Acidified milk powder fed to calves as well as preparation method of acidified milk powder and feeding method of calves

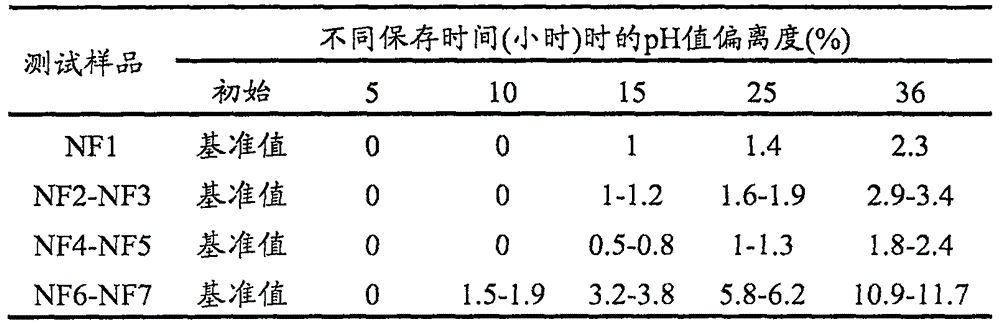

A feeding method and technology for acidifying milk, applied in the field of animal husbandry, can solve the problems of unsuitable storage of fresh milk, loss of pastures or breeding plants, and calves cannot freely drink milk substitutes, etc., so as to prevent too short shelf life and good pH value stability. , the effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0046] Preparation Example 1: Preparation of acidified milk powder

[0047] A1: Weighing milk powder and food-grade solid formic acid respectively, grinding the food-grade solid formic acid, and passing through a 300-mesh sieve to obtain solid formic acid powder;

[0048] A2: At a temperature lower than 8°C, mix 125 parts by mass of the milk powder and 1 part by mass of solid formic acid powder, and thoroughly mix them according to the following mixing method, so as to obtain the acidified milk powder for feeding calves, and name it is NF1;

[0049] The mixing method is:

[0050] B1: adding the whole amount, that is, 1 part by mass of the solid formic acid powder into the container;

[0051] B2: add milk powder (that is, 0.5 parts by mass) that is half the mass of solid formic acid, and fully stir and mix to obtain the first mixed powder;

[0052] B3: adding milk powder (that is, 0.75 parts by mass) that is half the mass of the first mixed powder, and fully stirring and mix...

preparation example 2-7

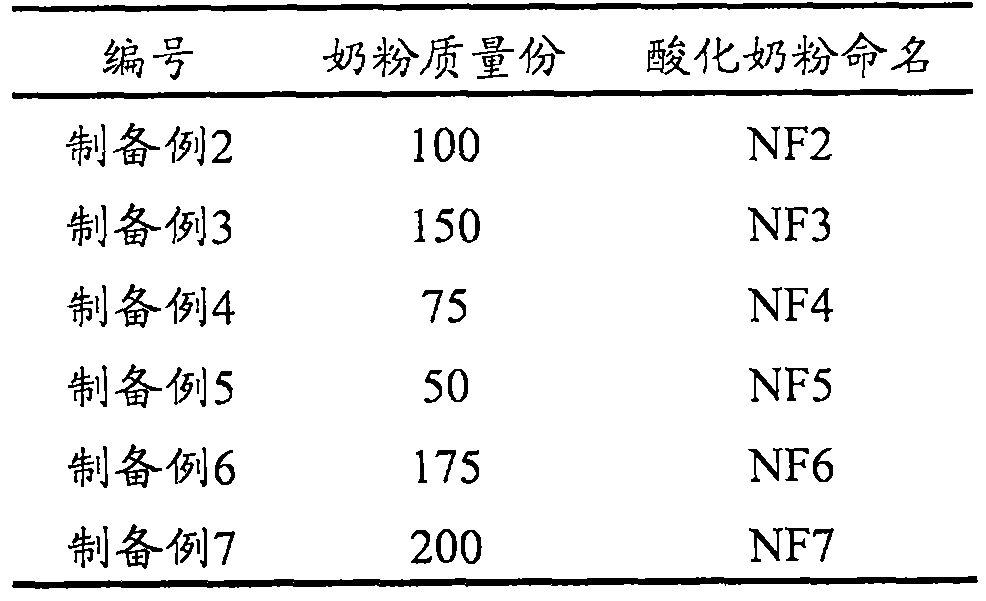

[0055] Preparation Example 2-7: Preparation of acidified milk powder

[0056] In addition to modifying the mass parts of milk powder in step A2 of Preparation Example 1 to the following mass parts, other operations remain unchanged, thereby repeating the implementation of Preparation Example 1 to obtain Preparation Examples 2-7, the mass parts of milk powder used and the resulting acidification The names of milk powder are shown in Table 1 below.

[0057] Table 1

[0058]

preparation example 8-16

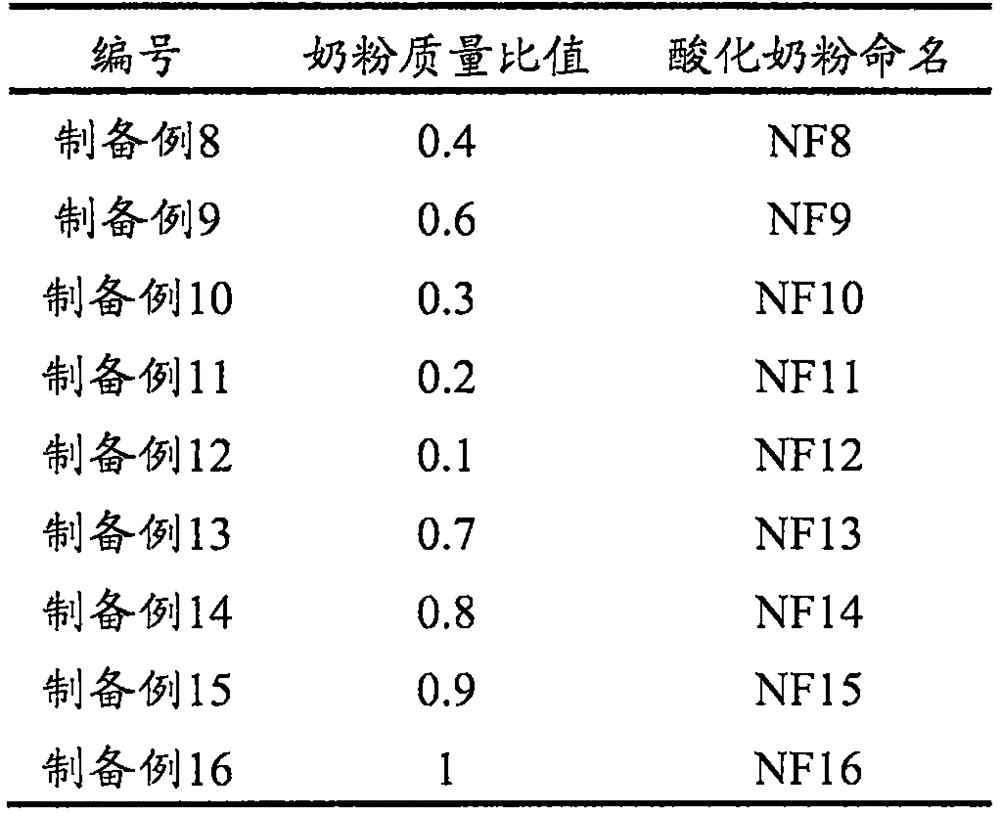

[0059] Preparation Example 8-16: Preparation of acidified milk powder

[0060] Except that the milk powder mass ratio that adds in the step B2 of preparation example 1 relative to solid formic acid powder is revised into following ratio (being the ratio of milk powder quality and solid formic acid powder quality, in preparation example 1, because the milk powder that adds is solid formic acid Half the mass of powder, so this ratio is 0.5), other operations are all constant, thereby repeat implementation Preparation Example 1, obtain Preparation Example 8-16, the milk powder mass ratio used and gained acidified milk powder nomenclature are shown in the following table 2.

[0061] Table 2

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com