Three-dimensional ordered macroporous perovskite type composite metal oxide catalyst and preparation method and application thereof

A three-dimensional ordered, perovskite-type technology, applied in the field of air pollution control, can solve problems such as restricted development and biological toxicity, and achieve excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

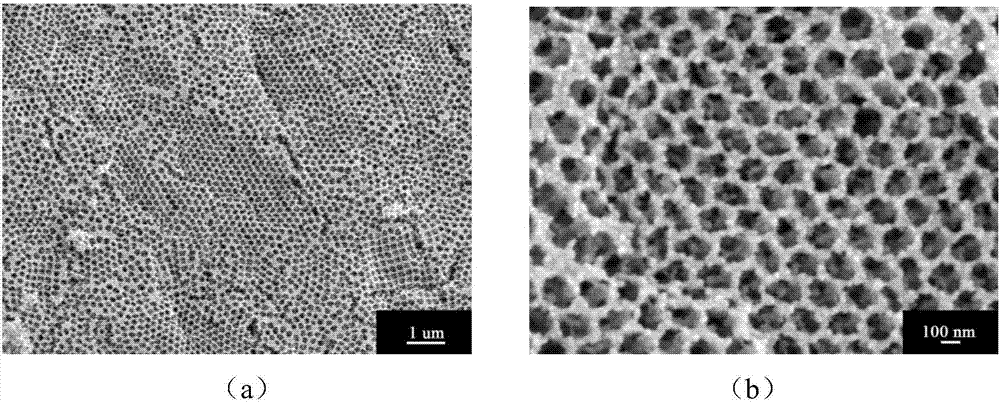

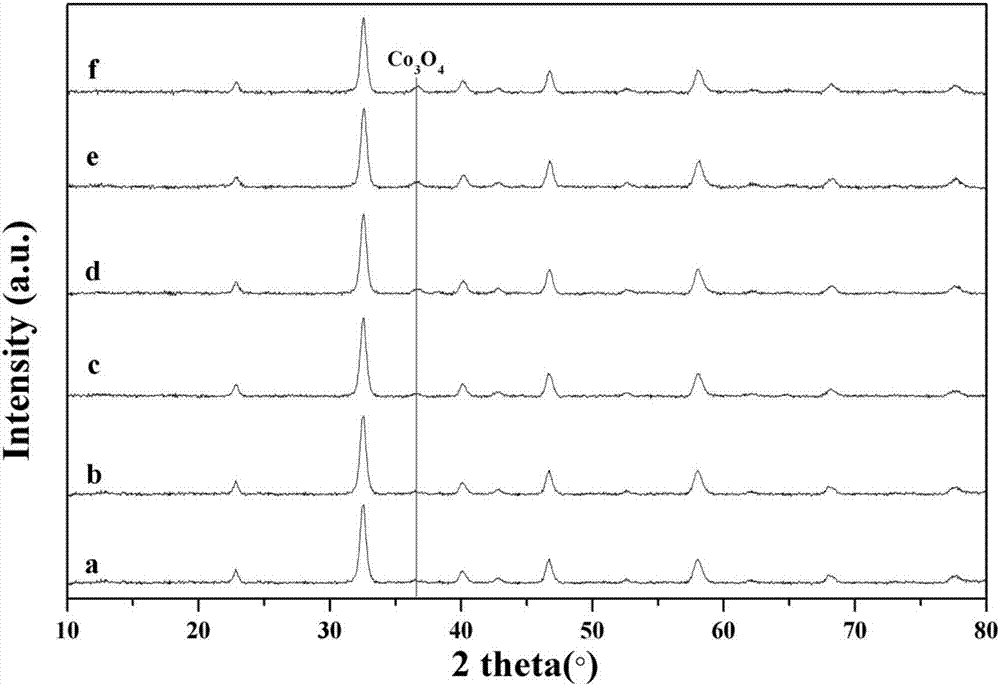

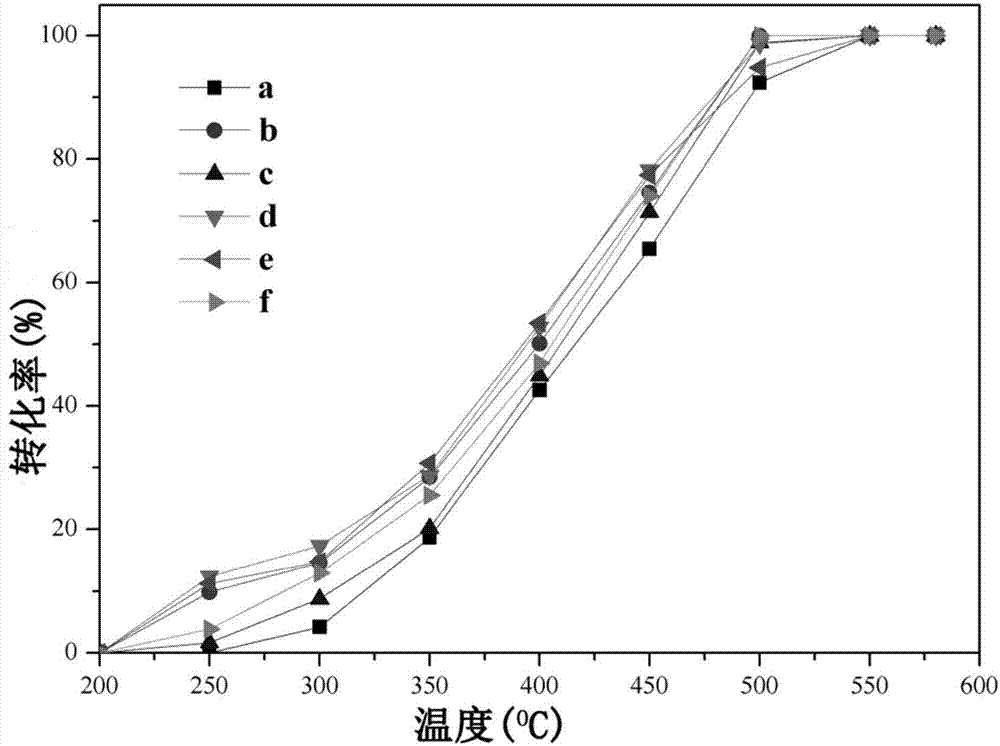

[0037] The present invention is a three-dimensional ordered macroporous perovskite composite metal oxide suitable for industrial chlorine-containing volatile organic compounds (CVOCs), a) it is a three-dimensional ordered macroporous structure in appearance; b) calcium The simplified formula of titanium ore composite metal oxide catalyst is ABO 3 , where the A position is an alkaline earth or rare earth metal (La, Sr), and the B position is a transition metal element (Fe, Co); c) supporting a transition metal oxide Co on the surface of the catalyst 3 o 4 Optimal modification is carried out, and the loading amount of transition metal oxide is 5-16wt% (wt% is the mass fraction, the same below). d) The perovskite-type metal composite oxide has a stable structure, and has excellent oxidation and chlorine resistance to chlorine-containing volatile organic pollutants. The specific steps of the preparation method are as follows:

[0038] 1) Preparation of PMMA template;

[0039] ...

Embodiment 1

[0055] Add 650mL deionized water into the three-neck flask, 2 Under the atmosphere, stir in a water bath at 70°C until the water is free of oxygen, then add 65mL of methyl methacrylate (MMA) containing 0.03wt% p-hydroxybenzoic acid, continue the reaction for 15min, and add 20mL of potassium persulfate solution with a concentration of 0.01g / mL , The reaction is about 45min. After the reaction was completed, pour it into 1800 mL deionized water and mix evenly. The resulting solution was placed in a constant temperature water bath at 70° C. for 8 hours to obtain a PMMA solid hard template.

[0056] Weigh 0.01mol of lanthanum nitrate, strontium acetate, iron nitrate and cobalt nitrate as precursors, dissolve in 7mL of ethylene glycol at room temperature, stir the solution to a clear state, add 1.5g of P123 dissolved in anhydrous methanol to the resulting solution, Stir for 1h. Add 2g PMMA to impregnate for 6h, vacuum filter and dry at room temperature. The obtained sample is in...

Embodiment 2

[0058] The preparation of PMMA template is with embodiment 1;

[0059] Weigh 0.01mol of lanthanum nitrate, strontium acetate, iron nitrate and 0.012mol of cobalt nitrate as precursors, dissolve in 7mL of ethylene glycol at room temperature, stir the solution to a clear state, add 1.5g of P123 dissolved in anhydrous methanol to the resulting solution In, stir for 1h. Add 2g PMMA to impregnate for 6h, vacuum filter and dry at room temperature. The obtained sample is in N 2 conditions, 350 ° C for 3 h; then under air conditions, 650 ° C for 4 h to obtain a three-dimensional ordered macroporous perovskite-type composite metal oxide catalyst (5wt% Co 3 o 4 / 3DOMLa 0.5 Sr 0.5 f e0.5 co 0.5 o 3 ). see figure 2 , image 3 Among them, b is its XRD spectrum and activity assay curve, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com