Patents

Literature

259 results about "Souring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Souring is a cooking technique that uses exposure to an acid to cause a physical and chemical change in food. This acid can be added explicitly (for example, in the form of vinegar, lemon juice, lime juice, etc.), or can be produced within the food itself by a microbe such as Lactobacillus.

Natural texture modifier delivering body and sweetness to frozen confection products

InactiveUS20150296833A1Light and creamy and smooth textureIncrease bodyFrozen sweetsAdditive ingredientSweetness

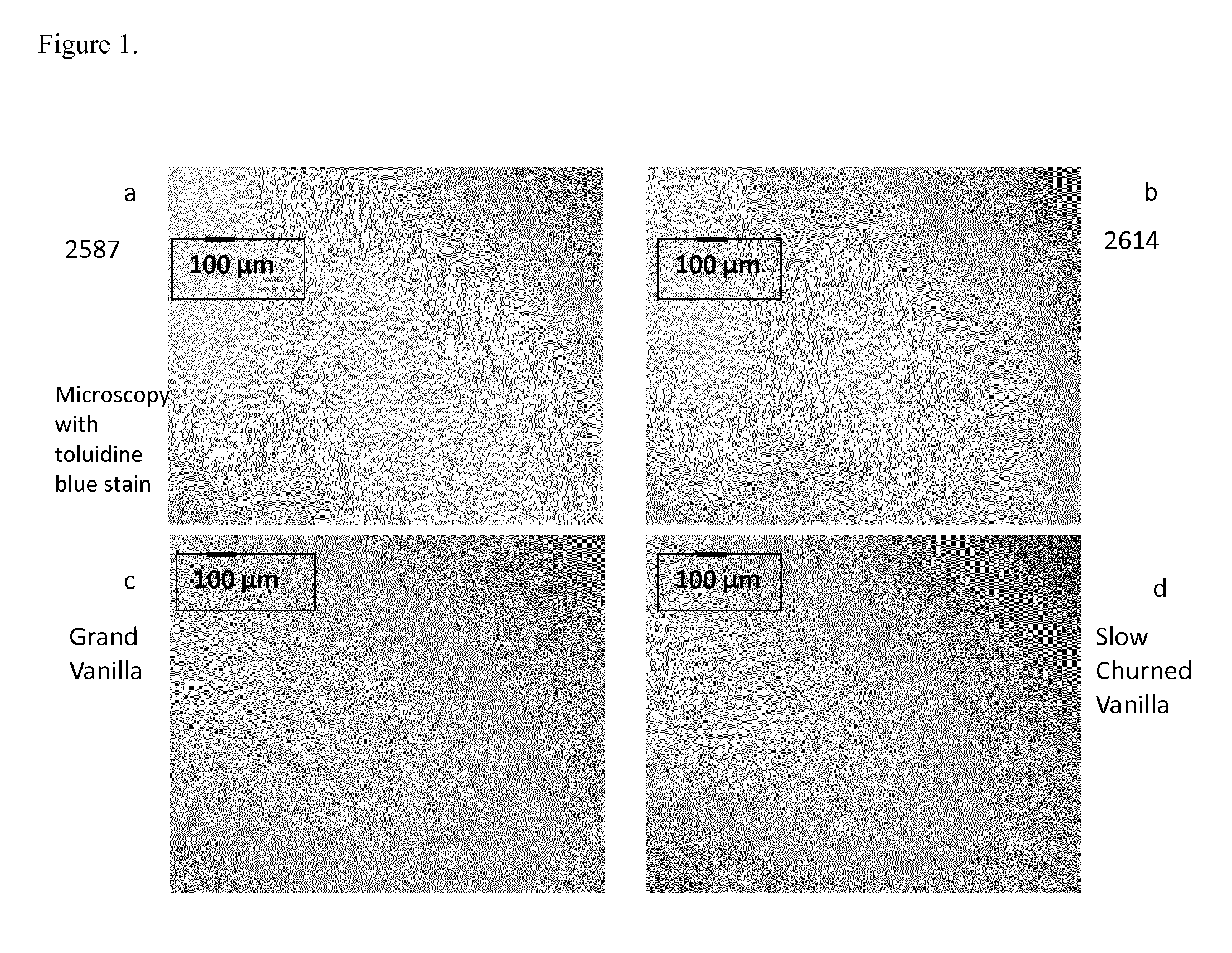

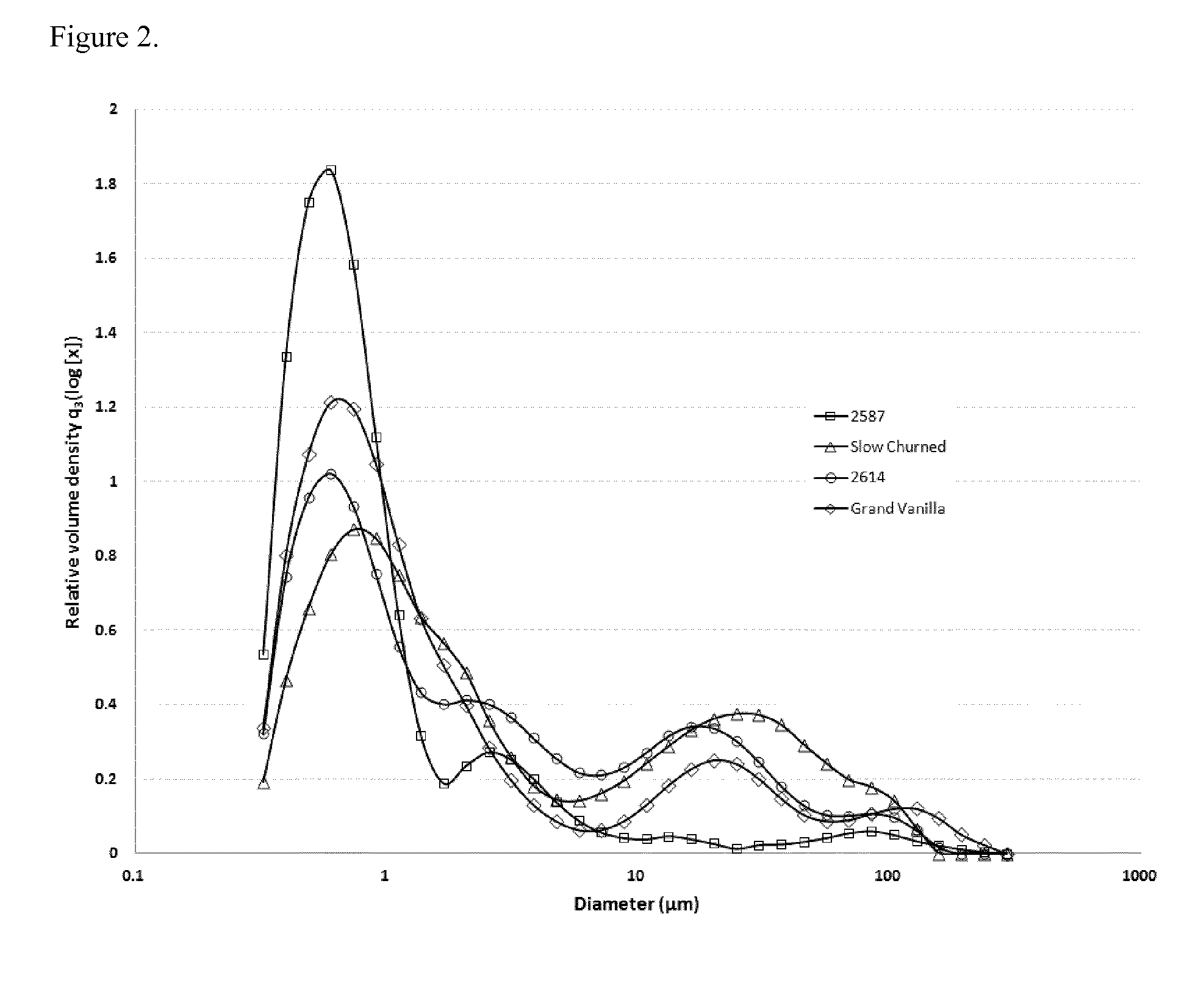

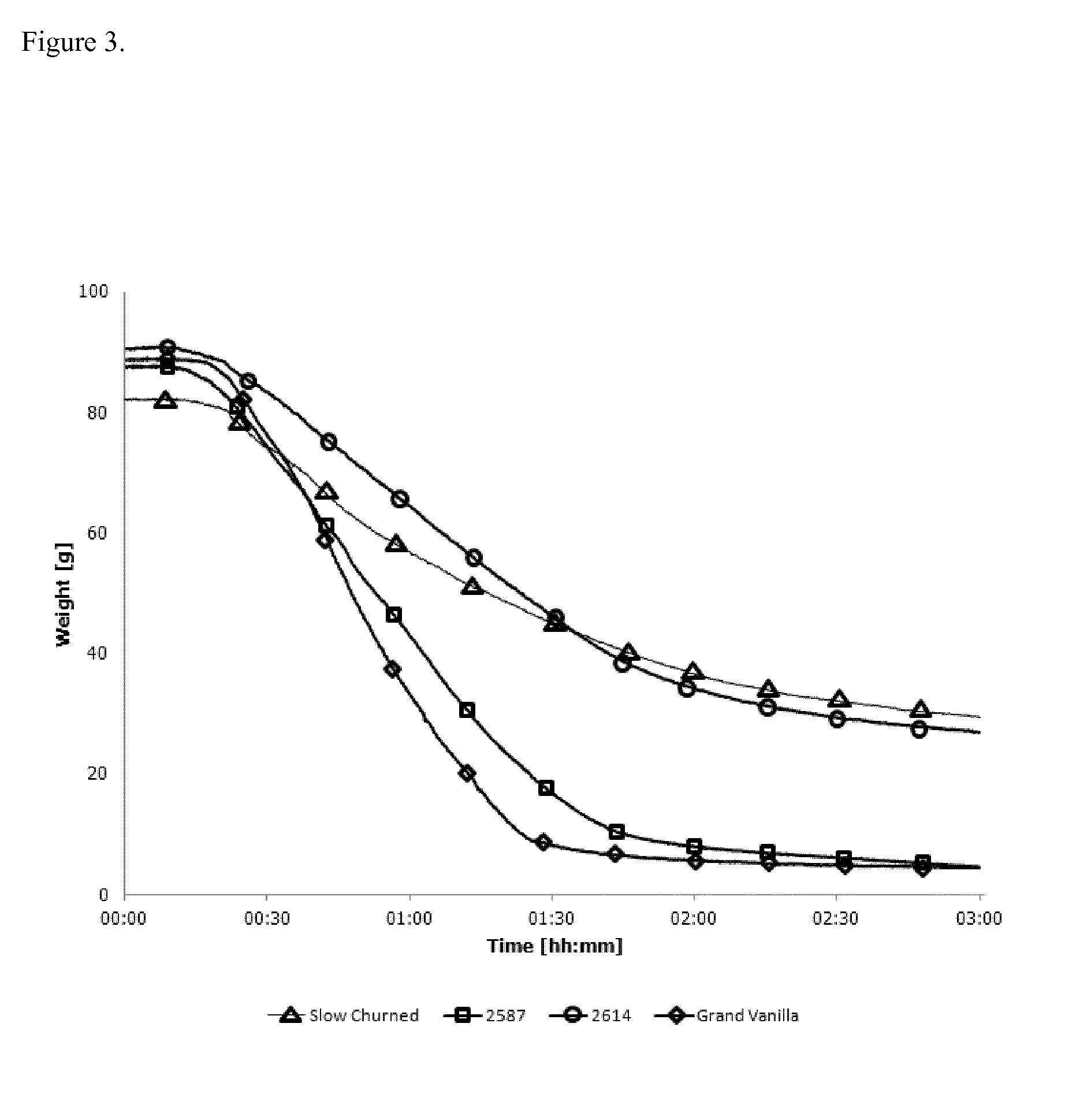

The present invention relates to a frozen confection product comprising oat syrup, a natural sweetening agent. Preferably the frozen confection product is prepared by using a standard freezing step followed by low temperature extrusion and by acidifying the ingredient mix for preparing the frozen confection product. Furthermore, the invention relates to a method of preparing the frozen confection product.

Owner:SOC DES PROD NESTLE SA

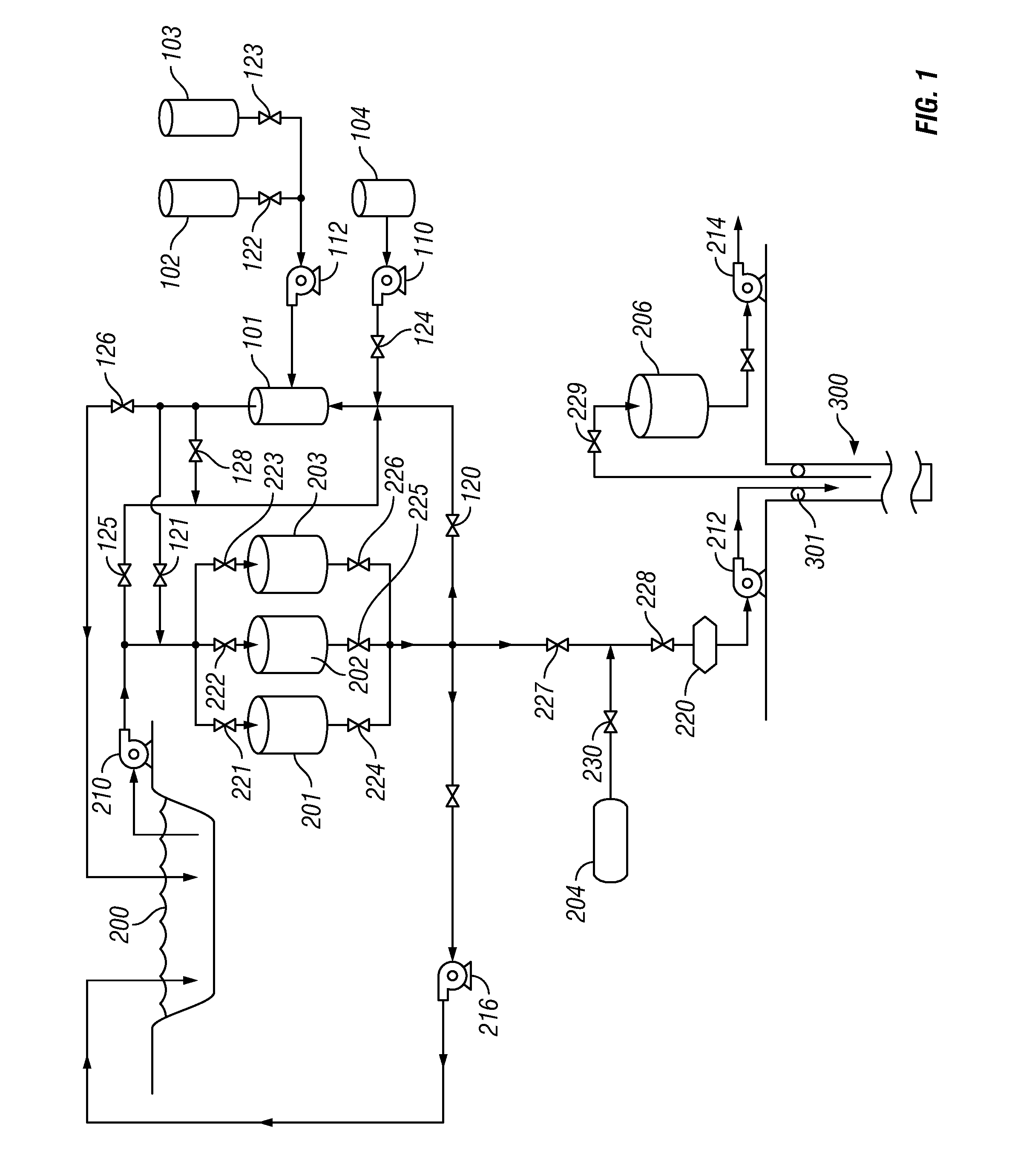

Fracturing fluids for delayed flow back operations

InactiveUS7256160B2Prevents oil wettingAvoid damageFlushingDrilling compositionSulfate-reducing bacteriaBiopolymer

It has been discovered that certain fracturing fluid compositions can be used to fracture a subterranean formation and be permitted to stay within the formation for a relatively extended period of time, for example 28 days or more, before being flowed back or produced. At least two embodiments are envisioned, a bacteria-containing formulation and an anti-bacterial formulation. Both systems would be expected to prevent the potential of the fluid to oil wet the formulation (water block condition) by keeping the formation water wet through the use of water wetting surfactants or solvents. Additionally, both formulations would control reservoir crude souring (H2S generation by in situ sulfate-reducing bacteria), reservoir plugging (via slime biopolymers generated by in situ microbes, inorganic scale deposition like calcium carbonate or barium sulfate, and clay fines migration).

Owner:SUPERIOR ENERGY SERVICES LLC

Shelf-stable acidified food compositions and methods for their preparation

InactiveUS20060024412A1Reduced pHEnhancing their shelf-stabilityDough treatmentConfectioneryOrganic acidGram

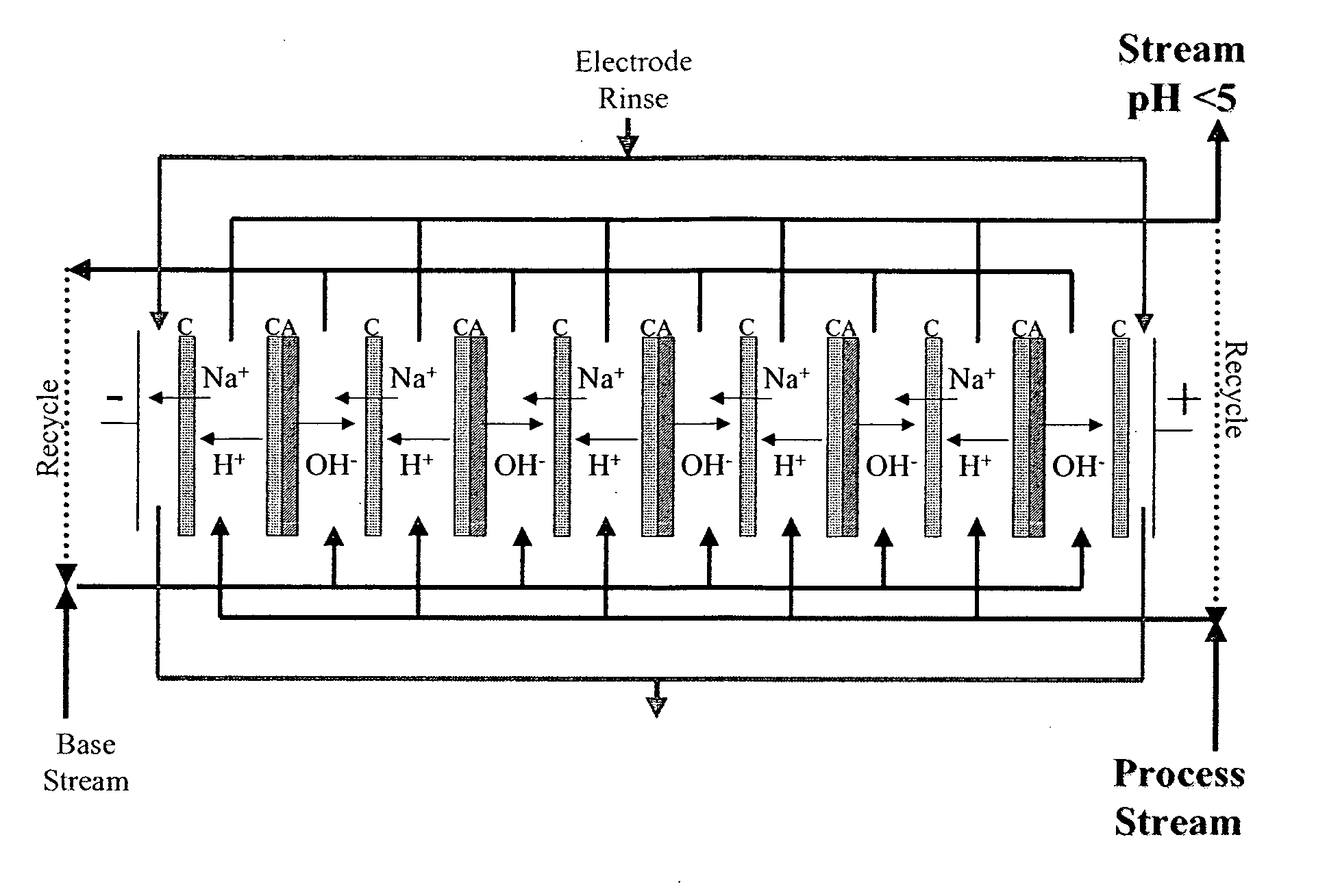

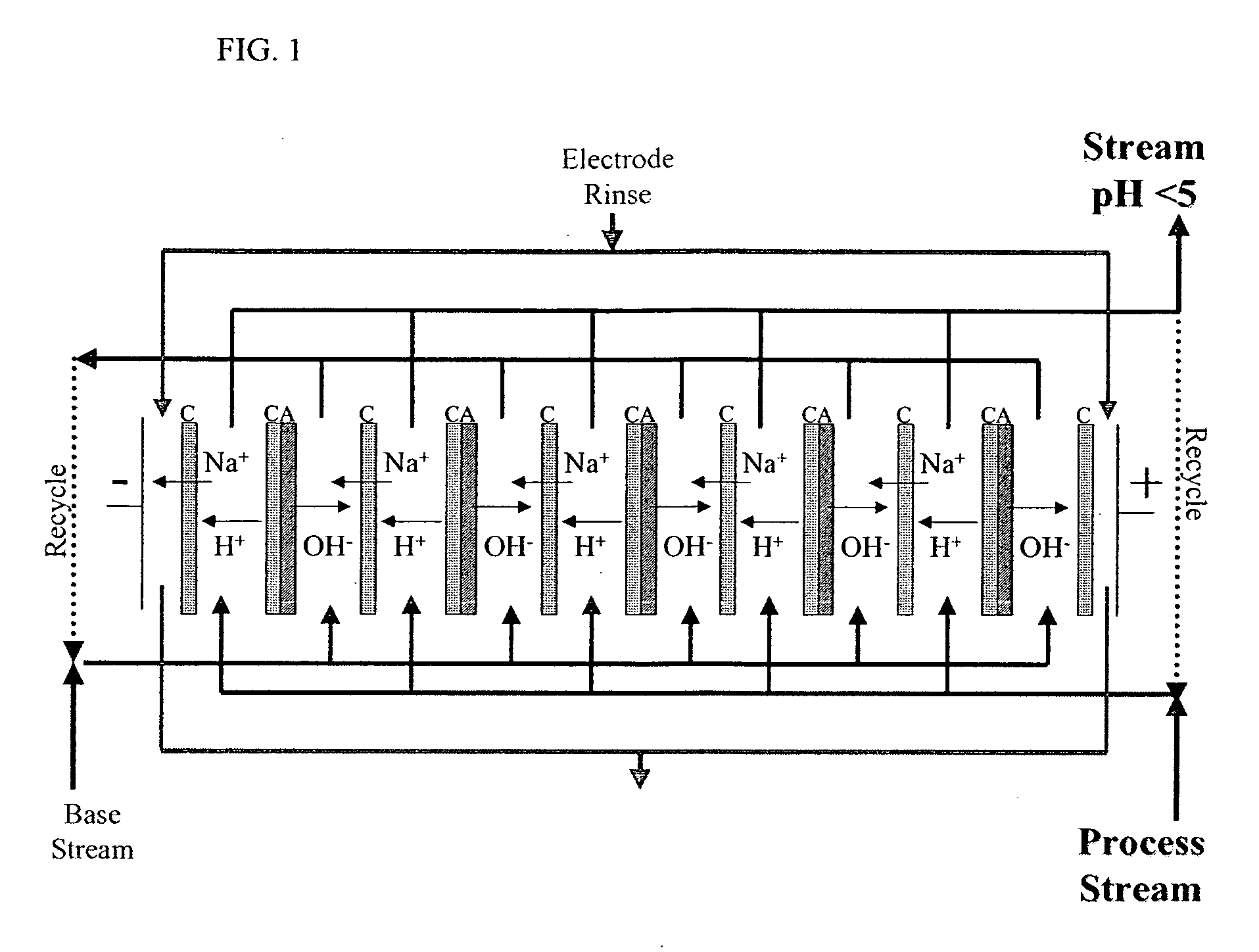

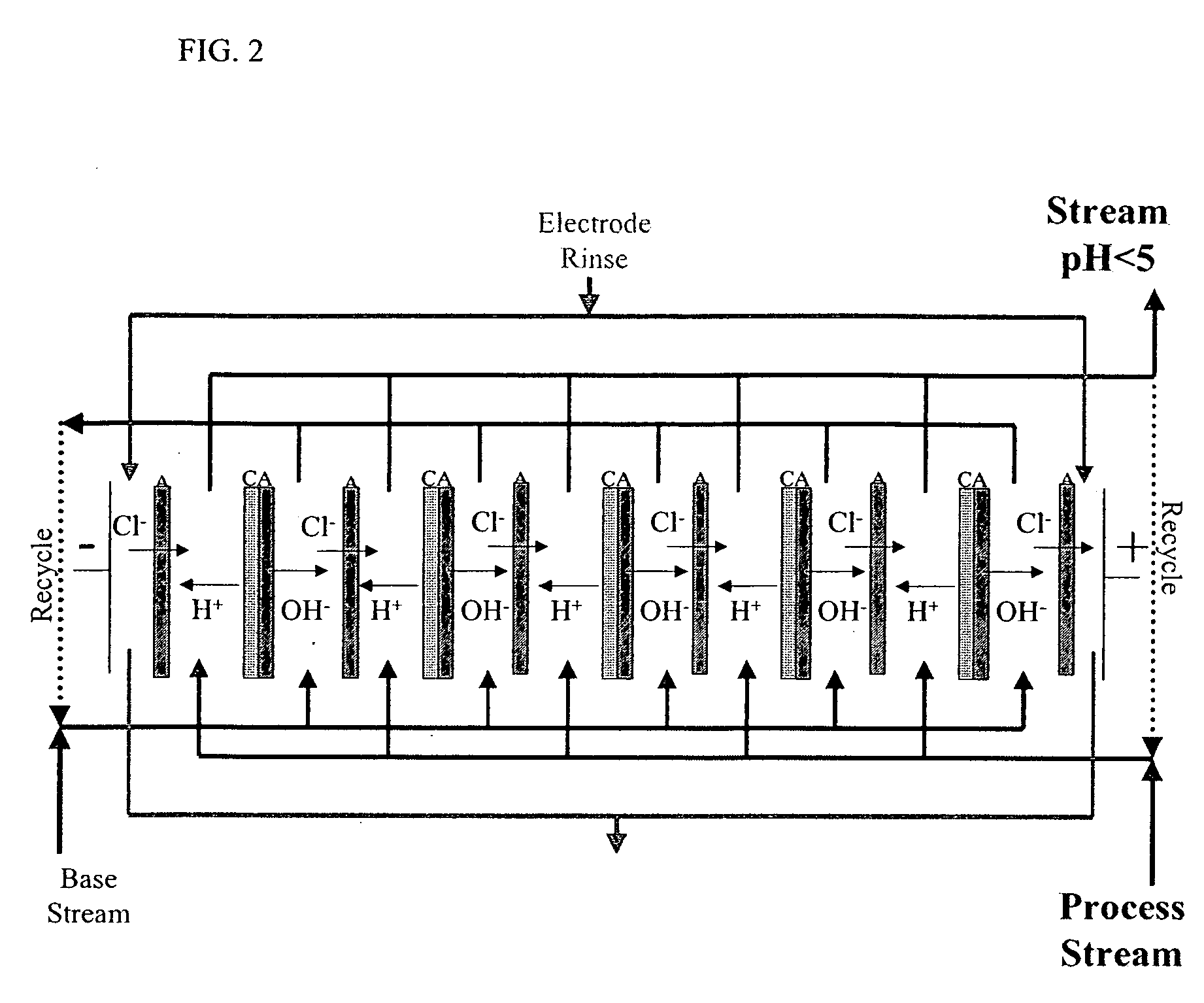

Low pH, high moisture, shelf stable food composition with reduced sourness and methods of making them are provided. The food composition is acidified with a low sourness acidulent having an acidifying power of at least about 0.005 mole / liter per gram of the acidulant at pH 4.0 in amount effective for providing a food composition having an Aw of about 0.90 or greater with a final pH of 5.0 or less, and particularly 4.2 or less. The low pH food composition particularly may contain total organic acids content of 0.22 moles per 1,000 grams of food composition or less, which aids in avoiding undue sourness. New or improved low pH, high-moisture shelf stable food components and products with reduced sourness, and their methods of preparation, are also provided, including in one aspect an improved electrodialysis method and system for preparing ED compositions useful for food preparation.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

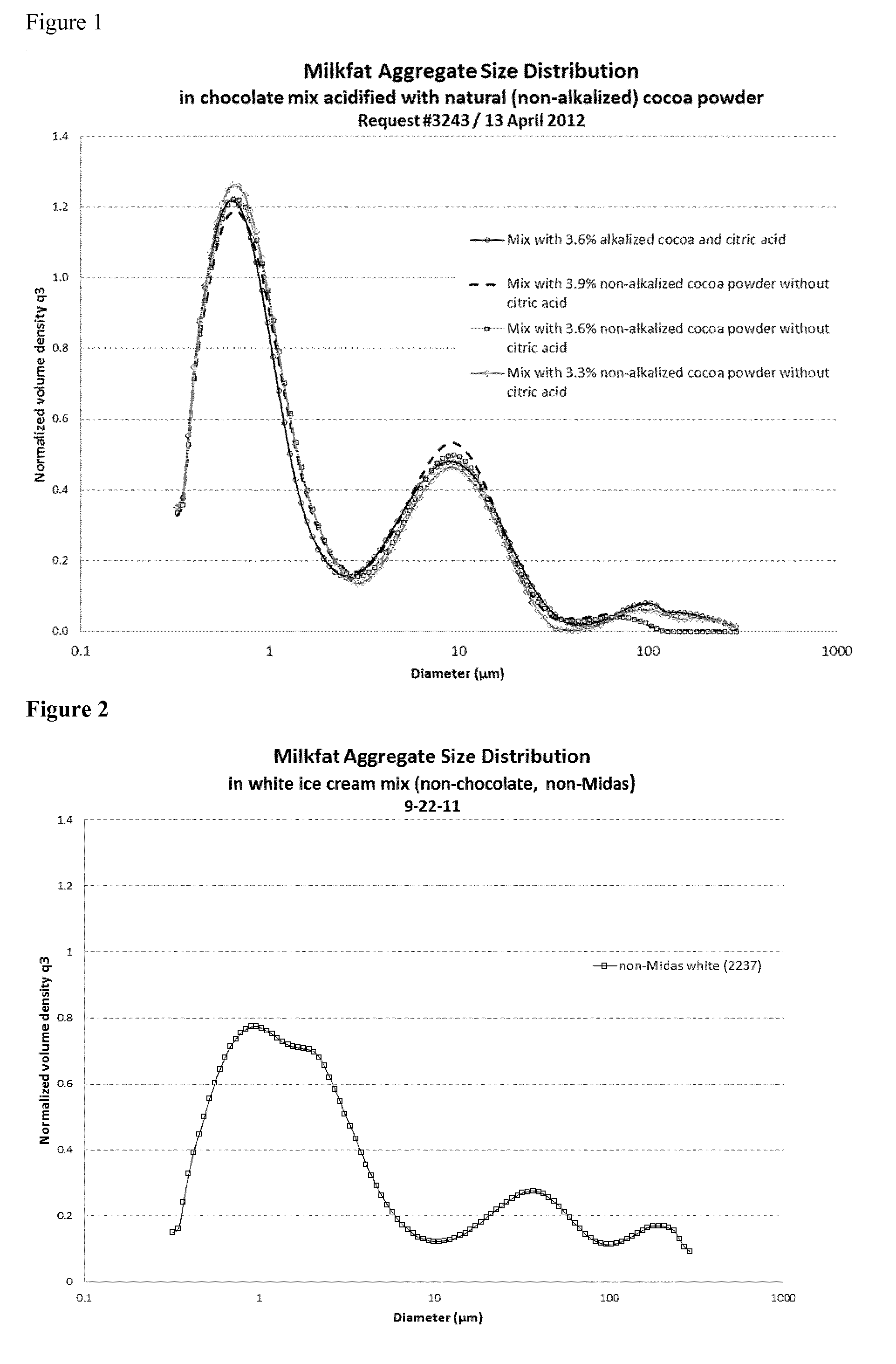

Natural acidification of frozen dairy desserts using natural plant sources

InactiveUS20160309740A1Improved texturalImproved sensorial propertyFrozen sweetsCocoaAdditive ingredientPlant Sources

The present invention relates to a frozen confection product comprising natural bean extract as acidifying agent. The present invention also relates to a method of producing a frozen confection product by adding natural bean extracts to an ingredient mix and then homogenize, pasteurize, and freeze the mix. Preferably the method uses a standard freezing step followed by low temperature freezing.

Owner:NESTEC SA

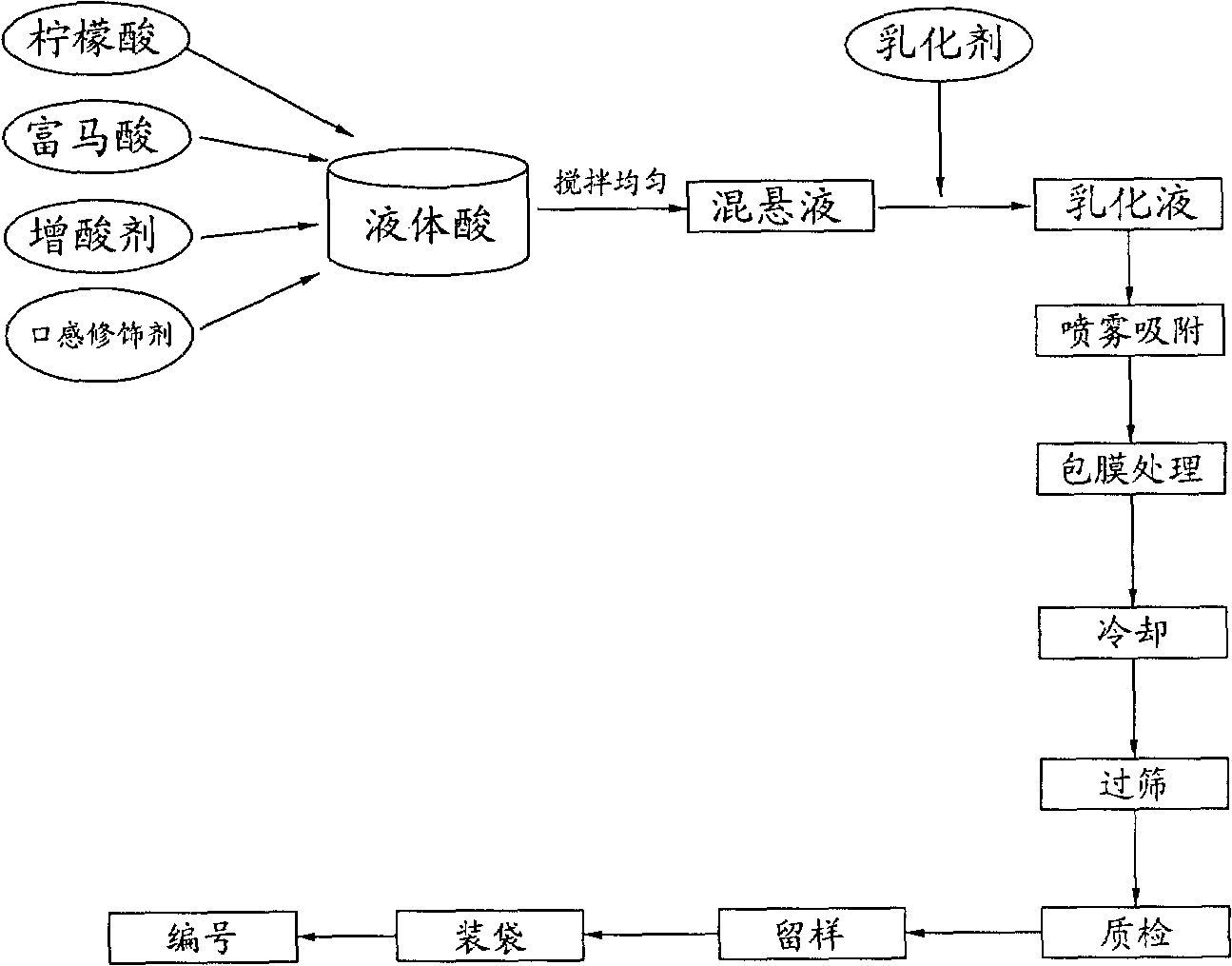

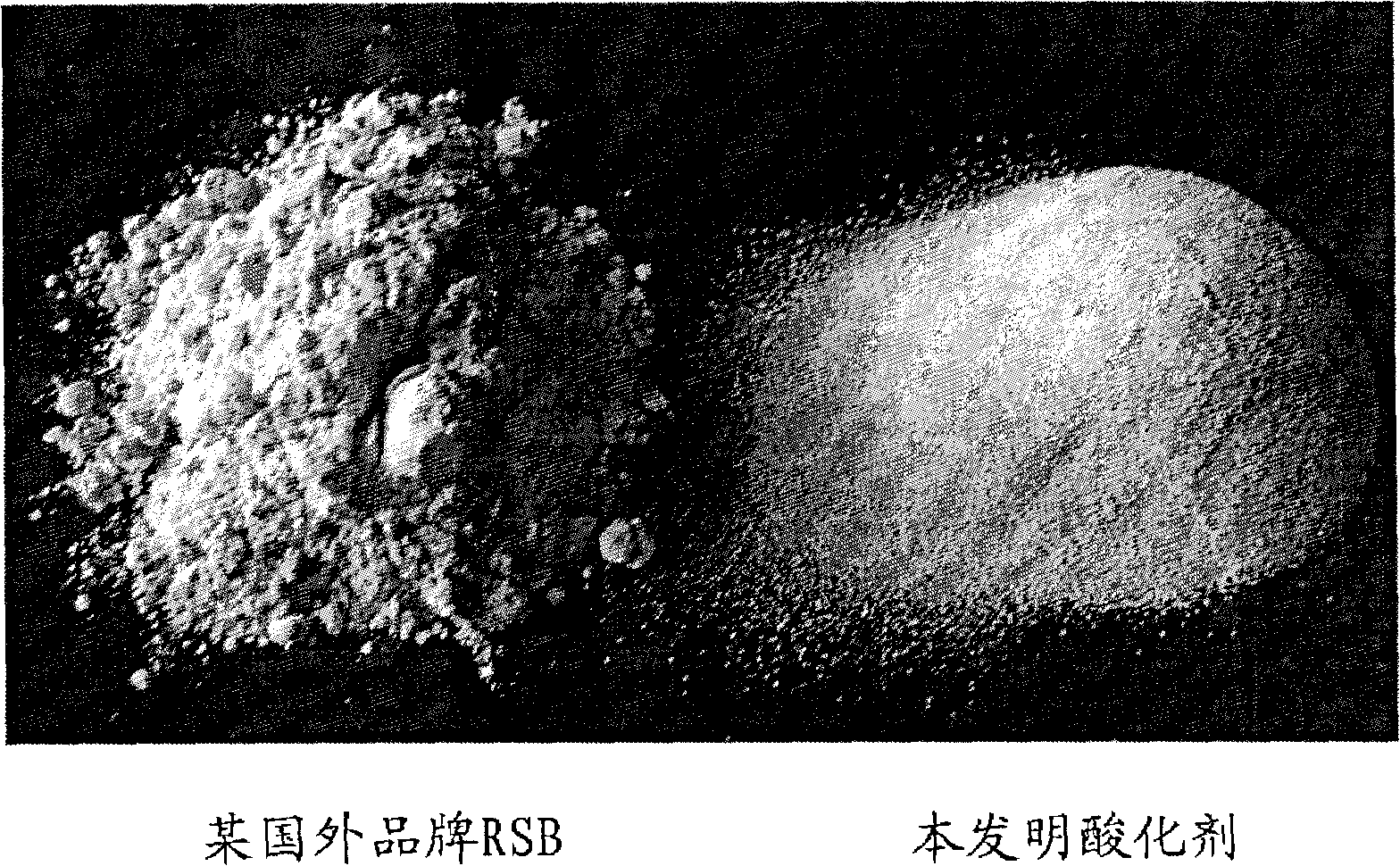

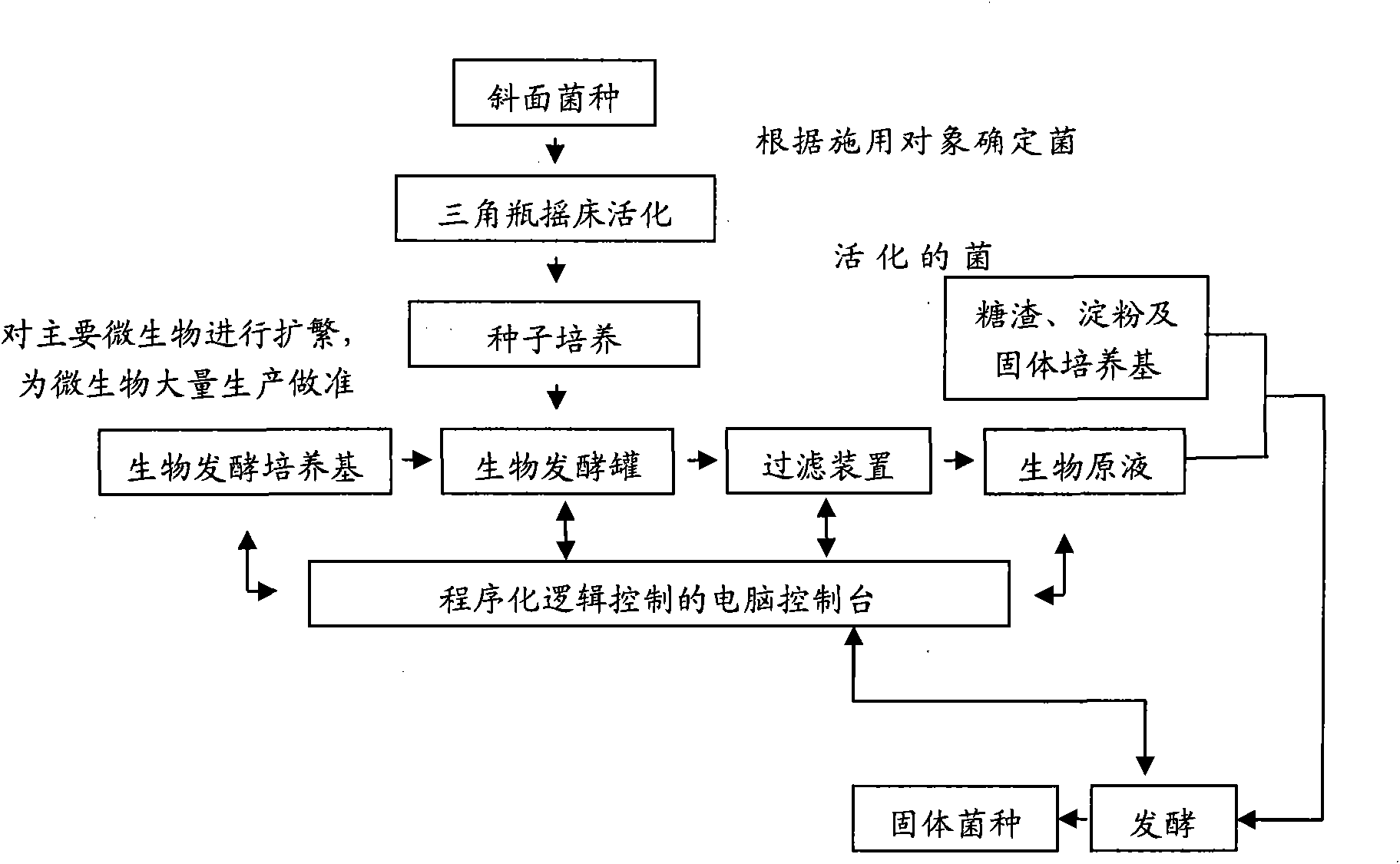

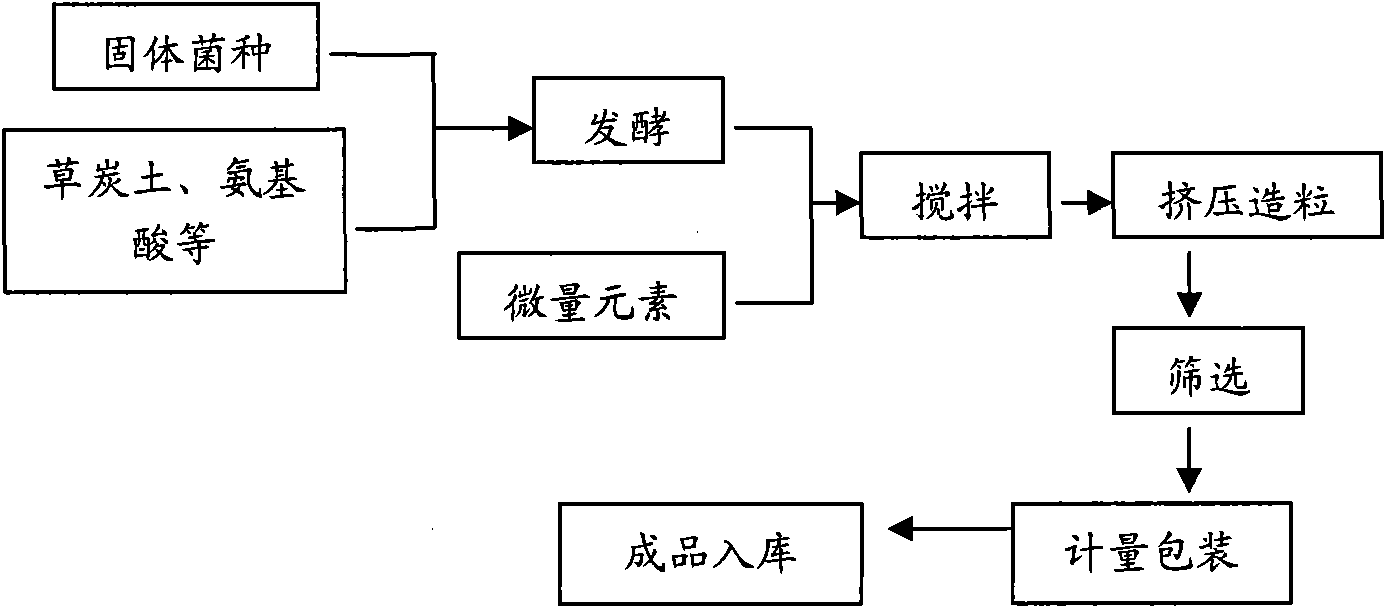

Feeding acidifier prepared by emulsifying technology and preparing method thereof

ActiveCN101513222AFully dispersedFully emulsifiedAnimal feeding stuffAccessory food factorsPhosphoric acidMoisture absorption

The present invention relates to a feeding acidifier prepared by emulsifying technology and a preparing method thereof. The invention belongs to the technical field of animal feed additive preparing. The feeding acidifier comprises the following components according to content: 8-20 parts of lemon acid; 5-20 parts of fumaric acid; 10-15 parts of phosphoric acid; 5-20 parts of malic acid; 15-25 parts of lactic acid; 6-15 parts of formic acid; 2-10 parts of acetic acid; 2-5 parts of mouthfeel modifying agent; and 3-5 parts of silicon dioxide. The invention provides a novel preparation form of acidifier and combines the physical and chemical properties of shaping material for developing the novel producing technique of acidifier according to the sustained-release control principle. The feeding acidifier prepared according to the emulsifying technique of the invention effectively settles the problem of stomach digesting of acidifier and the effect directly gets to the intestinal canal. The feeding acidifier prepared by emulsifying technology according to the invention has the advantages of reliable safety, excellent free-running property, strong moisture absorption resistance, convenient processing, growth promotion, diarrhea prevention, etc.

Owner:MYRON XIAMEN BIOTECH

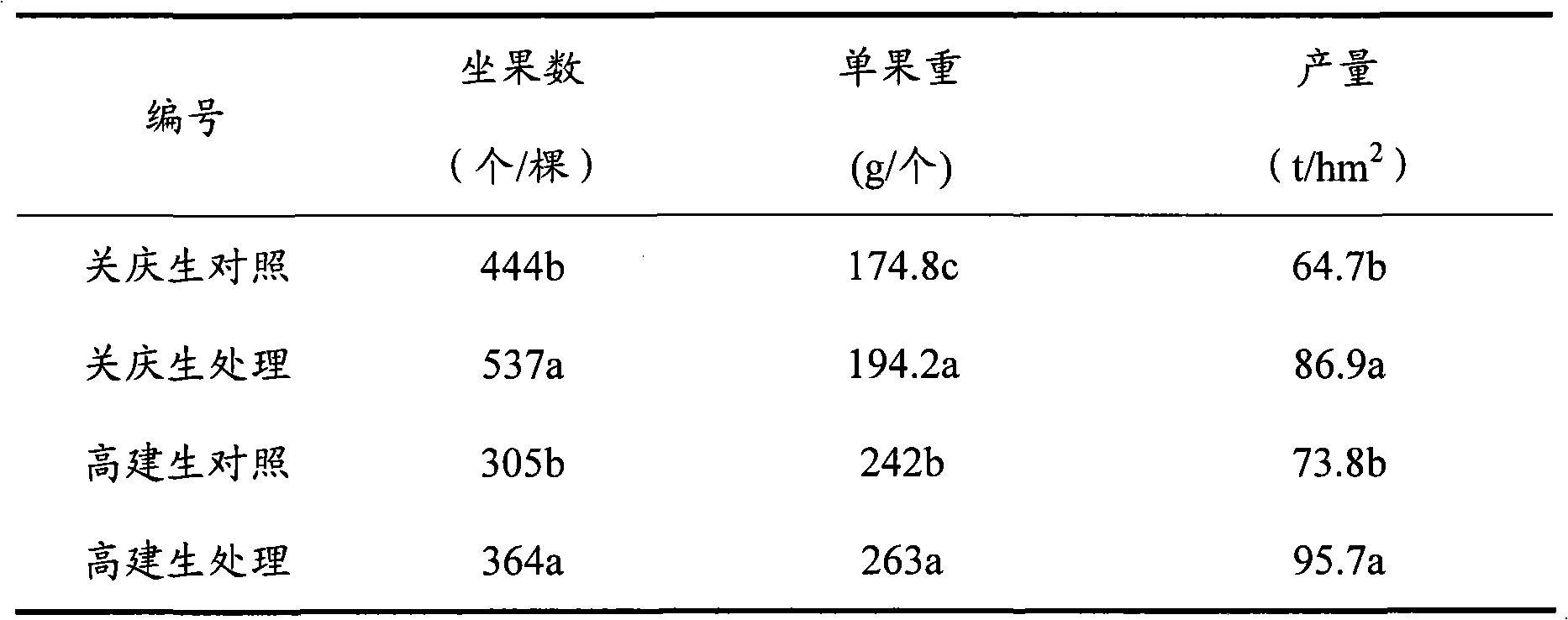

Special bio-organic fertilizer for peaches and preparation method thereof

InactiveCN101817702AReduce compactionImprove water and fertilizer retention performanceOrganic fertilisersFertilizer mixturesFruit setInorganic compound

The invention relates to a special bio-organic fertilizer for peaches and a preparation method thereof. The bio-organic fertilizer comprises the following components in parts by weight: 15-85 parts of a fertilizer organic matter; 0-30 parts of an organic compound; 0-50 parts of an inorganic compound; 0-10 parts of sulfuric acid; 0-2 parts of souring and ripening powder; 0-2 parts of a deodorant; and 5-35 parts of biological bacteria liquid. The bio-organic fertilizer of the invention can improve fruit setting percentage, average weight of single fruit, yield and quality factors of peach trees, and lower the content of titratable acid, thus greatly improving the economic benefit of peach farmers.

Owner:BEIJING JINTUDI FERTILIZER

Preparation method of decolored fructus momordicae fruit juice and fruit juice prepared by the method

ActiveCN101283831APreserve natural nutrientsHigh sweetnessFood preparationBiotechnologyDiabetes mellitus

The invention discloses a method for preparing decolorized grosvenor momordica juice and the decolorized grosvenor momordica juice prepared by the method. The method comprises following steps: selecting materials and pre-processing, passing through a cation column, decolorizing, acidifying for the first time, concentrating and acidifying for the second time. The decolorized grosvenor momordica juice is white or yellow-like transparent liquid with Baume degree more than 10 or brix more than 60, wherein the juice contains, calculated by dry weight, mogroside with a volume content equal to or larger than 30%. The grosvenor momordica juice prepared by the method keeps the natural nutriment of grosvenor momordica and has high sweetness and low sugar content. Meanwhile, the method solves the color change problem of the grosvenor momordica juice, and the product is suitable for various consumers, in particular to patients with diabetes, hypertension, etc.

Owner:GUILIN NATURAL INGREDIENTS CORP

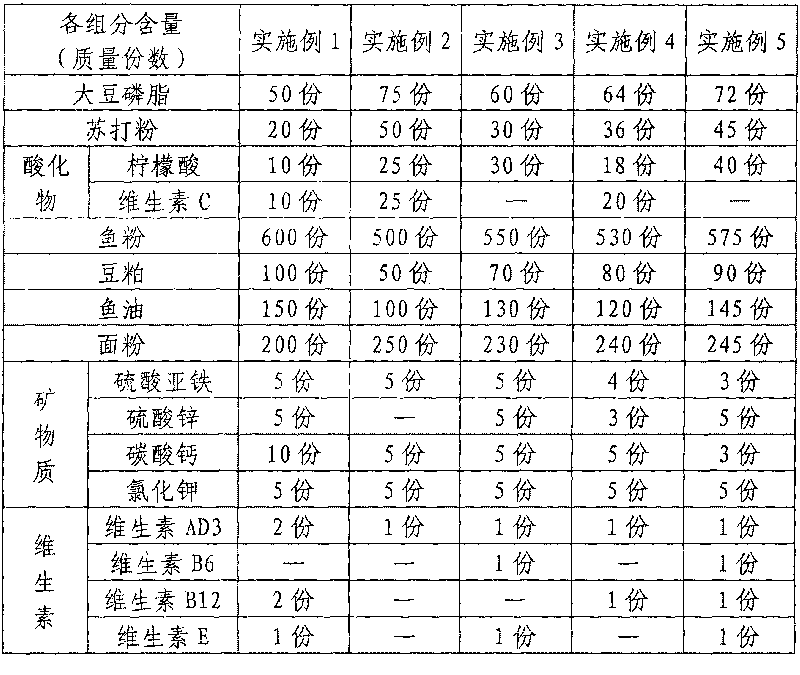

Slowly floating aquatic product feed and production process thereof

InactiveCN101715890AObserve feedingPrevent leakageClimate change adaptationAnimal feeding stuffAquatic productFish oil

The invention relates to a slowly floating aquatic product feed, which is characterized by comprising the following components in part by mass: 50 to 75 parts of soybean lecithin, 20 to 50 parts of soda powder, 20 to 50 parts of acidifying substances, 100 to 150 parts of fish oil, 500 to 600 fish meal, 50 to 100 parts of bean pulp and 200 to 250 parts of flour. The slowly floating aquatic product feed is convenient for a user to observe ingestion condition, and has the advantages of good ingestion and less water body pollution.

Owner:佛山市顺德区全兴水产饲料有限公司

Pig homologous raw material-free attracting starter compound feed for porkets

ActiveCN102389061AKeep the original scentIncrease total intakeAnimal feeding stuffBiotechnologyWeight gaining

The invention discloses pig homologous raw material-free attracting starter compound feed for porkets. According to a technical scheme adopted by the invention, the feed is composed of the following raw materials by weight percent: 35-45% of a puffed raw material, 5-8% of a soybean protein concentrate, 10-15% of fermented soybean meal, 4-5% of hydrolyzed wheat protein, 6-10% of lactose, 4-8% of whole milk powder, 3-5% of a casein, 2-5% of a nucleotide, 2-5% of fish meal, 1-3% of amino acid, 0.5-2% of glutamine, 0.5-1% of an acidifying agent, 2-5% of plant oil, 0.02-0.1% of a composite vitamin, and 0.1-0.5% of a composite trace element. Application of the feed in the invention presents strong feed attraction to porkets which can start feed taking in1-2d with rapidly increasing intake. With balanced and comprehensive nutrition similar to breast milk, the feed provided in the invention is characterized by high digestibility in porkets, no diarrhoea, effective overcoming of weaning stress, and rapid weight gain, and can effectively increase the porket weaning weight and the weight after two weeks of weaning, as well as improve porket survival rate and production performance. Free of plasma protein powder, dried porcine soluble and other pig homologous raw materials, the feed of the invention has no risk of homologous pig pathogen infection, and boasts significant biosecurity.

Owner:HARBIN QINGHE TECH

Imitation cheese compositions for use in the manufacture of cheese loaves, slices and the like, and method of producing such compositions

An imitation cheese composition containing moisture, preferably in an amount that is at least 60% by weight, a hydrocolloid, a cheese-derived component in an amount less than about 15% by weight of the composition, cheese flavoring that is natural or artificial and an acidulents in an amount that causes a pH of the composition to be not greater than 4.6. The composition is sufficiently firm such that it can be at least one of sliced, cut, shredded or grated. Preferably, no more than 1% protein is present, and / or the acidulent is in a total titrateable amount of less than 1.5% by weight of the composition, resulting in an imitation cheese having a flavor, texture and consistency that was only previously attainable in a pasturized process cheese product.

Owner:AFP ADVANCED FOOD PROD LLC

Novel string cheese and preparation method thereof

InactiveCN102090457AAdd hot water to scaldShorten acidification timeCheese manufactureFiber structureFlavor

The invention relates to novel string cheese and a preparation method thereof. The preparation method comprises the following steps of: making a cheese coagulum by using lactic acid bacteria and acidulant chymosin; performing steam jet or hot-water hot iron on the cheese coagulum; stretching at a high temperature to obtain a cheese block mass; adding emulsifying salt, table salt and seasoner into the cheese block mass; and extruding to obtain a product, wherein the product can be eaten without being cooked and has a hand-torn string texture and various flavors. On the basis of a Mozzarella cheese technology and the novel string cheese and the preparation method thereof, the acidulant is used, the hot-water hot iron is performed, a minor-diameter long-distance outlet molding method is used, and the positive effects of shortening acidification time, increasing the adaptability to production conditions and improving the uniformity and the stability of a cheese fiber structure are achieved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Temperature resistance type fuel egg low fat salad sauce and its producing method

The present invention discloses a kind of temperature resistant full egg low fat salad dressing and its production process, and belongs to the field of food producing technology. The temperature resistant full egg low fat salad dressing is produced with full egg as main material and through initial emulsification, final emulsification, diluting gelatinization, acidification, homogenization and other steps. It has unique recipe, and is creamy white, mellow, not fat, smooth, heat resistant and low in fat content. The present invention expands the application range of salad dressing and raises the food safety of salad dressing.

Owner:王利群

Beverage of Chinese chestnut, and preparation method

InactiveCN1957772AYellowish colorImprove stabilityFood preparationMilk substitutesNutritive valuesFiltration

A chestnut beverage with high nutritive value is prepared from chestnut, sweetening agent, souring agent, stabilizer, and oligose through choosing chestnut, removing shell and film, grinding, protecting color, filtering, liquefying, boiling, saccharifying, mixing, homogneizing, filling it in containers, and sterilizing.

Owner:SHENYANG AGRI UNIV

Method for processing weakly acidic normal temperature fresh-keeping wet noodles

InactiveCN102308956AGuaranteed shelf lifeAvoid "sour" problemsFood preparationProcess engineeringSouring

The invention discloses a method for processing weakly acidic normal temperature fresh-keeping wet noodles. The method adopts added natural nisin as an antiseptic, and adopts processes of post-slaking, post-washing, alcohol spraying and packaging with high resistance and isolation film bags, and a high temperature and short time sterilization technique to produce, so a problem of "souring" of the noodles caused by an acid dipping technology for reaching a shelf-life of traditional wet noodles in later processes is avoided, thereby shortages of soft rotten and non-chewy noodles caused by high temperature and long time sterilization in the later processes are solved.

Owner:FUZHOU CHANGSHENG FOOD

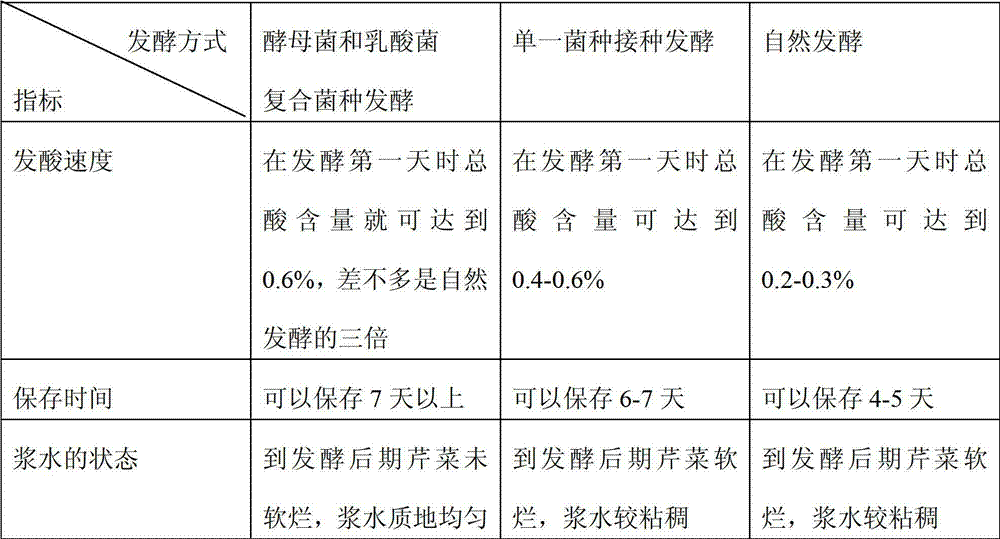

Method for making serofluid dish

The invention discloses a method for making serofluid dish. The method comprises the following steps of: making the serofluid dish by vaccinating a composite strain of saccharomycetes and lactic acid bacteria; respectively vaccinating bacteria liquids of the saccharomycetes and the lactic acid bacteria by using a vaccination amount with 5-15% of surface liquid volume, wherein a volume ratio of the bacteria liquid of the saccharomycetes to the bacteria liquid of the lactic acid bacteria is (0.2-1):1; fermenting at a temperature of 30-43 DEG C for 3-6 days and stirring for one time per 24 hours, so as to obtain the serofluid dish after fermentation. According to the method provided by the invention, the serofluid dish obtained by vaccinating the composite strain of the saccharomycetes and the lactic acid bacteria for fermenting has the advantages of rapid souring, pure sour taste, rich nutrient substance, long storage time, fresh scent of smell and specific smell of the fermentation of the saccharomycetes and the lactic acid bacteria, and higher and more stable quality.

Owner:SHAANXI UNIV OF SCI & TECH

Moringa oleifera pig feed

InactiveCN102805253ALow in crude fatReduce cholesterolFood processingAnimal feeding stuffBiotechnologyLean meat

The invention provides moringa oleifera pig feed, which is characterized by consisting of the following components in percentage by mass: 38 to 60 percent of corn, 10 to 16 percent of bean pulp, 12 to 18 percent of rice bran, 7 to 38 percent of moringa oleifera powder and 0.2 to 1 percent of salt. The moringa oleifera pig feed contains rich crude protein, crude fiber, mineral substances, vitamine, and multiple antioxidative, antibacterial and antiphlogistic active ingredients such as moringa oleifera flavone; the content of crude fat is low; the ratio of amino acid is appropriate; any chemical medicine or chemical raw material is not added; the moringa oleifera pig feed does not have toxic or side effects; after being fed, pigs gain weight quickly; the metabolic capacity of pig organisms can be improved; immunity and disease resistance are strengthened; the marketing time is short; the lean meat percentage is high; the cholesterol is low; acidification can be lightened; the generation of pale soft exudative (PSE) pork is prevented; and quality of the pork is improved.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Beverage made of Chinese onion as raw material

A beverage for nourishing blood, invigorating the function of stomach, preventing disease and taking care of health is proportionally prepared from Chinese onion, red jujube, sweetening agent, water and selective souring agent and / or thickening agent. Its advantages are strong fragrance and unique taste.

Owner:程征云

Soybean yoghourt pudding and preparation method thereof

ActiveCN102613495APromote digestion and absorptionEasy to storeFood preparationBiotechnologyPasteurization

The invention discloses soybean yoghourt pudding and a preparation method thereof. The method comprises the following steps of: 1) soaking, pulping and boiling soybean, adding unsalted butter, and mixing uniformly for homogenization to obtain soybean milk; 2) cooling the soybean milk obtained in the step 1), adding lactic acid bacteria, and fermenting at constant temperature to obtain curdy soybean yoghourt; 3) crushing, sterilizing and homogenizing the curdy soybean yoghourt obtained in the step 2) to obtain a soybean yoghourt homogenized solution; and 4) boiling a stabilizer, flavoring agents, sugar and water to obtain a colloidal liquid, cooling, and uniformly mixing the colloidal liquid and the soybean yoghourt solution obtained in the stop 3) to obtain the soybean yoghourt pudding. The lactic acid bacteria are used for fermentation to generate acid, acidity regulators are not added, and unique vitamin B of a fermented food is generated, so that the nutritional value of the soybean yoghourt pudding is higher than that of the common pudding on the market; and the lactic acid bacteria are killed through pasteurization, so that the product cannot be postacidified and is easy to store, the shelf life is prolonged and the quality of the product is stable.

Owner:CHINA AGRI UNIV

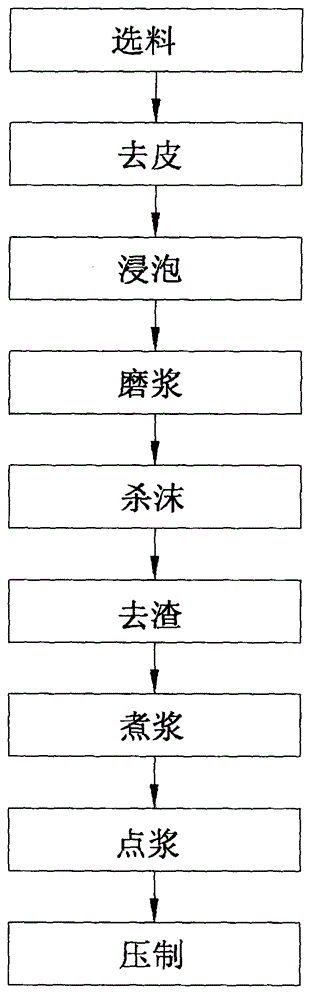

Novel preparation method for soybean slurry water beancurd and beancurd product prepared by method

The invention discloses a novel preparation method for soybean slurry water beancurd. The method comprises the following steps: (1) selecting raw materials; (2) peeling; (3) soaking; (4) grinding; (5) removing froth; (6) removing residues; (7) boiling soybean slurry; (8) solidifying; (9) pressing. The invention further discloses a beancurd product prepared by implementing the novel preparation method for the soybean slurry water beancurd; a preparation process of the method provided by the invention is simple, convenient and easy to realize; soybean slurry water is utilized for solidification to form beancurd jelly, the soybean slurry water is formed by fermenting and souring water pressed out during beancurd preparation in the presence of lactobacilli, and other chemical substances do not need to be extra added, that is to say, gypsum, brine and other curing agents are not added in the preparation process, so that a fact that the beancurd is prepared from original soybean slurry is guaranteed and the product is guaranteed to be green, healthy and safe; the soybean slurry water beancurd product provided by the invention has remarkable characteristics that the soybean slurry water beancurd product is smooth and tender in mouth feel, rich in soybean aroma, indissoluble after being boiled for a long time, gradually expandable when being fried in a frying pan, relatively long in storage time, and the like; moreover, the soybean slurry water beancurd product is rich in nutriment, favorable for body health after being eaten for a long term, and favorable for wide popularization.

Owner:孙怀兵

Castable used for electric furnace slag/iron notch as well as method for pouring electric furnace slag/iron notch

The invention provides a castable used for electric furnace slag / iron notch and a method for pouring the electric furnace slag / iron notch. The castable used for the electric furnace slag and the iron notch comprises the following components by weight percent: 50-60wt% of carborundum grains, 12-16wt% of silicon carbide fine powder, 0-8wt% of Al203 micro powder, 0-5wt% of silicon micro powder, 0-5wt% of additive, 5-9wt% of binding agent, additionally added 5-9wt% of binding agent and 1-4wt% of coagulant, wherein the carborundum grains, the carborundum fine powder, the Al203 micro powder, the silicon micro powder and the additive are mixed on a mixing mill after being blended; adding the binding agent, milling and souring. When the castable is poured on site, the binding agent and the coagulant are additionally added and evenly stirred to obtain the castable used for the electric furnace slag and the iron notch, wherein the additive is at least one of sodium hexametaphosphate, sodium tripolyphosphate, carboxymethylcellulose and calcium lignosulphonate; and the binding agent is at least one of the sodium hexametaphosphate, phosphoric acid and aluminium phosphate.

Owner:PANZHIHUA WANTENG REFRACTORY MATERIALS

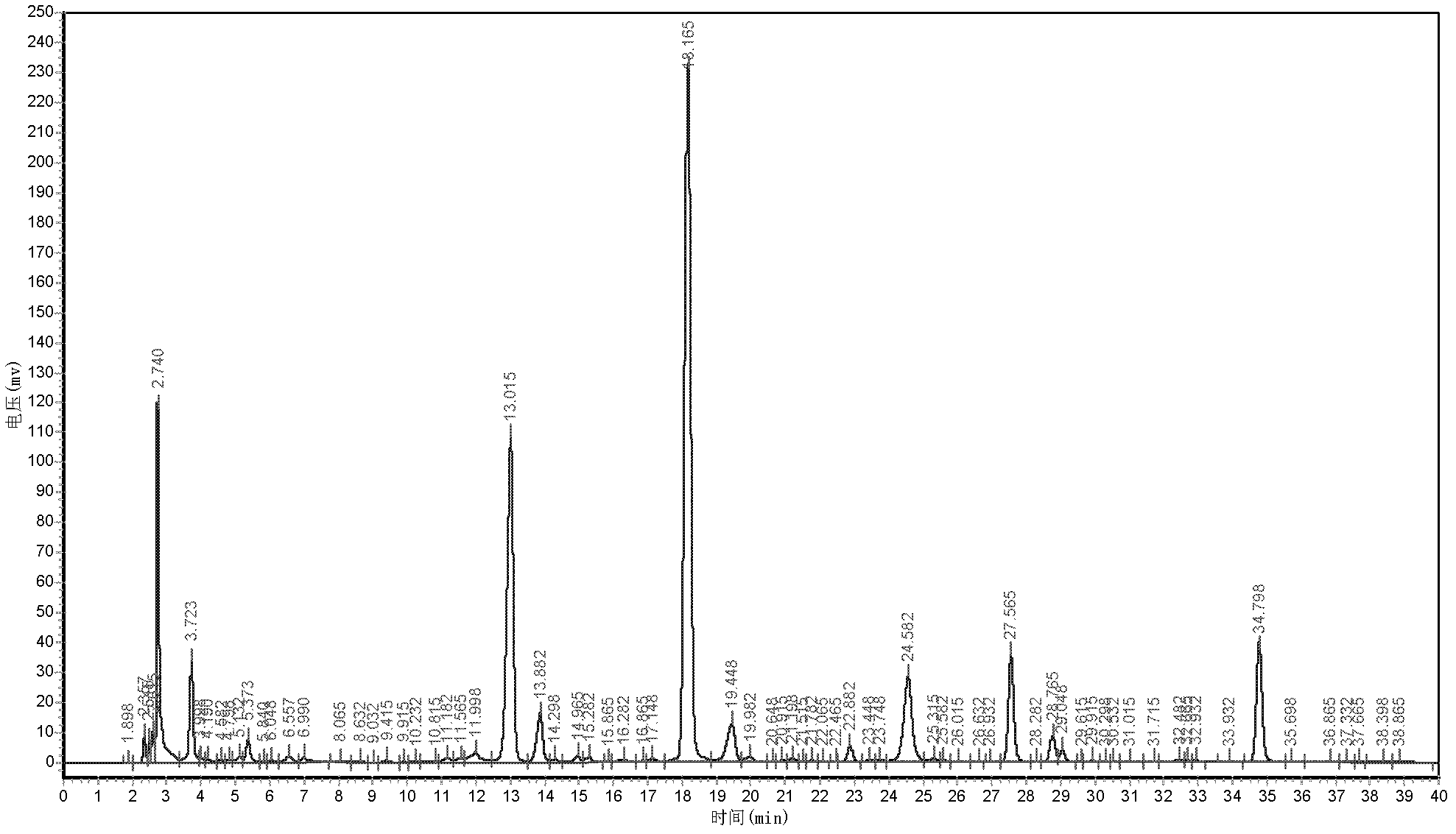

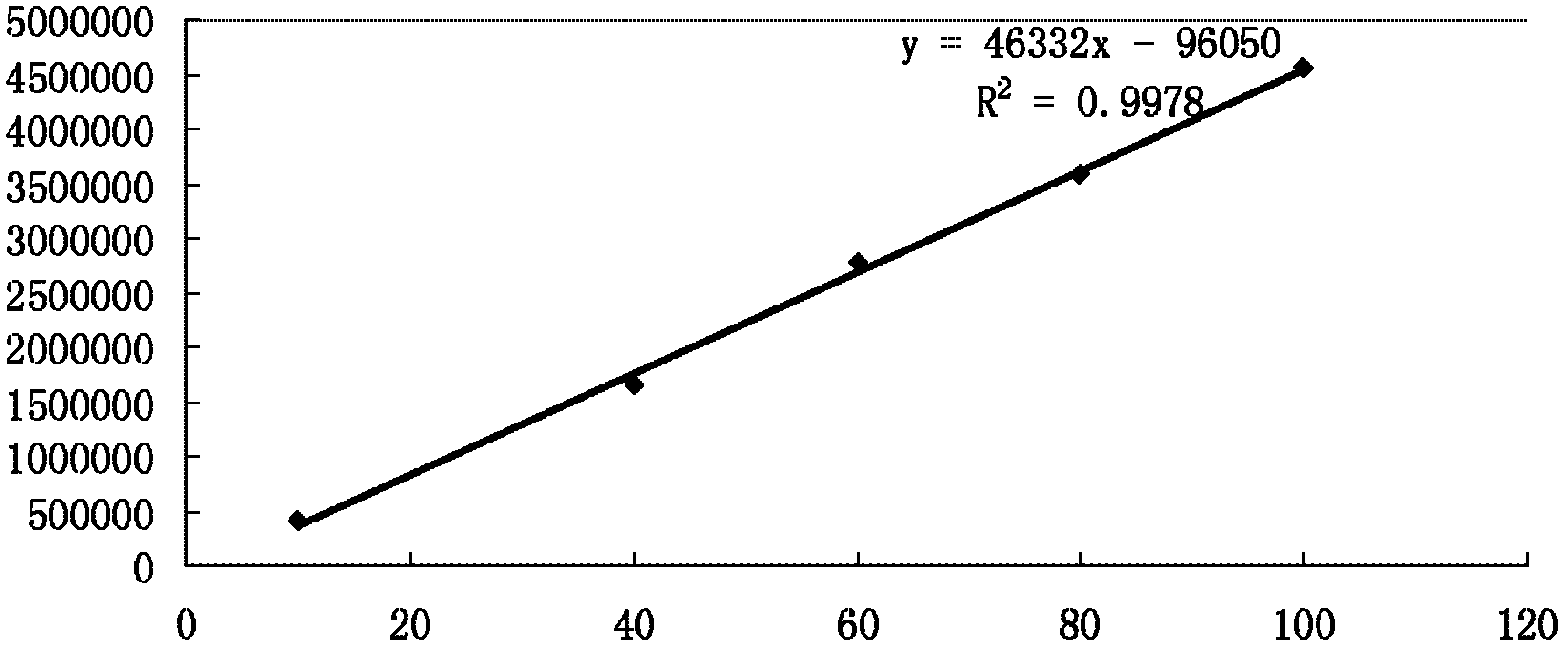

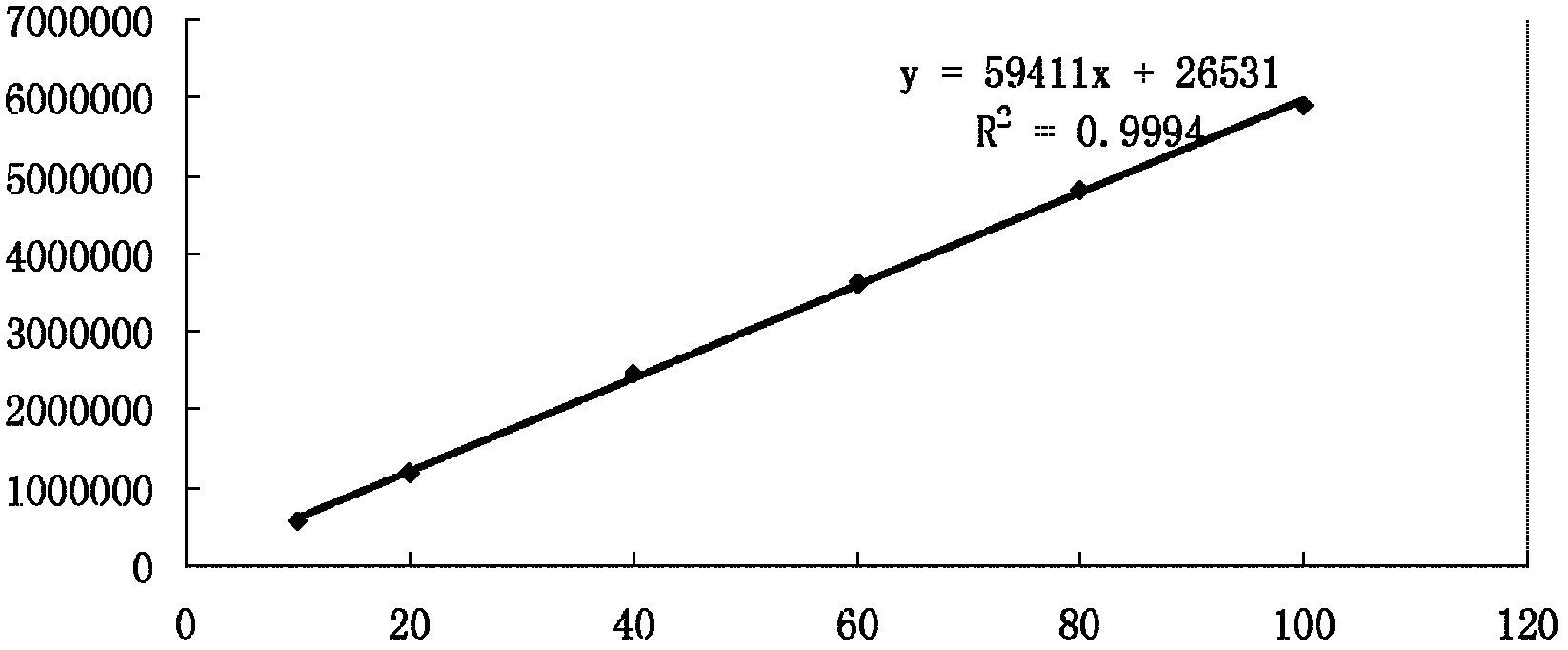

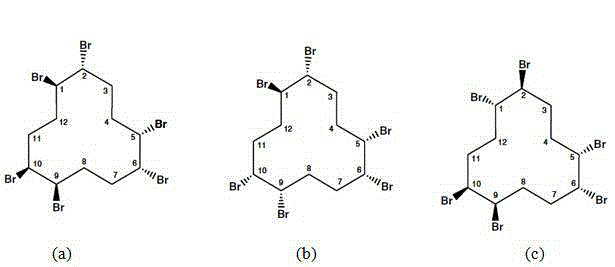

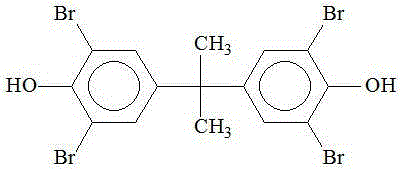

Method for simultaneous determination of hexabromocyclododecane isomer and tetrabromobisphenol A in fat food

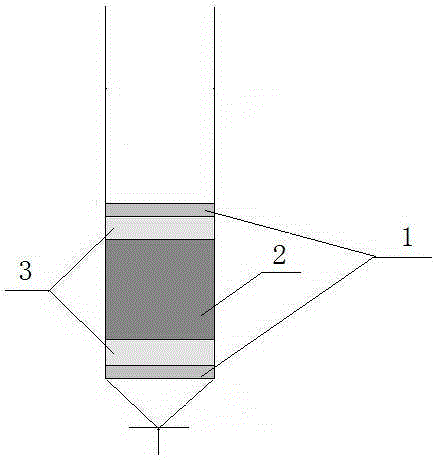

InactiveCN105181865AOptimizing pre-processing technologyMeet the requirements for analyzing actual samplesComponent separationTetrabromobisphenol AMicrosphere

The invention provides a method for simultaneous determination of hexabromocyclododecane isomer and tetrabromobisphenol A in fat food. The method is characterized by mainly including sample extraction, extract purification and determination. The extract purification uses mesoporous zirconia hybrid column as a solid phase extraction column containing an anhydrous sodium sulfate layer, a mesoporous zirconia microsphere layer, an acidified silica gel layer, a dielectric hole oxide zirconium microsphere layer and an anhydrous sulfate sodium layer from bottom to top. The recovery rate of hexabromocyclododecane isomer and tetrabromobisphenol A in plant oil, fish, meat, egg, milk and other fat food sample reaches 87.5%-114.4%. The preparation of reusable mesoporous zirconia microsphere optimizes the pretreatment technology, and saves a large amount of solvent; the detection limit, quantification limit, recovery rate and precision can meet the requirements for analysis of real samples; and reliability of the method and result accuracy are verified through the standard substance in international comparison.

Owner:INST OF AGRI QUALITY STANDARDS & TESTING TECH RES HUBEI ACADEMY OF AGRI SCI

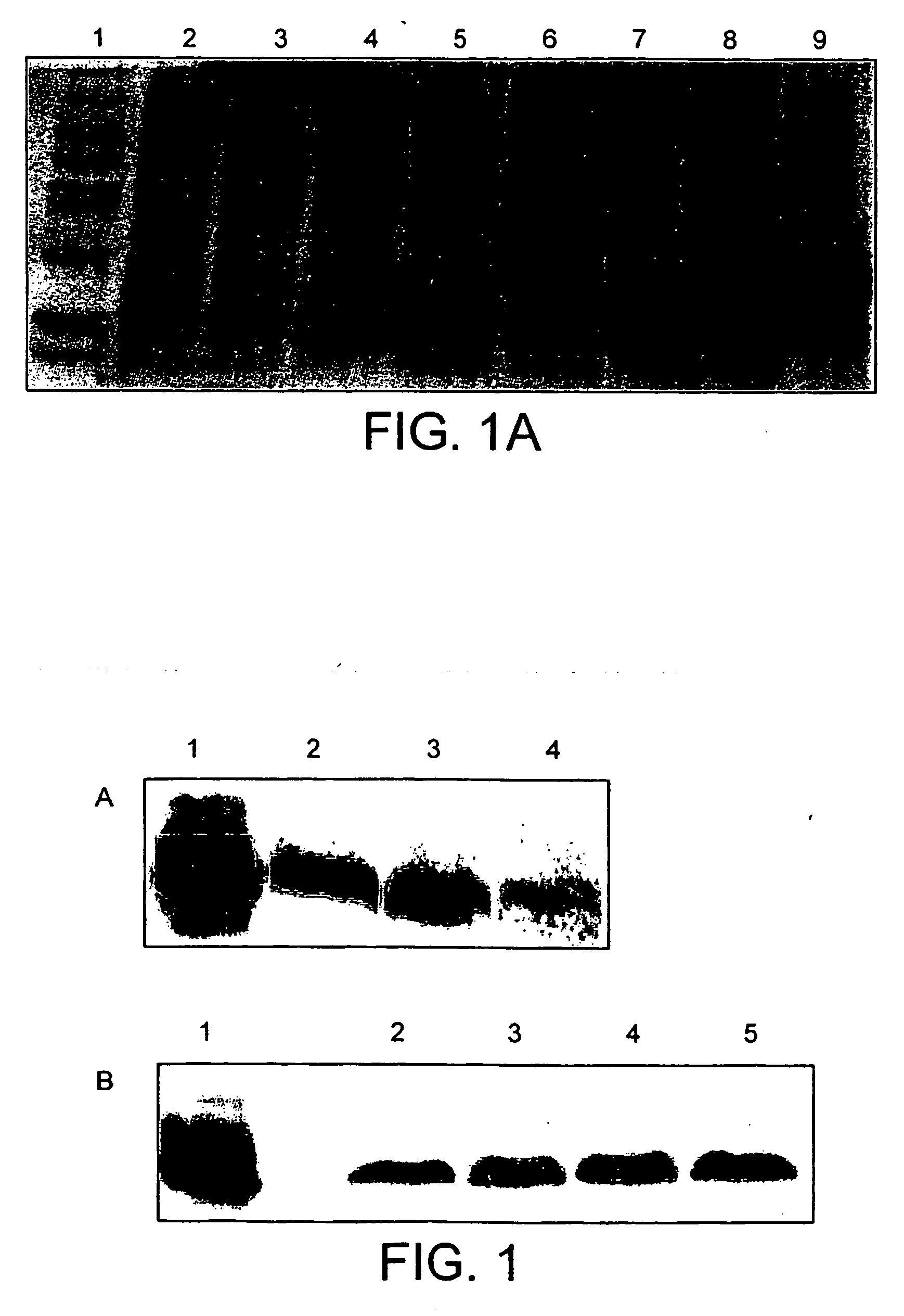

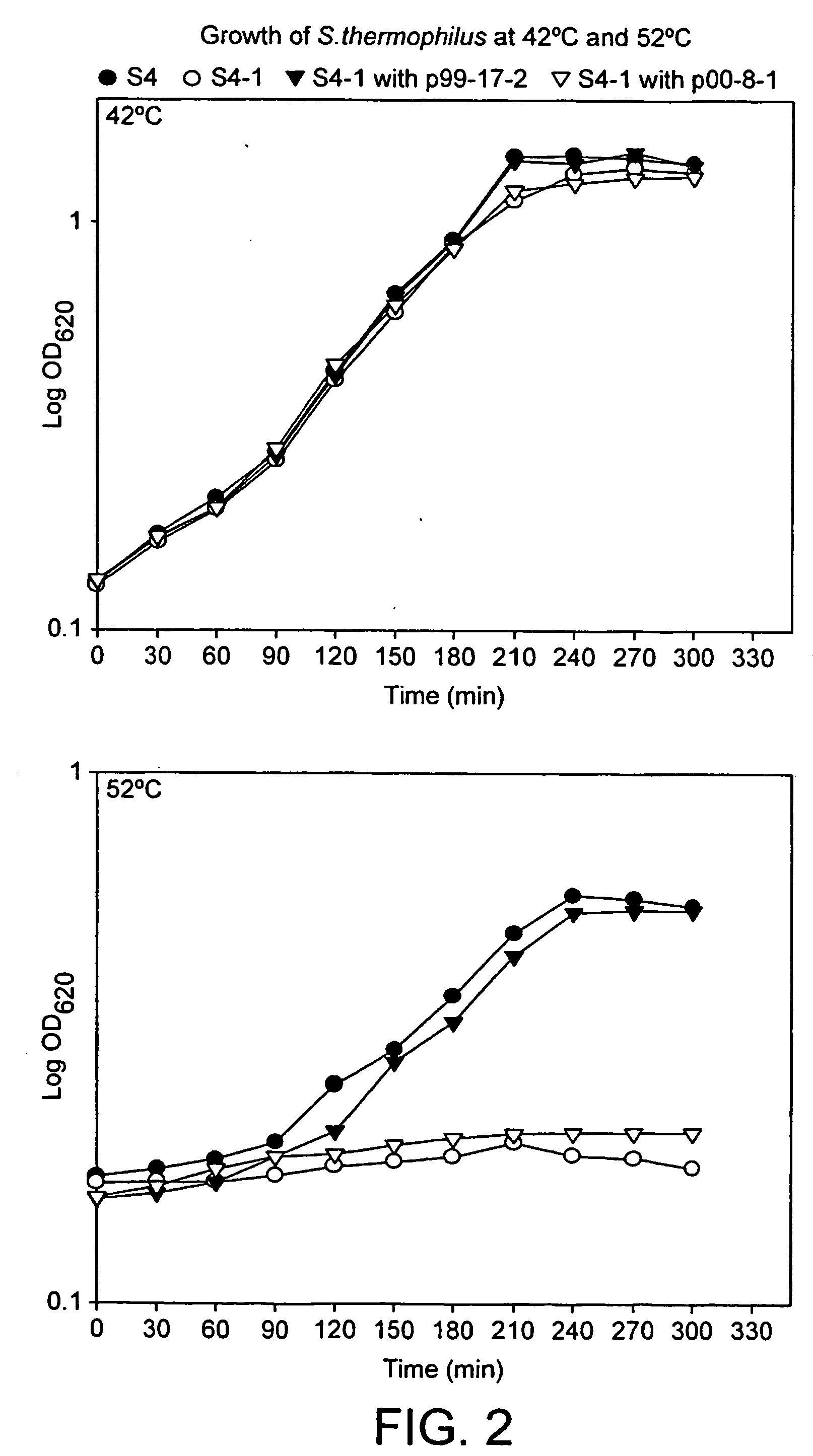

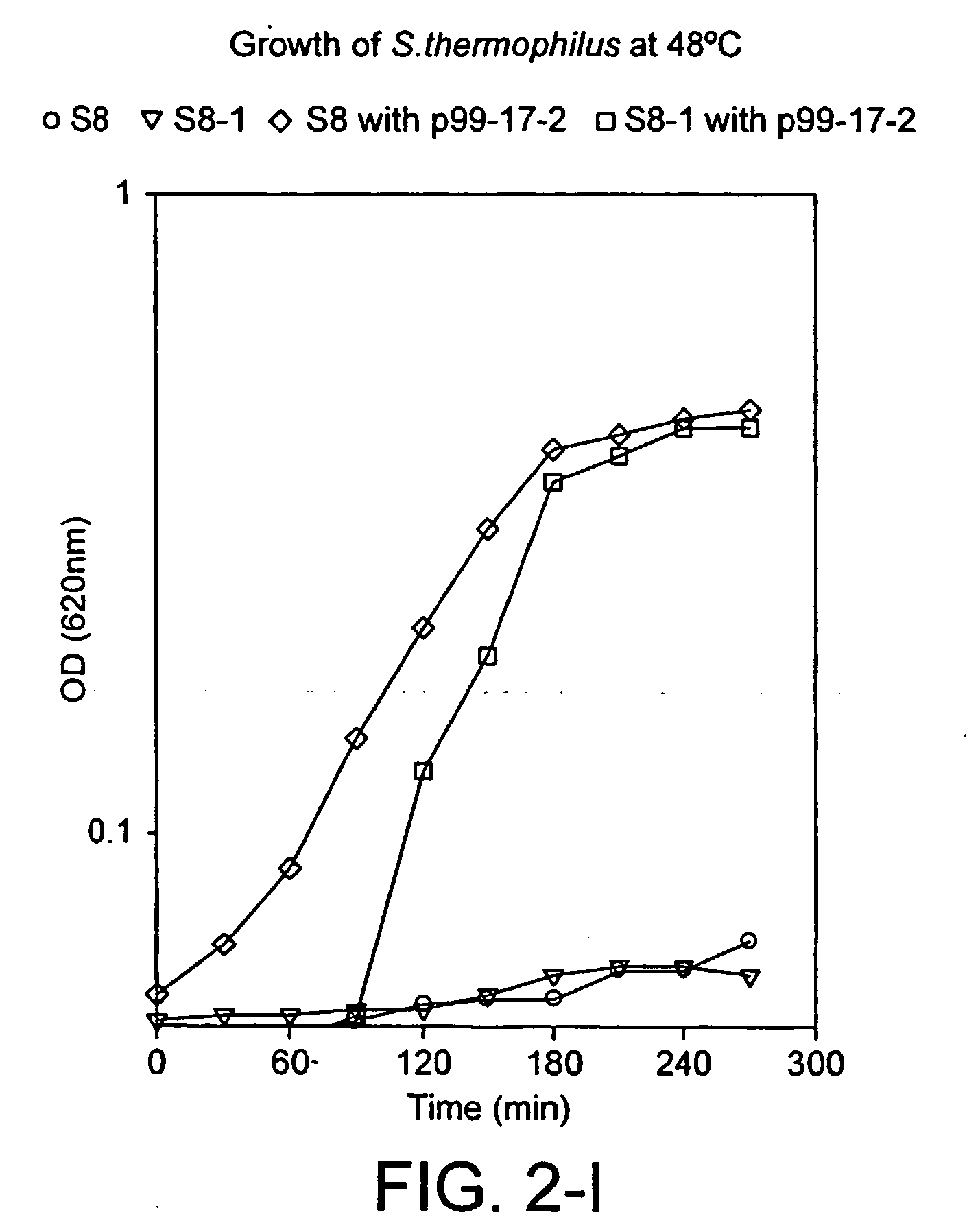

Method of improving food fermentation procedures

InactiveUS20050158423A1Less sensitiveMilder taste characteristicMilk preparationFungiIncreased toleranceStaphylococcus lactis

The present invention relates to the field of food fermentation procedures involving lactic acid bacteria and in particular to improving the quality of dairy products like acidity, post-fermentation acidification, aroma, flavor, mildness, consistency and texture. Specifically, the present invention provides a method for making dairy products using the thermophilic Streptococcus thermophilus and the mesophilic Lactococcus lactis carrying plasmids encoding small heat shock proteins which allow fermentation to be carried out at temperatures higher than the regular fermentation temperatures. The thermophilic and mesophilic lactic acid bacterial species expressing said small heat shock proteins also exhibit increased tolerance to lower pH and higher salt concentrations as well as reduced sensitivity to bacteriophage attack at the elevated fermentation temperatures.

Owner:DUPONT NUTRITION BIOSCIENCES APS

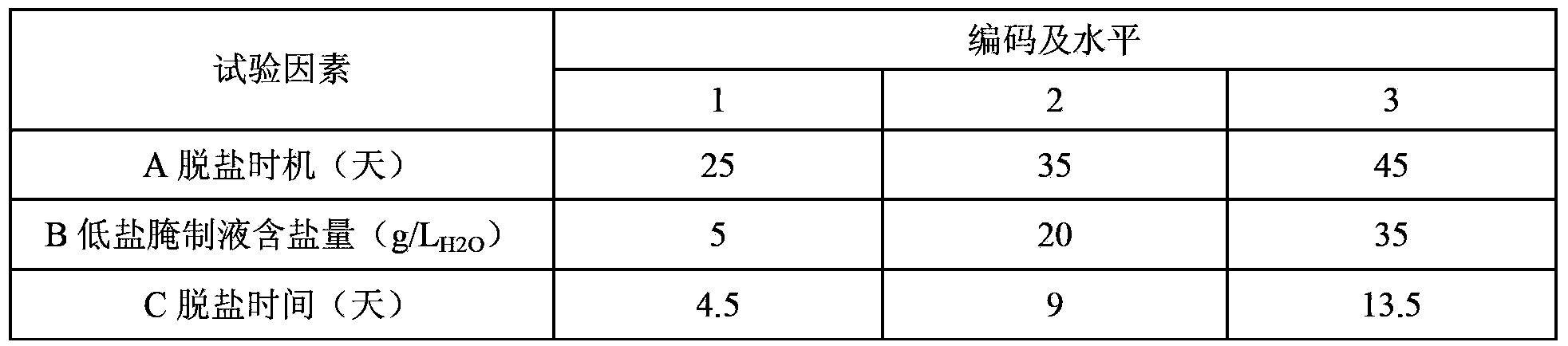

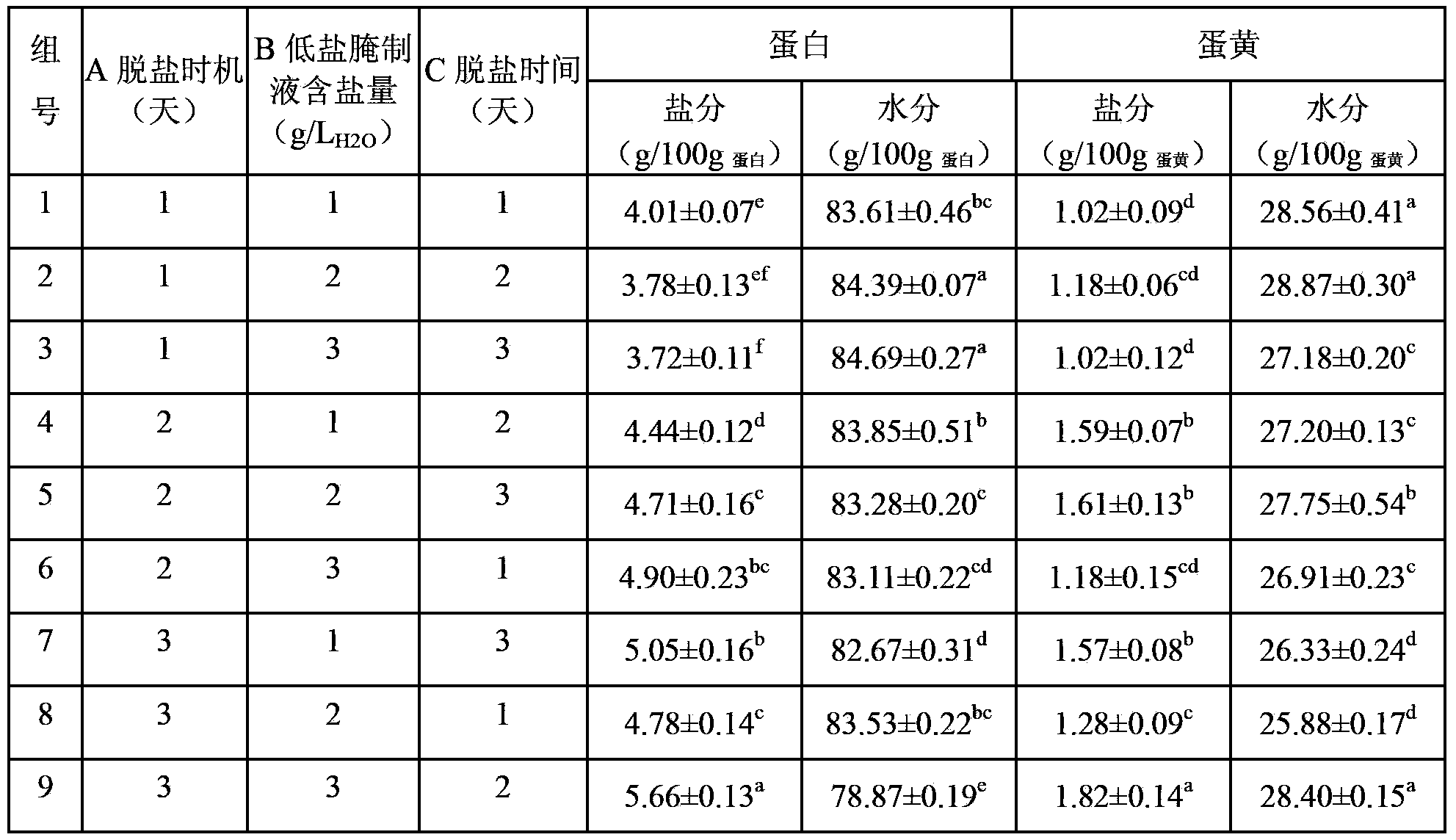

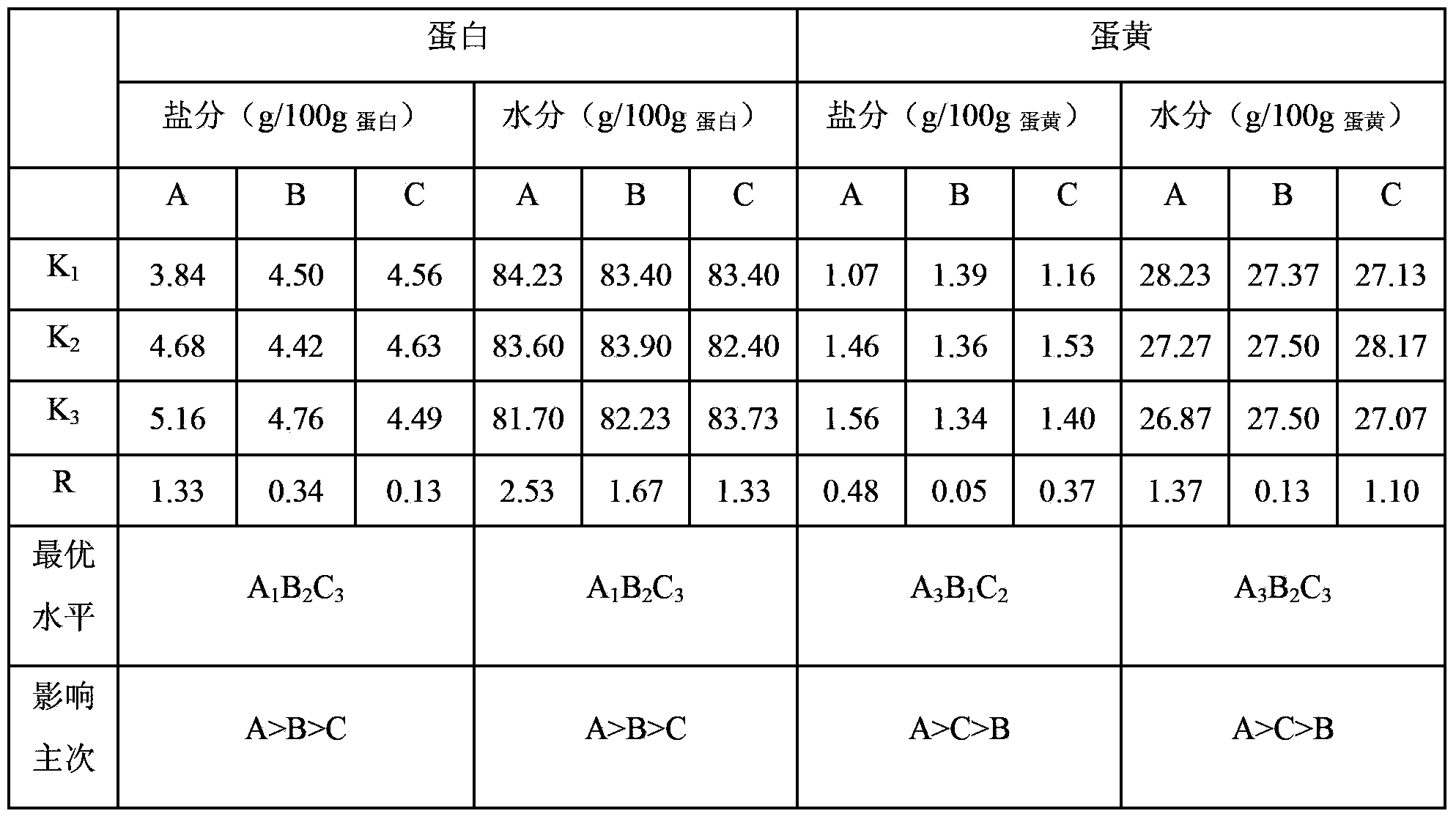

Low-salt salted duck egg dynamic sousing salinity regulation and control method

The invention relates to a low-salt salted duck egg dynamic sousing salinity regulation and control method and belongs to the technical field of deep processing of animal products. The method comprises the steps as follows: firstly, dynamically sousing egg stuff in a high-salt sousing liquid for 2-3 hours by cooperating ultrasound with bubbles; secondly, continuously dynamically sousing the egg stuff in the high-slat sousing liquid under the condition of bubbling of a gas pump for 25-35 days; lastly, transferring the egg stuff to a low-salt sousing liquid for dynamic sousing under the condition of bubbling for 4.5-13.5 days, taking out the egg stuff from a tank, and cleaning, drying and packing the egg stuff to obtain the finished product. According to the invention, salt in the sousing liquid can be uniformly distributed by cooperating the ultrasound with the bubbles for dynamic souring; with the adoption of bubbling dynamic souring, the souring liquid and the egg stuff can be agitated, the salt more quickly infiltrates into egg whites and yolks from the sousing liquid, so as to shorten the processing cycle; the high-salt reverse infiltration of the egg whites can be achieved by adopting low-salt bubbling dynamic souring, the salinity of the egg whites of the finished product of the salted duck eggs is effectively lowered, and the moisture is improved, as a result, the product quality is improved, and a modern processing method for mass production of low-salt salted duck eggs is supplied.

Owner:NANJING AGRICULTURAL UNIVERSITY

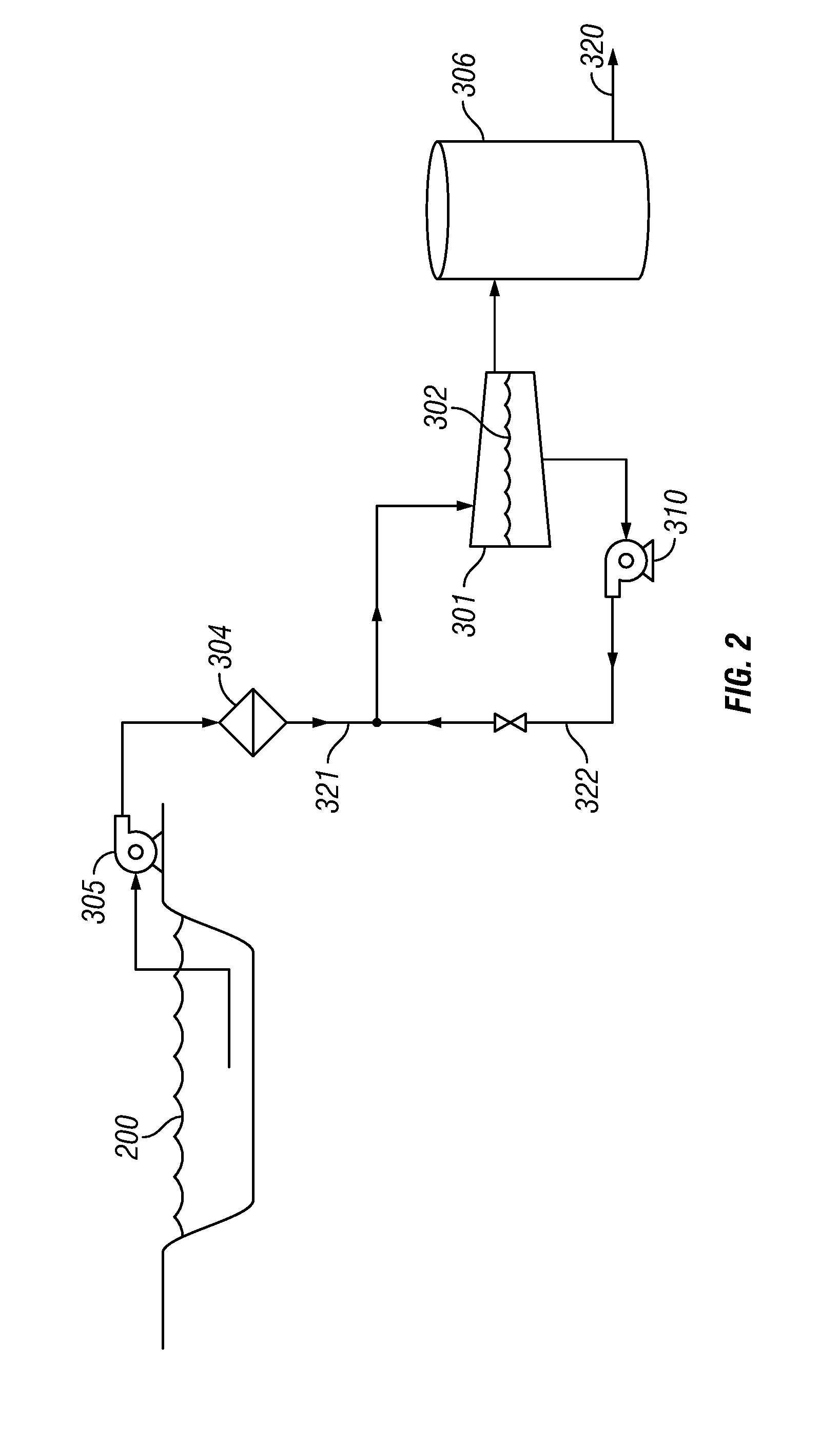

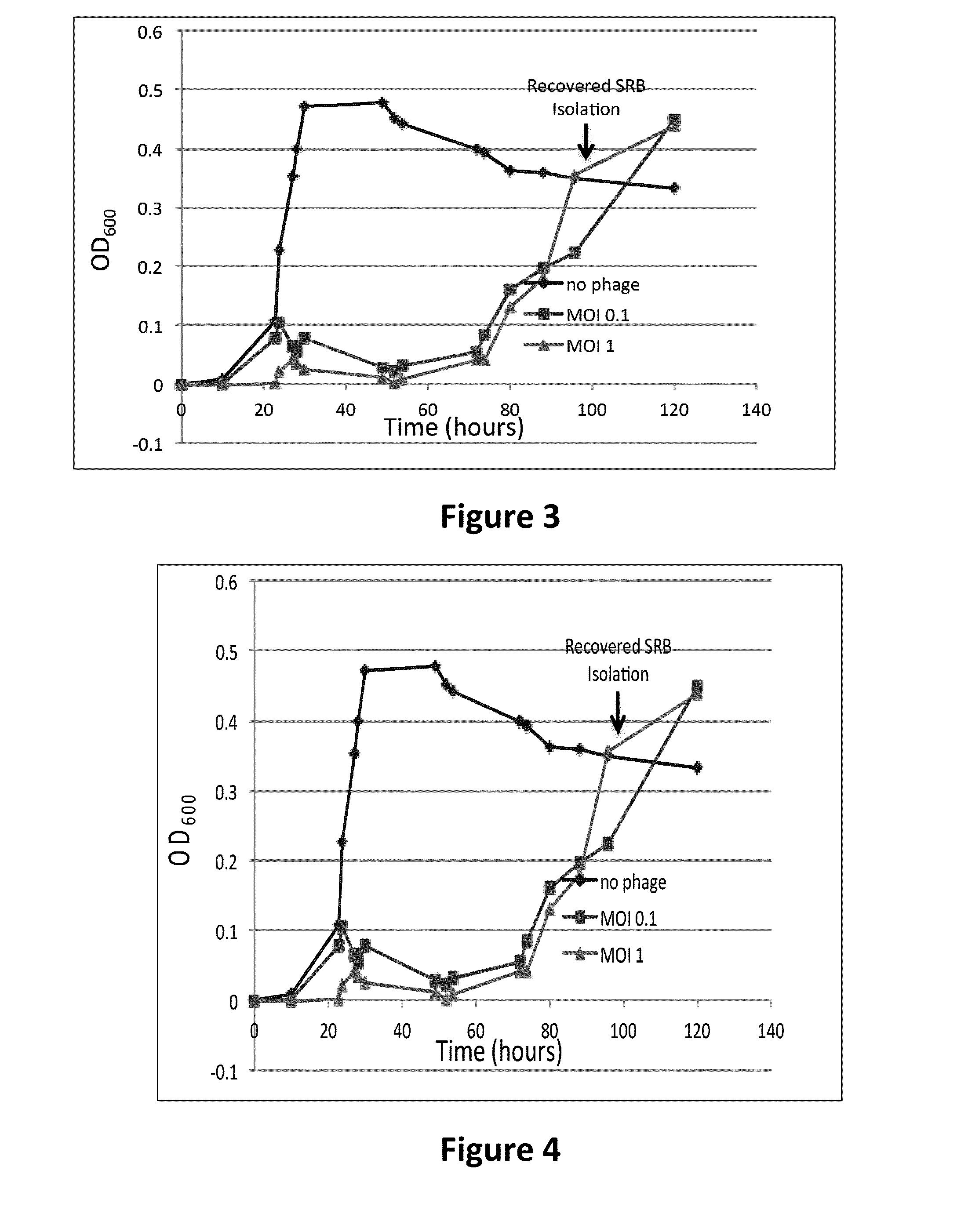

Prevention and Remediation of Petroleum Reservoir Souring and Corrosion by Treatment with Virulent Bacteriophage

InactiveUS20140061123A1Combating loss of effectivenessExtended service lifeRecovery/purificationWater/sewage treatment using germicide/oligodynamic-processWater useBacteriophage

There is provided a safe, natural, environmentally sound means of controlling bacterial contamination, corrosion, and souring of oil and gas wells and reservoirs that result from bacteria-contaminated water in a well. In one aspect it is a process for remediation of souring of petroleum reservoirs and coalbeds by adding to the water used in flooding and “fracing” operations an effective amount of virulent (non-lysogenic) bacteriophages (phages) specific for problematic target bacteria. The invention also provides a means for combating loss of effectiveness of bacterial control by staging bacteriophage production and application to control dominant and sub-dominant target bacteria in a community of target bacteria.

Owner:DOW GLOBAL TECH LLC

Mixed fruit coconut milk beverage and its production process

The invention relates to a mixed fruit cocoanut juice beverage and its production method. Said beverage contains (wt%) 95-5% of fruit juice and / or fruit raw pump, 4-93% of cocoanut milk or cocoanut paste, 0.1-3.0% of high ester pestin, 0-85% of water, 0-0.7% of souring agent and 0-0.5% of buffer agent. It possesses unique fruit flavour, complete nutrients, good taste, high-grade quality and long storage time.

Owner:北京海爵食品有限公司

Polyporus frondosus oral liquor and its prodn. method

InactiveCN1751694ARealize comprehensive utilizationEffective dissolutionMetabolism disorderFungi medical ingredientsMyceliumColloid

An oral liquid of Symplocos paniculata flower is prepared through preparing its fermented liquid, heating, proportionally mixing it with hydrolyzed liquid of animal protein, sweetening agent, souring agent, and stabilizer, regulating pH=4-7, colloid grinding, high-pressure homogenizing, sterilizing and pouring it in containers.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

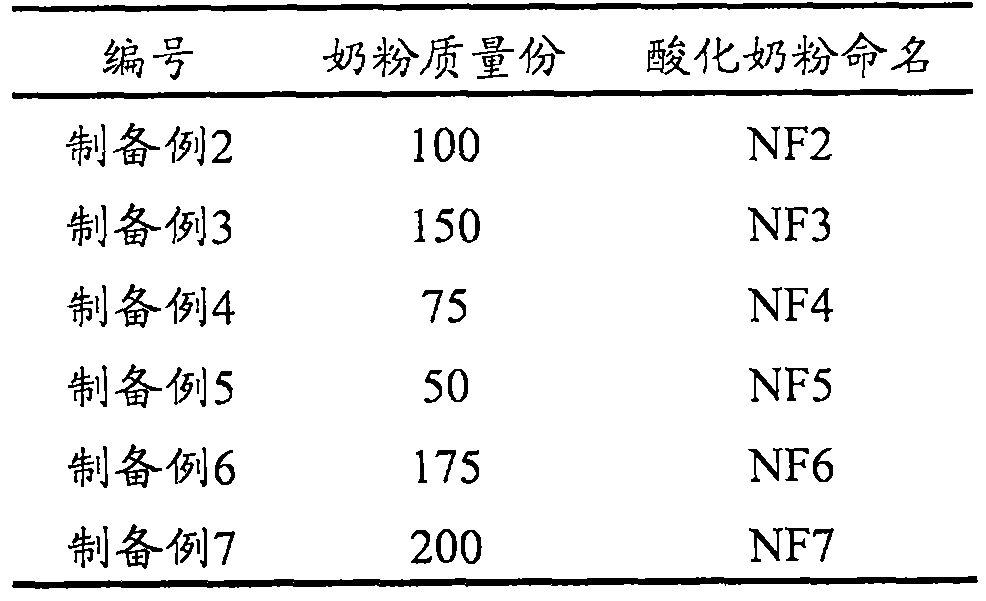

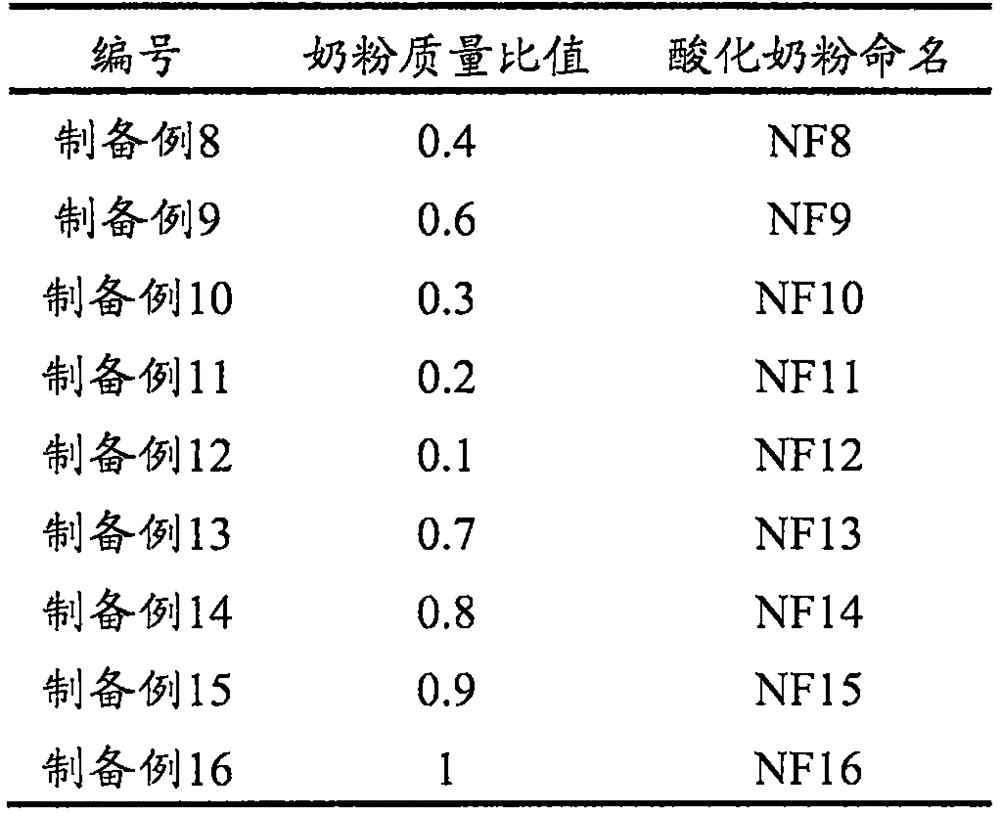

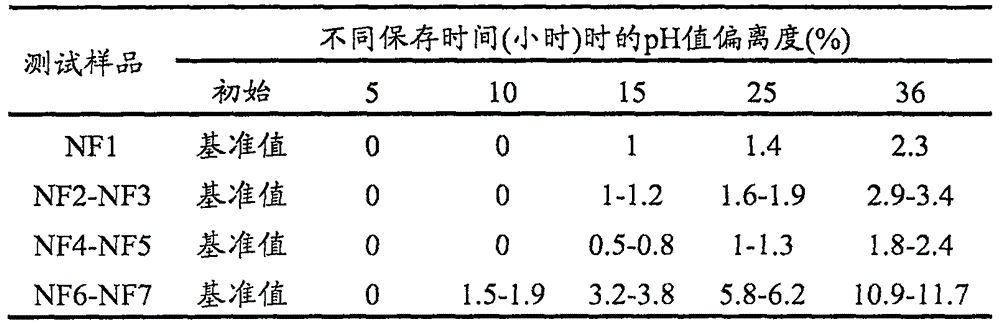

Acidified milk powder fed to calves as well as preparation method of acidified milk powder and feeding method of calves

ActiveCN105053209ACompatible with pH rangeGood storage stabilityMilk preparationAnimal feeding stuffBiotechnologyAnimal science

The invention provides acidified milk powder fed to calves as well as a preparation method of the acidified milk powder and a feeding method of the calves. The preparation method comprises the following steps: A1: respectively weighing milk powder and food-grade solid formic acid, grinding the weighed food-grade solid formic acid, and screening the ground food-grade solid formic acid through a 300-mesh sieve so as to obtain solid formic acid powder; and A2: under the condition that the temperature is below 8 DEG C, compounding the milk powder and the solid formic acid powder in the mass ratio of the milk powder to the solid formic acid powder being 50-200: 1, and thoroughly mixing the milk powder and the solid formic acid powder according to a specific mixing manner so as to obtain the acidified milk powder fed to the calves. The feeding method comprises the following steps: C1: firstly, preparing the acidified milk powder fed to the calves according to the preparation method; C2: pouring the acidified milk powder into water of which the temperature is 10-20 DEG C, and sufficiently stirring the acidified milk powder and the water until the acidified milk powder is melted so as to obtain acidified milk; and C3: supplying the acidified milk to the calves so that the calves freely drink the acidified milk. The acidified milk powder, the preparation method and the feeding method have quite important realistic significance and economic value in the field of breeding industry or dairy industry.

Owner:CHINTEM TECH CONSULTING BEIJING CO LTD

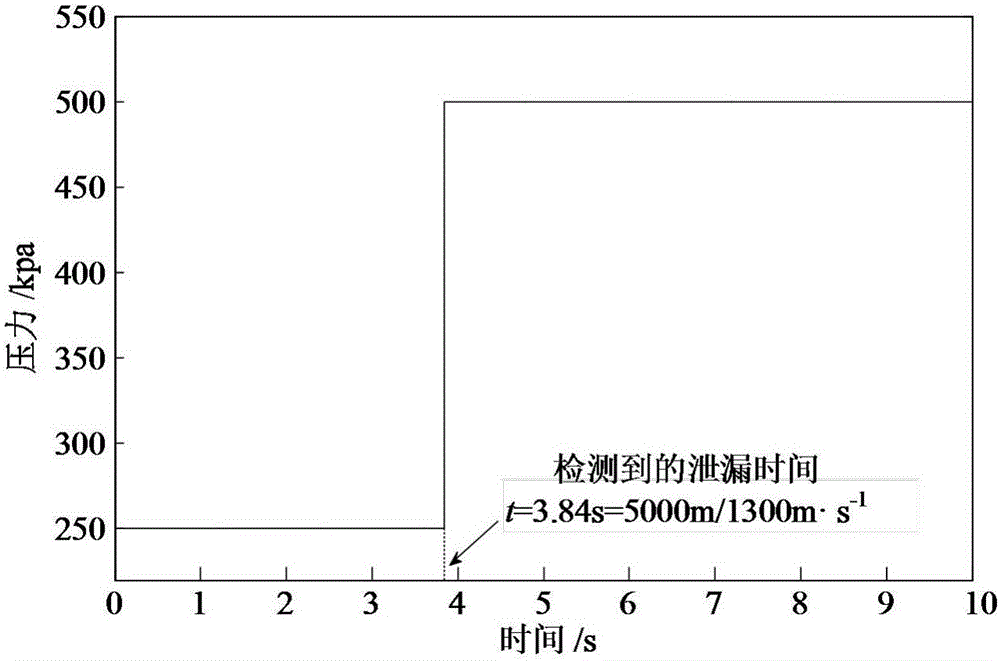

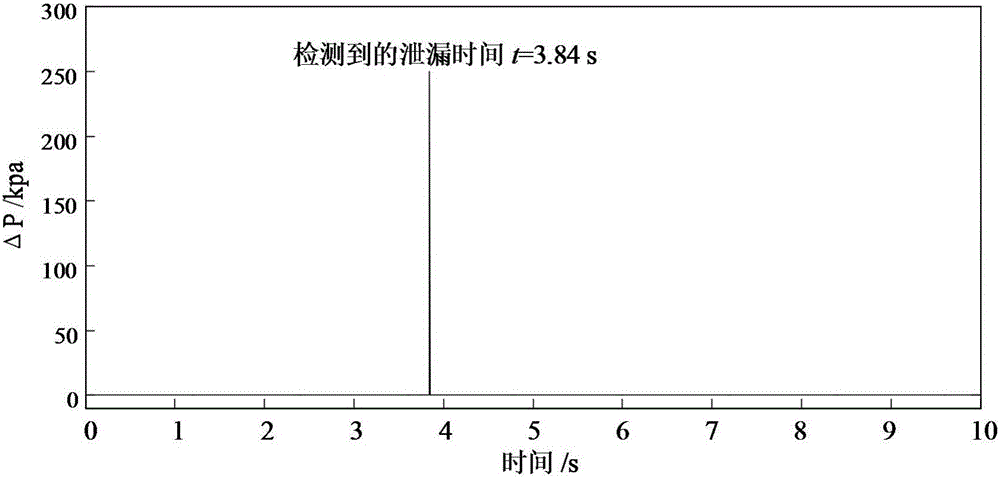

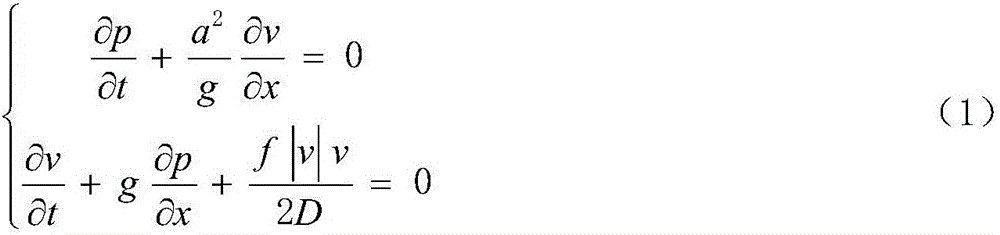

Adjoint matrix-based water supply pipe network leakage fault reverse souring method

ActiveCN106096243ASourcing is fastUniversalInformaticsSpecial data processing applicationsEngineeringSouring

The invention relates to an adjoint matrix-based water supply pipe network leakage fault reverse sourcing method. The method is characterized by comprising the following steps of: establishing a pipe network flow field transient equation; constructing a sensitivity function on the basis of pressure wave influences formed on a flow field by pipe network leakage; deriving an intensity of pressure according to the sensitivity function, and carrying out reverse processing in the aspects of space and time on an adjoint equation; and carrying out analog simulation by applying MATLAB, verifying an obtained analytical solution and determining a final reverse sourcing model. According to the method provided by the invention, a judging model for detecting a leakage position is obtained through deriving the intensity of pressure P, a function and a displacement x; a time for detecting the leakage position or a leakage position is set through MATLAB simulation, so that a corresponding leakage position or detection time is found; and finally, the leakage positioning in the aspects of time and space is realized. The method has the advantages of being scientific, reasonable, high in sourcing speed, and high in practical value.

Owner:CHONGQING XINJIE ENVIRONMENTAL PROTECTION TECH

Suckling pig creep compound feed and preparation method thereof

InactiveCN107889950AIncrease weightGood dispersionFood processingAnimal feeding stuffBroken riceMonocalcium phosphate

The invention discloses a suckling pig creep compound feed and a preparation method thereof, and belongs to the technical field of feed preparation, wherein the suckling pig creep compound feed includes the following raw materials: corn, wheat flour, broken rice, soybean meal, glucose, a grass carp powder, dried porcine solubles, monocalcium phosphate, edible salt, 5-nitroguaiacol sodium salt, 1,3-di-o-tolyl guanidine, an acidifier, an emulsifier, a microecological preparation, choline chloride, a premixture, an additive A1 or A2, an additive B, and an additive C; the suckling pig creep compound feed is prepared by sun-drying, crushing, mixing, drying and other steps. The suckling pig creep compound feed has reasonable preparation and rich nutrition, and can rapidly improve the average weight of suckling pigs.

Owner:HUNAN QIWEI TECH CO LTD

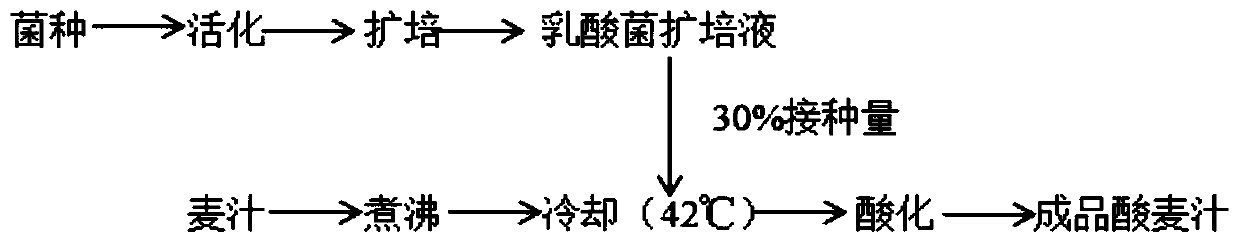

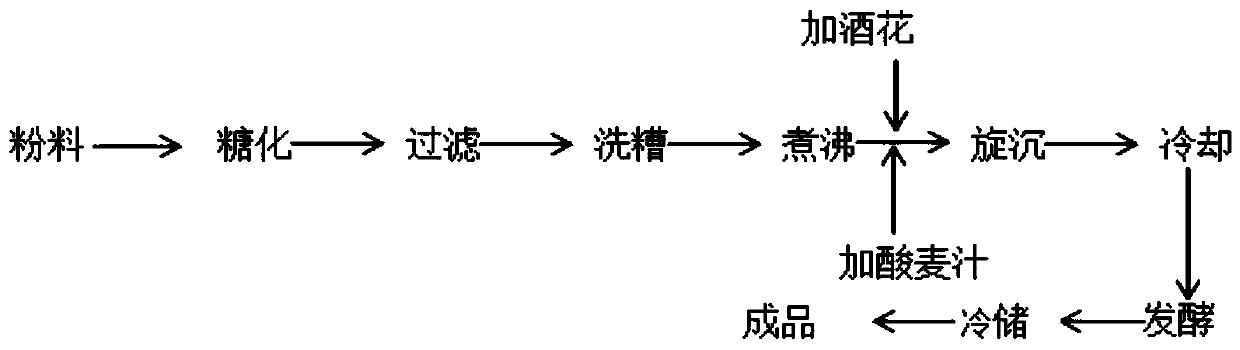

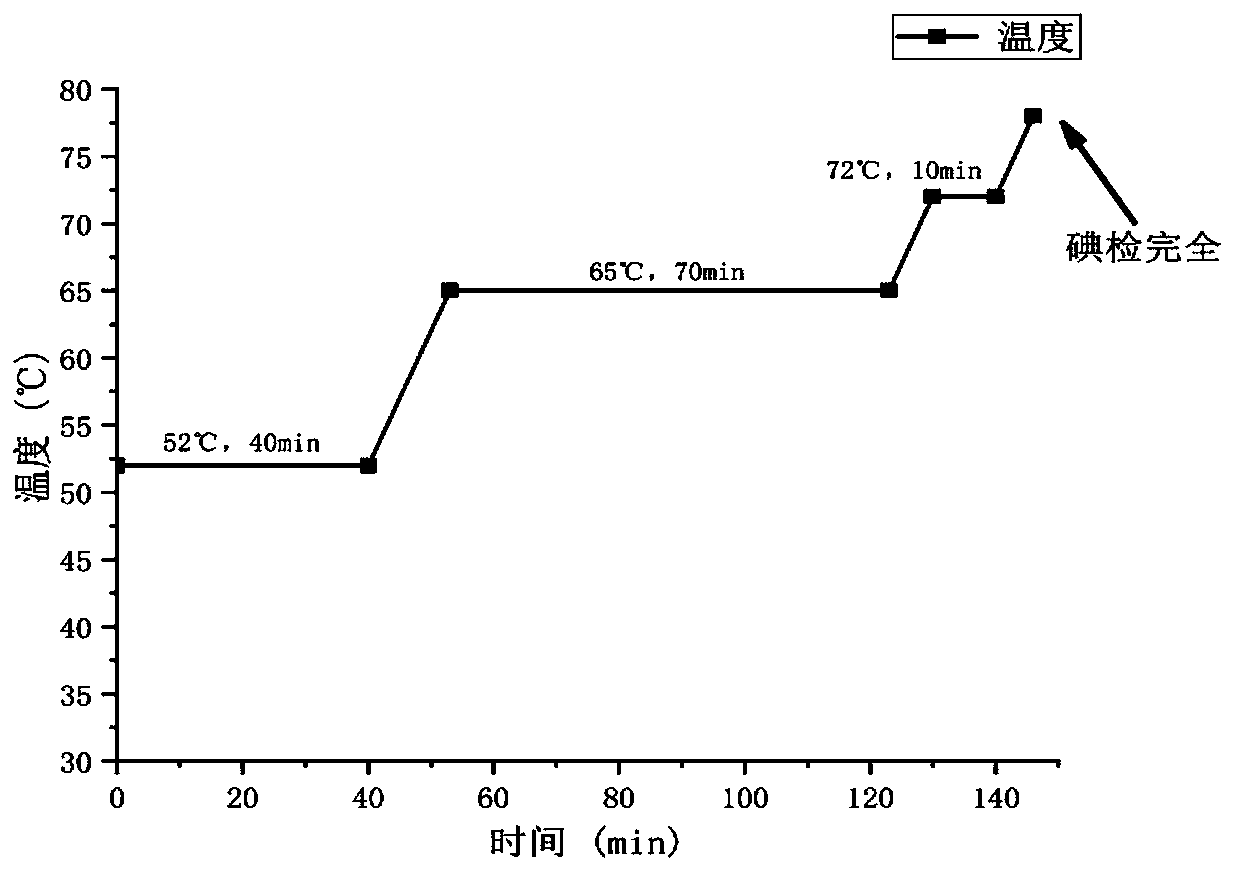

Brewing method of acid beer

InactiveCN111548874AThe brewing process is simpleEasy to operateBacteriaBeer fermentationBiotechnologyChaptalization

The invention relates to a brewing method of acid beer. According to the method, water, malt, hops and yeast are taken as main raw materials, sour wort is taken as an auxiliary raw material, malt is crushed and then subjected to wort saccharification, filtration and vinasse washing, wort obtained after vinasse washing is heated and boiled, hops are added in the boiling process, the sour wort is added in 5 min before boiling is finished, the adding amount of the sour wort is 1-10% of the mass of the wort, after boiling is finished, cyclotron precipitation is carried out to obtain raw wort, theraw wort is subjected to cooling and oxygenating, and beer yeast for fermentation is inoculated to obtain sour beer, wherein the sour wort is prepared by a biological acidification method. The sour beer is brewed by adding the sour wort in the wort boiling process, the brewing method is simple and easy to operate, the production cost is reduced, the brewing period is shortened, the brewed sour beer is rich in aroma, the malt aroma, the ester aroma and the hops aroma are mutually balanced and pleasant, the acidity is balanced, and the overall flavor and taste of the final beer are good.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com