Machine for automatic hole opening and juice extraction of coconut, and method for hole opening and juice extraction

A juice extractor, coconut technology, applied in juice extraction, shelling, pod removal, etc., can solve the problems of inconvenience to carry and eat, powder blowing away, low execution efficiency, etc., achieve fast and fast clamping process, and prevent cutter blockage. , The effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

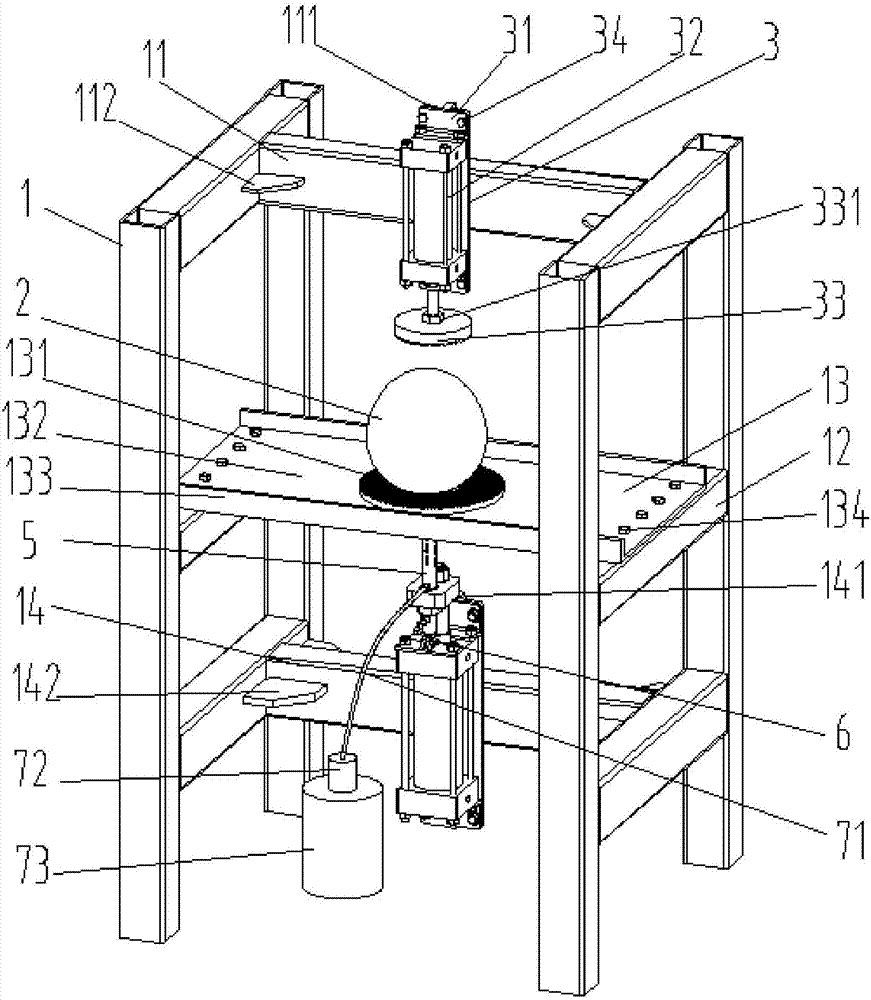

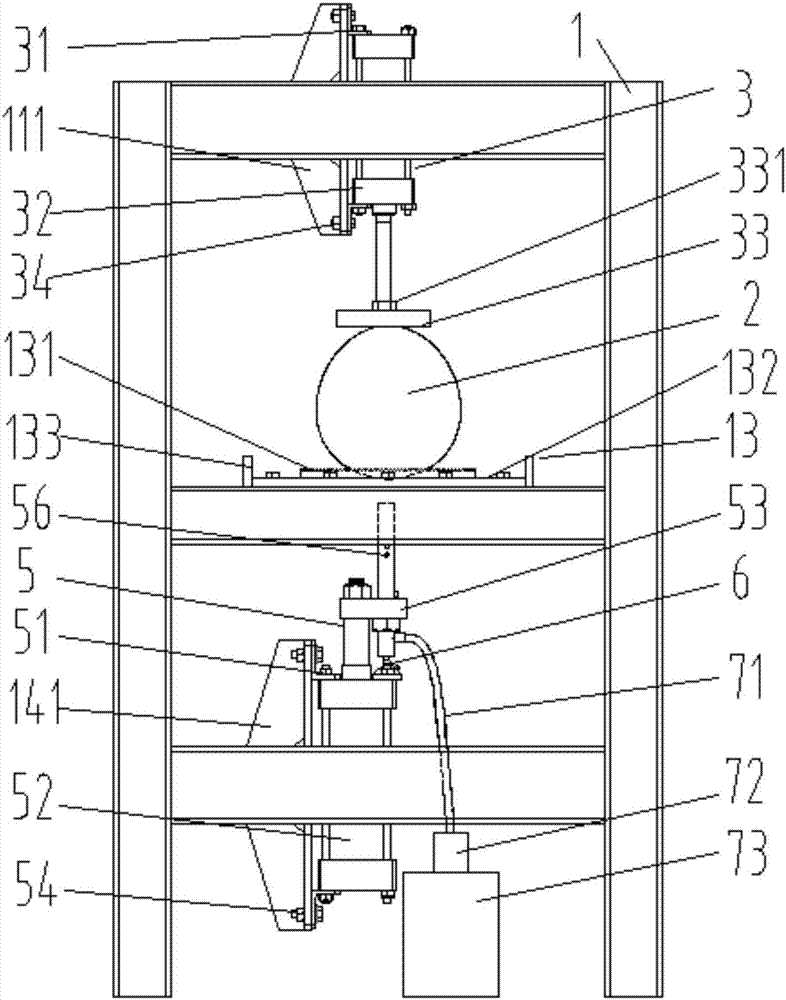

[0058] Present embodiment one provides the specific structure of a kind of automatic coconut juice extraction machine, specifically as figure 1 , figure 2 As shown, this mainly includes:

[0059] Frame 1, and the clamping mechanism 3 and the opening mechanism 5 that are arranged in the frame 1, the clamping mechanism 3 is provided with clamping cylinder 32 and clamping top plate 33, and opening mechanism 5 is provided with drilling cylinder 52, drilling tool And the slag removal assembly 6, the clamping cylinder 32 and the perforated cylinder 52 are all connected with the air source assembly 4 through the air pipeline 8, the air source assembly 4 is the pressure energy of the motor mechanical energy converted into air by the air compressor 41, and then in Under the control of the control element 45 and the cooperation of the auxiliary elements, the coconut 2 is clamped and fixed by the clamping cylinder 32. After the coconut 2 is fixed, the hole opening tool installed on the...

Embodiment 2

[0074] The second embodiment provides an assembly line system, the structure of which is basically the same as that of the automatic coconut juice extraction machine in the first embodiment. Multiple automatic coconut juice extractors can connect the supporting tray mechanisms of multiple automatic coconut juice extractors side by side, and simultaneously carry out the drilling and liquid extraction of multiple coconuts, thereby further simplifying the operation process and improving production efficiency.

Embodiment 3

[0076] The third embodiment provides a method for extracting juice by opening holes, such as Figure 7 , Figure 8 As shown, the method includes the following steps:

[0077] S1. Place the coconut 2 on the supporting tray mechanism;

[0078] S2, drive the clamping mechanism 3 to move vertically downward, so as to clamp and fix the coconut 2 on the supporting tray mechanism 13;

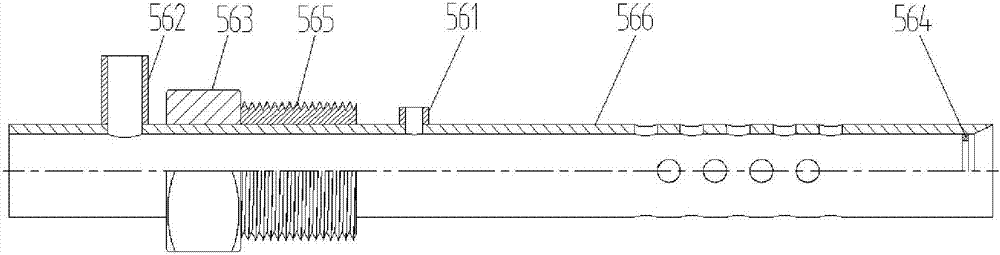

[0079] S3, drive the hole cutter 56 to move vertically upwards to punch holes at the bottom of the coconut 2. When the hole cutter 56 is inserted into the inside of the coconut 2, the peel 22 inside the coconut 2 is concentrated in the hole cutter 56, and is positioned at the hole. Between the hole cutter 56 and the slag removal top plate 65 of the slag removal assembly 6;

[0080] S4, drive the hole cutter 56 to move vertically downward, so that the hole cutter 56 is taken out from the inside of the coconut 2, and the coconut milk 21 inside the coconut 2 flows out along the inside of the hole cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com