Patents

Literature

448 results about "Cocos nucifera" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The coconut tree (Cocos nucifera) is a member of the palm tree family and the only known living species of the genus Cocos. The term "coconut" (or the archaic "cocoanut") can refer to the whole coconut palm, the seed, or the fruit, which botanically is a drupe, not a nut.The term is derived from the 16th-century Portuguese and Spanish word coco, meaning 'head' or 'skull' after the three ...

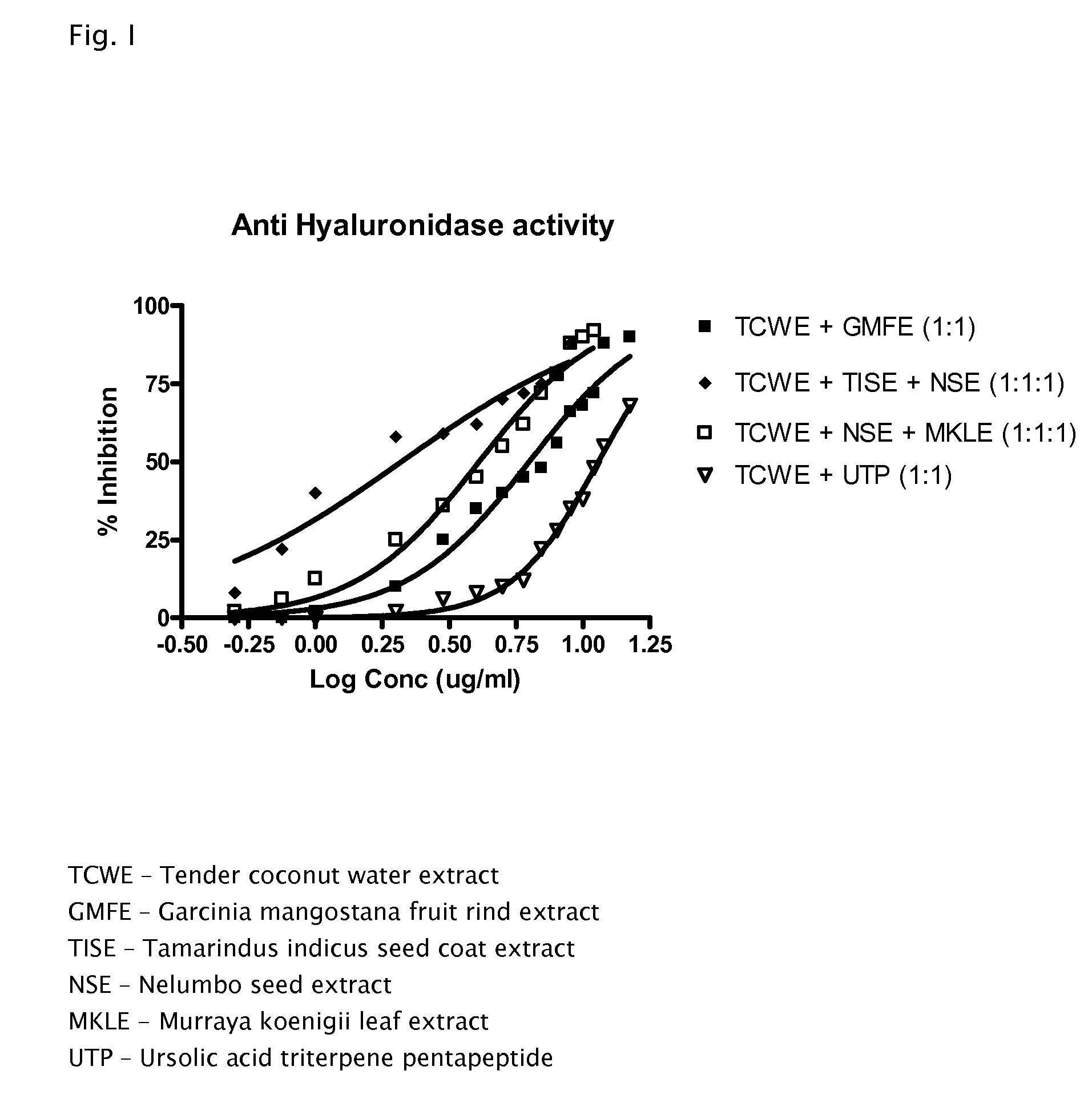

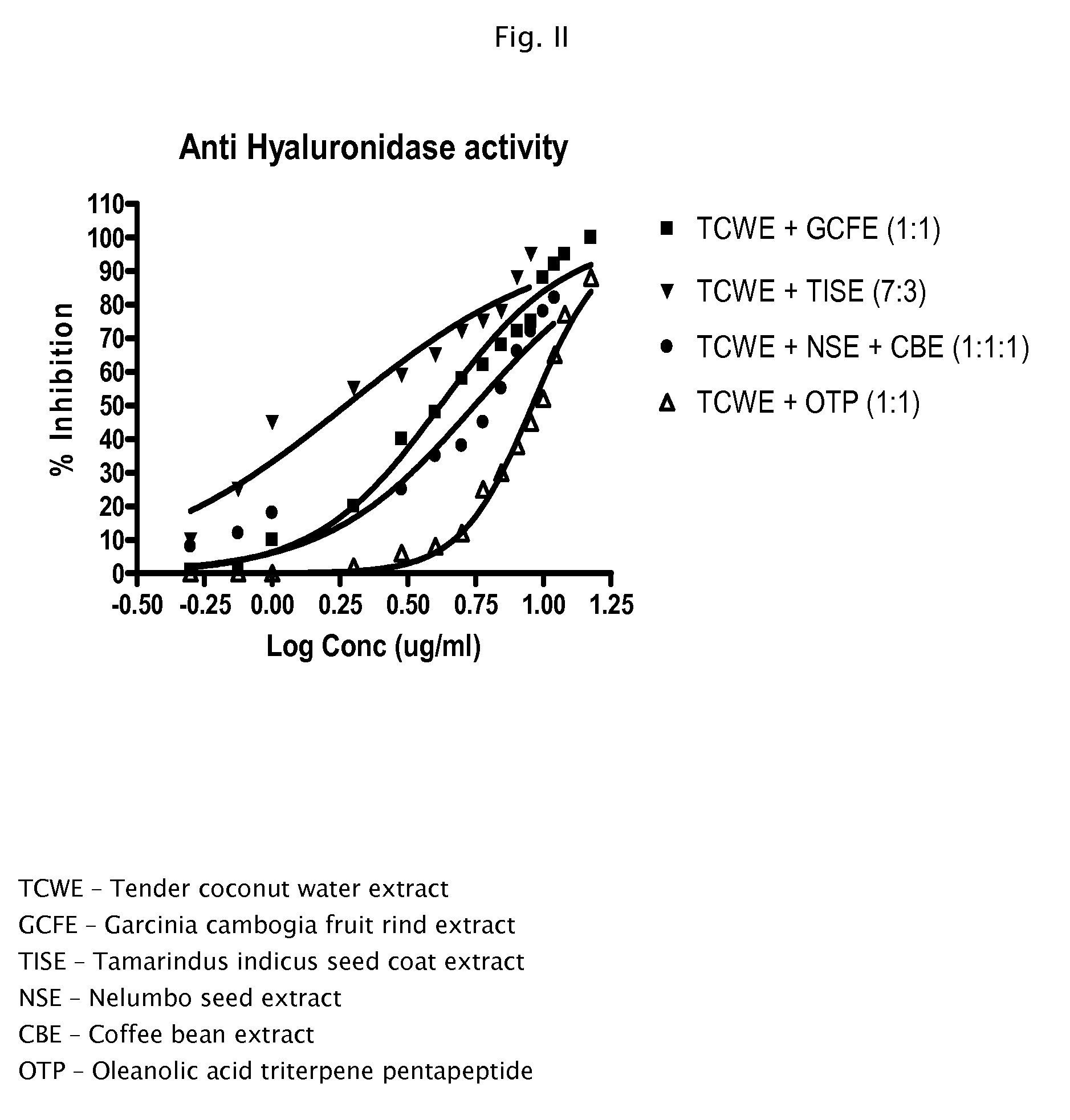

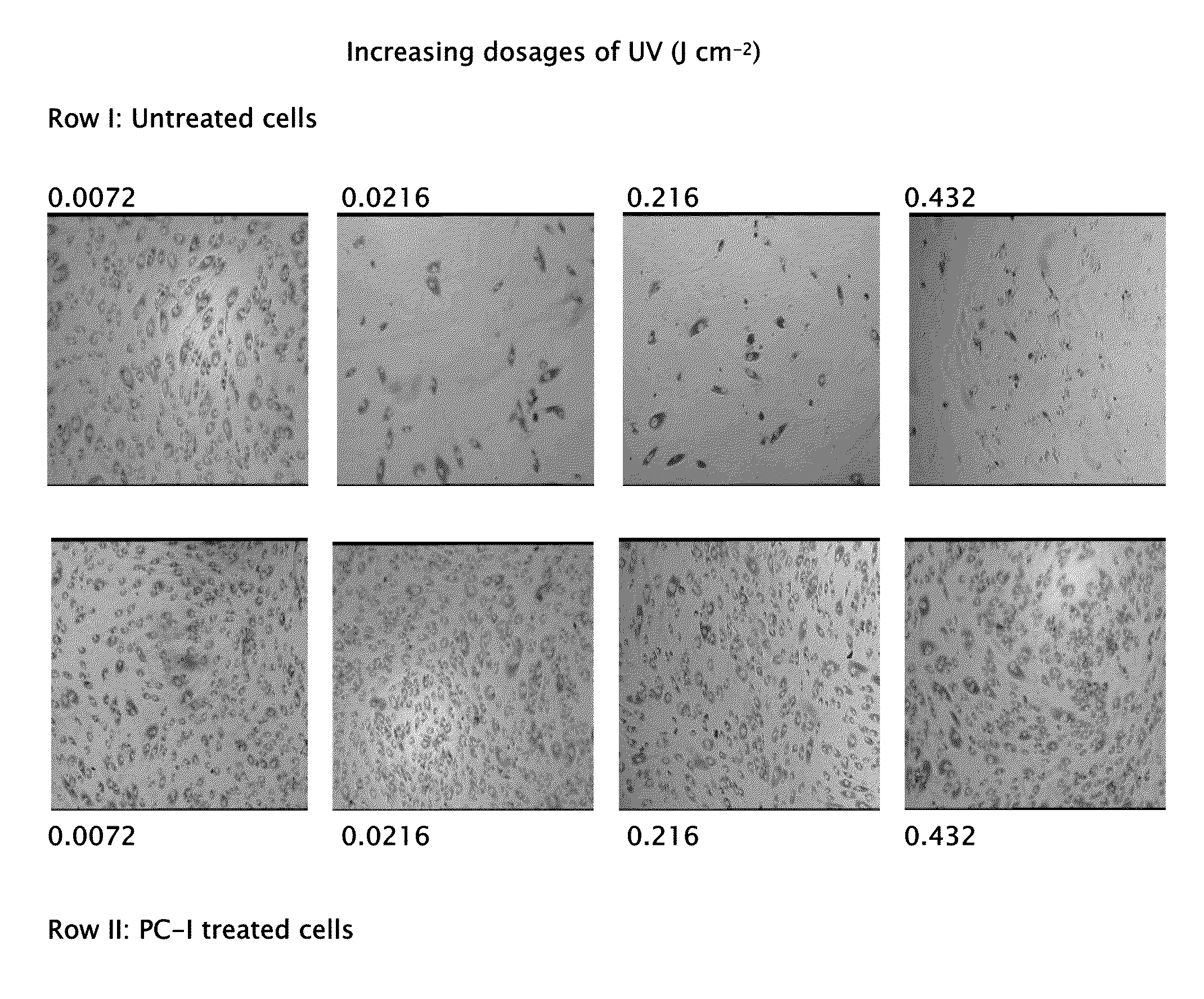

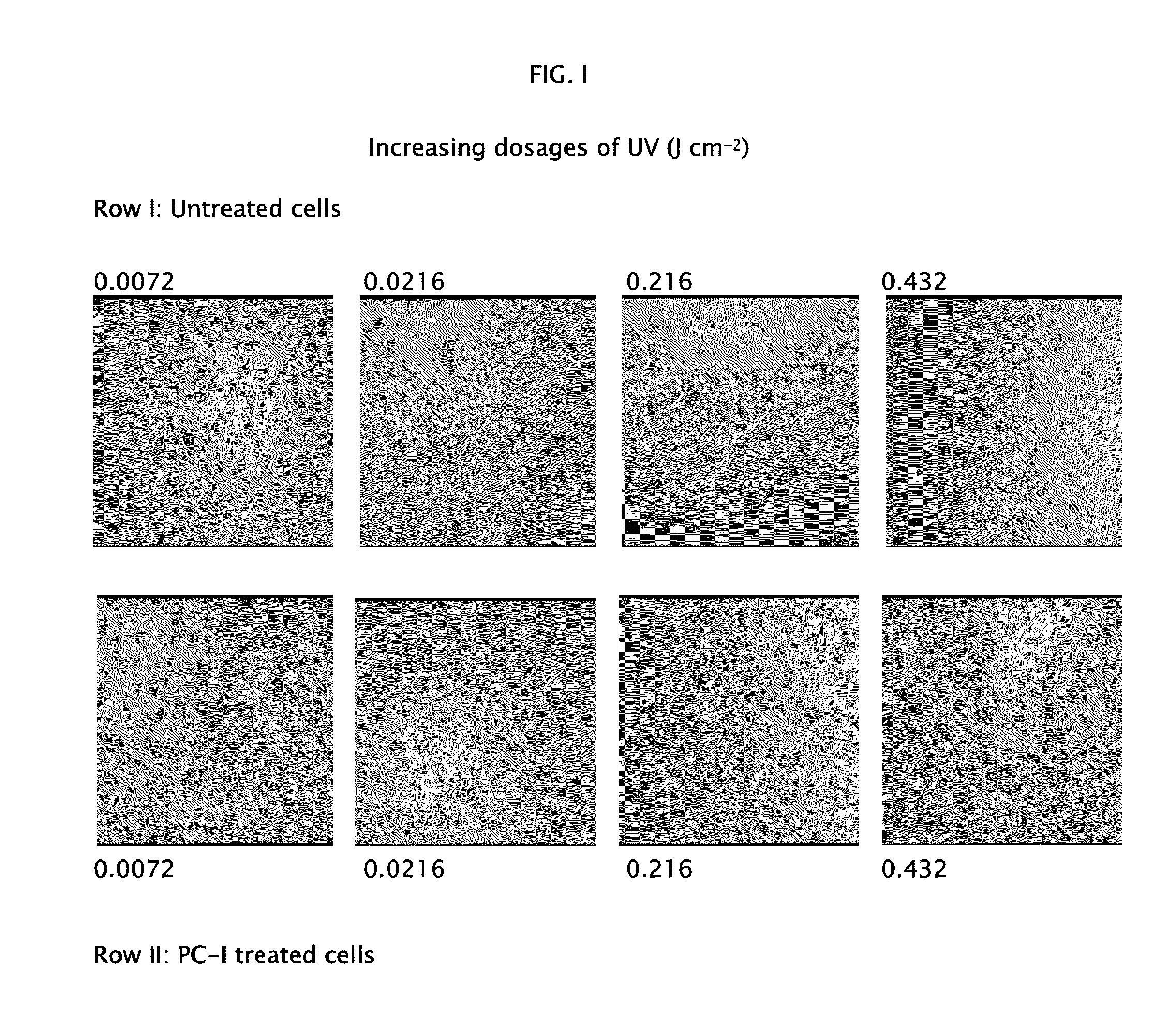

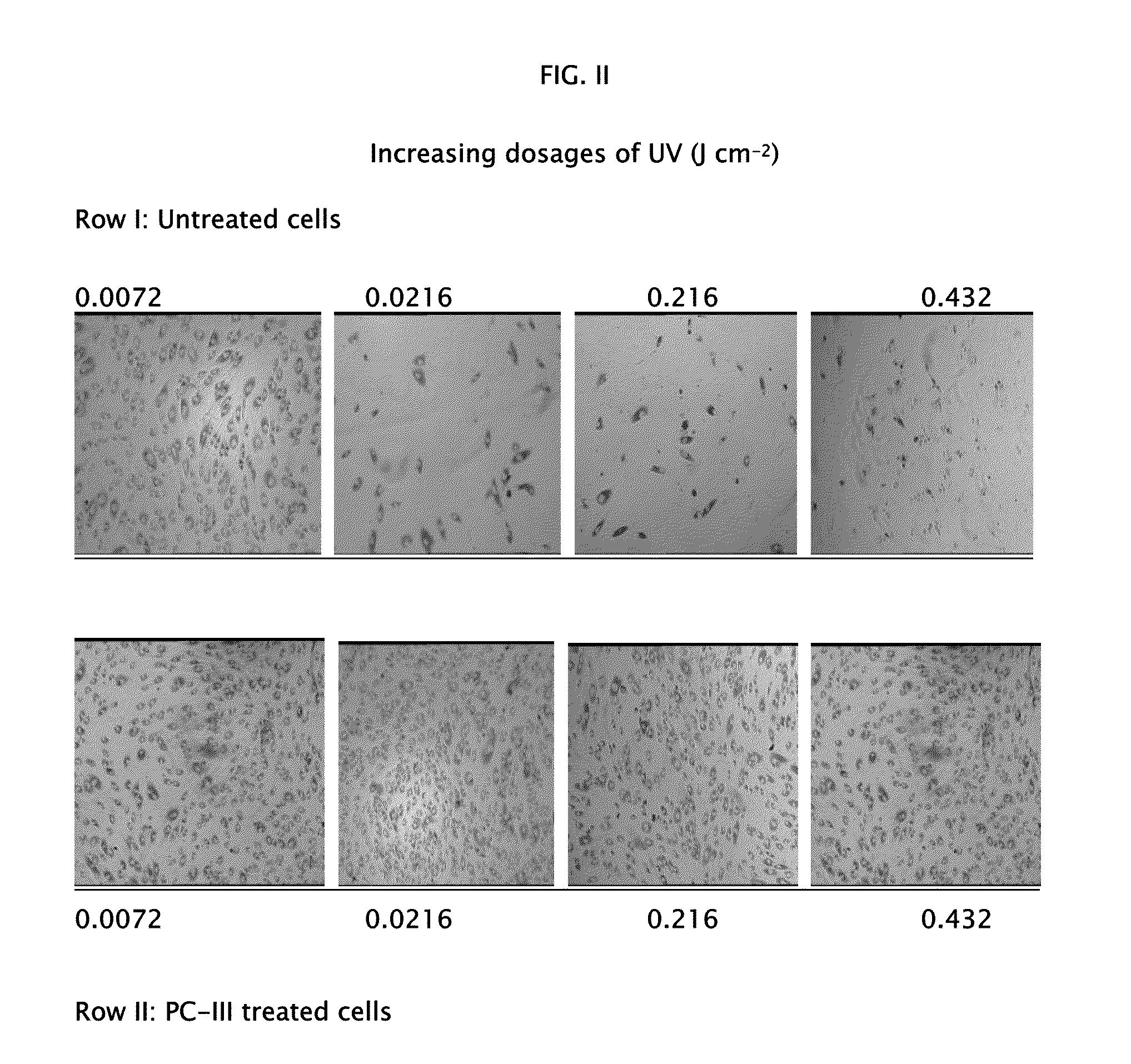

Anti-skin damage compositions with complimentary dual mode of action

InactiveUS20090169651A1ConstantMaintenanceBiocideCosmetic preparationsChlorogenic acidAdditive ingredient

Disclosed are skin care compositions exerting a novel complementary dual mode of action in protecting the skin from day-to-day insults. The skin care compositions of the present invention comprise the extract from the liquid endosperm of Cocos nucifera as the principle ingredient along with one or more actives including the fruit rind extracts of Garcinia cambogia, Garcinia indica and Garcinia mangostana, seed coat extract of Tamarindus indicus, Chlorogenic acid extract from the beans of Coffea arabica, seed extracts of Nelumbo species, the leaf extracts of Murraya koenigii and the triterpene pentapeptides of oleanolic acid and ursolic acid. While the extract of Cocos nucifera has been included as a nutritional supplement (a natural cell culture medium) to ensure the maintenance of the viability and constant renewal of the cells of the skin, the other actives have been carefully chosen based on one or more of their effective skin care properties. The compositions of the present invention offer a safe prophylactic / therapeutic management solution to the wide range of pathological states associated with skin insults and the associated psycho-social issues.

Owner:SAMI LABS LTD

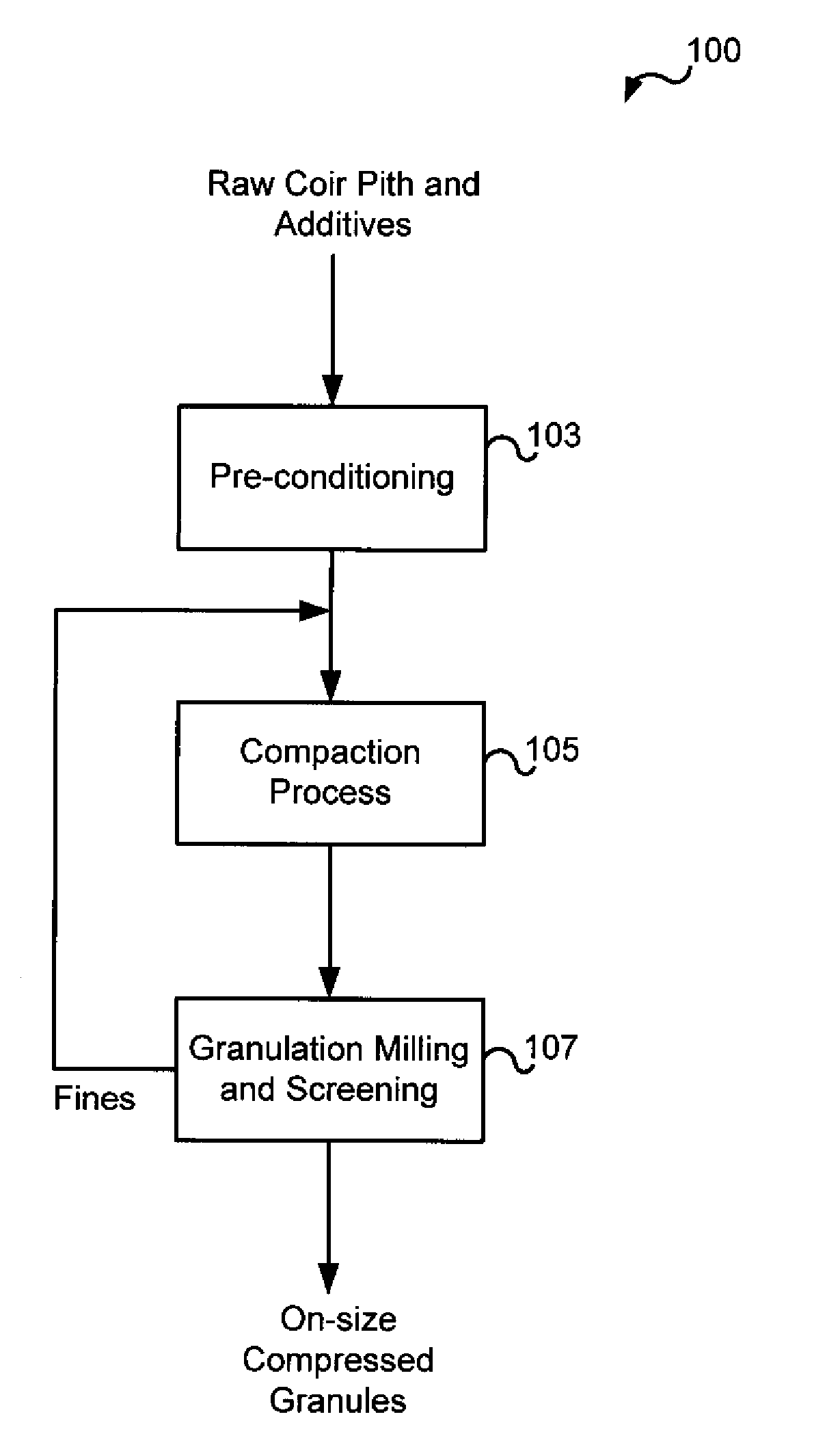

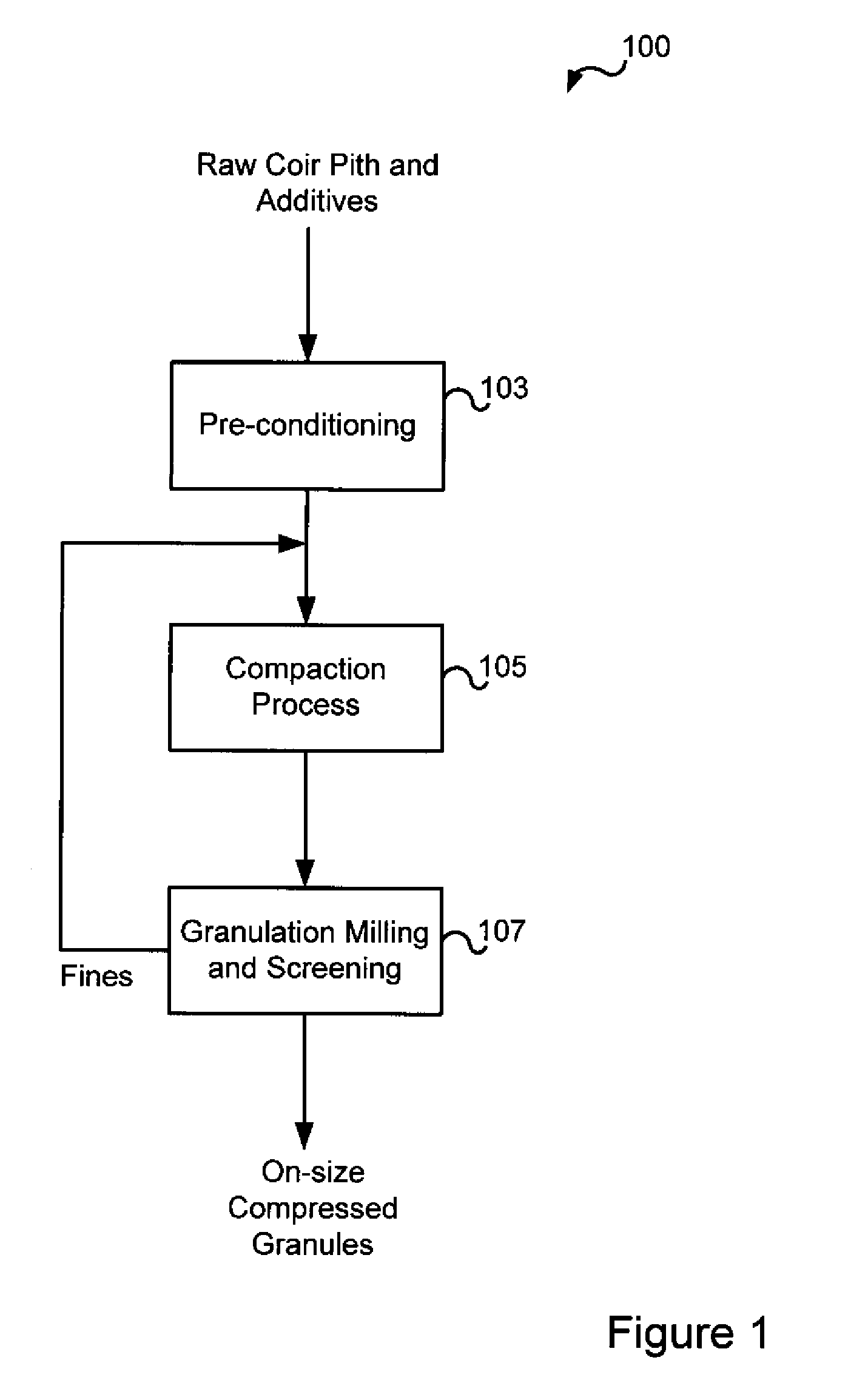

Compressed Coconut Coir Pith Granules and Methods for the Production and use Thereof

Owner:OMS INVESTMENTS INC

Eating five-element corn-vegetable-fruit health product

InactiveCN101971985AClear mechanismClarify the mechanism of health careFood preparationBiotechnologyUncooked Foods

The invention relates to an eating five-element corn-vegetable-fruit health product comprising more than 40 raw materials, such as naked oat flour, cichory flour, bitter almonds, coixseeds, white lablab seeds, burdocks, white turnips, white fungi, yam, ginkgo, coconuts, highland barley, brassica campestris, green tea powder, cowberries, green apples, peas, green beans, spinach, cacti, spirulina, Chinese goosebeeries, black tartary buckwheats, agaricus blazei murill, blackcurrant, mulberry powder, black kerneled rice, teata glycinis, niger seeds, dried purple seaweed, mushrooms, black fungi, Tibetan red beans, and the like, which is white, green, black, red or yellow corn-vegetable-fruit grains or integrative five-color corn-vegetable-fruit grains prepared by a specific technology. The eating five-element corn-vegetable-fruit health product is produced on the basis of a traditional Chinese medical five-element theory and a modern nutriology theory, has excellent raw materials, edible safety, pure taste and rich nutrition, is especially used for raw foods, provides complete, balanced and reasonably-matched nutrients for a human body, has obvious opsonization for sub-health physiques and various chronic diseases, is easy to industrially popularize and has positive social and economic benefits.

Owner:崔晓廷

Date Palm Seed-Based Lost Circulation Material (LCM)

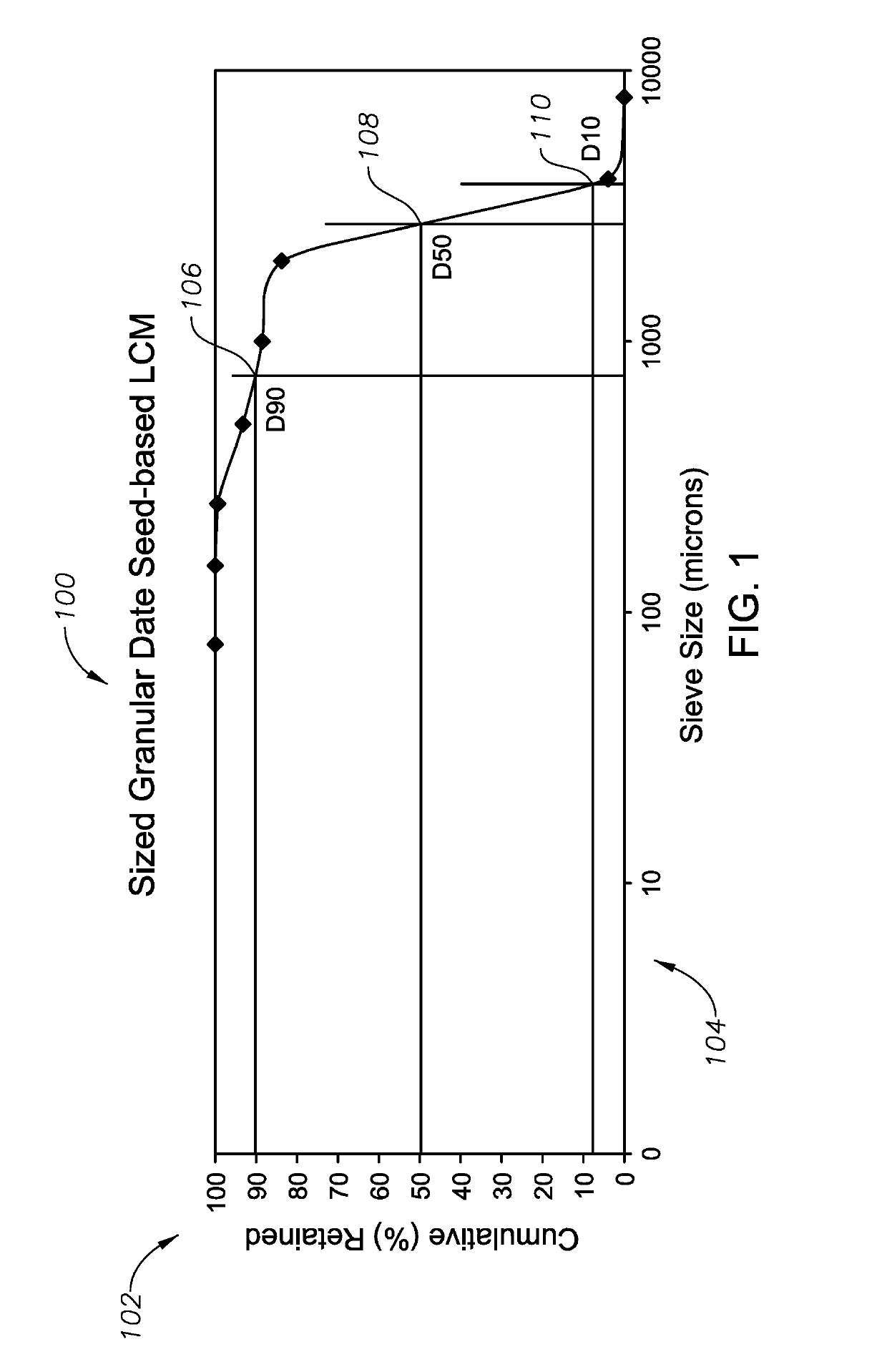

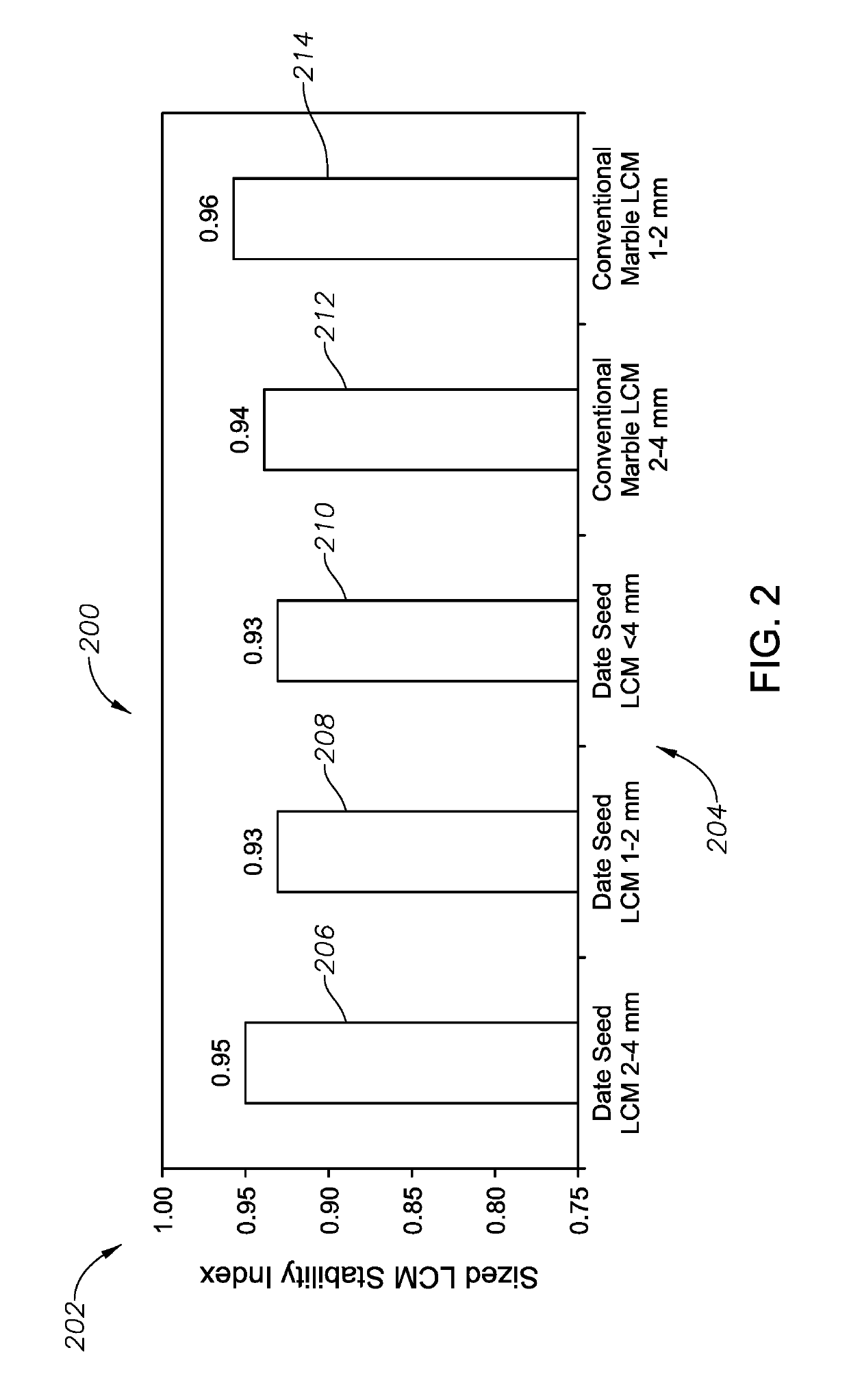

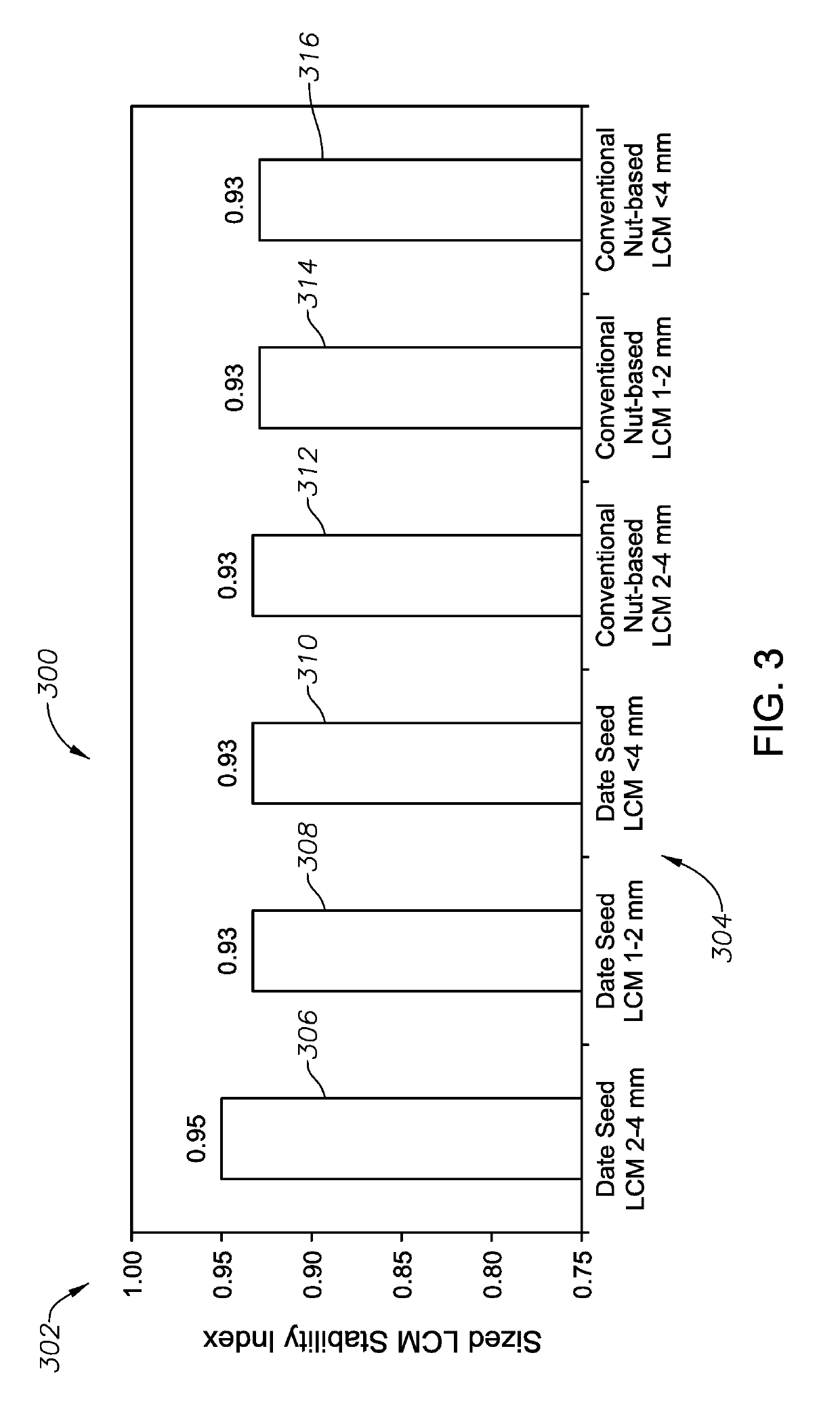

A date palm seed-based lost circulation material (LCM) is provided. A date palm seed LCM may be manufactured by drying date palm seeds and grinding the dried date palm seeds to create a plurality of particles. The particles may have sizes less than 4 mm, from 1 mm to 2 mm, or from 2 mm to 4 mm. The date palm seed LCM may have a volumetric swelling greater than an LCM formed from tree nuts and may have a volumetric swelling of at least 0.3 cubic centimeters per gram. The date palm seed LCM may have a D50 shift factor less than an LCM formed from calcium carbonate and may have a D50 shift factor of at least 0.38%. The date palm seed LCM may have a stability index of at least 0.95. Methods of lost circulation control and manufacture of a date palm seed LCM are also provided.

Owner:SAUDI ARABIAN OIL CO

Topical skin formulations comprising botanical extracts

ActiveUS20110052737A1Improve visual appearanceExtended maintenance periodBiocideCosmetic preparationsCupaniopsis anacardioidesEucalyptus coolabah

Disclosed are compositions and corresponding methods of their use that include Nymphaea gigantea, Syzygium moorei, Cupaniopsis anacardioides, Archidendron hendersonii, Tristaniopsis laurina, Brachychiton acerifolius, Stenocarpus sinuatus, Alphitonia excelsa, Eucalyptus coolabah, Plumeria alba, Cocos nucifera, or Tamarindus indica extract.

Owner:MARY KAY INC

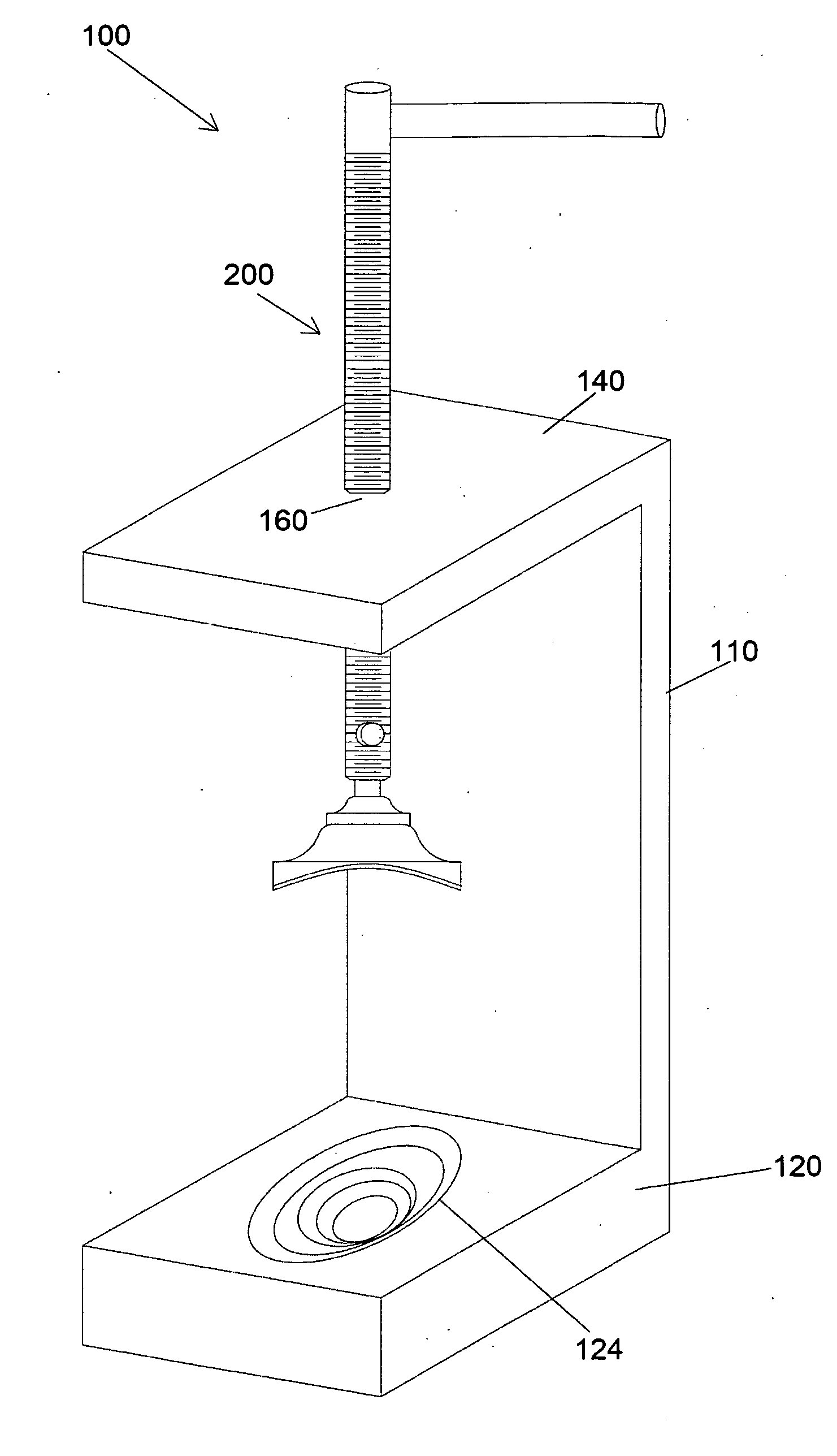

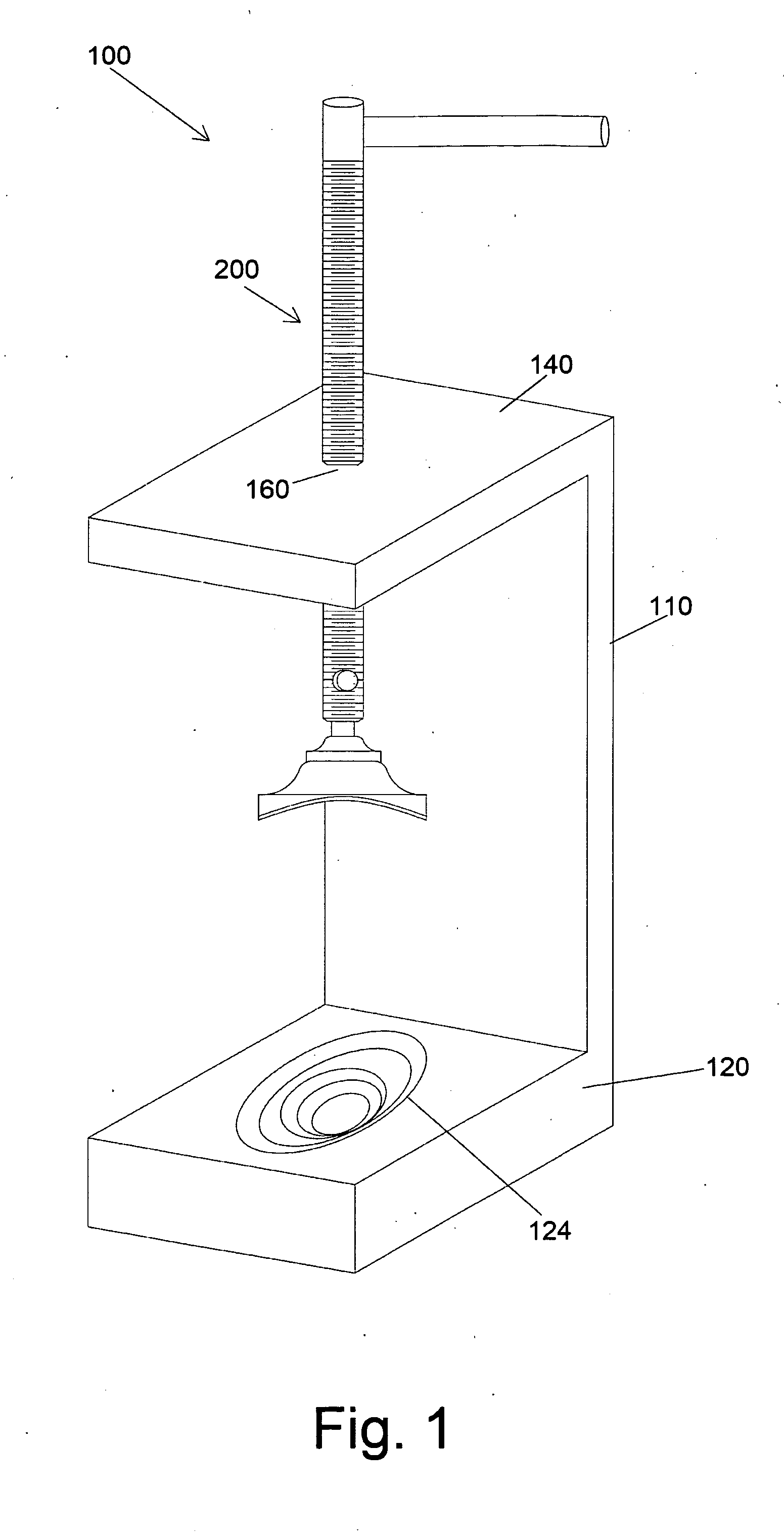

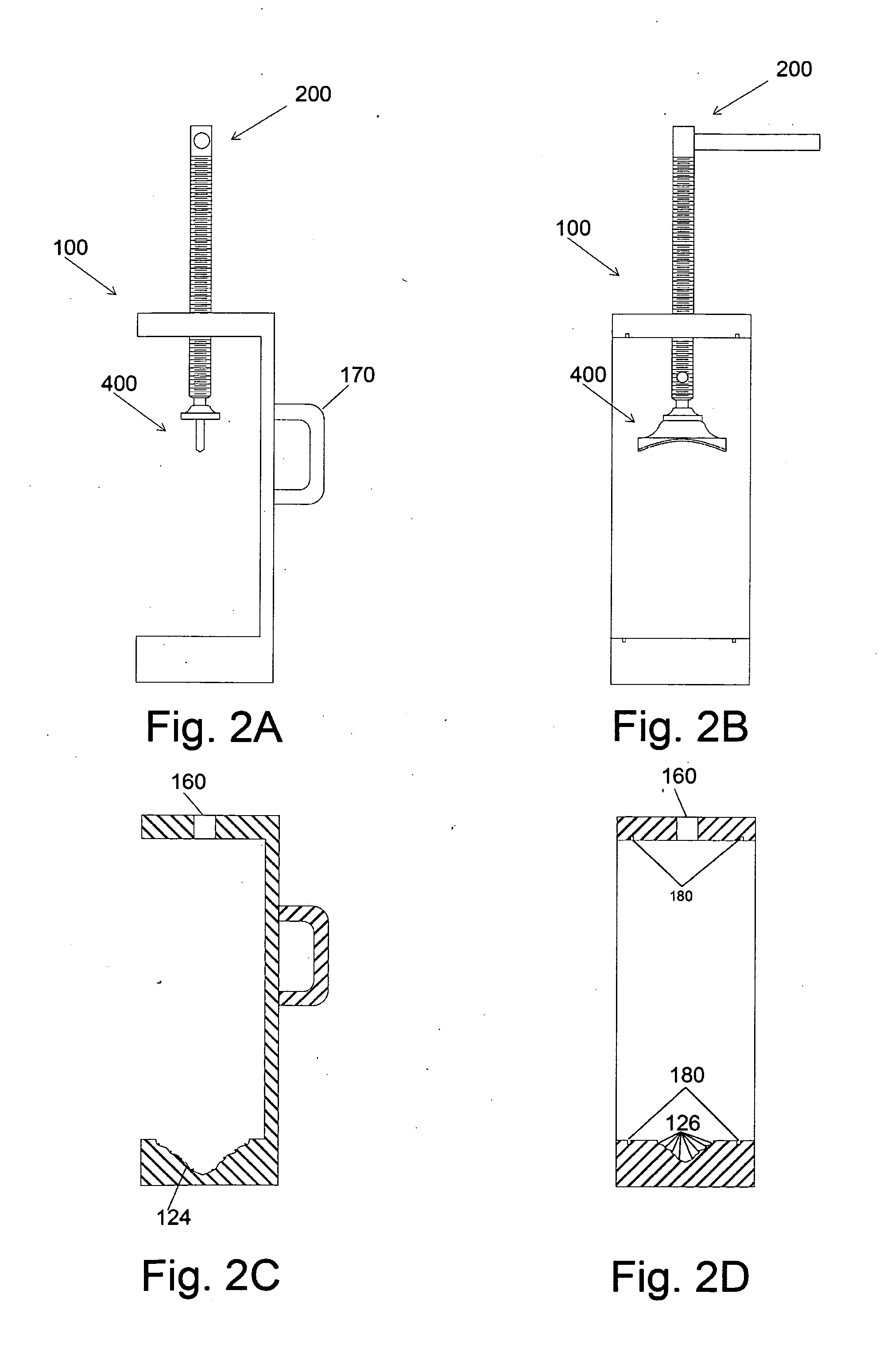

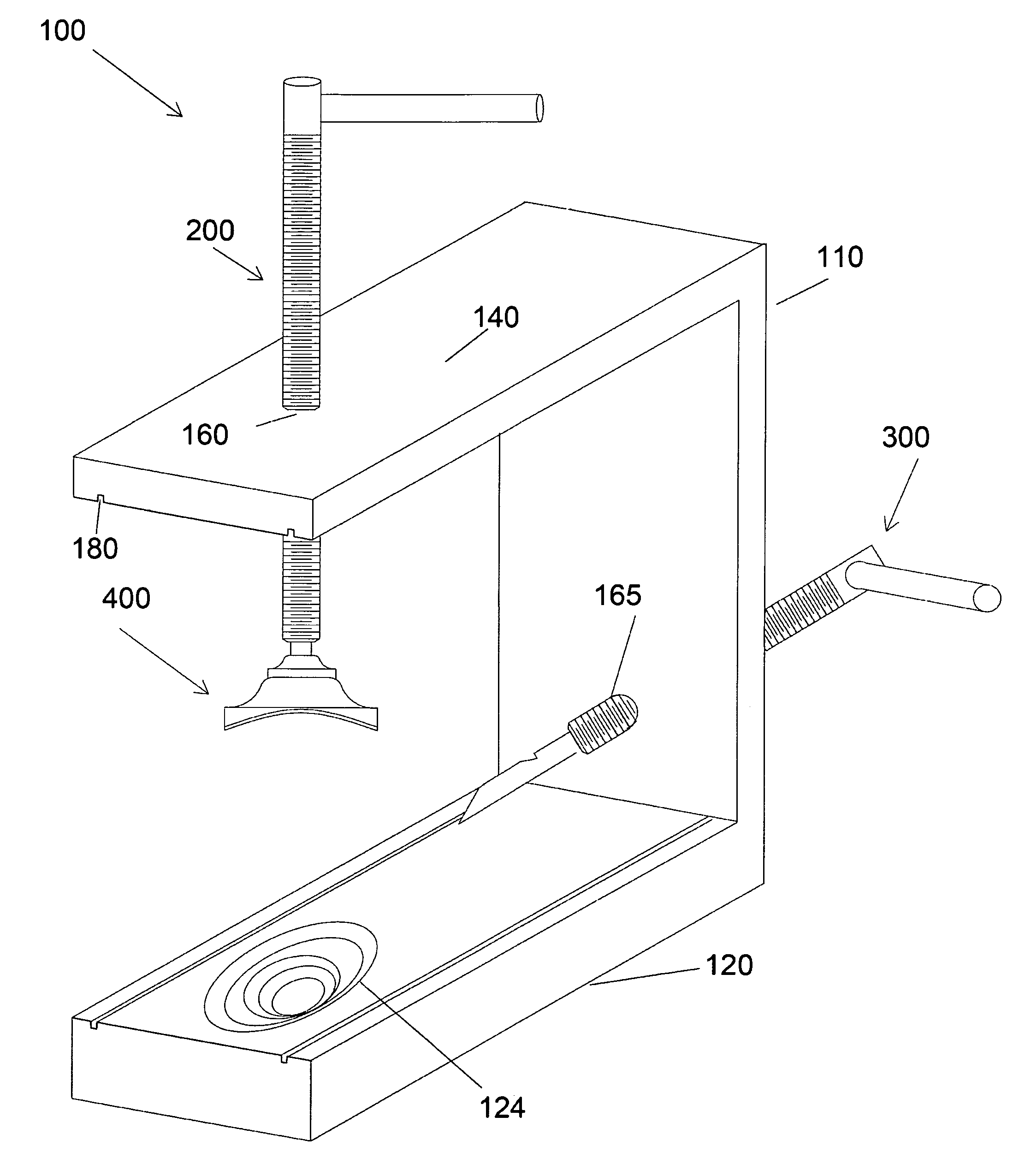

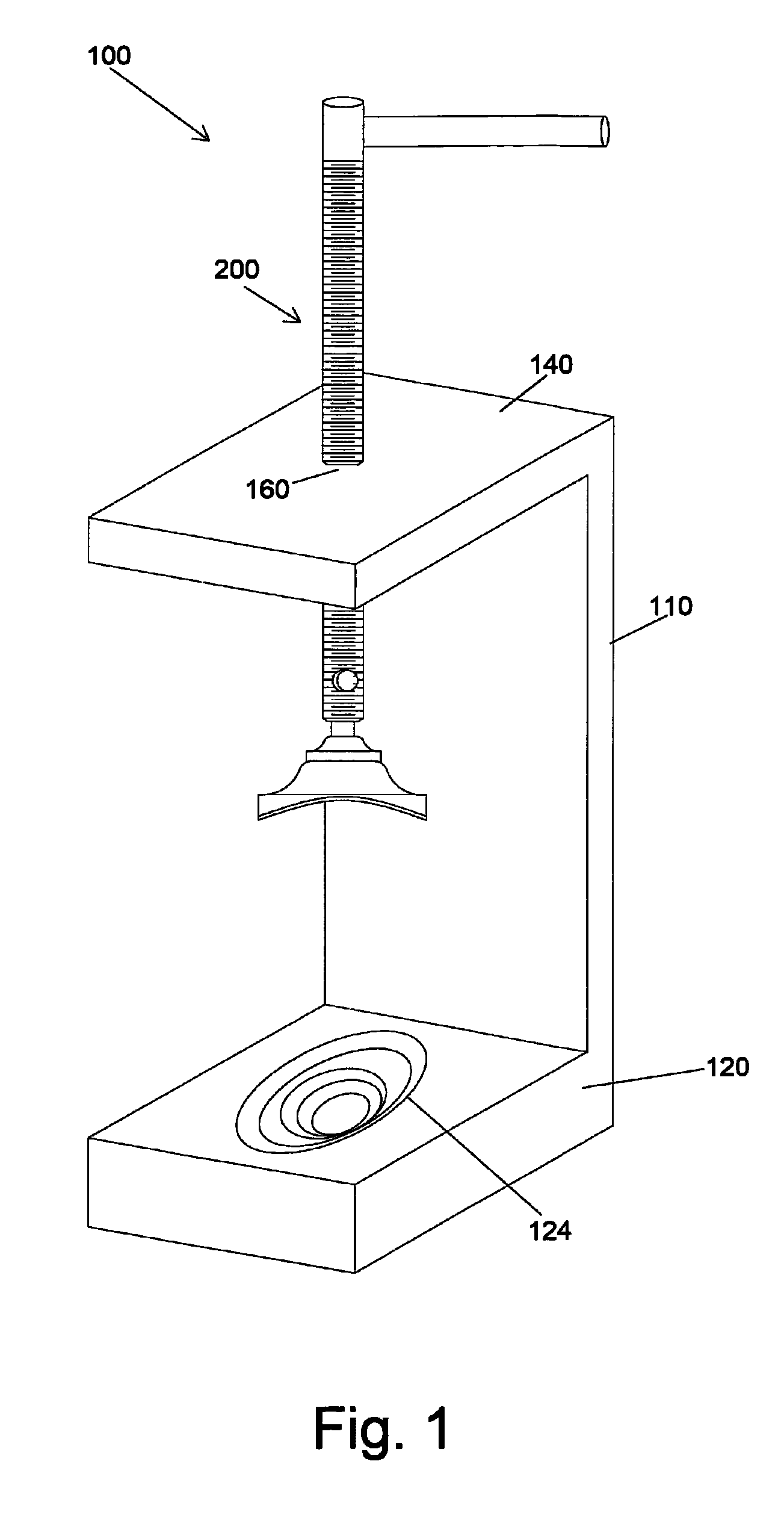

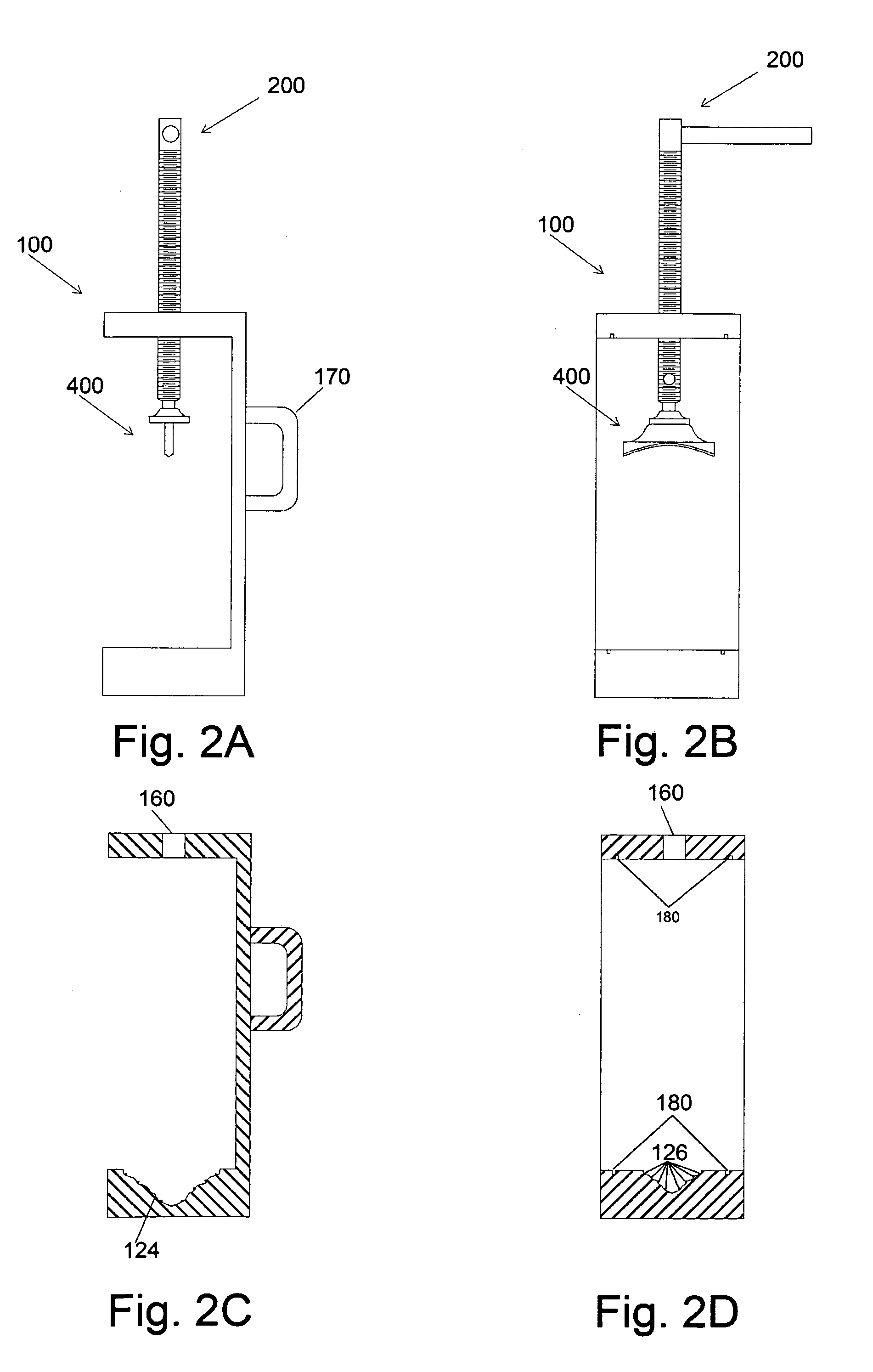

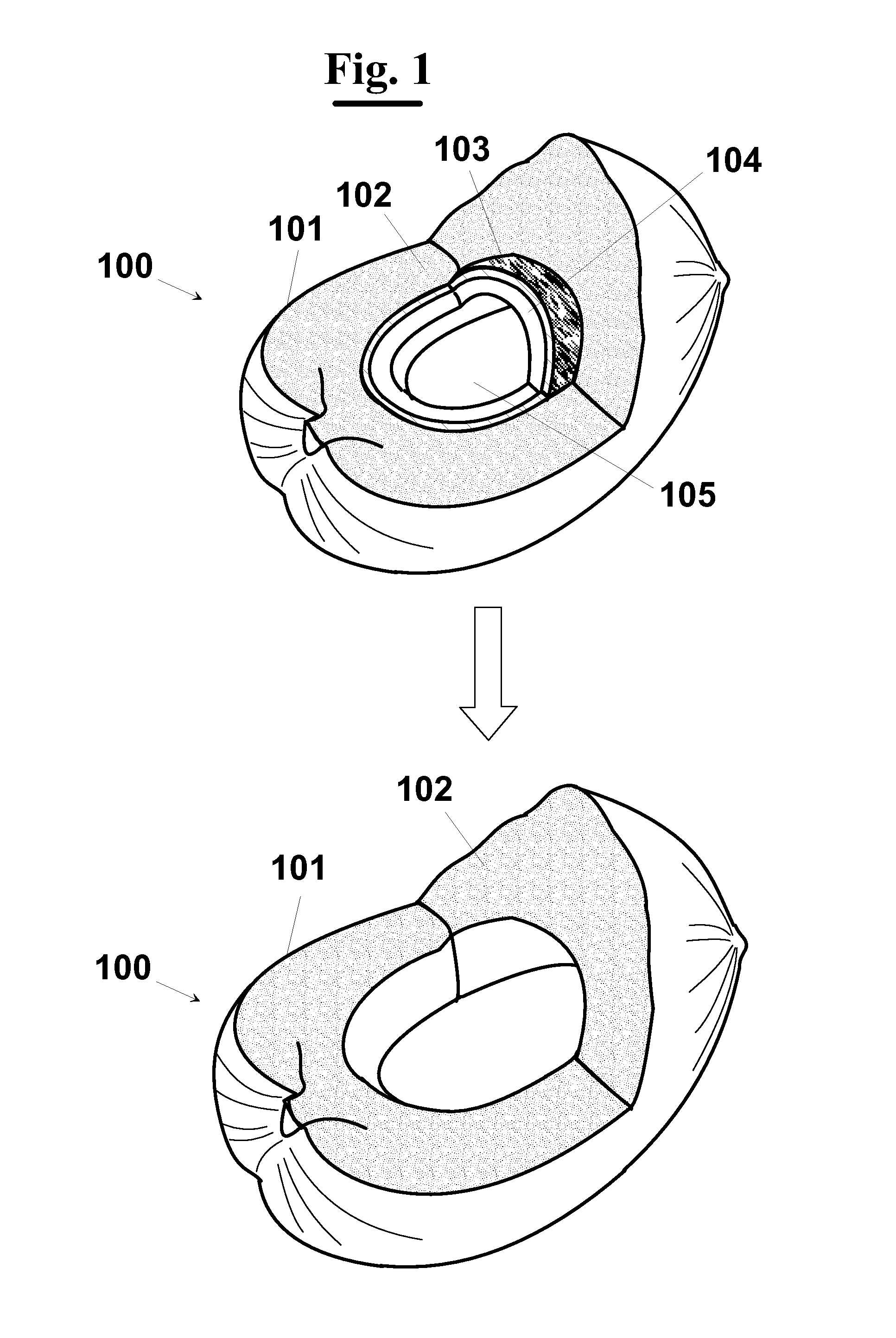

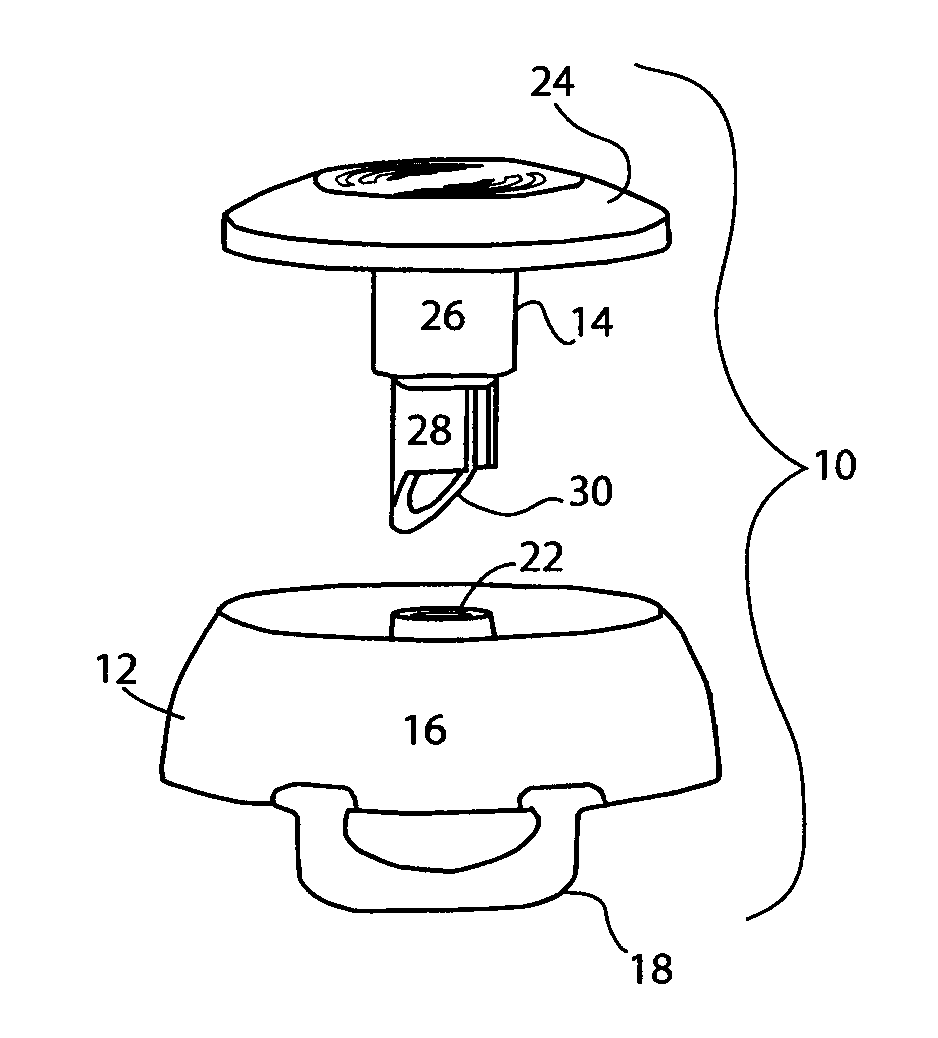

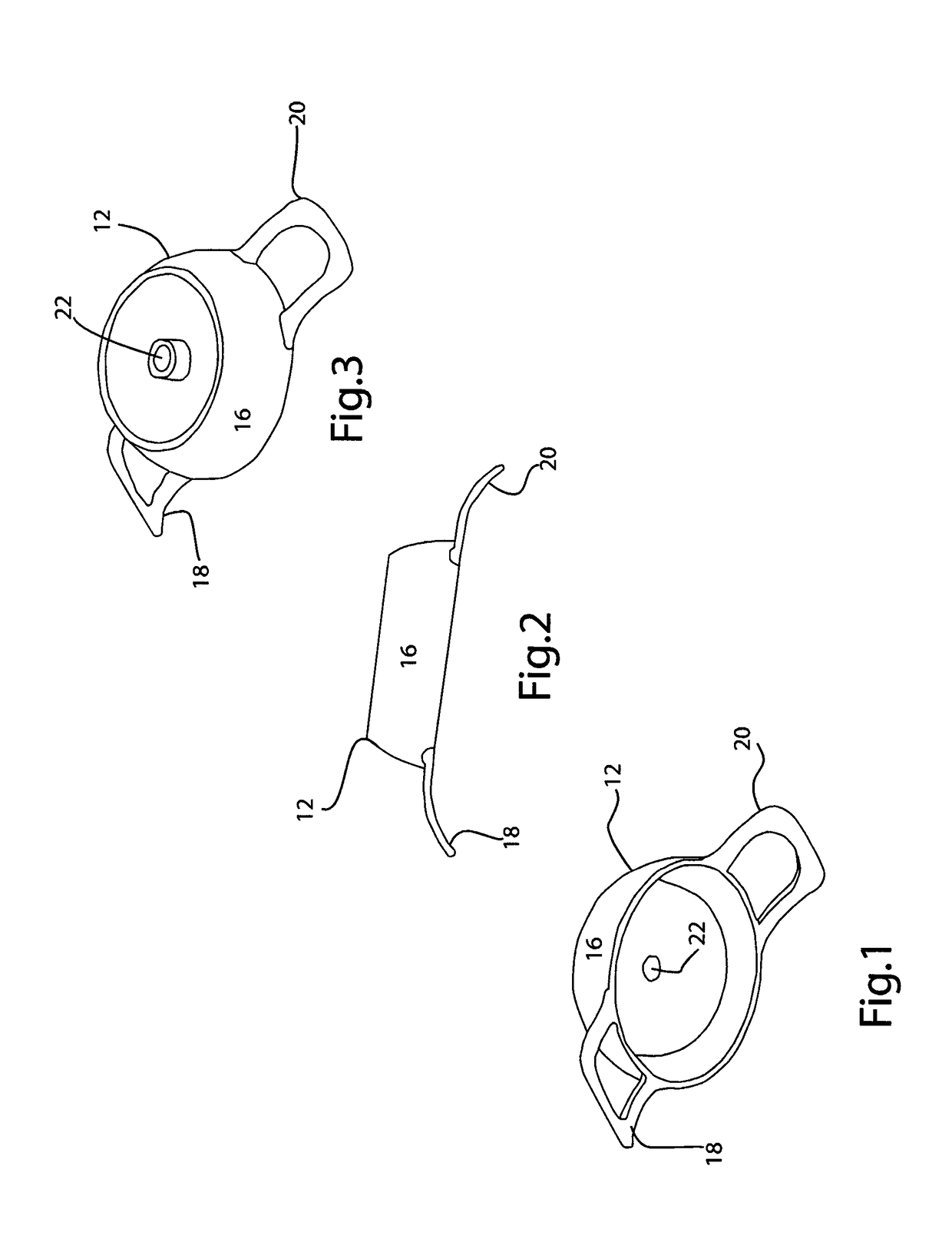

Tool to pierce and split a coconut

InactiveUS20100124595A1Hazard reductionJuice extractionCross-cut reciprocating sawsEngineeringMechanical engineering

One embodiment of a tool to pierce and split a coconut to facilitate removal of the water and meat from the nut. The tool includes of a body (100), comprising a frame (110) sufficient in size to accommodate a coconut and a constrictor cup (124), a shaft (210) which has releasably engaged tap assembly (300) and a releasably engaged splitter assembly (400). The body has a hub aperture (160) to receive the shaft (210). The shaft has means to urge both the cutting and the splitting end into coconut. Other embodiments are described and shown.

Owner:PATTENDEN JOHN MAURICE

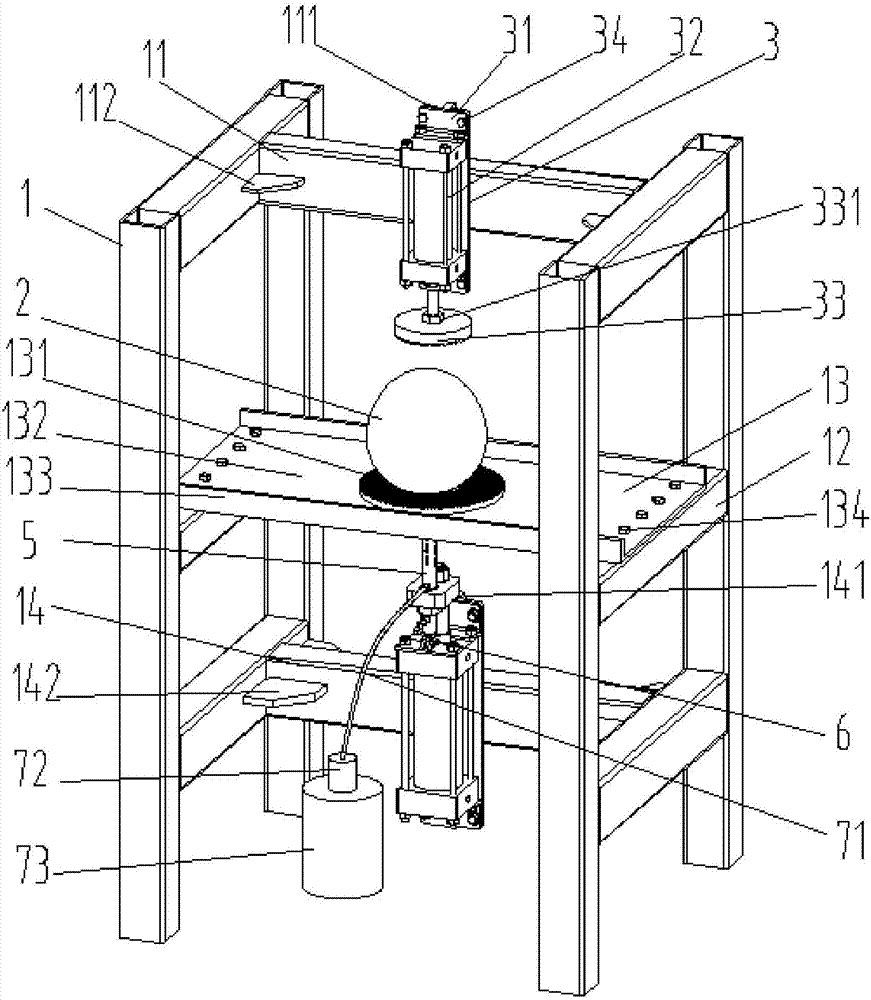

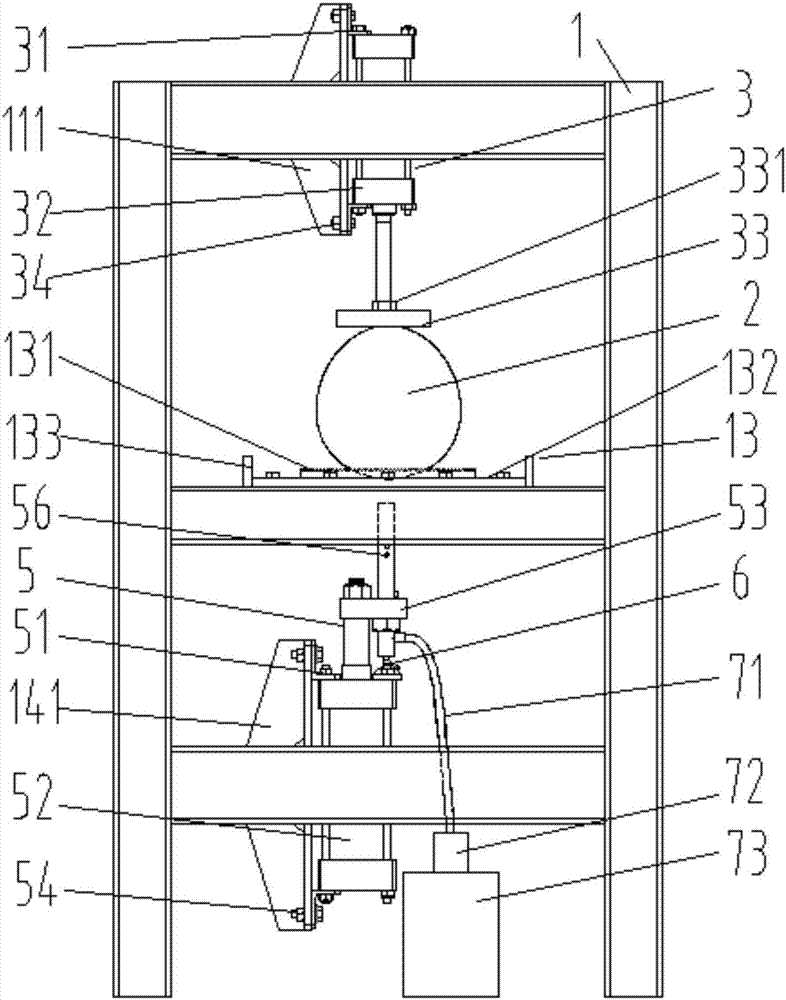

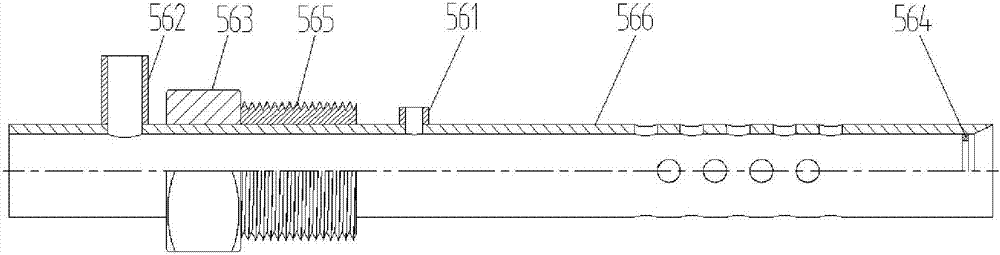

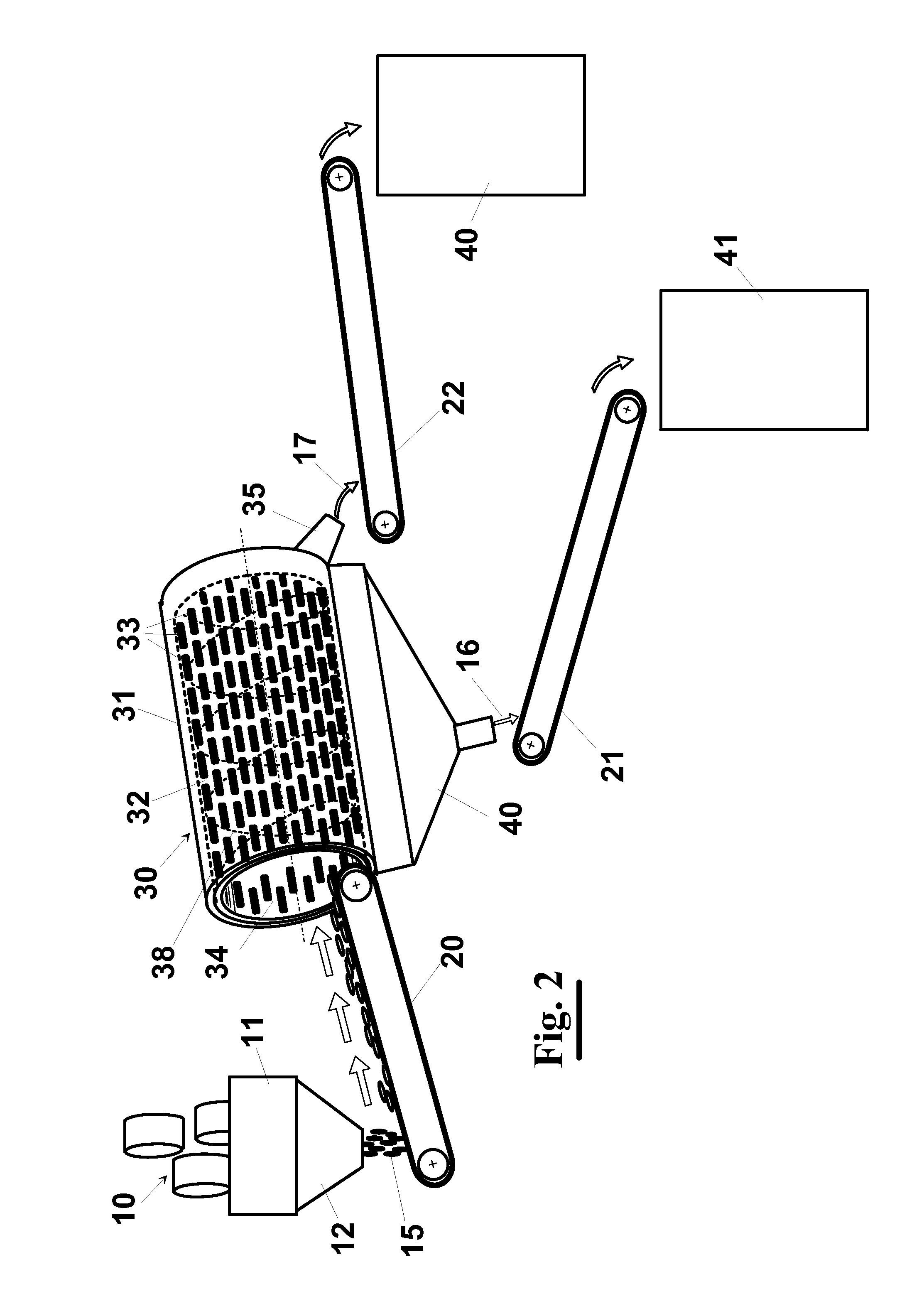

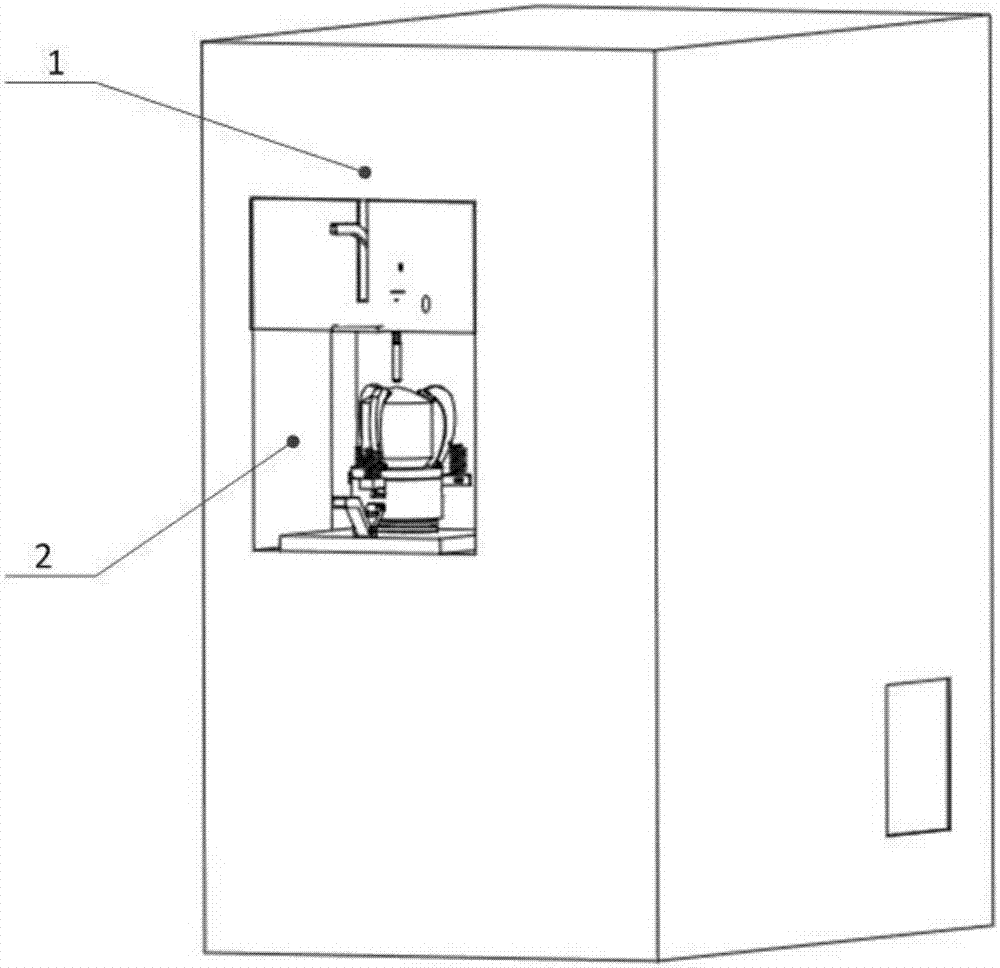

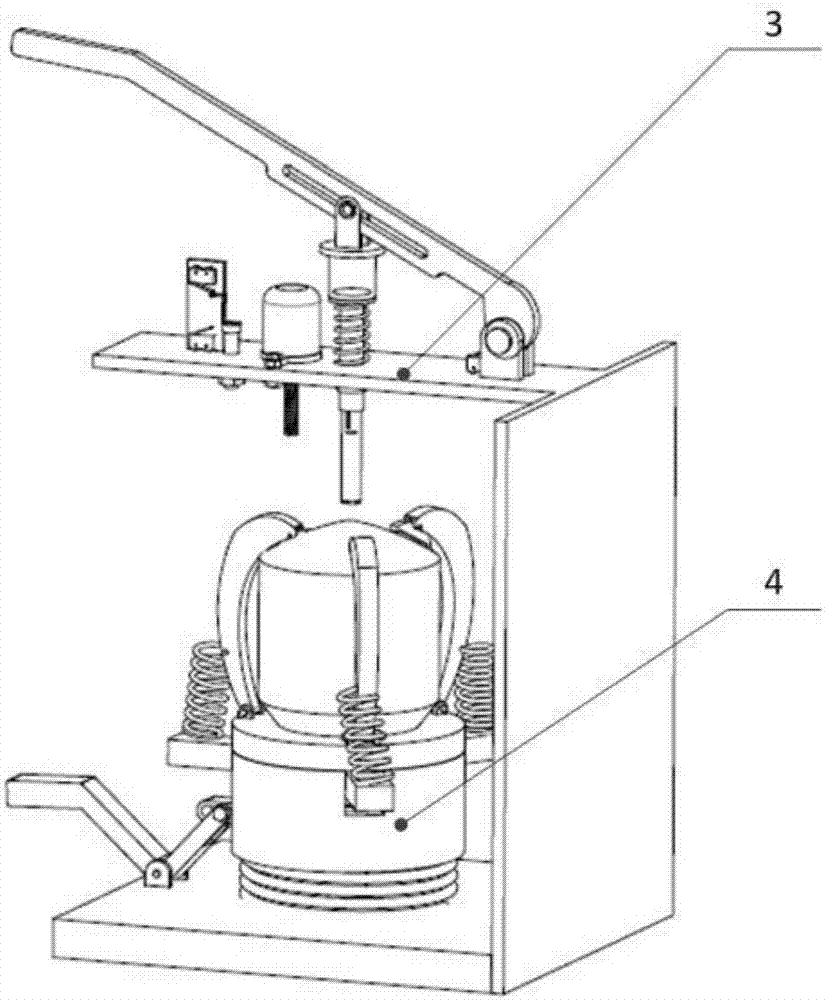

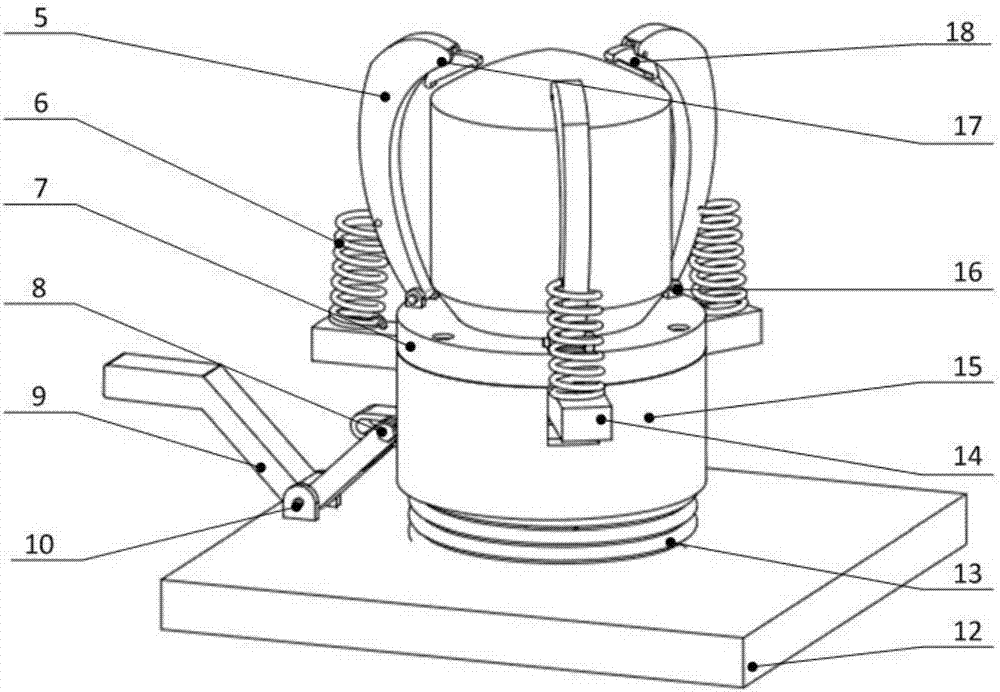

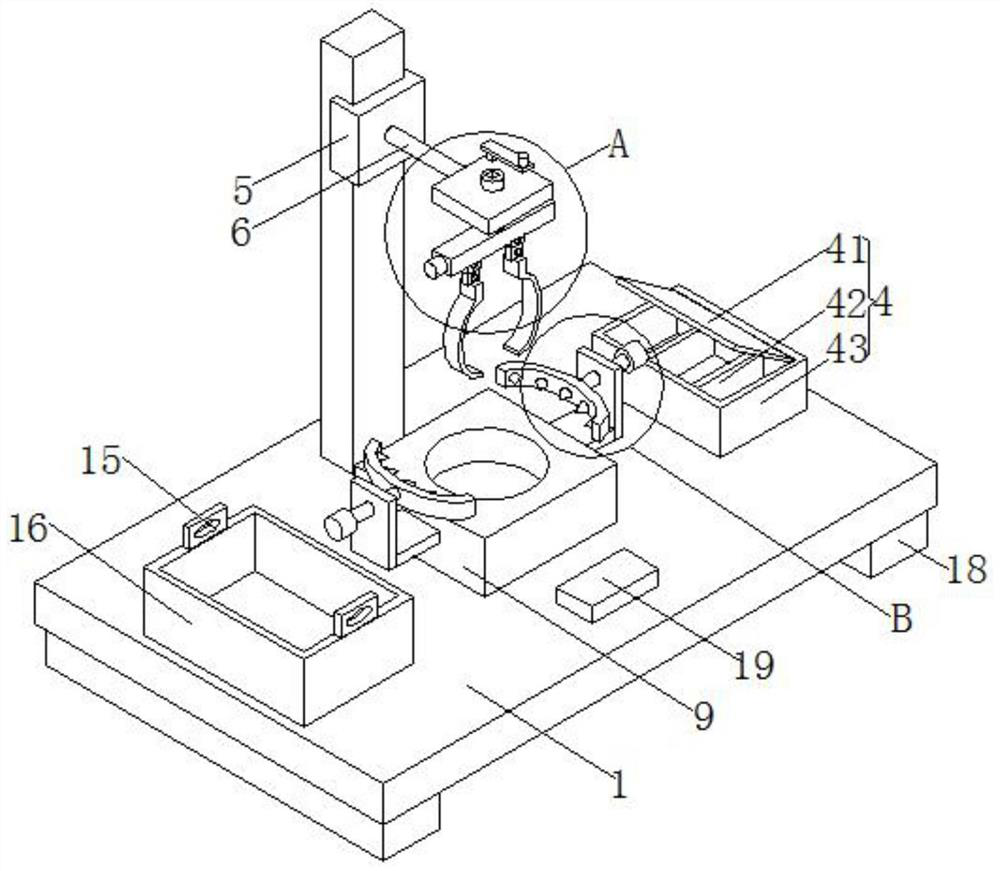

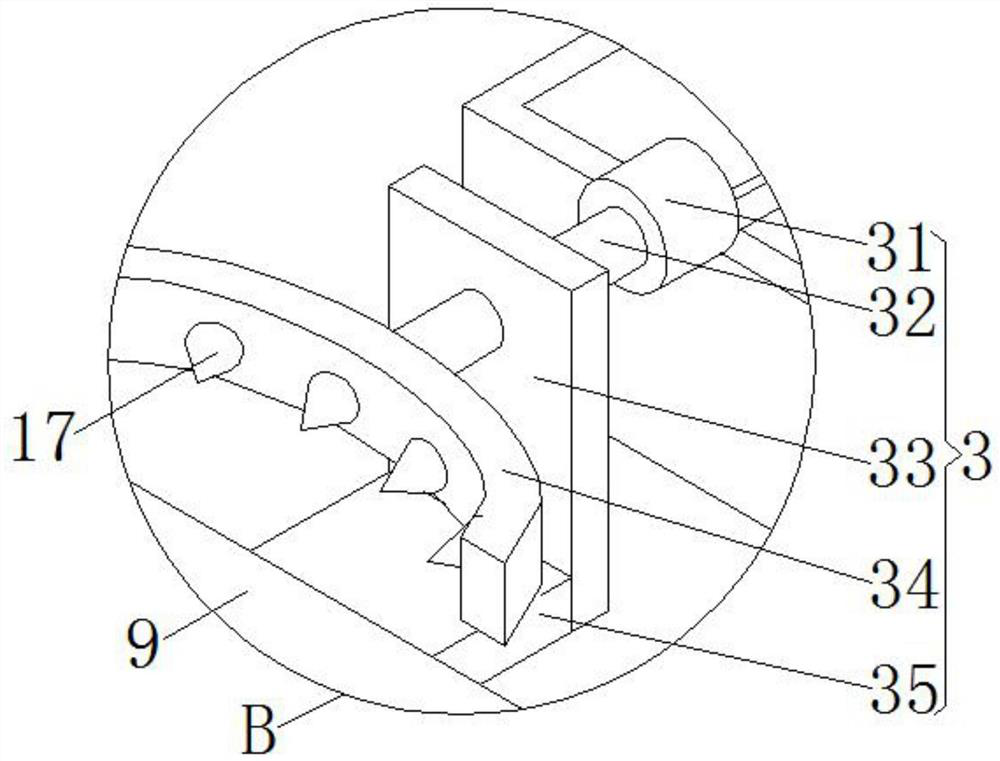

Machine for automatic hole opening and juice extraction of coconut, and method for hole opening and juice extraction

ActiveCN107242584AReliable clamping forceAvoid blockingJuice extractionHuskingMechanical engineeringCocos nucifera

The invention relates to the technical field of fruit processing equipment and especially relates to a machine for automatic hole opening and juice extraction of a coconut, and a method for the hole opening and juice extraction. The machine for the automatic hole opening and juice extraction of the coconut provided by the invention comprises a supporting tray mechanism and at least one set of clamping mechanism and hole opening cutter, wherein each set of clamping mechanism and hole opening cutter are coaxially disposed on two sides of the supporting tray mechanism and can be moved relatively along the axis; and each clamping mechanism is used to clamp and fix the coconut on the supporting tray mechanism, and the hole opening cutter is inserted into the coconut for synchronous hole opening and juice extraction of the coconut. The machine and method for the automatic hole opening and juice extraction of the coconut have the advantages that the juice extraction operation can be executed automatically during the hole opening; operation processes are simplified; the structure is simple; and production efficiency is increased.

Owner:HAINAN UNIVERSITY

Tool to pierce and split a coconut

InactiveUS7959967B2Hazard reductionJuice extractionCross-cut reciprocating sawsEngineeringMechanical engineering

One embodiment of a tool to pierce and split a coconut to facilitate removal of the water and meat from the nut. The tool includes of a body (100), comprising a frame (110) sufficient in size to accommodate a coconut and a constrictor cup (124), a shaft (210) which has releasably engaged tap assembly (300) and a releasably engaged splitter assembly (400). The body has a hub aperture (160) to receive the shaft (210). The shaft has means to urge both the cutting and the splitting end into coconut. Other embodiments are described and shown.

Owner:PATTENDEN JOHN MAURICE

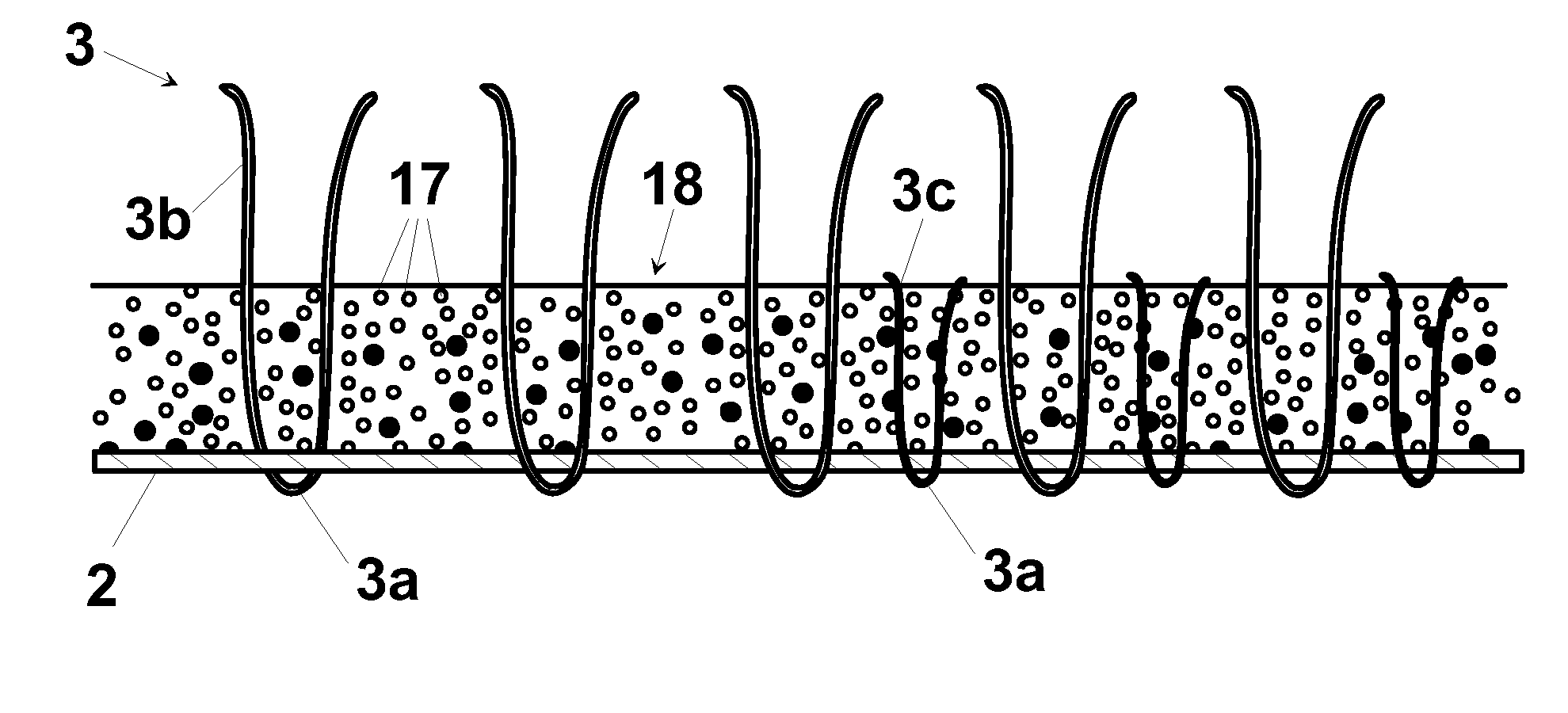

Method for producing synthetic turfs

ActiveUS20100166984A1Cheaply and easilyAvoid chalkingDead plant preservationArtificial flowers and garlandsInfillFilling materials

Method for making a synthetic turf comprising laying a turf (1) consisting of a mat (2) on which a plurality of blades (3, 3a, 3b, 3c) of synthetic material is woven. An infill material (18) is obtained using the granular and fibrous part (17) of a loose product based on ground coconut, alone or with addition of other material such as rubber in granules or sand or other loose vegetable material such as cork. The raw material based on coconut, having a heterogeneous granulometry set between about 500 micron and several mm, is obtained loading a loose product based on ground coconut by a hopper on a conveyor belt for being fed in a sieve, for example a rotating screen that separates the powder part from the granular and fibrous part. In particular, the powder part of the raw material, is gathered on a conveyor belt and from here sent to a storage reservoir. The granular and fibrous part of the raw material, which represents the main product of the process, is, instead, sent by a conveyor belt to a storage, reservoir from where it is taken for the process to provide infill material for a synthetic turf.

Owner:LIMONTA SPORT SPA

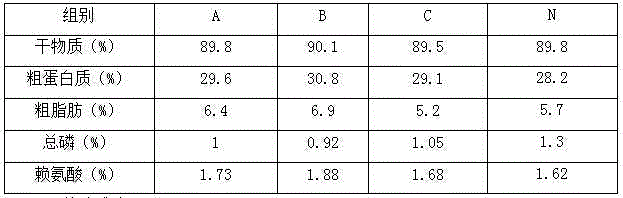

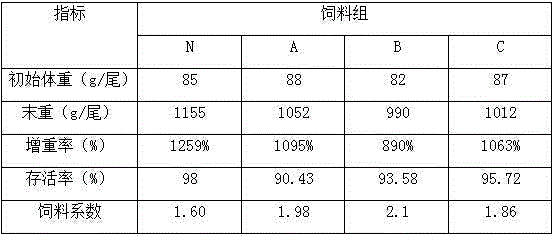

Microcapsule bait, bait feeding method and bait feeding device for grouper larvae

InactiveCN102934751AMeet the nutritional needs of growthMeeting nutritional needsClimate change adaptationAnimal feeding stuffAnimal scienceNutrition

The invention provides a microcapsule bait, a bait feeding method and a bait feeding device for grouper larvae. The microcapsule bait comprises ingredients of maize meals, coconut cakes, rice bran, chicken bone powders, pea powders, silkworm chrysalis powders, sesame powders, sleeve-fish powders, and the like. According to the microcapsule bait, the bait feeding method and the bait feeding device for the grouper larvae, an innovative formula and a processing technology are utilized, the nutritional requirements for larva growth can be met, the nutrition is comprehensive, the palatability is good, the water stability is good, and the like; the bait can be produced in a batch mode, is convenient to store, transport and feed and applicable to factorial offspring seed production, simultaneously, the corresponding feeding method and feeding device are utilized, the growth and survival rate of the grouper larvae can be improved, and the microcapsule bait, the bait feeding method and the bait feeding device for the grouper larvae are applicable to large-scale popularization and usage.

Owner:ZHEJIANG OCEAN UNIV

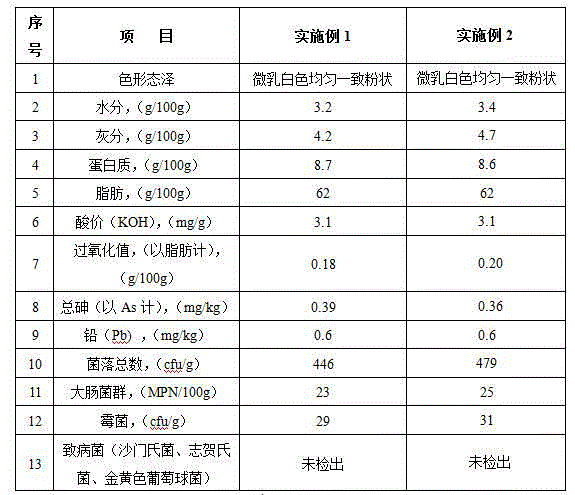

Novel preparation process for natural coconut powder

ActiveCN104824582AUniform textureFine and even textureFood ingredientsFood preparationSpray driedOrganic chemistry

The invention belongs to a preparation method of a food and particularly relates to a novel preparation process for natural coconut powder. The process flow comprises the following steps: trimming and planing; cleaning; spraying; crushing; smashing; juicing; filtering; dosing; filtering; homogenizing; spraying and drying; re-drying; cooling; powder screening; bagging; weighing; carrying out bag sewing; and putting into a storeroom. The coconut powder prepared by the preparation method provided by the invention is uniform in texture, good in stability, high in dispersity and excellent in solubility.

Owner:HAINAN NANGUO FOODSTUFF IND

Mixed fruit coconut milk beverage and its production process

The invention relates to a mixed fruit cocoanut juice beverage and its production method. Said beverage contains (wt%) 95-5% of fruit juice and / or fruit raw pump, 4-93% of cocoanut milk or cocoanut paste, 0.1-3.0% of high ester pestin, 0-85% of water, 0-0.7% of souring agent and 0-0.5% of buffer agent. It possesses unique fruit flavour, complete nutrients, good taste, high-grade quality and long storage time.

Owner:北京海爵食品有限公司

Natural re-hydrating and energizing beverage based on coconut water, fruit juices and incorporated nutritive components

InactiveUS7157109B2Reduced activityAcidic flavorVitamin food ingredientsFood preservationFruit juicePassion fruit

A natural re-hydrating and energizing beverage based on coconut water, fruit juices and incorporated nutritive components, to produce a natural isotonic beverage with a striking or gasified aspect in a mixture of coconut water, concentrated fruit juices (pineapple, passion fruit and lemon) and components that confer and / or incorporate energetic and vitamin characteristics as well being gasified by means of direct injection of CO2 into a basic syrup of the product itself that is already formulated, as well as the addition of mineral salts, vitamins and stimulant extracts.

Owner:KIPFER MARC

Method for preparing coconut shell and thermoplastic plastic composite material

The invention discloses a process for preparing composite materials of coir and thermo-plastical plastic. The process enables coir to be crushed into 30-120-item coir powder of which the moisture content is equal to or less than 3% by drying. Coupling agent solution is sprayed to the coir powder at the temperature of 80 DEG C to 110 DEG C, then modified coir powder is produced and is homogenously mixed with thermo-plastical plastic resin, compatilizer, lubricant, stabilizer, stuffing material, flame retardant and the like, and then coir-plastic mixture is achieved and added to an extrusion machine to be squeezed out, consequently the composite materials of coir and plastic are achieved. The invention resolves the problems of the compatibility of the coir fiber and the thermo-plastical plastic and the treatment technology of the surface of the raw materials, thereby realizing the synthetic utilization of the coconut fruit and substitution for lumber which is lack in resource, increasing the added value of the coconut fruit, and solving the problem of the utilization of the coir waste. The composite materials prepared by the invention have the advantages of the combination of lumber and plastic, and the composite materials not only have graceful appearance, but also are capable of being antiseptic, moisture proof, borer proof and fire resistant.

Owner:GUANGZHOU SCUT BESTRY TECHNOLOGY CO LTD

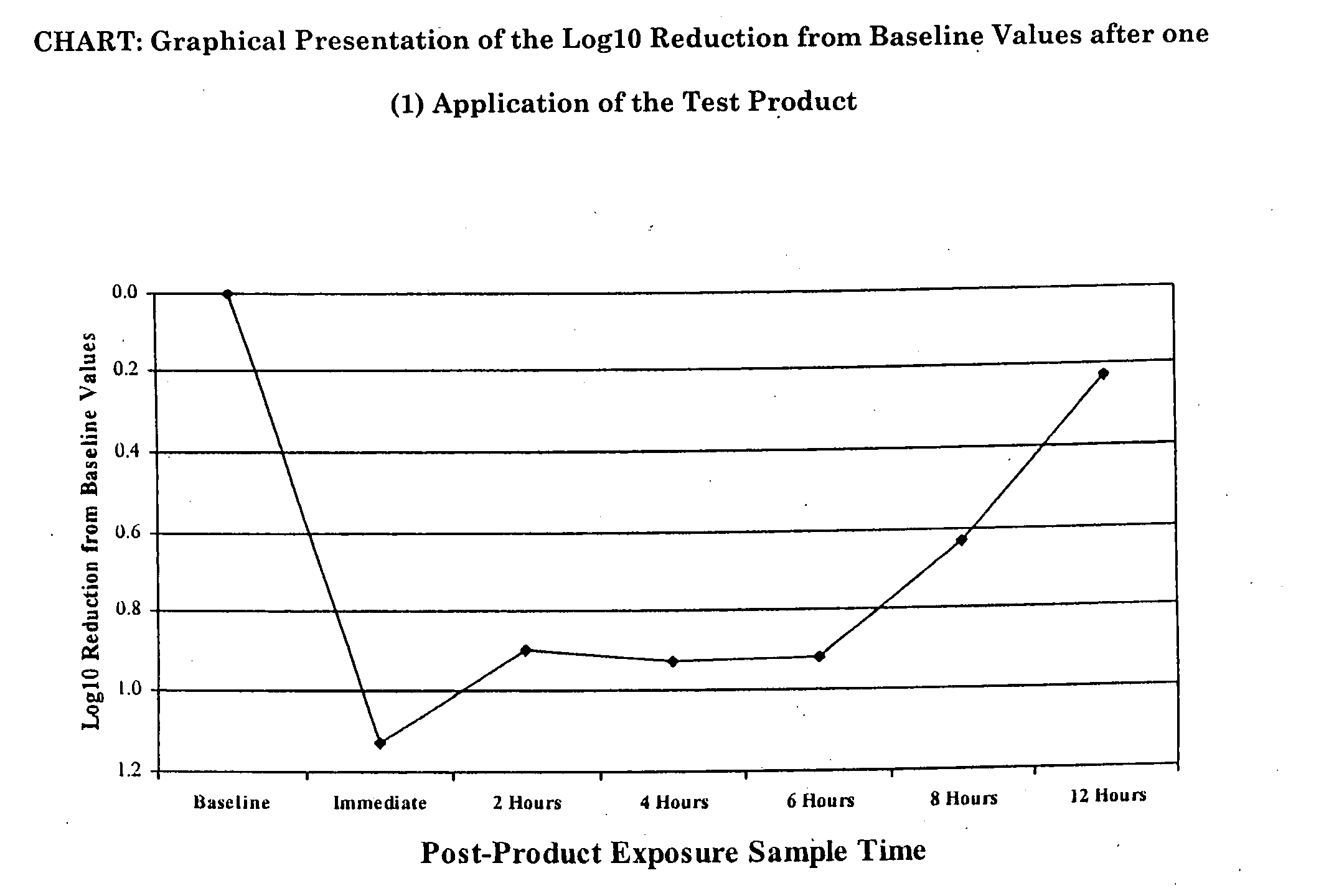

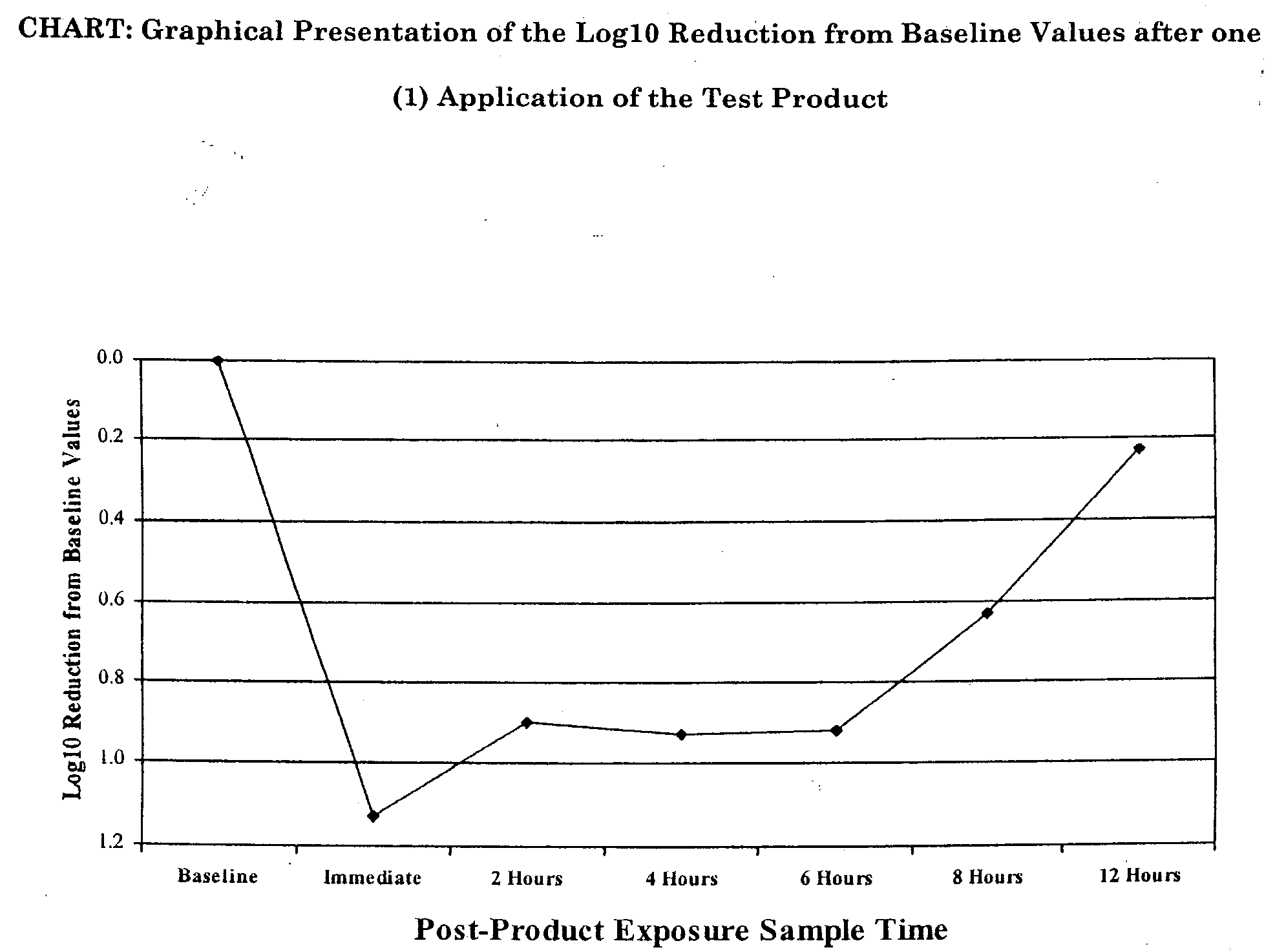

Antimicrobial and antiviral composition

InactiveUS20090011042A1Avoid problemsEnhance natural filtration propertyAntibacterial agentsBiocideAdditive ingredientBilateral nares

An antimicrobial and antiviral barrier composition for topical application to the proximal anterior nares includes an antiseptic solution in combination with cocos nucifera (coconut oil) and one or more citrus oils such as, for example, citrus sinensis (orange oil). Various embodiments may also include one or more of the following additional ingredients: lauric acid; d-limonene; soy oil; emu oil; grapefruit seed extract; glycine soja; simmondsia chimensis (Jojoba); aloe vera; and a preservative, such as sodium benzoate, BHT, benzalkonium chloride, vitamin E.

Owner:GLOBAL LIFE TECH

Rubber tree embryoid induction culture medium, induction method for embryonic callus and culture method of resistant callus

ActiveCN108575761AHigh differentiation induction rateIncreased rate of induction of differentiationHorticulture methodsPlant tissue cultureSalicylic acidEmbryo

The invention provides a rubber tree embryoid induction culture medium, an induction method for an embryonic callus and a culture method for regenerating resistant callus plant, and belongs to the technical field of plant tissue culture. The rubber tree embryoid induction culture medium takes an improved MS culture medium as a basic culture medium, and is prepared from Kt, NAA, 6-BA, salicylic acid, spermidine, acid hydrolyzed casein, coconut liquid endosperm coconut water, active carbon, saccharose and phytagel. The somatic embryo induction rate of the embryoid induction culture medium provided by the invention for inducing the embryonic callus of a rubber tree anther somatic embryo is increased by 2.04 to 2.16 times in comparison with that of an anther dedifferentiation callus.

Owner:HAINAN UNIVERSITY

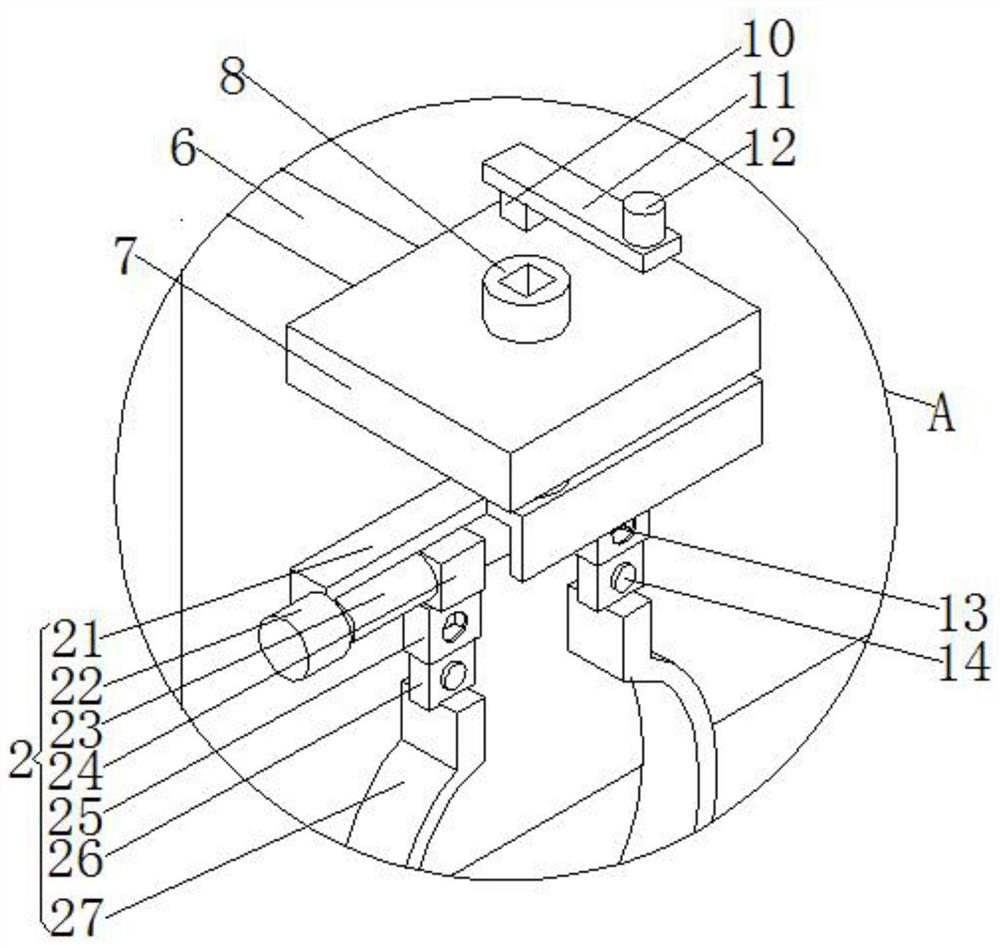

Automatic residue removal coconut perforating device facilitating assembly and clamping for vending machine and working method of device

InactiveCN107411114ATroubleshoot hard-to-fix problemsRealize automatic slag removal functionApparatus for dispensing fluids/granular materialsHuskingElectricityElectric drive

The present invention relates to a convenient clamping and self-cleaning coconut punching device which can be used in vending machines and its working method, comprising a coconut punching device main body which can be embedded in the vending machine, the lower part of the punching device main body It is a three-jaw type coconut automatic centering manual clamping device, and the upper part of the main body of the punching device is a self-cleaning slag punching device connected with the driving device. The present invention clamps the coconut through a manual self-centering clamping device, which solves the problem that it is difficult to fix the coconut in the process of manual punching; the electric drive method is used for punching, and the coconut can be punched quickly and lightly; The slag cleaning device can prevent the coconut shell slag from falling into the coconut juice, improve the drinking taste, and ensure the reliability of the continuous operation of the present invention.

Owner:魏云鹏

Antimicrobial and antiviral composition

InactiveUS20070026085A1Avoid problemsEnhance natural filtration propertyBiocideHydroxy compound active ingredientsAdditive ingredientBilateral nares

An antimicrobial and antiviral barrier composition for topical application to the proximal anterior nares includes an antiseptic solution in combination with cocos nucifera (coconut oil) and one or more citrus oils such as, for example, citrus sinensis (orange oil). Various embodiments may also include one or more of the following additional ingredients: lauric acid; d-limonene; soy oil; emu oil; grapefruit seed extract; glycine soja; aloe vera and a preservative, such as sodium benzoate.

Owner:GLOBAL LIFE TECH

Protective Compositions for Dermal Papilla Cells

ActiveUS20110033565A1Avoid cell damagePromote hair growthCosmetic preparationsBiocideGlucose & ProteinHair growth

Disclosed are novel protective compositions for dermal papilla cells. In an embodiment the protective compositions of the present invention comprise 0.25% w / w or above of compositions comprising at least 10% w / w and above of 1-O-galloyl-β-D-glucose (β-glucogallin). In an embodiment, the said protective composition additionally comprises 50% to greater than 50% gallates including mucic acid 1,4-lactone 5-O-gallate, mucic acid 2-O-gallate, mucic acid 6-Methyl ester 2-O-gallate, mucic acid 1-Methyl ester 2-O-gallate and ellagic acid. In another embodiment the invention also encompasses synergistic protective compositions comprising the said protective compositions and 0.5% concentrate of liquid endosperm of Cocos nucifera, for dermal papilla directed towards helping the dermal papilla cells to form sufficient numbers and to retain a healthy morphology conducive for hair growth.

Owner:SAMI LABS LTD

Preparation method of cocos nucifera essence for cigarettes

ActiveCN103396887AIncrease profitIncrease productionTobacco preparationTobacco treatmentAlcohol contentFlavor

The invention discloses a preparation method of a cocos nucifera essence for cigarettes. The preparation method comprises the following steps of: (1) opening a fresh cocos nucifera, and taking out coconut meat and coconut juice; (2) cleaning and mincing the coconut meat, adding 50 to 80 percent ethyl alcohol into the coconut meat, performing soaking for 10 to 20 days under the condition of backlight, extracting a soak solution, and performing concentration under the reduced pressure until alcohol is removed so as to obtain a concentrated solution, wherein the capacity of the ethyl alcohol is 4 to 8 times of the weight of the coconut meat; (3) adding alcohol into the coconut juice until the alcohol content reaches 30-50%, standing for 18 to 30 hours, and performing filtration through a filter membrane to obtain a filter solution for later use, wherein the pore size of the filter membrane is 0.5 to 1.2 microns; (4) mixing the concentrated solution obtained in the step (2) with the filter solution obtained in the step (3) in a volume ratio of 1:(4-8), and performing concentration under the reduced pressure to obtain the cocos nucifera essence. The prepared cocos nucifera essence is capable of enriching the cigarette flavor of the cigarettes, smoothening cigarette gas and improving the taste. Compared with an existing cocos nucifera essence, the cocos nucifera essence has the advantages that the fragrance is soft and smooth, and the cocos nucifera essence is tasty. The cocos nucifera is high in utilization rate, the essence is large in yield, the preparation method is simple, and the production cost is low.

Owner:HUBEI CHINA TOBACCO IND +1

Cassava coconut biscuits and preparation method thereof

InactiveCN102461618AFor long-term storageNot perishableBakery productsBiotechnologyManihot esculenta

The invention provides cassava coconut biscuits, which comprise the following components: 60 to 80 parts of cassava starch, 25 to 35 parts of coconut powder, 25 to 35 parts of egg white, 5 to 15 parts of white granulated sugar and a proper amount of water. The cassava coconut biscuits have the advantages that: 1) the cassava starch, the coconut power and other raw materials are fully mixed uniformly to form a dough; 2) the blended dough is extruded and formed; 3) the extruded and formed dough is baked at 180DEG C for 10 minutes; and 4) cooling and packaging are performed.

Owner:NANTONG GOLDEN LAND GREEN FOOD

Coarse cereal nutritional granules and preparation method thereof

The present invention discloses coarse cereal nutritional granules and a preparation method thereof. The coarse cereal nutritional granules are prepared from the following raw materials: wheat, dried scallops, cashew nuts, American ginseng, coconuts, haws, blueberries, black sesame seeds, black beans, Chinese yams, konjac, fortunella margarita fruits, ginseng fruits and bamboo charcoal. The raw materials consist of the following components in parts by weight: 25-35 parts of wheat, 12-18 parts of dried scallops, 10-16 parts of cashew nuts, 5-10 parts of American ginseng, 12-18 parts of coconuts, 14-20 parts of haws, 18-24 parts of blueberries, 10-16 parts of black sesame seeds, 5-12 parts of black beans, 12-18 parts of Chinese yams, 16-20 parts of konjac, 12-18 parts of fortunella margarita fruits, 10-16 parts of ginseng fruits and 8-16 parts of bamboo charcoal. The coarse cereal nutritional granule is good in taste and rich in nutrition and has health-care function.

Owner:ANHUI YANZHIFANG FOOD HEFEI

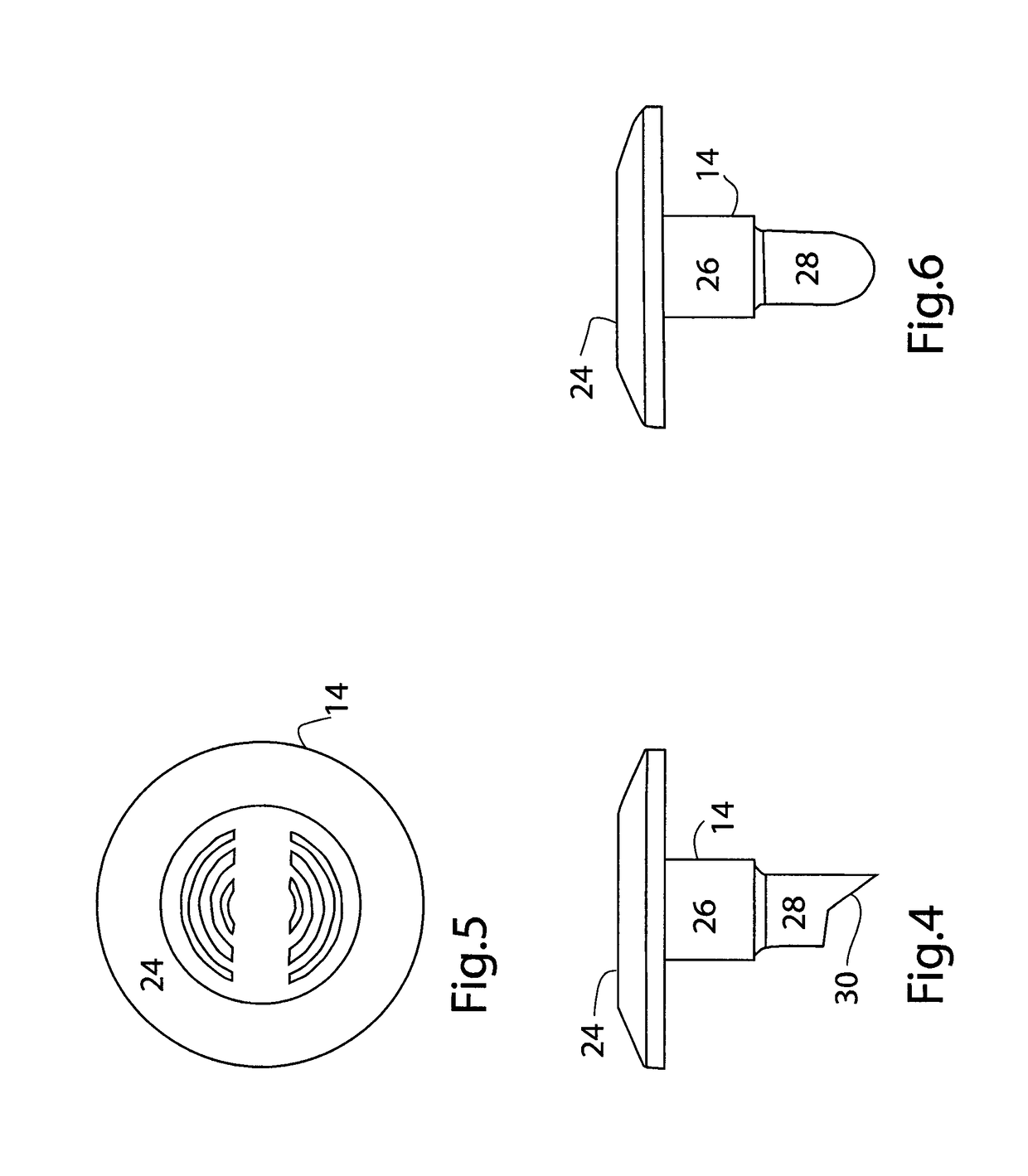

Coconut opener

InactiveUS20170209003A1Reduce consumptionEfficient use ofKitchen equipmentHuskingFresh coconutEngineering

A coconut opener for accessing and removing coconut water from a fresh coconut, comprises a coconut shell penetrating hollow shaft comprising, at a distal end, a blade with a sharp, pointed tip, a disc affixed centrally and transversely atop a proximal end of the shaft and comprising a central aperture within a top surface of the disc, the aperture aligned with the hollow shaft such that in use, a straw may be inserted through the aperture and through the hollow shaft to access the coconut water; and wherein a plurality of grip indentations are formed in an outer rim of the disc.

Owner:FRESH DIRECT PROD

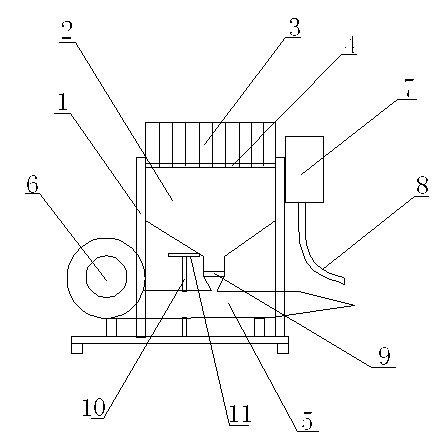

Ripe coconut pulp digging device

ActiveCN111743171AImprove mining efficiencySolve the time-consuming and labor-intensive problem of manual miningHuskingHullingElectric machineEngineering

The invention discloses a ripe coconut pulp digging device, which comprises a bottom plate, a pulp separating unit, a fixing unit, a linear motor, an electric push rod, a fixing plate and a rotating shaft. According to the bottom plate, the linear motor is arranged on the rear side of the top end of the bottom plate, the electric push rod is arranged on the front side face of a linear motor moverbase, the fixing plate is arranged at the front end of the electric push rod, the rotating shaft is rotationally connected to the middle of the fixing plate, and a containing unit is arranged on the right side of the top end of the bottom plate; the pulp separation unit comprises a fixed block, a motor, a two-way lead screw, a movable block, a connecting block, an inserting block and a scraper, the middle of the top of the fixing block is connected with the bottom of the rotating shaft; the two-way lead screw is rotationally connected into a groove in the bottom end of the fixing block, the motor is arranged on the left side face of the fixing block, an output shaft of the motor is connected with the left end of the two-way lead screw, threads at the two ends of the two-way lead screw areopposite, and the ripe coconut pulp digging device is easy to operate, convenient to use, firm in fixing and high in coconut pulp digging efficiency.

Owner:张永根

Method for producing microcrystalline cellulose by using coconut whole fruit as raw materials

ActiveCN103788216AImprove qualityNo wasteMicroorganism based processesFermentationBiotechnologyAcid hydrolysis

The invention relates to a method for producing microcrystalline celluloses by using coconut whole fruit as raw materials. The method using the coconut whole fruit as the raw materials comprises the following steps: fermenting coconut water so as to produce biological cellulose gel, and then drying and crushing so as to obtain biological cellulose powder; by using the rest of coir, coconut shells and coconut flesh as raw materials, crushing, grinding into thick liquid, degreasing, oxidizing, and drying to obtain coir, coconut shell and coconut flesh dry powder; mixing the biological cellulose powder with the coir, coconut shell and coconut flesh dry powder, and carrying out acid hydrolysis, washing, drying and grinding to obtain the microcrystalline cellulose products. The method has the advantages that the coconut water, the coir, the coconut shells and the coconut flesh are utilized to the maximum degree, and no waste is generated; the coir, the coconut shells and the coconut flesh which contain more impurities are pretreated by using a hydrogen peroxide screw extrusion method, and the microcrystalline celluloses are prepared by adopting a two-step acid hydrolysis method, so that needless components in the coir, the coconut shells and the coconut flesh can be removed, and the microcrystalline cellulose products with excellent quality are obtained.

Owner:钟春燕

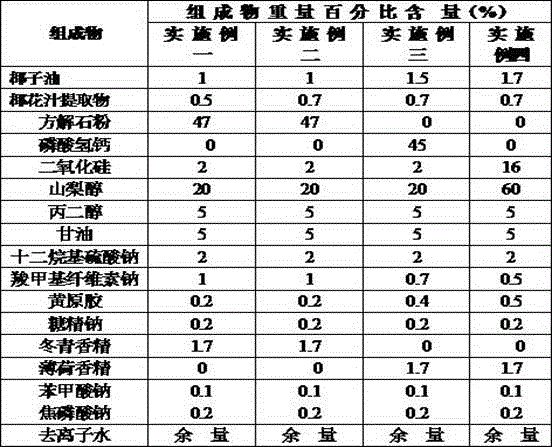

Coconut toothpaste

InactiveCN105596260ADoes not increase drug resistanceImprove the bactericidal effectCosmetic preparationsToilet preparationsMedicineAdditive ingredient

The invention discloses coconut toothpaste which not only has the effects of whitening teeth, resisting oxidation, strengthening the gingival, fixing the teeth and preventing the decayed teeth, but also is wide in raw material source of active pharmaceutical ingredients and a preparation method of the coconut toothpaste. Application of coconuts is widened, the value of the coconuts is fully exerted, and the value chain of coconut products is prolonged. According to the coconut toothpaste, a toothpaste body is prepared from, by weight, 1.5%-7.55% of coconut extract, and the coconut extract comprises coconut oil and coconut flower juice extract; the coconut extract has the effects of killing bacteria, strengthening the gingival, fixing the teeth and preventing the decayed teeth.

Owner:海南宇星日用化工股份有限公司

Environment-friendly compound feed for reservoir ctenopharyngodon idellus

InactiveCN104938856APromote healthy developmentReduce attachment growthAnimal feeding stuffBiotechnologyIntestinal tract diseases

The invention relates to environment-friendly compound feed for reservoir ctenopharyngodon idellus and belongs to the technical field of fish feed. The feed comprises 10-15 parts of flour, 2-5 parts of fish meal, 5-10 parts of peanut meal, 3-8 parts of coconut meal, 3-8 parts of rubber seed meal, 3-10 parts of apple seed meal, 15-25 parts of rapeseed meal, 5-10 parts of citric acid waste, 20-25 parts of soybean meal, 1.5-3 parts of monocalcium phosphate, 0.3-0.5 part of decavitamin premix, 0.5-1 part of compound trace element premix, 0.03-0.1 part of mildew preventive, 0.02-0.1 part of glucan, 0.01-0.1 part of mannan oligosaccharide, 0.02-0.1 part of L-malic acid, 0.05-0.1 part of sodium butyrate and 0.05-0.1 part of bile acid. The feed can well promote the healthy development of the gut and thickening of the intestinal mucosa, reduce the adhesion hyperplasia of harmful germs on the gut, improve digestibility, reduce the occurrence of gut diseases, reduce the loss of nutrients and reduce pollution to water.

Owner:TONGWEI

Antimicrobial and antiviral composition

Owner:GLOBAL LIFE TECH

Coconut milk vinegar beverage and processing method thereof

ActiveCN103948095AComprehensive and balanced nutritionSweet and sour tasteFood preparationFood ingredient as mouthfeel improving agentBiotechnologyNutrition

The invention discloses a coconut milk vinegar beverage and a processing method thereof. The coconut milk vinegar beverage is prepared from 20-40 parts by weight of coconut milk, 10-18 parts by weight of longan aril, 8-12 parts by weight of fruit kernel of Shinyleaf Yellowhorn, 8-12 parts by weight of walnut kernel, 2-4 parts by weight of royal jelly, 2-3 parts by weight of flower of Puerarialobata, 2-3 parts by weight of dandelion, 1-2 parts by weight of Sida rhombifolia L., 1-2 parts by weight of ganoderma lucidum, 1-2 parts by weight of radix curcumae, 2-3 parts by weight of polygala fallax hemsl, 1-2 parts by weight of polygala root, 1-2 parts by weight of Caltha palustris L., 8-10 parts by weight of a nutrition additive and a proper amount of rice vinegar and water. The coconut milk vinegar beverage has rich and balanced nutrition, a sour-sweet taste and a coconut and vinegar fragrance, is suitable for various people, can improve human immunity, can clear heat and remove toxins, moisten the intestines and relax bowel, and promote digestion absorption, and is beneficial for human health.

Owner:海南亨德威食品有限公司

Process for making biopreform from monocotyledonous caudex plant, biopreform obtained thereby, and use thereof

InactiveUS20040126561A1Simpler pyrolyticImprove accuracyAdhesive processesSynthetic resin layered productsAnatomical featureBiology

A method of making biopreform from the stem of monocotyledonous caudex plant, that is suitable for liquid infiltration and gaseous transportation of materials, is disclosed. Wood from caudex stem of trees such as coconut (Cocos nucifera), palmyra palm (Borassus flabellifer), date palm (Phoenics dactylifera), is used as a precursor material which is transformed under simple pyrolitic conditions under self-generated ambient atmosphere to biopreform having microstructural features typical of a monocotyledonous caudex tree. The biopreform is capable of liquid infiltration and gaseous transportation processing of materials in an appreciably shorter processing periods, because of its preservation of the structural and anatomical features of the parent plants with high precision.

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com