Lithium battery recycling equipment and recycling method thereof

A technology for recycling and lithium batteries, which is applied in the field of lithium battery recycling and recycling equipment and its recycling, can solve the problems of inability to fit and remove lithium battery shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

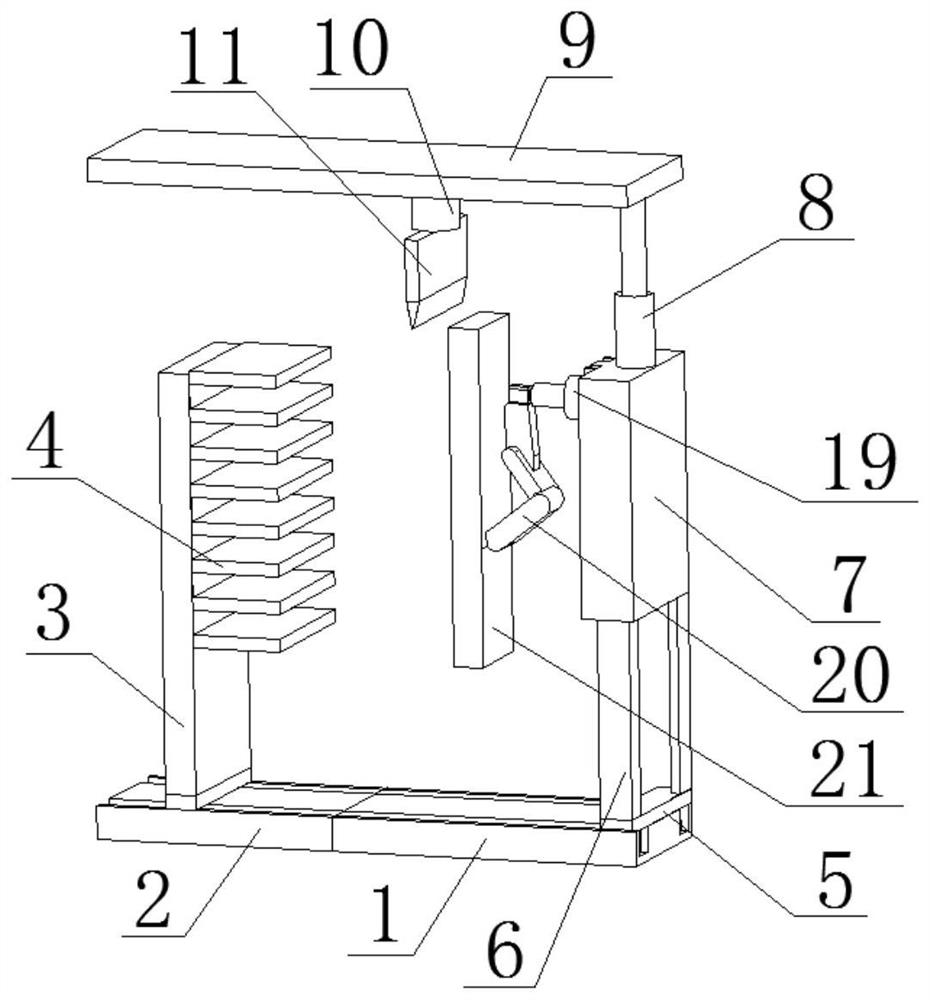

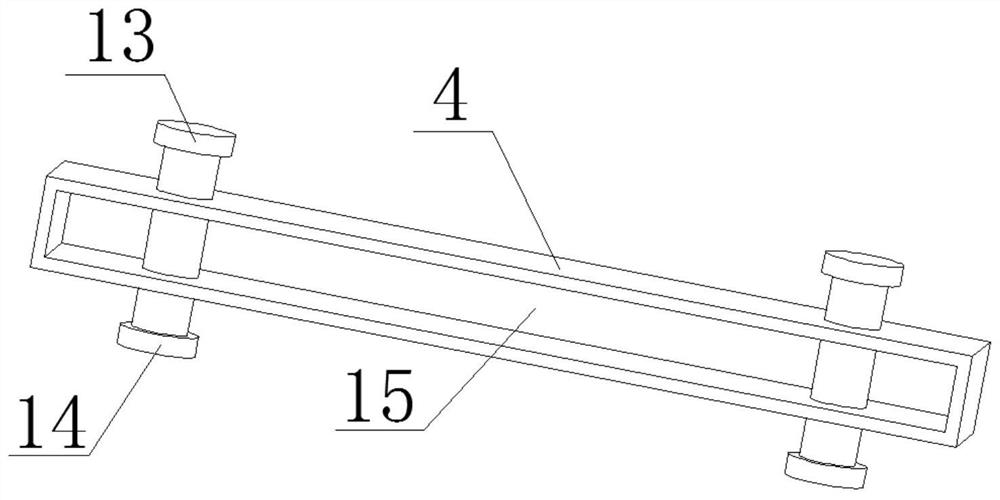

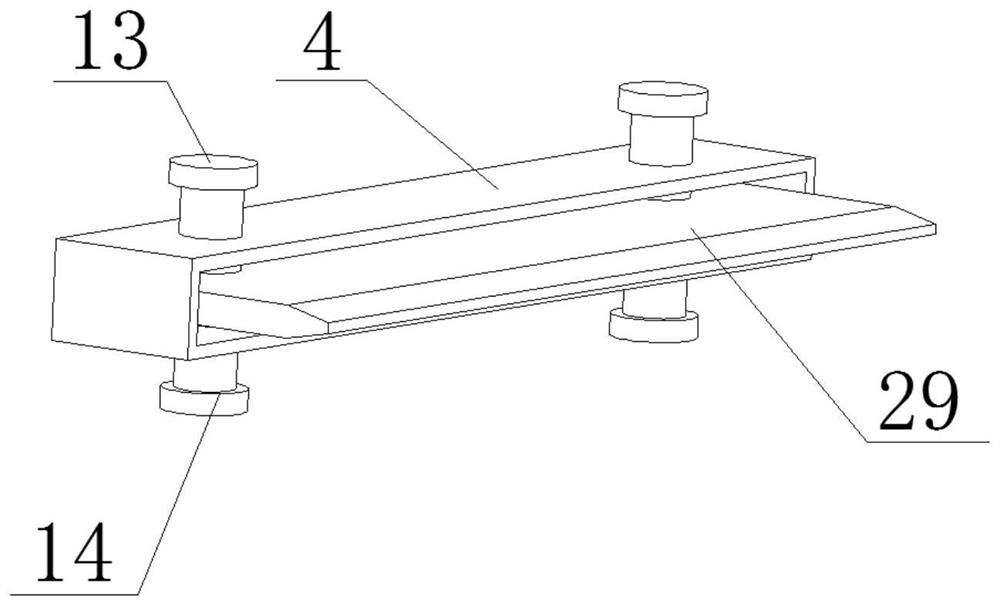

[0036] The thickness of the lithium battery case to be cut is 0.8mm-1.0mm.

[0037] In the peeling device, the default position of the slider 5 is the end of the first guide rail 1 away from the second guide rail 2, the default position of the slider on the surface of the second guide rail 2 is the end of the second guide rail 2 away from the first guide rail 1, and the side extension column The default state of 19 is the fully retracted state of the side extension column 19; the default state of the second telescopic column 10 is the fully retracted state of the second telescopic column 10; the default state of the electric telescopic column 8 is the fully extended state of the electric telescopic column 8; The arm 20 can rotate at multiple angles, and the control of the mechanical arm 20 is realized through the programming of the programmer, wherein the essential function is at least 180 ° of flipping, and the position of each electric slider is installed on the protrusion 25...

Embodiment 2

[0040] The thickness of the lithium battery case to be cut is 1.01mm-1.2mm.

[0041]In the peeling device, the default position of the slider 5 is the end of the first guide rail 1 away from the second guide rail 2, the default position of the slider on the surface of the second guide rail 2 is the end of the second guide rail 2 away from the first guide rail 1, and the side extension column The default state of 19 is the fully retracted state of the side extension column 19; the default state of the second telescopic column 10 is the fully retracted state of the second telescopic column 10; the default state of the electric telescopic column 8 is the fully extended state of the electric telescopic column 8; The arm 20 can rotate at multiple angles, and the control of the mechanical arm 20 is realized through the programming of the programmer, wherein the essential function is at least 180 ° of flipping, and the position of each electric slider is installed on the protrusion 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com