Composite rotating shaft mechanism

A composite, rotating shaft technology, applied in the direction of supporting machines, mechanical equipment, pivot connections, etc., can solve problems such as high cost, insufficient product competitiveness, and rising cost of SIP phones, achieve low cost, ensure rotation stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

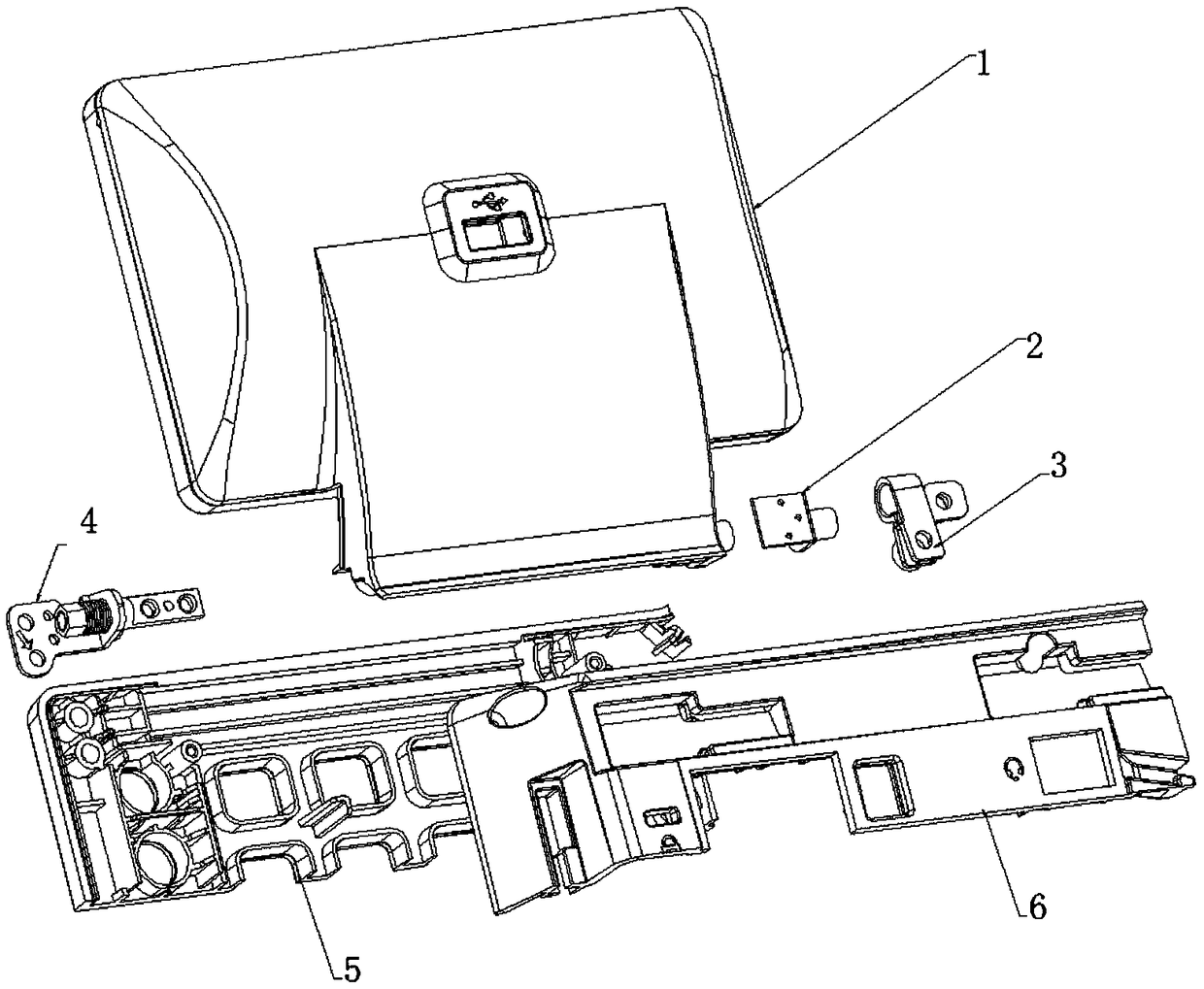

[0045] like figure 1 and figure 2 As shown, the low-cost shift-type rotating shaft mechanism in this embodiment includes the following spare parts: a face shell, a bottom shell, a liquid crystal module, a conventional rotating shaft, a fixing bracket, a reinforcing shaft, and screws.

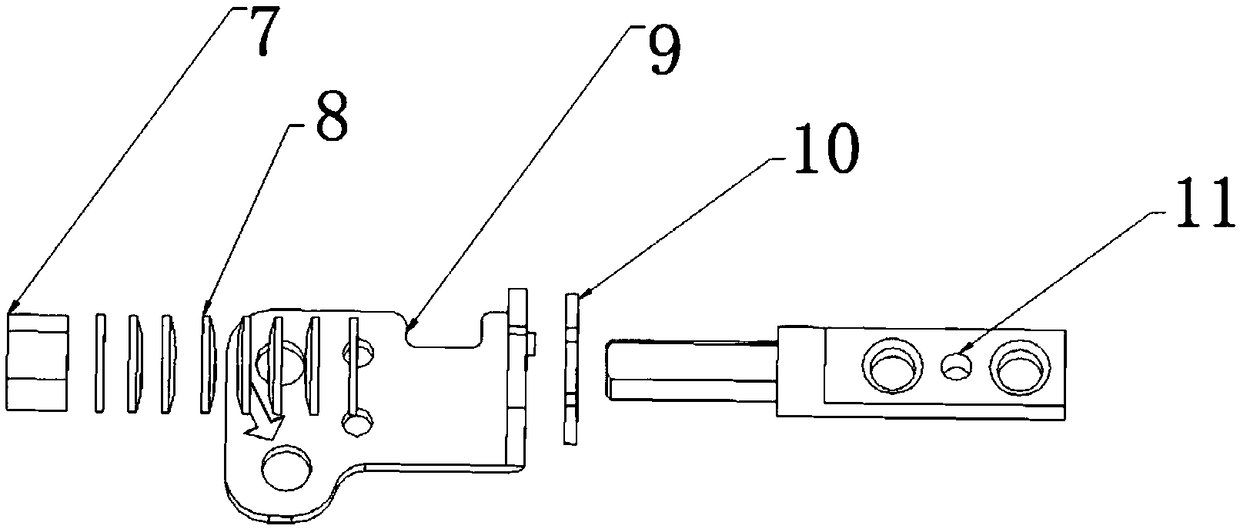

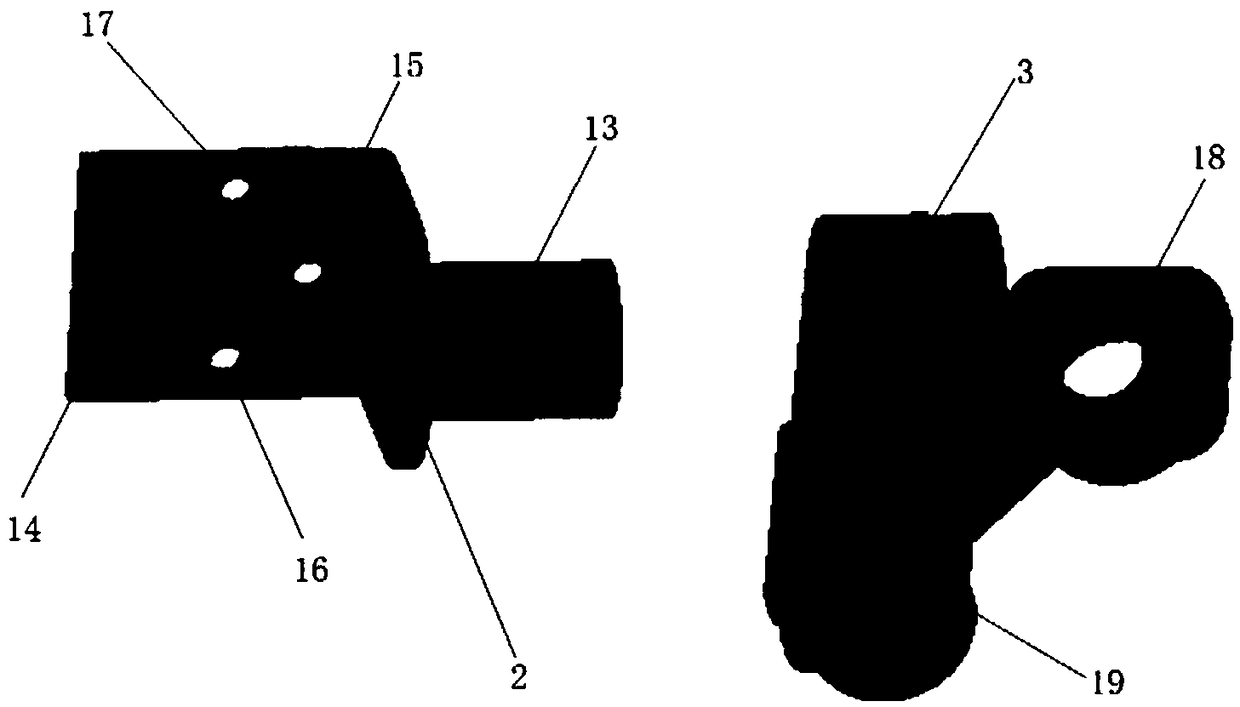

[0046] like figure 2 The fixed bracket shown is a sheet metal part or a high-strength plastic part, and a screw mounting hole and a reinforcement shaft adapter port are provided. The reinforcement shaft adapter port is designed in an Ω shape to facilitate assembly on the reinforcement shaft; The hardware includes a fixed end and a rotating end. The fixed end is provided with three screw mounting holes, which are fixed to the liquid crystal component through screw locks. The rotating end is inserted into the reinforcing shaft adapter port on the fixed bracket; the limiting rotating shaft includes a fastening nut , a spring washer, a movable frame, a spacer and a mandrel, and the mandrel inclu...

Embodiment 2

[0063] An assembly method of a composite rotating shaft mechanism, characterized in that the steps include:

[0064] (1). If figure 2 As shown, assemble the limit shaft and adjust the torque value to meet the design requirements;

[0065] (2). If Figure 4 As shown, fix the conventional rotating shaft on the liquid crystal component through screw locks, and fix the reinforcing shaft on the liquid crystal component through screw locks;

[0066] (3). If Figure 5 As shown, fit the fixing bracket to the reinforcing shaft;

[0067] (4). If Image 6 As shown in the figure, assemble the liquid crystal component on the panel, and lock the rotating shaft and the fixing bracket with screws;

[0068] (5). If Figure 7 As shown, cover the bottom case and fix it with screws.

[0069] In this embodiment, the assembly of the fixing bracket on the reinforcing shaft is specifically as follows:

[0070] like Figure 8 and Figure 9 As shown, the opening of the mounting opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com