Rivet for friction-self piercing riveting (F-SPR) and F-SPR connecting system thereof

A technology of riveting and welding connection and rivets, which is applied in the direction of connecting components, welding equipment, screws, etc., can solve the problems of poor stability, misalignment of rivet axis and rotation axis, etc., and achieve the effect of reducing rivet weight and ensuring rotation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

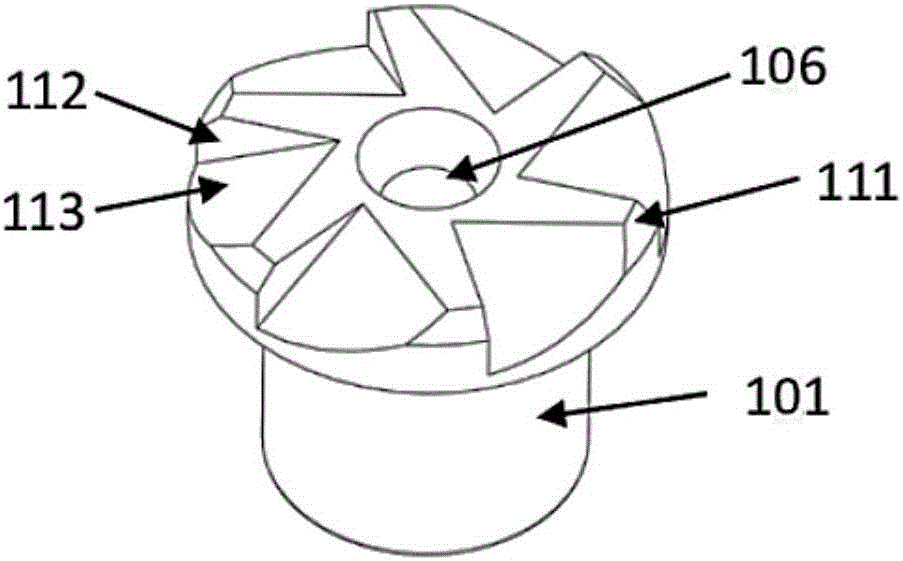

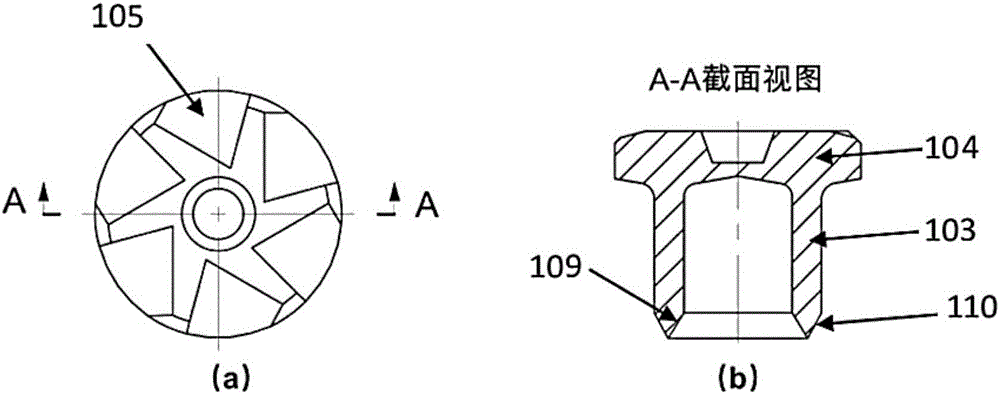

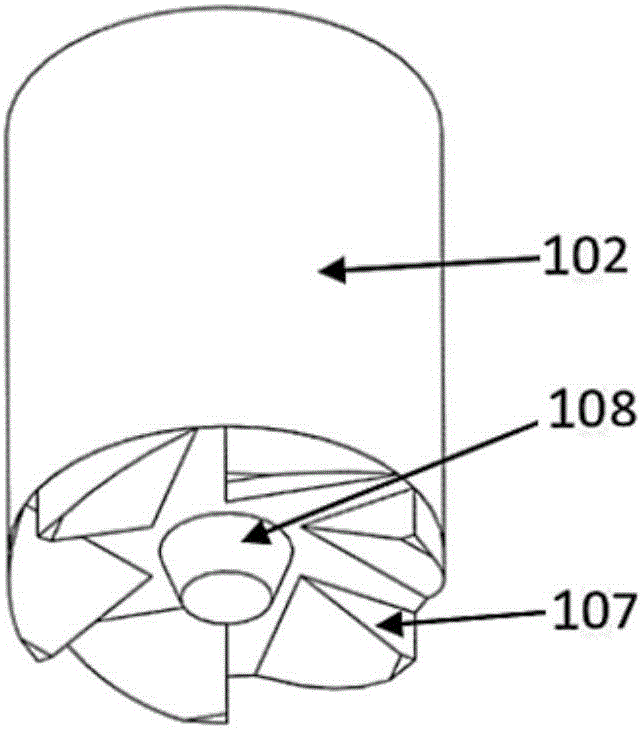

[0053] Such as Figure 1-Figure 2 As shown, this embodiment relates to a rivet 101 for self-piercing friction rivet welding, including: a semi-hollow rivet body 103 and a rivet cover 104 with six wedge-shaped notches 105 and positioning grooves 106 .

[0054] The inner diameter of the semi-hollow rivet body 103 is 4mm, the outer diameter is 6mm, and the depth is 5mm.

[0055] The diameter of the rivet cover 104 is 8mm and the height is 2mm.

[0056] The apex 109 of the wedge-shaped cone angle 110 at the bottom of the semi-tubular rivet body 103 is located between the inner wall and the outer wall, the radial distance from the inner wall is 0.4mm, and the radial distance from the outer wall is 0.6mm.

[0057] The upper edge of the rivet cover 104 is provided with a truncated cone 111 for easy loading and unloading, and the cone angle is 60°.

[0058] The six wedge-shaped notches 105 are evenly distributed on the edge of the rivet cover 104 in the circumferential direction, an...

Embodiment 2

[0077] The apex of the wedge-shaped cone angle at the bottom end of the semi-tubular rivet body 103 coincides with the outer wall.

[0078] Such as Figure 7 As shown in (a), the plate 14 in this embodiment is: aluminum alloy AA6061-T6+magnesium alloy AZ31B; the matching thickness of the plate is: 1.2mm+1.6mm.

[0079] The rivet 101 described in this embodiment, the driving rod 102 and the mold 15 with a protrusion 16 in the middle together realize the self-piercing friction rivet welding connection of the plate 14 .

[0080] Other implementation modes of this embodiment are the same as Embodiment 1.

[0081] After the self-piercing friction rivet welding process in this embodiment is over, the relative positional relationship of the rivet 101, the drive rod 102, the plate 14 and the middle belt convex die 15 is as follows Figure 7 As shown in (d), the finally obtained self-piercing friction riveting joint is as follows Figure 7 (e) shown.

[0082] Compared with the prio...

Embodiment 3

[0084] Such as Figure 8 As shown in (a), the plate 14 in this embodiment is: aluminum alloy AA6061-T6+cast aluminum Aural-2; the thickness of the plate is matched: 2mm+3mm.

[0085] The rivet 101 described in this embodiment, the driving rod 102 and the mold 15 with a flat-bottomed concave structure 17 in the middle together realize the self-piercing friction riveting connection of the plate 14 .

[0086] Other implementation modes of this embodiment are the same as Embodiment 2.

[0087] After the self-piercing friction rivet welding process in this embodiment ends, the relative positional relationship of the rivet 101, the drive rod 102, the plate 14 and the flat-bottom die 15 is as follows Figure 8 As shown in (d), the finally obtained self-piercing friction riveting joint is as follows Figure 8 (e) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com