Method for making serofluid dish

A technology for pulping water and vegetables, applied in the field of fermented vegetables, which can solve the problems of short product storage time, unstable fermentation quality, and easy corruption, etc., to weaken the ability to reduce nitrate, improve food safety, and avoid The effect of corruption fingerprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

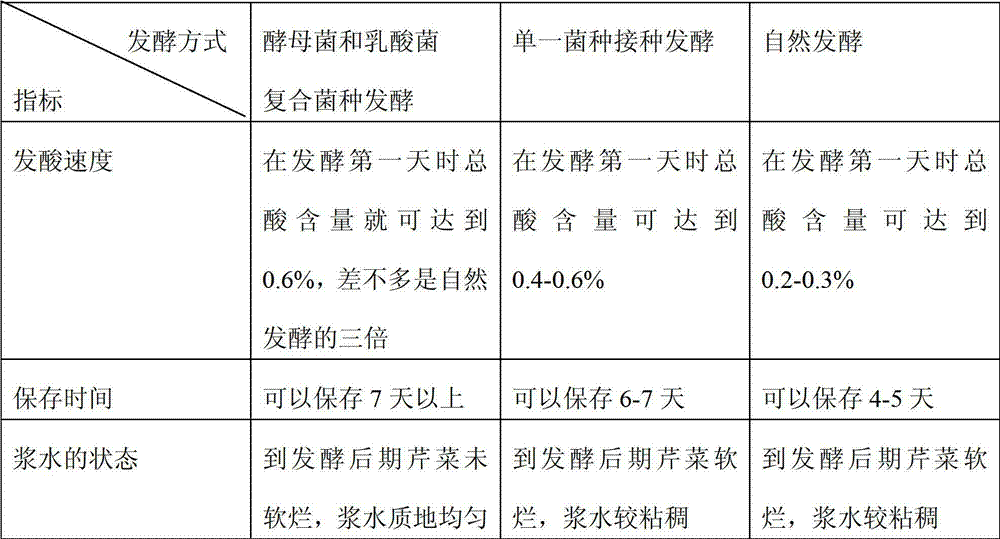

Image

Examples

preparation example Construction

[0037] Contains CaCO 3 Preparation of the MRS medium: first weigh the CaCO 3 Add an appropriate amount of distilled water to make a turbid solution, and sterilize it separately with the prepared MRS agar medium, and then mix the two on a clean bench before performing the subsequent operation of the mixed bacteria plate culture method.

[0038] Yeast: activate the fermented liquid of scallops in YPD liquid medium and vibrate with a vortex shaker to disperse the bacteria evenly, dilute them in gradient, streak and purify them on the YPD plate, pick typical colonies for microscopic examination, and separate and purify for many times , until pure colonies were obtained.

Embodiment 1

[0040] A kind of method of making water dish, comprises the following steps:

[0041] 1) Clean the vegetables (such as celery) used to make water vegetables, blanch them in boiling water for 2 minutes, cool and drain and cut into sections;

[0042] 2) Mix water and 3.0% flour by weight evenly, boil and keep for 2-5 minutes, and get noodle soup after cooling;

[0043] 3) Add noodle soup with 70% of the volume of the container into the container, add 0.2 times the mass of the noodle soup with cut vegetables, cover, boil and keep for 2-10 minutes, then cool to 33-40°C;

[0044] 4) Inoculate yeast and lactic acid bacteria with an inoculum of 8% of the volume of the noodle soup, in which the volume ratio of lactic acid bacteria: yeast liquid is 1:1; after the container is covered, ferment aerobically at 33°C 3 to 6 days, stirring once every 24 hours, after the fermentation is completed, the rice water dish is obtained.

[0045] The contents of microorganisms in the yeast liquid a...

Embodiment 2

[0051] A kind of method of making water dish, comprises the following steps:

[0052] 1) Clean the vegetables used to make the water vegetables, blanch them in boiling water for 3 minutes, cool and drain and cut into sections;

[0053] 2) Mix water and 5.0% flour by weight evenly, boil and keep for 5-10 minutes, and get noodle soup after cooling;

[0054] 3) Add noodle soup with 60% of the volume of the container into the container, add 0.2 times the mass of noodle soup with cut vegetables, cover, boil and keep for 2-10 minutes, then cool to 40-48°C;

[0055] 4) Use 10% and 5% of the volume of the noodle soup to inoculate yeast and lactic acid bacteria liquid respectively, where the volume ratio of lactic acid bacteria liquid: yeast liquid is 0.5:1; Ferment for 3 to 6 days, stir once every 24 hours, and obtain scallops after the fermentation is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bacteria | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com