Internal inclination angle testing device capable of analyzing influence of section diameter of O-shaped ring on high-pressure sealing performance

A high-pressure sealing and testing device technology, used in machine sealing ring testing, using liquid/vacuum for liquid tightness measurement, and measuring fluid acceleration and deceleration rates, etc. The selection of section diameter increases and other issues to achieve the effect of gas recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

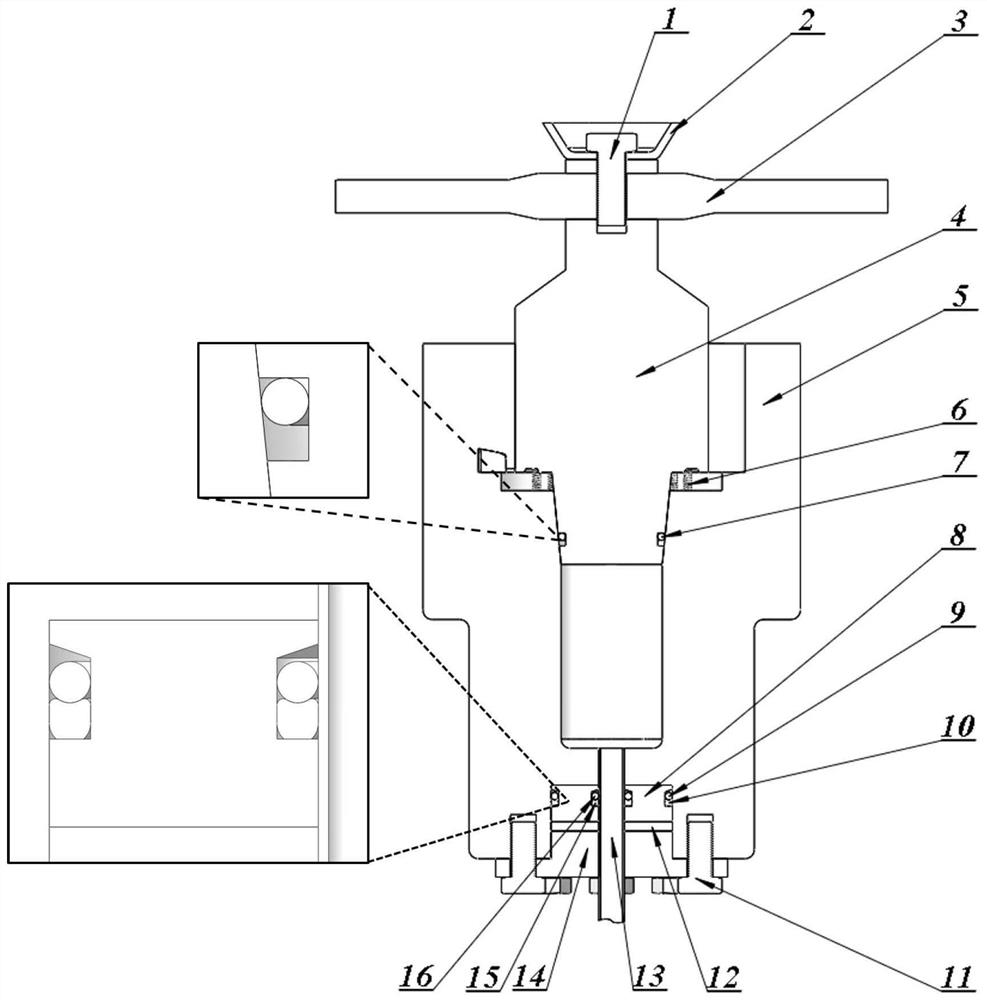

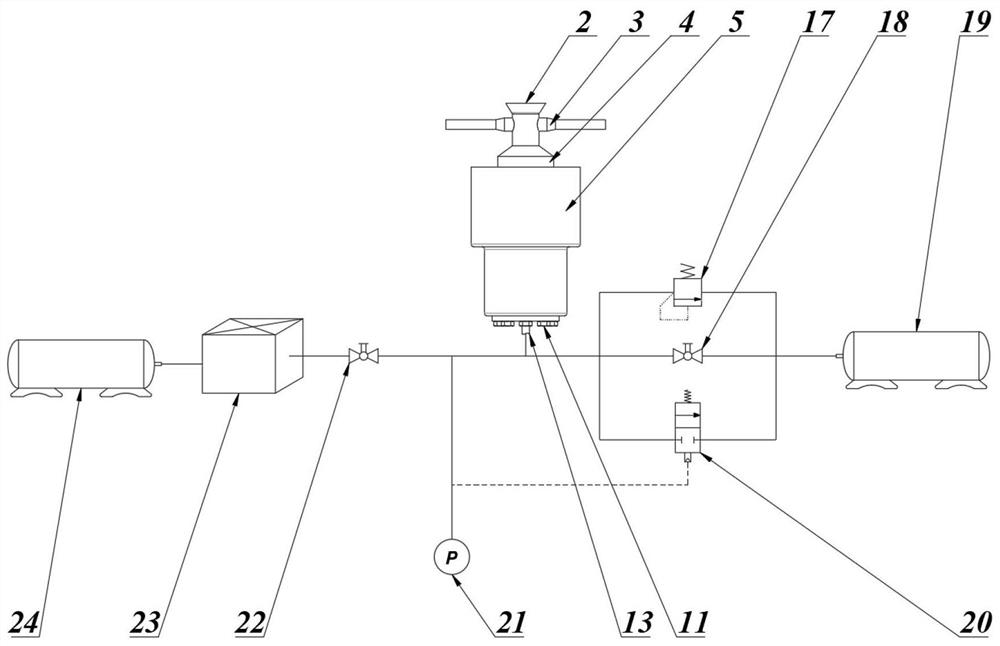

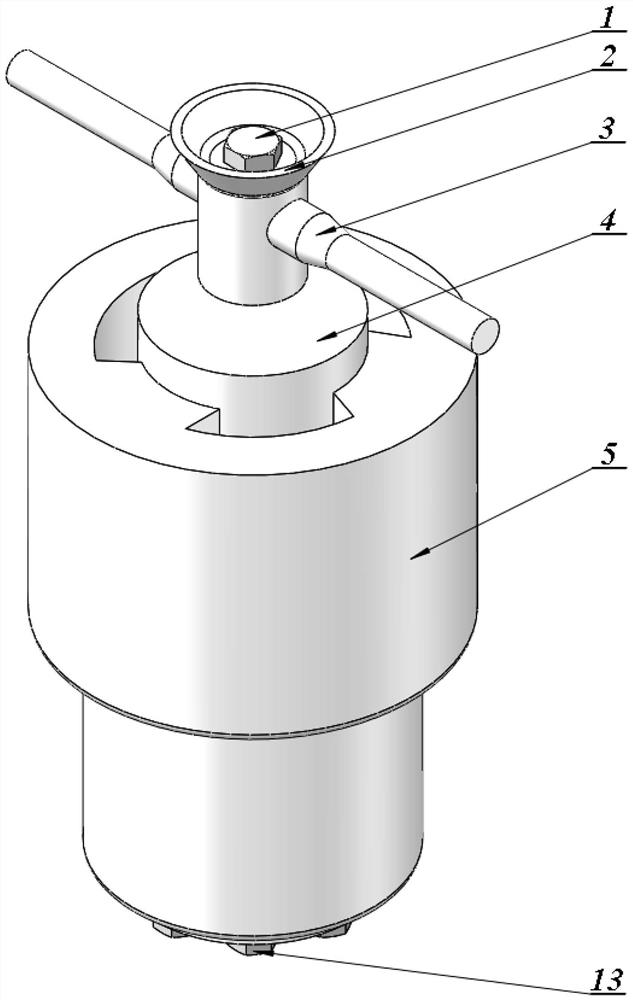

[0033] refer to figure 1 , figure 2 , image 3 , an internal inclination angle test device that can analyze the influence of the cross-sectional diameter of the O-ring on the high-pressure sealing performance, including a cylinder 5 and its movable cover 4, the middle and lower part of the movable cover 4 extends into the cylinder 5 and connects with the cylinder 5, and the movable The lower part of the cover 4 is a conical structure, and the corresponding inner wall of the cylinder body 5 is a conical surface structure matching the conical structure. The O-ring 7 for testing is arranged in the annular sealing groove on the outer wall of the conical structure. The rotation is realized by the cooperation of the protruding spiral block on the outer wall of the middle part with the spiral groove on the inner wall of the cylinder body 5 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com