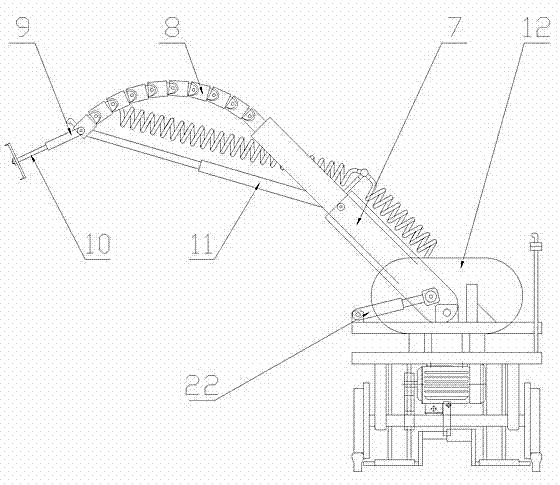

Deicing device for tunnel vault

The invention discloses a deicing device for tunnel vault. The deicing device for the tunnel vault comprises a deicing vehicle and is characterized in that wheels are arranged on the bottom of the deicing vehicle, a walking motor arranged on the deicing vehicle drives the wheels to rotate through a transmission pair, a rotating platform is arranged on the deicing vehicle, outer teeth are arranged on the outer ring of the rotating platform, driving teeth meshed with the outer teeth are arranged on an output end of a rotating motor fixed on the deicing vehicle, a primary cylinder is connected with the rotating platform in a rotating mode, a telescopic swinging arm is sleeved with the top end of the primary cylinder, a working cylinder is arranged on an end socket of the swing arm, a deicing machine is arranged on the front end oh the working cylinder, a secondary cylinder is further arranged between the middle part of the primary cylinder and the end socket of the swinging arm, an air storage tank for supplying air resource to the cylinders is arranged on the deicing vehicle, a swinging cylinder is further hinged with the rotating platform, and the other end of the swinging cylinder is hinged with the lower portion of the primary cylinder. The deicing device for tunnel vault is skilled in design, reasonable in arrangement, and can automatically clean icicle of the tunnel vault.

Owner:DALIAN ZHIHUIDA TECH CO LTD

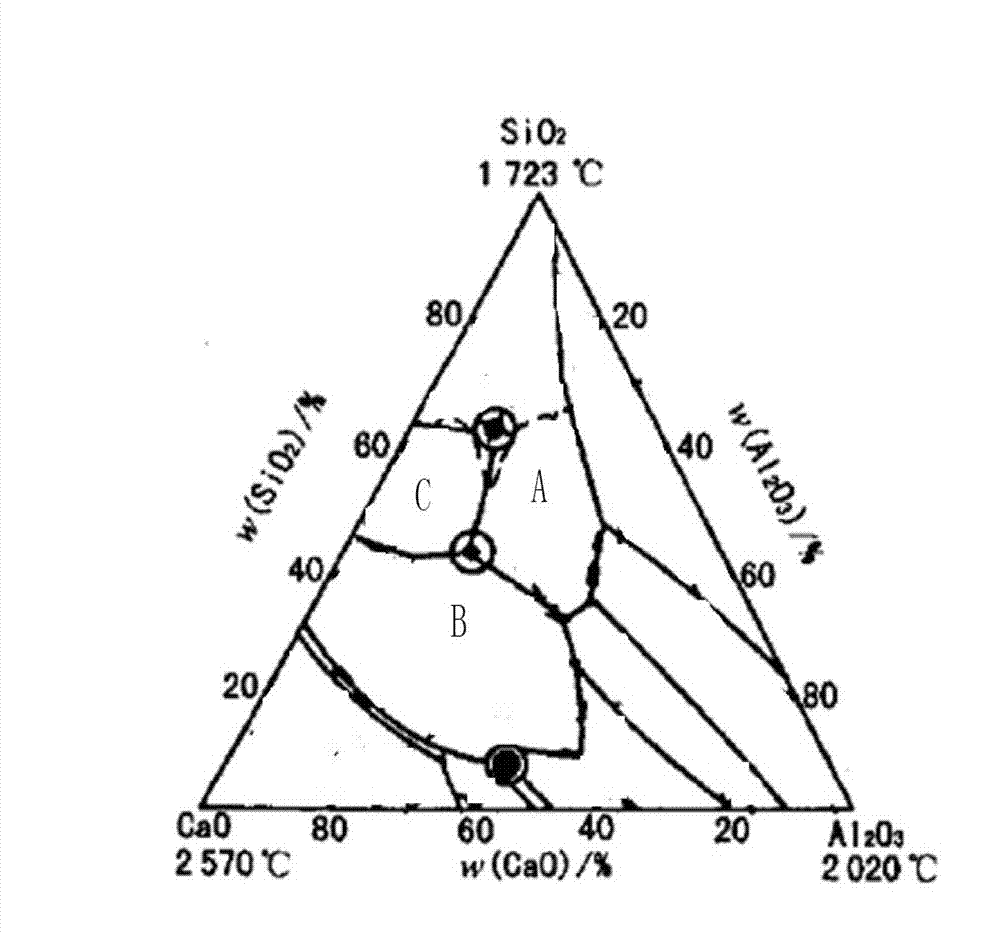

Novel process of steelmaking deoxidization by utilizing precipitator dust of refining furnace

ActiveCN103031409ALow slagging temperatureHigh speedRecycling and recovery technologiesElectric arc furnaceAlloy

The invention provides a novel process of steelmaking deoxidization by utilizing precipitator dust of a refining furnace, comprising the steps of 1, under the circumstance that the blowing process of a converter or an electric furnace is finished, the carbon end-point composition W[C] %=0.1-0.6% and the tapping temperature is 1580-1620 DEG C during the tapping, connecting the bottom to blow argon gas 2-4min before the tapping and carrying out gas stirring at the speed of 150-480L / min; and 2, after the tapping of the liquid steel in the converter or the electric furnace, starting to continuously add tons of steel aluminium blocks or alloy to carry out deoxidization, and when the quantity of the liquid steel is 7-17t in a steel ladle, starting to add the precipitator dust of the refining furnace along with the steel flow of the tapping of the furnace, wherein the adding quantity of the steel aluminium blocks or alloy is confirmed according to carbon content of the liquid steel before the tapping, the tapping time of the furnace is 2-8min, the adding of the precipitator dust of the refining furnace needs to be finished in 3-4min and the adding quantity is 1.2-6kg / ton of steel. According to the invention, the precipitator dust of the refining furnace is adopted as the deoxidizing agent, so that the novel process is suitable for silicon killed steel and silicon-aluminium killed steel.

Owner:XINJIANG BAYI IRON & STEEL

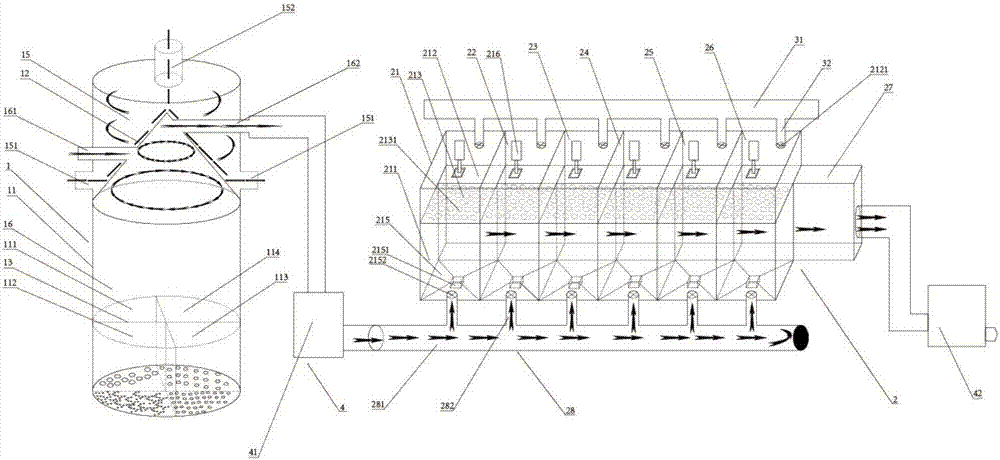

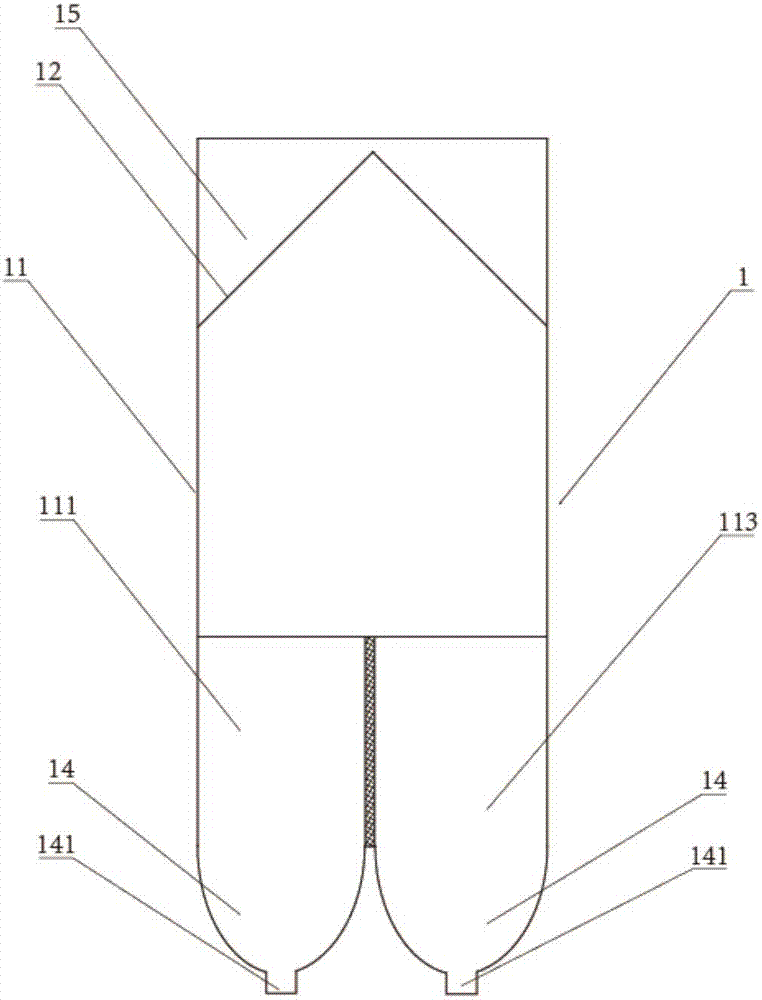

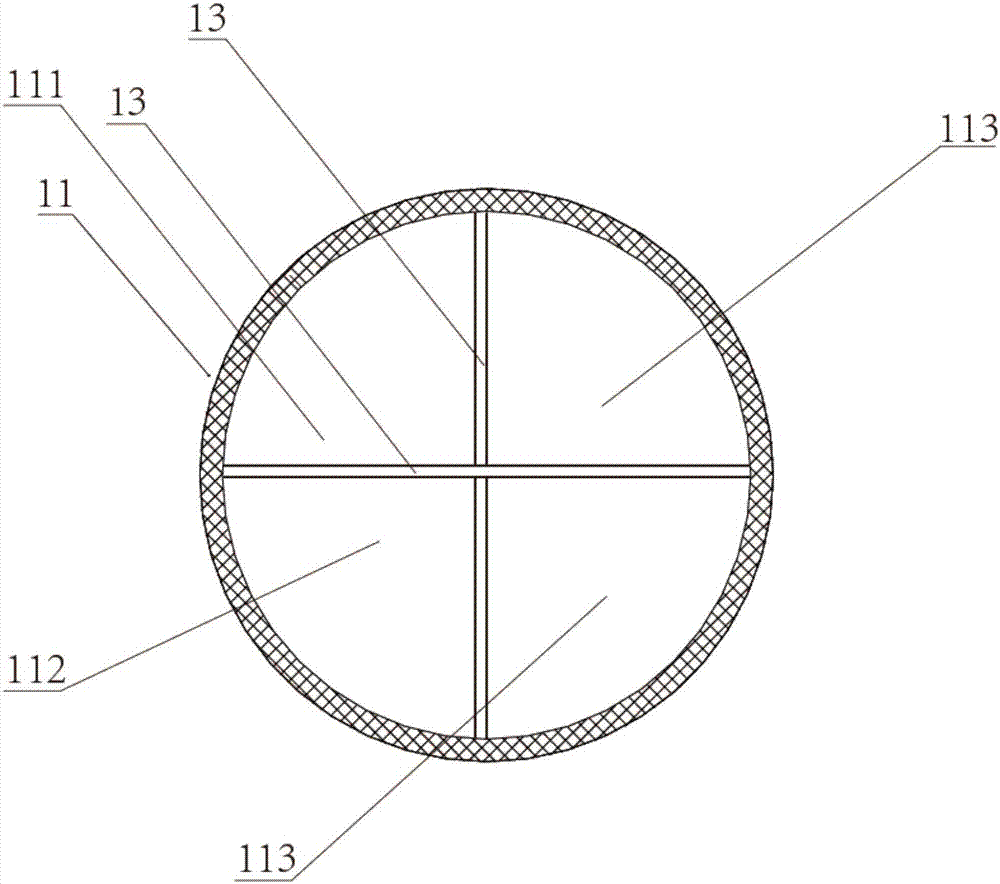

Pulsed type bag dedusting device

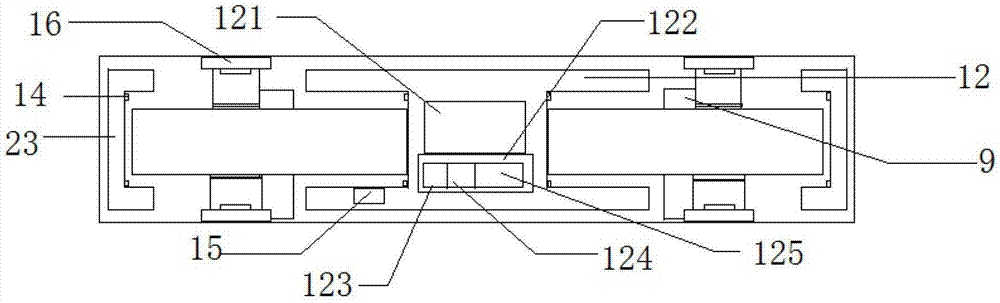

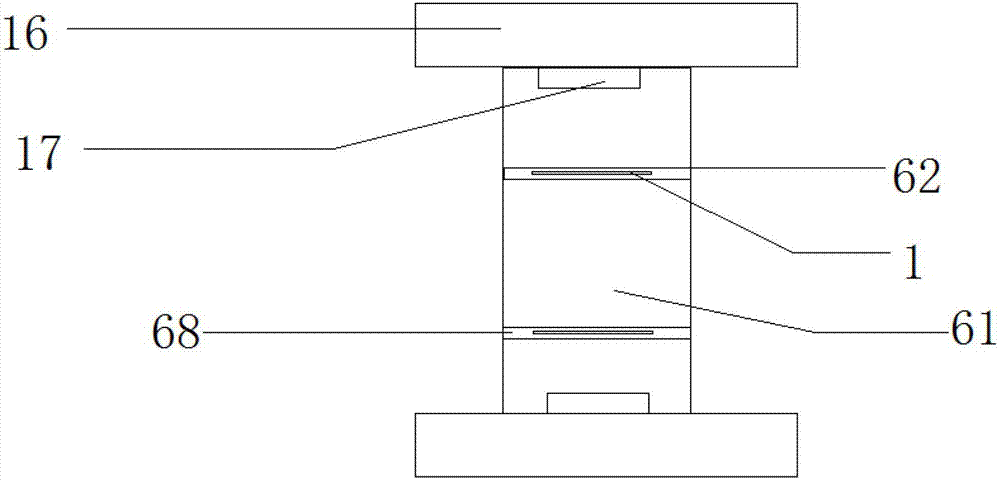

PendingCN107297107AImprove efficiency and effectivenessAchieving Recoil JitterDispersed particle filtrationTransportation and packagingEngineeringInlet channel

The invention discloses a pulsed type bag dedusting device which comprises a box combined type bag dust collector, a pulse airflow back-flushing cooling device and a second draught fan, wherein the pulse airflow back-flushing cooling device is arranged on the box combined type bag dust collector; the second draught fan is used for forming negative pressure suction in the pulse airflow back-flushing cooling device; the box combined type bag dust collector comprises at least two dedusting boxes, an exhausting channel, an air inlet channel and a dust collecting device; the dedusting boxes are successively arrayed from left to right; each dedusting box comprises a lower dust filtering chamber, an upper sealing air chamber, a sealing pattern plate, a cloth bag, a dust collecting hopper and a lifting valve device; the sealing pattern plate with a plurality of through holes is arranged between the lower dust filtering chamber and the upper sealing air chamber; the cloth bag is arranged on the position corresponding to the through holes on the sealing pattern plate; and an air inlet port of a second high temperature draught fan is communicated with an air outlet of the exhausting channel. The pulsed type bag dedusting device has the characteristics of reasonable structure design, complete function, high dedusting efficiency, safety, reliability, long service life and ultrahigh marketing value.

Owner:广东盛达穗南环保科技有限公司

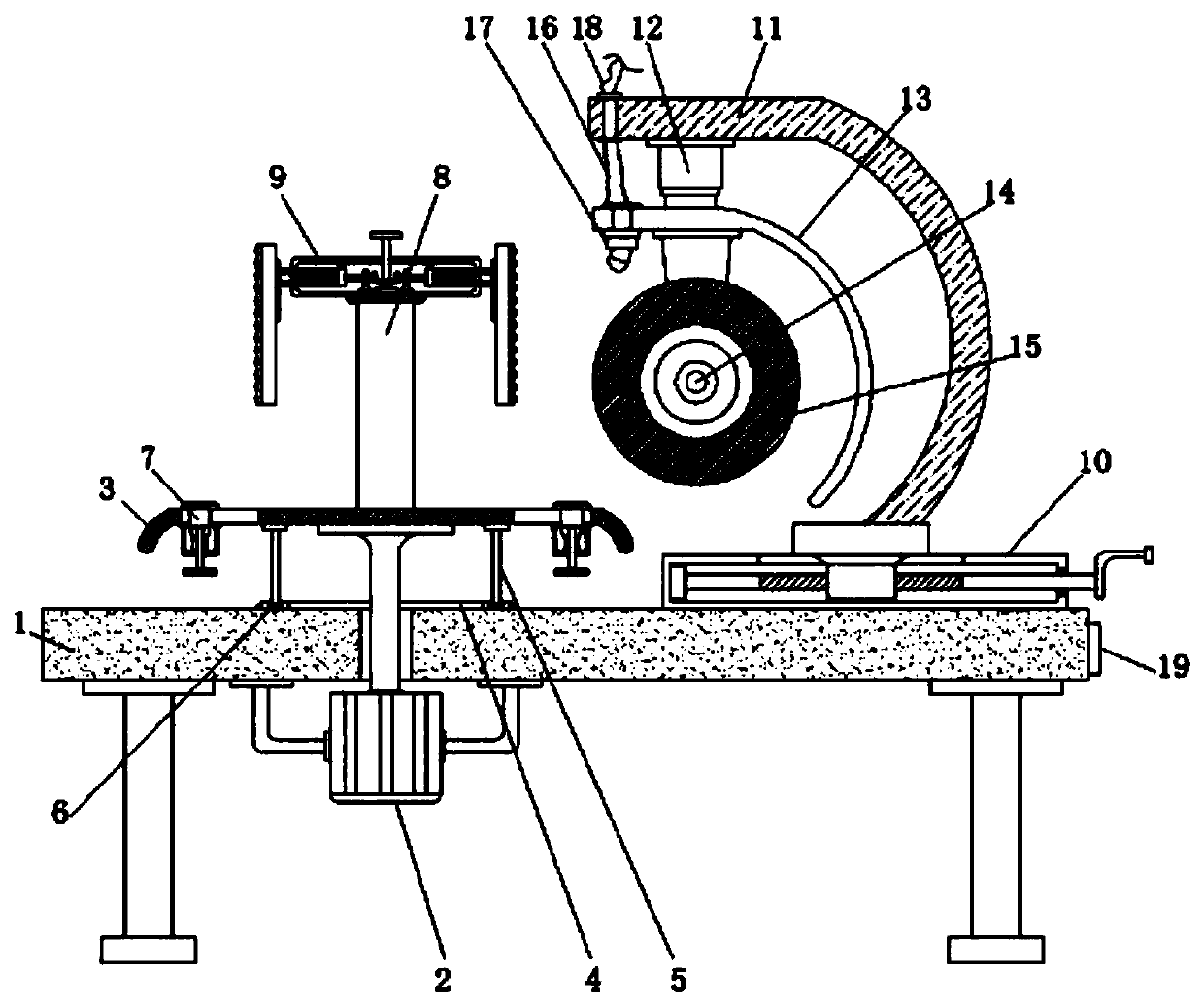

Cleaning equipment and method for vertical motor shell outer side wall machining

ActiveCN111545498AAvoid stickingEfficient scrubbingManufacturing dynamo-electric machinesCleaning using toolsElectric machineMachine

The invention relates to the technical field of vertical motor shell outer side wall machining, and discloses cleaning equipment and method for vertical motor shell outer side wall machining. The cleaning equipment comprises a machine body, the left side of the bottom of the machine body is fixedly connected with a low-speed motor through a fixing frame, and an output shaft of the low-speed motorpenetrates through a bottom through hole of the machine body and is fixedly connected with a rotating platform; and an annular sliding groove is fixedly connected to the top surface of the machine body, an auxiliary supporting rod is fixedly connected to the lower surface of the rotating platform, and a sliding groove roller is movably connected to the tail end of the auxiliary supporting rod through a pin shaft and located on the inner side of the annular sliding groove. The cleaning equipment is provided with the machine body, the low-speed motor, the rotating platform, a radial supporting and adjusting mechanism, a fixed stand column, an inward extrusion mechanism, a transverse position adjusting mechanism, an arc-shaped supporting frame, an electric lifting rod, a rotating motor, a disc type brush and a control panel which are matched with one another, so that the problem that machining chippings on the outer side wall of an existing vertical motor shell are not thoroughly cleanedis effectively solved.

Owner:南京鸿达机电有限公司

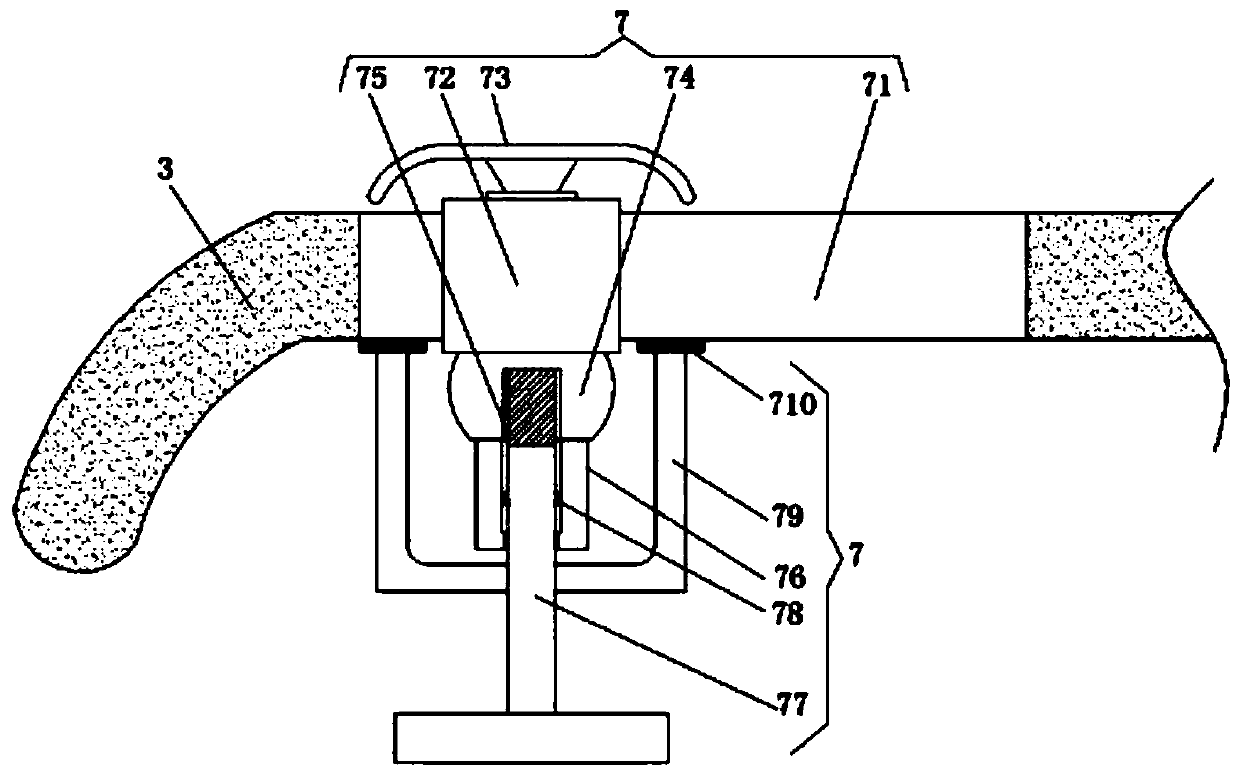

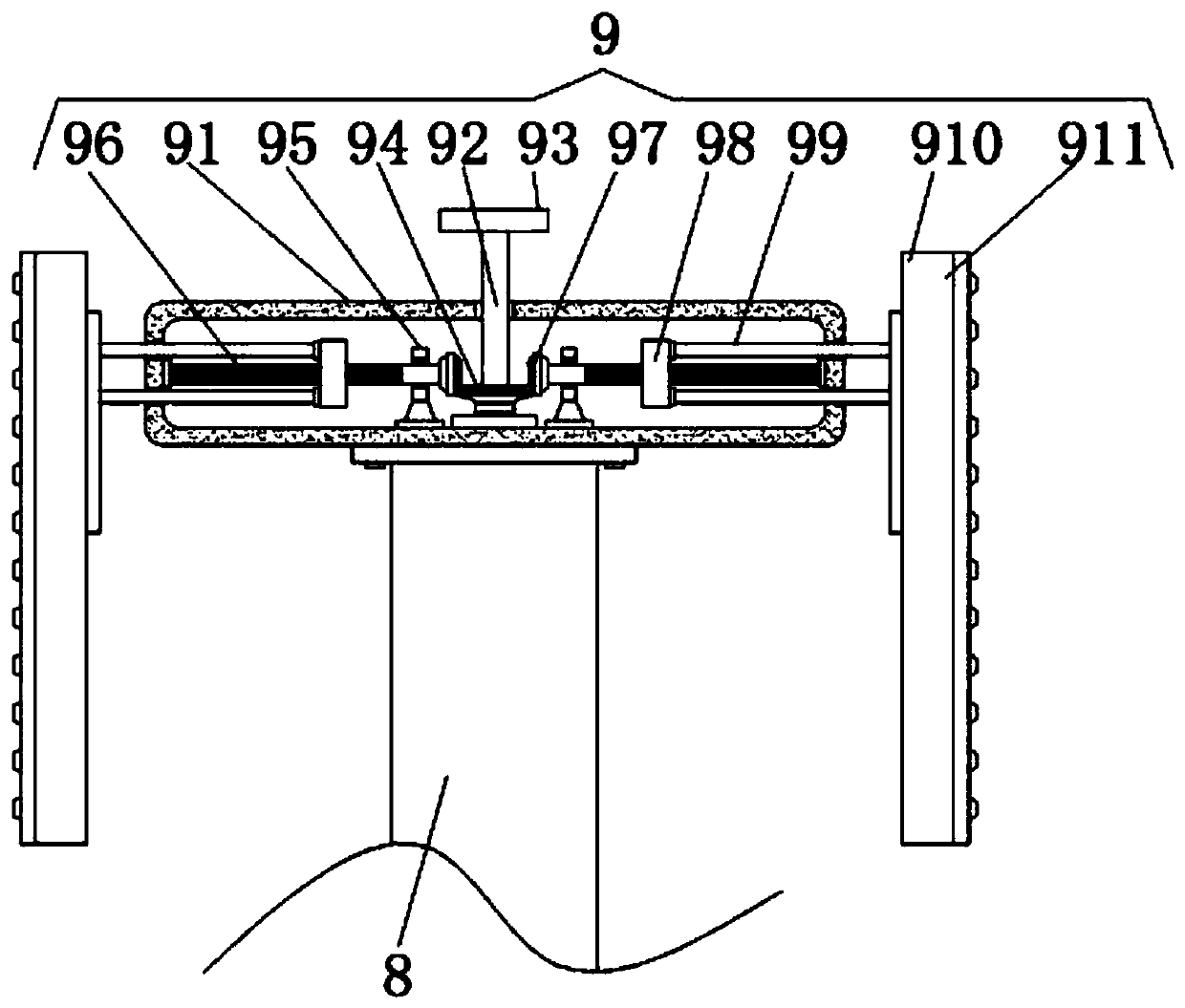

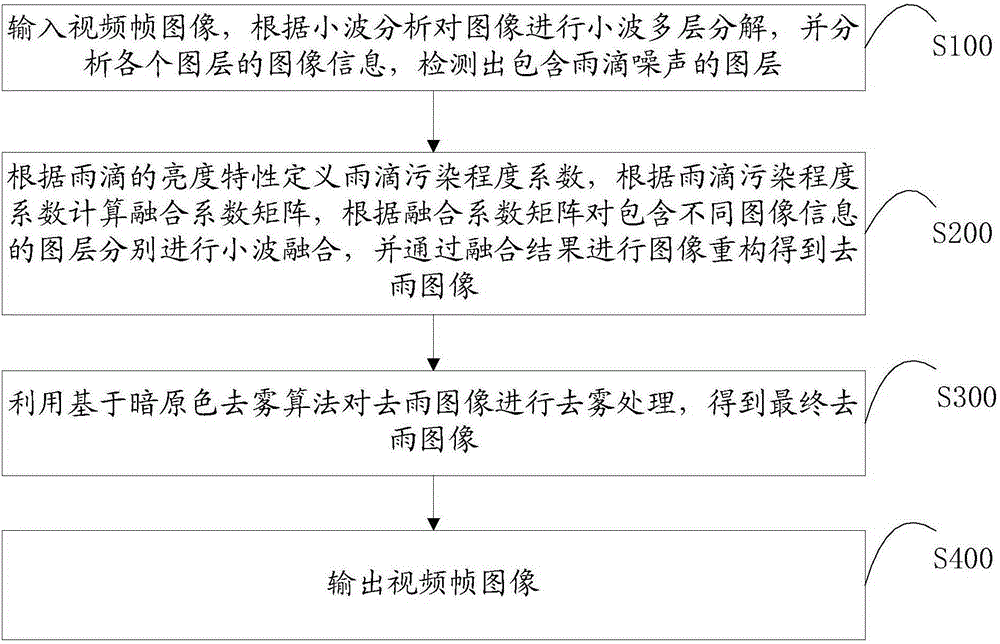

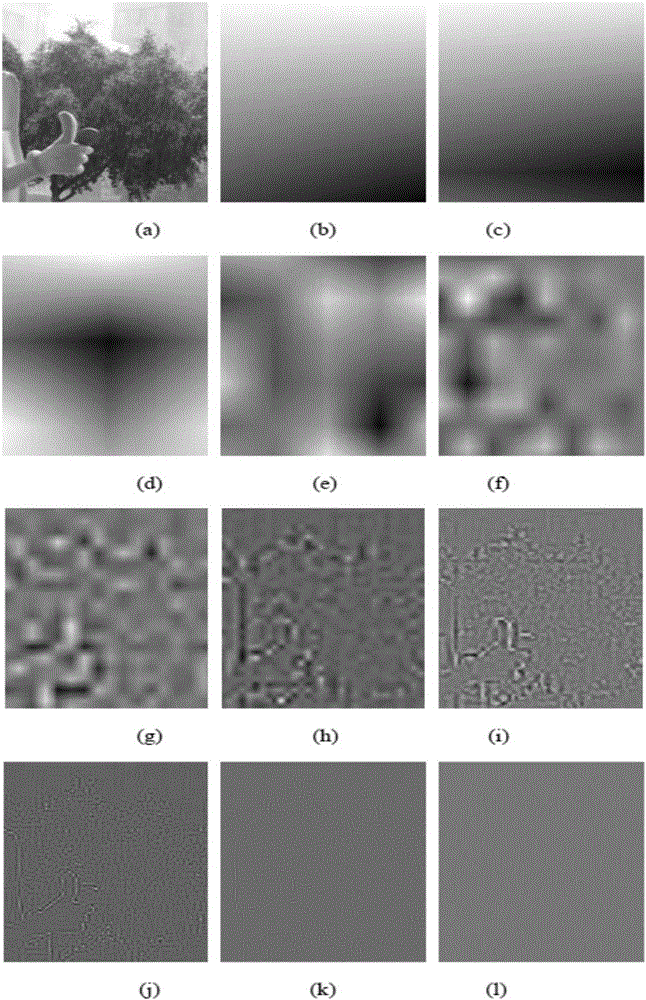

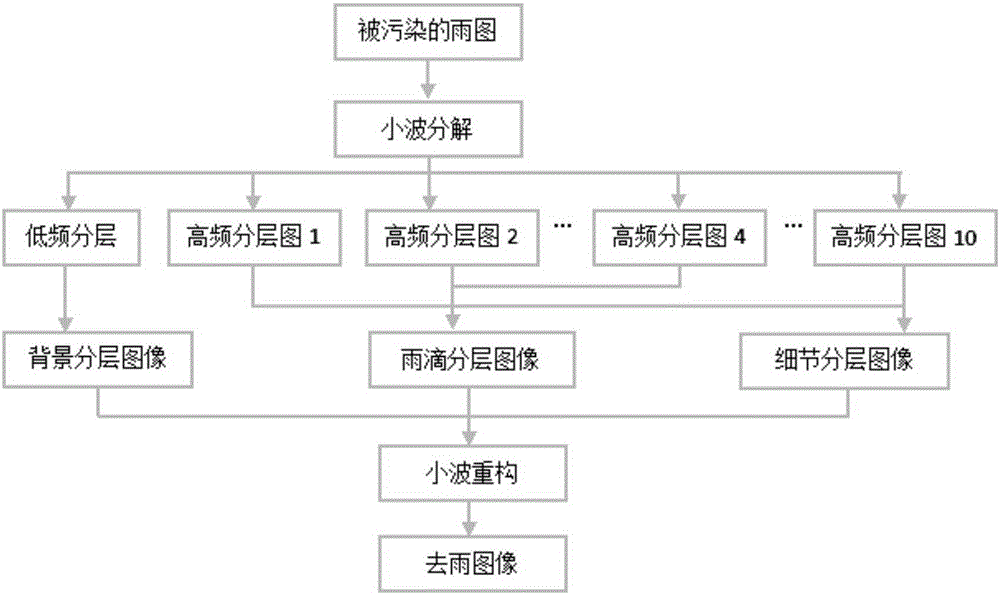

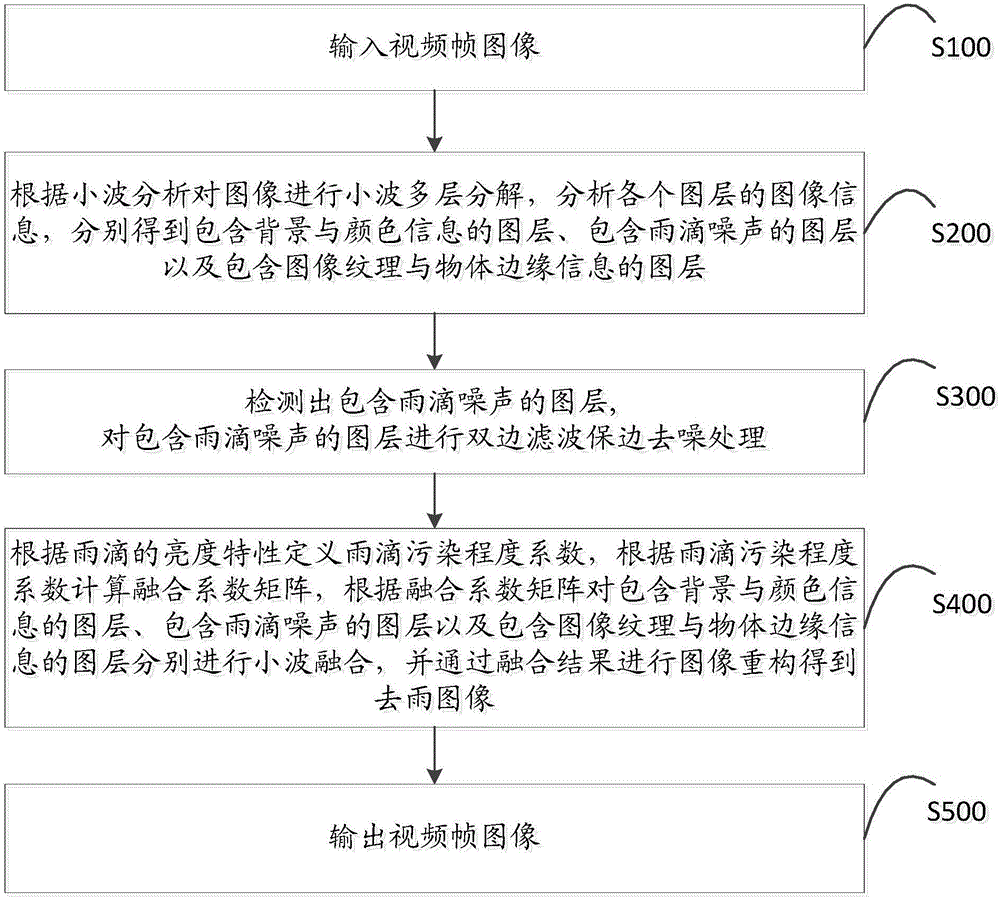

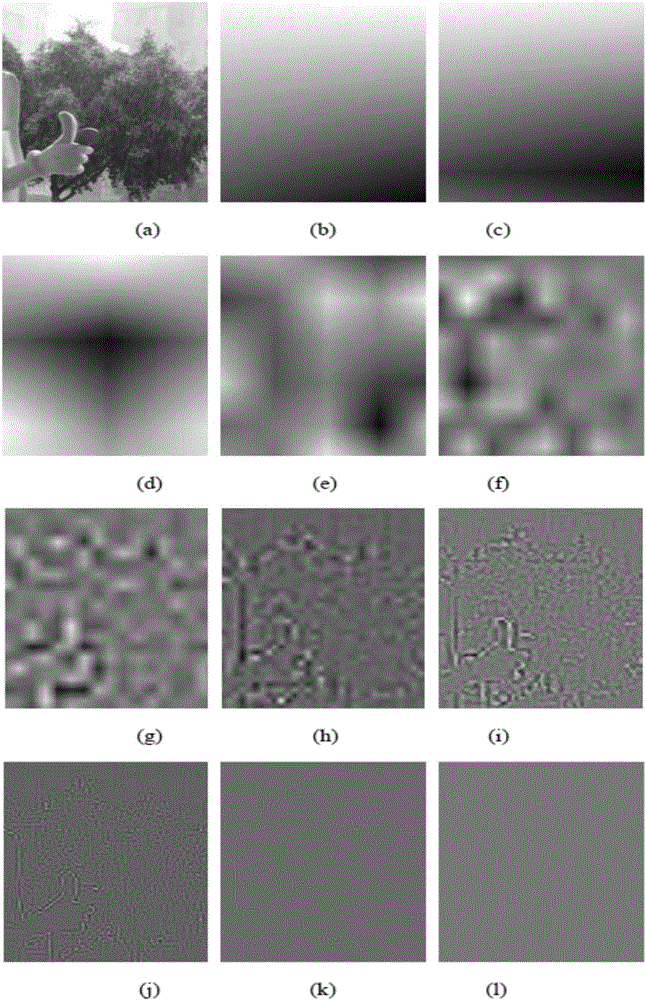

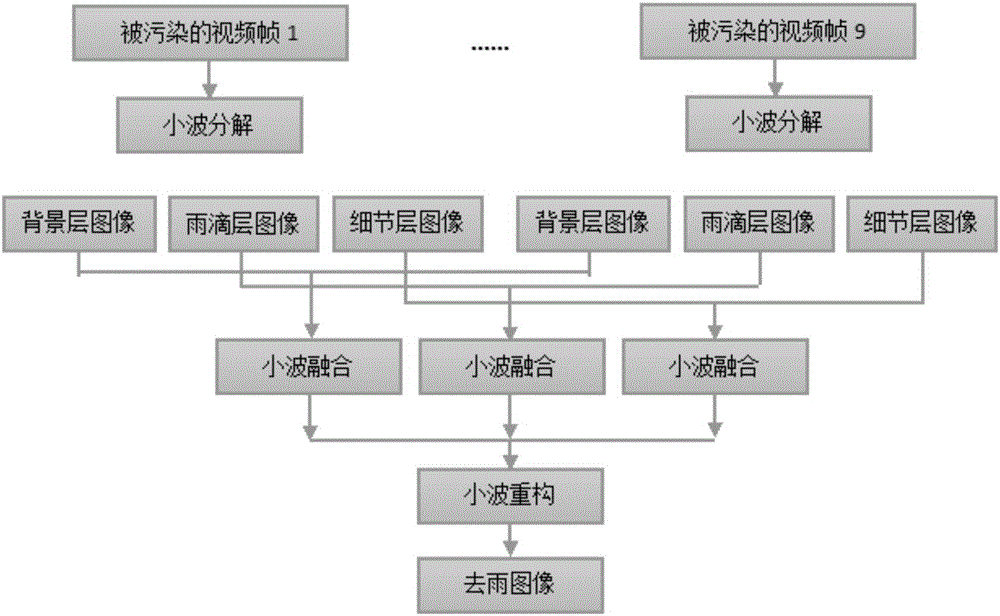

Image rain removing method based on wavelet analysis and system

InactiveCN105184761AAchieve the purpose of removingAccurate and effective removalImage enhancementImaging processingDecomposition

The invention belongs to the image processing technology field, and particularly relates to an image rain removing method based on a wavelet analysis and a system. The image rain removing method based on wavelet analysis comprises steps of performing wavelet multilayer decomposition on a video frame image according to wavelet analysis, analyzing image information of all image layers and detecting the image layer containing rain droplet noise, c determining a rain droplet contamination degree coefficient according to the brightness characteristic of the rain droplet, calculating a fusion coefficient matrix according to the rain droplet contamination degree coefficient, performing wavelet fusion on the image layer containing various image information according to the fusion coefficient matrix, and performing image reconstruction through the fusion result to obtain the rain removing image. The invention can avoid the interference of the dynamic characteristic, can more effectively and accurately remove rain droplet, can improve the usage scope of the algorithm, enables the algorithm to have a sound rain-removing effect even under the heavy rain, performs defogging operation on the rain removing image, optimizes the visual effect of the image and enables the algorithm to be more practical.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for removing proteins in protein-enriched wastewater

InactiveCN102659233AAchieve the purpose of removingHigh removal rateWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAcetic acidAdditive ingredient

The invention relates to a method for removing proteins in protein-enriched wastewater, which comprises the following steps of: carrying out isoelectric point analysis on ingredients of the proteins in the protein-enriched wastewater and determining a grouped and graded treatment scheme according to isoelectric points of the proteins from large to small; after carrying out pretreatment on the wastewater, transferring the wastewater into a reaction kettle; filling volatile weak acid gas into the reaction kettle, regulating the pH value of the wastewater to guarantee the pH value to reach the relatively large isoelectric point in the grouped and graded treatment scheme and guaranteeing the proteins at the relatively large isoelectric point to be sufficiently precipitated; carrying out solid-liquid separation to remove protein precipitates; continuing to fill the volatile weak acid gas into the reaction kettle and reducing the pH value of the solution grade by grade to sequentially obtain the protein precipitates on each corresponding grade and finally purified supernatant; and releasing the volatile weak acid gas in the finally purified supernatant and recovering the volatile weak acid gas. The volatile weak acid gas is CO2 or CO2 with acetic acid. Due to the adoption of the method disclosed by the invention, the protein removal rate is high; the treated wastewater has low subsequent treatment cost; and the wastewater treatment process is mild and reversible and has strong controllability.

Owner:TAIXIANG GRP TECH DEV +1

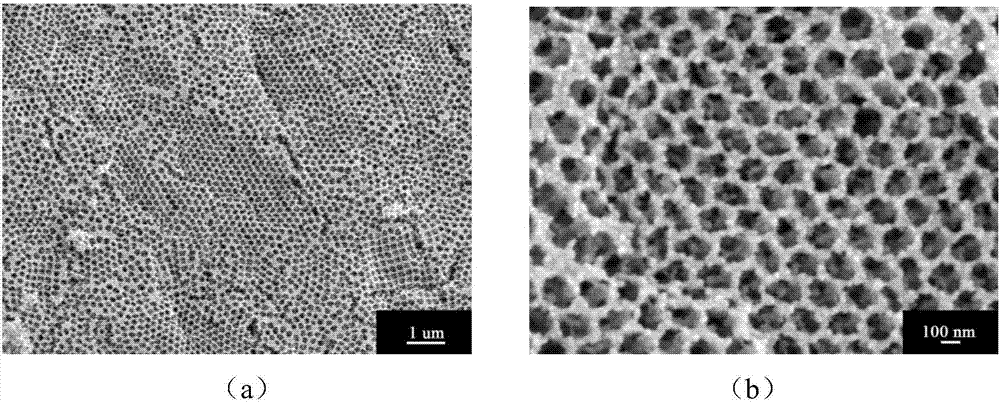

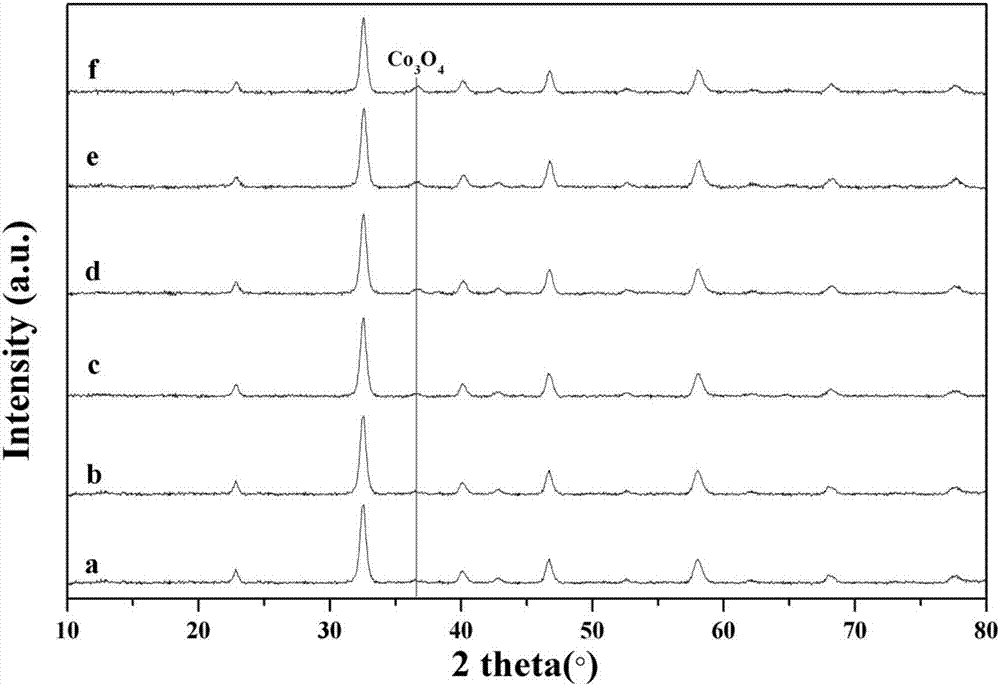

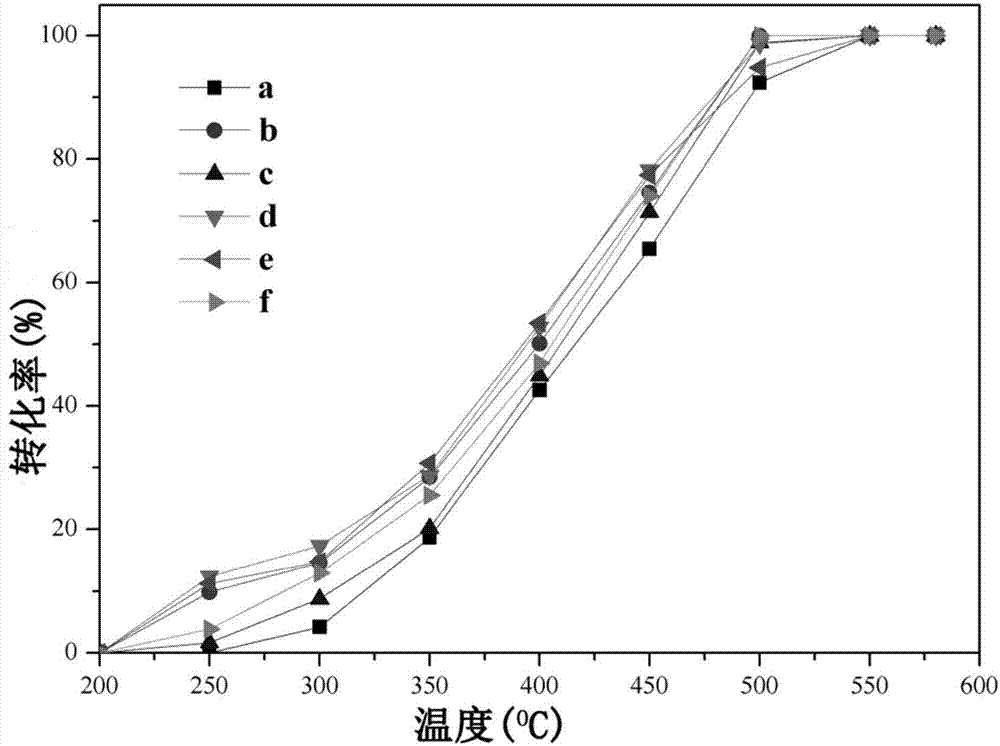

Three-dimensional ordered macroporous perovskite type composite metal oxide catalyst and preparation method and application thereof

InactiveCN106964359AImprove stabilityImprove chlorine resistanceGas treatmentHeterogenous catalyst chemical elementsSynthesis methodsCatalytic oxidation

The invention discloses a three-dimensional ordered macroporous perovskite type composite metal oxide catalyst and a preparation method and application thereof. The catalyst is excellent in high temperature resistance and chlorine resistance, capable of realizing complete oxidation of industrial typical CVOCs (1,2dichloroethane) under conditions that the reaction temperature is 450-500 DEG C, the reaction air speed is 40000-50000mL.h<-1>.g<-1> and the oxygen concentration is 10-40% and can be used for effective degradation of industrial CVOCs. In addition, by loading of transition metal oxides, catalytic oxidation efficiency of the catalyst can be improved effectively; oxidation performance and thermal stability of the catalyst can be improved effectively by modification through cheap transition metal oxides (such as Co3O4), and activity and selectivity of the catalyst have no dramatic decline after continuous reaction for 800min. A synthesis method of the catalyst is simple, and the three-dimensional ordered macroporous perovskite type composite metal oxide catalyst has a promising industrial application prospect.

Owner:XI AN JIAOTONG UNIV

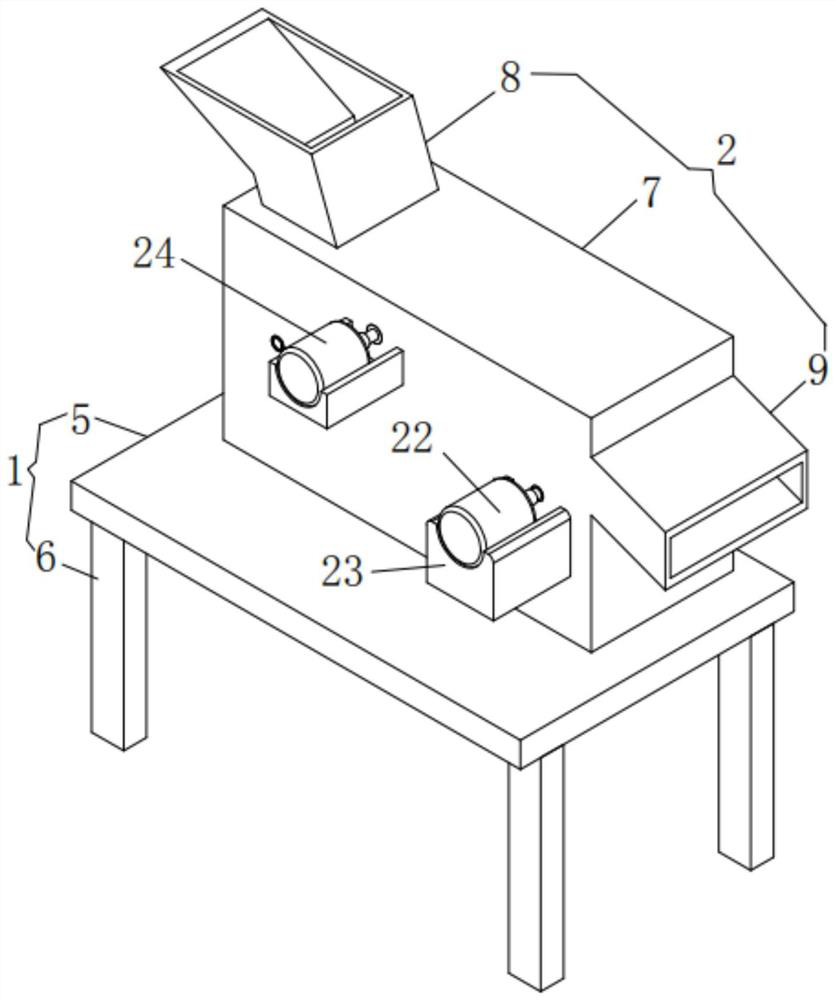

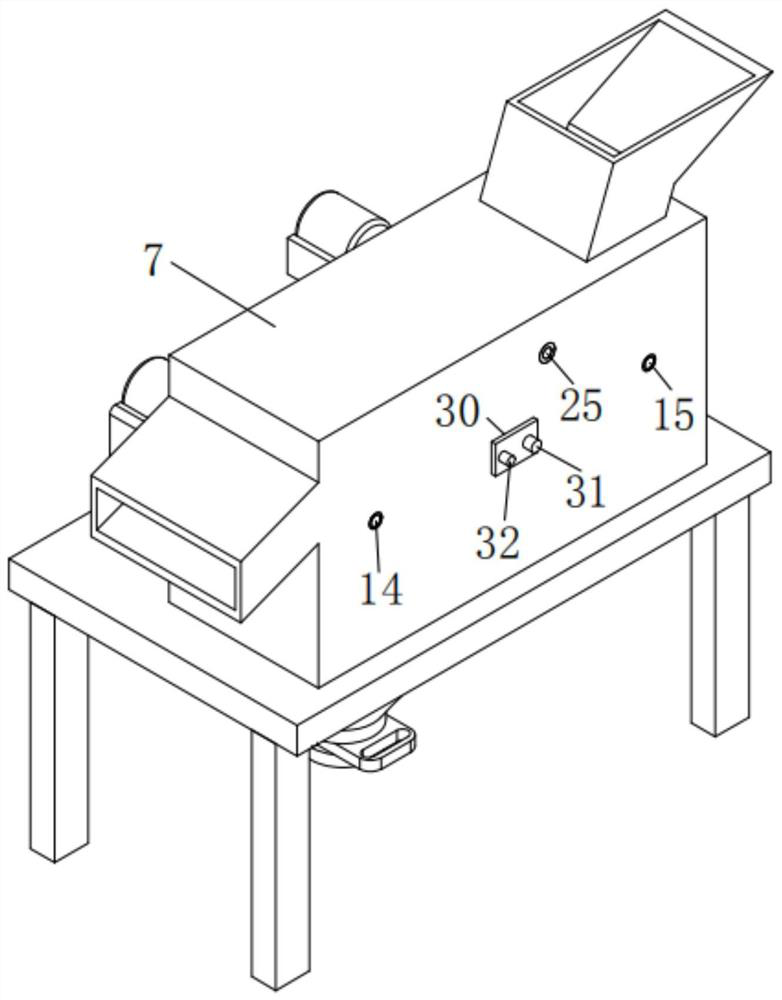

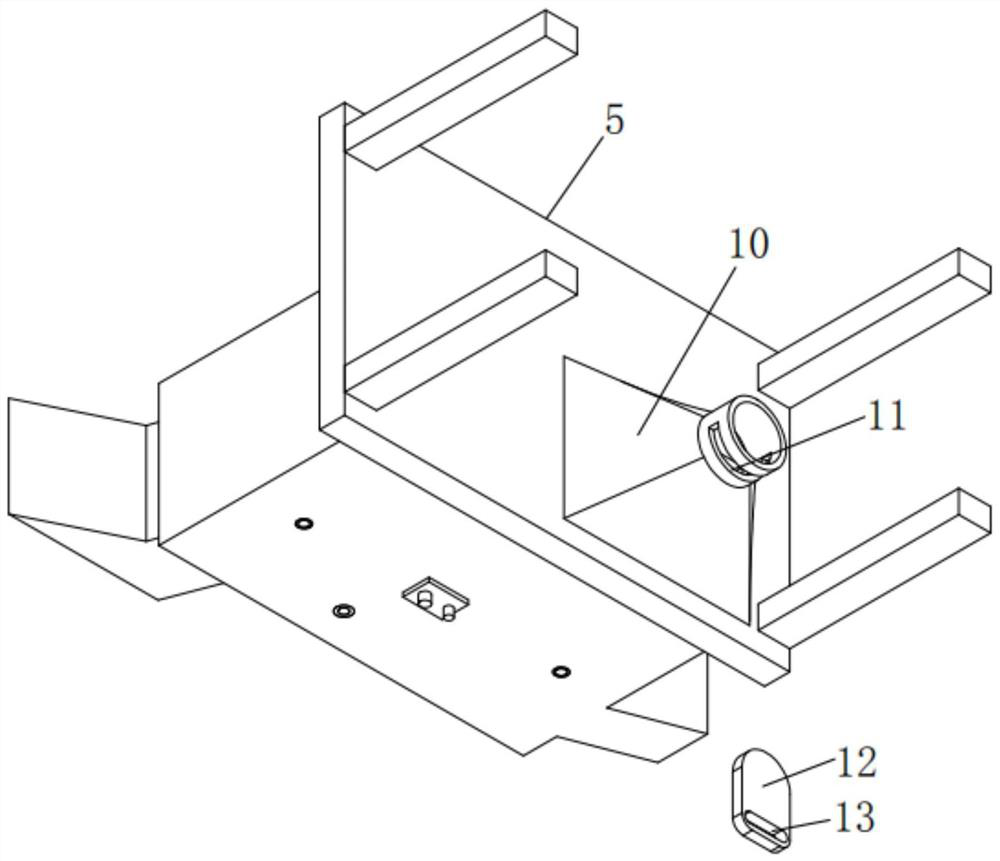

Civil engineering building waste treatment device

PendingCN111715344AAchieve the purpose of removingRealize the purpose of non-stop workCleaningMagnetic separationIron removalArchitectural engineering

The invention relates to the technical field of building waste treatment, in particular to a civil engineering building waste treatment device. The civil engineering building waste treatment device comprises a supporting unit, a rack, an iron removing unit and a dispersion unit. The rack is fixedly mounted on the upper portion of the supporting unit, and the iron removing unit is fixedly mounted on the rack. According to the civil engineering building waste treatment device, when removed iron impurities are cleaned away, non-halt work can be achieved, the working efficiency is greatly improved, the iron impurities mixed in smashed building waste are completely removed, the quality of the treated building waste is good, a good use foundation is laid for following reutilization of the treated building waste, the situation that the input smashed building waste is mixed with the separated iron impurities again can be effectively avoided, thus, the labor amount of workers is effectively reduced, the iron impurities attached to the surface of a conveying belt can be scraped and fall into a collecting hopper, and the iron impurities attached to the surface of the conveying belt can be effectively prevented from being mixed with the input smashed building waste again.

Owner:江苏航运职业技术学院

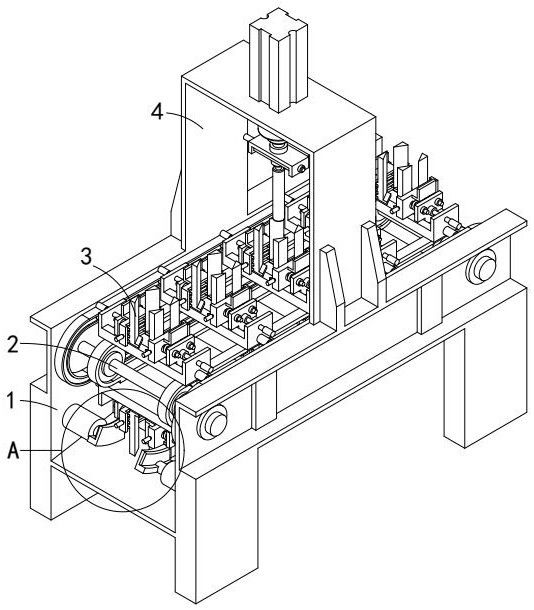

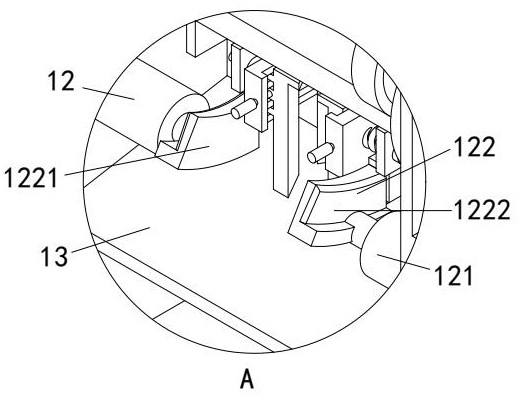

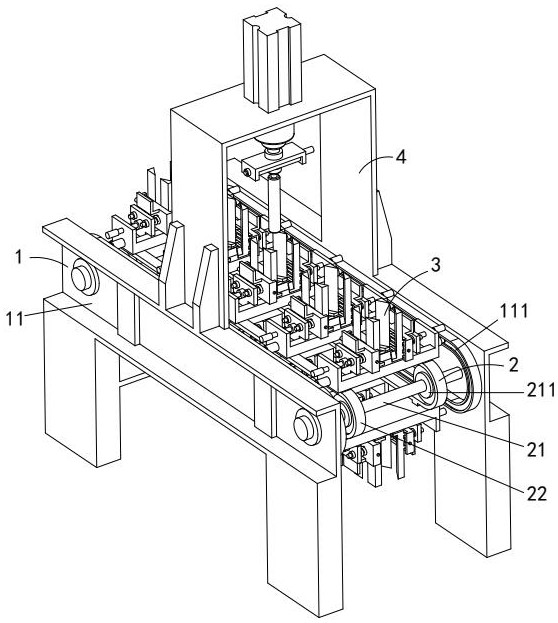

Nut inner screw hole batch polishing and deburring device

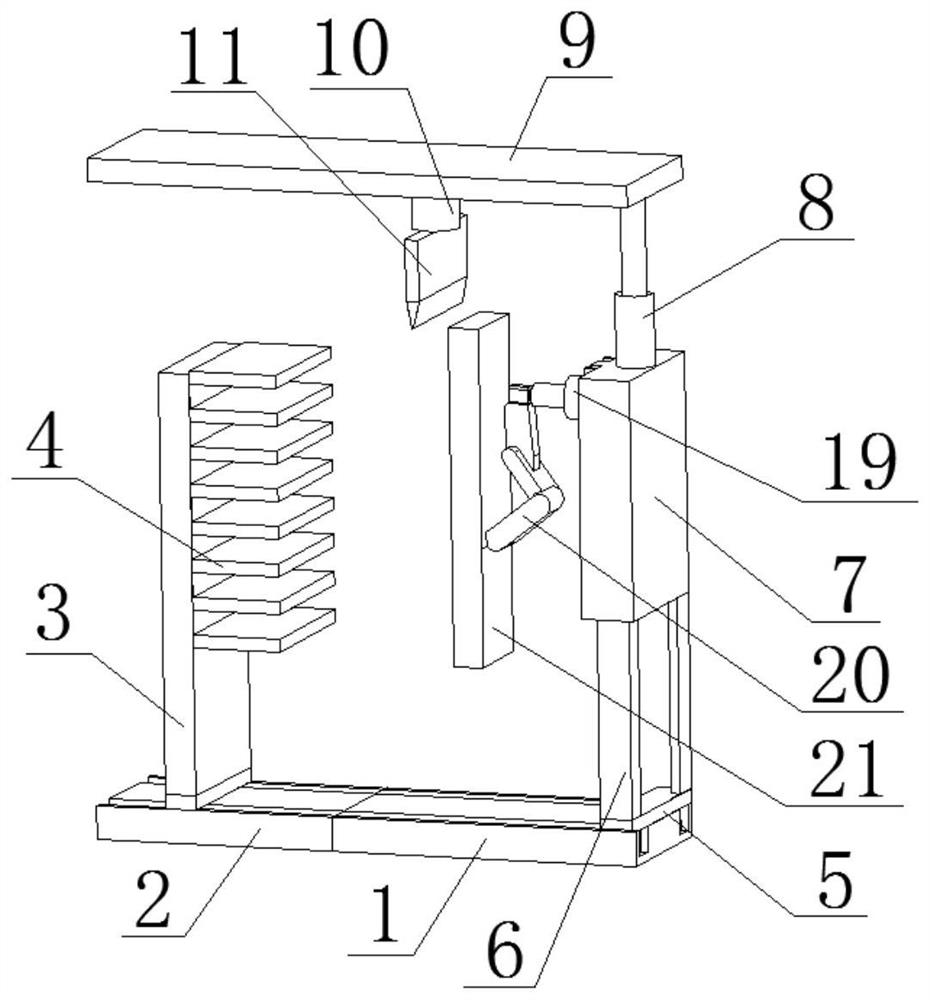

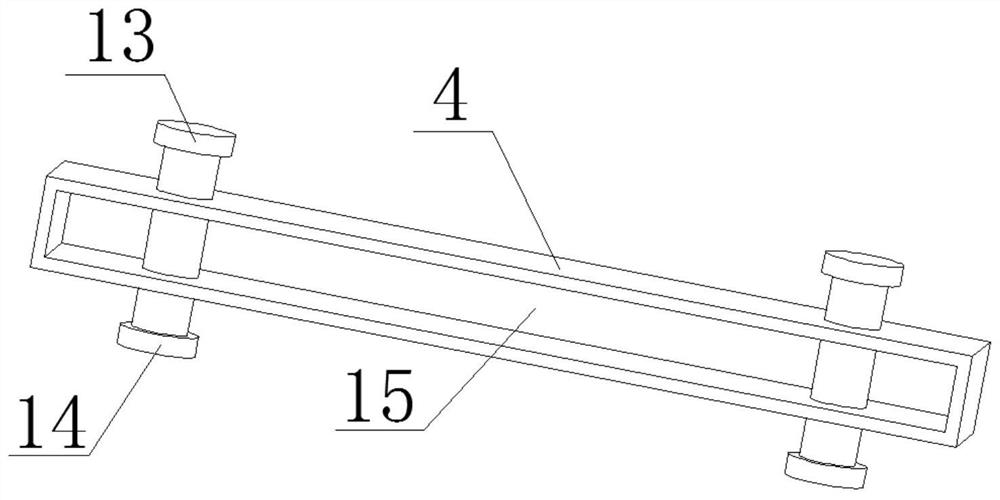

ActiveCN113523938ASolve the problem of assembly accuracyGuaranteed processing efficiencyEdge grinding machinesGrinding carriagesChain conveyorMachining

The invention relates to the technical field of fastener polishing and deburring machining, in particular to a nut inner screw hole batch polishing and deburring device which comprises a conveying table. The conveying table comprises two side vertical frames arranged side by side, a chain conveyor is arranged between the two side vertical frames, a plurality of positioning clamps used for positioning and placing nuts are evenly distributed on the chain conveyor, and a burr grinding mechanism used for removing burrs of nut screw holes is assembled between the top ends of the two side vertical frames. A plurality of nuts are positioned, clamped and positioned in a batched mode, an existing randomized inner hole deburring treatment mode is replaced with a simplest and direct rotary grinding removal mode, and on the premise that the treatment efficiency is guaranteed through batched treatment, and the problem that in an existing inner hole deburring treatment process, a non-burr part is abraded, eroded and damaged, and the assembly precision and the assembly strength of a bolt fastener are affected is solved.

Owner:徐州恒乾紧固件制造有限公司

Online extraction and dephenolization method of coal tar wastewater

ActiveCN105152437AAchieve the purpose of removingEliminate secondary pollutionWater contaminantsMultistage water/sewage treatmentRefluxBoiling point

The invention discloses an online extraction and dephenolization method of coal tar wastewater. The method comprises the following steps: heating water-containing coal tar, carrying out reduced pressure flash evaporation to obtain mixed steam, sending the mixed steam to a rectifying tower, introducing an extractant from the top of the tower as a reflux liquid, carrying out azeotropic rectification in the rectifying tower, extracting components with the boiling point of 170-210DEG C from the lateral line of the rectifying tower, fractioning components with the boiling point being greater than 210DEG C, allowing the components with the boiling point being greater than 210DEG C to heavy oil components in the middle portion of the tower, and extracting other components from the top of the tower; sending the components extracted from the top of the tower to a tower top condenser, cooling to a temperature being smaller than 40DEG C, sending the cooled components to a tower top refluxing tank, carrying out oil-water settlement separation, and separating to obtain water which is dephenolized water; and mixing oil obtained after the separation with the component extracted from the lateral line, sending the obtained mixture to a dephenolization device, and dephenolizing. The method directly realizes online extraction dephenolization in the rectifying tower in the coal tar rectification process, simultaneously realizes coal tar rectification and phenol substance removal purposes, and saves the cost.

Owner:王庆元

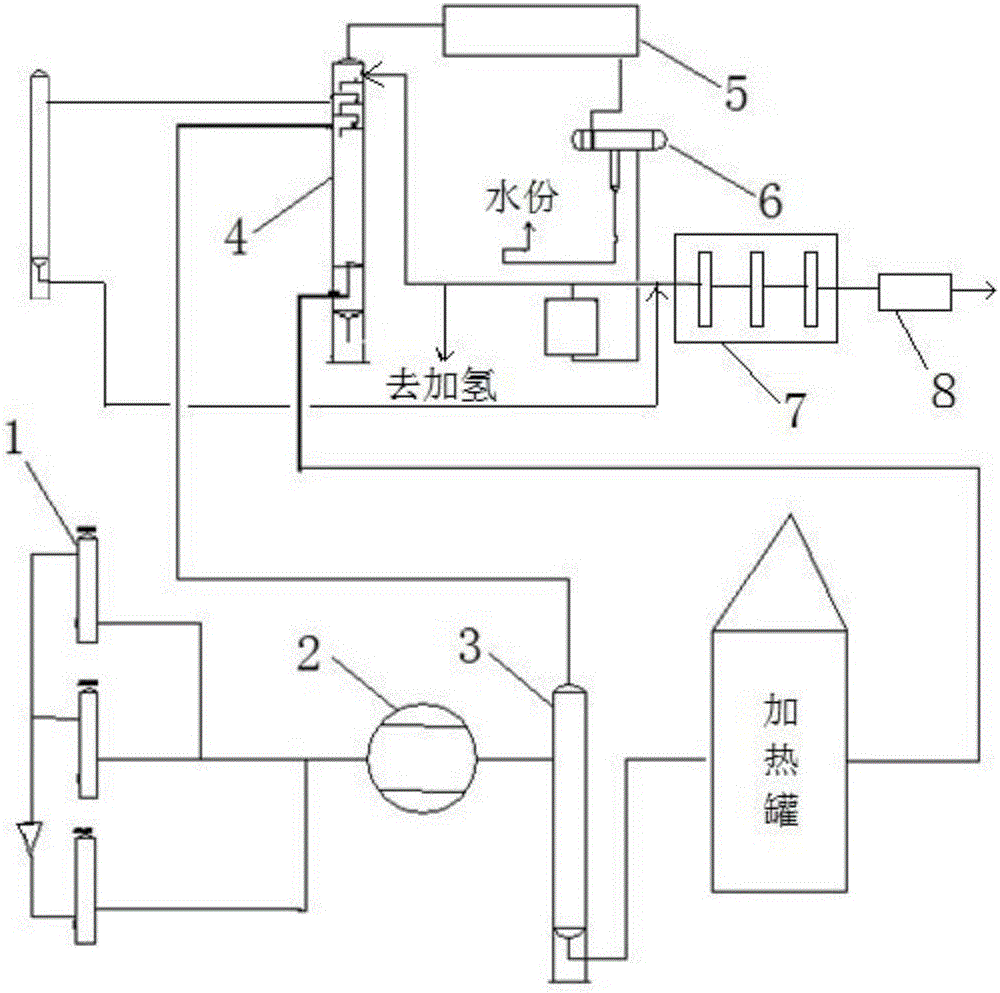

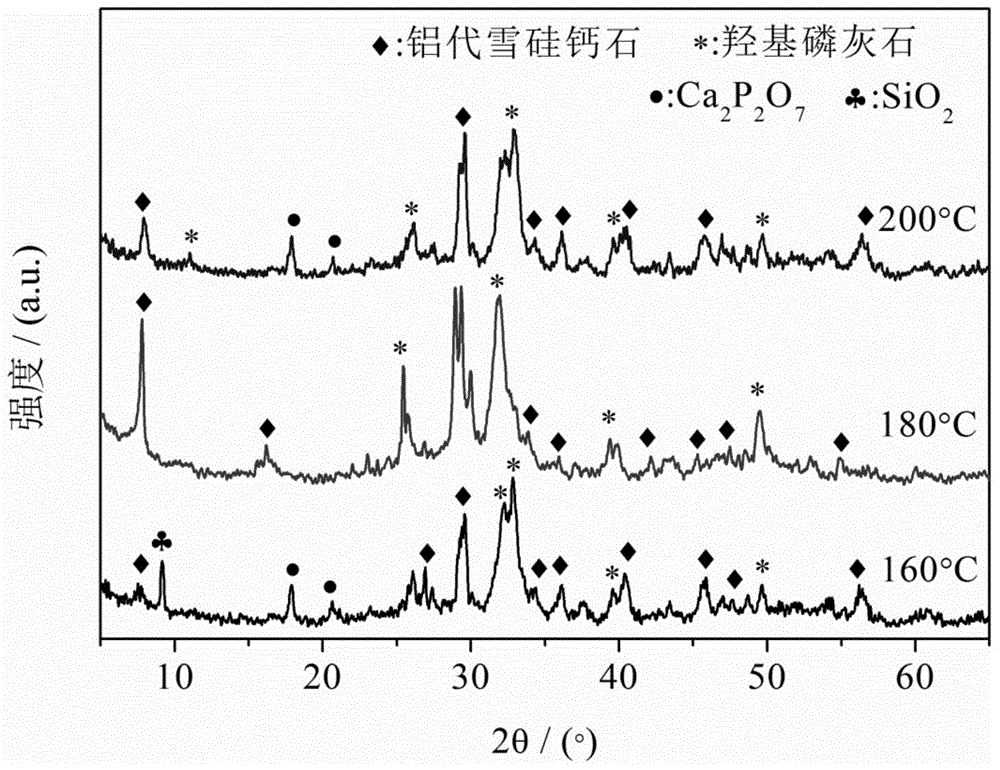

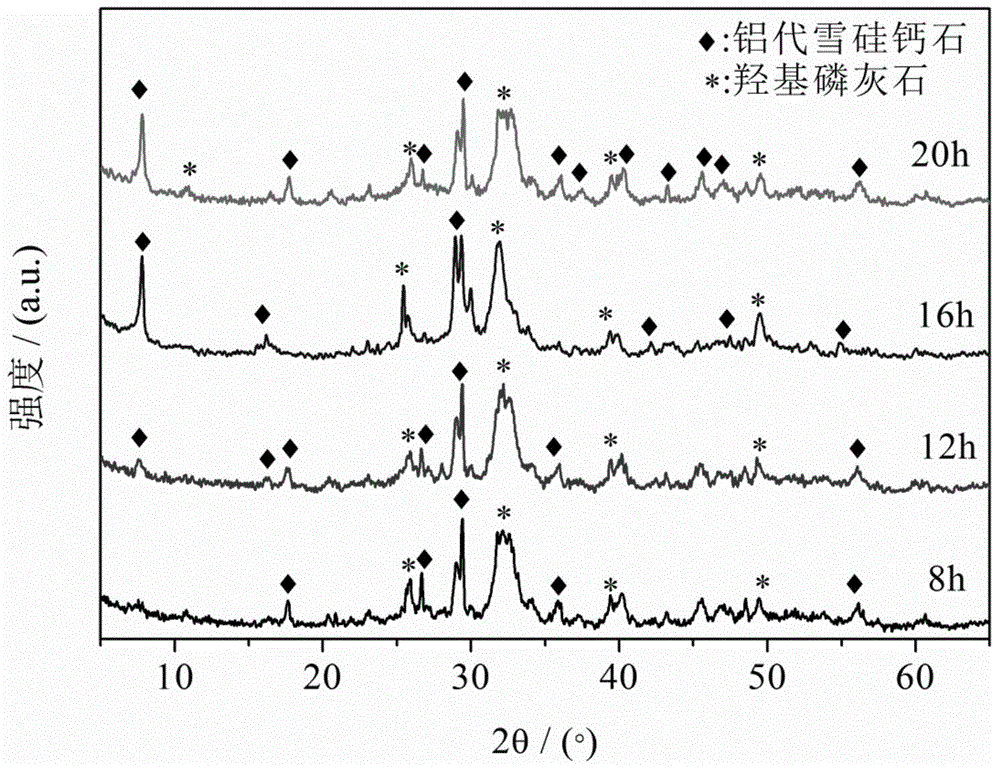

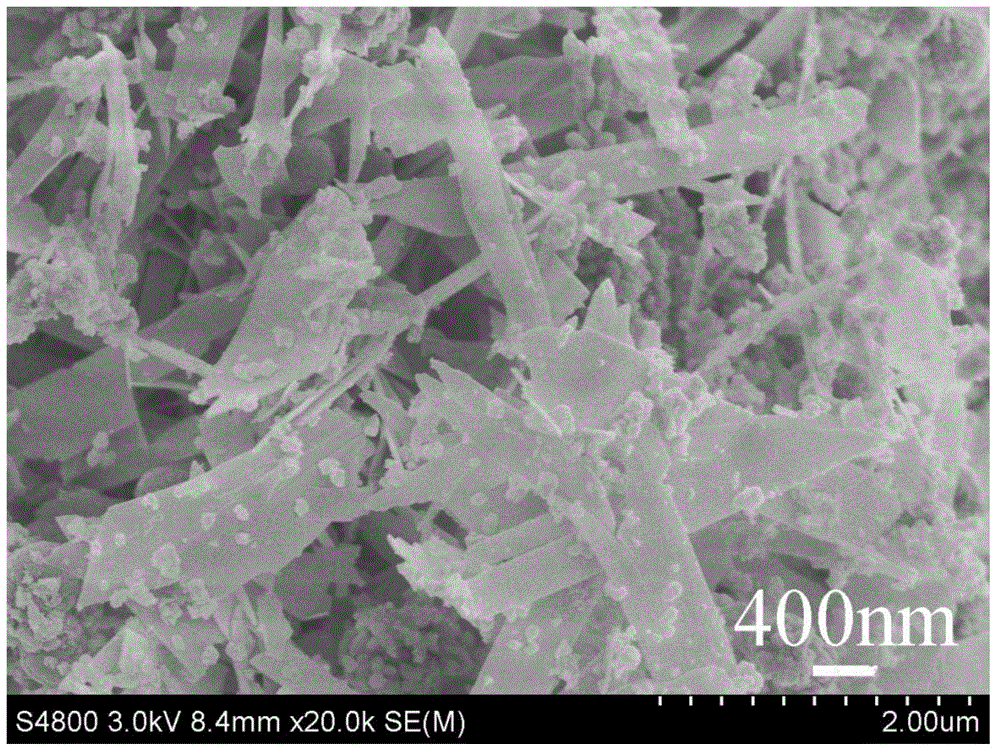

Al2O3-Tob/HA compound sewage treatment material, and preparation method and application thereof

ActiveCN104353409AMiscellaneousHigh purityOther chemical processesWater/sewage treatment by ion-exchangePhosphoric acidPulverized fuel ash

The invention discloses an Al2O3-Tob / HA compound sewage treatment material, and a preparation method and application thereof. The preparation method comprises the following steps: using pre-pickling pulverized fuel ash as a silicon source and an aluminium source, using slaked lime Ca(OH)2 as a symbiotic calcium source and using phosphoric acid as a phosphorus source; at first, adopting a sonochemistry method, and controlling the temperature and regulating the pH value to 10.5 to 11.5 to prepare an aluminum substituted tobermorite performed polymer; then adding a phosphoric acid solution to obtain an Al2O3-Tob and HA symbiotic co-polymer; finally adopting a hydrothermal vapor pressure method to prepare an Al2O3-Tob / HA compound sewage treatment material of which the compound ratio X is 2 to 4. Test results show that the product impurity phases are few, the purity is high, Al2O3-Tob and HA crystallization conditions are favorable, and the product has a net framework structure, large specific surface area, and a strong property for adsorbing and desorbing heavy metal ion Cd<2+>, and the adsorbing property is enhanced along with the increase of the compound ratio in an experimental scale. The production process is simple, the operation process is convenient, the production cost is low, and the preparation method is a practical and effective method for using pulverized fuel ash solid wastes.

Owner:SHAANXI UNIV OF SCI & TECH

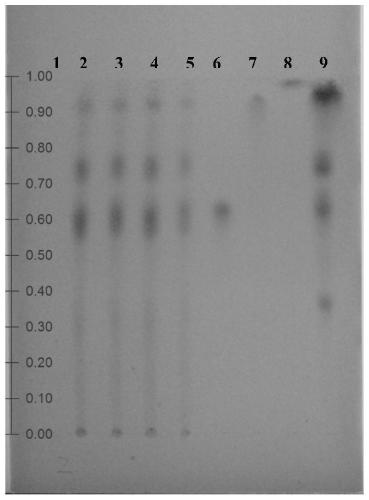

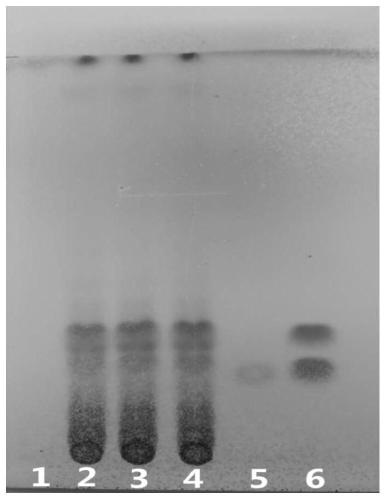

Composition and preparation for treating novel coronavirus pneumonia and application of composition

ActiveCN111467451AAchieve the purpose of removingSignificant clinical effectAntiviralsRespiratory disorderBiotechnologyRhizome

The present invention relates to a composition for treating novel coronavirus pneumonia. The composition is prepared from the following traditional Chinese medicines in parts by weight: 18-25 parts ofradix bupleuri, 8-15 parts of radix scutellariae, 8-15 parts of rhizoma pinellinae praeparata, 8-15 parts of fructus trichosanthis, 15-20 parts of radix codonopsis pilosulae, 8-15 parts of betel nuts, 15-20 parts of fructus tsaoko, 15-20 parts of officinal magnolia bark, 8-15 parts of rhizoma anemarrhenae, 8-15 parts of radix paeoniae rubra, 8-15 parts of liquorice, 8-15 parts of dried orange peels and 8-15 parts of giant knotweed rhizome. The composition furthest reserves accumulated medicine using experience of traditional Chinese medicine, and is also suitable for modern society, convenient to take and good in taste, widely applied and verified clinically, definite in curative effect and good in treatment effect.

Owner:劲牌持正堂药业有限公司

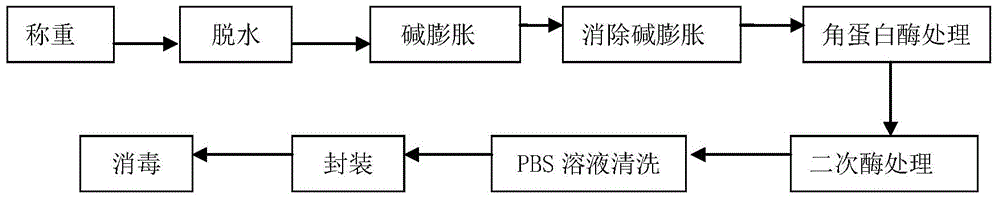

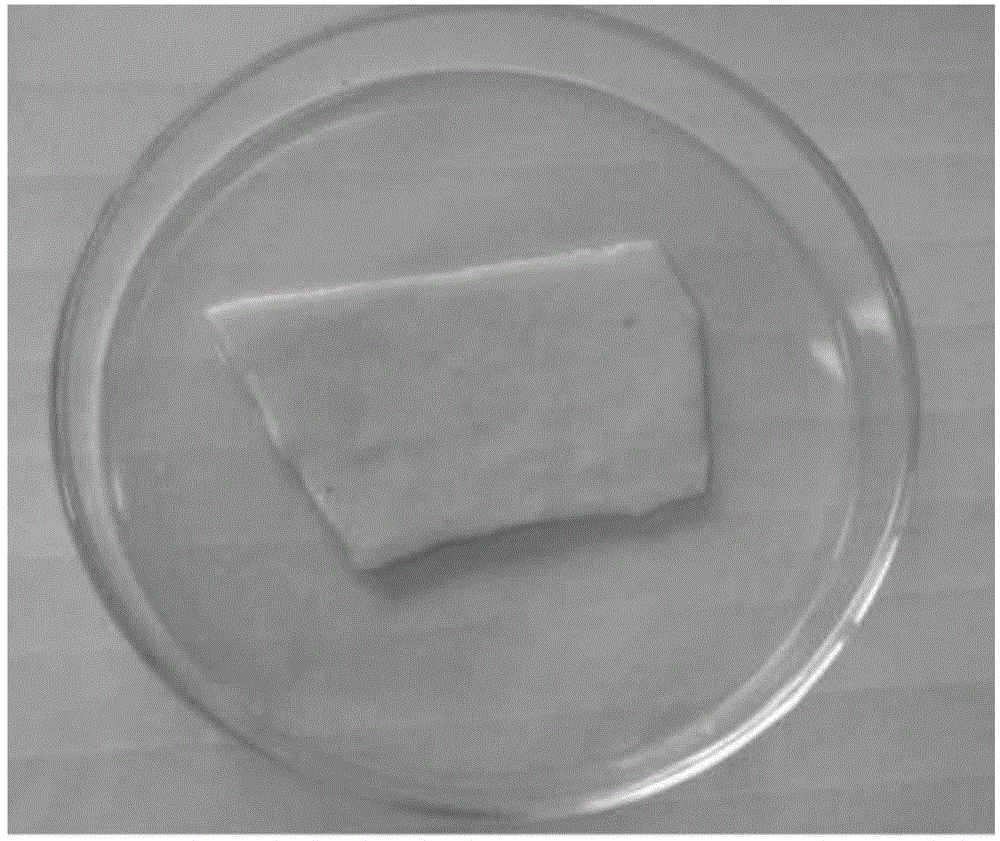

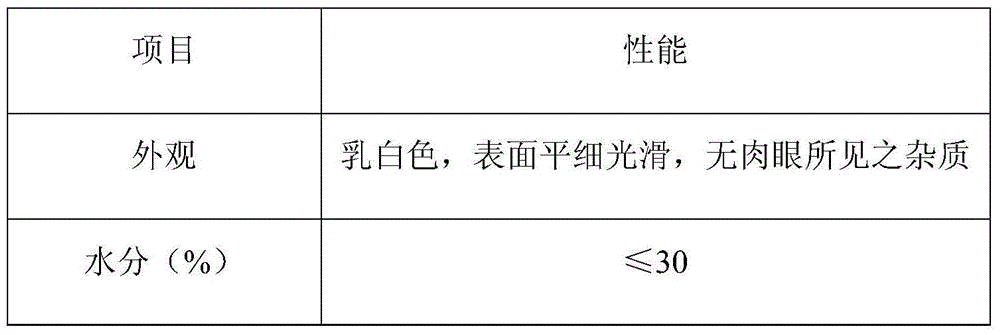

Preparation method for acellular xeno-dermal matrix

ActiveCN105268022AReduce pollutionSevere pollution eradicationProsthesisPorosityMoisture permeability

The invention relates to a preparation method for an acellular xeno-dermal matrix. Fresh salted pigskin is employed as a raw material, physical, chemical and biochemical combination methods are employed, the pigskin is subjected to a series of treatments of degreasing, alkaline swelling, alkaline swelling elimination, keratinase processing, secondary enzyme treatment and the like, and an acellular xeno (pig)-dermal matrix with excellent performances and wide purposes is prepared and obtained. In the method, keratinase processing and secondary enzyme treatment are employed, the method has low environmental pollution, and the acellular xeno (pig)-dermal matrix processed through the method has advantages of complete collagen three-dimensional structure, good moisture permeability, high porosity and excellent mechanical properties. The acellular xeno-dermal matrix can be applied in the burn and plastic surgery fields.

Owner:SHANDONG UNIV

Method for degrading naphthalene in soil through combination of microwave induction and catalytic oxidation

ActiveCN110961450AImprove adsorption capacityOxidative decomposition is goodContaminated soil reclamationPolycyclic aromatic hydrocarbonPtru catalyst

The invention discloses a method for degrading naphthalene in soil through the combination of microwave induction and catalytic oxidation. The method is characterized by comprising the following steps: mixing 5g of naphthalene-polluted soil sample, 10-50mg of catalyst and 0.6-1.0 g of distilled water, adding the above materials into a polytetrafluoroethylene reactor, and degrading the materials ina microwave digestion instrument for degradation, wherein the concentration of the soil sample is that 10mg of naphthalene is contained in every 1kg of soil, the microwave frequency is 2450MHz, the output power is 400-700W, the output pressure is 0.2 Mpa, and the microwave induction treatment time is 2-10min. A single microwave induction method and a catalytic oxidation method are combined, and the purpose of degrading polycyclic aromatic hydrocarbon in the soil through the combination of microwave induction and catalytic oxidation. The method is simple and easy to implement and has a good degradation effect on the refractory typical pollutant polycyclic aromatic hydrocarbon naphthalene in the soil.

Owner:上海达恩贝拉环境科技发展有限公司

Preparation method of catalytic oxidizer for metal pollutants in water

InactiveCN103041812AEfficient catalytic oxidationFast catalytic oxidationMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationIron powderCatalytic oxidation

The invention relates to a preparation method of a catalytic oxidizer for meal pollutants in water. The preparation can efficiently and quickly catalyze and oxidize the metal pollutants such as arsenic, ferrum, manganese and hexavalent chromium in the water, and then is adsorbed and filtered in order to realize the purpose of removing the metal pollutants. The preparation method of the catalytic oxidizer for the metal pollutants in the water comprises the following steps: 1) powdering: powdering high-level zeolite to 200 to 325 meshes; 2) mixing: fully mixing 60 to 80% of powdered zeolite, 10 to 20% of iron oxide powder, and 10 to 20% of high-quality coal dust with 200 to 325 meshes, so as to obtain the mixed powder; 3) forming: transferring the mixed powder into a ball forming mill, spraying by 1 to 3% of modified starch solution in order to centrifugally roll the composite powder into spherical particles of 1 to 4mm; and 4) roasting: naturally drying the spherical particles of the composite powder, transferring in a kiln furnace to roast for 30 to 60 minutes at 100 to 120 DEG C, and then roasting for 120 to 150 minutes at high temperature of 600 to 700 DEG C.

Owner:姜英杰

Novel device for preventing edge of colored tape from silk running and fuzzing

InactiveCN107541885AExtended service lifeImprove printing efficiencyMechanical cleaningPressure cleaningDust collectorElectrical and Electronics engineering

The invention discloses a novel device for preventing an edge of a colored tape from silk running and fuzzing. The novel device comprises a fuzzing-prevention colored tape box, wherein the tops of twosides of the fuzzing-prevention colored tape box are connected with colored tape conveying connectors; the tops of the colored tape conveying connectors are connected with the colored tape; the bottom end of the outer part of the fuzzing-prevention colored tape box is fixedly connected with a dust-removing control box; a ventilation opening is formed in the bottom end of the dust-removing controlbox; one end, which is far away from the fuzzing-prevention colored tape box, of the ventilation opening is communicated with a small-size dust collector; left and right sides of a dust collection opening of the small-size dust collector are communicated with fuzz removing and dust collection devices through a first dust collection pipe and a second dust collection pipe respectively. The novel device belongs to the technical field of printing equipment. By adopting the novel device for preventing the edge of the colored tape from silk running and fuzzing, the problems that the edge of an existing colored tape easily has the silk running and easily winds a colored tape wheel after being fuzzed, so that the colored tape wheel is clamped and the colored tape cannot be normally retracted backto the colored tape box are solved, the service life of the colored tape is prolonged to a certain extent and the printing efficiency of the colored tape is improved to a certain extent.

Owner:福建省闽清百园食品有限公司

Method for detecting total phosphorus in water by ammonium molybdate spectrophotometry

InactiveCN108918442AAchieve the purpose of removingImpact detectionColor/spectral properties measurementsSpectrophotometryChemistry

The invention belongs to the technical field of spectrophotometry, and particularly relates to a method for detecting total phosphorus in water by ammonium molybdate spectrophotometry. A problem thatsilica formed by a silicon element in a water sample affects the test accuracy during the testing of the phosphorus content by ammonium molybdate spectrophotometry exists in the prior art. The methodin the invention comprises the following steps: [1] digesting the water sample to obtain a digestion solution; [2] adding ascorbic acid, an antimony salt and ammonium molybdate to the digestion solution to obtain a blue complex solution; and [3] testing the blue complex solution by spectrophotometry to obtain the phosphorus content of the water sample, wherein the digestion solution is also treated, between step [1] and step [2], as follows: [1-1] quantitatively transferring the digestion solution, adjusting the pH value to 3-5, adding MgO to the digestion solution, and carrying out a stirringreaction; [1-2] adjusting the pH value of the digestion solution to 1-3, and making the volume of the digestion solution reach a constant volume; and [1-3] standing the digested solution having the constant volume, and filtering the obtained solution by an ultrafiltration membrane to remove obtained precipitate. The method is suitable for water quality testing.

Owner:郑州市通标环境检测有限公司

Lithium battery recycling equipment and recycling method thereof

ActiveCN113319098AEasy to replaceEfficient workSolid waste disposalReclaiming serviceable partsStructural engineeringMechanical engineering

The invention discloses lithium battery recycling equipment and a recycling method thereof. The lithium battery recycling equipment comprises a first guide rail; a second guide rail is installed at one side end of the first guide rail; an electric sliding block is installed on the upper end face of the second guide rail in a sliding mode; a side plate is vertically installed on the upper end face of the electric sliding block; a plurality of installation shells are installed on the surface of one side of the side plate; a sliding block is slidably installed on the upper end face of the first guide rail; installation columns are symmetrically installed on the upper end face of the sliding block through screws; the upper end faces of the two installation columns are connected to the lower end face of a third guide rail through screws; an electric telescopic rod is welded and fixed to the upper end face of the third guide rail; and a top plate is vertically installed on the upper end face of the electric telescopic rod. According to the lithium battery recycling equipment and the recycling method thereof, the whole operation is convenient and fast, the attaching degree is high, the defect that an existing peeling device cannot remove shells of lithium battery of various thicknesses in an attached manner can be effectively overcome, and the lithium battery recycling equipment has the advantages of being convenient and fast to install and replace.

Owner:东莞市亿晟包装制品有限公司

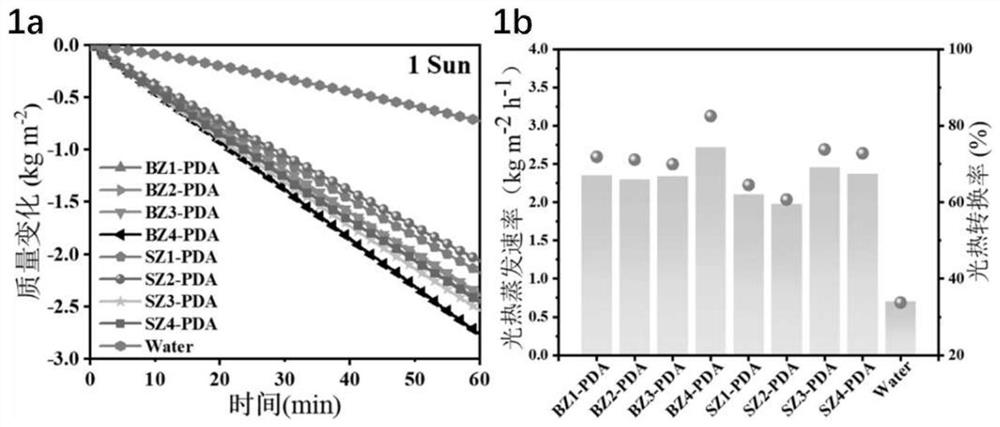

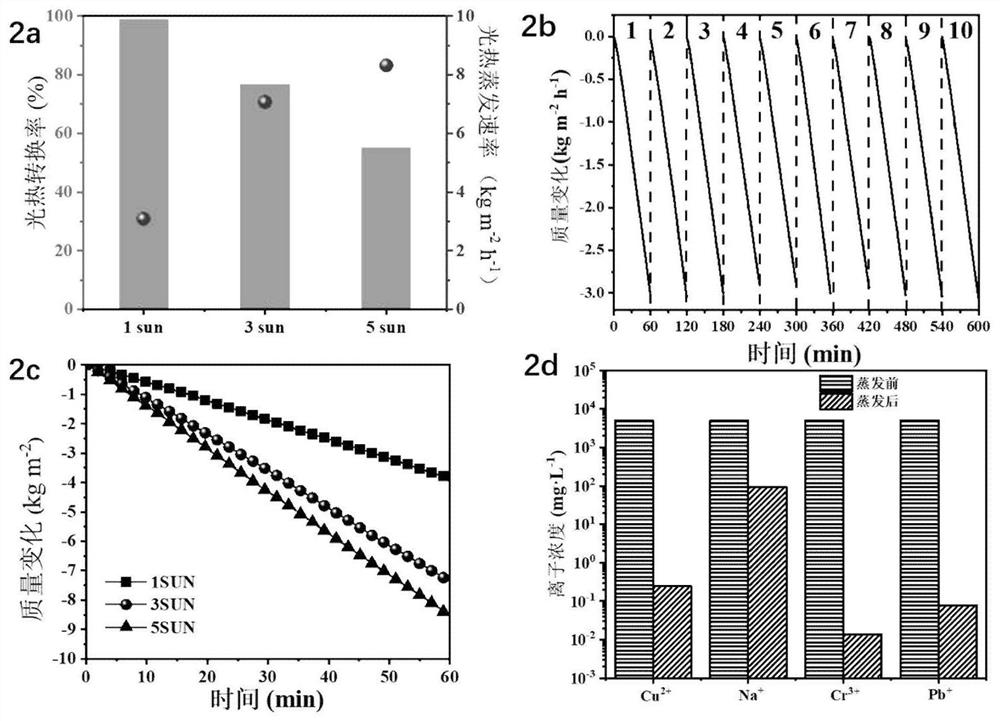

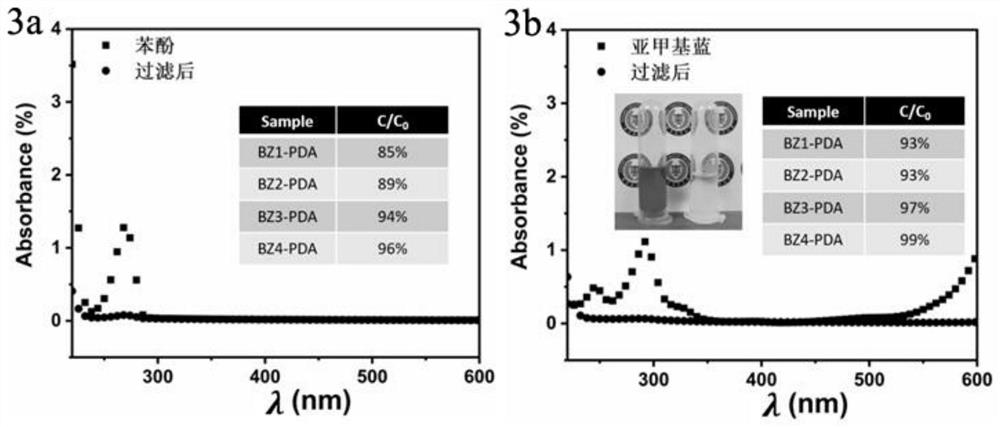

Wood-based composite material for photo-thermal purification of sewage as well as preparation method and application of wood-based composite material

ActiveCN113815072AStrong adsorption propertiesAchieve adsorptionGeneral water supply conservationWood treatment detailsMetal-organic frameworkPhotothermal conversion

The invention discloses a wood-based composite material for photo-thermal purification of sewage as well as a preparation method and application of the wood-based composite material, and belongs to the technical field of photo-thermal conversion. According to the method, after wood is subjected to vacuum impregnation through an MOF precursor solution, a metal organic framework material grows in wood pore channels, and the wood-based composite material for photo-thermal evaporation and heavy metal ion removal is prepared. The polydopamine photo-thermal material in the composite material can convert a solar spectrum into heat energy, so that purified water evaporation is efficiently carried out; the wood substrate can effectively reduce heat conduction loss, heat concentration is achieved, and the photo-thermal conversion efficiency is improved; in addition, the hydrophobic property of the wood accelerates the transmission and evaporation of water; the porous MOF nano material can adsorb pollutant ions. The aim of removing ions in the sewage is fulfilled. The composite material provided by the invention is low in preparation raw material cost, simple and convenient in process, high in repeatability and easy for large-scale production, and has a wide application prospect in multidisciplinary crossing fields such as seawater desalination and sewage purification.

Owner:NANJING FORESTRY UNIV

Image rain removing method and system based on wavelet analysis

InactiveCN106023112AAchieve the purpose of removingAccurate and effective removalImage enhancementImage analysisDynamic featureDecomposition

The invention relates to an image rain removing method and system based on wavelet analysis, and belongs to the technical field of image processing. The method comprises the steps that a) according to wavelet analysis, layer decomposition is carried out on a video frame image, image information of decomposed layers is analyzed, and a layer including background and color information, a layer including raindrop noise and a layer including image texture and object edge information are obtained; b) double-side filtering side-maintaining denoising is carried out on the layer including the raindrop noise; and c) a fusion coefficient matrix is calculated, wavelet fusion is carried out on the layer including background and color information, the layer including raindrop noise and the layer including image texture and object edge information according to the fusion coefficient matrix, and according to a fusion result, the image is reconstructed to obtain a rain-removed image. According to the method and system, interference of dynamic features is avoided, and the raindrops can be removed more accurately and more effectively.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

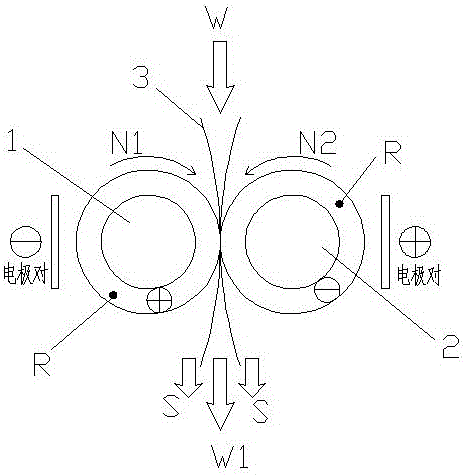

Device for rapidly removing heavy metal in sludge and removal method of device

ActiveCN106219917AAchieve the purpose of removingSludge treatment by de-watering/drying/thickeningWater contaminantsCircular discSludge

The invention discloses a device for rapidly removing heavy metal in sludge and a removal method of the device. The device comprises a cathode and an anode which are used for forming an electric field after voltage is applied, and an electrolytic chamber located between the cathode and the anode; the cathode and the anode work in a manner of rotary electrodes; a rotary direction of the rotary electrode of the anode is a clockwise direction and the rotary direction of the rotary electrode of the cathode is an anticlockwise direction; the electrolytic chamber is pressurized by adopting one of a filter pressing manner of a sludge belt type filter press or a rotary circular disc manner of a sewage treatment biological rotary table process, so that the distance between the cathode and the anode is 1mm to 3mm; electrolyte in the electrolytic chamber is a digested solution of the sludge so that electrically deposited matters are concentrated in the digested solution.

Owner:宁波市海智材料产业创新研究院 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com