Patents

Literature

126results about How to "Guaranteed operational stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for controlling single-bus modular digital actuator of robot

ActiveCN103753535AImprove performanceQuick responseProgramme-controlled manipulatorJointsOvervoltageClosed loop

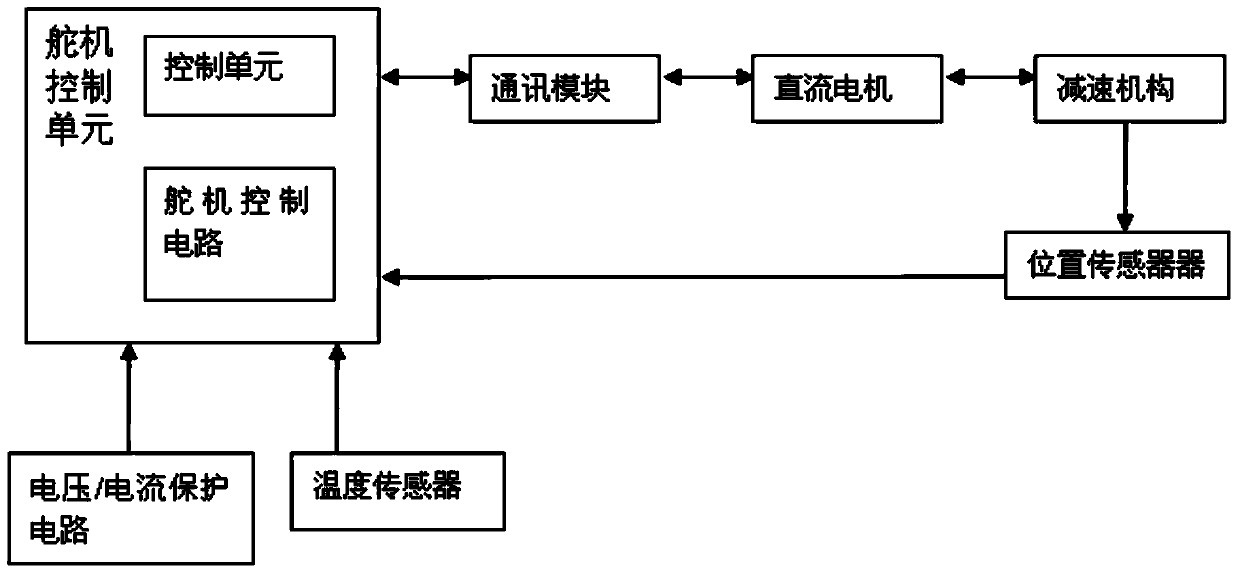

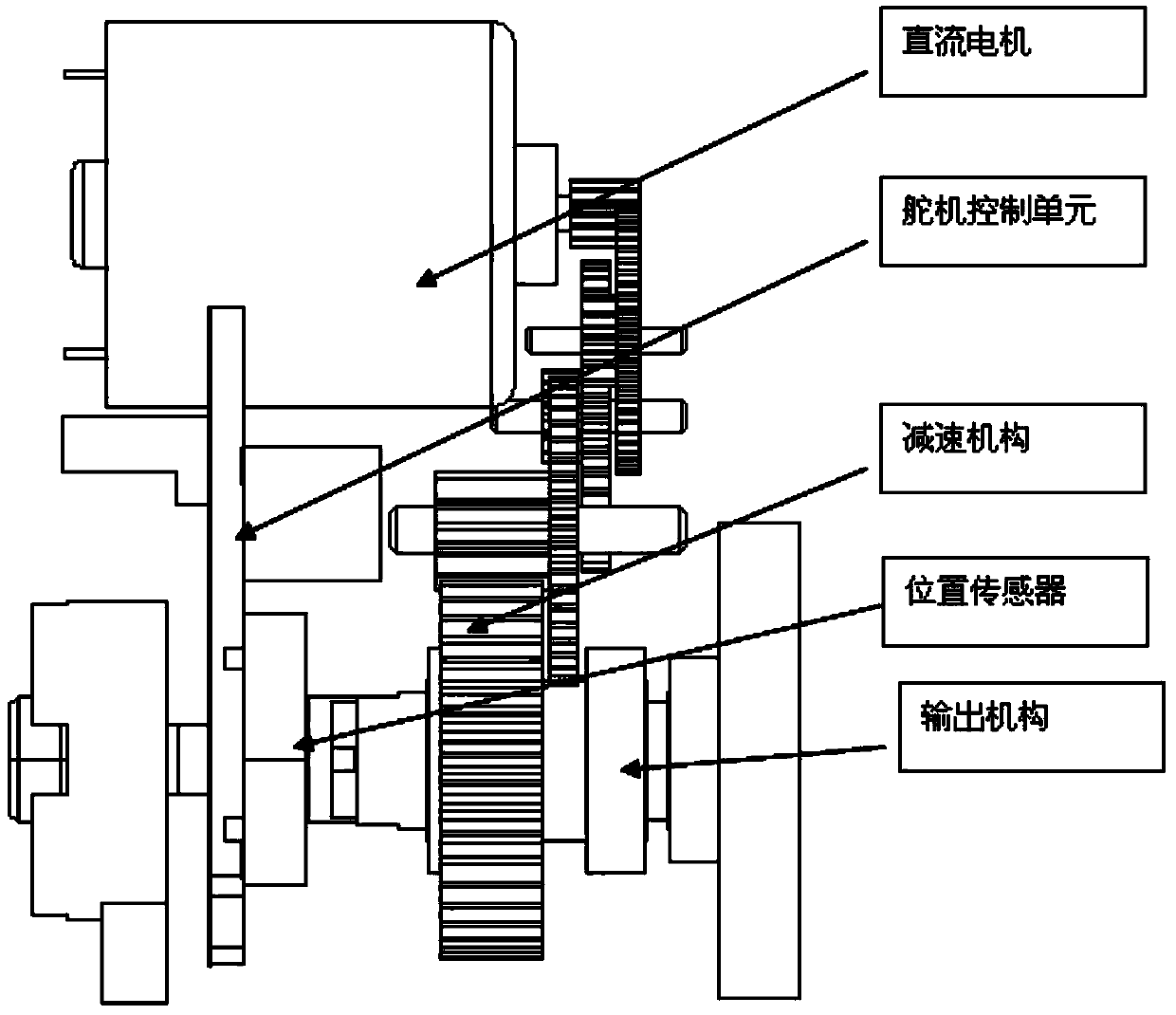

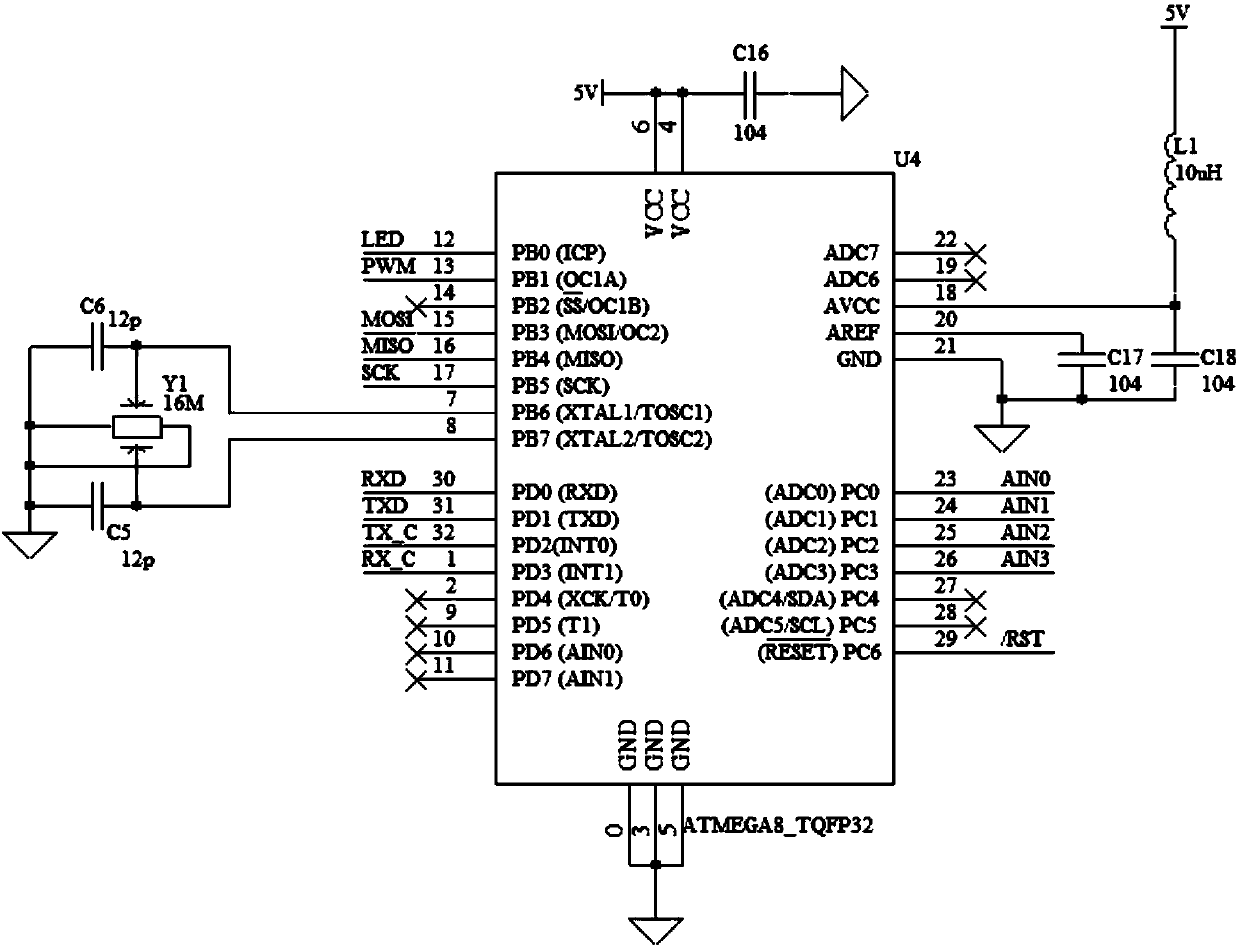

The invention relate to a device and a method for controlling a single-bus modular digital actuator of a robot. The device comprises an actuator control unit, a direct-current motor, a communication module, a speed reduction mechanism, position and temperature sensors and a current protection circuit. The method includes that the actuator control unit computes control parameters according to the running temperatures, driving currents of the motor and the position of the actuator and outputs the control parameters to a motor control circuit; the communication module receives control instructions of an upper computer and feeds information of the current position of the actuator, the current speed of the actuator and the like to the upper computer; a high rotational speed and low torque of the motor are converted into a low rotational speed and high torque by the speed reduction mechanism and an output mechanism, and the low rotational speed and the high torque are outputted by the speed reduction mechanism and the output mechanism; the position sensor, the temperature sensor and the current protection circuit are respectively used for feeding current position signals of the actuator, the running temperatures and the driving currents of the motor to the actuator control unit, so that closed-loop high-precision safety control can be implemented. The device and the method have the advantages of overcurrent, overvoltage and over-temperature protection, capability of preventing overload or over-temperature damage, high response speed, zero dead zones and high control precision.

Owner:UBTECH ROBOTICS CORP LTD +1

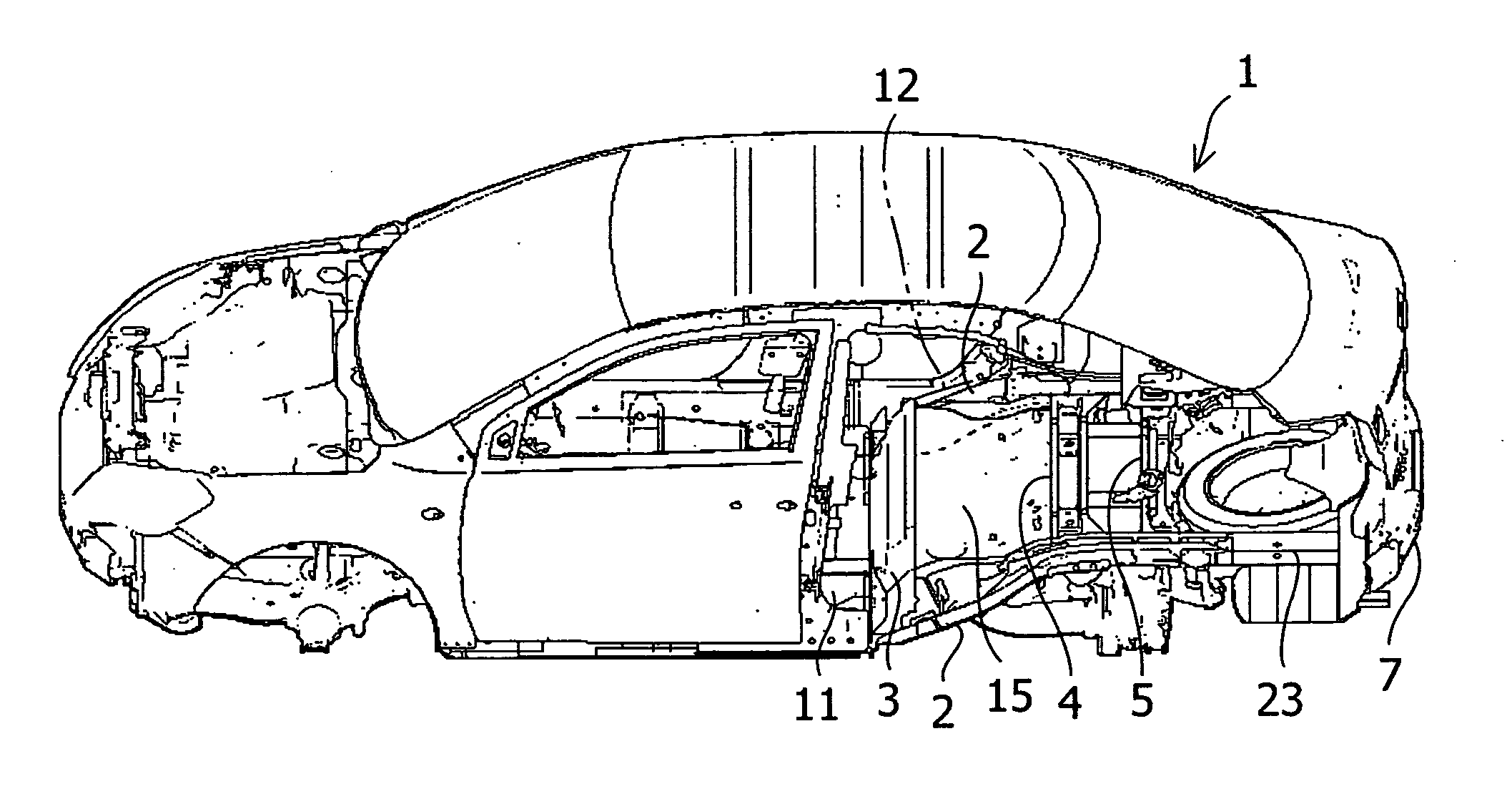

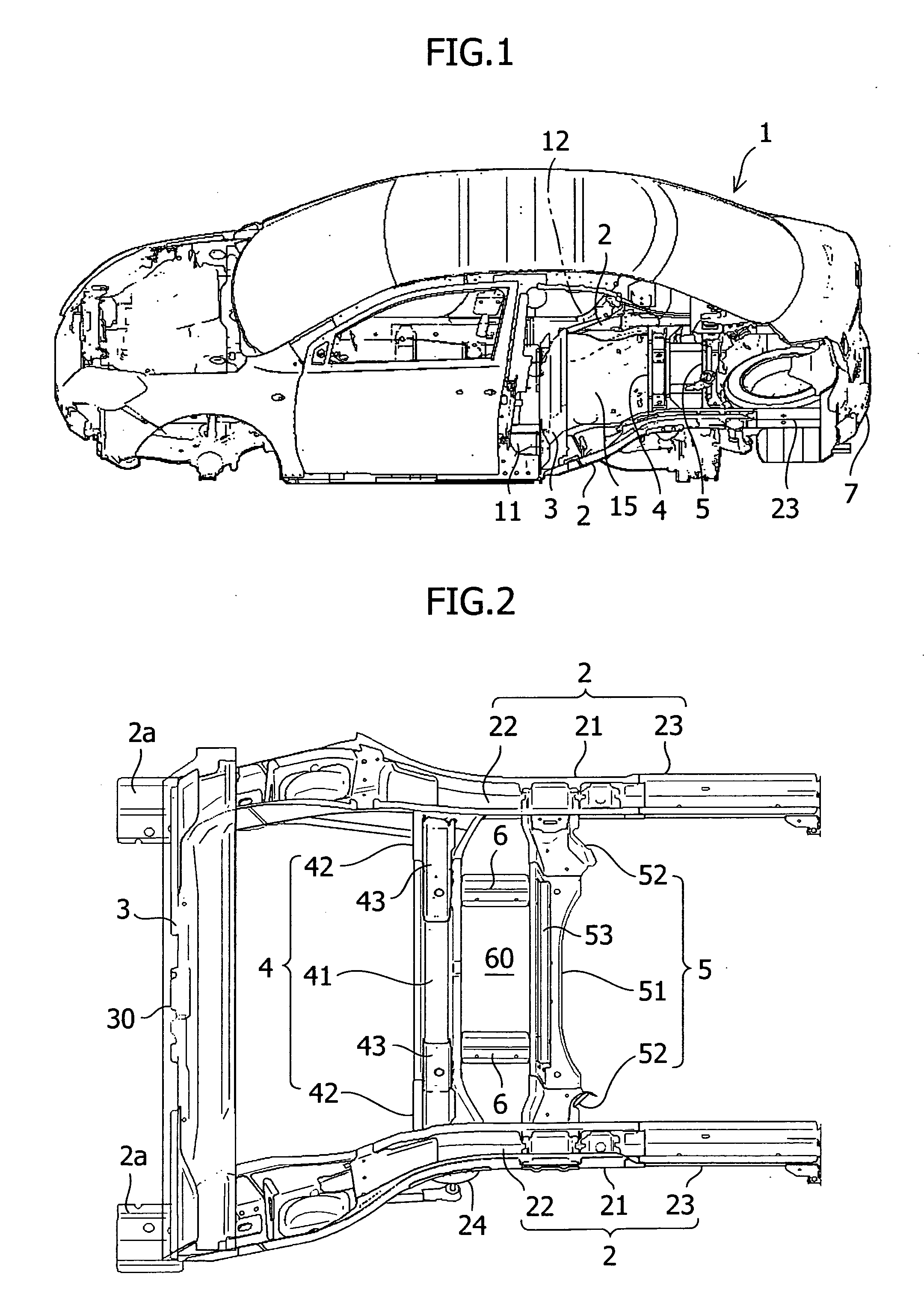

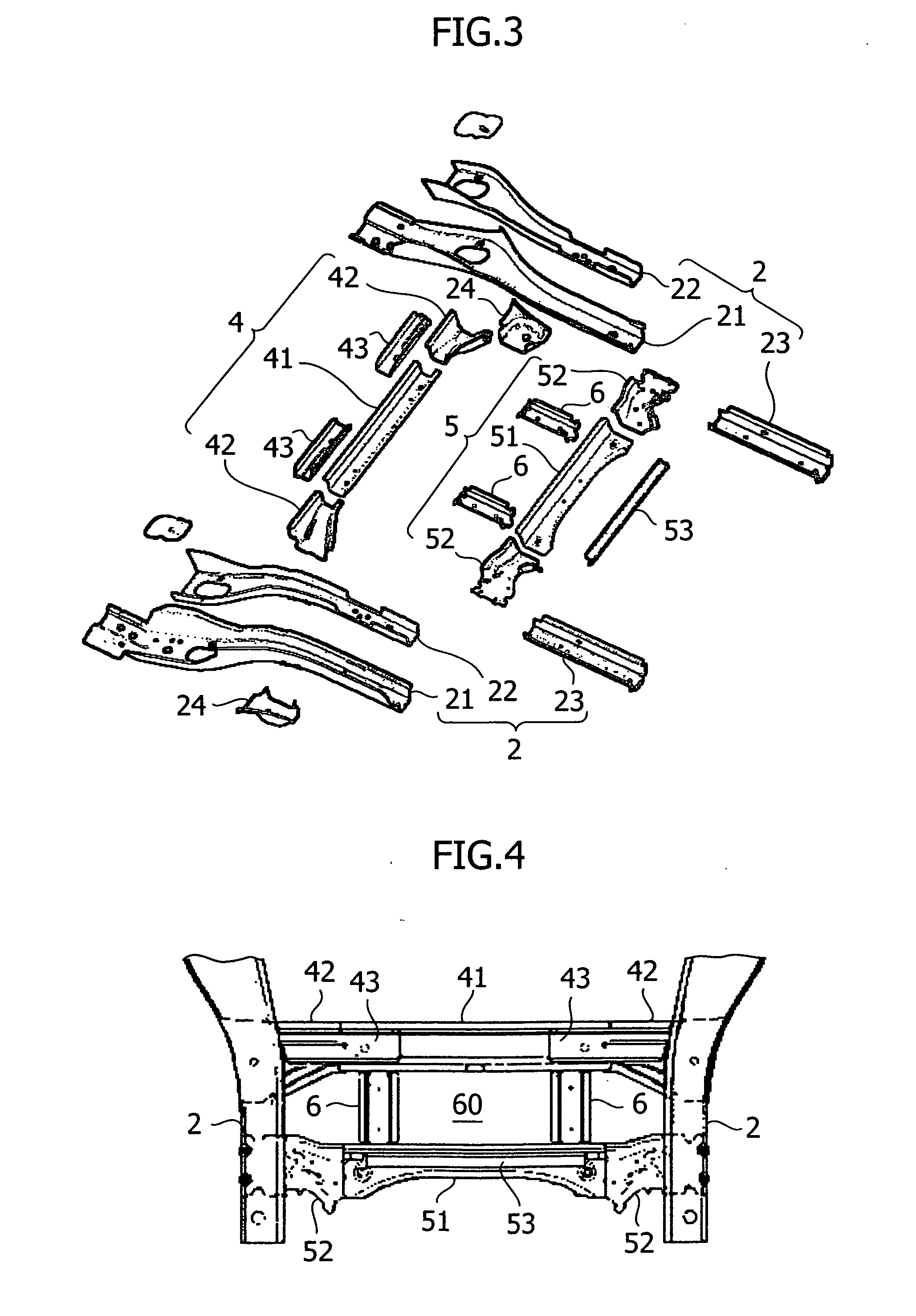

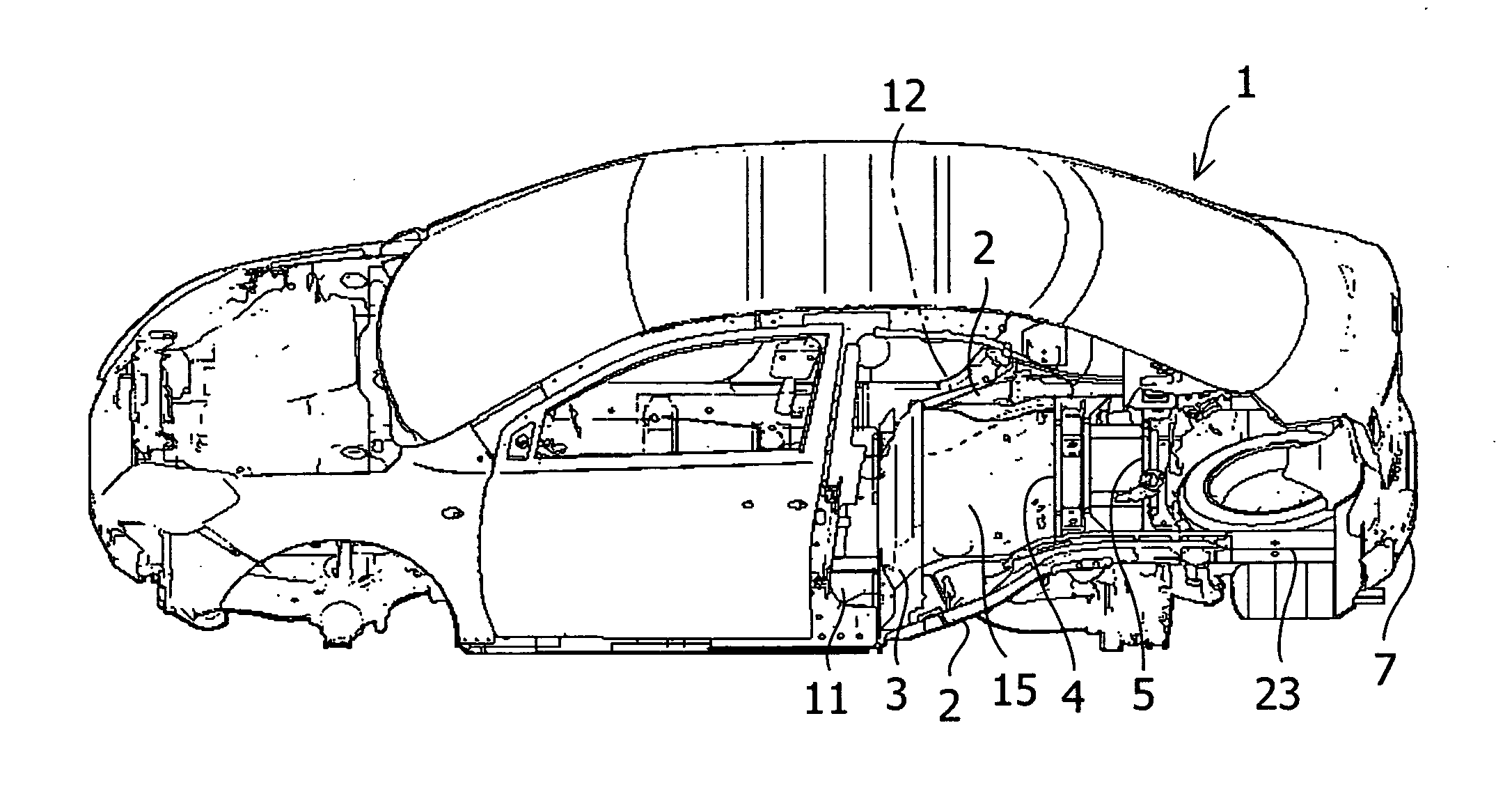

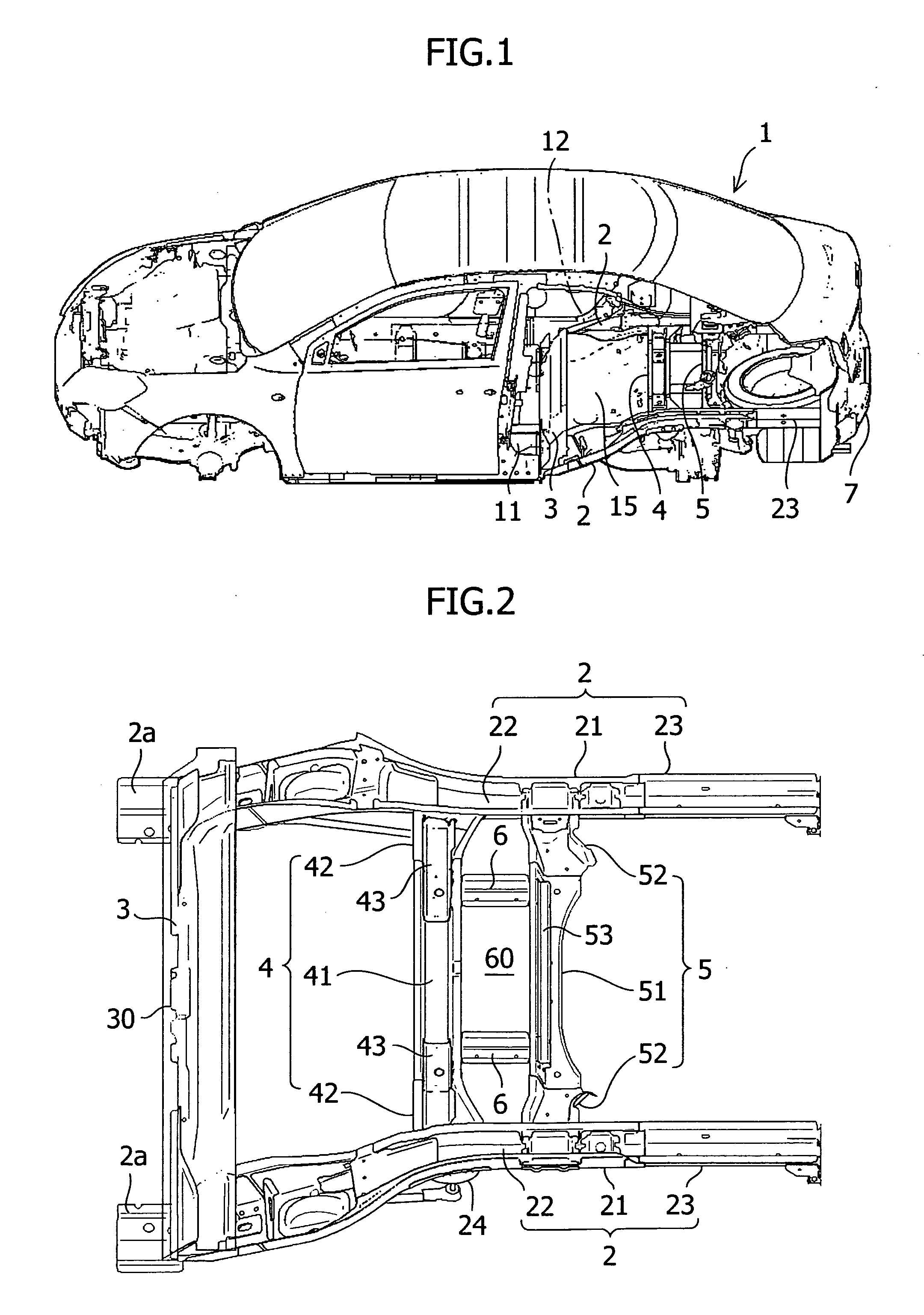

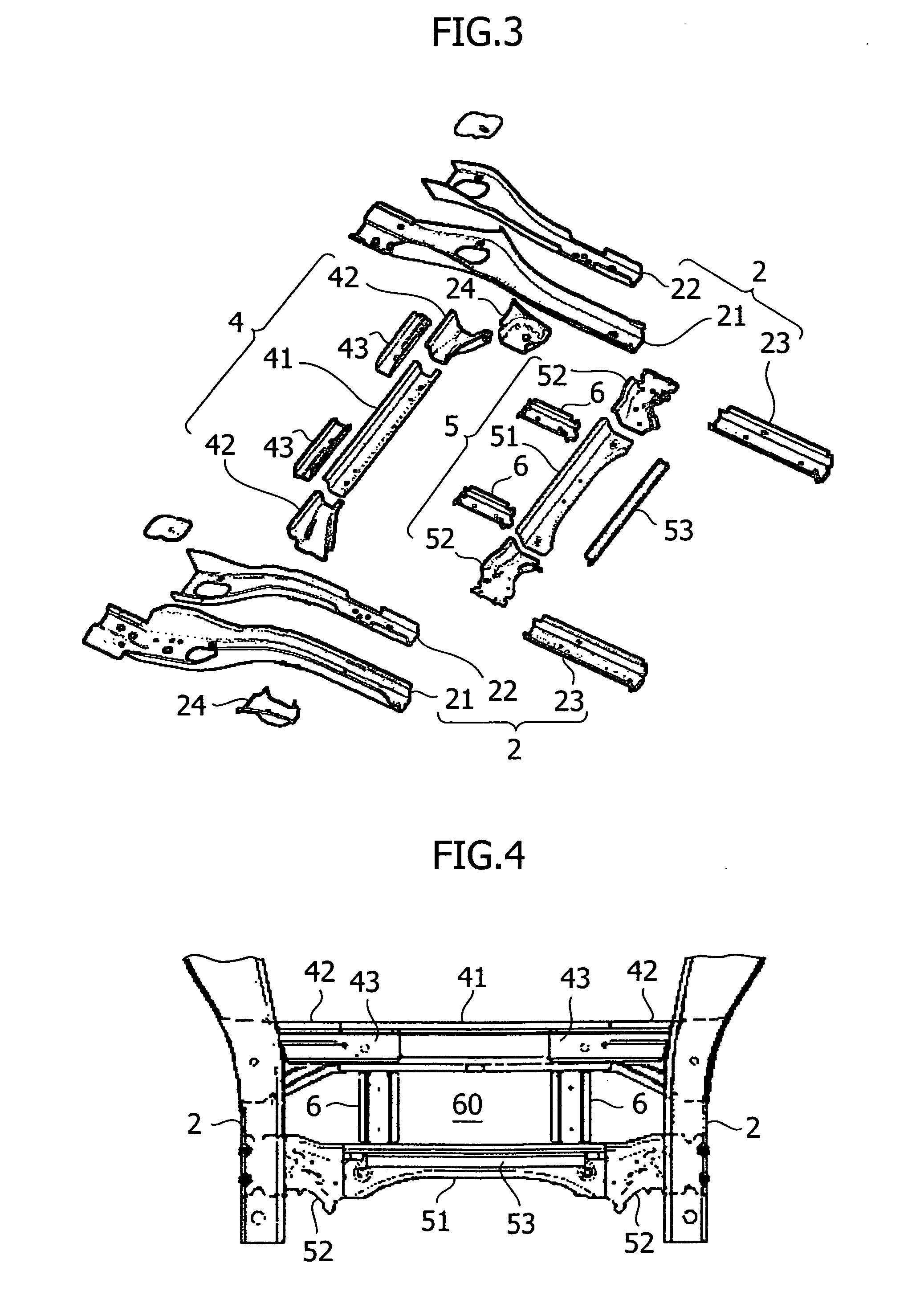

Vehicle body rear structure

InactiveUS20100072786A1Easy to assembleEasy maintenanceVehicle seatsUnderstructuresEngineeringImpact energy

Owner:SUZUKI MOTOR CORP

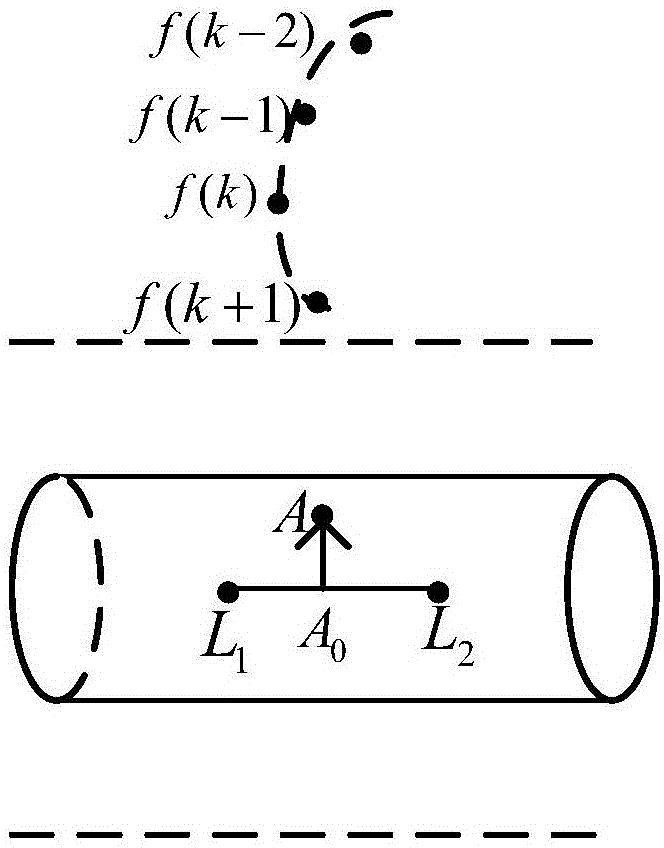

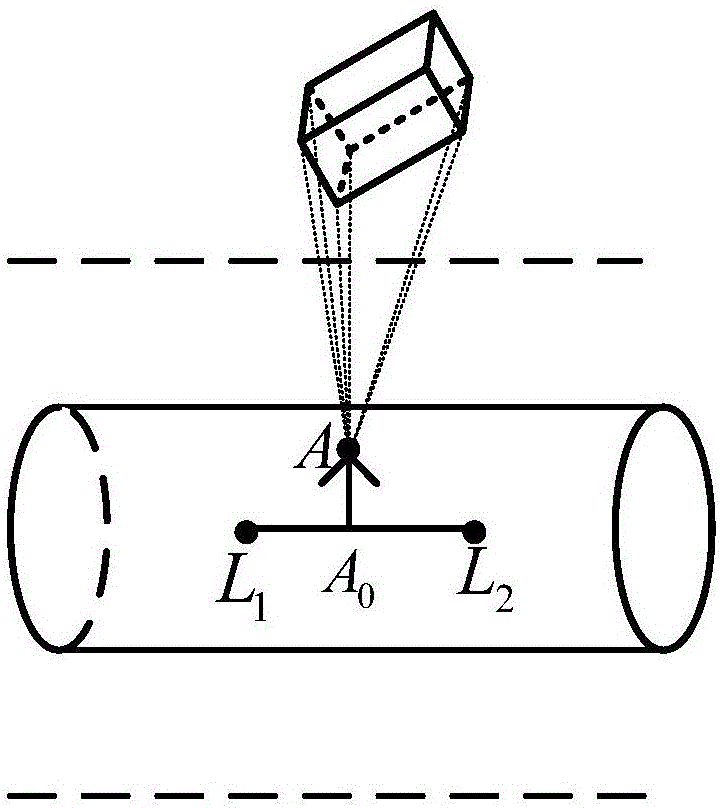

Virtual pipeline dynamic obstacle avoidance control method for remote operation man-machine interaction

ActiveCN105150210AEnsure safetyGuaranteed operabilityProgramme-controlled manipulatorObstacle avoidanceInstability

The invention discloses a virtual pipeline dynamic obstacle avoidance control method for remote operation man-machine interaction. A barrier in the environment is recognized through vision, and the control capacity is designed by calculating the real-time distance with the barrier so that safety and operation performance of remote operation can be guaranteed. The application occasion is that the tail end of a manipulator dynamically avoids the barrier during space remote operation and reaches a specific location. As the space environment is uncertain or operation instability is caused by unstructured environment factors, an operator can not control or operate the tail end to reach the specific location at the expected time. Therefore, it is required that during operation, the optimal route is updated in real time while the tail end point dynamically avoids the barrier, the operation efficiency is improved, and meanwhile operation stability is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

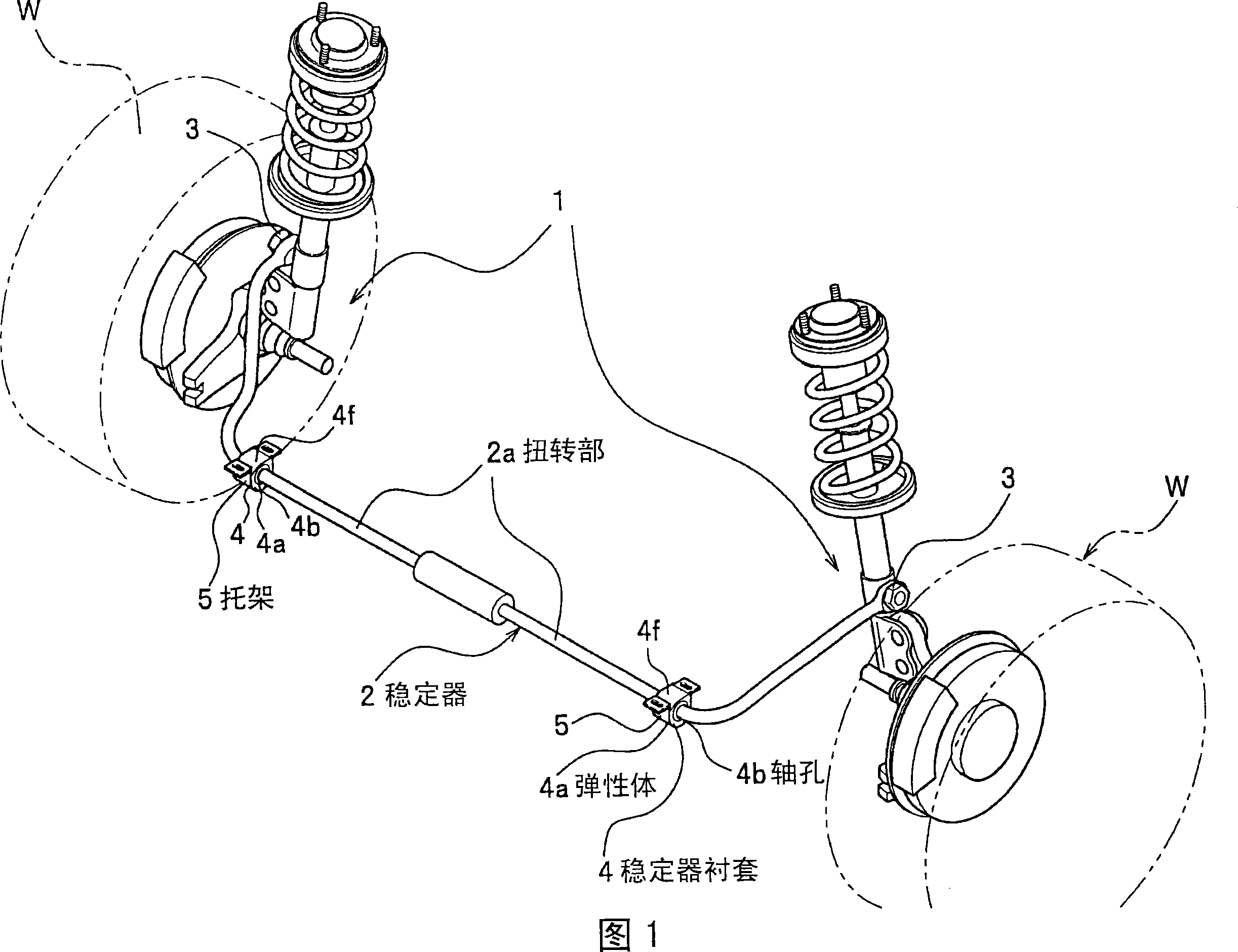

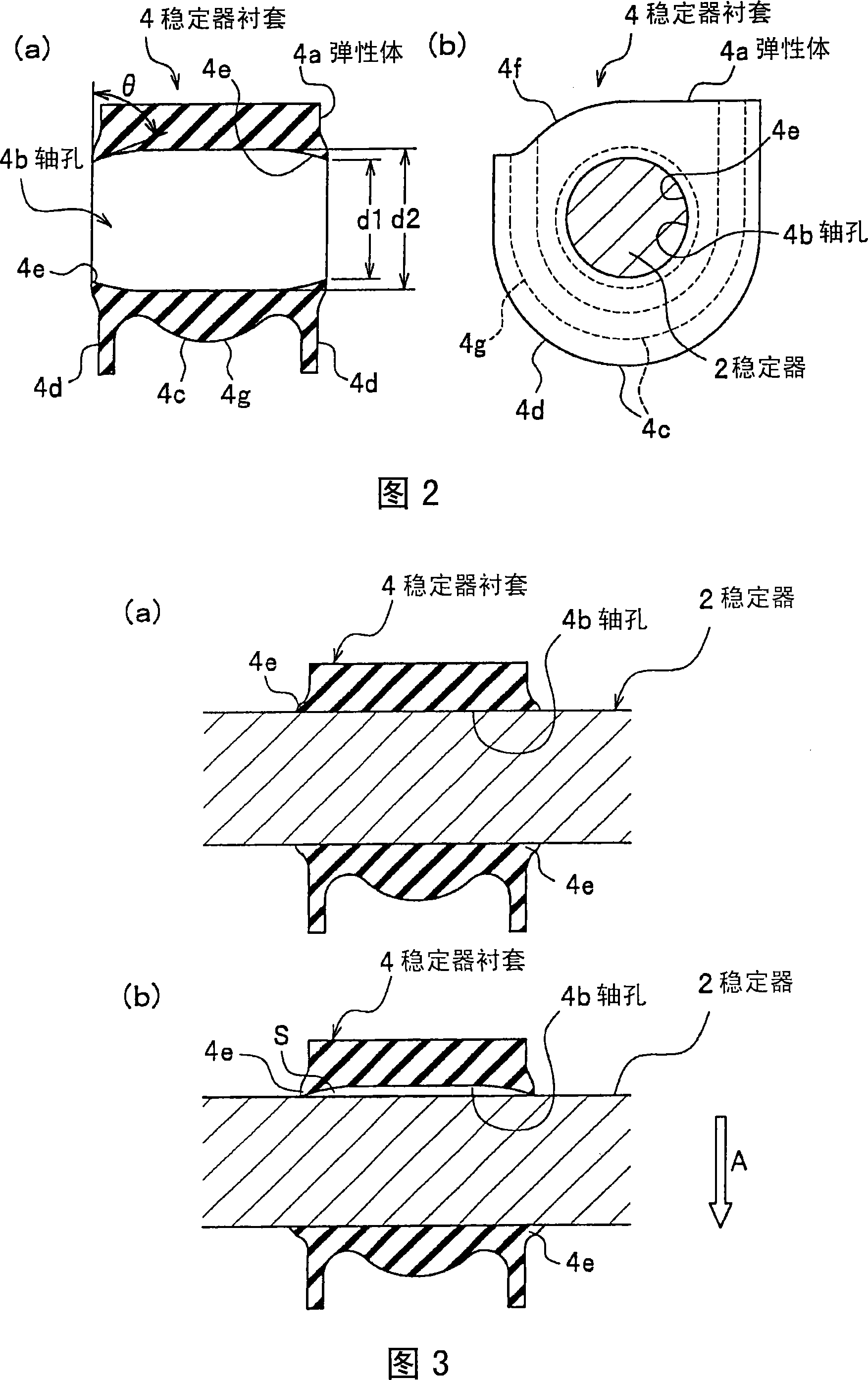

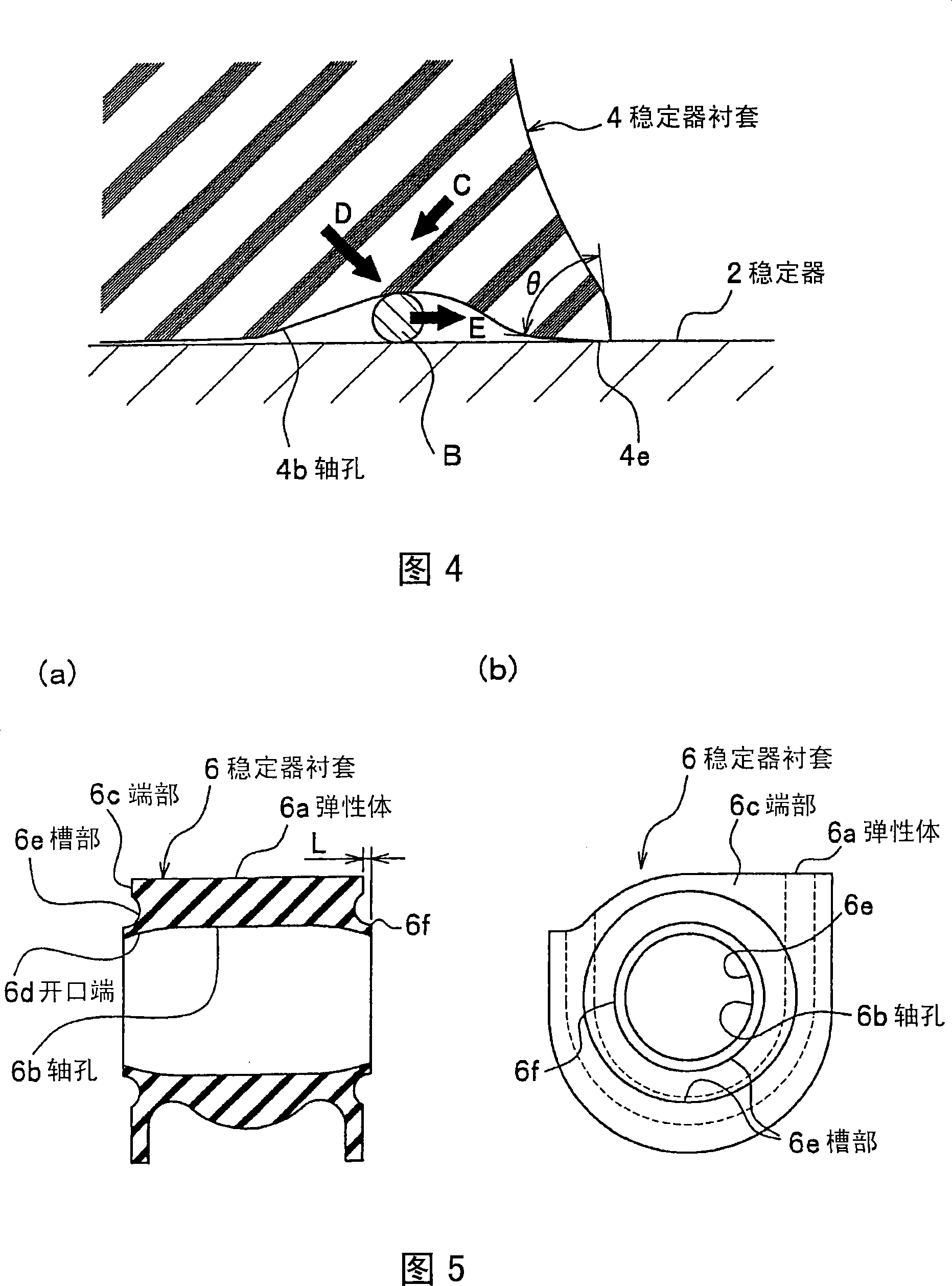

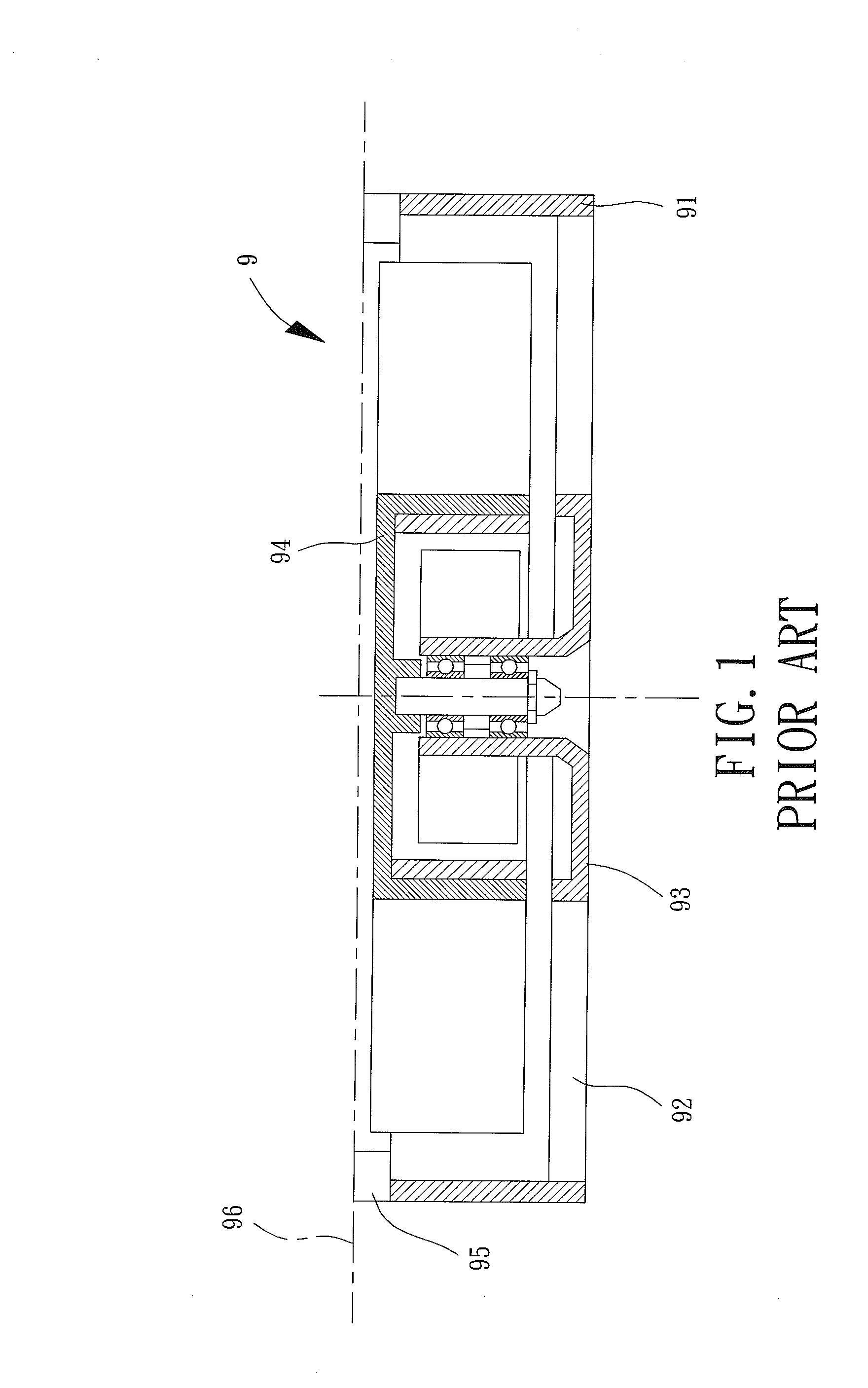

Stabilizer bush

InactiveCN101090834AGuaranteed operational stabilityPrevent intrusionNon-rotating vibration suppressionInterconnection systemsElastomerEngineering

A stabilizer bush (4) in which the torsion part (2a) of a stabilizer (2) is inserted and held in a shaft hole (4b) formed in an elastic body (4a) and the outer peripheral surface (4c) of the elastic body (4a) is held by a bracket (5) installed on a vehicle body. The shaft hole (4b) is so formed that its inner diameters (d1, d2) are gradually reduced from the axial center position to the outside.

Owner:HONDA MOTOR CO LTD

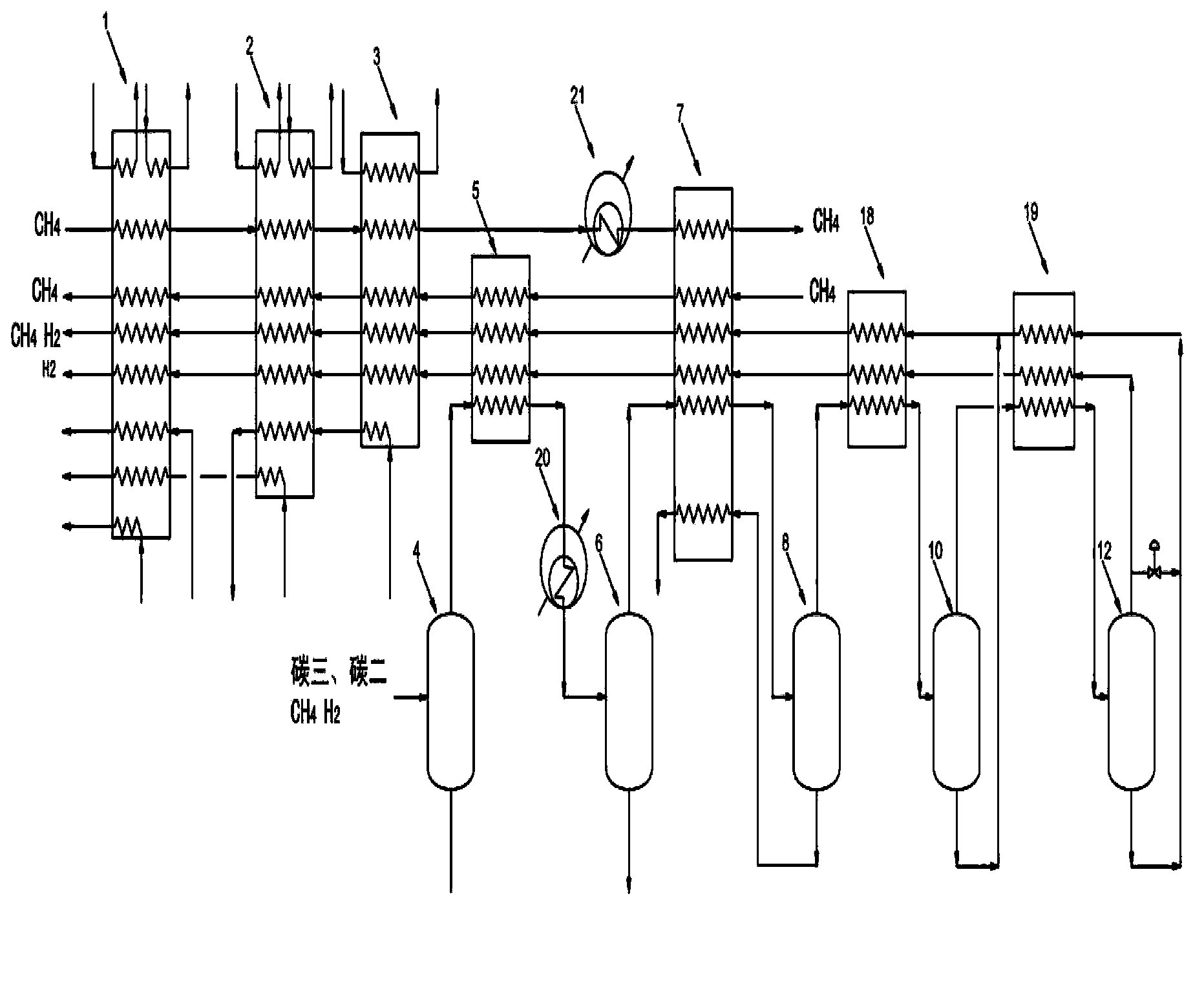

Ethylene cryogenic separation method for large-sized ethylene device

ActiveCN103542693AGuaranteed operational stabilityReduce the amount of materialSolidificationLiquefactionChemistrySeparation method

Owner:PETROCHINA CO LTD +1

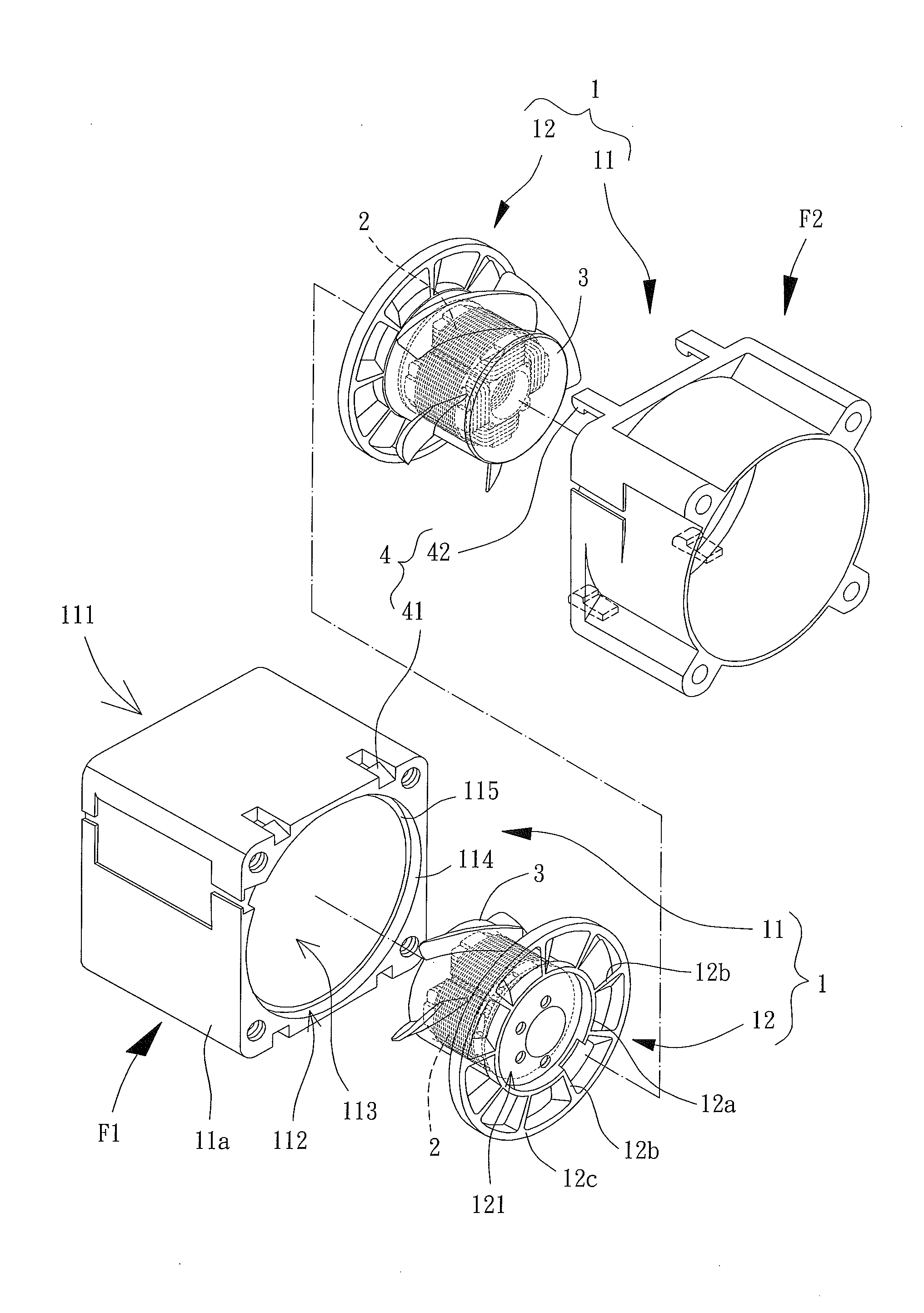

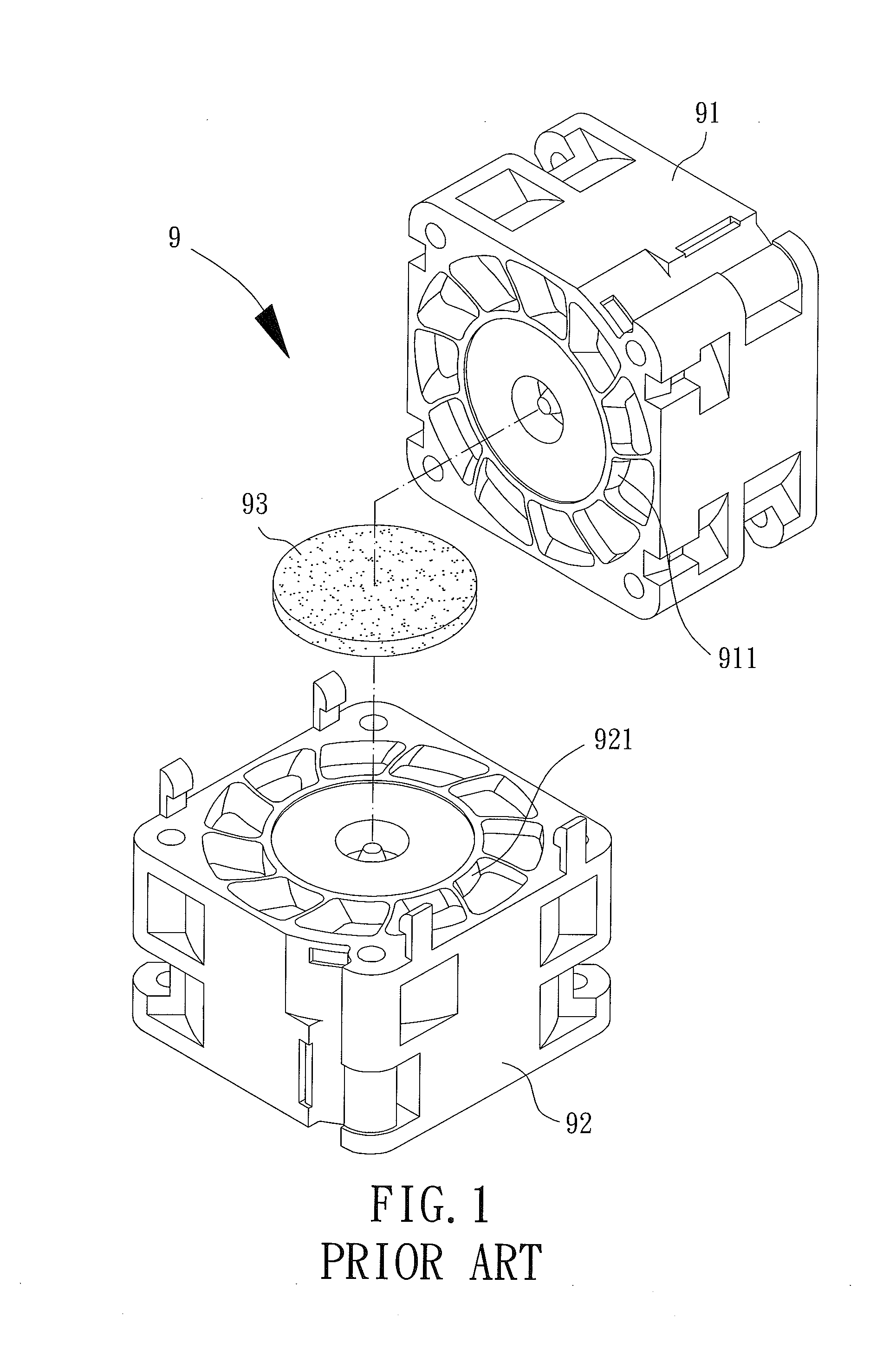

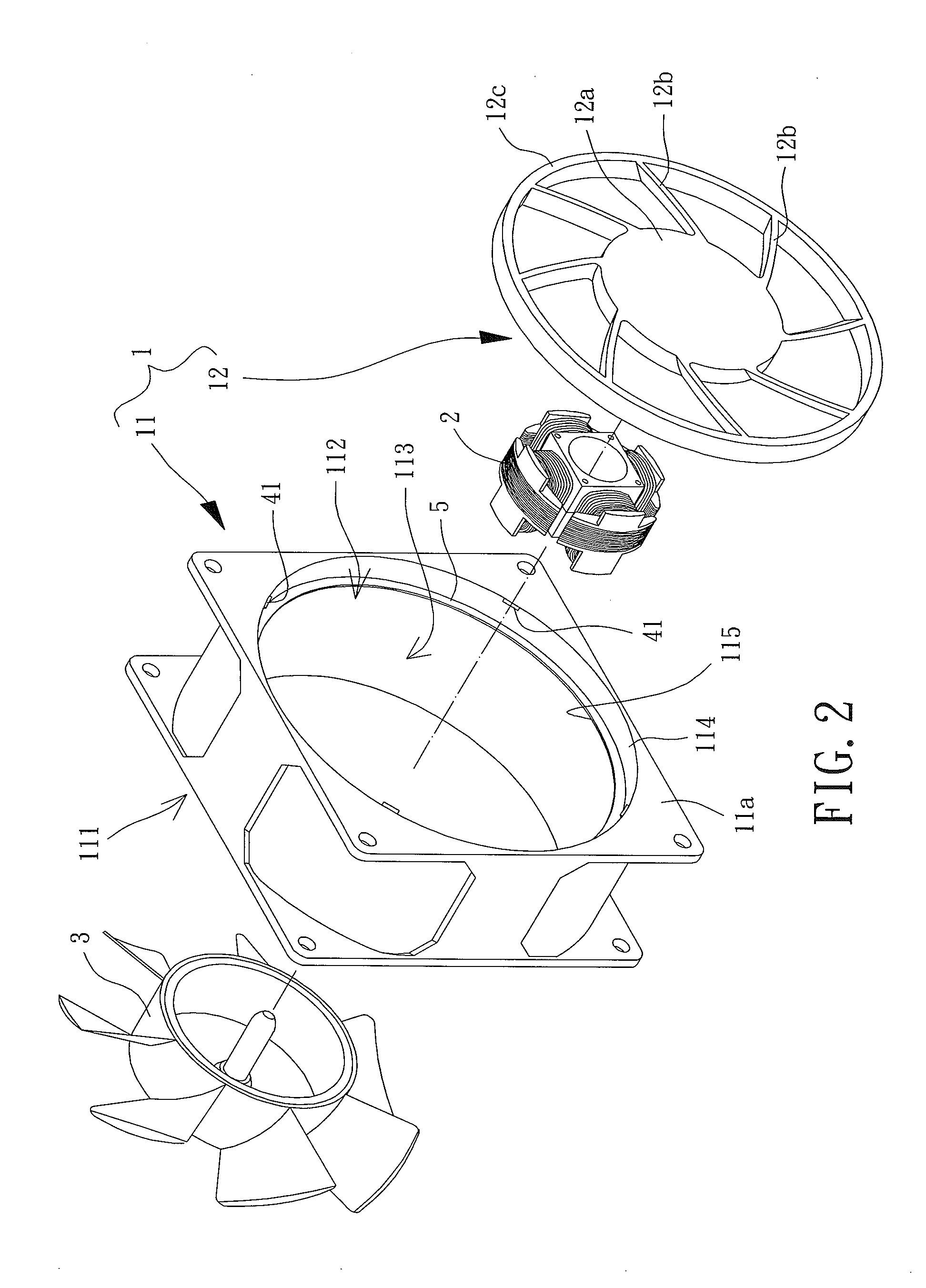

Serial Fan Device

InactiveUS20150023786A1Largely damp vibrationLower noisePump componentsStatorsEngineeringMechanical engineering

Owner:SUNONWEALTH ELECTRIC MACHINE IND

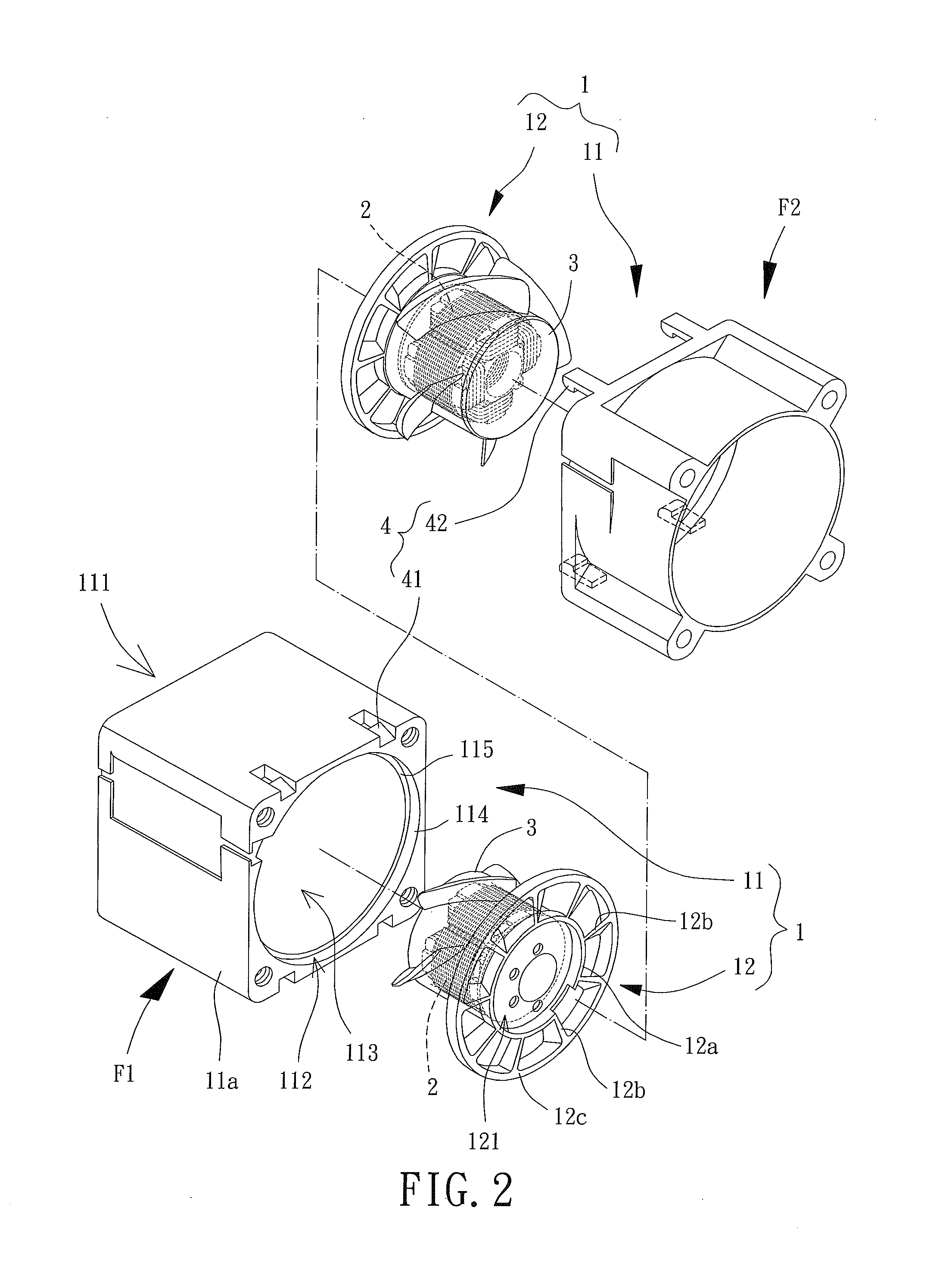

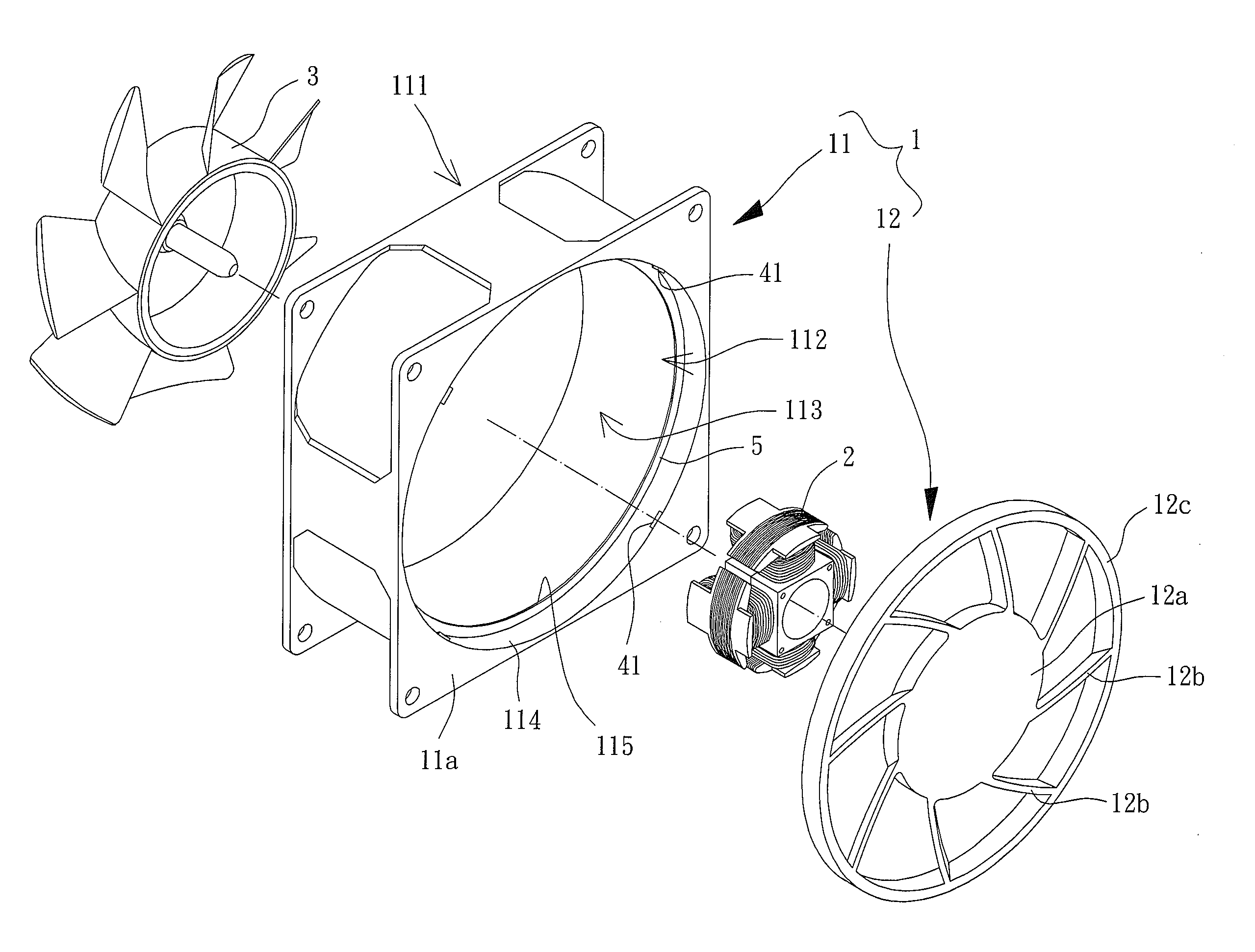

Low Vibration Fan

InactiveUS20150023779A1Reduce noiseExtended service lifePump componentsReaction enginesEngineeringMechanical engineering

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Vehicle body rear structure

Owner:SUZUKI MOTOR CORP

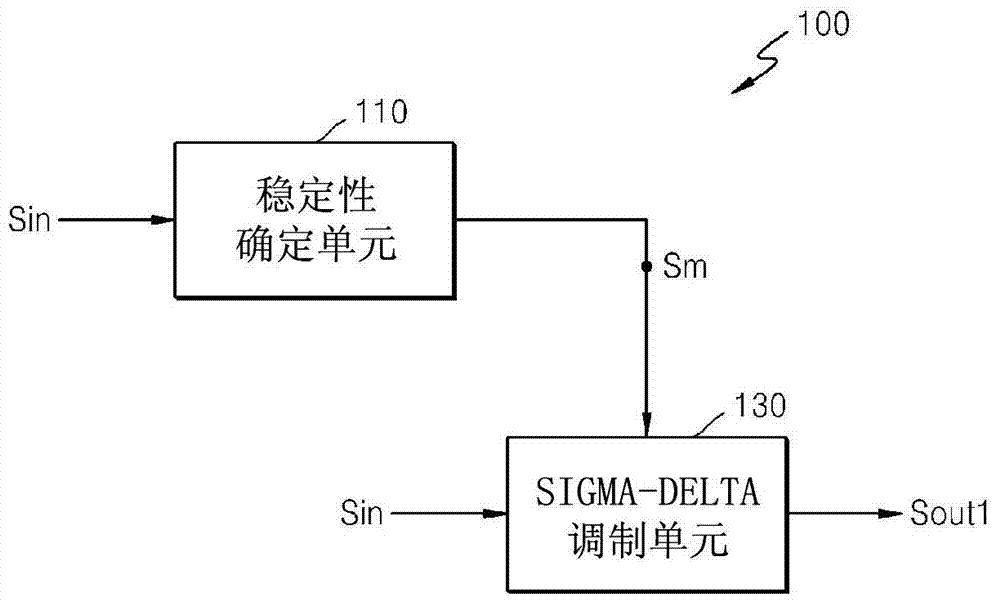

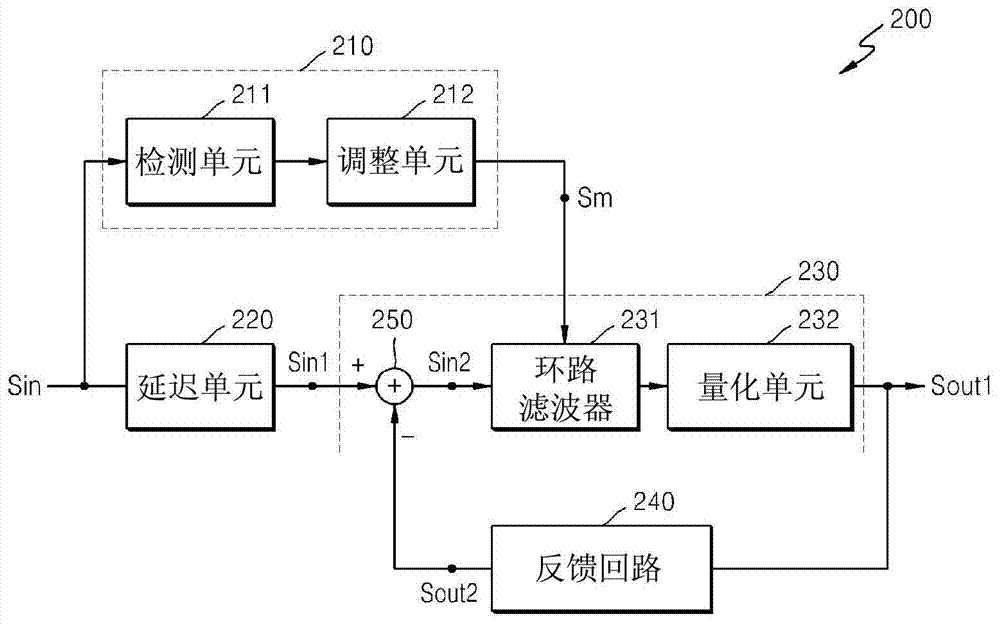

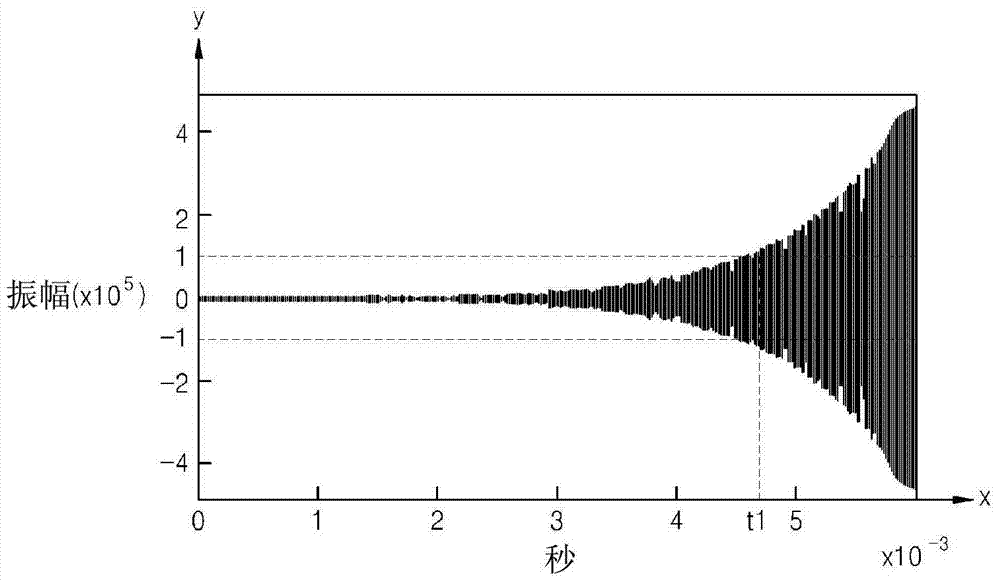

Audio signal processing method and audio signal processing apparatus therefor

InactiveCN103843061AGuaranteed operational stabilityImprove stabilityAnalogue conversionSpeech analysisAudio frequencyAudio signal

An audio signal processing apparatus and method are provided. The apparatus includes a stability determiner and a sigma-delta modulator. The stability determiner divides a frequency band of an input audio signal into one or more sub-frequency bands, compares a level of the input audio signal for each of the sub-frequency bands with a threshold for the sub-frequency band, and generates a stability determination signal according to a result of the comparison. The sigma-delta modulator sigma-delta modulates the input audio signal according to the stability determination signal, and outputs a modulation signal.

Owner:SAMSUNG ELECTRONICS CO LTD

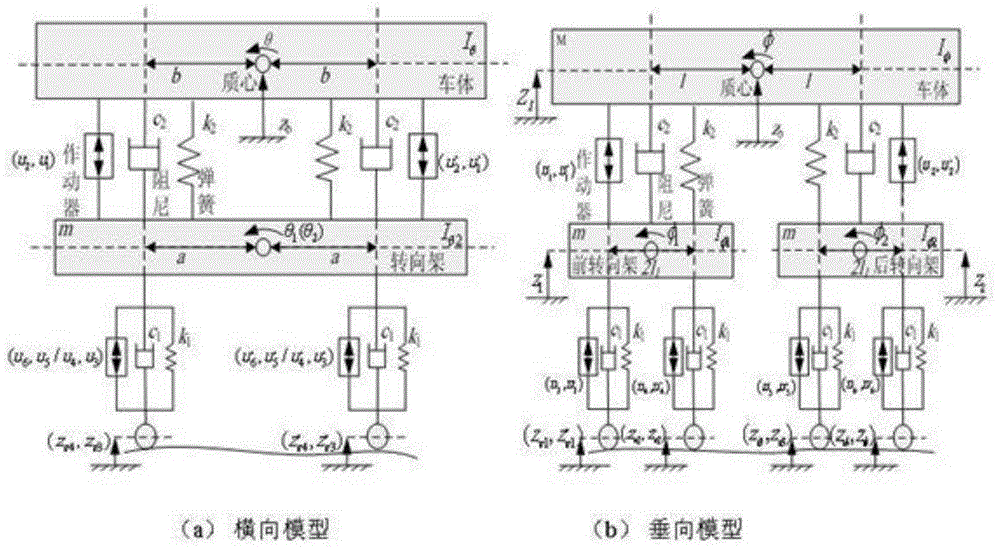

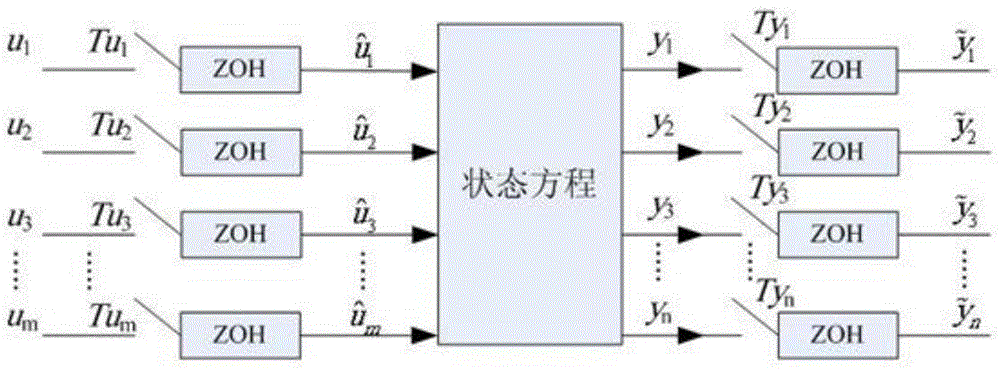

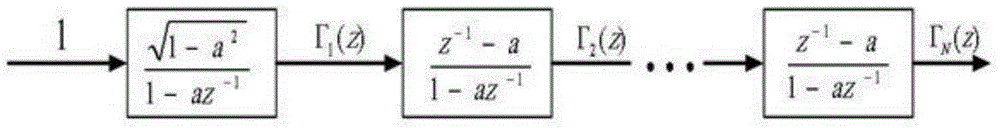

Multi-rate prediction control method applied to train active suspension system

InactiveCN104950667AOptimizing Active Vibration Control PerformanceGuaranteed operational stabilityAdaptive controlTime lagPredictive controller

The invention relates to a multi-rate prediction control method applied to a train active suspension system. On the basis of the active suspension system model of the high-speed train, prediction control algorithm researches based on a standard orthogonal basis function orthogonal basis function-Laguerre function are carried out. under the circumstances that a state space model of the suspension system is used as a prediction control model and basic principles like rolling optimization in prediction control are combined, a corresponding prediction control is designed for the active suspension multi-rate and time-lag-contained multi-rate system of the high-speed train by considering influence factors like uncertain track interference excitation during the train running process. According to the system model, the controller parameters can be adjusted and optimized continuously to enable the system to realize an optimum control effect, thereby optimizing the vibration active control performance during the high-speed train running process and guaranteeing operation stability and comfort during the training running.

Owner:EAST CHINA JIAOTONG UNIVERSITY

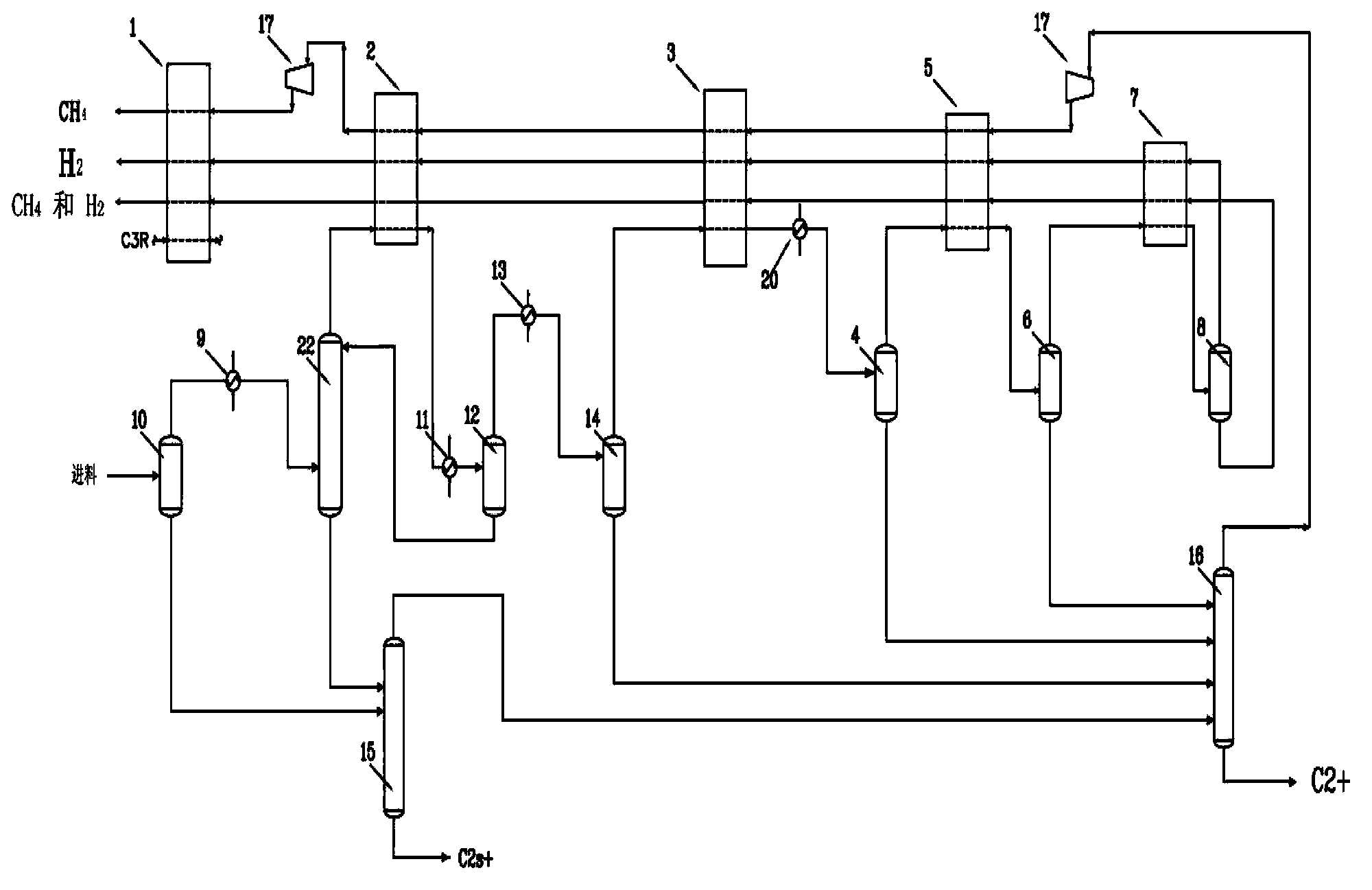

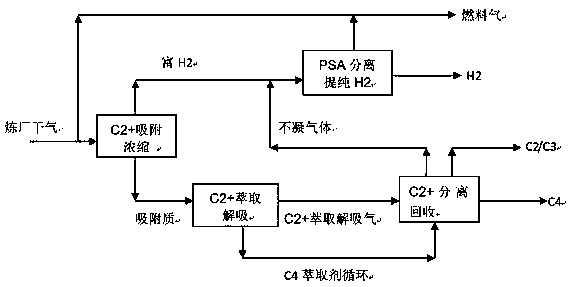

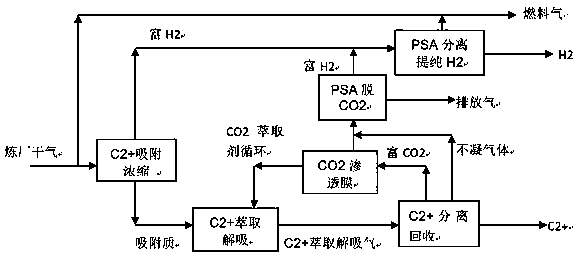

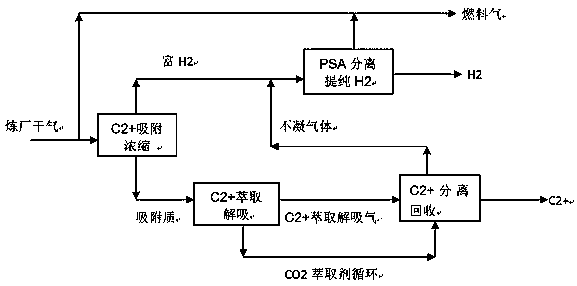

Full-temperature-range adsorption, extraction and separation method capable of recovering H2 and C<2+> from refinery plant dry gas

ActiveCN107778124ASolve the bottleneck problem of easy adsorption-difficult desorptionImprove unityHydrogen separationHydrocarbonsDesorptionSorbent

The invention discloses a full-temperature-range adsorption, extraction and separation method capable of recovering H2 and C<2+> from refinery plant dry gas. The method comprises the processes of performing adsorption and concentration on the C<2+>, performing extraction and desorption on the C<2+>, performing separation and recovery on the C<2+>, performing PSA separation and purification on thehydrogen (H2) and the like; the refinery plant dry gas passes through the C<2+> concentration and adsorption process, and most of C<2+> hydrocarbon components are adsorbed by an adsorption and concentration tower; H2-enriched gas flowing out of the top of the tower enters the process of performing PSA separation and purification on the H2 to obtain the H2 product with the purity of 98 to 99 percent; and the desorption gas is pressurized and returns to the C<2+> adsorption and concentration process to further recover the H2 and the C<2+>. After the adsorption step is completed, the effective component C<2+> is dissolved out by the C<2+> extraction and desorption process, the extraction and desorption gas enters the C<2+> separation and recovery process, the non-condensable gas H2 escapes, and the H2 and the H2-enriched gas are mixed to enter the process of performing PSA separation and purification on the H2; an extracting agent escapes, is regenerated, recovered and processed and thenis recycled; and the adsorption-extraction and desorption process is adopted, so the energy consumption investment is saved, the flow is shorter, the efficiency is higher, the service life of the adsorbent is longer and full-component recovery can be realized.

Owner:SICHUAN TECHAIRS

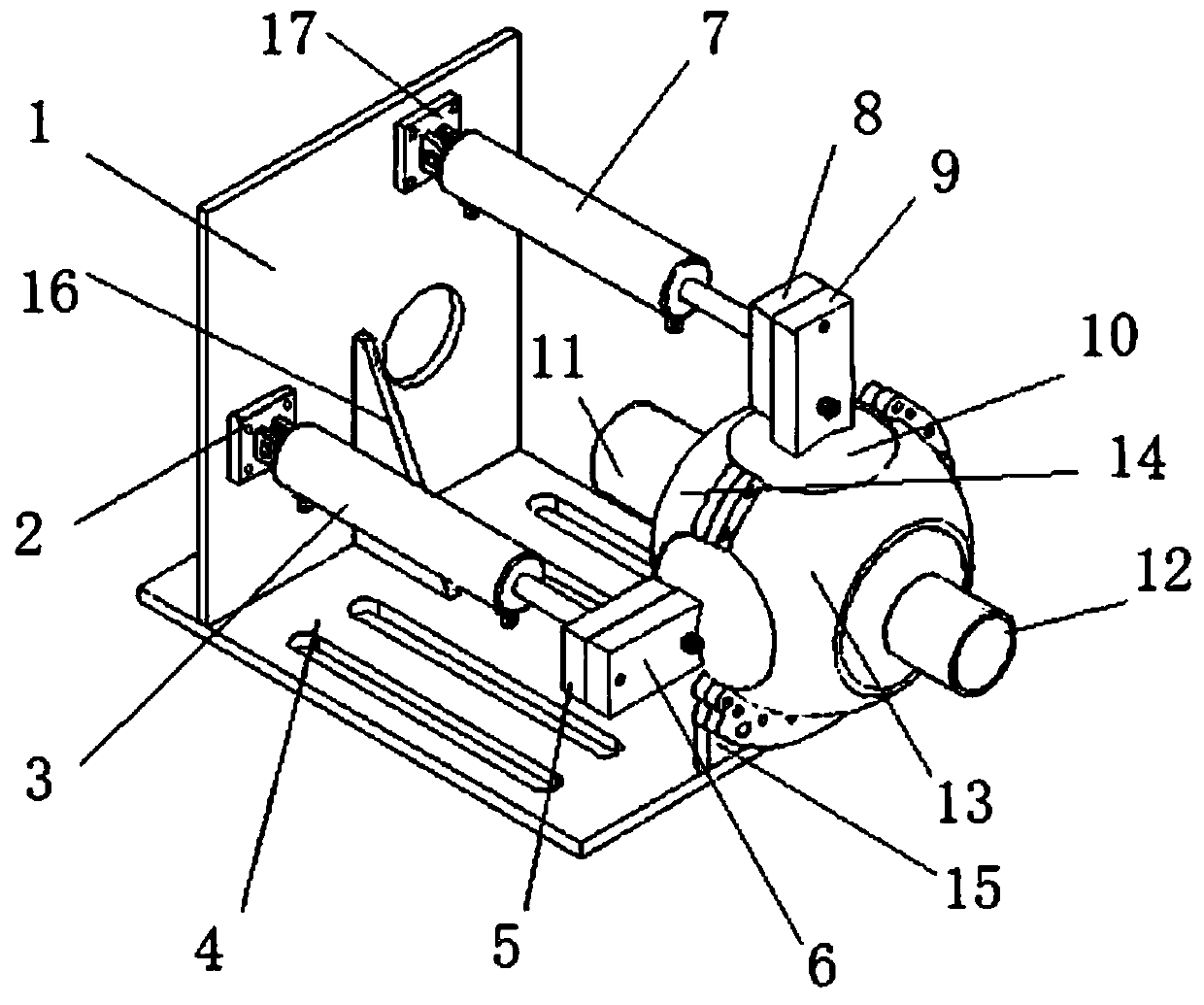

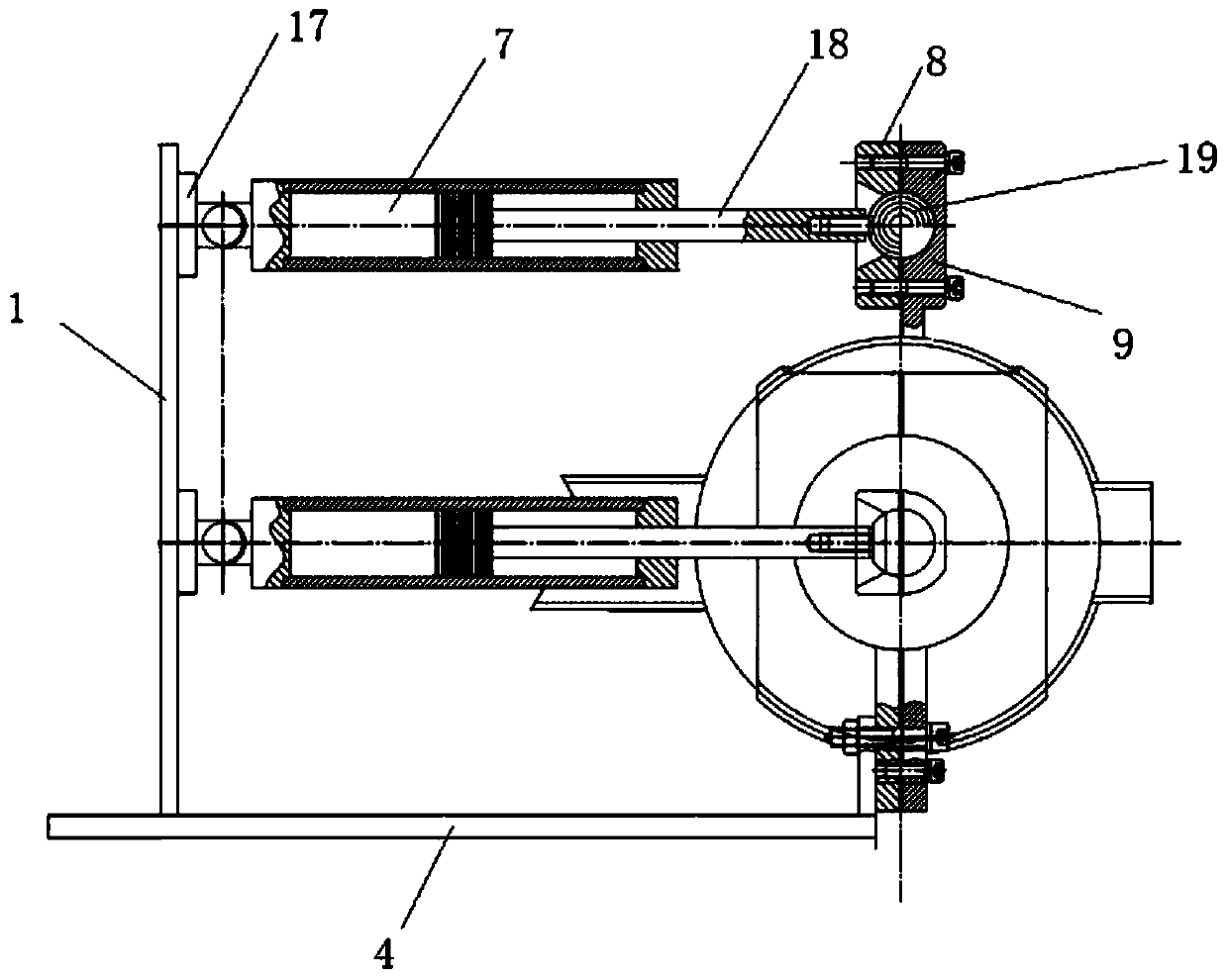

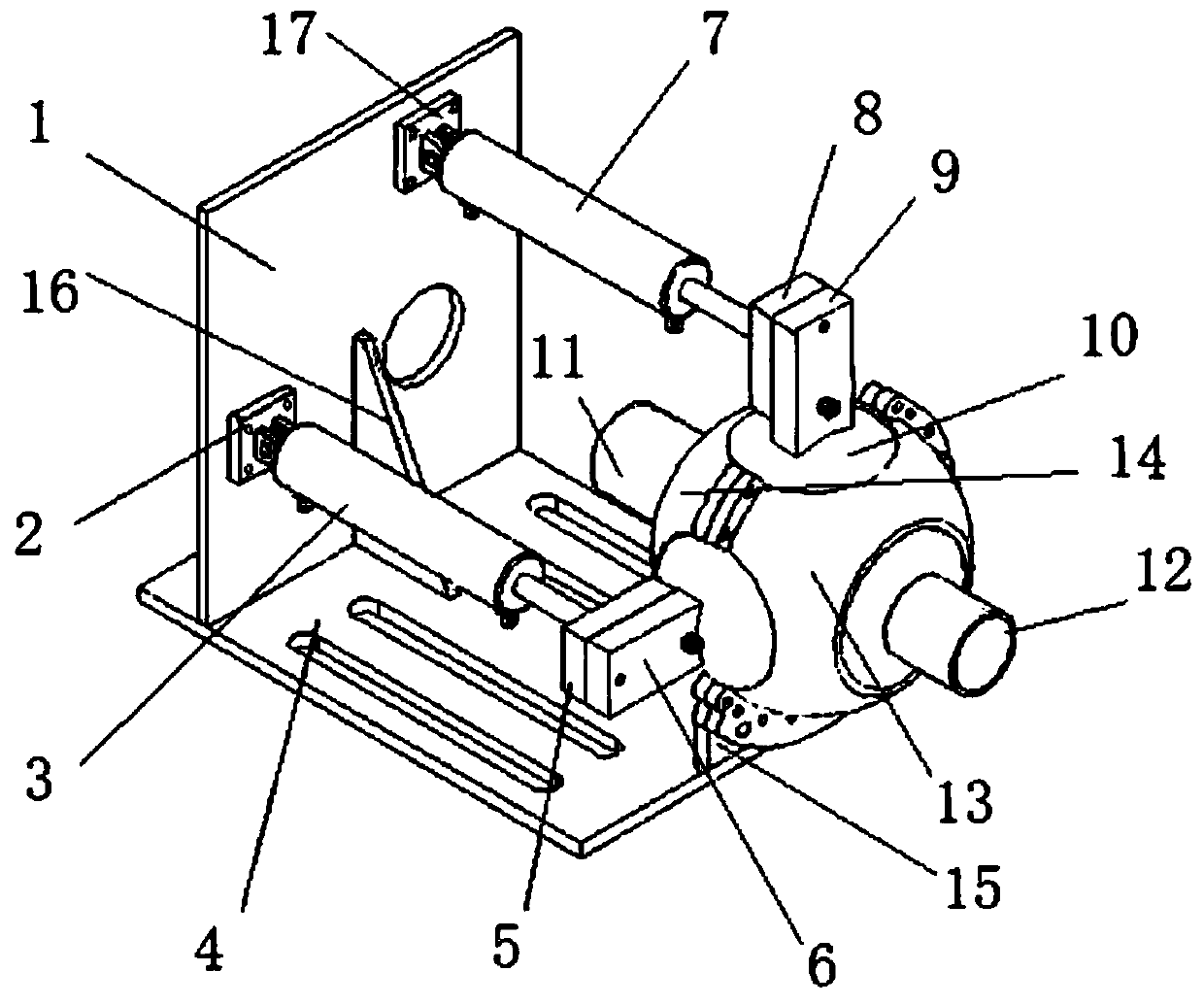

Vector water-jet propeller and vector water-jet propulsion method

ActiveCN111114729AGuaranteed operational stabilityClear structureAmphibious vehiclesPropulsive elementsPump-jetJet propulsion

The invention discloses a vector water jet propeller device and a vector water jet propulsion method, belongs to the technical field of water propulsion of ships and amphibious vehicles, and solves the problem that the existing water jet propulsion ship and amphibious vehicle cannot effectively control the posture of a vehicle body or a ship body. The vector water jet propeller mainly comprises awater inlet shell, a water outlet shell, a propeller support, a water jet propeller inner container and an oil cylinder assembly arranged on the propeller support. The spherical propeller inner container can rotate in the shell, the two ball supports which are perpendicular to each other are fixedly installed on the inner container, the water jet propeller inner container is pushed to rotate in the shell by controlling stretching and retracting of a piston rod of the oil cylinder assembly, the left-right angle and the pitching angle of a water spraying pipe on the inner container are adjusted,and the water spraying angle of the vector water jet propeller is controlled. Vector propelling force in different directions can be obtained by changing the angle of tail water jet flow, then the posture can be adjusted according to environmental disturbance and waves, and the seakeeping performance and navigation stability of amphibious vehicles or ships are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Preparation method of modified organosilicone dephenolized membrane

InactiveCN104258746AInnovativeStrong application prospectDistillationSeparation factorPolymer science

The invention belongs to the technical field of pervaporation membrane separation and in particular relates to a preparation method of a modified organosilicone dephenolized membrane. The preparation method of the modified organosilicone dephenolized membrane comprises the following steps: firstly, mechanically stirring room temperature vulcanization liquid silicone rubber with a solvent until the room temperature vulcanization liquid silicone rubber is dissolved and a transparent solution is formed; then, adding a crosslinking agent and a catalyst, and mechanically stirring for 5-20 minutes, wherein the mass ratio of the room temperature vulcanization liquid silicone rubber to the solvent to the crosslinking agent to the catalyst is 33:60:5:2; then adding oleic alcohol the mass of which is 1%-5% of that of the room temperature vulcanization liquid silicone rubber, mechanically stirring for 2-10 minutes, and uniformly mixing; and finally, casting the obtained solution on a supporting basement membrane to form a membrane, standing at room temperature for 4-5 hours, and then drying the membrane in a vacuum drying oven at the temperature of 60-80 DEG C for 8-12 hours. A preparation process of the modified membrane is simple and easy, and the obtained membrane has good comprehensive performance of separating phenol from water when being used for separating a phenol / water mixture; permeation flux of the membrane can be 526g.m<-2>.h<-1>, and a separation factor of the membrane can be 8.63; great potential in industrialized application is shown.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

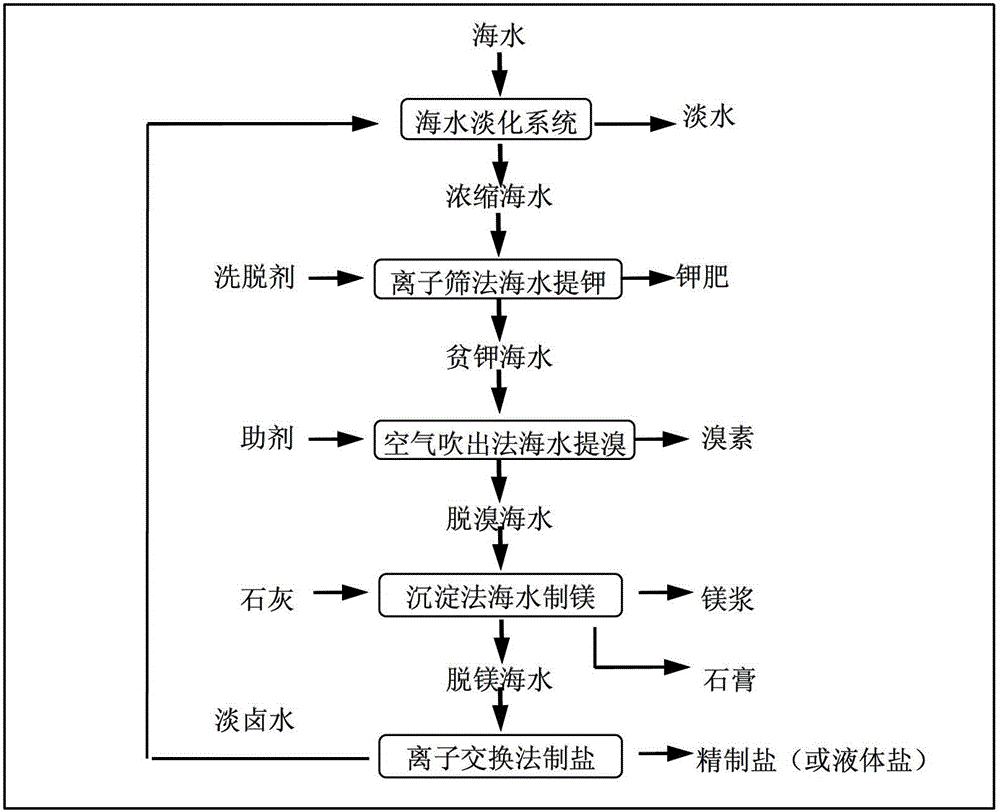

Seawater desalination treatment method adopting combination of wind energy power generation and salt chemical industry

ActiveCN102757138BReduce manufacturing costReduce wasteGeneral water supply conservationSeawater treatmentChemical industryChemical element

The invention provides a seawater desalination treatment method adopting combination of wind energy power generation and salt chemical industry. The method comprises the following steps of: performing desalination treatment on the seawater by using a reverse osmosis seawater desalination system to obtain fresh water and concentrated seawater; supplying power to the reverse osmosis seawater desalination system by a wind energy generator; treating the concentrated seawater by a potassium ion sieve and extracting potassium ions; extracting bromine in the concentrated seawater by using an air blowout method; extracting magnesium in the concentrated seawater by using a precipitation method; extracting salt from the concentrated seawater by using an ion exchange method to prepare refined salt or liquid salt and halogen fresh water subjected to desalination; and delivering the halogen fresh water to the reverse osmosis seawater desalination system. According to the seawater desalination treatment method adopting combination of wind energy power generation and salt chemical industry, the seawater is desalted by using a reverse osmosis method, chemical elements and rare metals in the concentrated seawater are extracted and recovered; and the resource waste is reduced while a large quantity of byproducts are acquired, so that the production cost of seawater desalination is indirectly reduced.

Owner:林晓

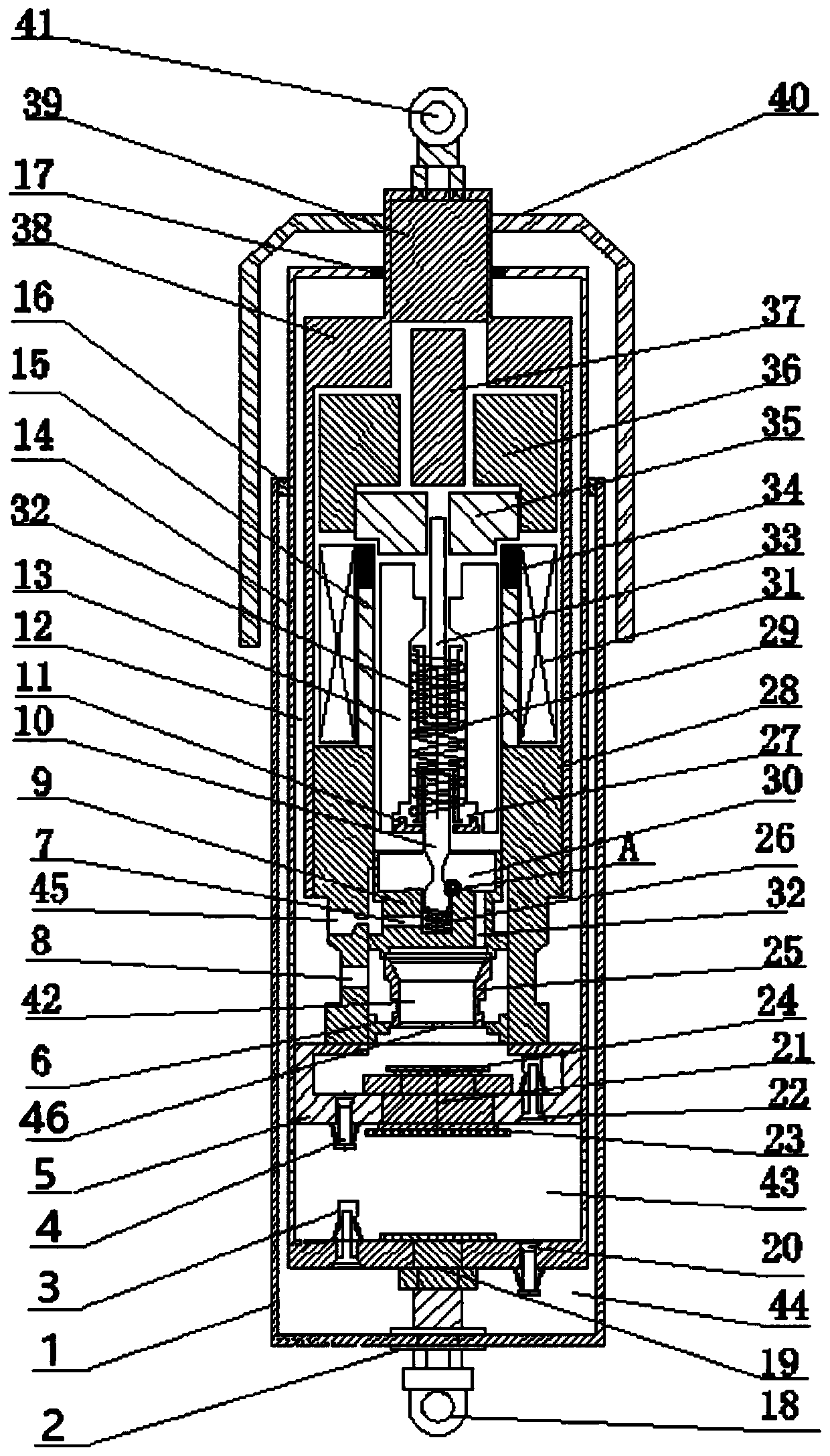

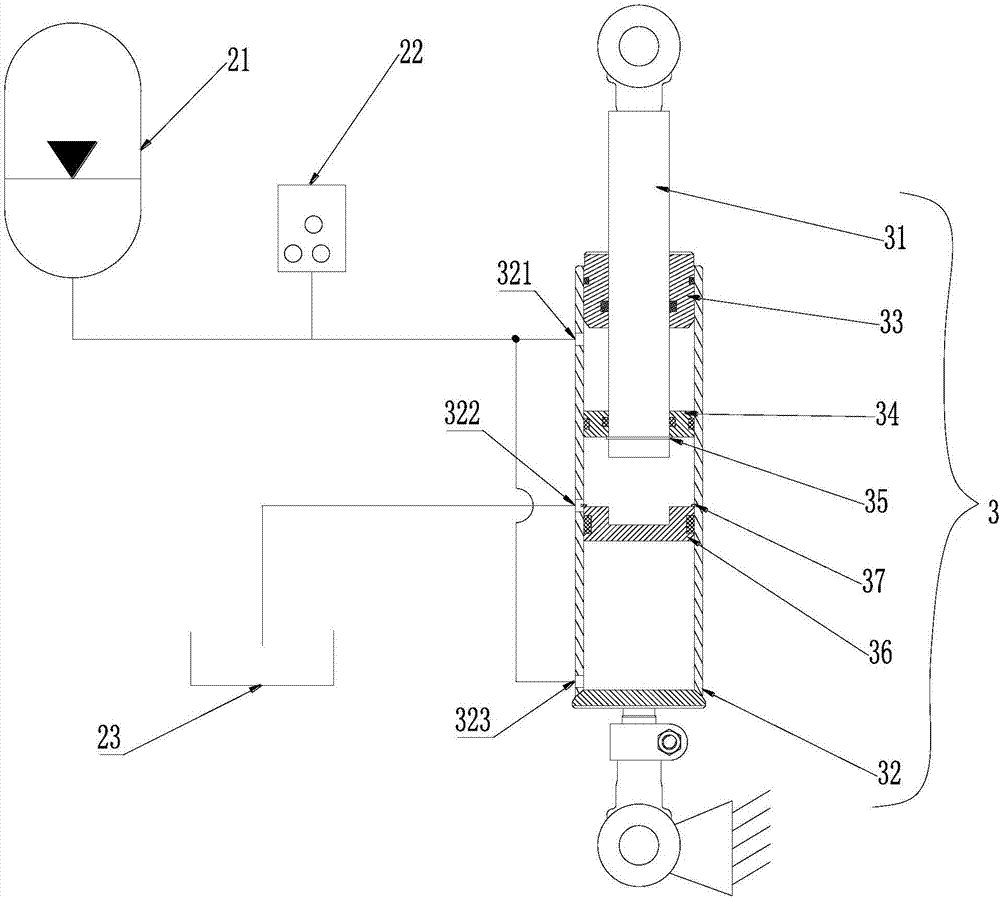

Built-in electromagnetic-valve-type semi-active damping-continuous-adjustable shock absorber, and control method

The invention belongs to the technical field of vehicle damping devices and specifically relates to a built-in electromagnetic-valve-type semi-active damping-continuous-adjustable shock absorber, anda control method. The built-in electromagnetic-valve-type semi-active damping-continuous-adjustable shock absorber comprises a shock absorber body and a shock absorber control system and is characterized in that the shock absorber body comprises a working cylinder barrel, an oil storage cylinder barrel, a shock absorber dustproof cover, a bottom valve assembly, a piston assembly and an electromagnetic valve assembly. The invention also discloses the control method for the built-in damping-continuous-adjustable shock absorber. The control method is characterized in that continuous switching control of different modes can be realized for soft and hard damping of the shock absorber; an electromagnetic valve can be rationally integrated with a piston inside the damping-continuous-adjustable shock absorber; different cross section structures are adopted for a valve core; guidance structures are designed around the valve core, so the valve core is more stable; damping is realized, and damping adjustment of different comfort degrees can be realized; use is convenient; space is saved; use prospect is wide; and promotion and use are easy.

Owner:XIAN UNIV OF SCI & TECH

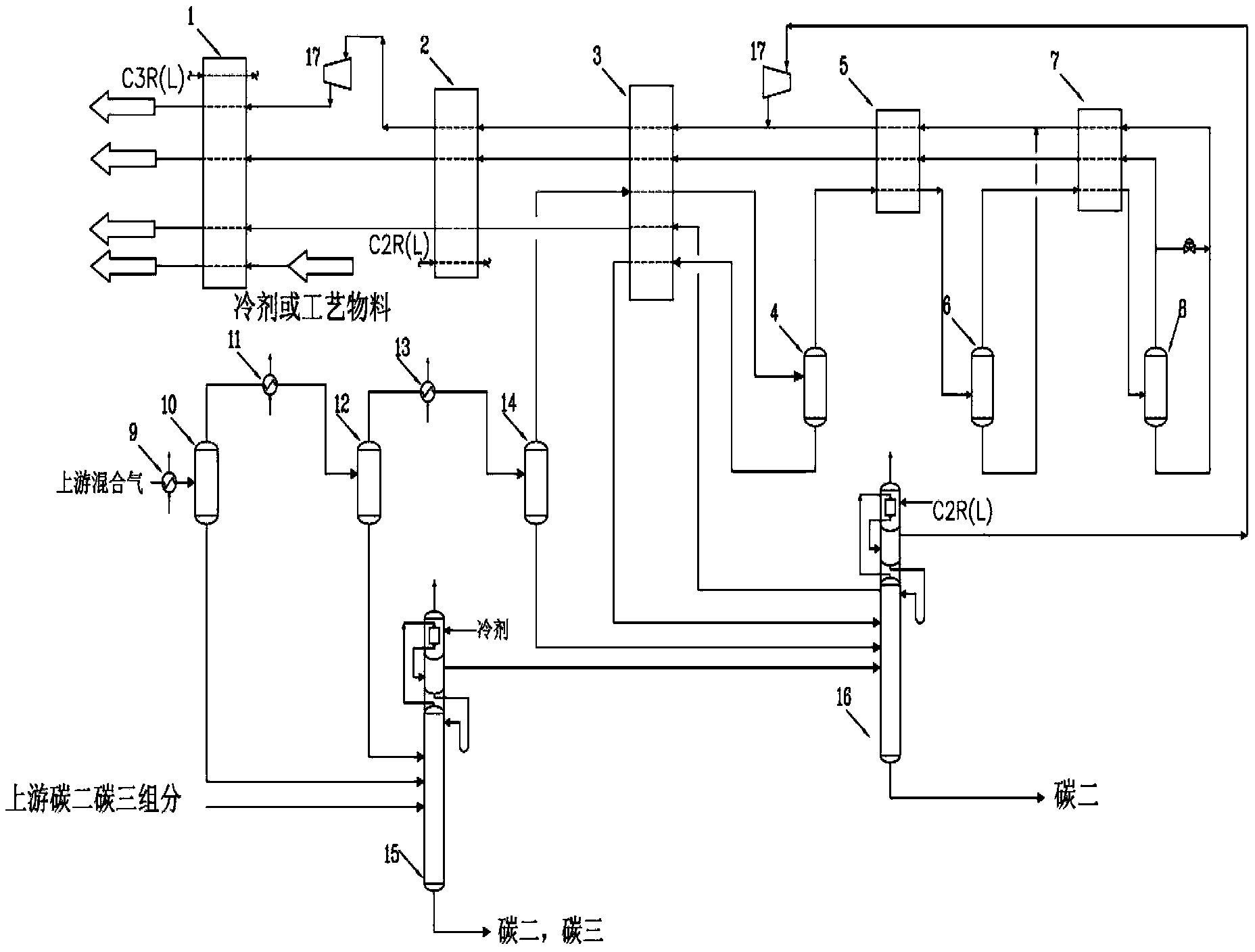

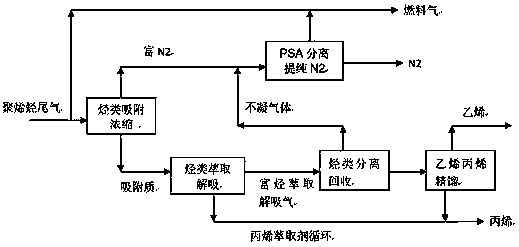

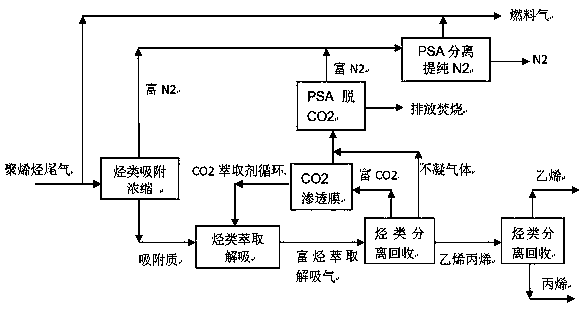

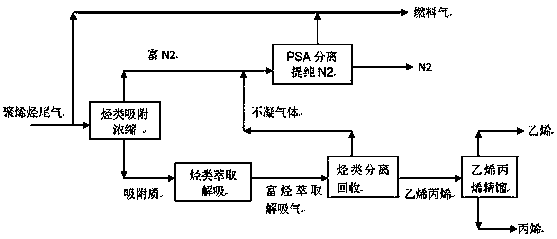

Method for recovering polyolefin tail gas hydrocarbons through full-temperature-range absorption extraction

ActiveCN107774096ASolve the bottleneck problem of easy adsorption-difficult desorptionImprove unityGas treatmentDispersed particle separationPolyolefinDesorption

The invention discloses a method for recovering polyolefin tail gas hydrocarbons through full-temperature-range absorption extraction. The method comprises a hydrocarbon adsorption and concentration process, a hydrocarbon extraction and desorption process, a hydrocarbon separation and recovery process and a PSA nitrogen separation and purification process. Polyolefin tail gas is subjected to the hydrocarbon adsorption and concentration process first, most of C<2+> hydrocarbon components are adsorbed in an adsorption tower, nitrogen-enriched gas flows out of the tower top and enters the PSA N2separation and purification process so as to obtain N2 by-products with the purity of 99%, and desorbed gas is pressurized to return to the hydrocarbon adsorption and concentration process to furtherrecover the N2 and C<2+> hydrocarbon components. After the adsorption step is completed, the hydrocarbon extraction and desorption process is performed, the active ingredients, namely C<2+> hydrocarbon components, are dissolved out, the extracted and desorbed gas enters the hydrocarbon separation and recovery process to be subjected to pressure reduction or condensation cooling, non-condensable gas N2 escapes out to be mixed with the nitrogen-enriched gas and then enters the PSA N2 separation and purification process. Then, the extraction agent escapes and is recycled for cyclic utilization. According to the method disclosed by the invention, energy consumption investment is reduced, the process is short, the efficiency is high, and the service life of the adsorbent is long.

Owner:SICHUAN TECHAIRS

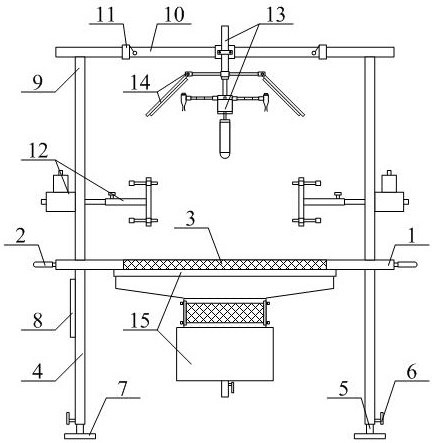

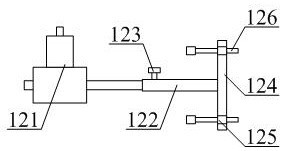

Multifunctional mechanical automatic mold processing device

InactiveCN111843777AEasy to operateGuaranteed ease of operationGrinding carriagesGrinding drivesAutomatic controlElectric machinery

The invention provides a multifunctional mechanical automatic mold processing device. The multifunctional mechanical automatic mold processing device comprises a rack, adjusting handles, a filter net,supporting pipes, adjusting rods, adjusting bolts, supporting foot stands, an automatic control screen, vertical bases, a linear sliding rail and limit switches, wherein the four corner parts of theouter side of the rack are in transversely threaded connection with the adjusting handles, and the middle position of the interior of the rack is in screw connection with the filter net. Turnover motors, movable adjusting pipes, square head bolts, mold blank clamping plates, internal thread holes and clamping bolts are arranged, by loosening the square head bolts, the positions of the movable adjusting pipes on the outer walls of output shafts of the turnover motors can be moved and adjusted, the positions are determined, the square head bolts are locked, mold blanks are placed between the mold blank clamping plates, the clamping bolts are abutted or screwed into the thread holes in the mold blanks, then turnover processing operation can be carried out through the turnover motors, and theoperation convenience is ensured.

Owner:东营市万隆精铸金属有限公司

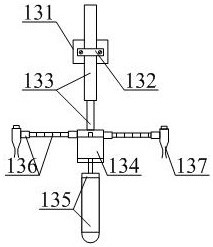

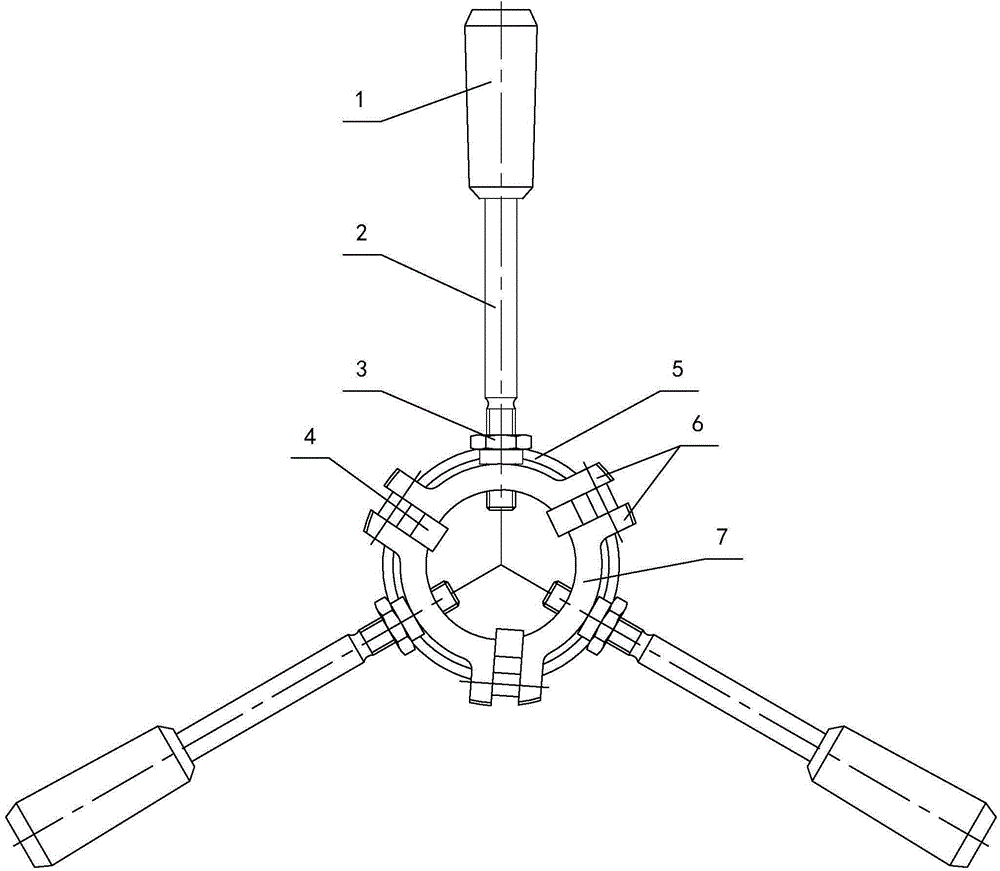

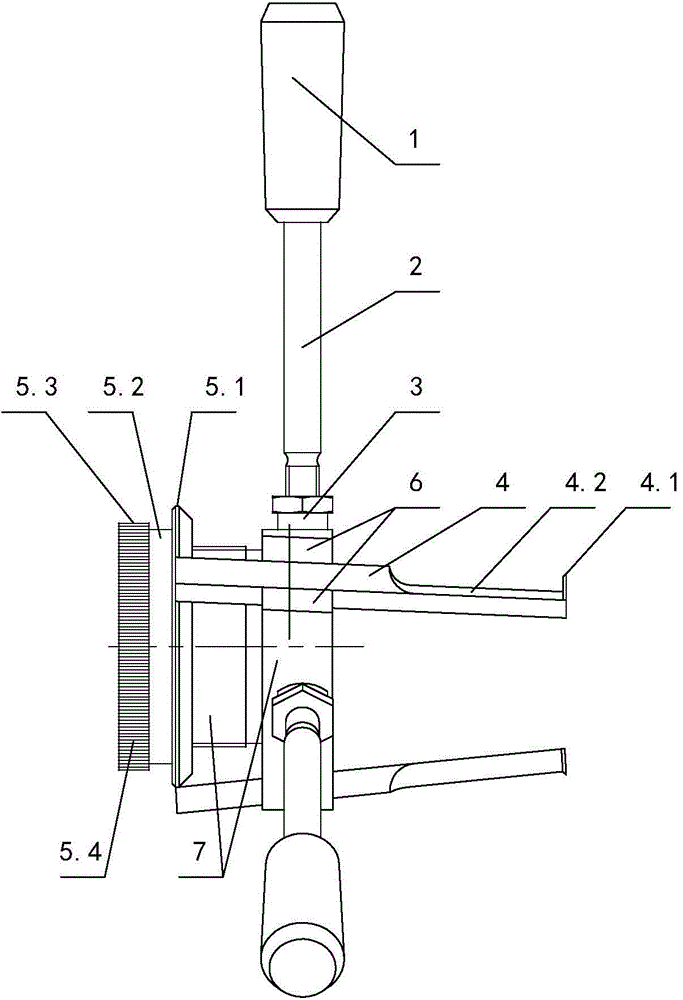

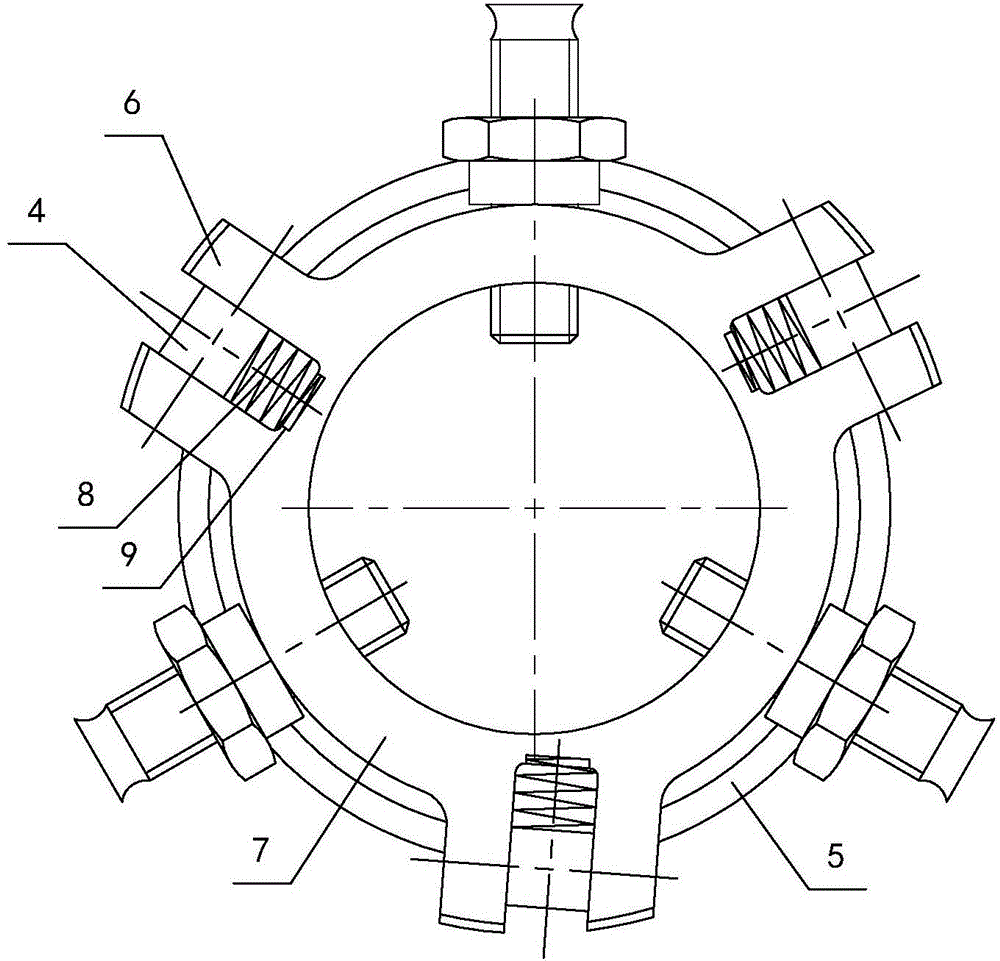

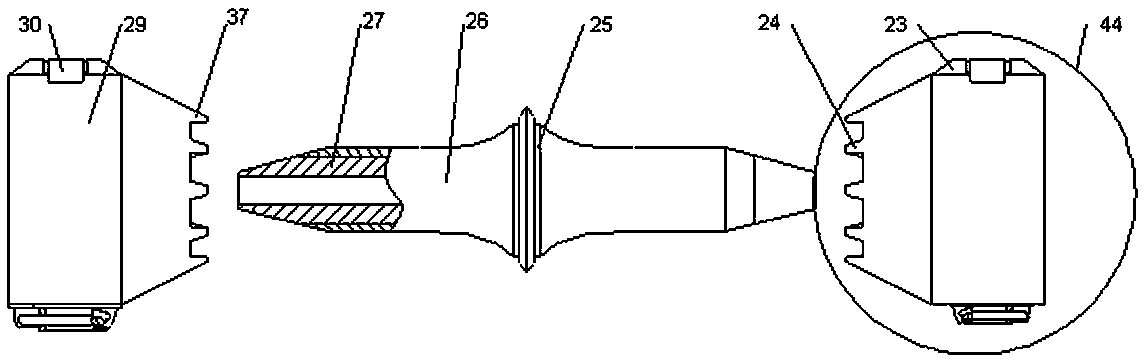

Cable peeler

The invention discloses a cable peeler, comprising handles, a cable fixing sleeve, cable clamping units and cutter head assemblies, wherein the cable clamping units and the cutter head assemblies are all connected on the cable fixing sleeve. The three cable clamping units are uniformly distributed on the side wall of the cable fixing sleeve along the circumference. The three cutter head assemblies are hinged on the side wall of the cable fixing sleeve along the circumference. The three cable clamping units and the three cutter head assemblies are distributed in an alternate manner. The three handles are respectively connected to end portions of the cable clamping units. The cable peeler also comprises a cutter-head angle adjuster, which is screwed to one end of the cable fixing sleeve and is connected with the cutter head assemblies. By adopting such a structure, the cut-in angle and the cut-in depth of a cutter head can be randomly controlled, therefore making it very convenient to peel a cable and improving the production efficiency. In addition, a cable sheath is helically peeled off while the cutter head is screwed to conduct the cut-in operation, so that the cable sheath can be completely peeled off.

Owner:象山石浦浦江工具厂 +1

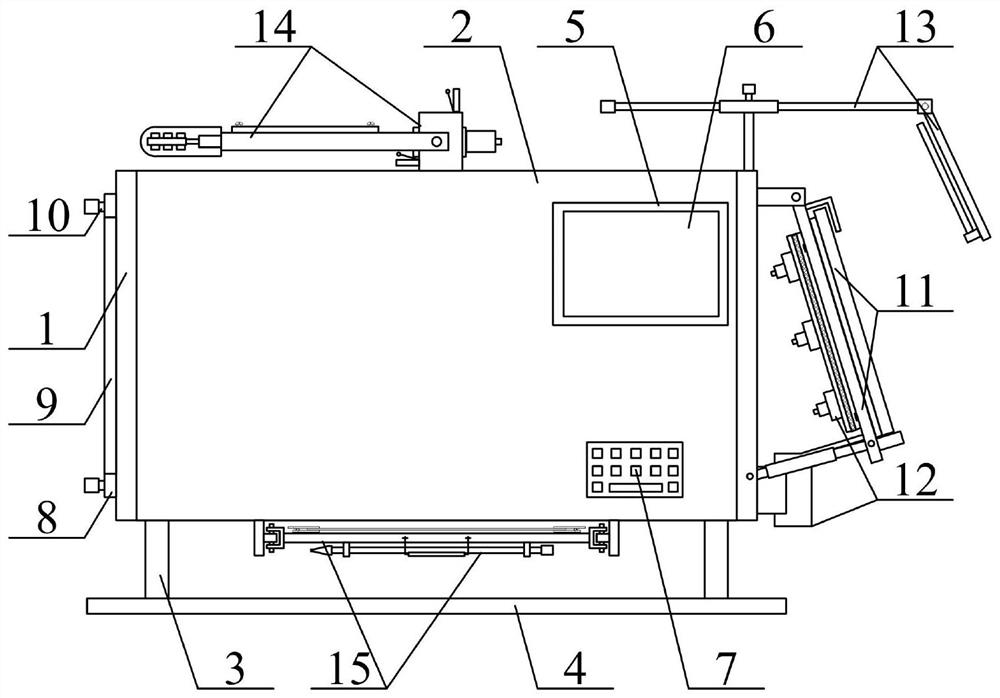

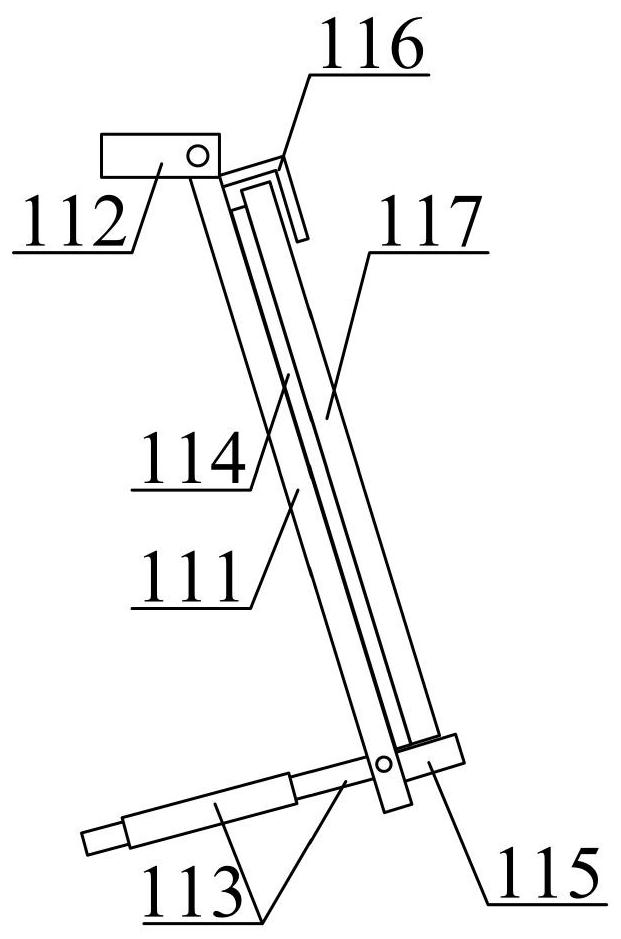

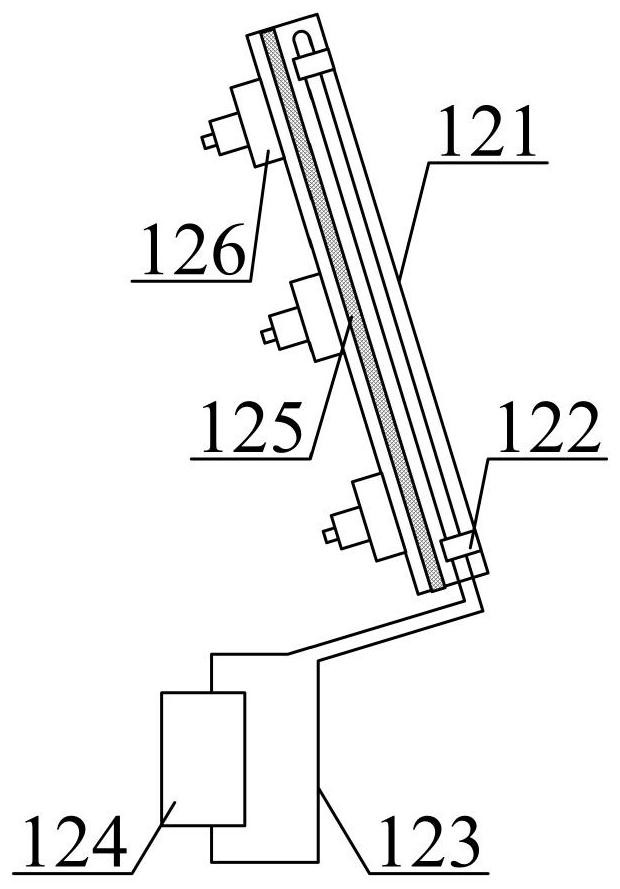

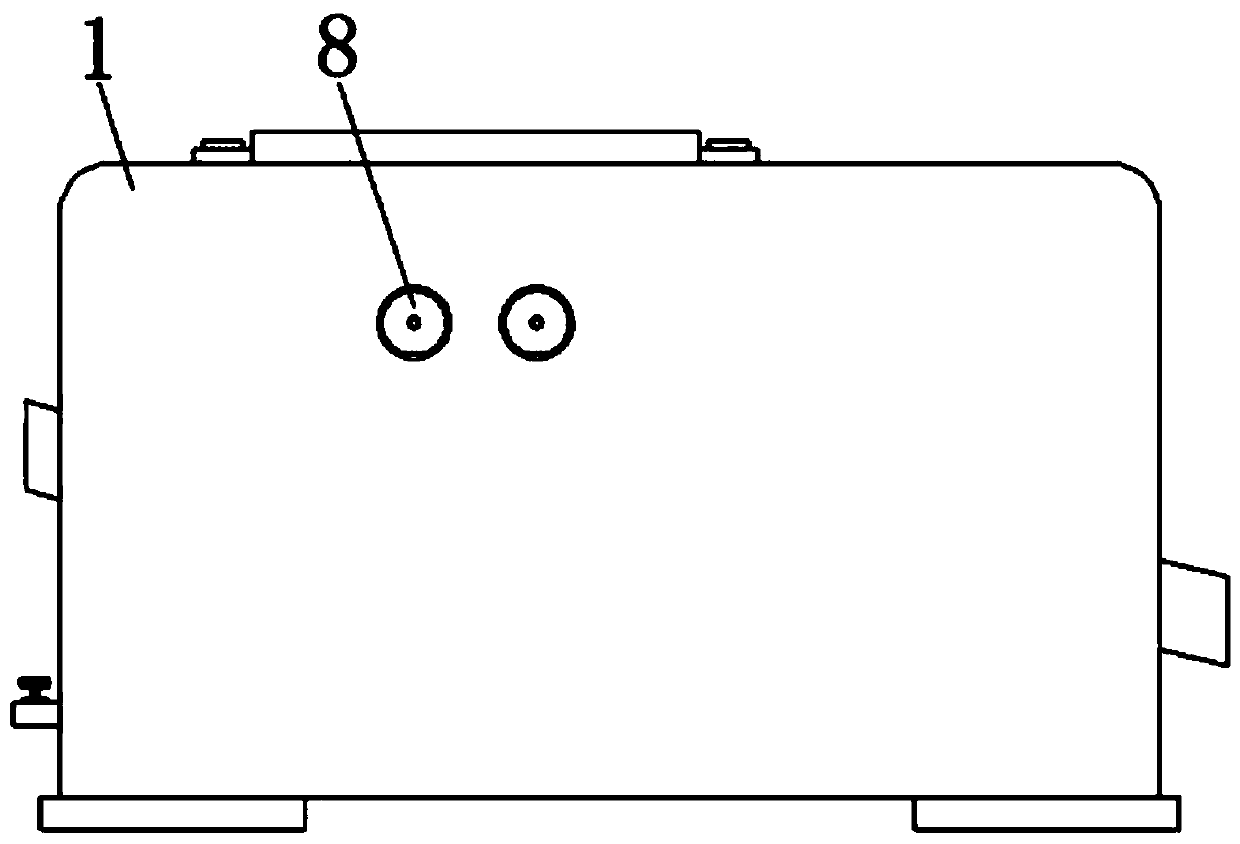

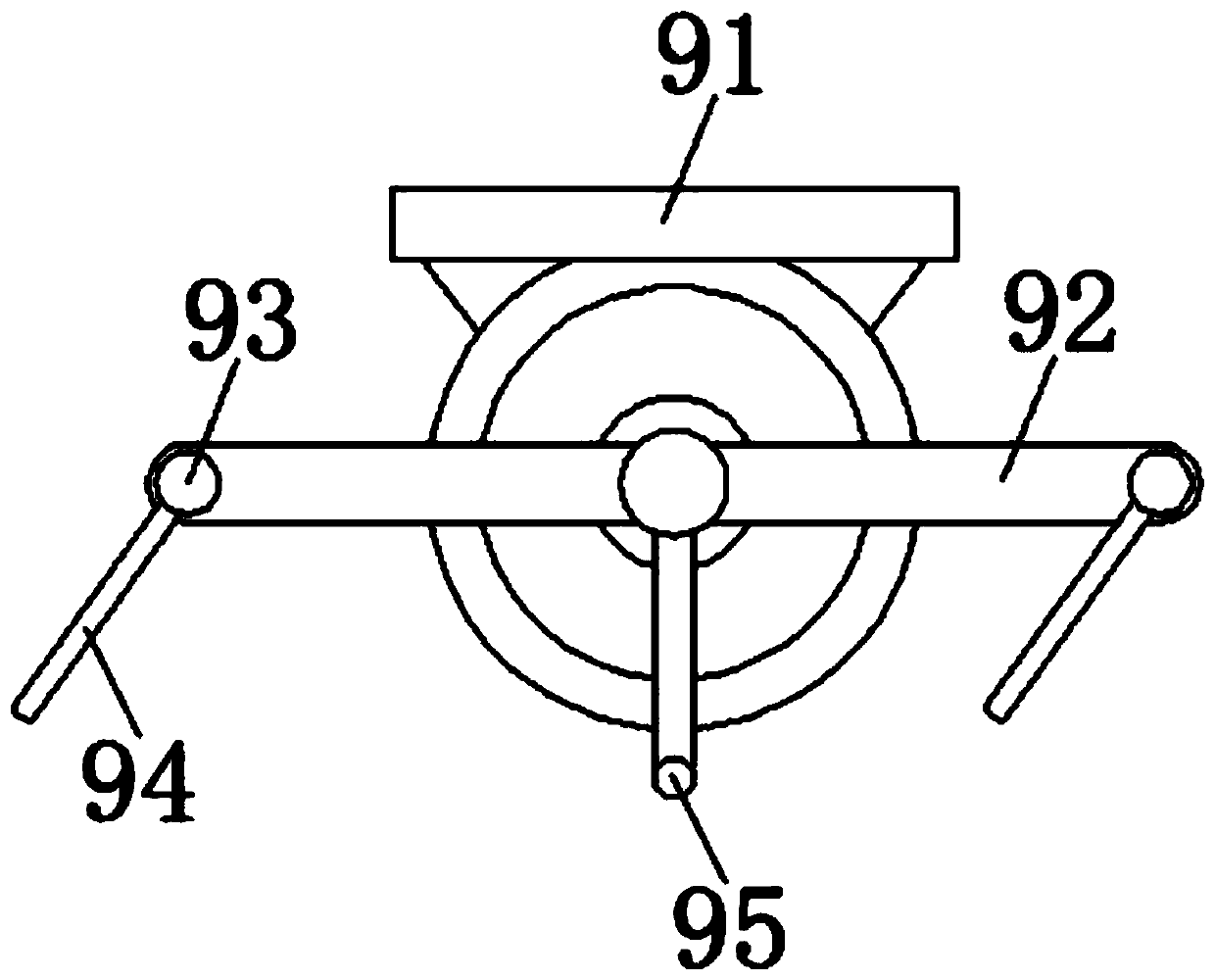

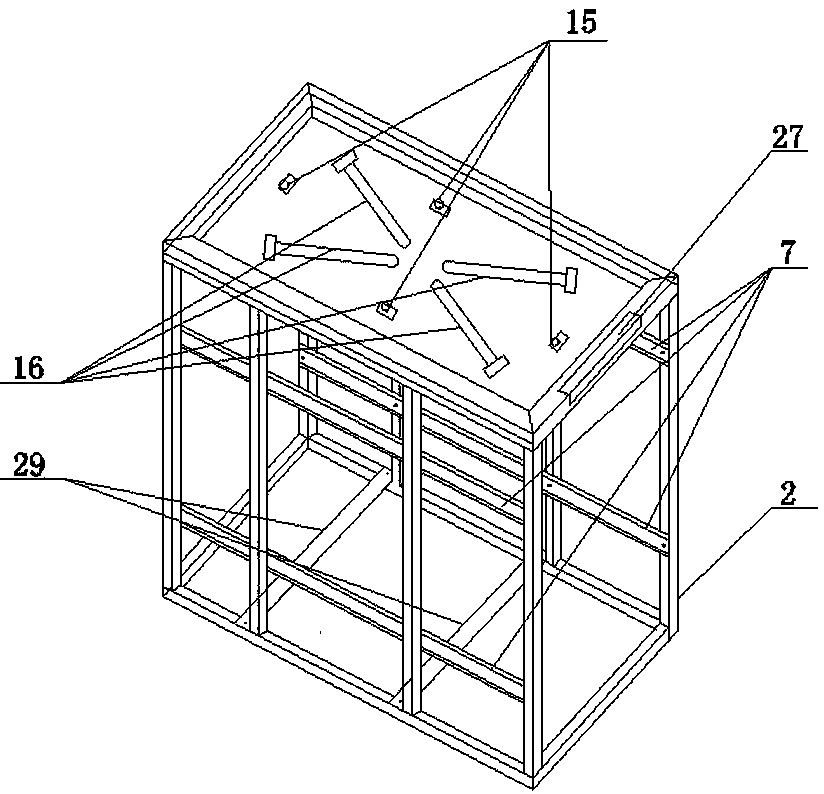

Electromechanical integrated control device

InactiveCN111800991AProvide job stabilityGuarantee job stabilityCasings with display/control unitsCasings/cabinets/drawers detailsMachineMotronic

The invention provides an electromechanical control device. The device comprises an electromechanical device mounting shell, an electromechanical integrated device is connected to the interior of theelectromechanical integrated device mounting shell through bolts; a rack is installed at the bottom of the electromechanical device mounting shell through a machine base, a maintenance frame is longitudinally arranged at a maintenance opening in the left end of the electromechanical device mounting shell and is fastened and connected through a quick-release bolt, and an observation window is embedded in the maintenance frame. A movable mounting plate, a connection lining seat, an electric adjusting rod, a hollow anti-static pad, a bottom blocking seat, an L-shaped clamping seat and a control device main body are arranged; according to the control requirements, a control panel controls the electric adjusting rod to push the movable mounting plate to act in the connecting lining base, afterthe inclination angle of the movable mounting plate is determined, the control operation can be conducted through the control device main body, and the use is convenient.

Owner:张少鹏

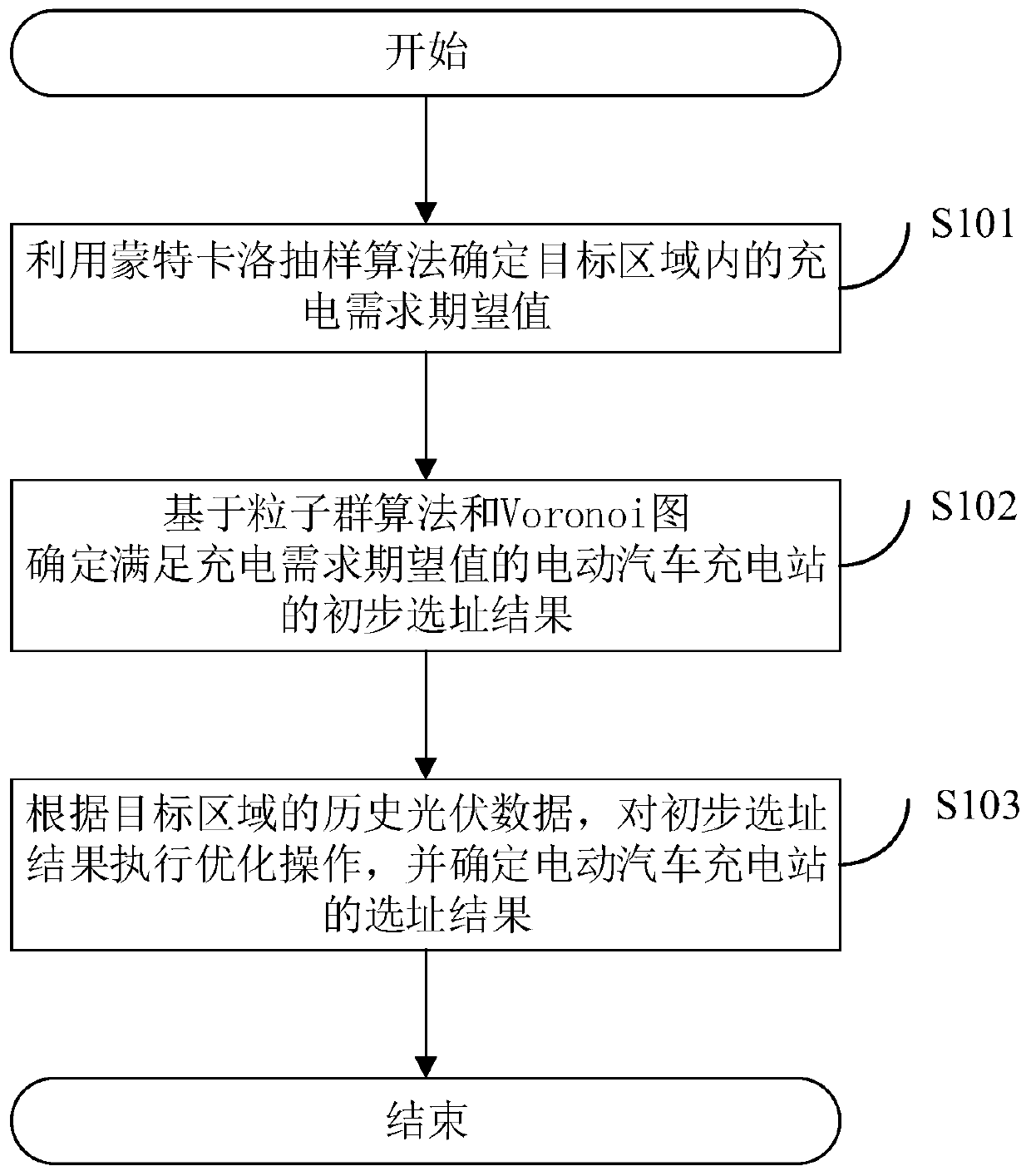

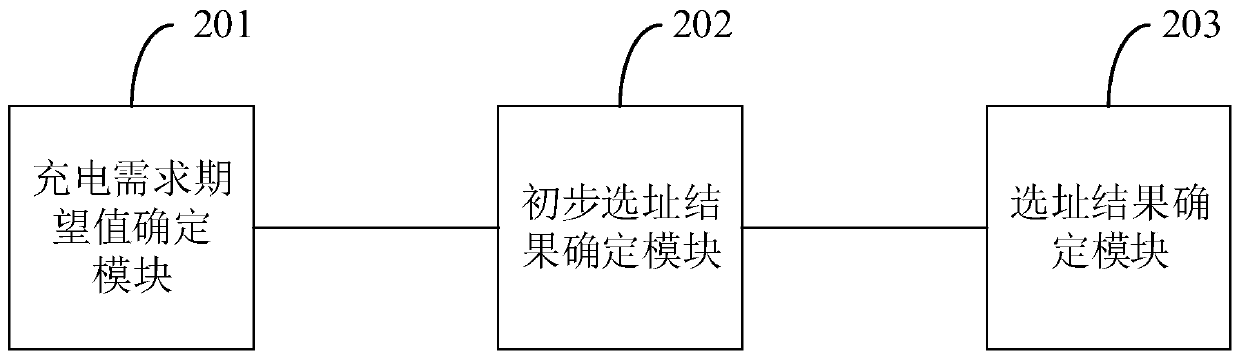

Electric vehicle charging station site selection method and system and related device

InactiveCN110163445AReduce shockGuaranteed operational stabilityForecastingSystems intergating technologiesPower gridPhotovoltaic power station

The invention provides an electric vehicle charging station site selection method. The electric vehicle charging station site selection method comprises: using a Monte Carlo sampling algorithm to determine a charging demand expected value in a target area; determining a preliminary site selection result of the electric vehicle charging station meeting the expected value of the charging requirementbased on a particle swarm algorithm and a Voronoi diagram. and according to the historical photovoltaic data of the target area, executing an optimization operation on the preliminary site selectionresult, and determining a site selection result of the electric vehicle charging station. According to the method, after a preliminary site selection result is determined, optimization operation is performed on the preliminary site selection result according to the historical photovoltaic data; that is to say, the preliminary site selection result is optimized and adjusted according to the photovoltaic power generation condition of the photovoltaic power station in the target area, the photovoltaic power station is used for providing electric power for the electric vehicle charging station, the impact on a power grid during subsequent electric vehicle charging can be reduced, and the operation stability and economy of the power grid are maintained. The invention further provides an electric vehicle charging station site selection system and device and a computer readable storage medium which all have the above beneficial effects.

Owner:GUANGDONG UNIV OF TECH

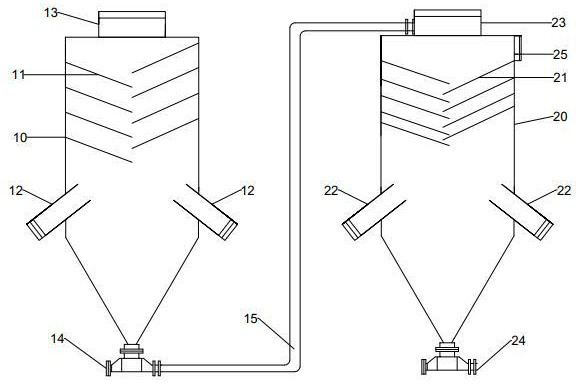

Treatment method of oily sludge and sand

ActiveCN113121076AImprove liquidityGuaranteed separation effectSpecific water treatment objectivesLiquid hydrocarbon mixture productionOil sludgeWasher

The invention relates to a treatment method of an oily sludge and sand, which comprises the following steps of: adding oily sludge and sand into a specially designed feeder, forcibly mixing the oily sludge and sand with water after passing through a distribution plate to obtain homogenization treatment, conveying the treated material to a specially designed sand washer, separating out large-particle-size coarse sand particles under the impact of a multi-stage distribution plate and inlet water, conveying to an impeller agitator, under the action of microbubbles generated by an impeller, and settling the materials in a grading manner, wherein the upper scum layer is high-oil-content sludge, and the lower settling layer is low-oil-content sludge. According to the feeder and the sand washer, oil sludge and sand are fully homogenized through the arrangement of multi-stage distribution plates and a water inlet mixing mode, and coarse sand separation is achieved. The oil content of the high-oil-content sludge separated by the method is greater than or equal to 40%, and the water content is less than or equal to 50%; the oil content in the low-oil-content sludge is less than or equal to 6%, and the water content is less than or equal to 40%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Remote control fire-fighting robot communication method and fire-fighting robot

InactiveCN105959981AImprove channel resource utilization efficiencyLow production costNetwork traffic/resource managementTransmission systemsDistribution methodChannel resource

The present invention relates to the field of the rotor technology, especially to a remote control fire-fighting robot communication method and a fire-fighting robot. The communication method employs the distribution mode with the same frequency range and different bandwidths occupied by different information at the same frequency range to improve the wireless communication channel utilization efficiency. The present invention further provides a fire-fighting robot, and the fire-fighting robot sends information by employing the remote control fire-fighting robot communication method. Through adoption of the distribution mode with the same frequency range and different bandwidths occupied by different information at the same frequency range, the types of information of the remote control are integrated into the same communication frequency range through a reasonable data distribution method in the premise of ensuring the operation stability of the robot so as to effectively improve the channel resource utilization efficiency and reduce the making cost of the robot.

Owner:QINGDAO KRUND ROBOT CO LTD

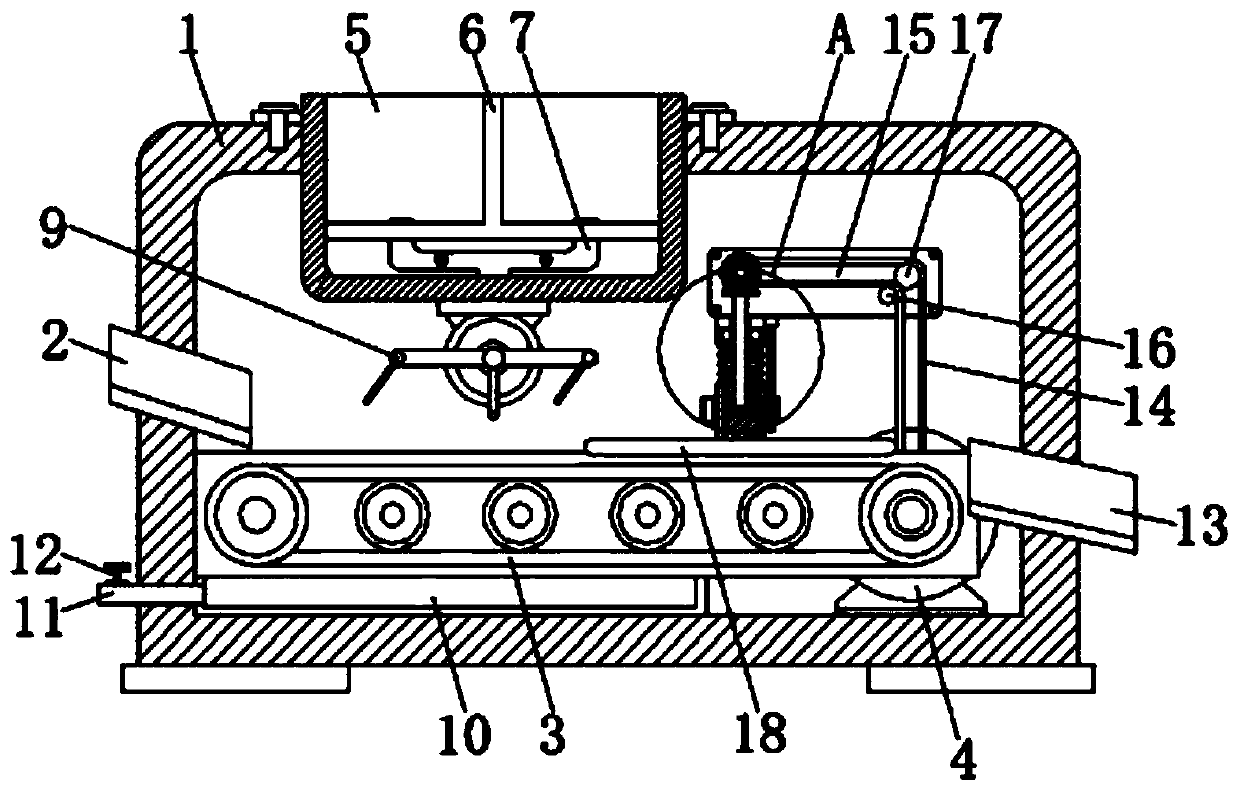

Yoga mat cleaning and sterilizing device and sterilizing method

InactiveCN111299208AGuaranteed drynessSolve the problem of low cleaning efficiencyDirt cleaningCleaning using toolsElectric machineDrive motor

The invention discloses a yoga mat cleaning and sterilizing device and sterilizing method, and relates to the technical field of yoga mats. The yoga mat cleaning and sterilizing device comprises a machine body, wherein a feeding plate is inserted into the middle part of the left side of the machine body, a conveying belt is arranged below the right side of the feeding plate, the conveying belt ismovably arranged at the bottom of an inner cavity of the machine body, the right end of the conveying belt is driven by a driving motor, the bottom of the driving motor is fixedly connected to the right side of the inner bottom of the machine body, a box body is arranged above the left side of the top of the conveying belt, and the box body is fixedly arranged in the left side of the top of the machine body. According to the yoga mat cleaning and sterilizing device, a yoga mat is cleaned in a manner of firstly applying a cleaning liquid and then applying water, so that dirt, sweat and the residual cleaning liquid on the surface of the yoga mat are removed, and meanwhile, the cleaned yoga mat is wiped through a wiping mechanism, so that the dryness of the yoga mat is further ensured, and the problem that at present, a yoga mat is cleaned manually, thereby causing the low efficiency is solved.

Owner:焦玉林

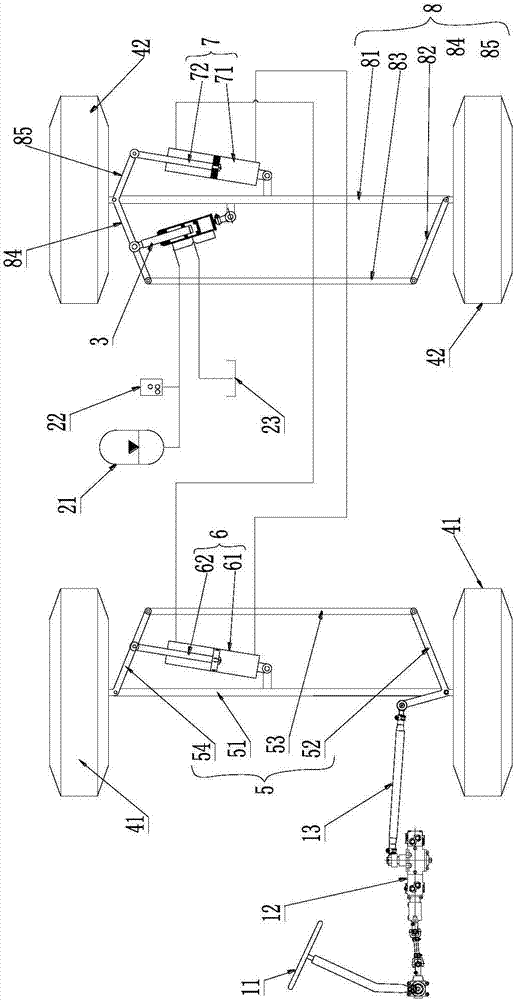

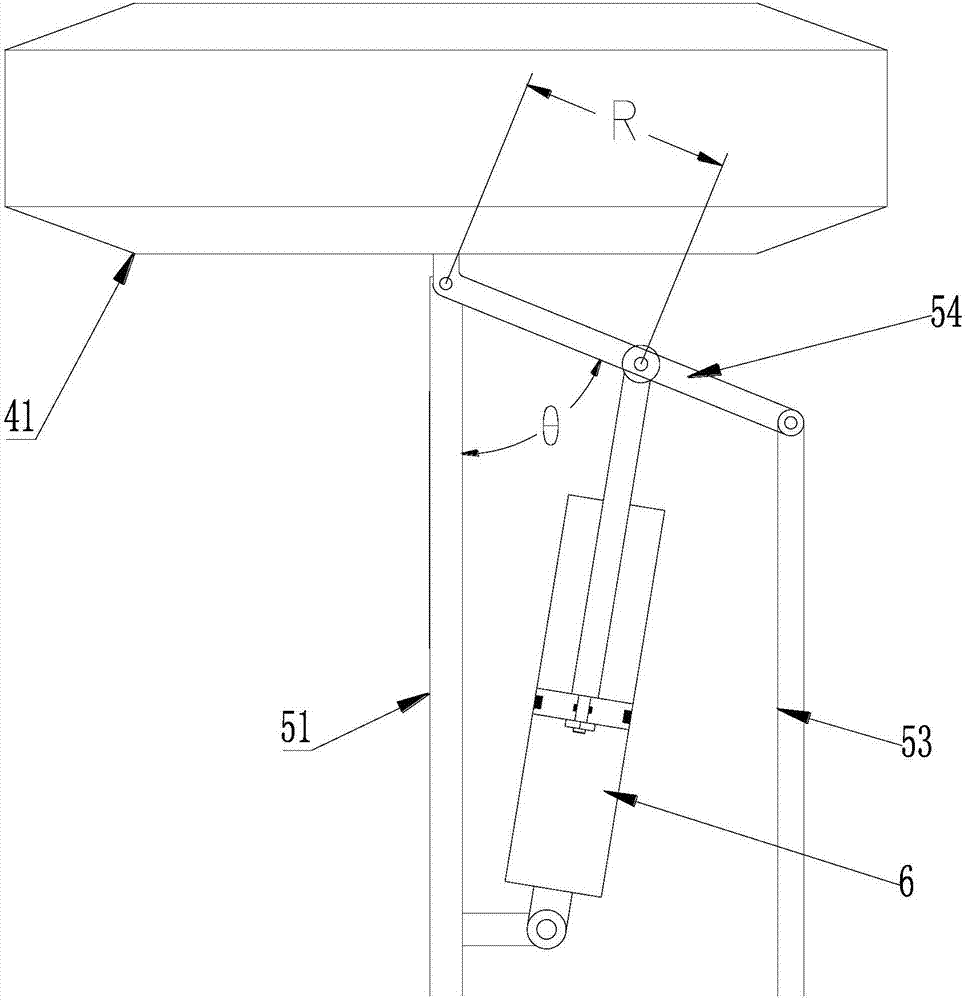

Steering axle linkage system and crane

The invention discloses a steering axle linkage system and a crane. The steering axle linkage system comprises a first oil cylinder, a second oil cylinder, a front steering axle and a rear steering axle. The first oil cylinder is arranged on the front steering axle and can synchronously stretch out and draw back along with steering of the front steering axle, and the second oil cylinder is arranged on the rear steering axle and can drive the rear steering axle to conduct steering. A rodless cavity of the first oil cylinder communicates with one in a rodless cavity and a rod cavity of the second oil cylinder, a rod cavity of the first oil cylinder communicates with the other one in the rodless cavity and the rod cavity of the second oil cylinder, thus stretching out and drawing back of thefirst oil cylinder can make the second oil cylinder to synchronously stretch out and draw back in a linkage mode, and the second oil cylinder stretches out and draws back so as to drive the rear steering axle to conduct steering to enable the steering direction of the rear steering axle to be opposite to that of the front steering axle. The steering axle linkage system is simple in structure and accurate in control.

Owner:ZOOMLION HEAVY IND CO LTD

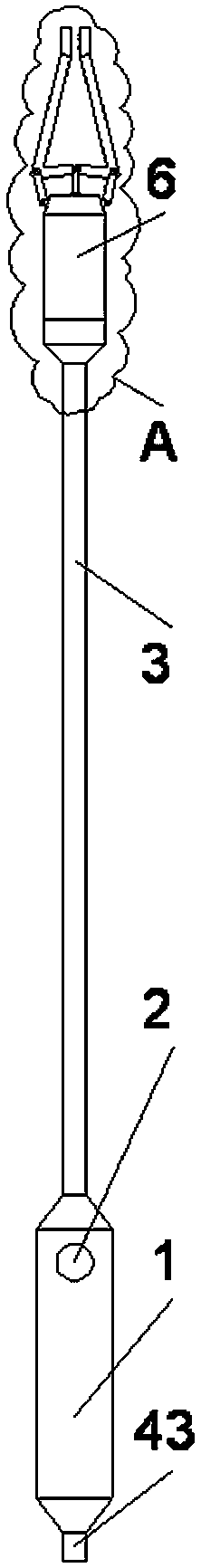

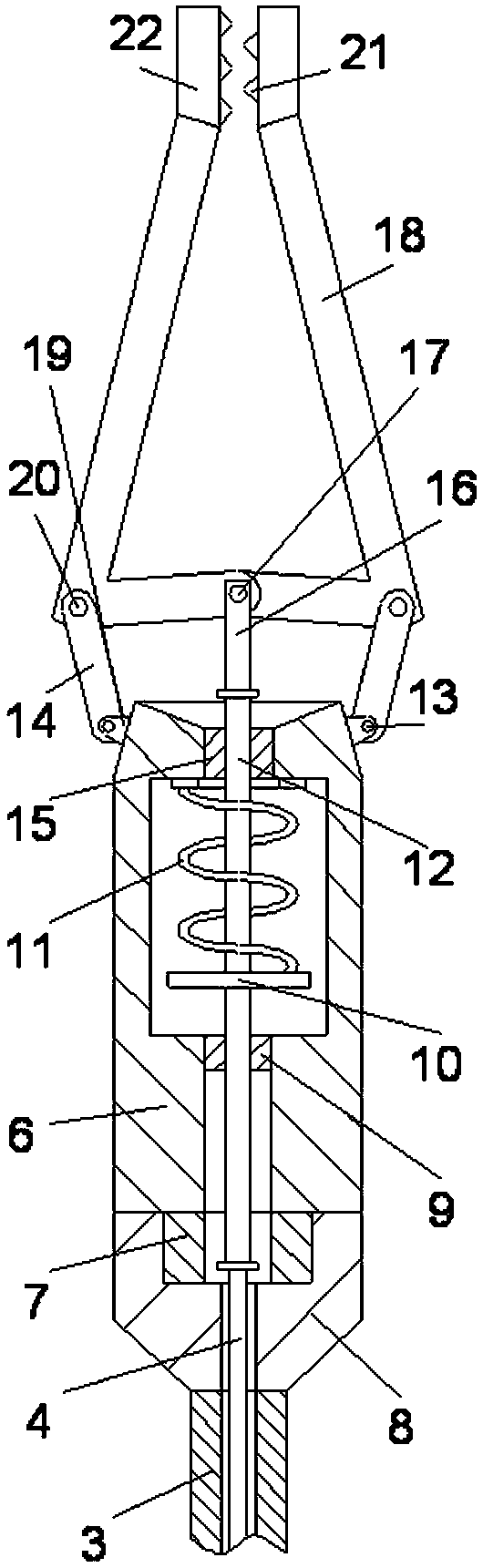

Intestinal anastomosis machine for infants

The invention discloses an intestinal anastomosis machine for infants. The intestinal anastomosis machine comprises an operating device and an auxiliary device, wherein the operating device comprisesa grasping handle, a wire passing pipe and a motion head; a hydraulic cylinder is mounted at the lower part of the inner side of the grasping handle; keys are mounted at the upper part of the front side of the grasping handle; an electricity connector is mounted at the bottom end of the grasping handle; the wire passing pipe is fixedly mounted at the top end of the grasping handle; a threaded seatis fixedly mounted at the top end of the wire passing pipe; the motion head is rotatably connected to the upper part of the threaded seat; and a pull rope is fixedly mounted at the top end of the hydraulic cylinder. The intestinal anastomosis machine disclosed by the invention is reasonable in structural design and ideal in matching effects; during operation, the situation that the fixation of the end surface is not firm, so that deflection and malposition are generated can be avoided; when the intestinal anastomosis machine is applied to a tiny intestine, the sewing operation is convenient to perform through arranged auxiliary equipment, and the surgery effect is better; compared with a rotation closing manner, the intestinal anastomosis machine disclosed by the invention is stable in clamping, and the situation that an intestine body slides from the open end can be avoided; and the technique of the intestinal anastomosis machine is subsidized by the 2017 National Natural Science Foundation of China (81770512) and 2018 "Sanming Project "(SZSM201812055) of Shenzhen city National Health and Family planning Commission.

Owner:SHENZHEN CHILDRENS HOSPITAL

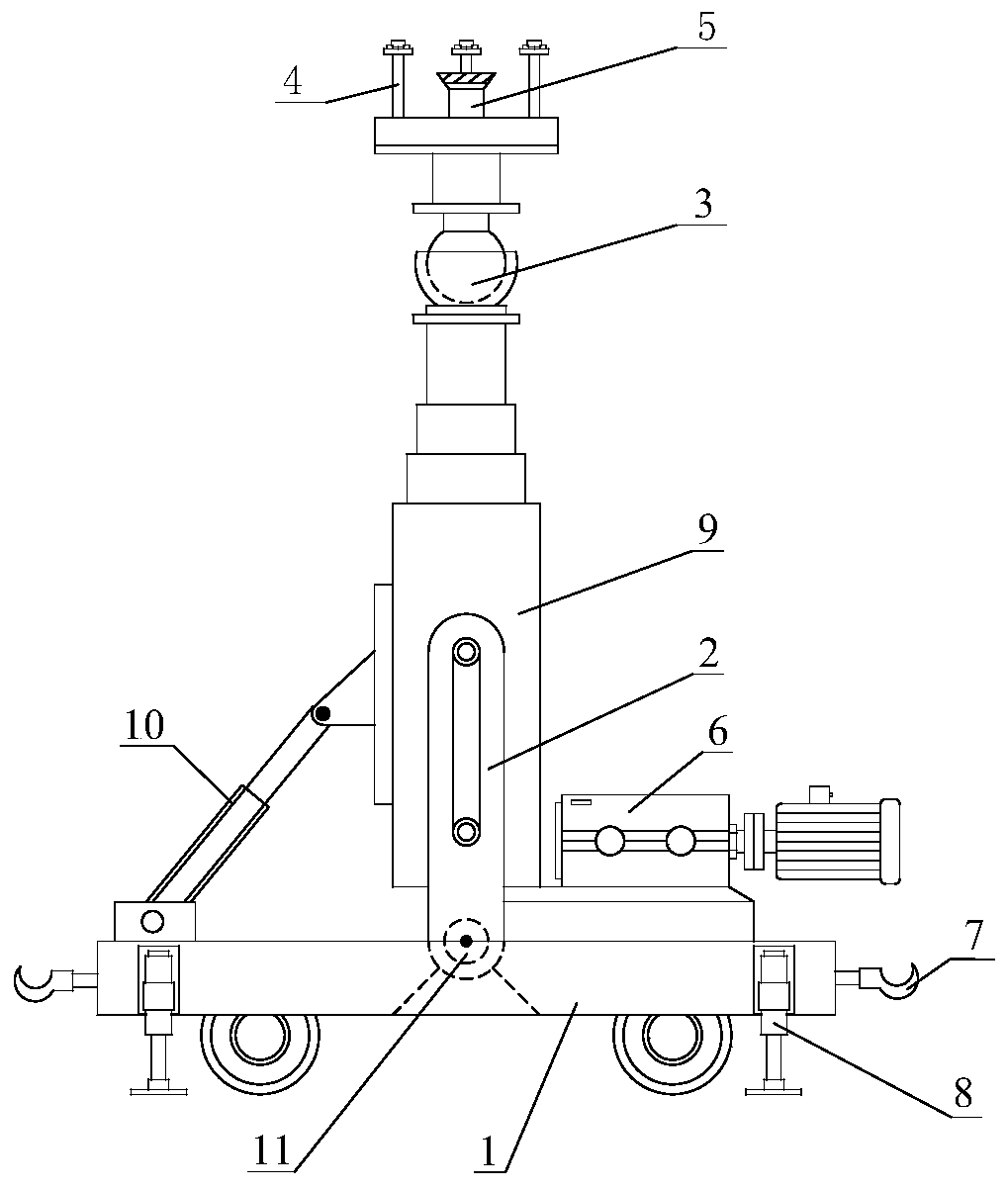

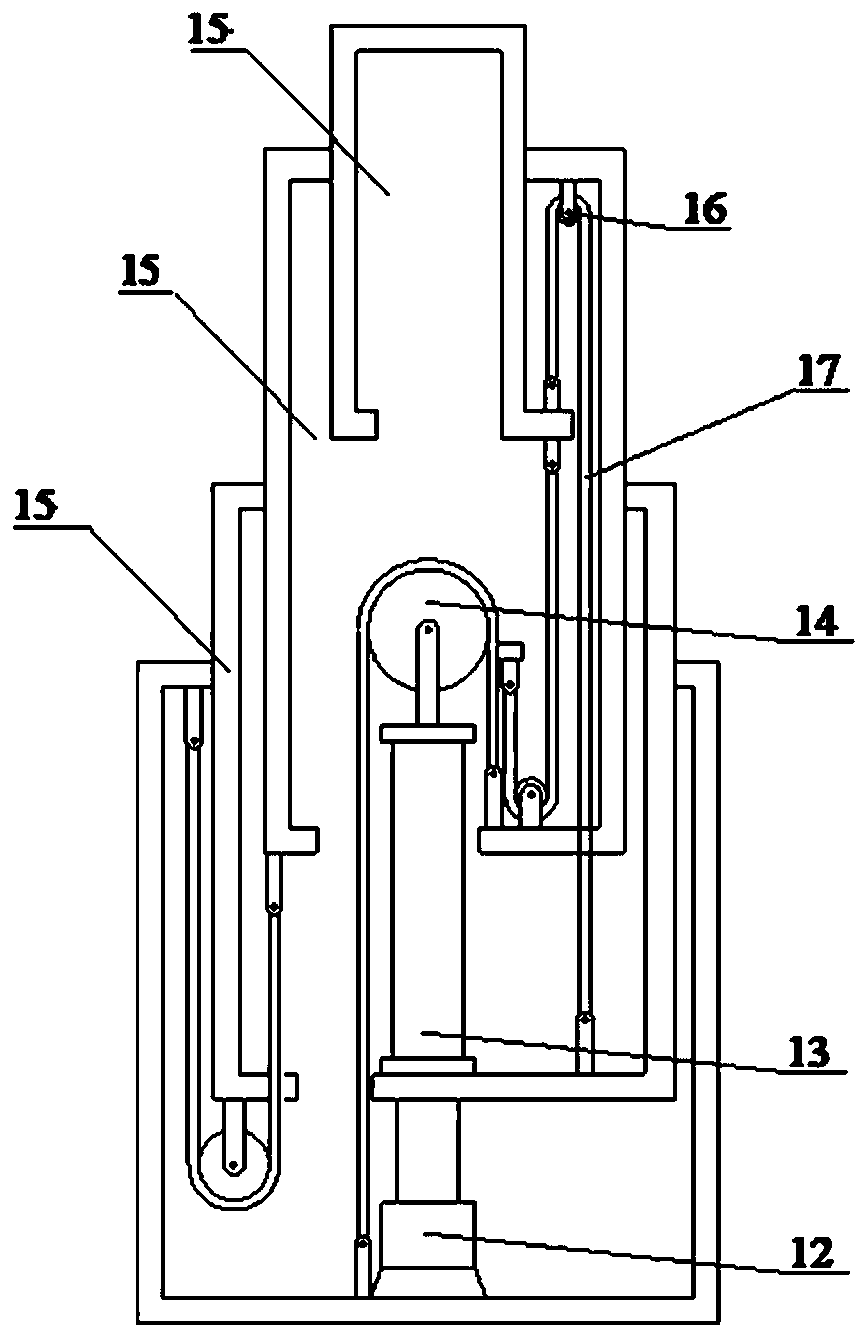

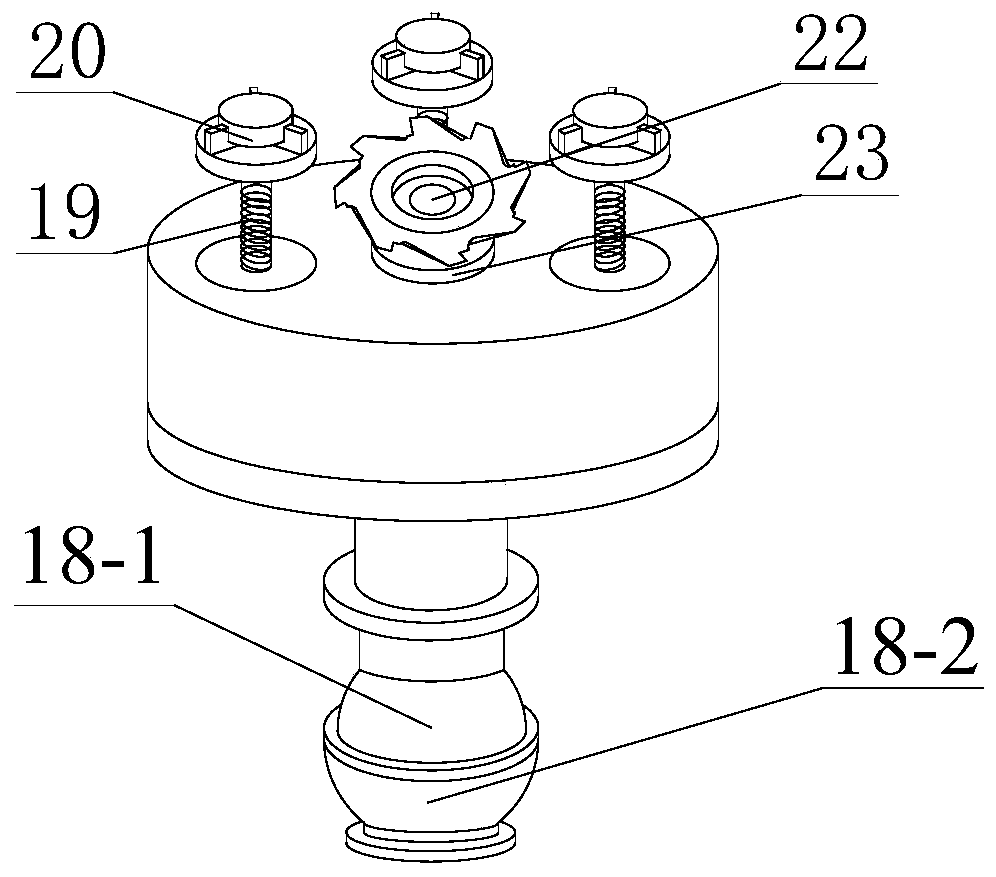

Cutting and supporting dual-purpose mechanical device and method for treating tunnel surrounding rock

InactiveCN111022094AAvoid skiddingSteady support effectTunnelsProtective coversSupporting systemArchitectural engineering

The invention discloses a cutting and supporting dual-purpose mechanical device and method for treating tunnel surrounding rock, and belongs to the technical field of tunnel and underground engineering auxiliary construction devices. The device is convenient to move by arranging a travelling mechanism, and by adjusting the lifting height and the tilt angle of a continuous pushing jack, a cutting and supporting system is close to the surrounding rock. A cutting mechanism and a hydraulic jacking mechanism are controlled correspondingly by a controller, two working modes of surrounding rock cutting and surrounding rock supporting are provided, the device is convenient to use, the time and labor are saved, the safety of operation is high, the entire device is small in size and can be suitablefor various tunnel environments, and the practicability is high.

Owner:CHANGAN UNIV

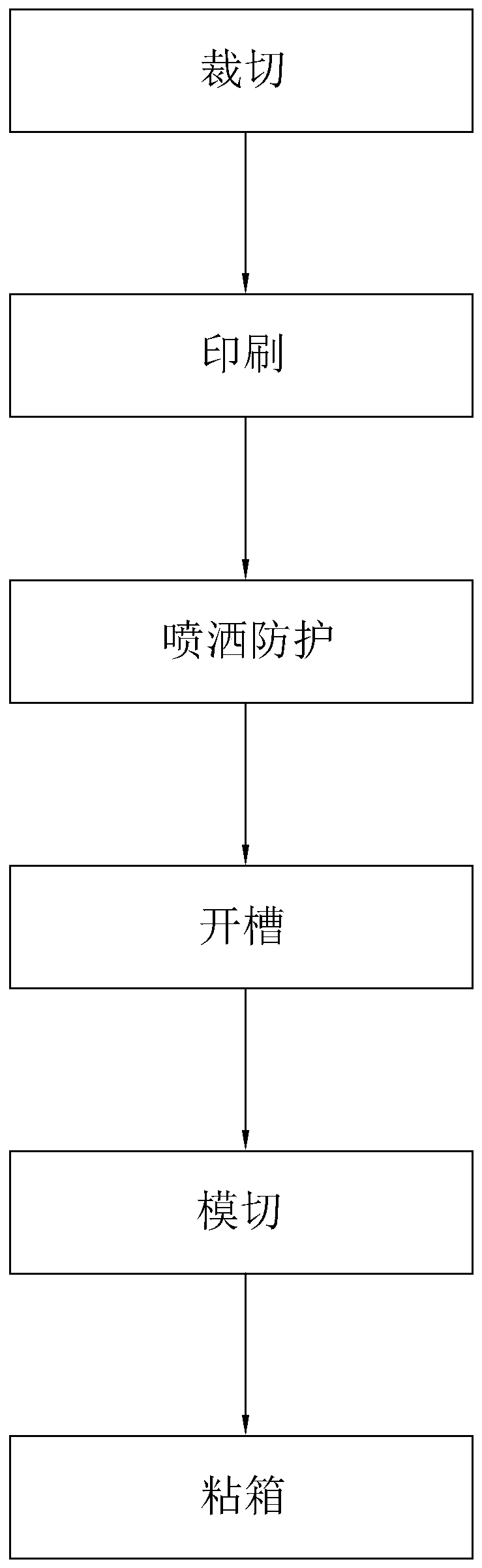

Manufacturing method of corrugated carton

InactiveCN111037991AImprove protectionReduce generationBox making operationsPaper-makingCartonPaperboard

The invention discloses a manufacturing method of a corrugated carton, and relates to the technical field of corrugated paper packaging. The manufacturing method comprises the following steps of 1, cutting, specifically, cutting a corrugated paper raw material to obtain a corrugated paperboard; 2, printing, specifically, conveying the cut corrugated paperboard to a printing machine, selecting an image-text printing plate, printing the corrugated paperboard, and obtaining a printed matter; 3, spraying protection, specifically, evenly spraying a protective agent to the surface of the printed matter, and obtaining a coated semi-finished product after complete drying; 4, slotting, specifically, slotting the dried coated semi-finished product through a slotting machine to obtain a corrugated paper sample plate; 5, die cutting, specifically, performing die cutting on the grooved corrugated paper sample plate through a die cutter, and obtaining a die cutting sample plate; and 6, box pasting,specifically, folding and bonding the die cutting sample plate through a carton bonding machine to obtain a corrugated carton finished product. In the actual application process, printed patterns arenot prone to being stained, and the overall quality of the corrugated carton can be guaranteed.

Owner:上海明丰印务有限公司

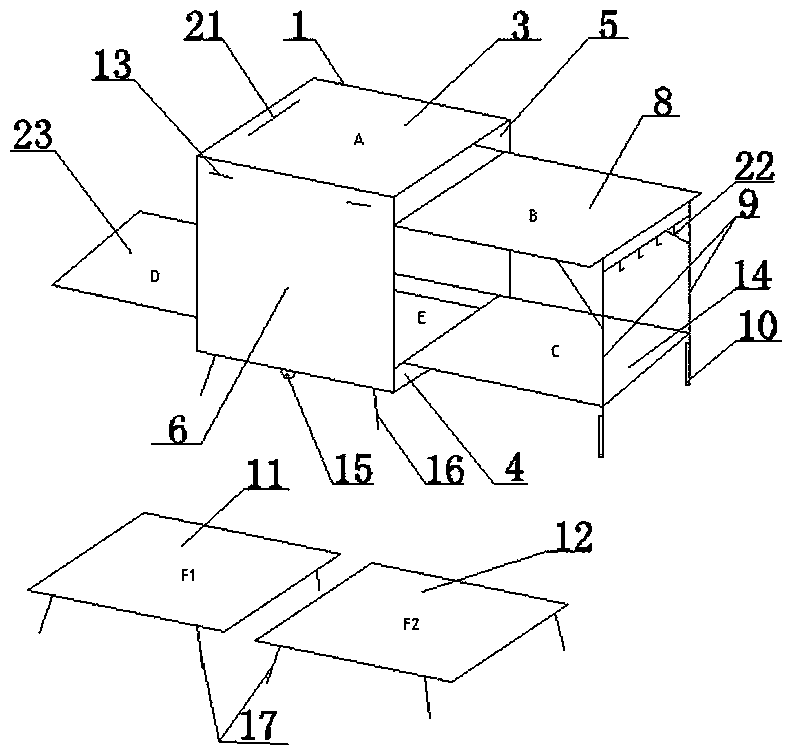

Multifunctional portable kitchen tool kit

The invention relates to a multifunctional portable kitchen tool kit. The multifunctional portable kitchen tool kit comprises a cabinet body; the cabinet body comprises a rectangular framework; the upper part of the rectangular framework is provided with an operation platform; the bottom of the rectangular framework is provided with a bottom plate; the front side and the back side of the rectangular framework are provided with surface panels; a plurality of slide rails are symmetrically arranged at the front side and the back side of the internal part of the rectangular framework; the internalpart of the rectangular framework is connected with an upper slide supporting plate and a lower slide supporting plate through the slide rails; the back surface internal side of the upper slide supporting plate is connected with telescopic foldable supporting legs through hinge joint; the bottom of each telescopic foldable supporting leg is provided with a height micro adjusting device; the leftside and the right side of the rectangular framework are connected with surface panels through detachable hinges; the surface panels on the left side, the right side, the front side and the back sideof the rectangular framework are provided with lock catches matching each other. The multifunctional portable kitchen tool kit is small in size; complete articles are stored in the multifunctional portable kitchen tool kit; the multifunctional portable kitchen tool kit is convenient for vehicle carrying, pulling, moving, and transportation; kitchen tools, cooking utensils, pots, tableware, light fixture, tables, and chairs can be stored in the cabinet body; unfolding and storage are convenient; and the multifunctional portable kitchen tool kit is simple and convenient to use.

Owner:曹玲

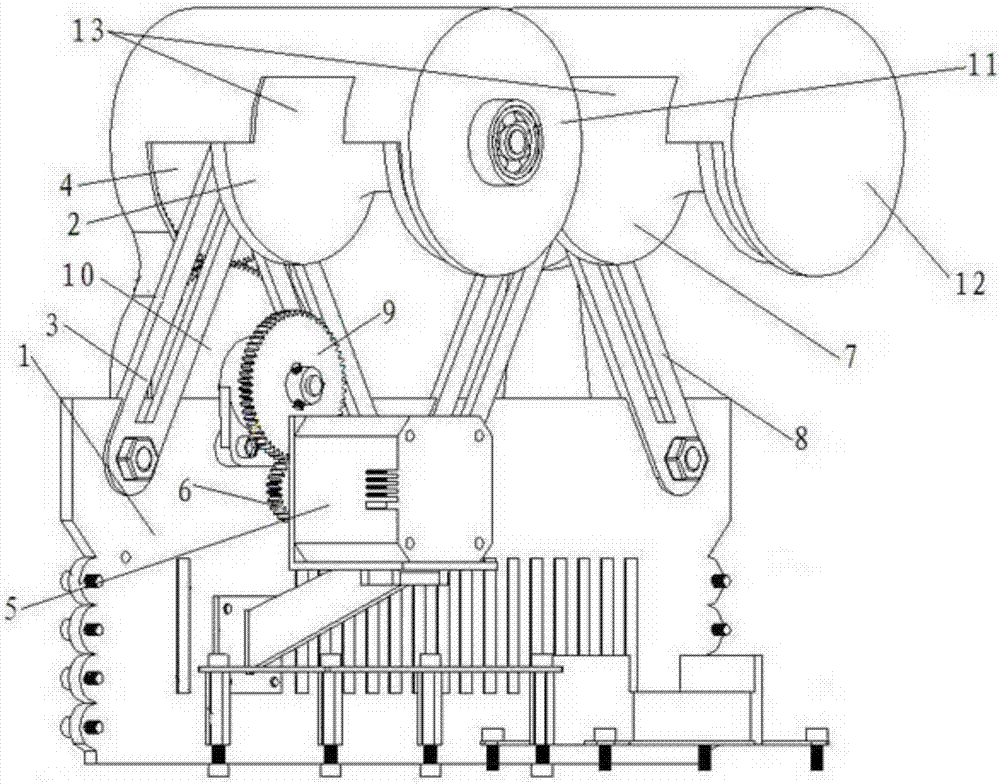

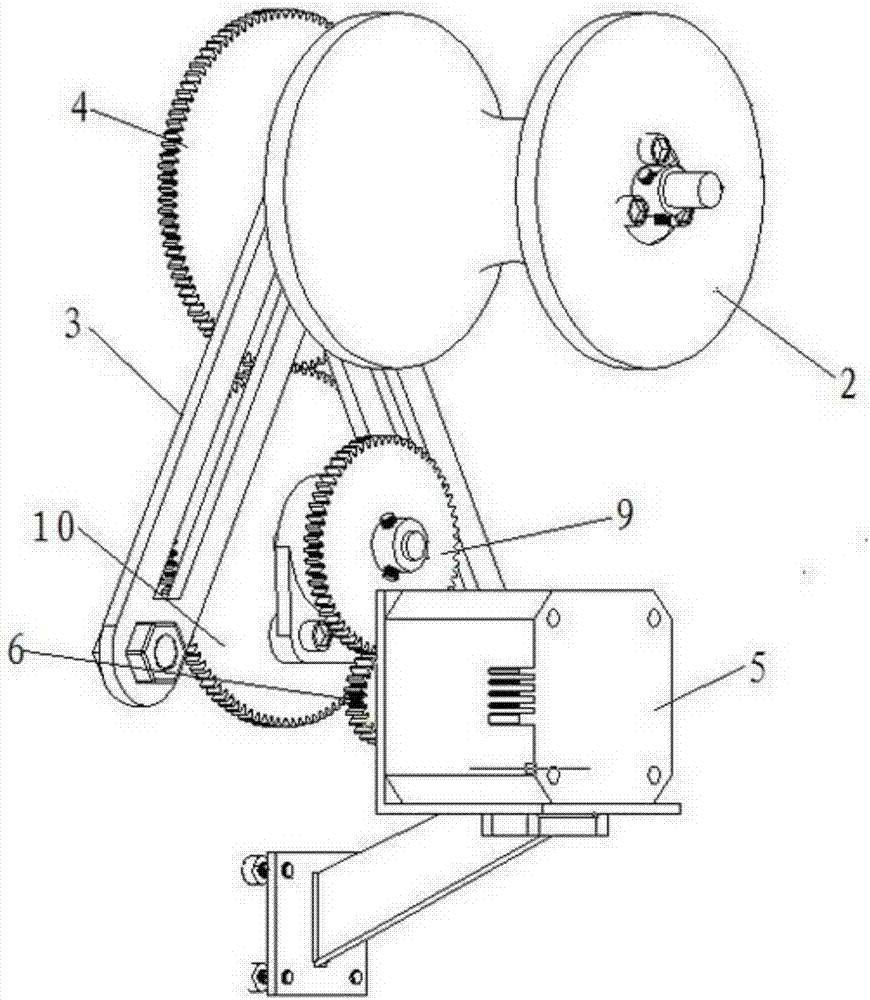

Driving device for automatic spraying device of high-voltage power line

InactiveCN107017581AEnsure personal safetySimple and fast operationSpraying apparatusApparatus for overhead lines/cablesDrive wheelEngineering

The invention discloses a driving device for an automatic spraying device of a high-voltage power line. The driving device comprises an equipment carrier, an equipment carrier driving device, an equipment carrier balancing device and a high-voltage power line guide rail, wherein the equipment carrier driving device comprises a driving wheel, a driving wheel fixing bracket and a driving device for the driving wheel; the driving wheel comprises a first groove idler wheel; a driven gear which is concentric with the first groove idler wheel is arranged on a side wall of the first groove idler wheel; a trolley balancing device comprises a driven wheel and a driven wheel hinge bracket; the driven wheel is arranged as a second groove idler wheel; a wheel axle of the second groove idler wheel is in rolling connection with the upper end of the driven wheel hinge bracket; the lower end of the driven wheel hinge bracket is hinged with the right upper end of the equipment carrier. The driving device has the characteristics of simple and convenient operation, safety, reliability and high working efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

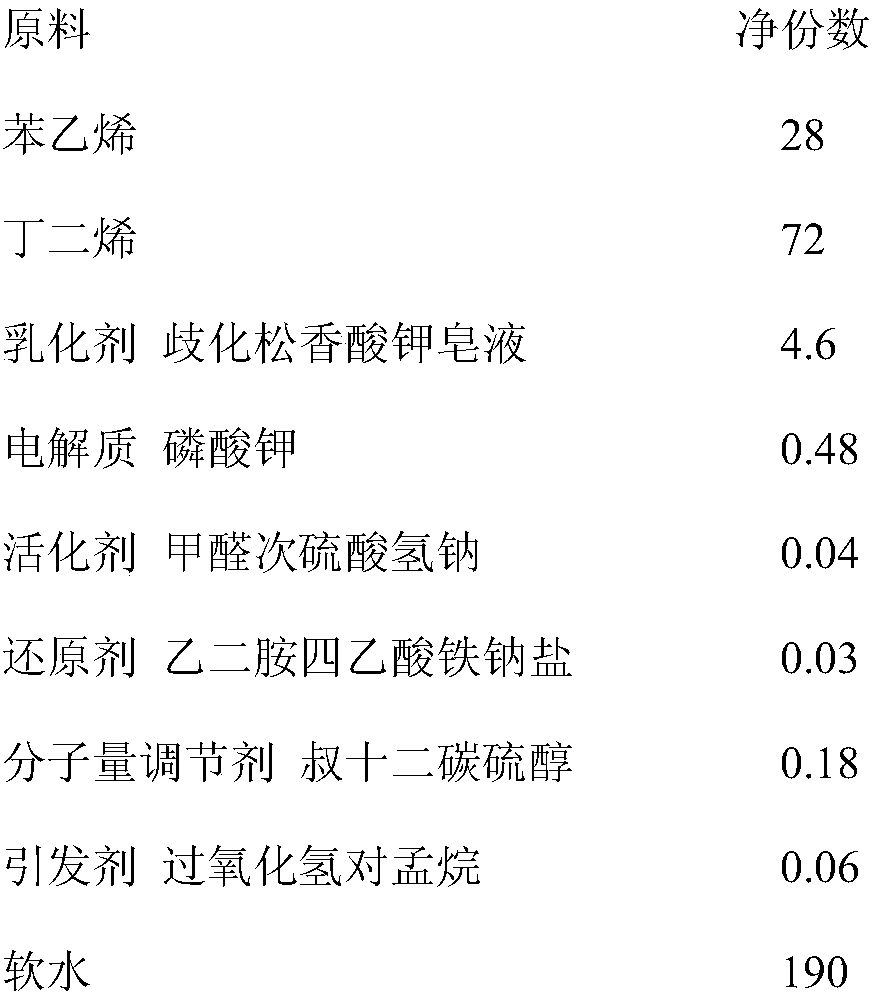

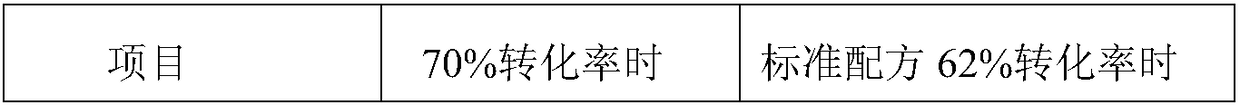

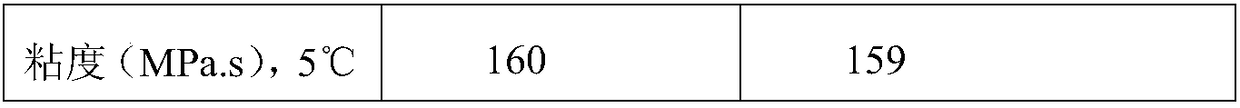

Preparation method of styrene butadiene rubber

ActiveCN108239226AImprove Primary UtilizationMitigating performance degradationButadiene DioxideLatex rubber

The invention provides a preparation method of styrene butadiene rubber. The preparation method comprises the following steps: performing emulsion polymerization of styrene and butadiene, wherein whenthe conversion rate of total monomers for emulsion polymerization reaches 58-62%, a sylvite aqueous solution is added into the reaction system of emulsion polymerization, and reacting is further conducted to obtain styrene butadiene rubber. In the method, viscosity of a polymerization system with a high conversion rate can be controlled to a viscosity level with low conversion rate, then the viscosity of the system is kept at a relatively low state, and the problems of performance degradation of the styrene butadiene rubber and decrease of latex heat transfer and stability caused by excessively high viscosity are relieved. Thus, the conversion rate of emulsion polymerization can be improved while the product performance and operation stability are maintained. The one-time utilization rateof the monomers is increased, the recycling energy consumption is reduced, and the production capacity of the polymerization equipment can be enhanced; and therefore, the method has great significance.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com