Novel preparation process for natural coconut powder

A technology of coconut flour and coconut meat, which is applied in food preparation, food science, application, etc., can solve the problems of unsuitable instant drinks, uneven texture, poor dispersion, etc., and achieve fine and uniform texture, uniform texture and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

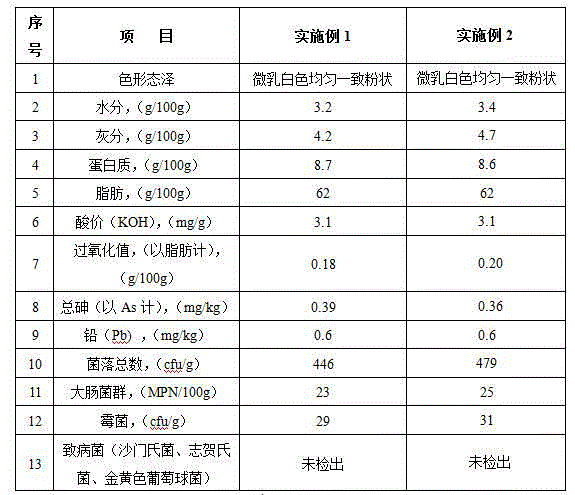

Examples

Embodiment 1

[0029] (1) Trimming and peeling: peel the peeled coconut meat again to make it free of black coconut skin, and pick out the deteriorated coconut meat;

[0030] (2) Cleaning: rinse the coconut meat with CIP cleaning equipment;

[0031] (3) Crushing: Use a crusher to break large pieces of coconut meat into small pieces and juice;

[0032] (4) Pulverization: use a planer to pulverize;

[0033] (5) Juicing: use the method of squeezing, using a combination of screw pressing and hydraulic pressing;

[0034] (6) Filtration: use a double filter for filtration to separate the squeezed juice from the fibers, solid particles mixed in and other solid impurities;

[0035] (7) Ingredients: Put in auxiliary materials maltodextrin and starch syrup, food additives sodium caseinate and tricalcium phosphate, and carry out high-speed mixing and emulsification treatment;

[0036] (8) Homogenization: Carry out homogenization treatment, the homogenization pressure is 50MPa; after homogenization, ...

Embodiment 2

[0041] (1) Trimming and peeling: peel the peeled coconut meat again to make it free of black coconut skin, and pick out the deteriorated coconut meat;

[0042] (2) Cleaning: rinse the coconut meat with CIP cleaning equipment;

[0043] (3) Crushing: Use a crusher to break large pieces of coconut meat into small pieces and juice;

[0044] (4) Pulverization: use a pulverizer to pulverize;

[0045] (5) Juicing: use the pressing method, first use screw pressing, and then use hydraulic pressing;

[0046] (6) Filtration: use a double filter for filtration to separate the squeezed juice from the fibers, solid particles mixed in and other solid impurities;

[0047] (7) Ingredients: Put in auxiliary materials maltodextrin and starch syrup, food additives sodium caseinate, tricalcium phosphate, papain, bromelain and cellulase, and carry out high-speed mixing and emulsification treatment;

[0048] (8) Homogenization: Carry out homogenization treatment, the homogenization pressure is 30...

Embodiment 3

[0053] (1) Trimming and peeling: peel the peeled coconut meat again to make it free of black coconut skin, and pick out the deteriorated coconut meat;

[0054] (2) Cleaning: rinse the coconut meat;

[0055] (3) Crushing: Use a crusher to break large pieces of coconut meat into small pieces and juice;

[0056] (4) Pulverization: use a planer to pulverize;

[0057] (5) Juicing: use the pressing method, first use screw pressing, and then use hydraulic pressing;

[0058] (6) Filtration: use a double filter for filtration to separate the squeezed juice from the fibers, solid particles mixed in and other solid impurities;

[0059] (7) Ingredients: Put in auxiliary materials maltodextrin and starch syrup, food additives sodium caseinate and tricalcium phosphate, and carry out high-speed mixing and emulsification treatment;

[0060] (8) Homogenization: Carry out homogenization treatment, the homogenization pressure is 60MPa; after homogenization, the particle size is less than 3μm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com