Brewing method of acid beer

A technology of beer and hops, applied in the field of sour beer brewing, can solve the problems of unbalanced acidity of sour beer, achieve balanced sour taste, improve utilization rate, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

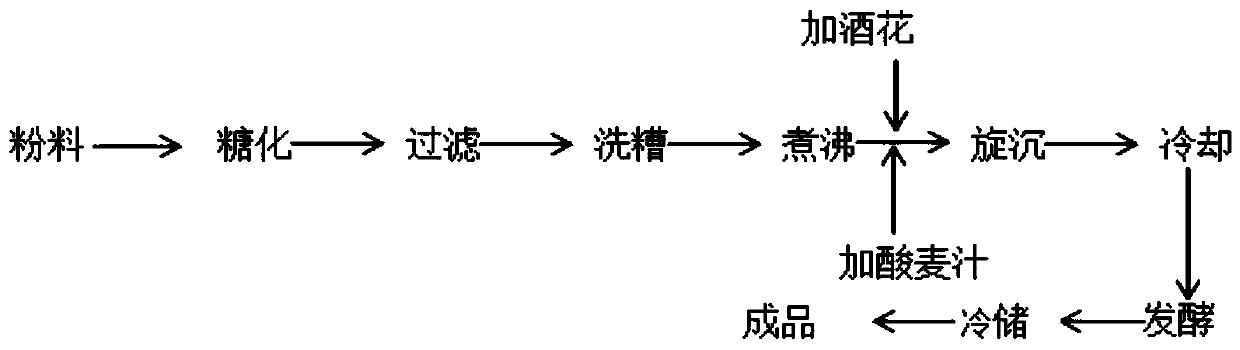

Method used

Image

Examples

Embodiment 1

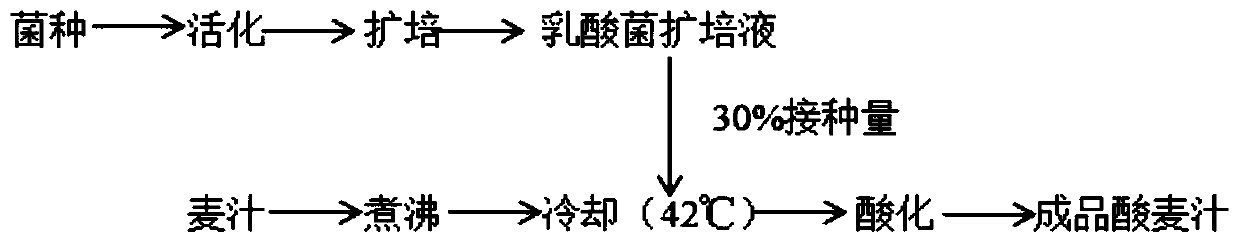

[0035] Preparation of sour wort:

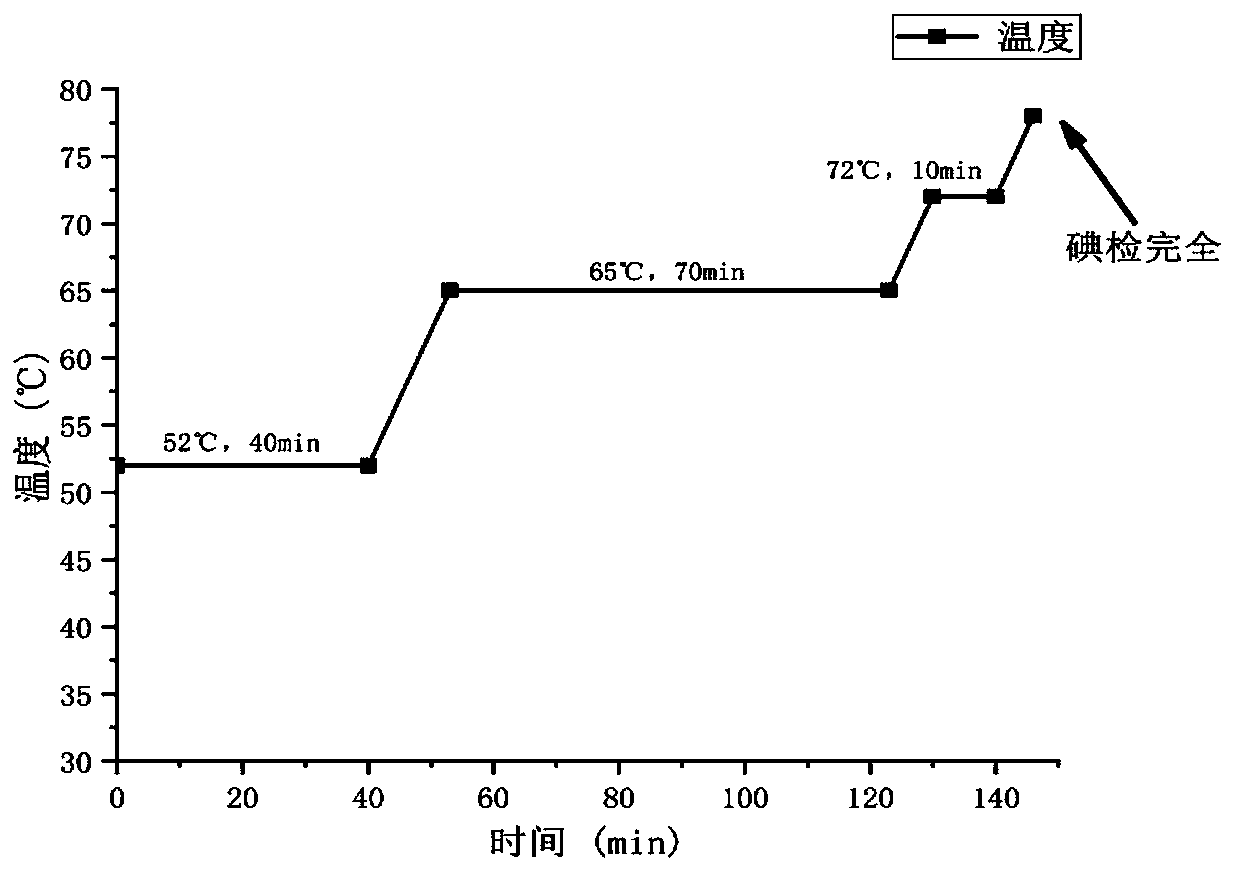

[0036] Grind the Pearson malt, and carry out saccharification according to the mass ratio of material and water of 1:3.5. After saccharification, take the first wort, adjust the concentration of the first wort with 78°C water, and obtain the wort with 14±0.3°P;

[0037] Add 2.0% agar to the above-mentioned wort at 14±0.3°P, heat to dissolve, sterilize at 121°C for 20 minutes, and then distribute it in test tubes to make a solid wort slant medium;

[0038] Divide the above-prepared wort at 14±0.3°P into Erlenmeyer flasks, and sterilize at 121°C for 20 minutes to prepare wort medium;

[0039] The preparation of sour wort adopts biological acidification method, and its technological process is as follows figure 1 As shown, L.delbrueckii (Lactobacillus delbrueckii) was inoculated on solid wort slant medium and cultured at 36°C for 48 hours to activate it, and then the activated strains were placed in 20mL wort medium with an inoculation loop. S...

Embodiment 2

[0047] The brewing method as described in Example 1, the difference is that the addition ratio of sour wort is 3%.

[0048] Gained finished product sour beer is tested by GB 4927-2008 standard:

[0049] The original wort concentration is 13.9°P, the alcohol content is 5.9%, the diacetyl is 0.065mg / L, the bitterness value is 13.2IBU, the chroma is 11.8EBC, the foam retention is 160s, and the carbon dioxide content is 0.61%.

Embodiment 3

[0051] The brewing method as described in Example 1, the difference is that the addition ratio of sour wort is 5%.

[0052] Gained finished product sour beer is tested by GB 4927-2008 standard:

[0053] The original wort concentration is 14.0°P, the alcohol content is 6.0%, diacetyl is 0.052mg / L, the bitterness value is 14.2IBU, the color is 12.3EBC, the foam retention is 180s, and the carbon dioxide content is 0.70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com