Wood-based composite material for photo-thermal purification of sewage as well as preparation method and application of wood-based composite material

A composite material and photothermal technology, applied in chemical instruments and methods, wood impregnation, wood treatment, etc., can solve the problems of inability to obtain natural liquid water, improve hydrophilicity and light absorption characteristics, accelerate transmission and evaporation, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

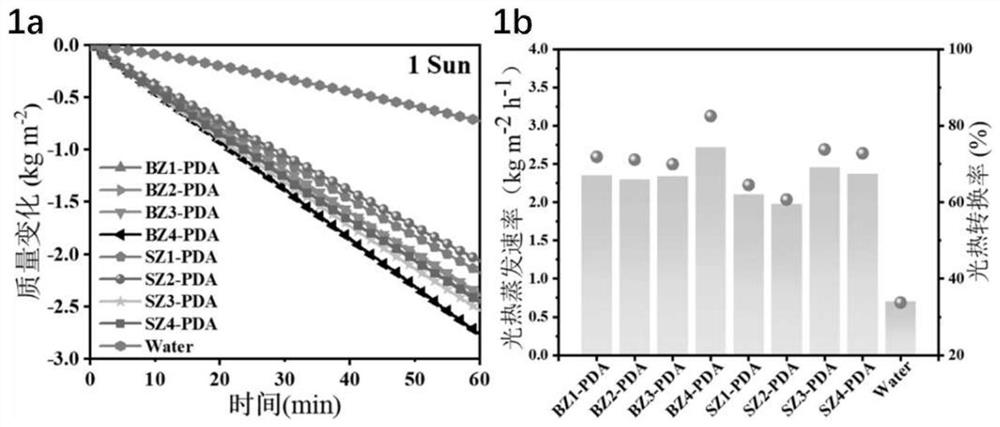

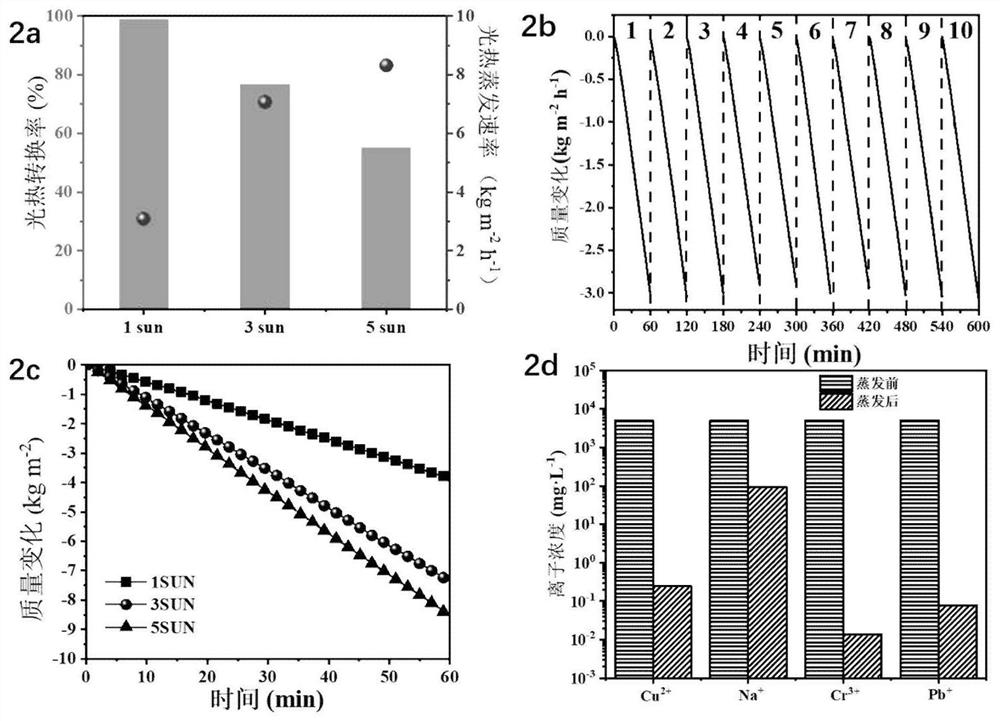

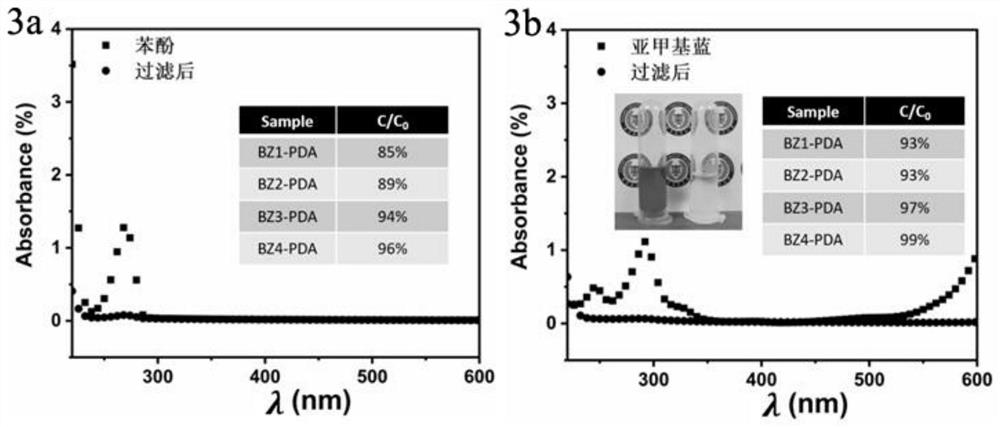

[0032] A method for preparing a wood-based composite material for photothermal purification of sewage, comprising the following steps:

[0033] (1) Add 9.5g of sodium chloroacetate and 1.2g of sodium hydroxide into 70mL of deionized water and stir evenly, put in balsa wood with a size of 1*1*0.5cm, and heat in a water bath at 80°C for 1h in a reaction kettle. Then take out the wood and put it into deionized water to stir and wash for 24 hours. After cleaning, use a pH meter to compare the pH of the cleaned solution with that of pure water. Carboxylation treated wood for later use;

[0034] (2) Dissolve 9.52g (0.032mol, 4 concentration) zinc nitrate hexahydrate in 20g methanol and 3g deionized water, stir evenly, put the dry wood after the carboxylation treatment into the above solution and place it in a closed container. After vacuum pumping, vacuum impregnation for 1-2h. Subsequently, 13.4g (0.16mol, 4 concentrations) of 2-methylimidazole (2-MeIm) was dissolved in 20g of me...

Embodiment 2

[0039] A method for preparing a wood-based composite material for photothermal purification of sewage, comprising the following steps:

[0040] (1) Add 9.5g of sodium chloroacetate and 1.2g of sodium hydroxide into 70mL of deionized water and stir evenly, put in fir trees with a size of 1*1*0.5cm, and heat in a water bath at 80°C for 1h in a reaction kettle. Then take out the wood and put it into deionized water to stir and wash for 24 hours. After cleaning, use a pH meter to compare the pH of the cleaned solution with that of pure water. Carboxylation treated wood for later use;

[0041] (2) Dissolve 7.15g (0.024mol, 3 concentration) zinc nitrate hexahydrate in 20g methanol and 3g deionized water, stir well, put the dry wood after the carboxylation treatment into the above solution and place it in a closed container. After vacuum pumping, vacuum impregnation for 1-2h. Subsequently, 10.1g (0.12mol, 3 concentrations) of 2-methylimidazole (2-MeIm) was dissolved in 20g of metha...

Embodiment 3

[0045] A method for preparing a wood-based composite material for photothermal purification of sewage, comprising the following steps:

[0046] (1) Add 9.5g of sodium chloroacetate and 1.2g of sodium hydroxide into 70mL of deionized water and stir evenly, put in balsa wood with a size of 1*1*0.5cm, and heat in a water bath at 80°C for 1h in a reaction kettle. Then take out the wood and put it into deionized water to stir and wash for 24 hours. After cleaning, use a pH meter to compare the pH of the cleaned solution with that of pure water. Carboxylation treated wood, denoted as B+S;

[0047] (2) Dissolve 2.38g (0.008mol, 1 concentration) zinc nitrate hexahydrate in 20g methanol and 3g deionized water, stir evenly, put the dry wood after the carboxylation treatment into the above solution and place it in a closed container. After vacuum pumping, vacuum impregnation for 1-2h. Subsequently, 3.35g (0.04mol, 1 concentration) of 2-methylimidazole (2-MeIm) was dissolved in 20g of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photothermal conversion efficiency | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com