Patents

Literature

47 results about "Ctenopharyngodon idellus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SNP (single nucleotide polymorphism) marker for evaluating growth performance of ctenopharyngodonidella, primer and evaluation method

ActiveCN106755527AEasy to identifyMicrobiological testing/measurementDNA/RNA fragmentationGenetic exchangeIntein

The invention provides an SNP (single nucleotide polymorphism) marker (comprising SNP1 and SNP4) for evaluating growth performance of ctenopharyngodonidella and a primer pair for amplifying a gene segment where an SNP locus is positioned by virtue of methods of molecular genetics and molecular biology. SNP1 is positioned at the 940th locus in a promoter of a complete sequence of a MyoD (myogenic determining factor) gene of the ctenopharyngodonidella, and a base T is inserted or deficient at the position; SNP4 is positioned in a 107th locus in a first intron of the complete sequence of the MyoD gene of the ctenopharyngodonidella, and a base at the position is A or T. The growth performance of the ctenopharyngodonidella is determined by detecting haplotypes of the two SNP loci. The adopted haplotypes are mutated according to bases generated in the MyoD gene, so that genetic exchange and further phenotype verification are avoided. By virtue of the haplotypes of the SNP marker, rapidly growing ctenopharyngodonidella can be simply and rapidly identified, and rapidly growing ctenopharyngodonidella of a new line can also be guided to be bred.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

Anti-stress and puffed mixed feed for ctenopharyngodon idellus and production method for feed

InactiveCN103815201AReasonable ratioNutritional balanceAnimal feeding stuffAnti stressMonocalcium phosphate

The invention relates to anti-stress and puffed mixed feed for ctenopharyngodon idellus and a production method for the feed. The mixed feed includes the following raw materials in mass percentage: 0-8% of meat and bone meal, 2-5% of broad bean albumen powder, 8-18% of soybean meal, 20-30% of rapeseed dregs, 10-15% of cottonseed meal, 10-20% of wheat, 10-20% of tapioca flour, 5-8% of rice bran, 2-4% of soya-bean oil, 0.2-0.4% of 50% choline chloride, 0.9-1.5% of monocalcium phosphate, 1-2% of vitamin premix, 1-2% of mineral premix, 1-2% of zeolite powder, 0.02-0.1% of GSH, 0.01-0.08% curcumin, 0.01-0.03% of tea polyphenol, 0.05-0.1% of taurine, 0.005-0.01% of rheum emodin, 0.01-0.02% of L-carnitine, and 0.02-0.03% of complex enzyme preparation. The anti-stress and puffed mixed feed improves the digestibility and deposition of feeding ctenopharyngodon idellus to nutrient substances of the feed, improves the immune, antioxidant and anti-stress ability of fish body and promotes growing of ctenopharyngodon idellus.

Owner:HUZHOU TEACHERS COLLEGE

Feed for procambarus clarkii

InactiveCN107028029AWide variety of sourcesLow priceClimate change adaptationAccessory food factorsSide effectAnimal science

The present invention discloses a feed for procambarus clarkia. The feed is prepared from the following components in parts by weight: 30-35 parts of corn flour, 25-30 parts of puffed soybean meal, 5-10 parts of distillers' grains, 2-3.5 parts of yeast powder, 20-25 parts of flour, 10-15 parts of spirulina platensis powder, 5-10 parts of green vegetable leaves, 2-3 parts of chicken intestine powder, 5-10 parts of earthworm powder, 2-3 parts of dried small ctenopharyngodon idellus powder, 5-10 parts of sunflower seed oil residues, 0.2-0.4 part of garlicin, 1-3 parts of Chinese yams, 2-3 parts of wild chrysanthemum, 0.5-1.2 parts of licorice, 2-4 parts of leonurus artemisia, 2-3 parts of honeysuckle, 1-1.5 parts of compound vitamins, and 1-1.5 parts of trace elements. Advantages are as follows: the feed contains various nutrients, is scientific in formula and comprehensive in nutrition, and satisfies basic nutrition of the procambarus clarkia. At the same time, the vitamins and trace elements are added, so that the feed ensures the procambarus clarkia to grow rapidly, improves immunity, and is free of toxic and side effects, and also harmful substance residues.

Owner:和县乌江镇雅轩家庭农场

Method for improving gel properties of Ctenopharyngodon idellus surimi and improving mouthfeel thereof

A method for improving gel properties of Ctenopharyngodon idellus surimi and improving mouthfeel thereof, comprising: using ctenopharyngodon idellus as a raw material to perform pretreatment, meat extraction, low-concentration saline solution based rinsing, ultrasonic treatment, cutting and stirring, two-stage heating, packaging and frozen storage. According to the method, the prepared surimi is good in gel properties, fine and smooth in mouthfeel, better in quality and longer in shelf-life. Rinsing is performed by using a low-concentration saline solution, so that the obtained surimi is high in saline soluble protein content, and high in purity. The ultrasonic technique enables the surimi to be more uniform, fine and smooth in texture, improves the gel strength and whiteness of the surimi, and the sterilization effect of the ultrasonic technique improves the quality of surimi products and prolongs the shelf-life of the surimi products. The two-stage heating method allows the surimi to pass a 50-70 DEG C gel deterioration temperature region quickly, so as to avoid surimi gel deterioration. The method is simple and convenient to operate, is low in cost, high in efficiency, and suitable for industrialized production, provides a novel idea for high-quality fresh water surimi production, and provides a novel method for fresh water surimi modification and industrialized production.

Owner:JIANGXI NORMAL UNIV

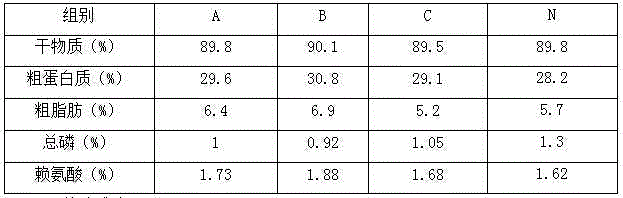

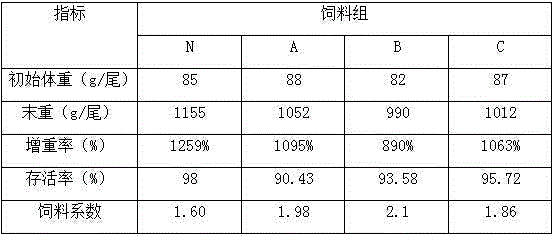

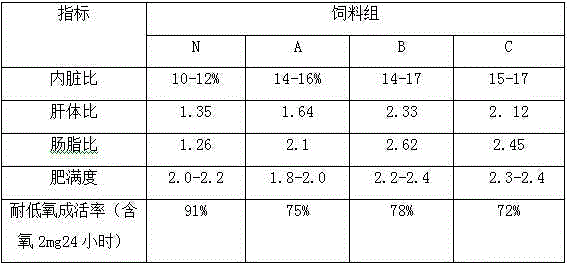

Toughened ctenopharyngodon idellus compound feedstuff

The invention discloses a toughened ctenopharyngodon idellus compound feedstuff which is prepared by using soybean meal, cottonseed meal, rapeseed meal, broad bean, broad bean peel, fish oil or soybean oil, choline chloride, calcium dihydrogen phosphate, a multi-vitamin and multi-mineral premix, and methionine. An outstanding characteristic of the invention is that with the feedstuff, the growth speed of the toughened ctenopharyngodon idellus is improved by approximately 50% than that of toughened ctenopharyngodon idellus fed with broad beans, a feed coefficient is reduced from 3-4 of a broad bean feeding method to 2.0-2.5, and growth performance of the toughened ctenopharyngodon idellus is close to that of ctenopharyngodon idellus fed with common feedstuffs. The feedstuff provided by the invention can be directly used for feeding, and pre-impregnation as required by broad beans is not needed, such that feeding work load is greatly reduced. Also, with the invention, the feedstuff dosage is reduced, feedstuff utilization rate is improved, culture waste discharge is reduced, pond water quality is improved, and toughened ctenopharyngodon idellus quality is improved.

Owner:SHANGHAI OCEAN UNIV

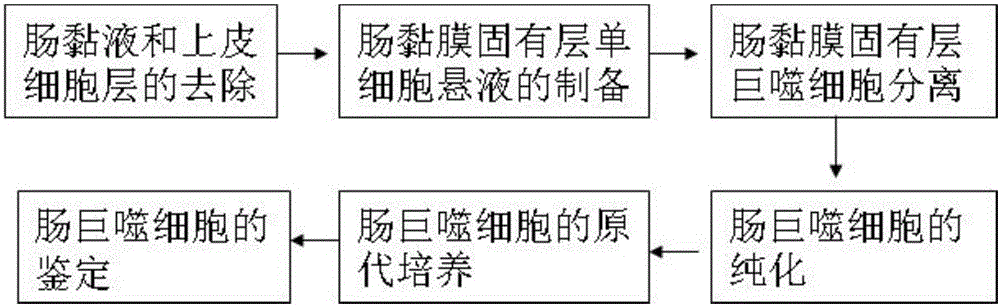

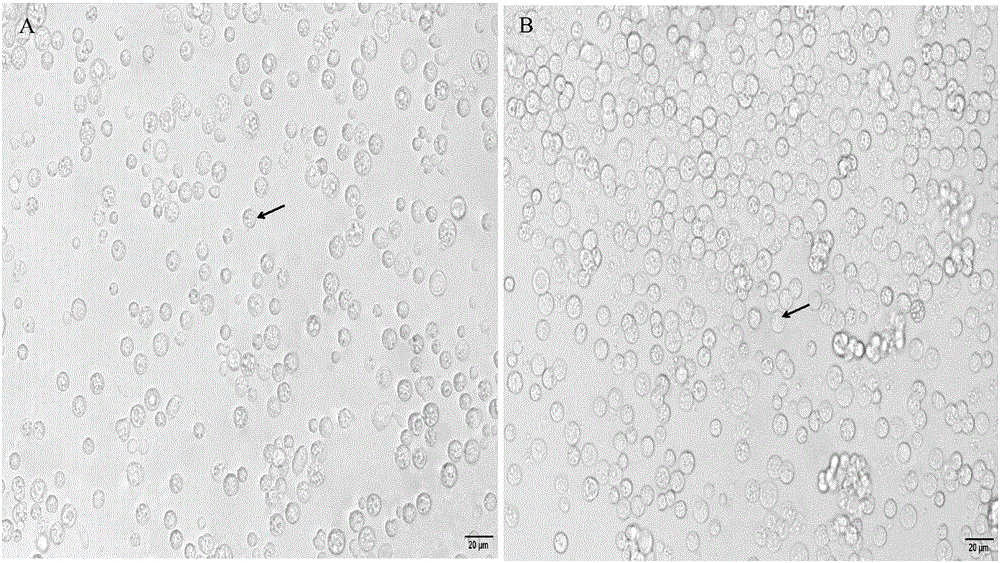

Separation, purification and primary culture methods of intestinal macrophages in Ctenopharyngodon idella

ActiveCN107523542AEasy to separateEasy to operateCell dissociation methodsCulture processIntestinal structureFeces

The invention relates to separation, purification and primary culture methods of intestinal macrophages in Ctenopharyngodon idella. The separation method comprises: taking out the rear middle segment of an intestine by aseptic operation, removing intestinal outer fat and mesentery, longitudinally cutting the intestine to clear excrement, and using aseptic bent-tip tweezers to scrape off the intestinal mucus and epithelial cell layer for 15 min; cutting the segment with the mucus and epithelial cell layer removed to obtain fragments, and digesting the fragments in collagenase IV digestive juice to obtain lamina propria single-cell suspension; using a separation kit of fish organ monocytes to separate the intestinal macrophages. The purification method comprises: using a differential wall attachment method to purify the intestinal macrophages. The primary culture method comprises: using RPMI (Roswell Park Memorial Institute medium) 1640 complete culture solution containing autoserum of Ctenopharyngodon idella to culture the intestinal macrophages, changing the solution once with lipopolysaccharide-containing RPMI 1640 complete culture solution after cells attach to the wall, and changing the solution once every other two days so that cells may survive for at least 20 days. The separation, purification and primary culture methods established herein have good operability and repeatability.

Owner:ANHUI AGRICULTURAL UNIVERSITY

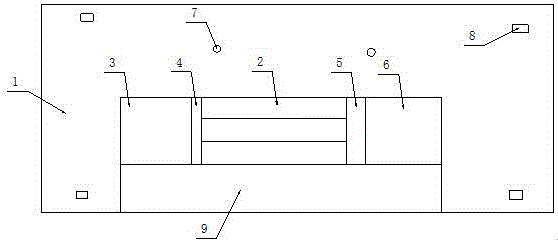

Method for cultivating Litopenaeus vannamei through circulating water fish-farming system

ActiveCN106234270ADelay or reduce useReduce usageClimate change adaptationPisciculture and aquariaSocial benefitsZoology

The invention relates to the field of aquaculture, in particular to a method for cultivating Litopenaeus vannamei through a circulating water fish-farming system. According to the method, Mylopharyngodon piceus, Ctenopharyngodon idella and Lateolabrax japonicus are farmed in a running water cultivating unit, and Litopenaeus vannamei are cultivated in a large pond. For a test pond having an area of 32.9 mu, fishes and shrimps of 49.18 tons in total can be produced by two crops in one year, the production goes to the yield per mu of 1494.8 kg, total output value is 969600 yuan, average output value per mu is 29470 yuan, total materialized cost is 555000 yuan, total profit is 414600 yuan, and average profit per mu is 12602 yuan; the whole cultivating process is free of emission of cultivation wastewater, zero emission of cultivation tail water is achieved, and ecological, economic and social benefits are good.

Owner:HANGZHOU AQUATIC PROD TECH PROMOTION GENERAL STATION

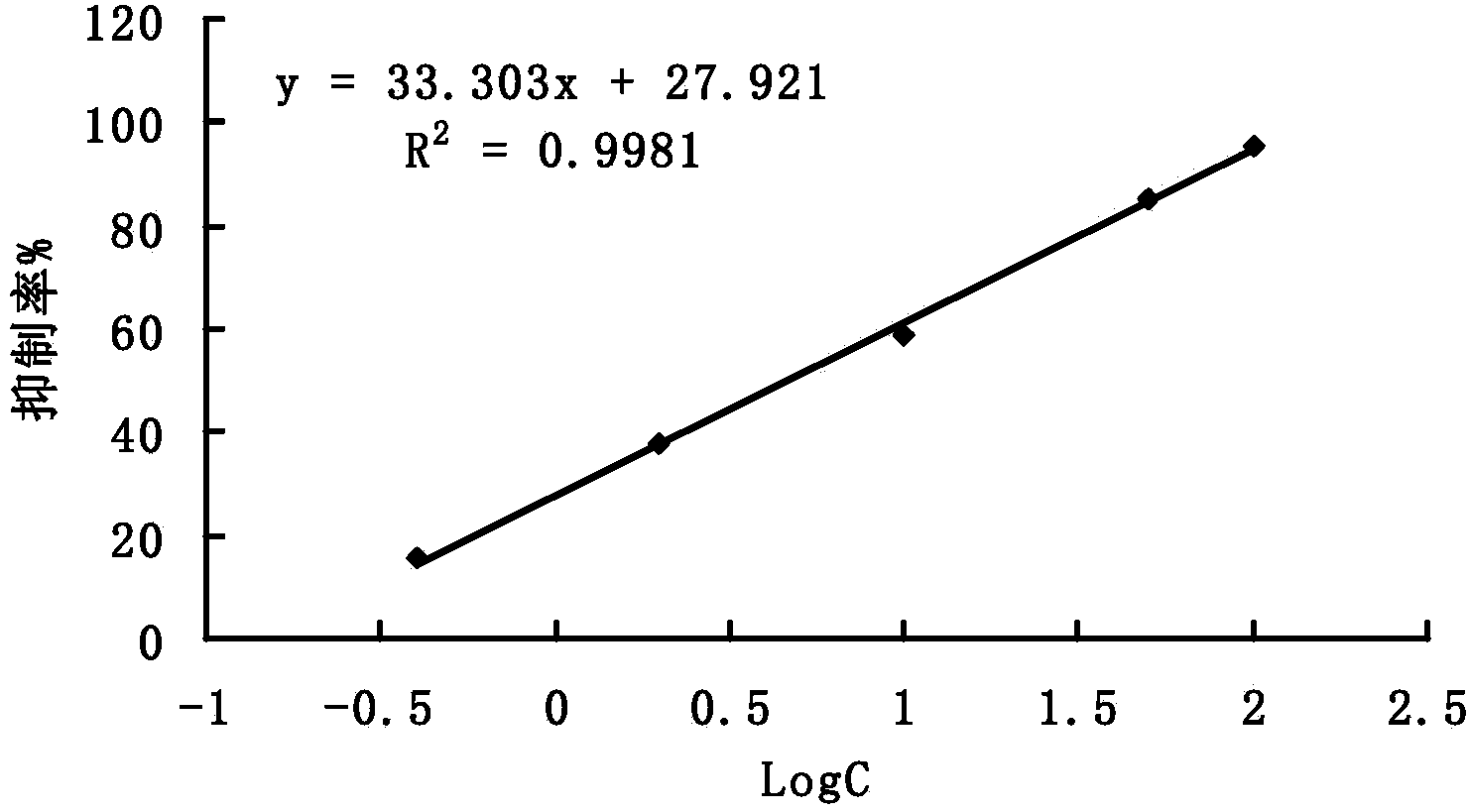

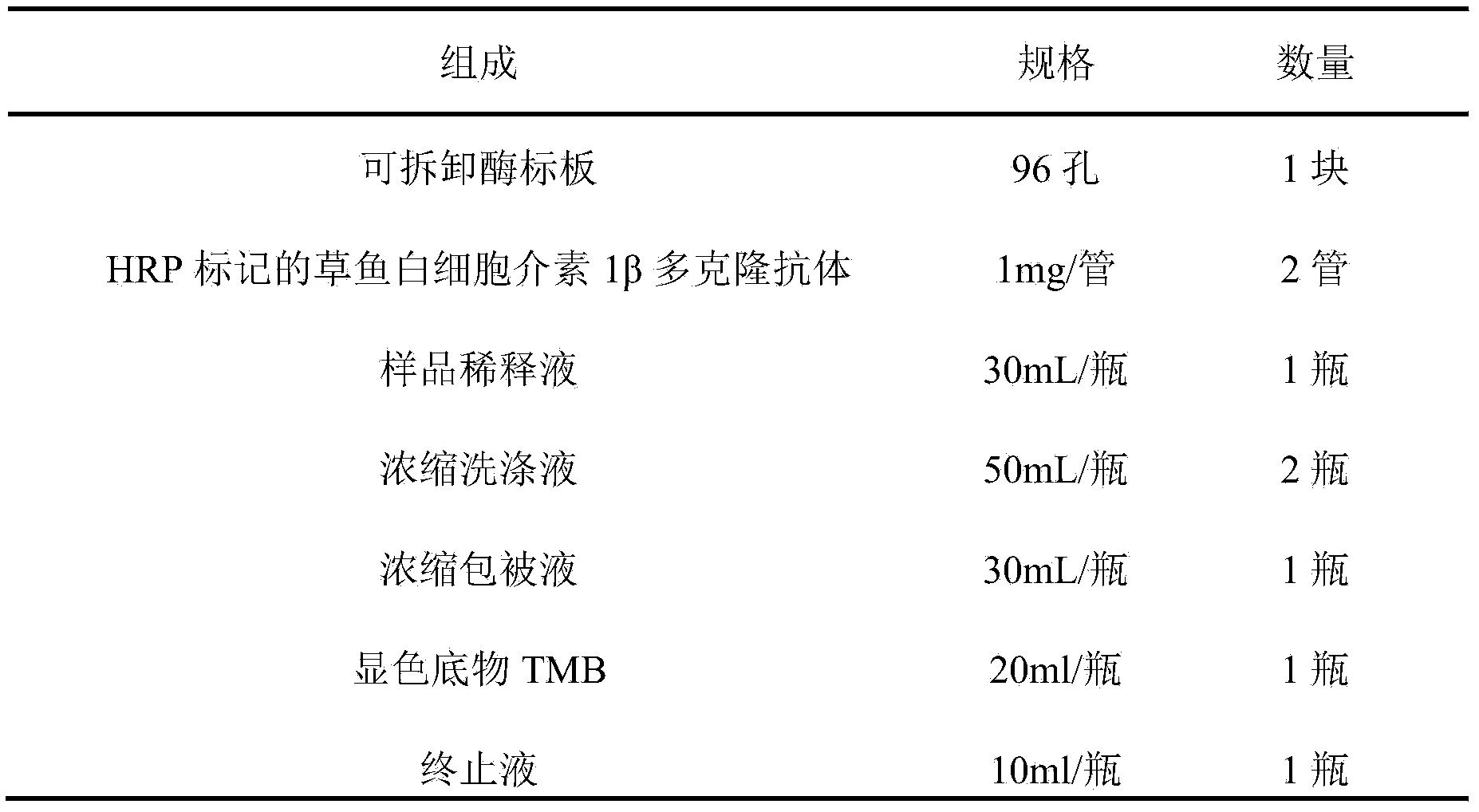

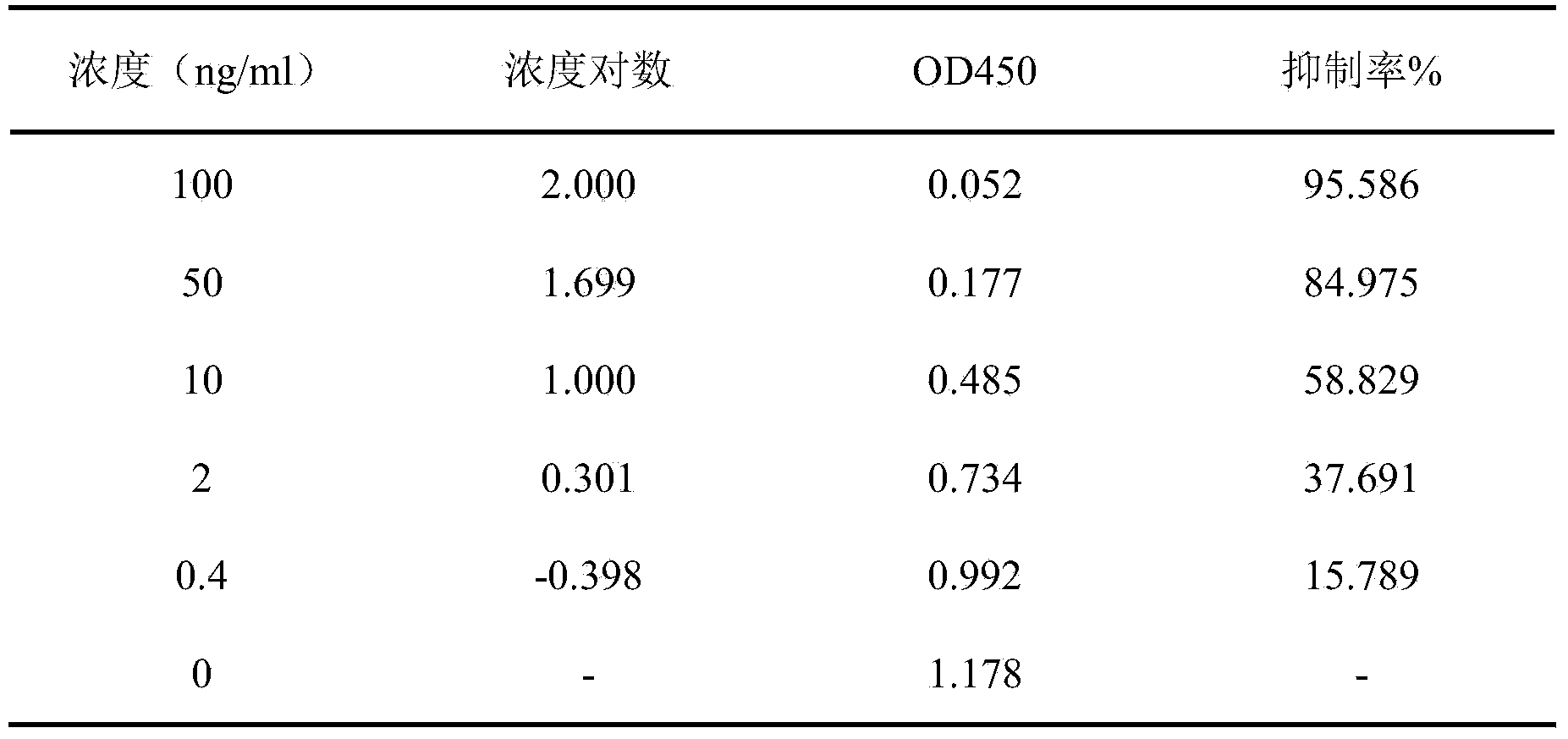

Ctenopharyngodon idellus interleukin-1beta (IL-1beta) enzyme-linked immunosorbent assay (ELISA) kit

InactiveCN104237529AEfficient detection meansLow costBiological testingChromogenic SubstratesWhite blood cell

The invention belongs to the biotechnology field and discloses a ctenopharyngodon idellus interleukin-1beta (IL-1beta) competitive inhibiting enzyme-linked immunosorbent assay (ELISA) kit. The kit comprises the following components: (1) an ELISA plate, (2) a horse radish peroxidase marked ctenopharyngodon idellus IL-1beta polyclonal antibody concentrated solution, (3) a sample diluent, (4) washing concentrate, (5) concentrated coating buffer, (6) a chromogenic substrate, (7) stop buffer and (8) standard ctenopharyngodon idellus IL-1beta. The kit has the characteristics of simplicity in operation, good repeatability, accuracy and specificity and wide linear detection range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

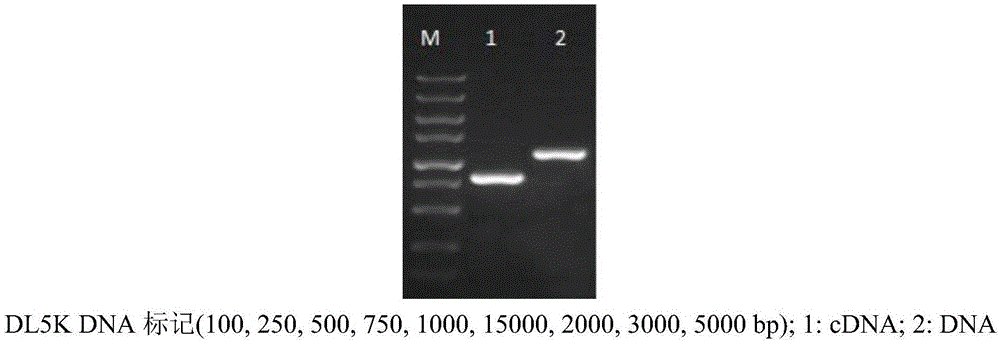

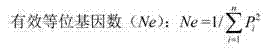

Method for distinguishing gynogenetic ctenopharyngodon idellus from common ctenopharyngodon idellus

InactiveCN103993081AStable amplificationThe result is stableMicrobiological testing/measurementAlleleBiology

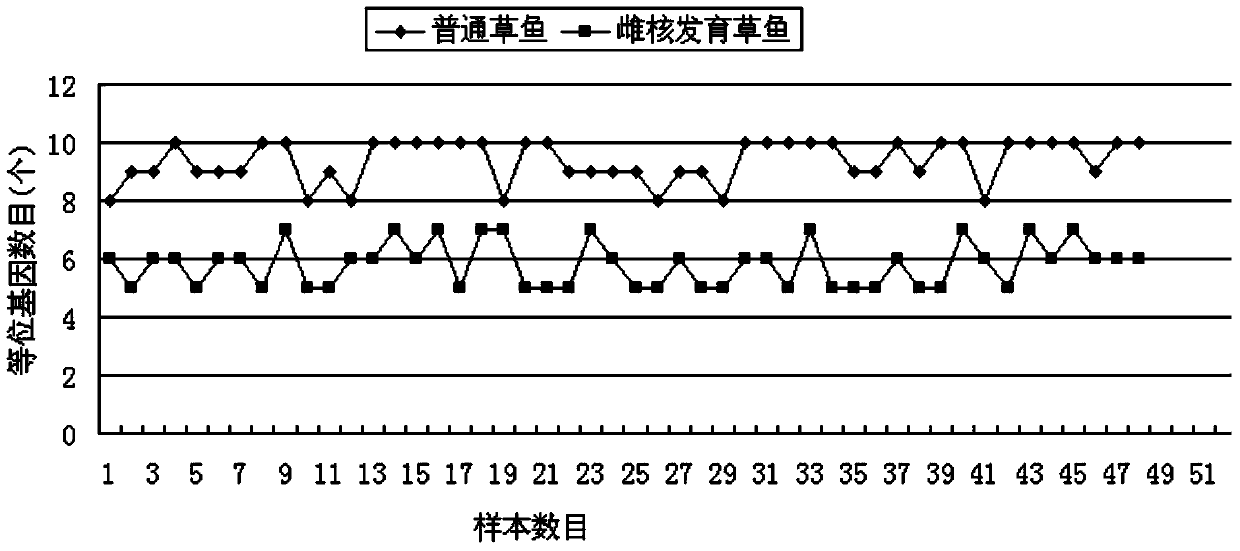

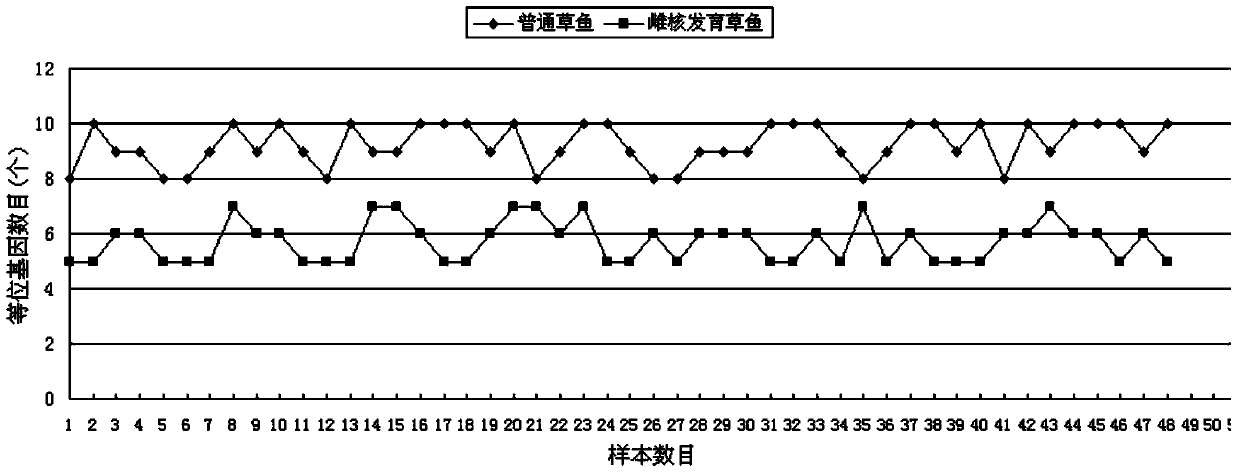

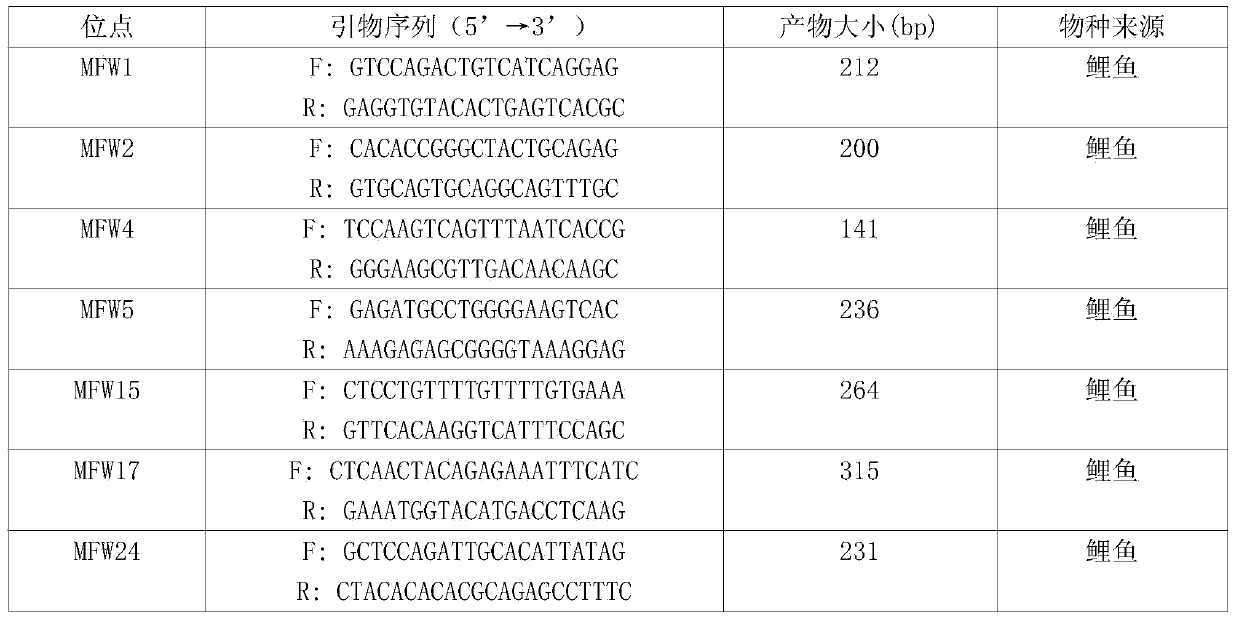

The invention provides a method for distinguishing gynogenetic ctenopharyngodon idellus from common ctenopharyngodon idellus, and particularly provides a molecular marking method having the advantages of high polymorphism, genetic stability, high detection success ratio, wide utilization and the like; the molecular marking method is capable of quickly and accurately distinguishing gynogenetic ctenopharyngodon idellus from common ctenopharyngodon idellus. According to the difference in genetic homozygosity, five SSR (Simple Sequent Repeats) which are stable in amplification, clear in bands, polymorphic and great in genetic homozygosity difference in a gynogenetic population and a wild population are screened out from 14 SSR markers. As the genetic homozygosity in the gynogenetic population is greatly improved, the number of alleles amplified in the population by virtue of the SSRs is also reduced. Statistical analysis shows that the actual number of alleles amplified in the common ctenopharyngodon idellus by virtue of the five SSRs is 8-10 while the number of alleles amplified in the gynogenetic ctenopharyngodon idellus is 5-7, so that the gynogenetic ctenopharyngodon idellus and the common ctenopharyngodon idellus can be distinguished from each other by comparing the number of alleles, and the theoretical value of the accuracy rate can be 99.92%.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI +1

Environment-friendly compound feed for reservoir ctenopharyngodon idellus

InactiveCN104938856APromote healthy developmentReduce attachment growthAnimal feeding stuffBiotechnologyIntestinal tract diseases

The invention relates to environment-friendly compound feed for reservoir ctenopharyngodon idellus and belongs to the technical field of fish feed. The feed comprises 10-15 parts of flour, 2-5 parts of fish meal, 5-10 parts of peanut meal, 3-8 parts of coconut meal, 3-8 parts of rubber seed meal, 3-10 parts of apple seed meal, 15-25 parts of rapeseed meal, 5-10 parts of citric acid waste, 20-25 parts of soybean meal, 1.5-3 parts of monocalcium phosphate, 0.3-0.5 part of decavitamin premix, 0.5-1 part of compound trace element premix, 0.03-0.1 part of mildew preventive, 0.02-0.1 part of glucan, 0.01-0.1 part of mannan oligosaccharide, 0.02-0.1 part of L-malic acid, 0.05-0.1 part of sodium butyrate and 0.05-0.1 part of bile acid. The feed can well promote the healthy development of the gut and thickening of the intestinal mucosa, reduce the adhesion hyperplasia of harmful germs on the gut, improve digestibility, reduce the occurrence of gut diseases, reduce the loss of nutrients and reduce pollution to water.

Owner:TONGWEI

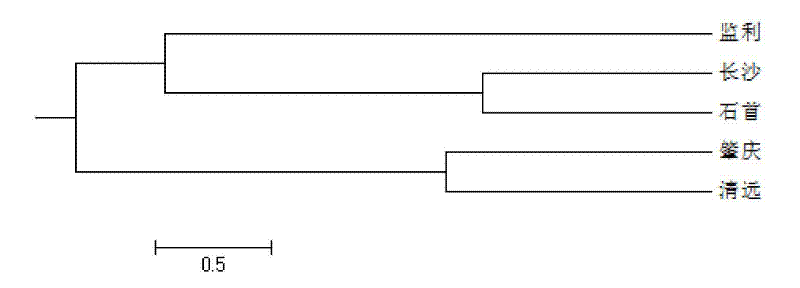

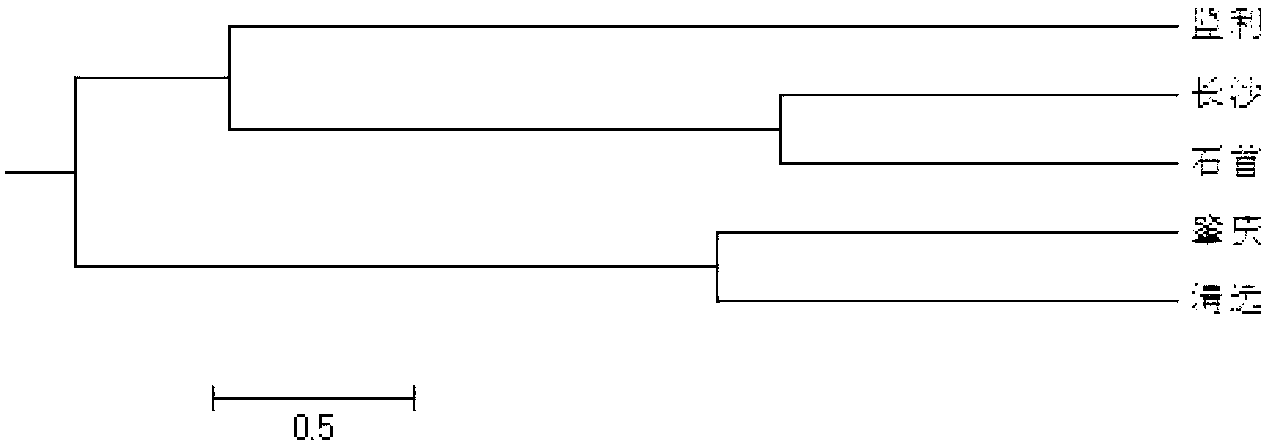

Method for classifying ctenopharyngodon idella based on expressed sequence tag-simple sequence repeats (EST-SSR) marker

InactiveCN102242222AAccurate identificationRapid identificationMicrobiological testing/measurementBiotechnologyGenetic architecture

The invention discloses a method for classifying ctenopharyngodon idella based on an expressed sequence tag-simple sequence repeats (EST-SSR) marker, which comprises the following steps of: extracting the deoxyribonucleic acid (DNA) of the ctenopharyngodon idella, amplifying by using the EST-SSR marker, and analyzing the genetic structure of the ctenopharyngodon idella according to an amplification result. Compared with the conventional method, the method has the advantages of high purposiveness and direct action effect, and is easy to operate, high in detection speed, low in detection cost, and convenient to widely popularize and use.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

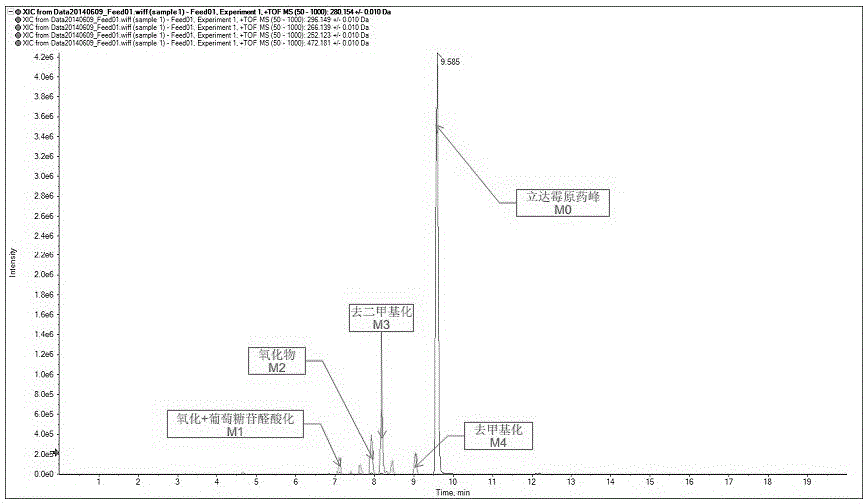

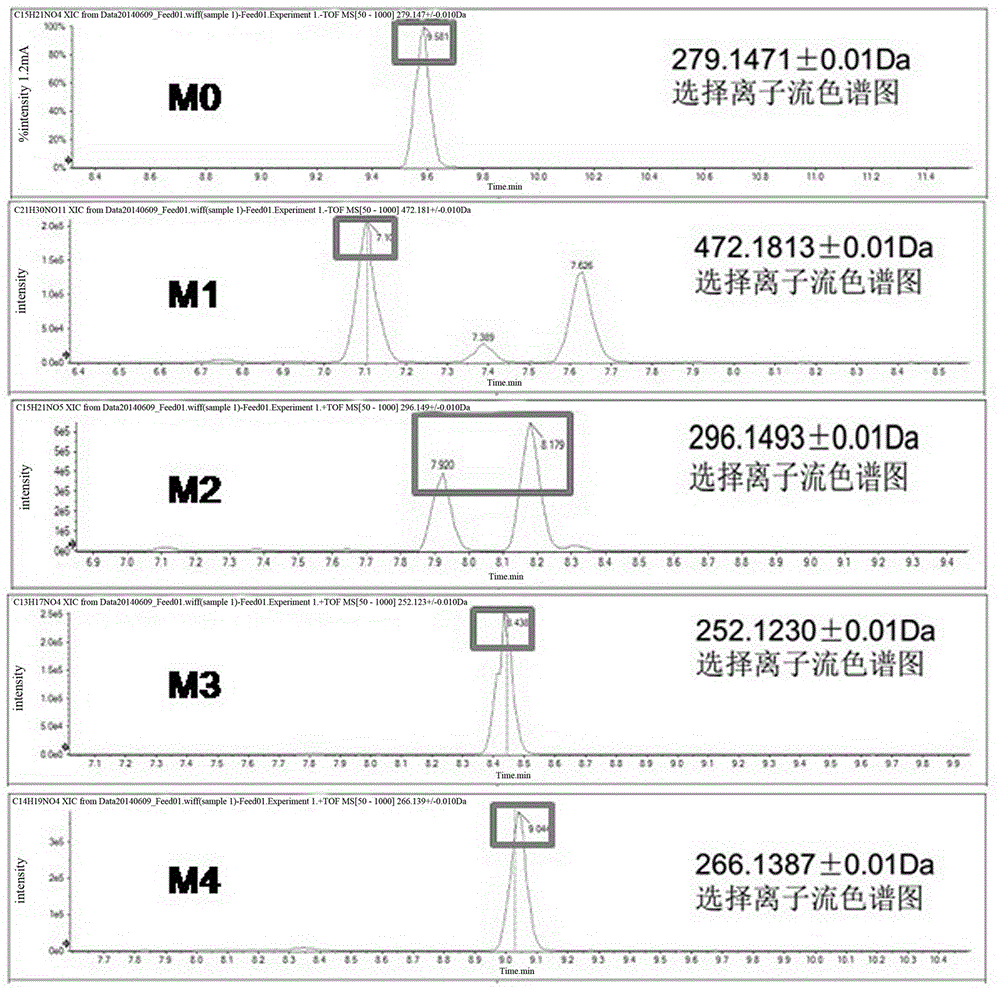

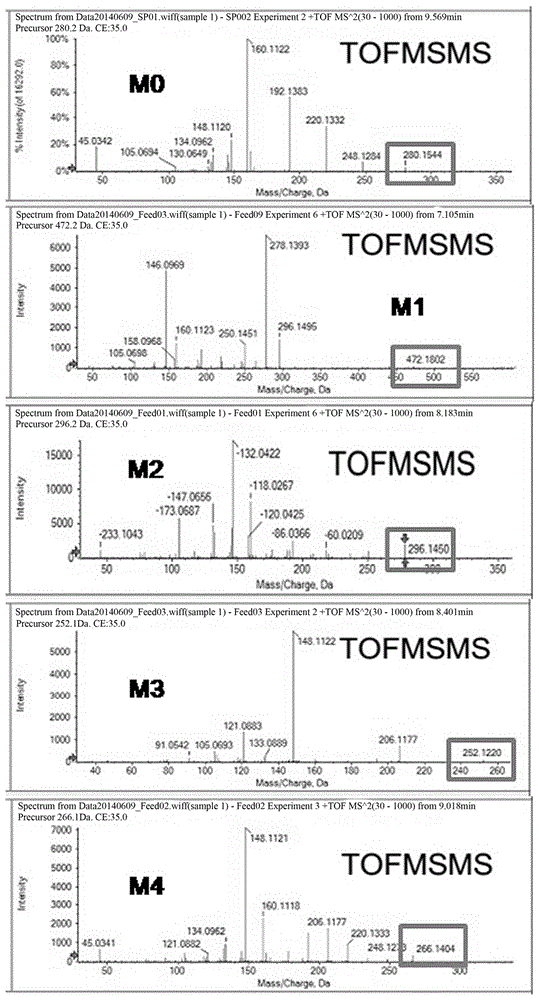

Metabolites of Ridomil in ctenopharyngodon idellus

InactiveCN106431962AAccurate qualitative analysisEfficient separationOrganic chemistryComponent separationMetaboliteAlanine methyl ester

The invention relates to metabolites of Ridomil in ctenopharyngodon idellus. The metabolites of Ridomil in ctenopharyngodon idellus can be N-(2-carboxyl-6-benzyl)-N-(methoxyacetyl)alanine, N-(2-hydroxymethyl)-6-tolyl-N-(glycolyl)alanine, N-(2, 6-xylyl)-N-(glycolyl)alanine or N-(2-hydroxymethyl-6-benzyl)-N-(methoxyacetyl)alanine methyl ester. After dosing ctenopharyngodon idellus with Ridomil, the invention for the first time finds that in a mouth filling group and a soaking group, Ridomil in liver tissue is based on prototype drug, and finds the metabolites of the aforementioned four Ridomil in ctenopharyngodon idellus.

Owner:SHANGHAI OCEAN UNIV

Compound feed for ctenopharyngodon idella

ActiveCN102696925AMeeting nutritional needsBroad experimental baseAnimal feeding stuffBiotechnologyCrude fibre

The invention discloses a compound feed for ctenopharyngodon idella. The compoound feed for ctenopharyngodon idella comprises the following nutrient components in percentage by mass: 22-33% of crude protein, 3-6% of crude fat, 36-50% of starch, 7-10% of ash, 6-10% of water, 1.18-1.34% of total phosphorus, 5-8% of raw fiber and 0.2-1.55% of crystallized nonessential amino acid. The compound feed for ctenopharyngodon idella has the advantages of effectively improving the body weight gain rate of ctenopharyngodon idella, increasing conversion rate of the feed, increasing deposition rate of protein, reducing fat accumulation of mesentery, improving the quality and edible proportion of ctenopharyngodon, saving culture cost greatly and improving economical benefits.

Owner:SUN YAT SEN UNIV

Culture method for reducing disease incidence of penaeus vannamei

InactiveCN107743901AReduced growth and reproductionReduce residual erbiumFood processingClimate change adaptationDiseaseResource utilization

The invention discloses a culture method for reducing a disease incidence of penaeus vannamei. The method comprises the following steps: step 1, building a pond and treating the pond: arranging an aerator, a bait throwing device and a water inlet and a water outlet in the pond, sterilizing and disinfecting the pond before cultivation, fertilizing bottom mud, and planting waterweeds at the bottom of the pond; step 2, performing throwing: throwing the disinfected penaeus vannamei larvae and ctenopharyngodon idellus fry; step 3, performing feed management: performing feed feeding for 3-4 times per day; and step 4, preventing diseases: inspecting the pond every day, observing water quality and activities of fishes and the penaeus vannamei, timely changing water and performing oxygenation, andapplying a mixed preparation of a traditional Chinese herbal medicine liquid and probiotics for 3-5 times per month. The invention provides the culture method for reducing the disease incidence of thepenaeus vannamei. According to the invention, through optimizing culture technologies, the residual feed is less, the resource utilization rate is high, the water exchange amount is less, and therefore outbreaks and epidemics of bacterial diseases and viral diseases are effectively inhibited; and the disease incidence of the penaeus vannamei is low, and the survival rate is high, so that the development of a culture industry of the penaeus vannamei is effectively promoted.

Owner:合肥申仁养殖有限公司

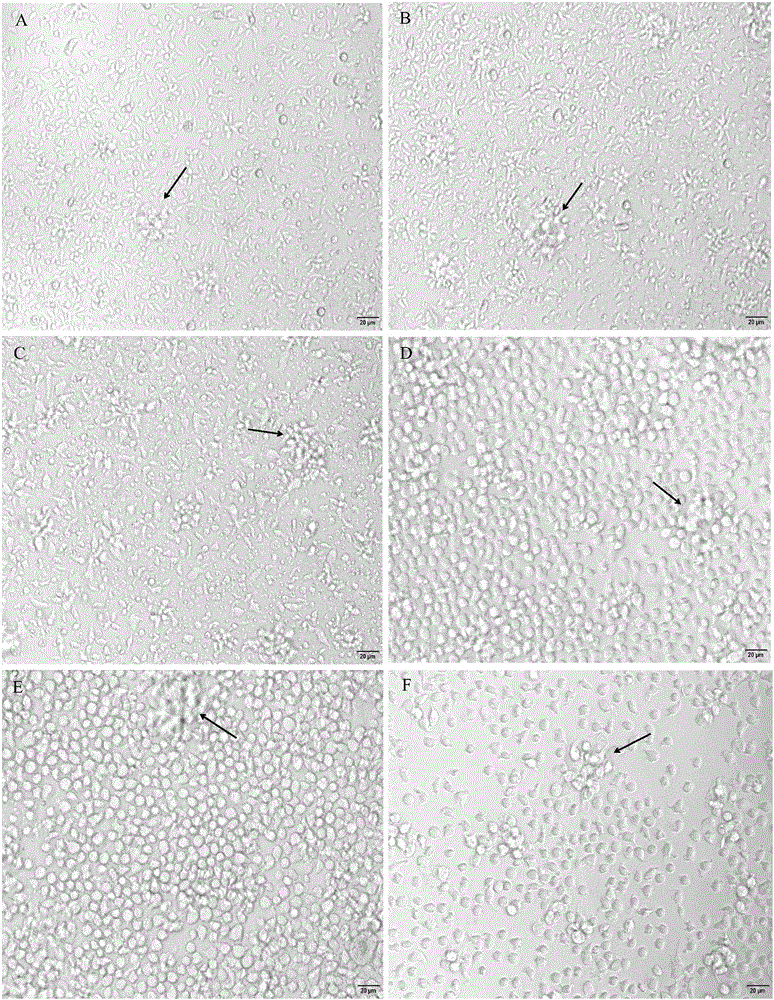

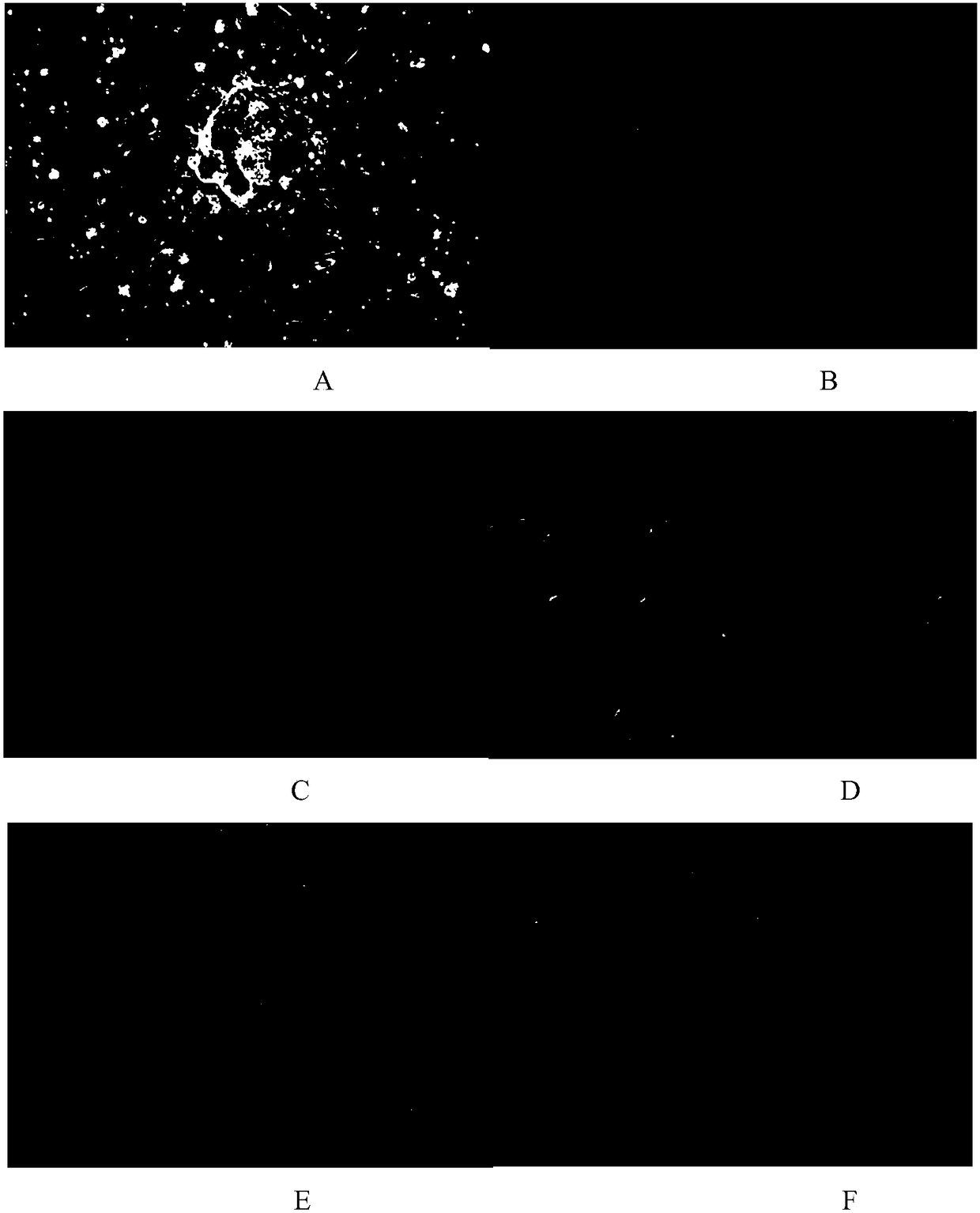

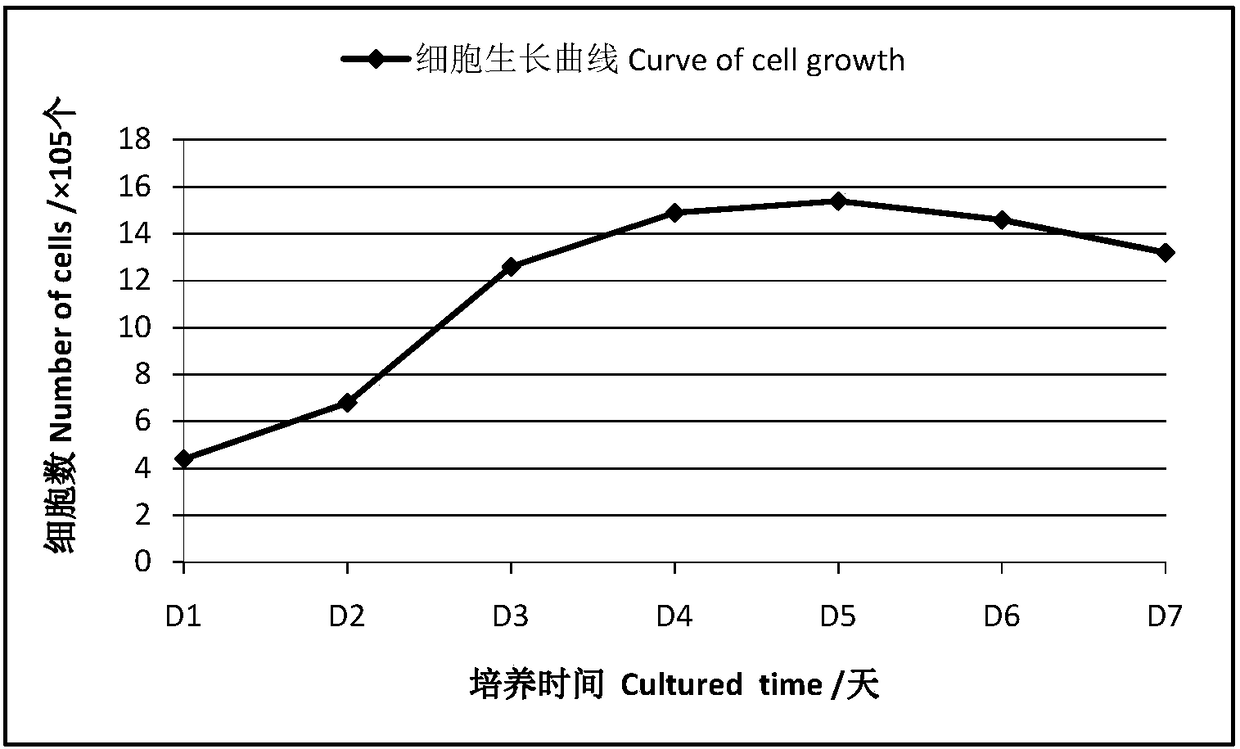

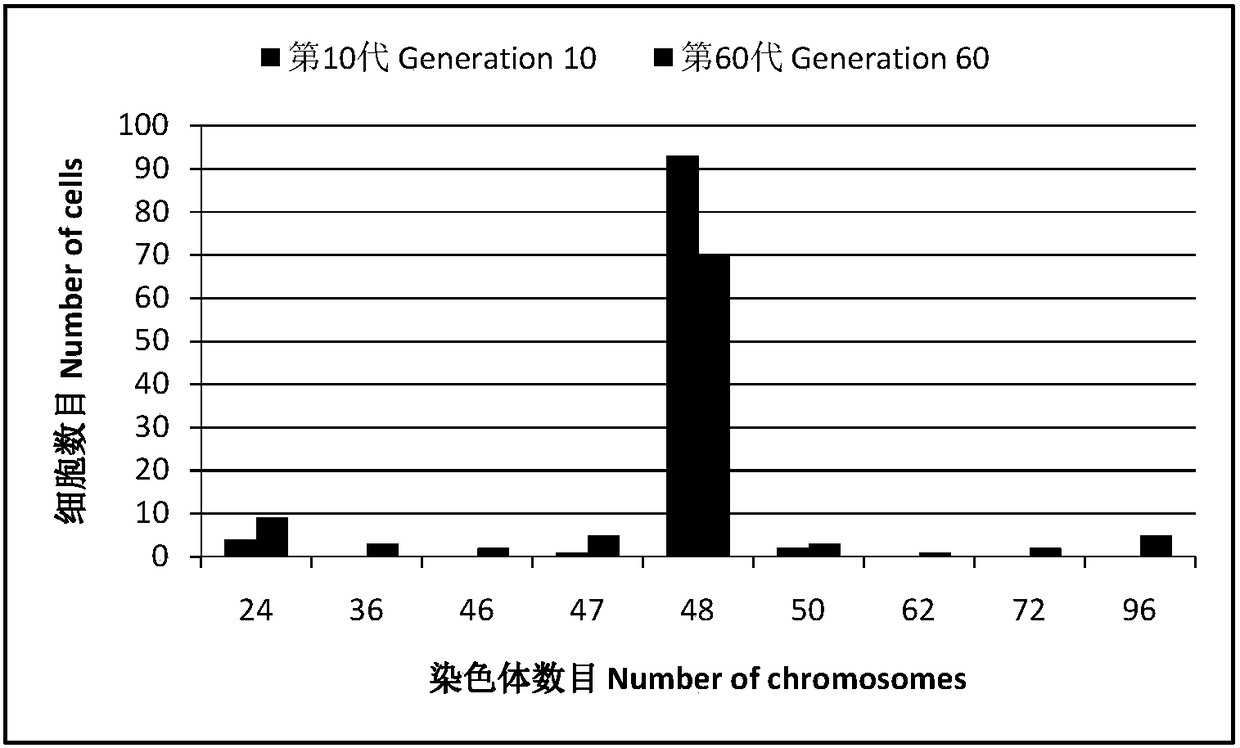

Ctenopharyngodon idellus muscle tissue cell line and application

ActiveCN108148803AReduce pollutionReduce deathMicroorganism based processesSkeletal/connective tissue cellsMuscle tissueMicrobiology

The invention discloses a ctenopharyngodon idellus muscle cell strain and a preparation method thereof. The preservation number of the cell strain is CCTCC NO. C201833. The preparation method comprises steps of (1) sterilizing ctenopharyngodon idellus muscle tissue, shearing the muscle tissue into pieces, inoculating, dry sticking to a culture box, adding cell culture liquid to cultivate, and emigrating cells at the sixth day; washing with PBS, adding pancreatin which contains EDTA to digest cells, after cells becomes round, eluting with culture liquid, centrifuging and collecting cells to cultivate, changing the culture liquid every two days till cells grow to primary muscle cells with 80%-90% cells converged; and (2) after a layer of primary ctenopharyngodon idellus muscle cells is grown, removing culture liquid, washing with PBS, digesting cells with pancreatin which contains EDTA, detaching the cells, absorbing the digestion liquid, adding cell culture liquid to scatter and float cells for subculture. The preparation method is simple, and the prepared cell strain can be well applied to separation and proliferation of ctenopharyngodon idellus reovirus and research of ctenopharyngodon idellus haemorrhage vaccine.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

Traditional Chinese medicine oral liquid for treating bacterial gill-rot disease of ctenopharyngodon idellus and preparation method thereof

InactiveCN104173743APreserve the combination effectDefinite curative effectAntibacterial agentsPlant ingredientsDiseaseCure rate

The invention relates to traditional Chinese medicine oral liquid for treating bacterial gill-rot disease of ctenopharyngodon idellus and a preparation method thereof. The traditional Chinese medicine oral liquid is prepared from rhubarb, scutellaria, cordate houttuynia, herba andrographitis, hyacinth bletilla and herba agrimoniae. The traditional Chinese medicine composition can be oral liquid and is prepared through the steps: (1) crushing the traditional Chinese medicines until the particle size is 60-80 meshes, weighing the traditional Chinese medicines according to a formula, and carrying out three-dimensional mixing, so as to obtain traditional Chinese medicine powder; (2) respectively adding the mixed traditional Chinese medicine powder and 300-600 parts of water into an extracting tank, and soaking for 5-20 hours; (3) heating to the temperature of 40-100 DEG C, and extracting for 10-15 hours; (4) filtrating and collecting liquid medicine; (5) continuing to add 300-600 parts of water into remnant medicine dregs, and extracting for 10-15 hours at the temperature of 40-100 DEG C; (6) filtrating to remove the medicine dregs, combining extracts obtained in two times, and carrying out depressurized concentration at the temperature of 30-70 DEG C until the volume is 10-20% that of the original volume; (7) filling into bottles in a manner that each bottle contains 250ml, thereby obtaining finished products. The traditional Chinese medicine oral liquid provided by the invention can be used for effectively treating the bacterial gill-rot disease of ctenopharyngodon idellus, and the cure rate is over 99%. The formula has the effects of clearing heat and detoxifying, evacuating carbuncle and pus, promoting tissue regeneration and reinforcing Qi and blood as well as astringing and stopping bleeding.

Owner:GREAT BIOLOGY PHARMA TIANJIN

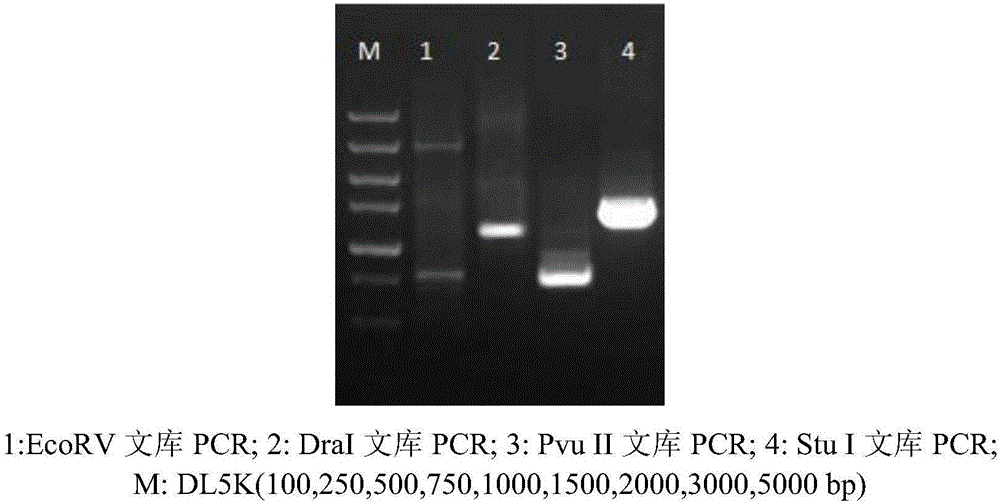

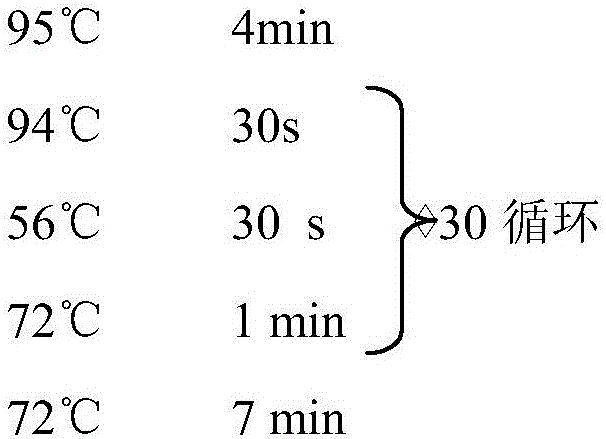

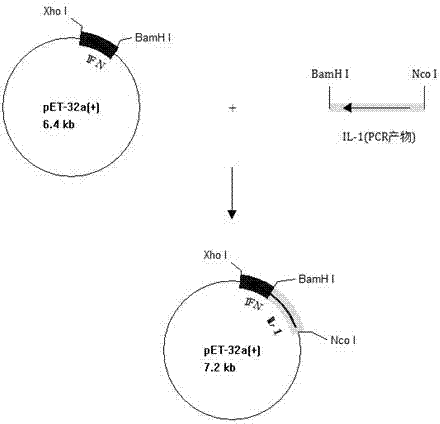

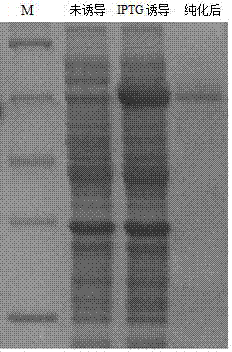

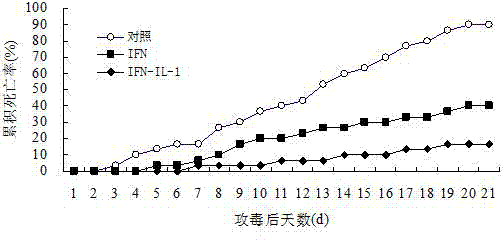

Preparation method and application of recombinant Ctenopharyngodon idella interferon-interleukin 1 bigeminal protein

InactiveCN103936861AOvercome the separate addition of IFNOvercome the amount of IL-1Peptide/protein ingredientsAntiviralsEscherichia coliDisease

The invention relates to a preparation method and an application of a recombinant Ctenopharyngodon idella interferon-interleukin 1 bigeminal protein. The method is characterized in that the method comprises the following steps: 1, cloning grass carp IL-1 gene; 2, constructing a combined expression vector Pet-32a(+) / CiIFN-IL-1 containing IFN and IL-1; and 3, expression and purification of the recombinant bigeminal protein: converting the combined expression vector Pet-32a(+) / CiIFN-IL-1 to Escherichia coli BL21(DE3)pLysS, carrying out IPTG induced expression of the recombinant protein IFN-IL-1, and purifying the obtained fusion protein through Ni-NTA affinity chromatography. The bigeminal protein can simultaneously have the immune efficacies of IFN and IL-1, overcomes the disadvantages of respective addition of IFN and IL-1 and accurate proportions thereof in a feed, and is an efficient non-toxic Ctenopharyngodon idella disease resistance preparation.

Owner:NANCHANG UNIV

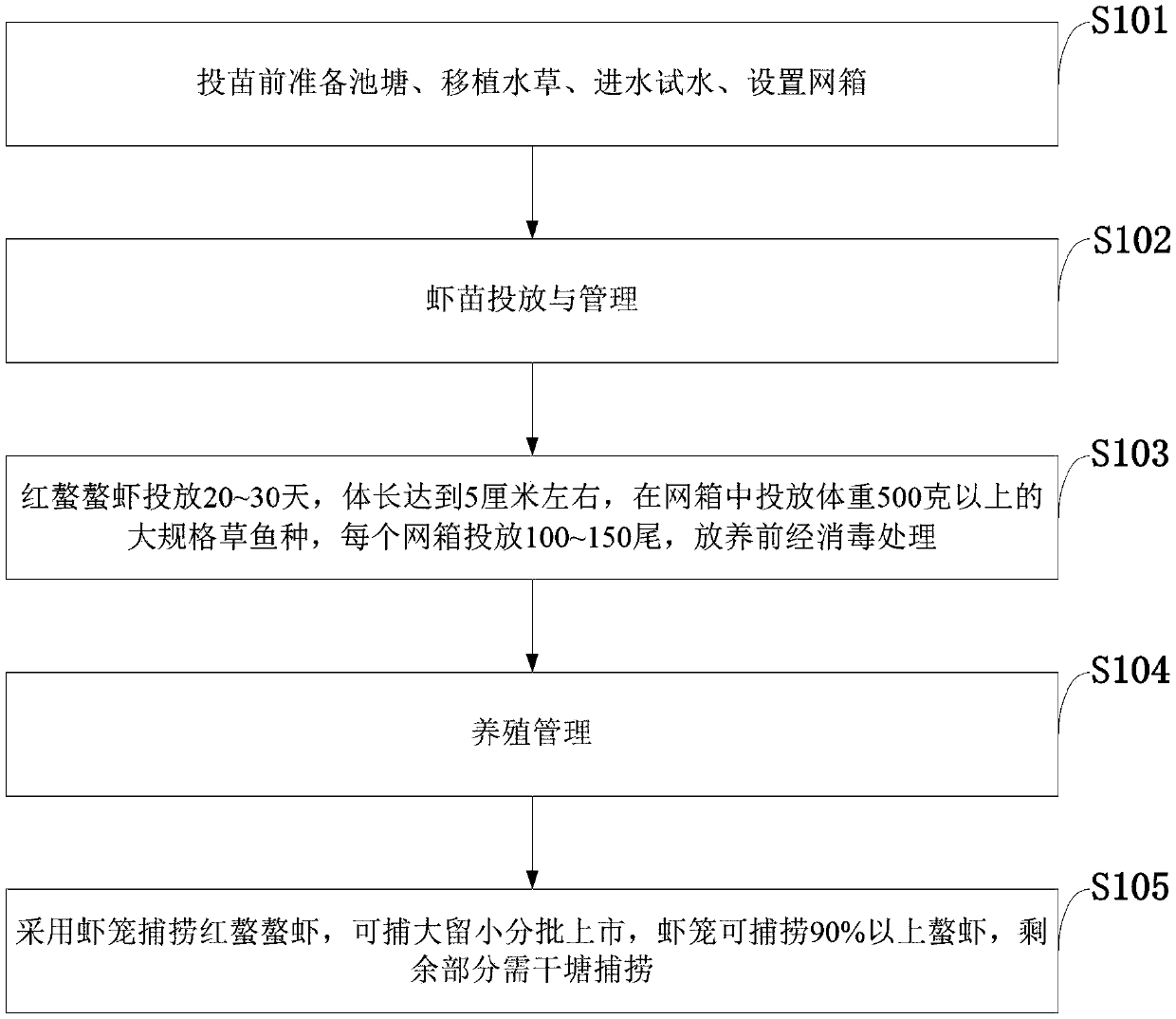

Ecological comprehensive breeding method of cherax quadricarinatus-ctenopharyngodon idellus-hydrilla verticillata

PendingCN109644911AFast growthIncrease productionClimate change adaptationPisciculture and aquariaFecesEcological environment

The invention belongs to the technical field of aquaculture, and discloses an ecological comprehensive breeding method of cherax quadricarinatus-ctenopharyngodon idellus-hydrilla verticillata; the preparation before dropping fries mainly comprises pond selection, pond clearing, water grass transplanting, water inflow testing, net cage setting and the like; young shrimps dropping and management; ctenopharyngodon idellus stocking; aquaculture management mainly comprises scientific bait casting, water quality management, anti-escape, anti-enemy harm and the like; fishing harvest of cherax quadricarinatus and ctenopharyngodon idellus. The hydrilla verticillata can provide a shelter and natural botanical bait for cherax quadricarinatus, and in addition, can purify water, increase dissolved oxygen and lower water temperature so as to create a good ecological environment. In the early stage of breeding, ctenopharyngodon idellus feed on artificial feed, and residual bait feces sink to the bottom of water and can be eaten by cherax quadricarinatus, the bottom of a net cage becomes a food intake and sheltering place for cherax quadricarinatus, the fertility of the pond can be improved, and the survival rate and growth rate of cherax quadricarinatus are conducive to being improved; in the late stage of breeding, ctenopharyngodon idellus mainly feed on hydrilla verticillata, the comprehensive utilization of aquatic plants is realized, and the adverse effects caused by the overgrowth of the aquatic plants are avoided.

Owner:GUANGXI ACADEMY OF FISHERY SCI

Selenium-rich ctenopharyngodon idellus feed and preparation method thereof

InactiveCN106562096AImprove immunityHigh nutritional valueFood processingClimate change adaptationBiotechnologyAquatic animal

The present invention relates to a selenium-rich ctenopharyngodon idellus feed and a preparation method thereof, and belongs to the technical field of aquatic animal breeding, wherein the raw materials of the selenium-rich ctenopharyngodon idellus feed comprise, by mass, 20-30% of corn powder, 20-30% of bean cake powder, 10-15% of straw powder, 5-10% of selenium-rich fish powder, 5-10% of selenium-rich bone powder, and 0.5-1.5% of an organic selenium additive, wherein the additive comprises (calculated as the total amount of the base diet) comprises 10-15% of sweet potato powder, 0.2-0.6% of edible salt, 1-3% of auxin, and 1-3% of calcium hydrogen phosphate. According to the present invention, the natural selenium-rich biological raw materials are added with the proper amount of the biological organic selenium to prepare the selenium-rich ctenopharyngodon idellus feed, such that the selenium content in the fish meat can be increased, the immunity of the ctenopharyngodon idellus is increased, the nutritional value of the ctenopharyngodon idellus is increased, and people can safely absorb and digest after people eat the ctenopharyngodon idellus so as to achieve the safe and healthy selenium supplementing purpose.

Owner:CHONGQING HONGQIAN AGRI DEV CO LTD

High protein ctenopharyngodon idellus feed

InactiveCN105285507ANutritional diversityNutritional balanceFood processingClimate change adaptationBiotechnologyNutrition

The invention discloses a high protein ctenopharyngodon idellus feed. The formula involves the following raw materials by weight: 30-50 parts of soybean powder, 20-40 parts of rice bran, 8-12 parts of fishbone powder, 10-15 parts of yam powder, 1-2 parts of palm oil, 1-2 parts of seaweed powder, 1-2 parts of sophora flavescens grass meal, 1-2 parts of dried orange peel powder, 1-2 parts of salt and 1-2 parts of compound vitamin. The feed provided by the invention has the advantages of comprehensive nutrition, balanced nutrition, high protein content, strong disease resistance, easy absorption and low cost, etc. After feeding ctenopharyngodon idellus with the feed provided by the invention, the yield of ctenopharyngodon idellus increases by about 10%, the produced fish meat is more delicious and has richer nutrition. Therefore, the feed has very good economic benefits.

Owner:王再青

Special environment-friendly high-yield feed for gold Ctenopharyngodon idellus

InactiveCN106107214AFast growthHarm reductionFood processingClimate change adaptationEutrophicationAdditive ingredient

The invention discloses special environment-friendly high-yield feed for gold Ctenopharyngodon idellus. The feed is prepared from the following raw materials in parts by weight: 20-40 parts of corn flour, 10-20 parts of purple sweet potato flour, 10-15 parts of soybean protein powder, 8-15 parts of rapeseed cake, 2-5 parts of spirulina powder, 1-4 parts of vivipara pulp, 2-9 parts of marine red yeast powder, 1-8 parts of beer yeast powder, 2-8 parts of peanut oil, 0.1-0.8 part of choline chloride, 0.05-0.2 part of astaxanthin, 0.1-0.5 part of anti-mildew agent, 0.05-0.1 part of multivitamin and 0.03-0.15 part of composite mineral. According to the special environment-friendly high-yield feed for gold Ctenopharyngodon idellus, the nutrient ingredients are scientifically matched according to the living habits of gold Ctenopharyngodon idellus, and the growing speed of gold Ctenopharyngodon idellus can be accelerated. Meanwhile, the utilization rate of gold Ctenopharyngodon idellus in feed protein and energy is improved, the discharge of N in metabolic waste of gold Ctenopharyngodon idellus is reduced, the pollution to the culture water environment is reduced, and the harm of ammonia and nitrite nitrogen in aquatic water to gold Ctenopharyngodon idellus is reduced. The feed is also capable of improving the utilization of phosphorus in plant raw material, reducing entry of phosphorus into culture water environment, improving the culture environment and preventing eutrophication of the water body caused by unbalanced N and P proportions.

Owner:邓师雄

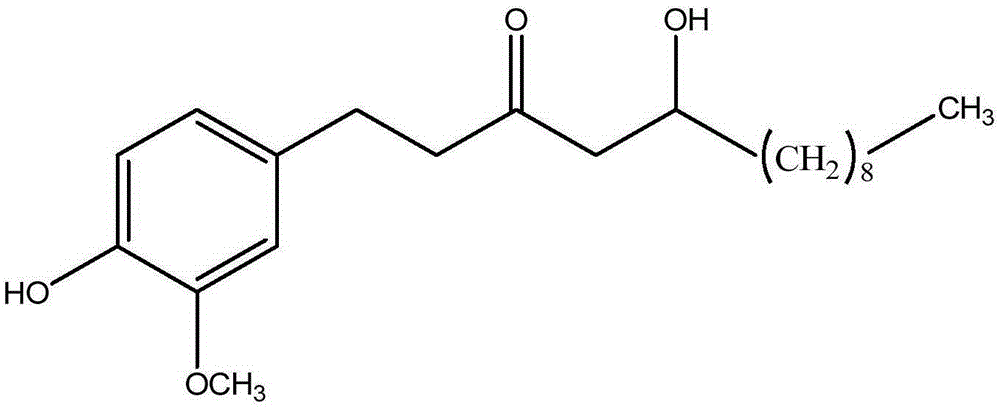

Application of 10-gingerol to preparation of medicines for preventing and treating epizoic ciliates of fishes

InactiveCN105267188AImprove the safety of useAvoid insecurityKetone active ingredientsAntiparasitic agentsLethal concentration 50Ichthyophthirius multifilis

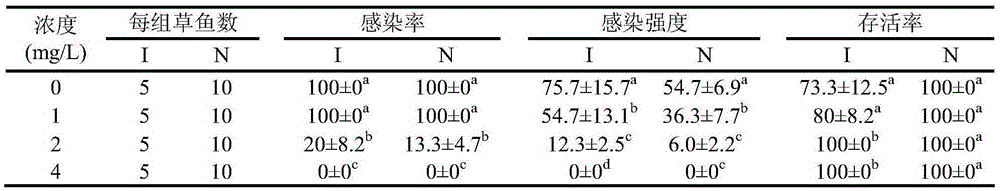

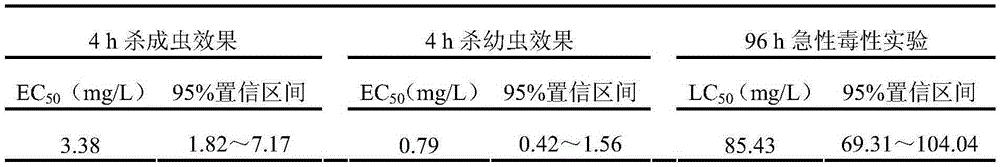

The invention discloses application of 10-gingerol to preparation of medicines for preventing and treating epizoic ciliates of fishes and belongs to the technical field of fishery medicines. The application has the advantages that the 10-gingerol is applied to preparation of the medicines for preventing and treating the epizoic ciliates of the fishes firstly, is particularly used for killing ichthyophthirius multifilis and is capable of killing 100% of ichthyophthirius multifilis within an effective dose range so as to play a role in effective prevention and treatment of the ichthyophthirius multifilis; zingiber officinale, the source of the 10-gingerol, is perennial herb of zingiberaceae, is an Asian traditional medical and edible dual purpose plant and is safe and free from environmental residues; LC50 (lethal concentration 50) of the 10-gingerol for ctenopharyngodon idellus is 85.43 mg / L which is 21.4 times of minimum effective concentration (4 mg / L) that the 10-gingerol kills the Ichthyophthirius multifilis, and accordingly the 10-gingerol is high in use safety; the zingiber officinale is high in 10-gingerol content, 10-gingerol extraction and preparation technologies are simple and mature, and the 10-gingerol is high in ciliate resisting activity and free from environmental pollution and residues, thereby being promising in application prospect on the field of novel environment-friendly fishery medicines.

Owner:JINAN UNIVERSITY

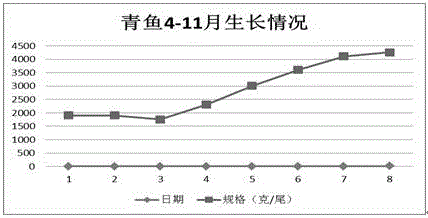

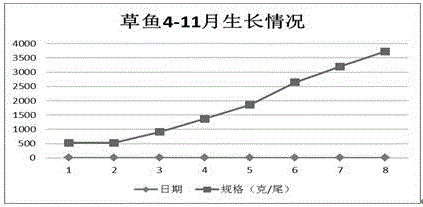

Breeding method for ctenopharyngodon idellus

InactiveCN109730004AReduce usageShorten the cultivation cycleClimate change adaptationAnimal feeding stuffAnti nutrientsMicroorganism

The invention discloses a breeding method for ctenopharyngodon idellus. The breeding method comprises the following steps: site selection and construction of a fish pond; fingerling stocking; breedingmanagement; water quality management and disease prevention and control. Beer sludge is paved at the bottom of the breeding pond to culture microorganisms in water to grow, so that the dosage of a feed is reduced. 350-500 g / grass carp is selected as a fingerling, the grass carps which are less than 2kg are fed as common ctenopharyngodon idellus, so that the culture period of crisped grass carps can be shortened. In a crisping middle period, the feed amount is adjusted according to water temperature. Fermented broad beans are adopted. Most anti-nutrient factors can be removed after the broad beans are fermented, so that the absorptivity of the grass carps to the broad beans can be improved and the crisping process is accelerated. In the feeding process, special feeds are used to provide abundant nutrients to growth of the grass carps, so that the fish meat quality is ensured.

Owner:刘海君

Culture method for ctenopharyngodon idellus

InactiveCN106577386AMaintain nutrientsGrow fastClimate change adaptationAnimal feeding stuffWater qualityPlastic film

The invention relates to a culture method for ctenopharyngodon idellus. The method comprises the following steps: (1) carrying out fish pond selection; (2) carrying out fish pond treatment; (3) carrying out fingerling stocking; (4) delivering a nitrogen fertilizer or compound fertilizer into fish ponds in March to April according to the ratio of 25kg / mu to 50kg / mu, wherein during delivery, the nitrogen fertilizer or compound fertilizer is sealed with plastic films and is loaded into woven bags, the woven bags and the plastic films are punctured with chopsticks, and 1 to 10 chopstick-sized holes are left in each woven bag and each plastic film; and (5) carrying out feed delivery. According to the method, the nitrogen fertilizer or compound fertilizer is delivered into the fish ponds in March to April and is slowly volatilized in water, so that nutrients in the water can be kept, water plants in the ponds can rapidly grow under the nutrients, and the water quality can be further improved by the photosynthesis of the water plants.

Owner:姚旭

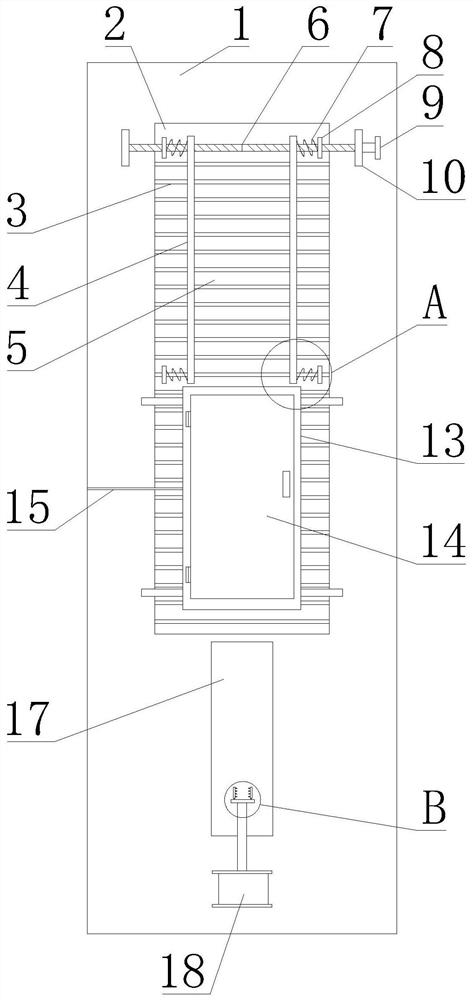

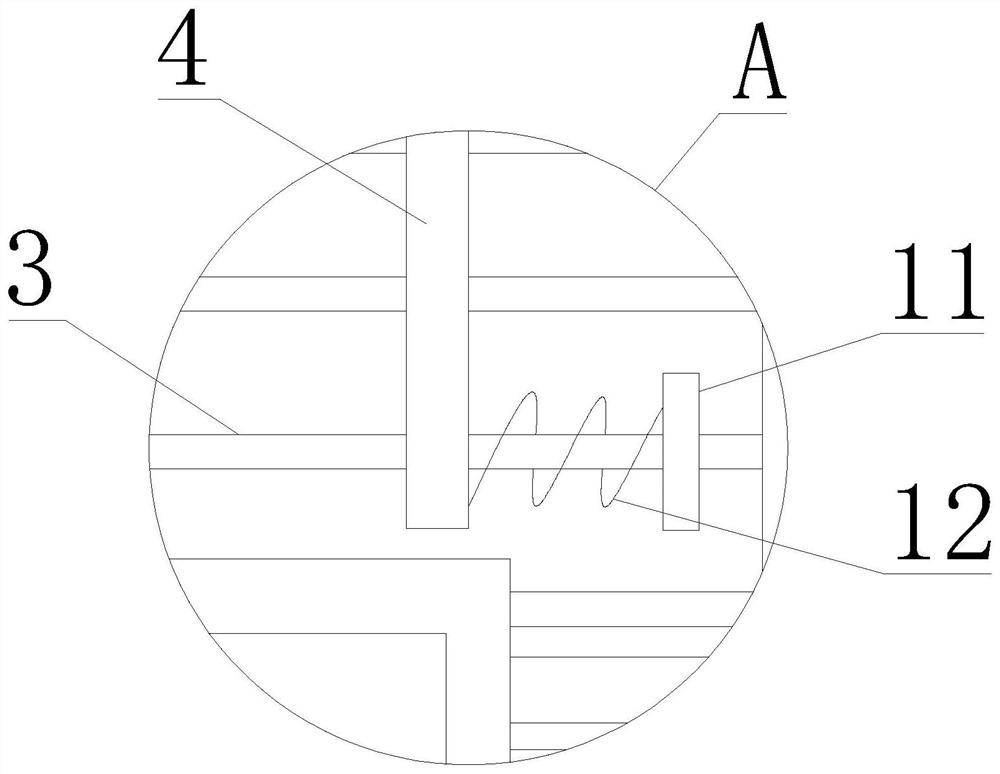

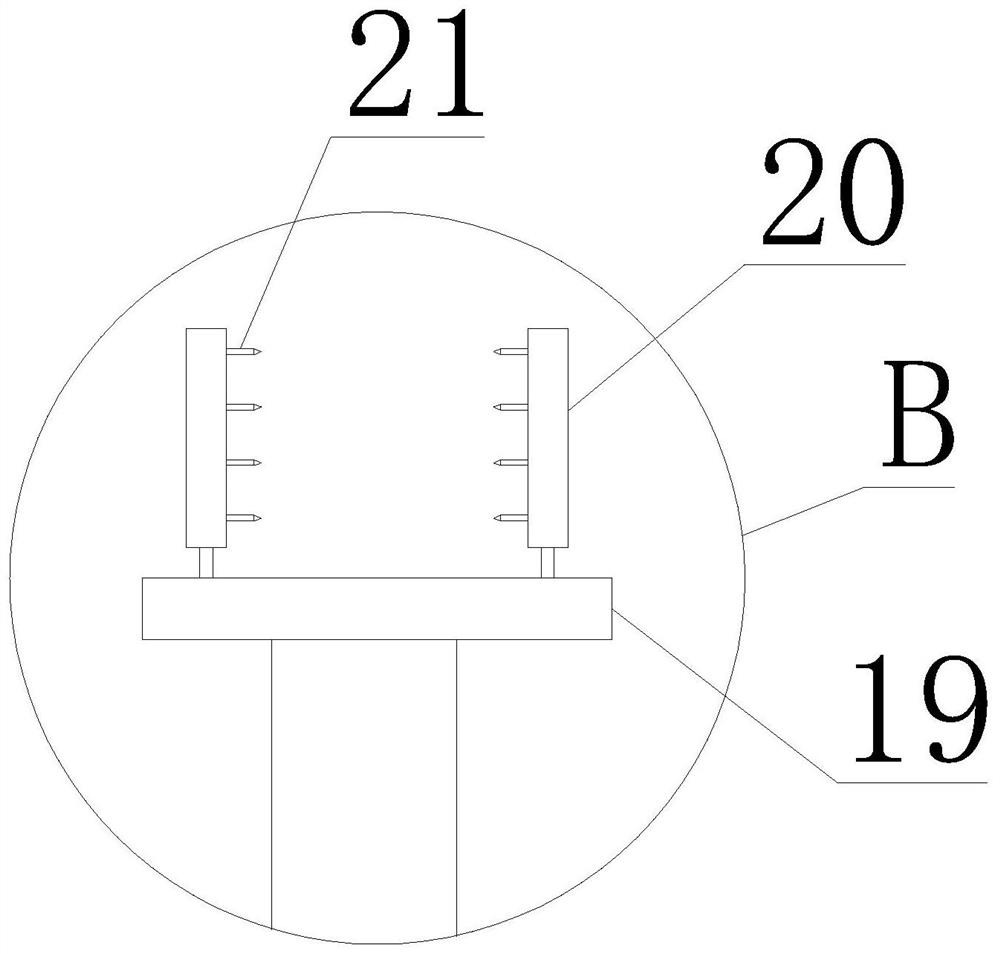

Automatic skin removing machine for fishes

InactiveCN111657329AImprove cleanlinessGood removal effectFish washing/descalingFish work-tablesFish processingCommon carp

The invention discloses an automatic skin removing machine for fishes. The automatic skin removing machine comprises a workbench, baffle plates, a cleaning box and a first telescopic device, wherein multiple groups of roll shafts are rotatably arranged in a first square hole on the upper end surface of the workbench; two groups of baffle plates are distributed in parallel and are in sliding connection with a plurality of roll shafts; the workbench is provided with driving components used for regulating a distance between two groups of baffle plates; a cleaning box is connected with the workbench through a fixed frame; two end surfaces, which are mutually far, of the cleaning box are independently provided with a first opening along a length direction of the workbench; the lower end surfaceof the cleaning box is provided with a second opening; the upper end surface of the cleaning box is provided with an end cover; a cleaning component used for removing surface skin scales of fishes isarranged in the cleaning box; the first telescopic device is installed on the workbench and is positioned on one side, which is far away from two groups of baffle plates, of the cleaning box; and thetelescopic end of the first telescopic device is provided with a clamping component used for clamping and fixing the tail part of the fish. The automatic skin removing machine is simple to operate, is convenient to use, can quickly and efficiently remove fish scales of ctenopharyngodon idellus, ccyprinus carpio and the like, and improves fish processing efficiency.

Owner:湛江市卓成食品机械有限公司

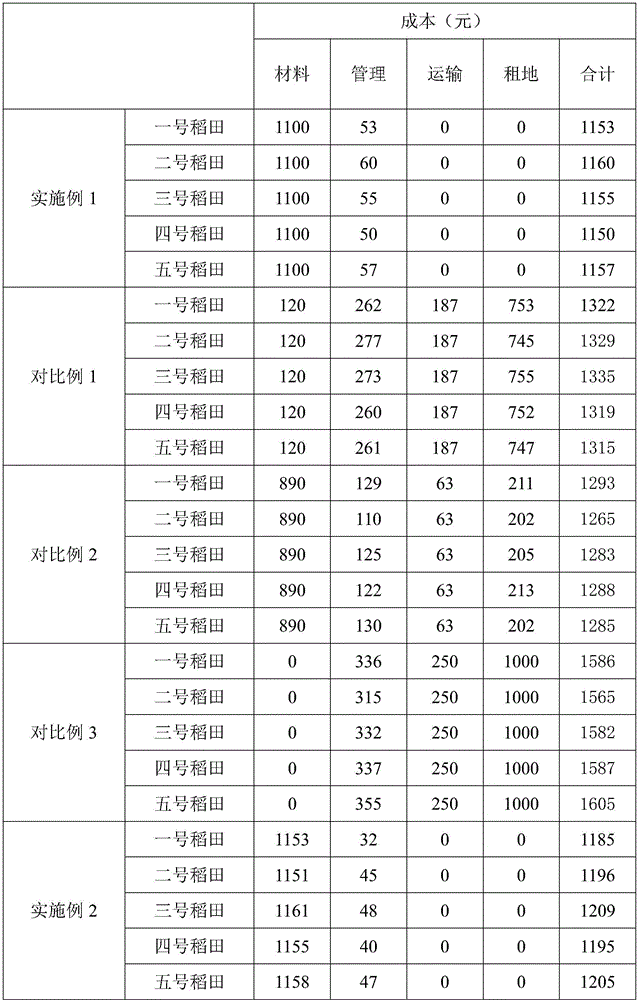

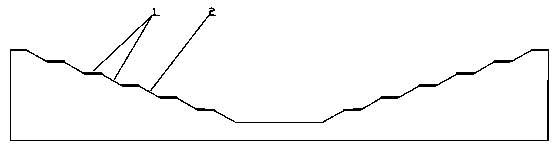

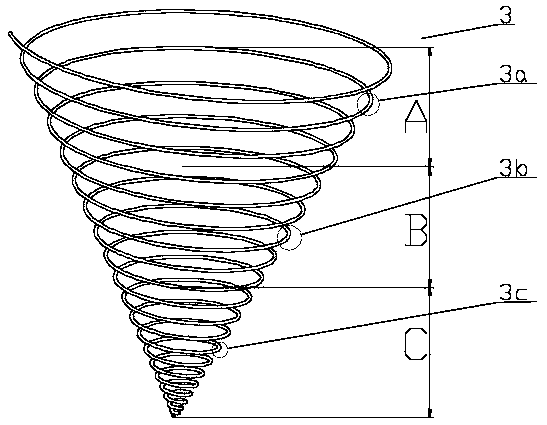

Method for simultaneously producing rice grains and ctenopharyngodon idellus

InactiveCN106472194ASimplify the breeding processIncreased bowel movementsClimate change adaptationAnimal feeding stuffAquatic productPaddy field

The invention belongs to the field of ecological aquaculture and relates to a method for simultaneously producing rice grains and ctenopharyngodon idellus. The method comprises the steps: (1) selecting a rice field; (2) constructing fish ditches and fish pits; (3) carrying out disinfecting treatment; (4) carrying out pre-fertilization; (5) carrying out rice seedling transplanting; (6) arranging culture trays and culture dishes: selecting the culture trays, of which bottoms have frames and are sealed with the frames, filling up the culture trays with a base fertilizer, placing the culture trays in the rice field in a manner that the culture trays are located above the fish ditches and are arranged above the fish ditches at intervals of 3 to 5 meters, arranging turntables on the ground aside the fish pits, erecting the turntables, arranging the culture dishes at the periphery of each turntable, sufficiently applying a base fertilizer into the culture dishes; (7) planting forage: planting zea Mexicana in the culture trays and the culture dishes; (8) carrying out fingerling stocking; (9) feeding the ctenopharyngodon idellus; (10) carrying out weeding and deinsectization on the rice field; and (11) carrying out rice harvesting. According to the method, on the premise of not affecting the growth of rice, the growing environment of the ctenopharyngodon idellus is optimized, and the yield of the ctenopharyngodon idellus is increased.

Owner:贵州山至金生态农业有限公司

Method for preparing feedstuff for ctenopharyngodon idellus

InactiveCN112293613AWith detoxificationWith spleenFood processingClimate change adaptationBiotechnologyAdjuvant

The invention discloses a method for preparing feedstuff for ctenopharyngodon idellus. Preparation raw materials for the feedstuff comprise the following ingredients in parts by mass: 30-35 parts of rapeseed cakes, 26-31 parts of peanut shell powder, 30-35 parts of corn protein powder, 10-15 parts of bovine vertebrae, 15-20 parts of tunas, 7-9 parts of Sudan grass, 4-5 parts of lolium perenne, 5-7parts of Pham Thanh Thao, 10-15 parts of rapes, 10-15 parts of Chinese cabbages, 5-6 parts of malt, 0.1-0.5 part of fat emulsifier and 5-7 parts of adjuvants, wherein the adjuvants are prepared fromthe following raw materials in parts by weight: 10-15 parts of rice, 2-6 parts of flos chrysanthemi indici, 5-7 parts of basil seeds, 7-9 parts of brown sugar, 2-3 parts of diatomite and 1-2 parts ofrhizoma zedoariae. Mixed protein powder and meat and bone meal are mixed, the corn protein powder contains relatively low lysine and arginine, the meat and bone meal contains relatively high lysine and arginine, the corn protein powder and the meat and bone meal are fed in a mixed manner, then, a supplementary action is exerted, essential amino acids can be balanced, and thus, the utilization ratio of proteins is increased; and the fat emulsifier can be used for lowering occurrence of diseases such as fatty liver and meanwhile preventing abdominal fat deposition and promoting growth of the ctenopharyngodon idellus, and the obtained income is higher.

Owner:荆州格力特生物科技有限公司

Original ecological method for culturing gold Ctenopharyngodon idellus

InactiveCN110741987AImprove qualityReduce the cost of farmingClimate change adaptationAnimal feeding stuffBiotechnologyZoology

The invention relates to an original ecological method for culturing gold Ctenopharyngodon idellus, wherein the gold Ctenopharyngodon idellus is fed with plant baits of sudan grass and / or ryegrass andrice bran according to a mass ratio of 8-4: 1. The original ecological method for culturing the gold Ctenopharyngodon idellus is simple to operate, and effectively improves the culture space and efficiency of the original ecological method for culturing the gold Ctenopharyngodon idellus. The original ecological method combining fish culture and grass planting is used for planting plant baits of the gold Ctenopharyngodon idellus on the pond side, and thus a cool culture environment is provided for culturing the gold Ctenopharyngodon idellus, and meanwhile, the baits of the gold Ctenopharyngodon idellus are convenient to collect and feed.

Owner:衡阳香樟苑农业综合开发有限公司

Chinese herbal medicine feed additive for preventing and treating enteritis of grass carp

PendingCN113875904AHeat-clearing and detoxifyingWith astringent hemostasisAntibacterial agentsDigestive systemBiotechnologyWolfiporia extensa

The invention relates to a Chinese herbal medicine feed additive for preventing and treating enteritis of grass carp (ctenopharyngodon idellus). The Chinese herbal medicine feed additive is characterized by comprising the following raw materials of astragalus membranaceus, radix scutellariae, Chinese yam, hawthorn, poria cocos, flos lonicerae, wild chrysanthemum, folium mori, folium isatidis and a carrier. The preparation method of the feed comprises the following steps of putting the components into a mixer, fully mixing, pulverizing in an ultrafine pulverizer, and screening the pulverized material to obtain the Chinese herbal medicine feed additive for preventing and treating enteritis of grass carp. After the powder additive is added, the immunity and the oxidation resistance of the grass carp can be improved, the stress is improved, the disease resistance is enhanced, a feed applicable to the feed additive does not need to be added with an anti-biological medicine, and a produced fish product is a pollution-free green and environment-friendly food.

Owner:YANCHENG INST OF TECH

Method for classifying ctenopharyngodon idella based on expressed sequence tag-simple sequence repeats (EST-SSR) marker

InactiveCN102242222BAccurate identificationRapid identificationMicrobiological testing/measurementBiotechnologyGenetic architecture

The invention discloses a grass carp classification method based on EST-SSR markers. The method includes extracting the DNA of the grass carp, using EST-SSR markers to amplify, and analyzing the genetic structure of the grass carp according to the amplification result. Compared with the traditional method, the method of the invention has the advantages of strong purpose and direct effect. And the operation is simple, the detection is fast, the detection cost is low, and it is convenient to be popularized and used widely.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com