Vector water-jet propeller and vector water-jet propulsion method

A technology of water jet propulsion and propeller, which is applied in the direction of propulsion components, ship propulsion, ship construction, etc., can solve the problems of large installation and arrangement space of water jet propulsion pump, high requirements for upper control algorithm and high manufacturing cost, etc. Low processing and manufacturing costs, reduced assembly complexity, and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

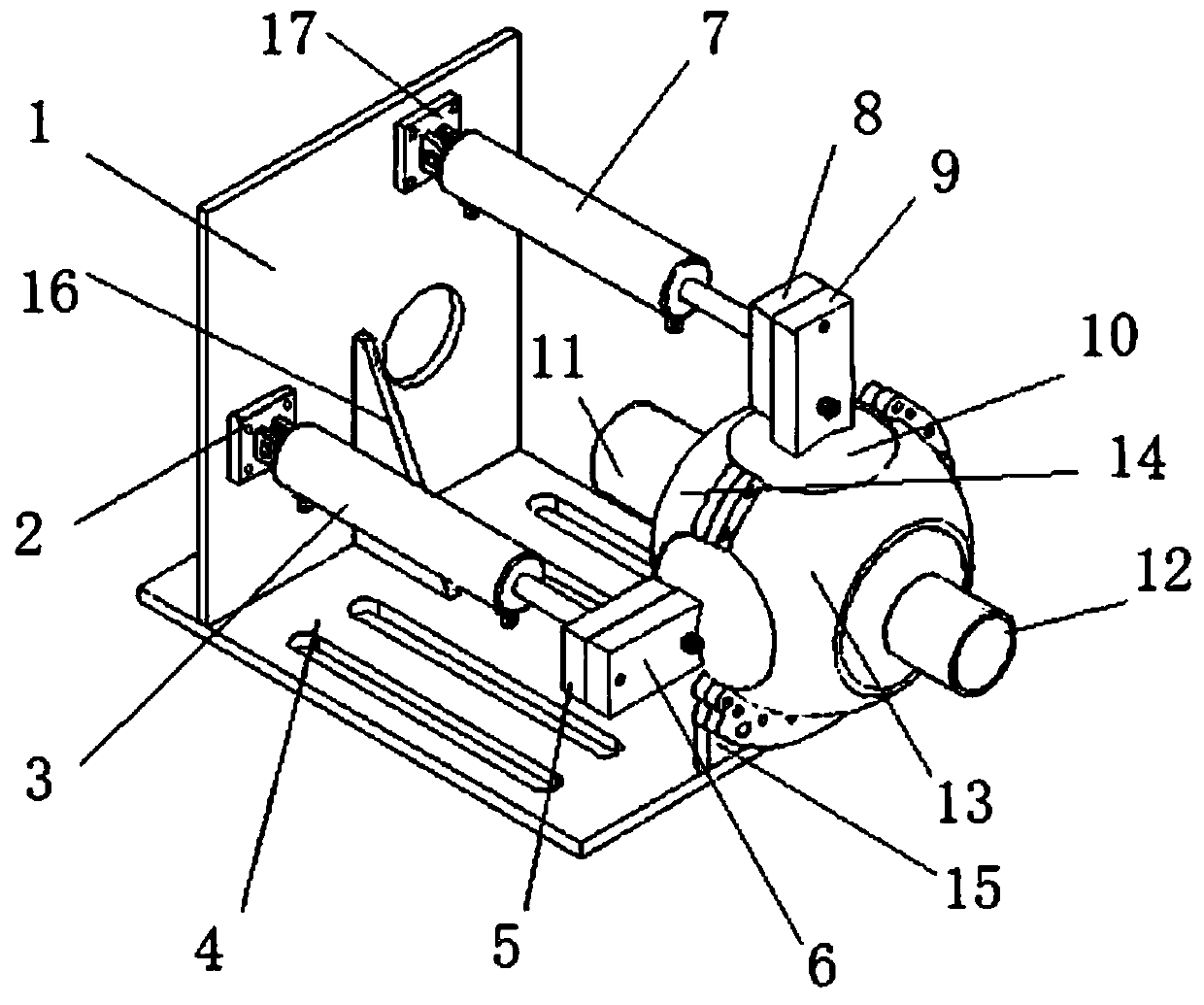

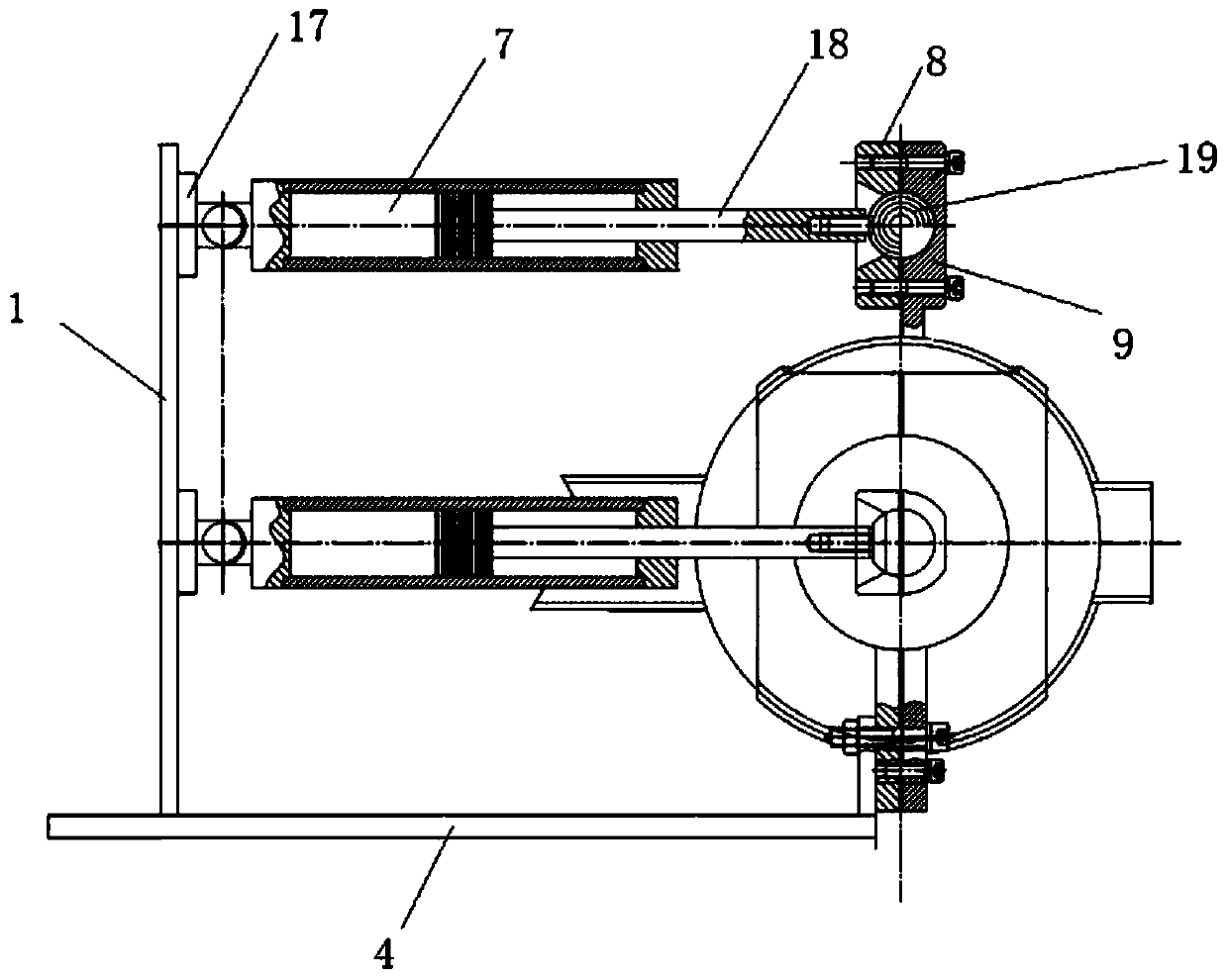

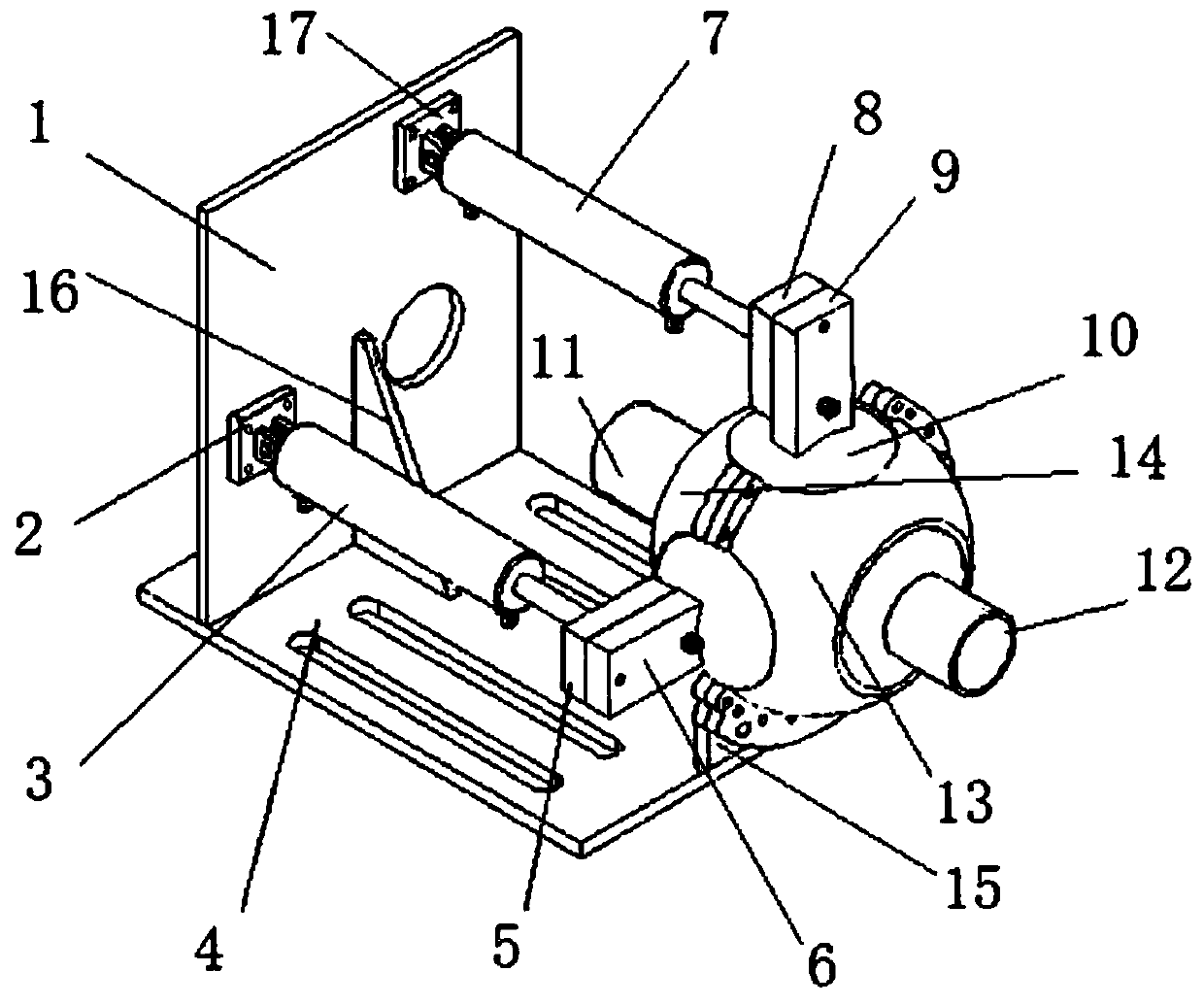

[0044] A specific embodiment of the present invention discloses a vector water jet propeller, comprising: a propeller bracket, a servo hydraulic cylinder assembly installed on the propeller bracket, a propeller shell and a water jet propeller inner tank. The oil cylinder assembly controls the angle of pushing the inner tank of the water jet propeller by controlling the expansion and contraction of the piston rod, and further controls the water spray angle of the vector water jet propeller. The water jet propeller liner is installed inside the propeller shell and can rotate in the propeller shell. The water jet propeller liner is driven to rotate by the servo hydraulic cylinder assembly to realize the vector adjustment of the water spray angle.

[0045]In this embodiment, the water jet propulsion tank is composed of the propeller tank 10, the first ball bracket 6, the second ball bracket 9, the water inlet pipe 14 and the drain pipe 13, through the first hydraulic cylinder 3 and...

Embodiment 2

[0078]This embodiment provides a vector water jet propulsion method of a vector water jet propeller, using the vector water jet propeller provided in Embodiment 1 as a power source, and adjusting the reverse propulsion by adjusting the water jet angle of the vector water jet propulsion Angle, and then realize the adjustment of the attitude and direction of travel of the ship or amphibious vehicle.

[0079] The specific steps of the vector water jet propulsion method of the present embodiment include:

[0080] Step 1. Connect the circuit and the oil circuit, and conduct the voltage stability test of the circuit and the cleanliness and safety inspection of the oil in the oil circuit.

[0081] Step 2. The controller sends the control amount to the servo solenoid valve; the two servo solenoid valves respectively control the expansion and contraction of the piston rod of the servo hydraulic cylinder assembly.

[0082] Step 3, through the expansion and contraction of the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com