Mixing machine

A technology for mixers and motors, which is used in mixers, mixers with rotating containers, mixer accessories, etc., can solve problems such as irregular component wear, geometric deviation, and large wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

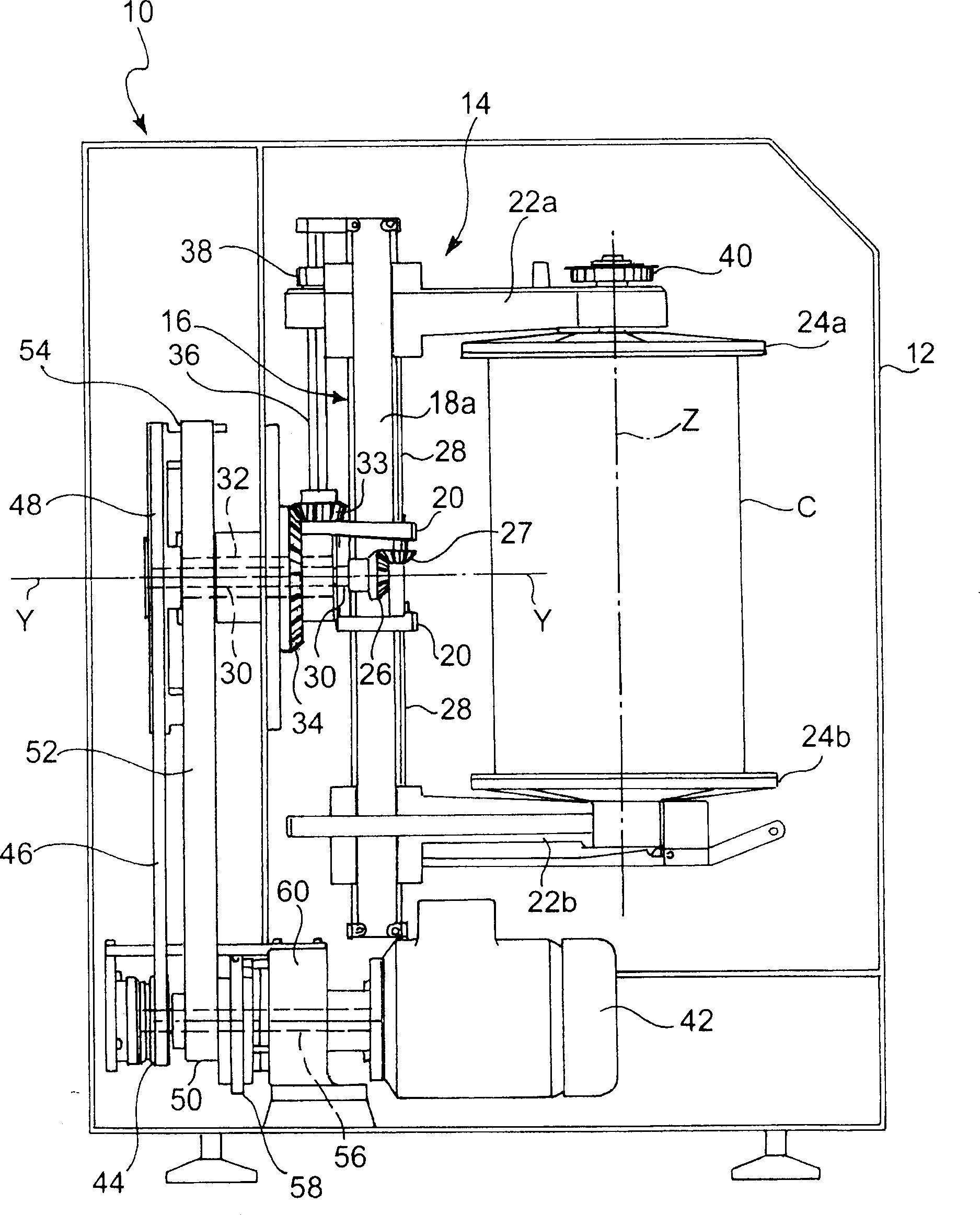

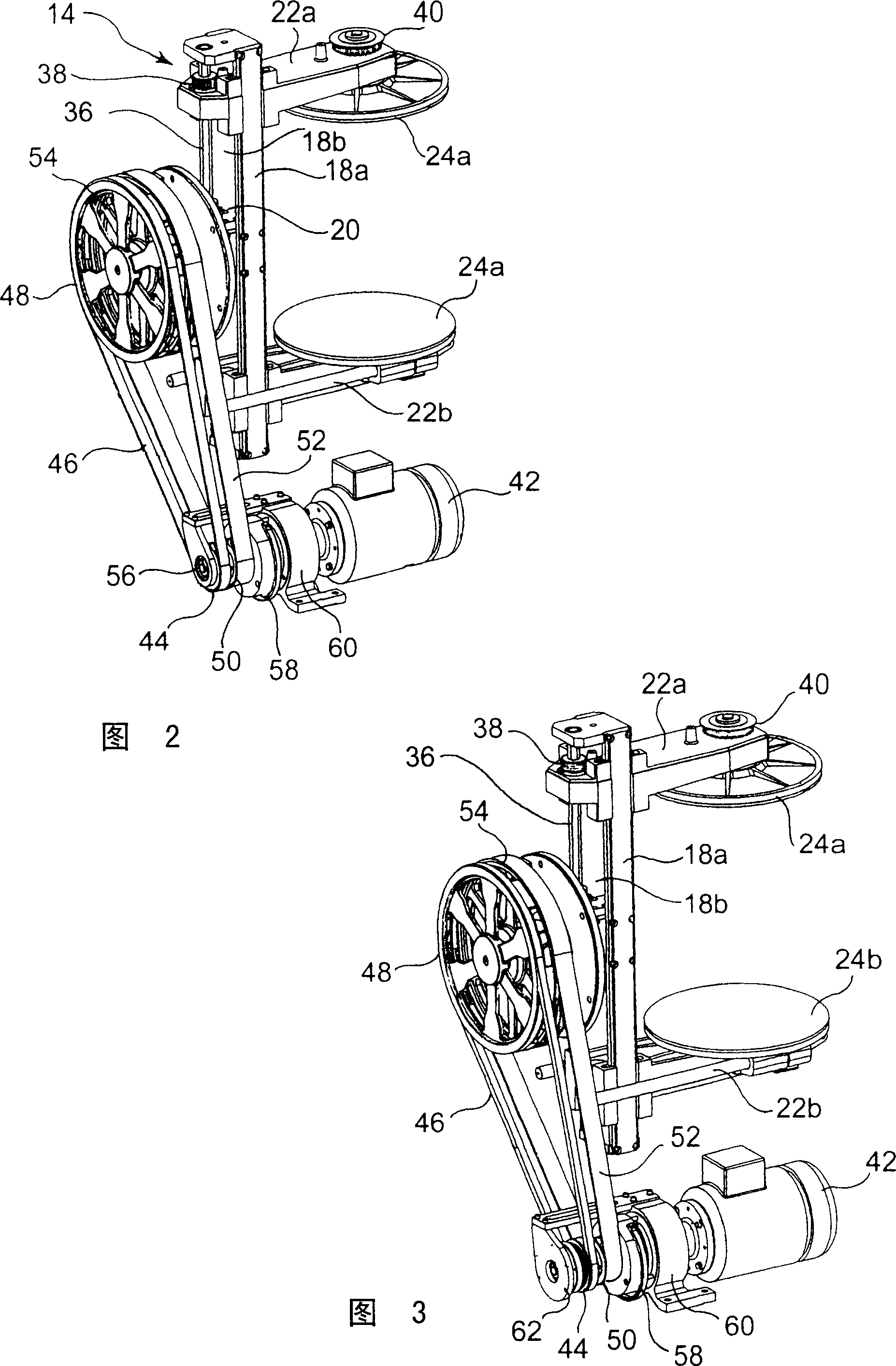

[0019] First refer to figure 1 , a mixer for mixing varnishes, paints, powdered products, seeds, etc. is indicated generally at 10 and comprises a frame 12 which accommodates and supports a container or tank C arranged to grip the product to be mixed and to make the The mechanism by which a container or tank rotates both about its longitudinal axis Z (vertical axis) and about a second axis Y (horizontal axis) perpendicular to the first axis.

[0020] These mechanisms consist first of all of a clamping structure, shown generally at 14, supported by a frame 12 for rotation about a horizontal axis Y. The clamping structure 14 includes a swivel arm 16 comprising a pair of straight guide rods 18a, 18b (more clearly seen in FIGS. They are arranged in parallel and fixed centrally to the fork hub 20 . A pair of support members 22a, 22b with clamping plates 24a, 24b, respectively, are slidably fitted on two straight guide rods 18a, 18b, on opposite sides with respect to the Y axis, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com