Driving device for automatic spraying device of high-voltage power line

A driving device and automatic spraying technology, applied in the direction of spraying device, overhead line/cable equipment, etc., can solve the problems of reduced reliability of transmission power, complex power distribution environment, high cost, etc., to achieve easy operation, ensure personal safety, reduce The effect of small consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

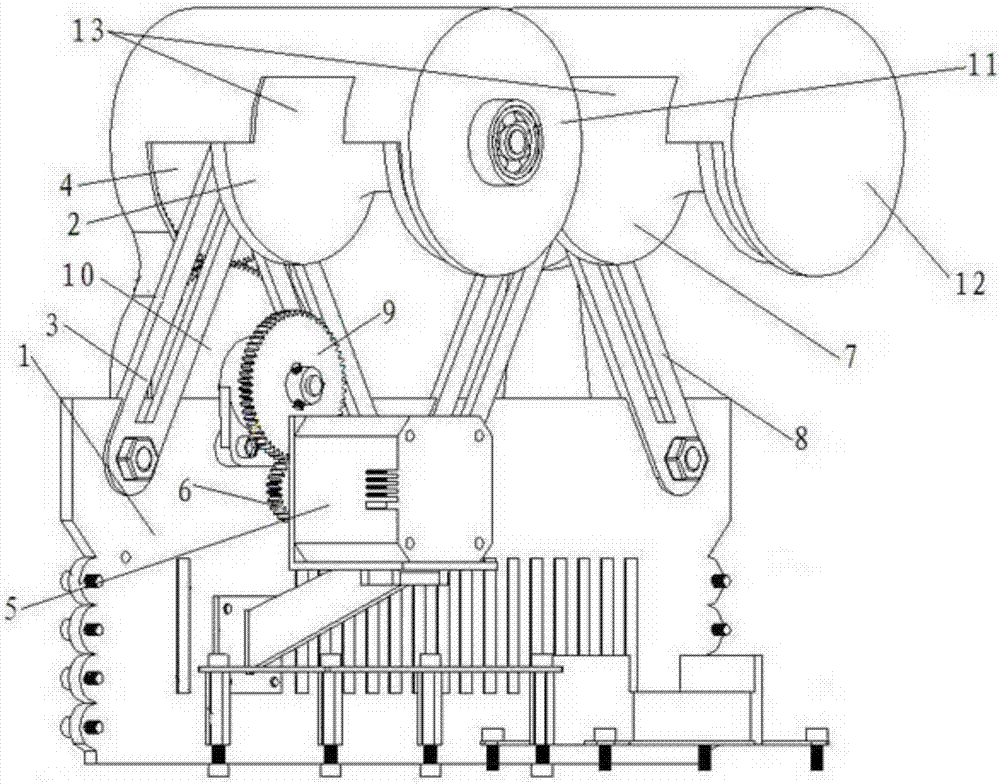

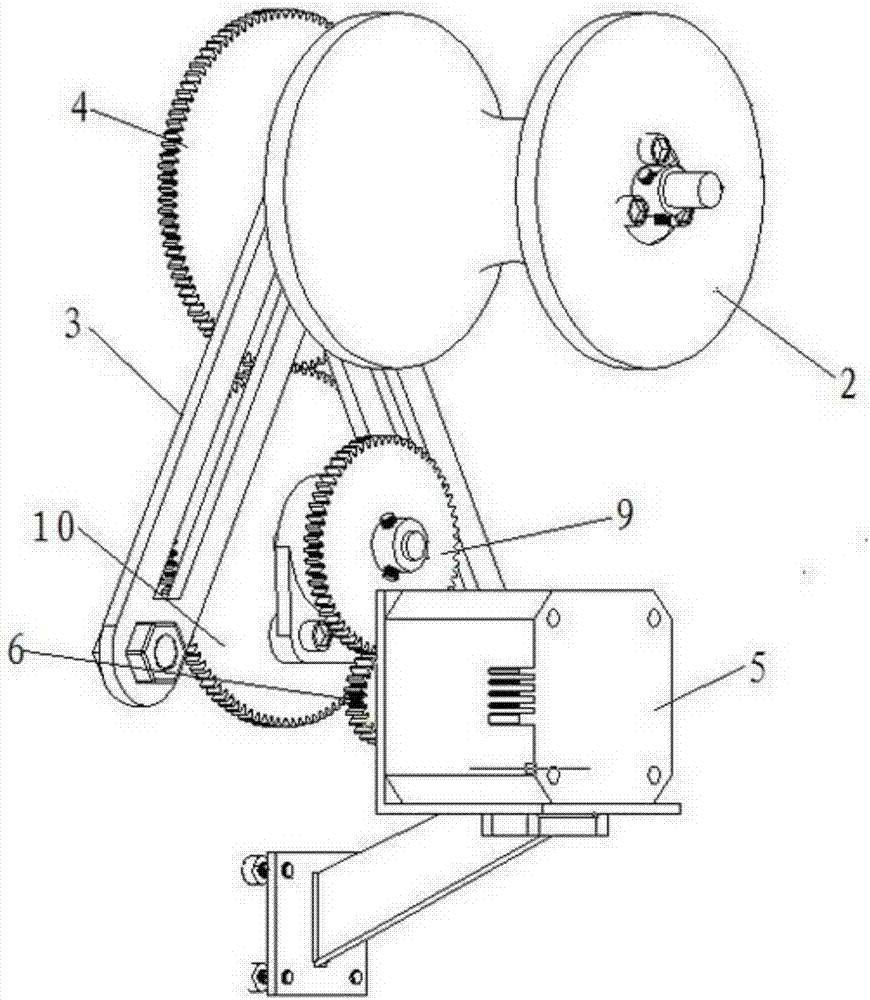

[0021] Depend on Figure 1-2 It can be seen from the illustrated embodiment that this embodiment includes an equipment carrier 1, an equipment carrier driving device, an equipment carrier balancing device and a high-voltage line guide rail; the device carrier driving device includes a driving wheel, a driving wheel fixing bracket 3 and a driving wheel driving device , the driving wheel comprises a first grooved roller 2, a driven gear 4 coaxial with the first grooved roller 2 is provided on the side of the first grooved roller 2, the wheel shaft of the driving wheel and the upper end of the driving wheel fixing bracket 3 Rolling connection, the lower end of the driving wheel fixed bracket 3 is fixedly connected with the upper left end of the equipment carrier 1, the driving wheel driving device includes a driving motor 5 arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com