Feeding acidifier prepared by emulsifying technology and preparing method thereof

An acidifier and feeding technology, which is applied in application, animal feed, animal feed, etc., can solve problems such as ineffective fumigation, loss of feed nutrients, and insufficient storage time, so as to avoid the loss of nutrients and promote Effects of absorption and surface tension reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A feed acidifier produced by emulsification technology comprises the following components and contents (in parts by weight): citric acid: 16 parts; fumaric acid: 8 parts; phosphoric acid: 13 parts; malic acid: 9 parts; Lactic acid: 25 parts; formic acid: 14 parts; acetic acid: 8 parts; mouthfeel modifier: 2 parts; silicon dioxide: 5 parts.

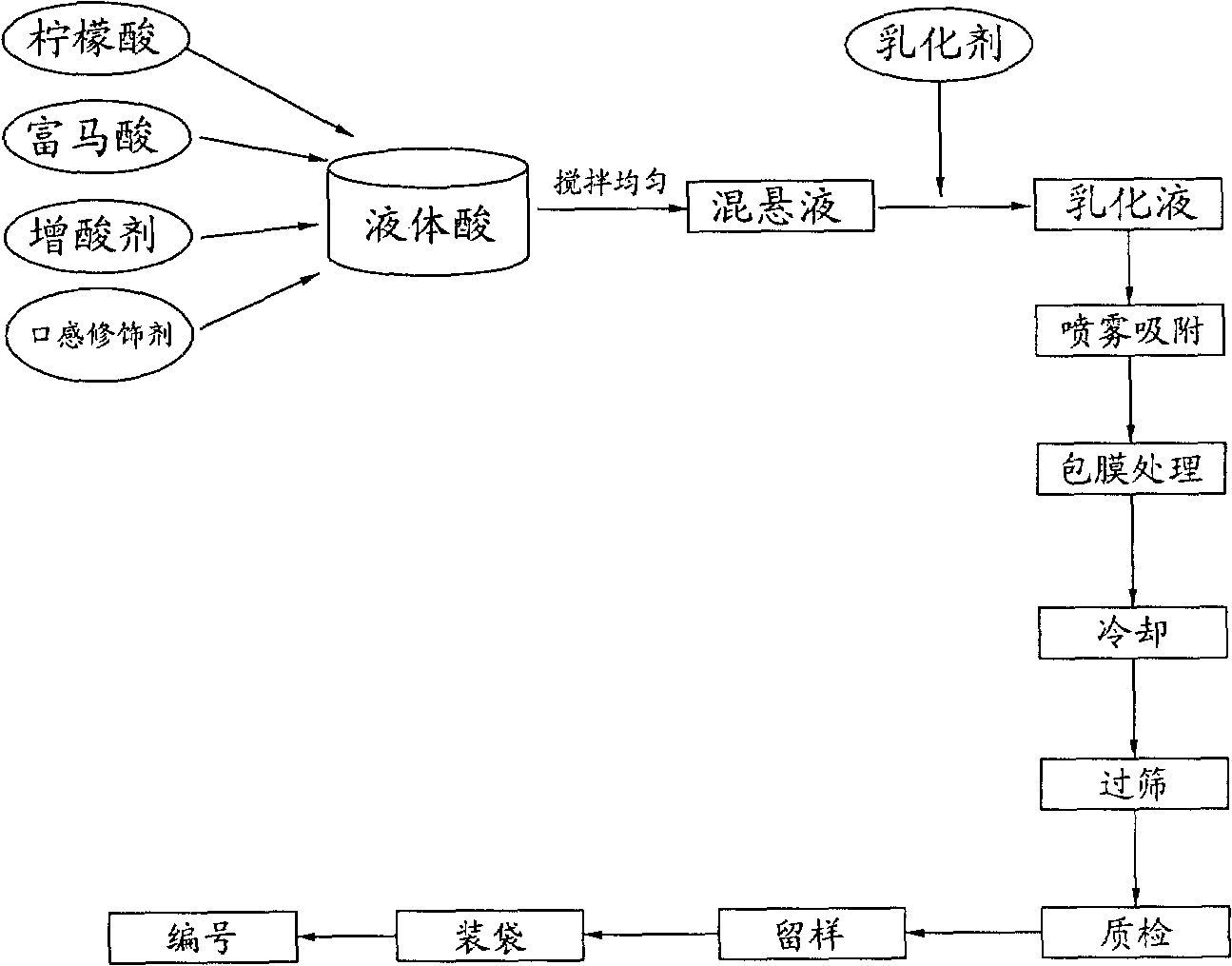

[0041] This emulsification technology produces feed acidulant preparation method, such as figure 1 shown, including the following steps:

[0042] Put citric acid, fumaric acid, malic acid, and mouthfeel modifier solid materials into lactic acid, phosphoric acid, formic acid, and acetic acid liquid acid materials according to the above-mentioned ratio, fully stir and mix, and make a suspension;

[0043] Add an ester emulsifier to the suspension, emulsify in an emulsifier, and homogenize the material in the liquid phase to form an emulsion;

[0044] Spray the emulsion on the silica carrier through a medical stabilized ...

Embodiment 2

[0055] Embodiment 2: A feed acidifier produced by emulsification technology comprises the following components and contents (in parts by weight): citric acid: 15 parts; fumaric acid: 15 parts; phosphoric acid: 12 parts; malic acid: 13 parts; Lactic acid: 20 parts; formic acid: 8 parts; acetic acid: 9 parts; mouthfeel modifier: 3 parts; silicon dioxide: 5 parts. (Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0056] Embodiment 3: A feed acidifier produced by emulsification technology comprises the following components and contents (in parts by weight): citric acid: 18 parts; fumaric acid: 10 parts; phosphoric acid: 14 parts; malic acid: 8 parts; Lactic acid: 23 parts; formic acid: 14 parts; acetic acid: 8 parts; mouthfeel modifier: 2 parts; silicon dioxide: 3 parts. Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com