Device for rapidly removing heavy metal in sludge and removal method of device

A technology for heavy metals and sludge, applied in sludge treatment, electrochemical sludge treatment, chemical instruments and methods, etc., can solve the problems of low electric field action efficiency, fast and effective removal of difficult sludge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

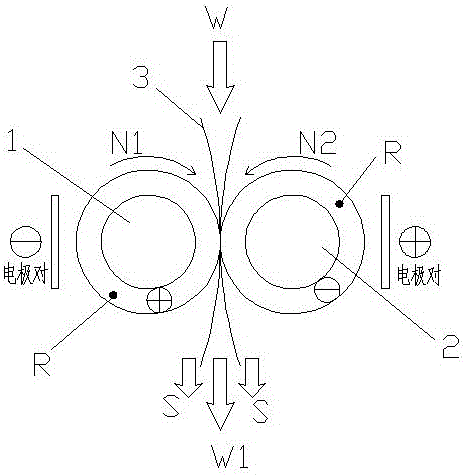

[0023] figure 1 It is a schematic diagram of the principle of the embodiment of the present invention.

[0024] The reference signs are as follows: 1 is the anode, N1 indicates the direction of rotation of the anode, 2 is the cathode, N2 indicates the direction of rotation of the cathode, 3 is the spacer, W indicates the direction of entry of sludge containing electroplating wastewater, W1 indicates the direction of dehydration The direction of sludge discharge, S represents the water extracted from the sludge.

[0025] figure 1 It is a schematic diagram of the working principle of the present invention. As shown in the figure, a device for quickly removing heavy metals in sludge of the present invention includes a cathode 2 and an anode 1 that are used to form an electric field after applying a voltage and between the cathode 2 and the anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com