SiO2/TiO2 composite nanometer photocatalysis membrane for treating indoor light pollution air and preparing method thereof

A micro-pollution, treatment chamber technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve problems such as low catalytic effect and no fundamental elimination of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

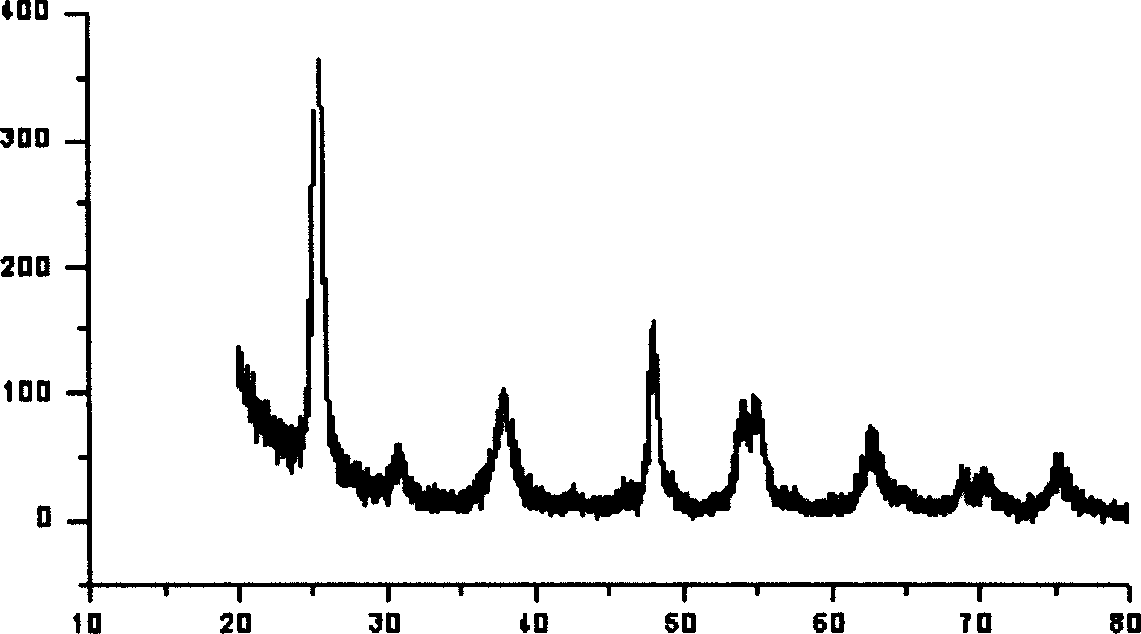

Embodiment 1

[0051] SiO 2 / TiO 2 The preparation method of catalytic membrane is described as follows:

[0052] Put 70ml of diethanolamine into 700ml of absolute ethanol, then add 0.24ml of ethyl orthosilicate, stir for 2 hours, then add 170ml of tetrabutyl titanate, continue stirring for 2 hours, add dropwise a mixed solution of 100ml of absolute ethanol and 36ml of water After stirring for two hours, 4 g of polyethylene glycol 2000 was added, ultrasonically oscillated for 30 min, and aged for one week. Put the glass fiber into hydrochloric acid, sodium hydroxide and acetone and ultrasonically clean it for 5 minutes.

[0053] Put the treated glass fiber into the aged sol, pull it at a speed of 1.8mm / min, and dry it at 100°C. Repeat fourteen times. Finally, the coated film was baked at 500°C for 1 hour, and cooled to room temperature naturally.

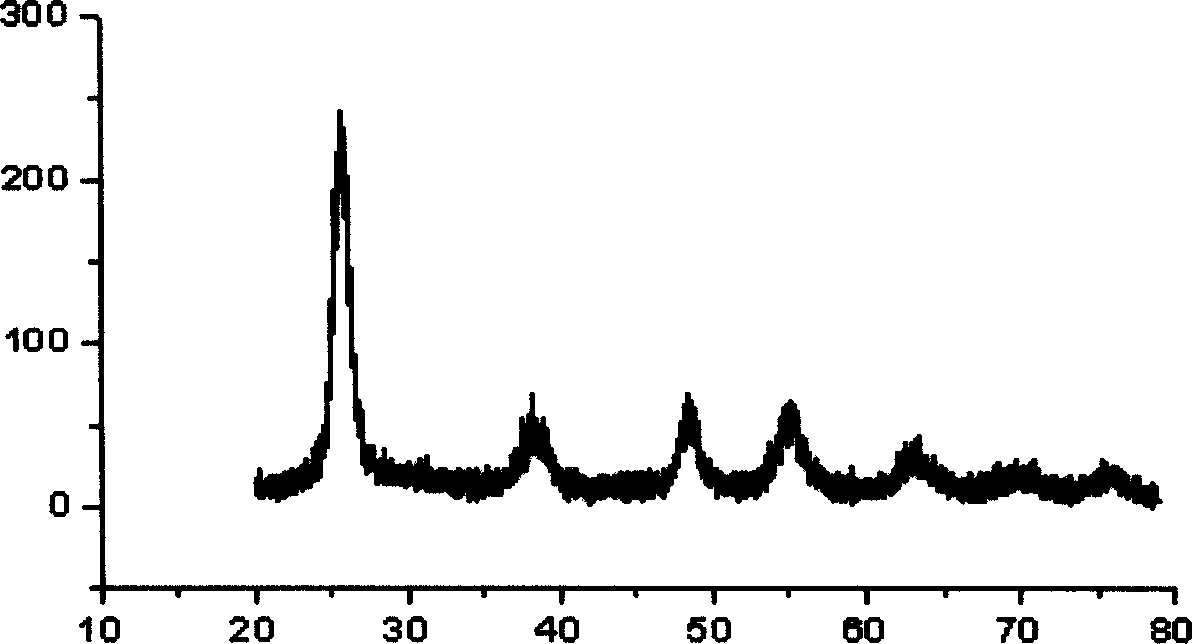

Embodiment 2

[0055] Take 50ml of diethanolamine and put it into 254ml of absolute ethanol, then add 11.8ml of ethyl orthosilicate, stir for 2h, then add 170ml of tetrabutyl titanate, continue stirring for 2h, add dropwise the mixed solution of 100ml of absolute ethanol and 27ml of water After stirring for two hours, 12 g of polyethylene glycol 2000 was added, ultrasonically oscillated for 30 min, and aged for one week. Put the glass fiber into hydrochloric acid, sodium hydroxide and acetone and ultrasonically clean it for 5 minutes.

[0056] Put the treated glass fiber into the aged sol, pull it at a speed of 1.8mm / min, and dry it at 100°C. Repeat fourteen times. Finally, the coated film was baked at 500°C for 1 hour, and cooled to room temperature naturally.

Embodiment 3

[0058] Put 100ml of diethanolamine into 772ml of absolute ethanol, then add 6ml of ethyl orthosilicate, stir for 2h, then add 170ml of tetrabutyl titanate, continue stirring for 2h, add dropwise a mixed solution of 100ml of absolute ethanol and 9ml of water, After stirring for two hours, 10 g of polyethylene glycol 2000 was added, ultrasonically oscillated for 30 min, and aged for one week. Put the glass fiber into hydrochloric acid, sodium hydroxide and acetone and ultrasonically clean it for 5 minutes.

[0059] Put the treated glass fiber into the aged sol, pull it at a speed of 1.8mm / min, and dry it at 100°C. Repeat fourteen times. Finally, the coated film was baked at 500°C for 1 hour, and cooled to room temperature naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com