Patents

Literature

46results about How to "Improve Primary Utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Casting method for polycrystalline silicon ingot

ActiveCN104562192AImprove photoelectric conversion efficiencyShorten the production cyclePolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

The invention discloses a casting method for a polycrystalline silicon ingot. The casting method comprises a crucible pretreatment process and an ingot casting process, wherein the crucible pretreatment process comprises the steps of preparing silicon nitride slurry from silicon nitride powder, silica sol and water, spraying the silicon nitride slurry at the side wall and bottom of a crucible, and spraying other silicon nitride slurry at the bottom of the crucible; and soaking silicon powder in an acid solution with strong oxidizing property for 30-60 minutes, then, separating, washing to be neutral, drying the washed silicon powder, next, preparing slurry from the dried silicon powder, the silica sol and the water, spraying the slurry at the bottom of the obtained crucible, and sintering the treated crucible; and the melting stage of the ingot casting process comprises the step of immediately opening a cage to cool when a silicon material floats from the bottom of the crucible. The polycrystalline silicon ingot produced by using the casting method disclosed by the invention has the characteristics of short production period, low cost, long silicon ingot minority carrier lifetime, high primary silicon material utilization ratio and the like, and the obtained polycrystalline silicon wafer has the characteristics of uniform grain size, small defect density, high photoelectric conversion efficiency and the like.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

Preparation method of black-edge-free high-efficiency polycrystalline silicon ingot

ActiveCN104328490AImprove photoelectric conversion efficiencyLow efficiency leakage ratio is reducedPolycrystalline material growthSingle crystal growth detailsMolten siliconBlack edge

The invention discloses a preparation method of a black-edge-free high-efficiency polycrystalline silicon ingot, which comprises the following steps: applying a high-purity quartz sand slurry on the inner side surface of an increased quartz crucible for polycrystalline cast ingots to form a high-purity coating; applying a high-purity fine sand slurry to form a fine sand coating, and carrying out high-temperature quick sintering for 1 hour; spraying a silicon nitride slurry on four walls in the crucible with the two high-purity coatings to form a high-purity silicon nitride coating as a mold release agent; laying a fine silicon material layer on the bottom of the crucible with the silicon nitride coating as a seed crystal layer, and putting a primary silicon material on the seed crystal layer; and opening the heat insulation cage to the height of 5-6cm in the melting stage, testing the residual height of the silicon material with a quartz rod, quickly cooling when the residual height is 5-6mm, entering the crystal growth stage, and controlling the temperature gradient in the crucible to form vertical temperature gradient in the crucible from bottom to top so as to induce the growth of the molten silicon material by utilizing the seed crystal layer laid on the bottom, thereby obtaining the black-edge-free high-efficiency polycrystalline silicon ingot.

Owner:江苏美科太阳能科技股份有限公司

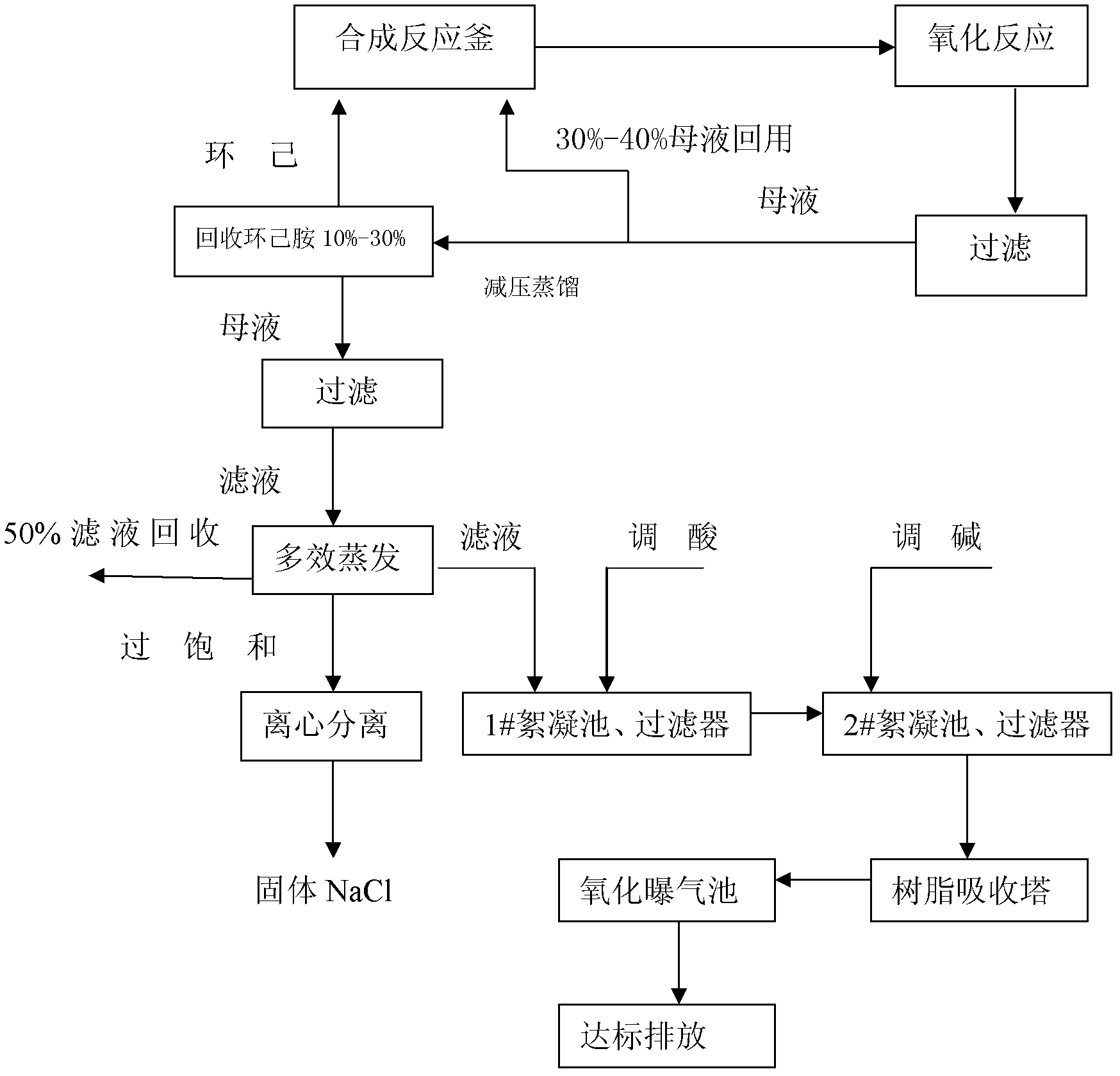

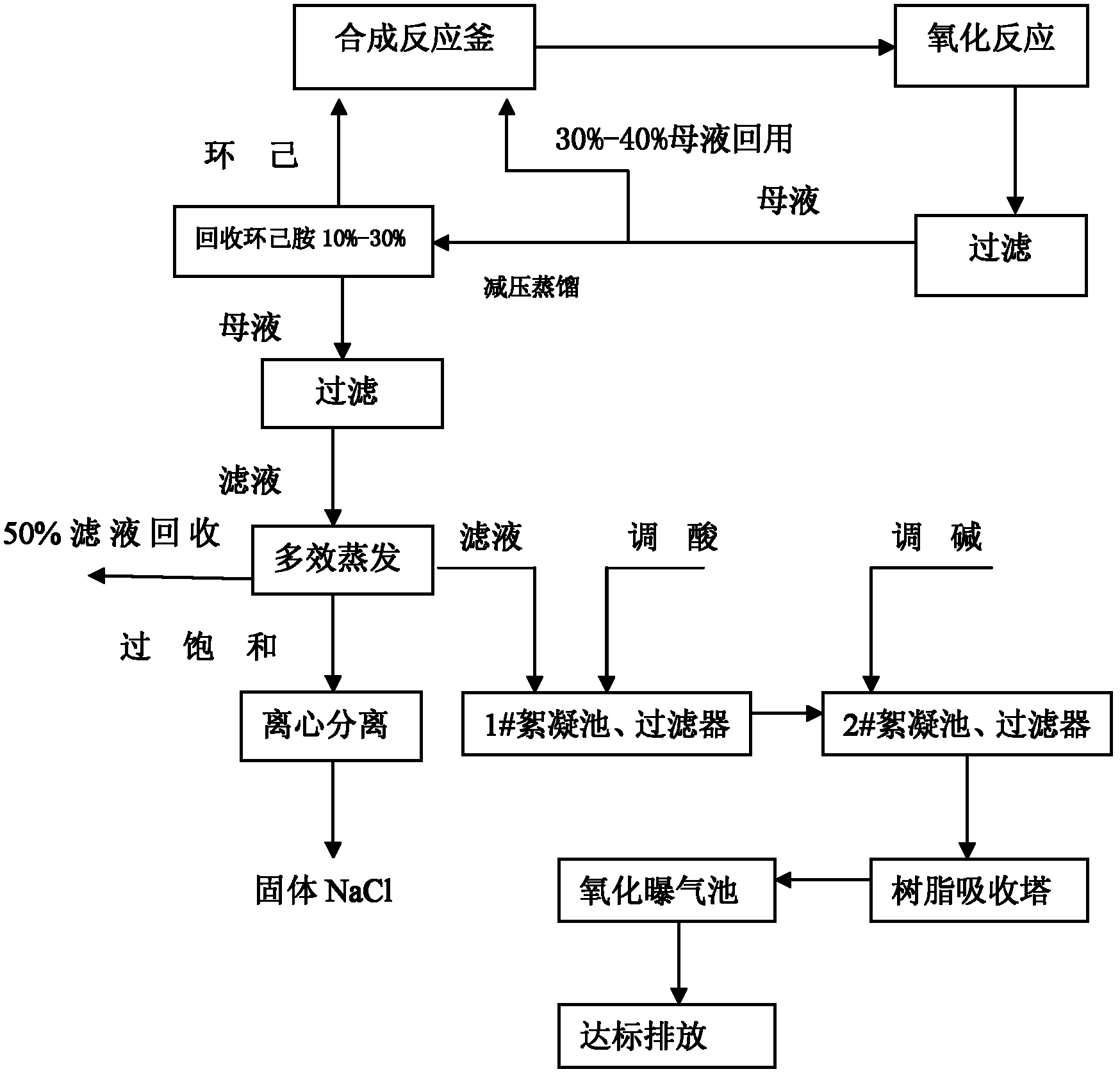

Method for treating wastewater of rubber vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfonamide

InactiveCN102432136AEfficient extractionEfficient removalAmino compound purification/separationMultistage water/sewage treatmentVulcanizationEvaporation

The invention belongs to a method for treating wastewater of a rubber vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfonamide (CZ). The method comprises: returning 30%-40% of generated wastewater into a CZ synthesis reaction vessel for indiscriminate application, subjecting the rest part to vacuum distillation, recovering cyclohexylamine; precipitating organic components dissolved in cyclohexylamine, filtering the recovered mother liquid, and putting the precipitated organic matter into the synthesis reaction vessel for continuous reaction, and leading the filtrate to multiple-effect evaporation so as to obtain a sodium chloride saturated solution, conducting concentration so as to obtain a supersaturated solution of sodium chloride, and carrying out centrifugation, thus obtaining sodium chloride; returning part of the evaporated water to the device for reuse, and leaving the left part to biochemical treatment. In order to make the raw material M completely reacted during production, excess cyclohexylamine is added, so that a great amount of cyclohexylamine is contained in the wastewater. By adopting a mother liquid indiscriminate application technology, the mother liquid can be recycled, the primary utilization rate of cyclohexylamine can be enhanced, simultaneously the mother liquid treatment cost can be reduced, and the CZ yield can be improved. After mother liquid indiscriminate application, the CZ product has no abnormal change in appearance, and no obvious change in melting point as well as ash content.

Owner:KEMAI CHEM

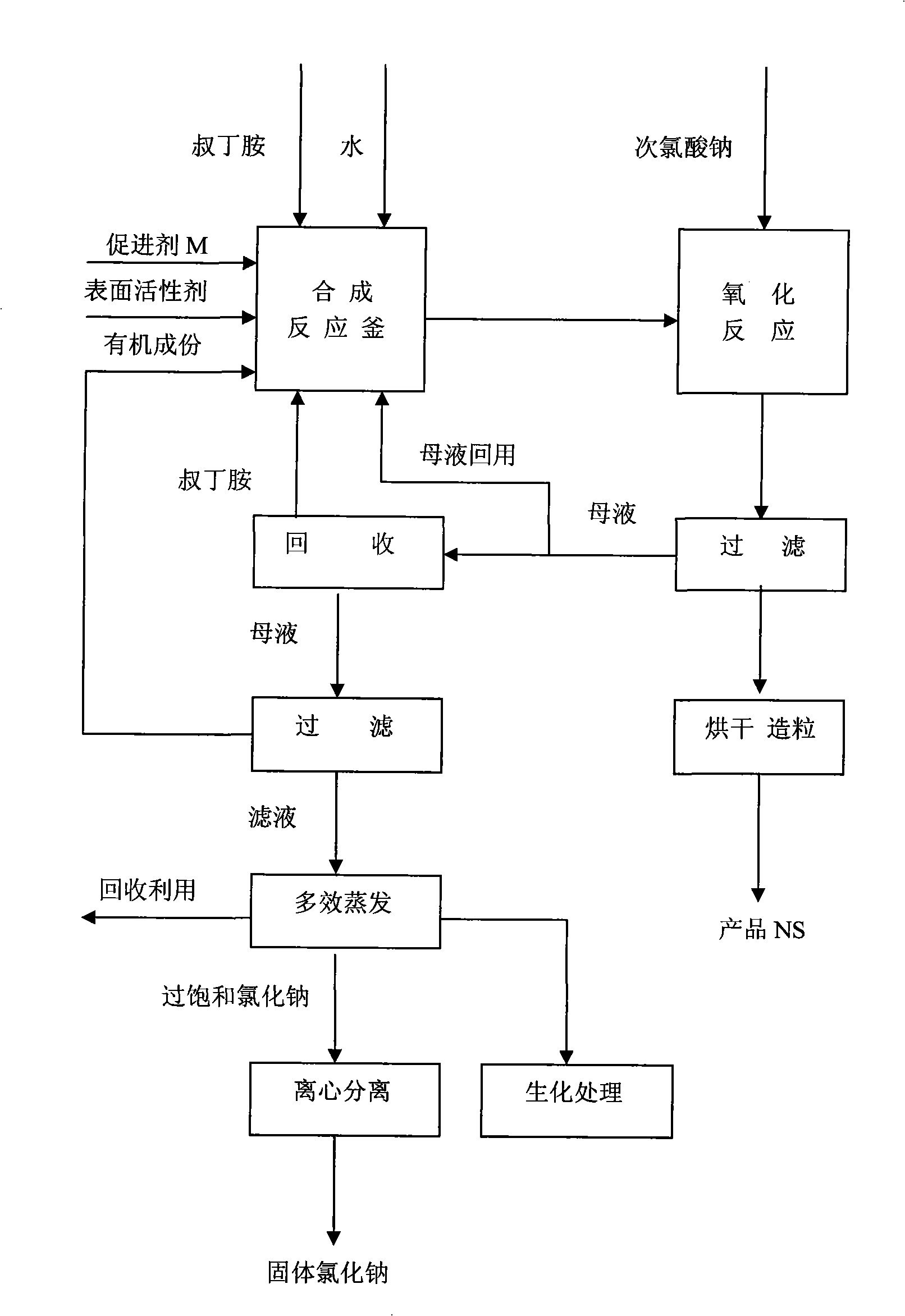

Process for treating waste water of rubber vulcanization accelerator NS production

ActiveCN101407344AEfficient extractionSolve intractableAmino compound purification/separationWater/sewage treatment by heatingVulcanizationEvaporation

The invention provides a thiofide NS wastewater treatment process as follows: process water, a raw material M, a surfactant are blended and stirred according to proportion, then tert-butylamine is added into a synthesis reaction kettle for fully beating; after warming and activating, an NS slurry is obtained by dropping sodium hypochlorite solution to carry out oxidation synthesis reaction at a certain temperature, a part of filtered NS mother liquor is returned to the NS synthesis reaction kettle to apply, a part of filtered NS mother liquor is vacuum-distilled to recover tert-butylamine, organic components such as NS dissolved in tert-butylamine are separated out, the recycled mother liquid is filtered, the separated organic substances are put into the synthesis reaction kettle to continue reaction, the filter liquor is led to carry out multiple effect evaporation, sodium chloride saturated solution is obtained, and a part of the evaporable water is returned to the device to recycle, while the other part thereof is carried out biochemical treatment.

Owner:SHANDONG YANGGU HUATAI CHEM +1

Efficient continuous crackless flattening method of bamboo

ActiveCN105751334AImprove physical and mechanical propertiesBeautiful colorCane mechanical workingPre treatmentUltimate tensile strength

The invention discloses an efficient continuous crackless flattening method of bamboo. The method includes following process steps: (1), pre-treating fresh bamboo tubes; (2), enabling the bamboo tubes to enter a heating pipeline for heating treatment; (3), flattening the bamboo tubes in a heat-insulating space connected with the heating pipeline; (4), post-treating flattened bamboo chips. The method has the advantages that when the fresh bamboo tubes are placed in a high-temperature separated pipeline with temperature of 130-160 DEG C, quick heating and heat-moisture treatment of high-temperature overheated steam are utilized to enable temperature of the bamboo tubes to reach softening points of lignin, cellulose and hemicellulose, and in a subsequent section of the heat-insulating space for high-temperature heating, multiple bamboo tubes or bamboo chips with certain radian are sequentially flattened, cooled and set through flattening rollers which widens progressively. By using the method, treatment temperature for bamboo flattening and labor intensity of workers during operation are lowered, harsh environment for the workers during operation is improved, and production automation level is high; finished products do not need de-yellowing treatment, flattened bamboo is better in physical and mechanical performance, attractive in color and luster and suitable for being used for making artware and furniture and home decoration.

Owner:NANJING FORESTRY UNIV

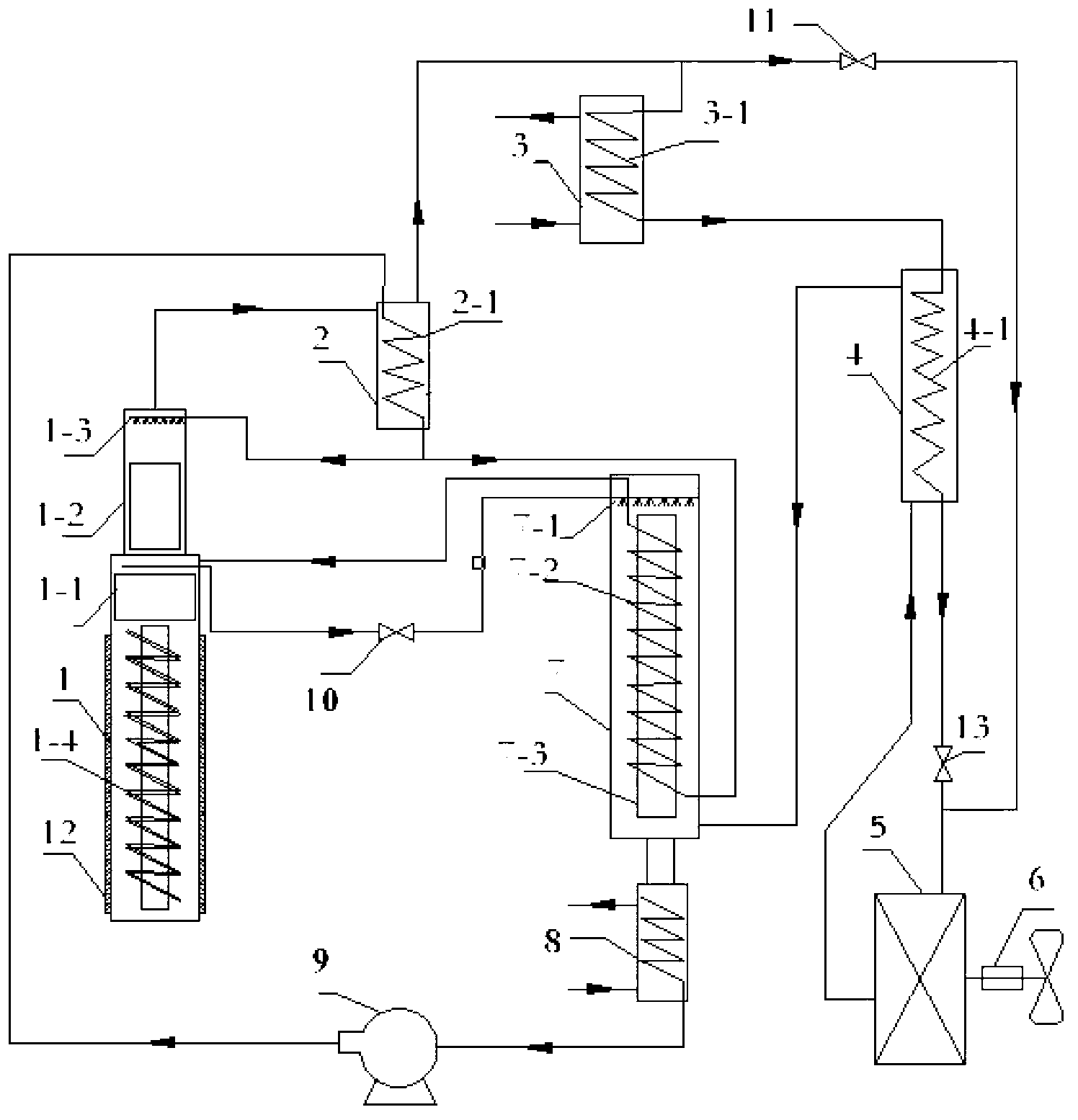

Solar energy air source absorption heat pump device

ActiveCN102840719AImprove Primary UtilizationImprove efficiencyHeat pumpsRefrigeration safety arrangementUnit operationEngineering

The invention discloses a solar energy air source absorption heat pump device. The solar energy air source absorption heat pump device is characterized in that natural energy source solar energy is taken as the driving energy of the unit, and the solar energy is input by a heating exchanger in a generator to the solar heat pump device to provide power for unit operation; energy in the air is absorbed through an air source heat exchanger coil; and the two parts of energy are released through condensation of refrigerant vapor and fusion heat of the refrigerant vapor and dilute solution, and transferred to hot water, thus the energy utilization rate is improved.

Owner:SHANDONG QIWEITE SOLAR TECH CO LTD

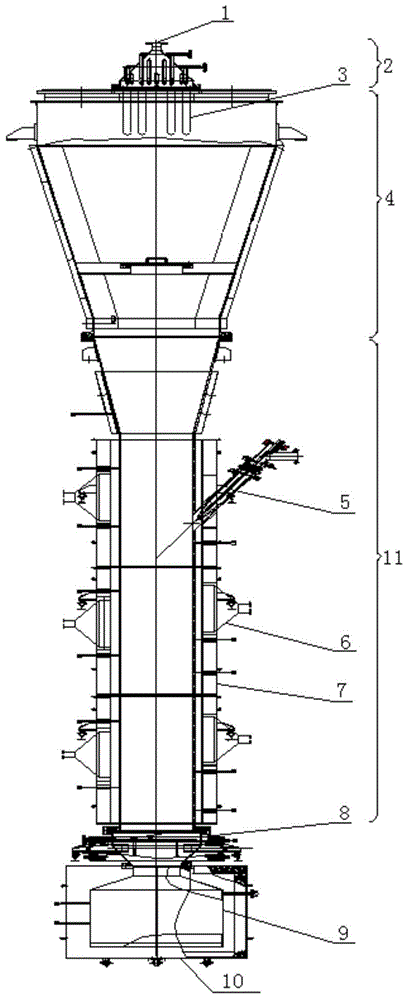

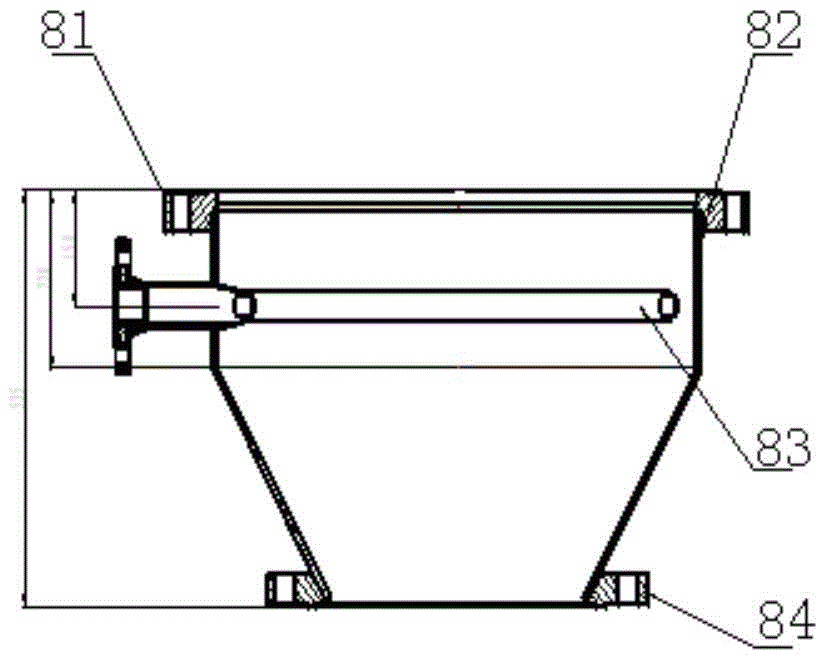

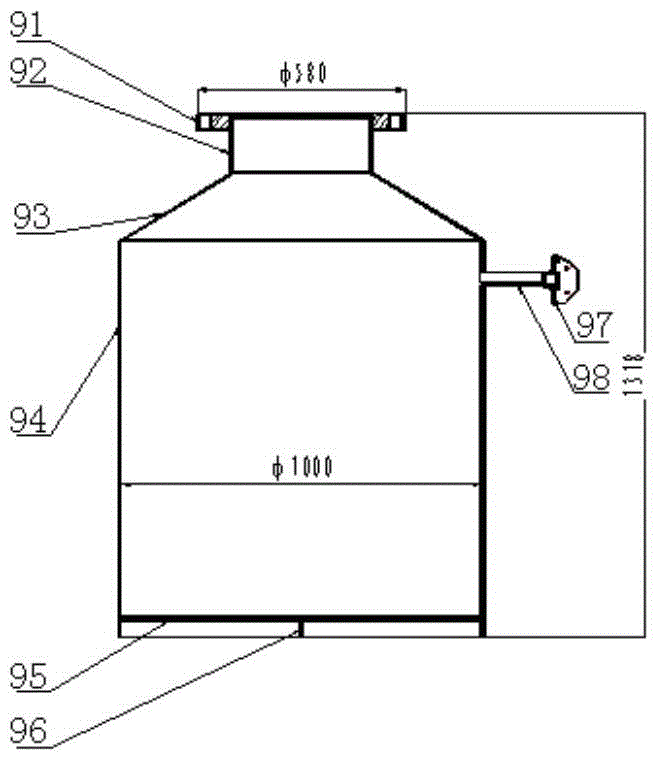

Novel columnar vertical fluorination reactor

InactiveCN104437273AImprove Primary UtilizationLower control temperatureChemical/physical processesProduction rateProduction line

The invention provides a novel columnar vertical fluorination reactor. The novel columnar vertical fluorination reactor comprises a furnace gas outlet upper flange, dust removing devices, a filter pipe, an upper expanded section, a discharging inclined pipe, an air exhausting opening, a heating device, a gas chamber, a slag pot, a lead layer shielding sleeve and a main reactor. The novel columnar vertical fluorination reactor has the characteristics that the primary utilization rate of fluorine gas is high, the slag production rate is low, the control temperature is low, the structure is simple, the operation is simple, the maintenance is convenient and the like, and is suitable for a uranium conversion fluorination process production line which takes refined uranium tetrafluoride as a raw material and enables uranium tetrafluoride to react with the fluorine gas to generate uranium hexafluoride.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

Joint preparation method of potassium chloroplatinite and potassium chloroplatinate

ActiveCN102774894AIncrease profitSimple processRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPotassium tetrachloroplatinatePotassium

The invention relates to a joint preparation method of potassium chloroplatinite and potassium chloroplatinate. The joint preparation method comprises the steps of: completely dissolving metal platinum which is taken as a raw material by aqua regia, and adding hydrochloric acid to remove nitrogen compound to obtain chloroplatinic acid solution; neutralizing the chloroplatinic acid solution by using potassium hydroxide solution until the pH value is 5.5-7.5; adding potassium oxalate for reducing to obtain the potassium chloroplatinite; and separating out crystal, and adding hydrogen peroxide into the rest mother liquor to obtain the potassium chloroplatinate. The joint preparation method can be used for preparing two products by charging for once, is simple in technology and short in process flow, does not generate platinum-containing mother liquor, and is high in platinum utilization rate and good in product quality. The potassium chloroplatinite and the potassium chloroplatinate prepared by the invention are mainly used for manufacturing catalysts, chemically analyzing, preparing platinum-containing complexes and platinum-containing metallorganic compounds and the like, and are widely applied to industries such as military industry, electronic industry, medical industry, etc.

Owner:天津市风船化学试剂科技有限公司

High-temperature tunnel kiln type flattening method for bamboo tubes

ActiveCN105710946AReduce labor intensityReduce harsh environmentCane mechanical workingReed/straw treatmentTunnel kilnPre treatment

The invention relates to a high-temperature tunnel kiln type flattening method for bamboo tubes. The method comprises the following process steps of: (1) pre-treating fresh bamboo tubes; (2) stacking the bamboo tubes; (3) flattening the round bamboo tubes in a tunnel kiln; and (4) performing post-treatment on the flattened bamboo chips. The method provided by the invention has the advantages that in a high-temperature divided tunnel kiln at the temperature of 130-160 DEG C, the temperature of the bamboo tubes reaches the softening points of lignin, cellulose and hemicellulose by means of quick heating and heat-moisture treatment of high-temperature superheated steam on fresh round bamboo tubes. Under such a circumstance, under the pressure of a top-mounted oil cylinder in a bamboo tube flattening room, the round bamboo tubes with saw joints are flattened, so that the bamboo flattening treatment temperature as well as the labor intensity and severe environment during operation of workers is reduced. The manufactured flattened bamboos are more excellent in physical and mechanical properties and the like, are attractive in color and luster and are suitable for manufacture of artware and furniture and home decoration. The method provides a more excellent processing method for bamboo industry.

Owner:NANJING FORESTRY UNIV

Efficient production method of small-diameter-log composite wood

ActiveCN107498656AImprove Primary UtilizationSustainableOther plywood/veneer working apparatusWood treatment detailsTunnel kilnMetallurgy

The invention relates to an efficient production method of small-diameter-log composite wood. The efficient production method comprises the following technological steps of (a) small-diameter-log pretreatment, (b) saturated vapor heating and softening, (c) gluing and hot press molding, and (d) continuous plate blank heating curing and drying. The efficient production method has the beneficial effects that gluing is carried out on small diameter log obtained after high temperature saturated treatment while it is hot, then same-direction paving compression is carried out, the small diameter log can be heated and is easily extruded to be in a similar hexagon shape, gaps between the small diameter log will be filled, the small diameter log makes contact with each other and is glued into a whole, the small diameter log is manufactured into the composite wood with different cross sections according to needs, and the composite wood is fixed into a mold to be cured and dried through a high temperature tunnel kiln. According to the composite wood produced through the process, the small diameter log using rate is high, the production efficiency is high, quality is good, and material sources are sustainable.

Owner:NANJING FORESTRY UNIV

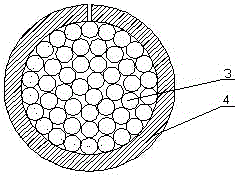

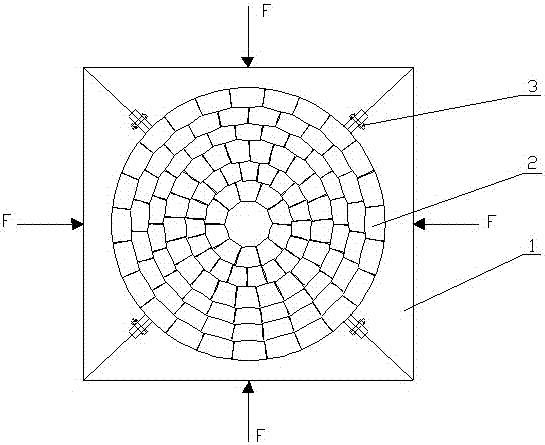

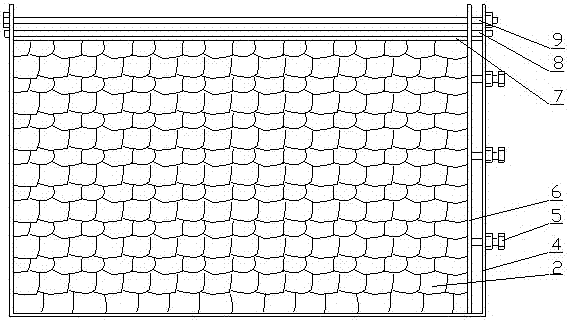

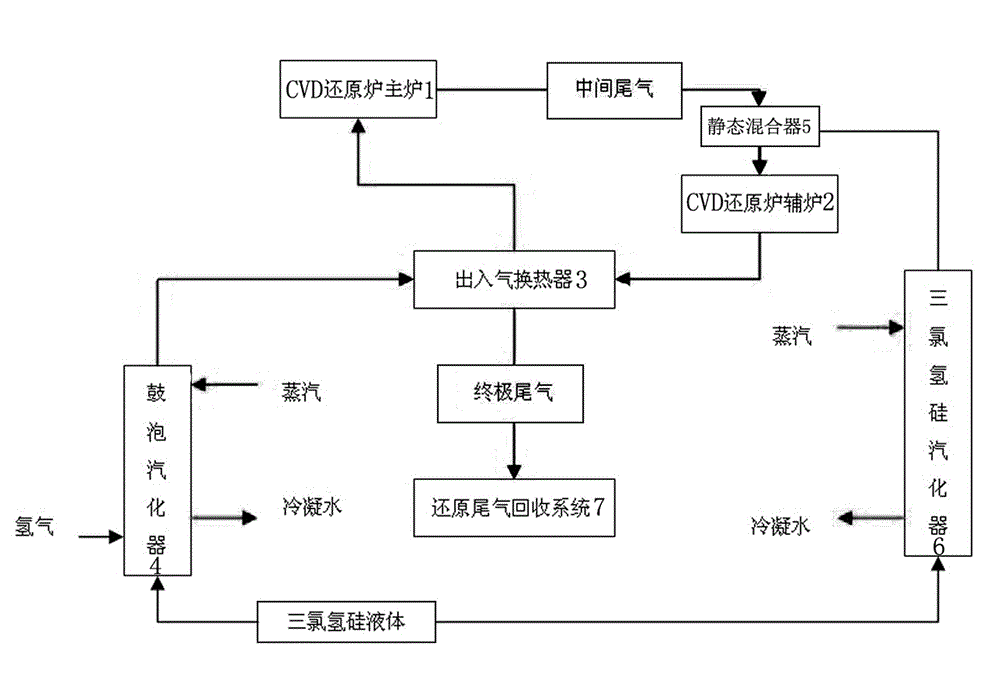

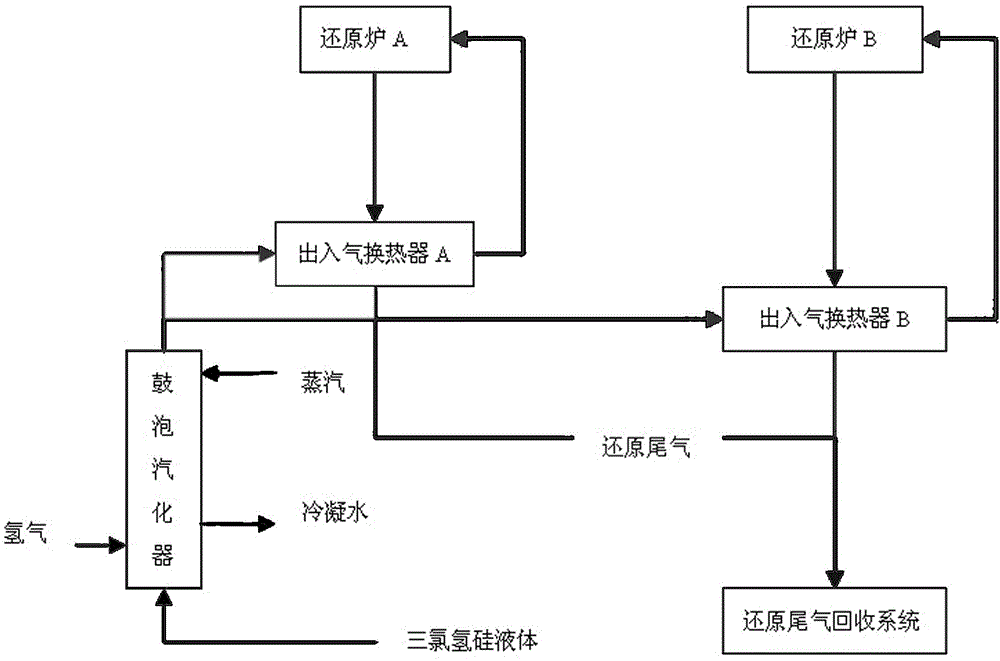

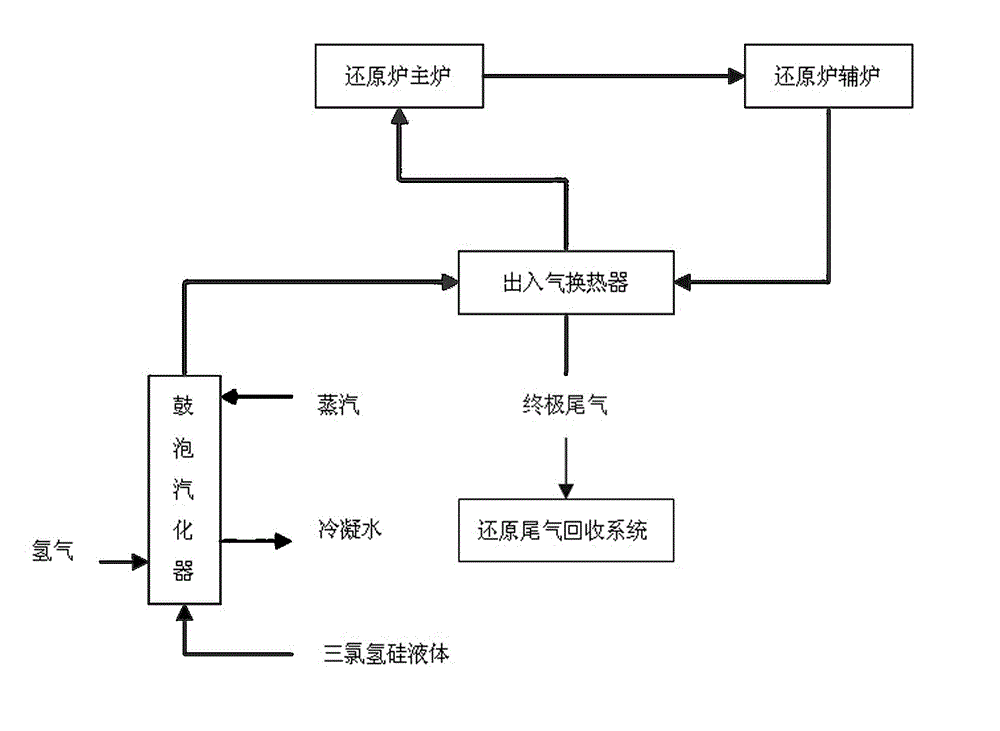

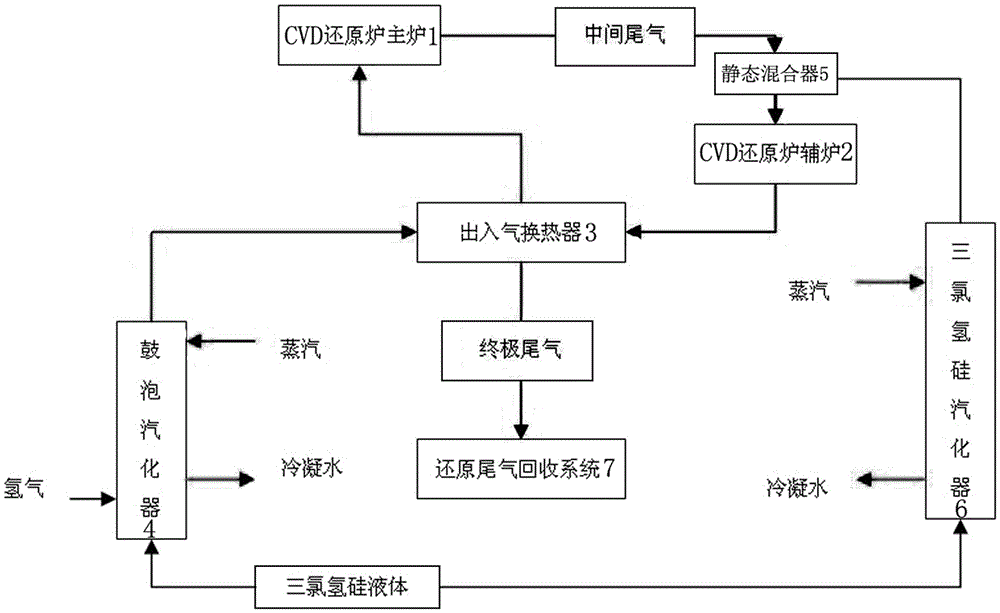

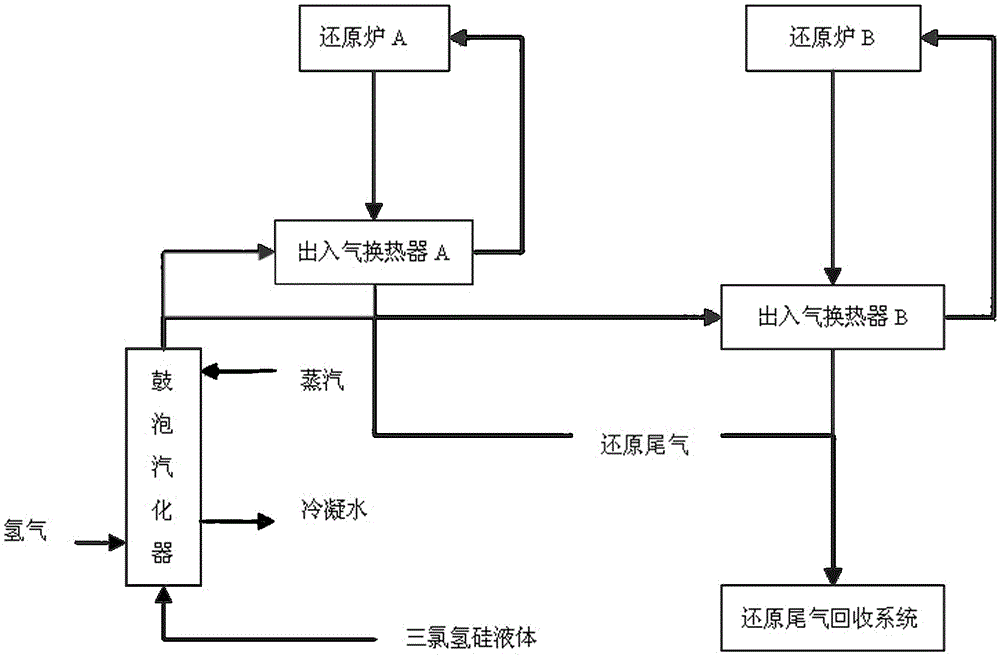

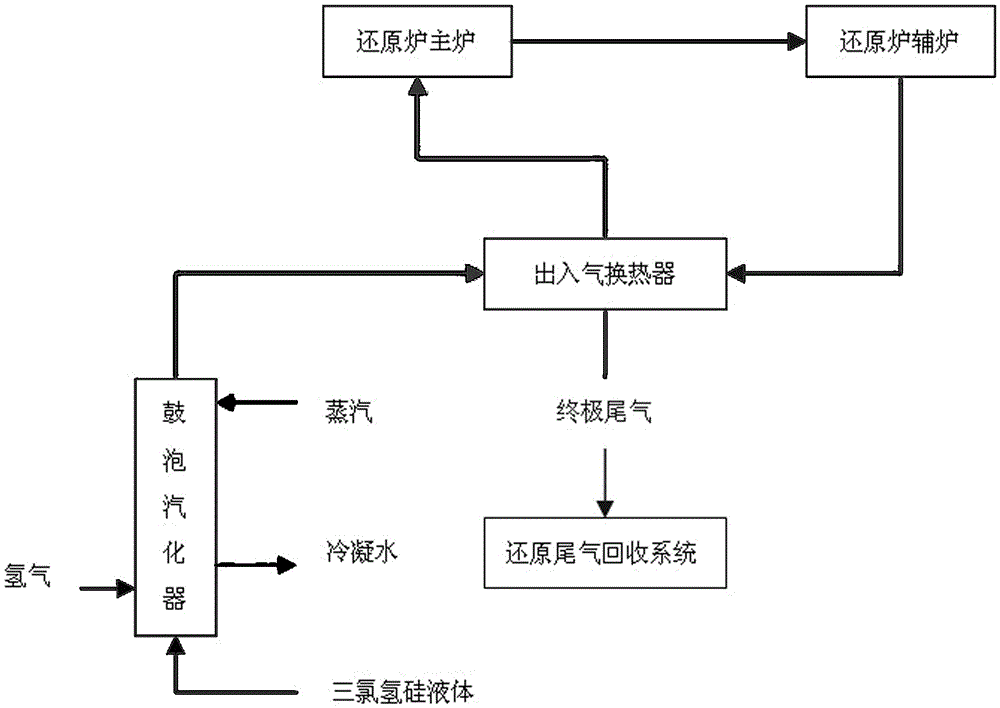

Polycrystalline silicon production process and production system used for same

ActiveCN102745694AAvoid it happening againReduce the temperatureSilicon compoundsChemical vapor depositionMixed gas

The invention relates to a polycrystalline silicon production process and a production system used for the same. The polycrystalline silicon production process comprises the following steps of: mixing fine trichlorosilane with the concentration of more than 99.99% and hydrogen in the mol ratio of the hydrogen to the fine trichlorosilane of (4-3):1 to be used as a mixed gas feeding material; introducing the mixed gas feeding material into a CVD (Chemical Vapor Deposition) reduction furnace, wherein the mixed gas feeding material sequentially passes through a bubble type gasifying device, a heat exchanger of an inlet / outlet device, and a main furnace of the CVD reduction furnace and an auxiliary furnace of the CVD reduction furnace which are connected in series; carrying out heat exchange on the final exhaust tail gas exhausted by the auxiliary furnace of the CVD reduction furnace and introducing the gas into the main furnace of the CVD reduction furnace to carry out reaction on the surface of a silicon core in the main furnace of the CVD reduction furnace to generate polycrystalline silicon, wherein a byproduct is middle tail gas; mixing the middle tail gas with the supplemented fine trichlorosilane gas and introducing the mixed gas into the auxiliary furnace of the CVD reduction furnace to react on the surface of the silicon core in the auxiliary furnace of the CVD reduction furnace to generate the polycrystalline silicon, wherein the byproduct is the final exhaust tail gas; and carrying out the heat exchange on the final exhaust tail gas which is discharged out of the furnace, and the mixed gas feeding material, and introducing into a reduction tail gas recycling system. The process and the production system disclosed by the invention can be used for manufacturing the high-quality electronic-grade polycrystalline silicon in a high-efficiency and low-cost manner.

Owner:巴彦淖尔聚光硅业有限公司

Water heating synthesis of yttrium-diethyltriamine pentacetate

InactiveCN1680393AImprove reaction efficiencyAdapt to the needs of industrial productionGroup 3/13 element organic compoundsChemical synthesisAcetic acid

A hydrothermal synthesis of gadolinium-diethylentriaminepentaacetic acid is carried out by using gadolinium oxide and diethylentriaminepentaacetic acid, hydrothermal synthesizing, and obtaining gadolinium- diethylentriaminepentaacetic. It is an inorganic complex chemical synthetic technology. Its advantages include less impurities, high reacting speed and output efficiency.

Owner:EAST CHINA NORMAL UNIV

Automatic assembly method of recombined bamboo

InactiveCN106426501APromote healthy developmentImprove qualityFlat articlesDomestic articlesEngineeringUtilization rate

The invention discloses an automatic assembly method of recombined bamboo. The automatic assembly method comprises the following process steps that (a) bamboo skin / bunch gumming and drying are carried out; (b) weighing is carried out; (c) bamboo bunches are automatically lifted and placed into parallel cells on a base plate; and (d) the bamboo bunches in the parallel cells slide down to the base plate. The automatic assembly method has the beneficial effects that through the bamboo recombined bamboo, the one-time utilization rate of moso bamboo and other large-diameter bamboo can be increased to 80% or above from 20%-50%, and the utilization rate of small-diameter bamboo, sympodial bamboo and other bamboo which cannot be industrially utilized reaches up to 80% or above. The bamboo recombined bamboo is produced through pavement via the method, high-quality scrimber can be obtained and used as materials for floors or furniture or buildings, and in addition, the labor intensity of staff is relieved. Production of the recombined bamboo of automatic pavement is possible, and guarantees are provided for healthy development of the recombined bamboo.

Owner:NANJING FORESTRY UNIV

Preparation process of ultralow-viscosity dimethyl silicone oil

The invention discloses a preparation process of ultralow-viscosity dimethyl silicone oil. Low-molecule separation of dimethyl silicone oil is performed in a rectification manner, high-boiling-point components can be reserved to the greatest extent and low-boiling-point components can be separated to the greatest extent under the set rectification conditions, the content of octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane and other molecules in the ultralow-viscosity dimethyl silicone oil with the higher boiling point can be further better controlled, application requirements in certain special high-end application fields such as the personal care industry can be met, besides, ultralow-viscosity linear dimethyl silicone oil with the lower boiling pointer can be captured from rectification fractions, and the one-time yield of a reaction is increased.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Automatic weighing and assembling method for cold-pressed recombination bamboo

ActiveCN106863506AFast growthBreeding is easyWood treatment detailsPlant material mechanical workingEngineeringUltimate tensile strength

The invention provides an automatic weighing and assembling method for cold-pressed recombination bamboo. The method includes the following technological steps that (1) impregnated bamboo split drying and separation are performed; (2) bamboo split aligned weighing and bundling are performed; (3) bamboo split bundles are automatically stacked; and (4) water content balancing and pavement of the bamboo split bundles are performed. The automatic weighing and assembling method for the cold-pressed recombination bamboo has the advantages that bamboo splits are subjected to on-line weighing and bundled on an existing impregnated bamboo split drying and separation line, the bundled bamboo splits are automatically stacked through rollers and a lifting device, the water content is balanced, and then two or four bamboo split bundles are delivered into an assembling trough. Existing cold-pressed recombination bamboo production technologies are improved through the method, the production procedures are optimized, the cold-pressed recombination bamboo pavement uniformity is improved, the labor intensity of workers is relieved, the production efficiency and quality are improved, and sound development of the cold-pressed bamboo and the recombination bamboo is guaranteed.

Owner:NANJING FORESTRY UNIV

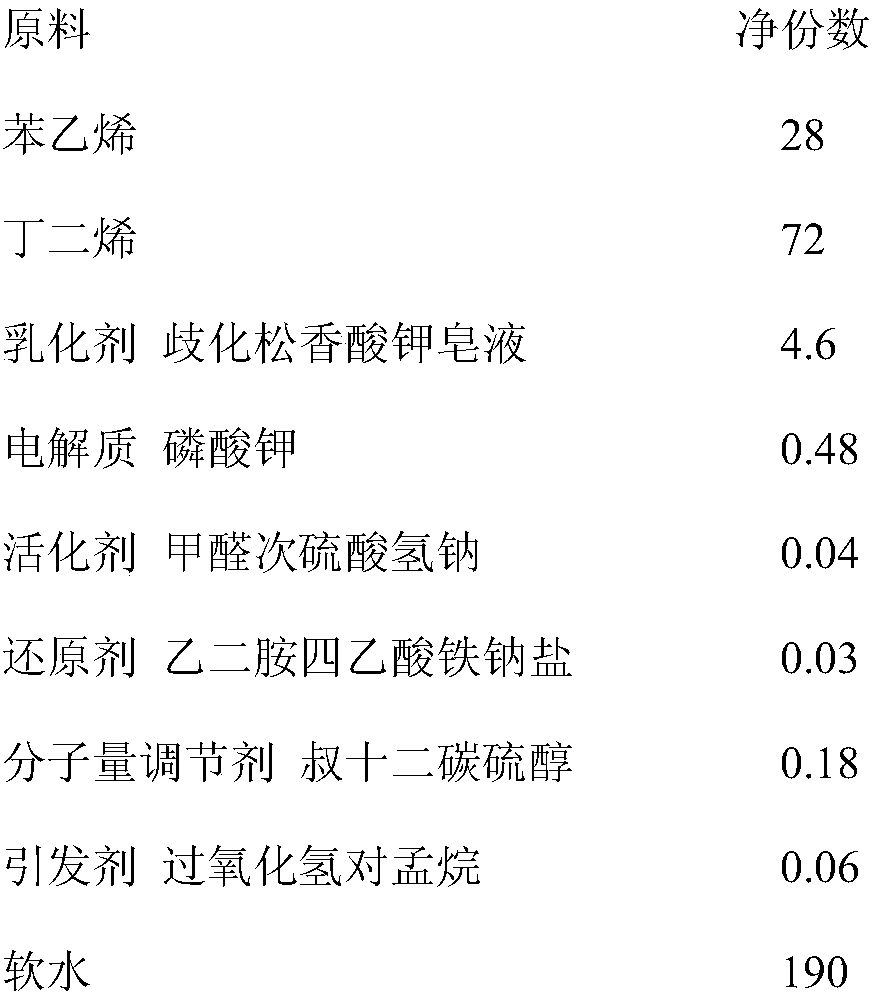

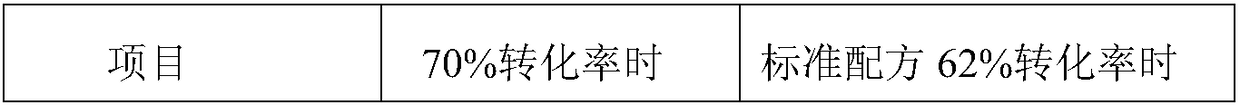

Preparation method of styrene butadiene rubber

ActiveCN108239226AImprove Primary UtilizationMitigating performance degradationButadiene DioxideLatex rubber

The invention provides a preparation method of styrene butadiene rubber. The preparation method comprises the following steps: performing emulsion polymerization of styrene and butadiene, wherein whenthe conversion rate of total monomers for emulsion polymerization reaches 58-62%, a sylvite aqueous solution is added into the reaction system of emulsion polymerization, and reacting is further conducted to obtain styrene butadiene rubber. In the method, viscosity of a polymerization system with a high conversion rate can be controlled to a viscosity level with low conversion rate, then the viscosity of the system is kept at a relatively low state, and the problems of performance degradation of the styrene butadiene rubber and decrease of latex heat transfer and stability caused by excessively high viscosity are relieved. Thus, the conversion rate of emulsion polymerization can be improved while the product performance and operation stability are maintained. The one-time utilization rateof the monomers is increased, the recycling energy consumption is reduced, and the production capacity of the polymerization equipment can be enhanced; and therefore, the method has great significance.

Owner:PETROCHINA CO LTD

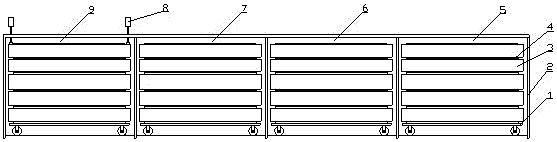

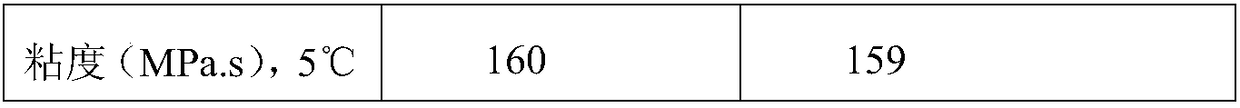

Device and technique for recovering melamine exhaust by using urea unit

ActiveCN104370775ASolve the use problemImprove Primary UtilizationUrea derivatives preparationProductsPulp and paper industryTower

The invention provides a device and technique for recovering melamine exhaust by using a urea unit, relating to the technical field of melamine exhaust recovery treatment. The device comprises an exhaust compressor and a urea unit with a primary decomposing tower, wherein the side wall of the primary decomposing tower corresponding to the bottom of the lower separating section is provided with an exhaust inlet; and the exhaust compressor is communicated with the primary decomposing tower through the exhaust inlet. The technique comprises the following steps: sending pressurized melamine exhaust to the primary decomposing tower, introducing a urea solution heated by a primary heater into the primary decomposing tower, injecting a urea solution in a preseparator into a pre-rectifying section, controlling the urea solution at the outlet of the primary heater at 155-160 DEG C, and cooling the gas-liquid mixture in a methylamine condenser to 90-100 DEG C. The device and technique can well utilize the heat of the melamine exhaust, are stable in the production process and convenient to control, and do not increase energy consumption generated by the urea unit.

Owner:HUAQIANG CHEM GRP

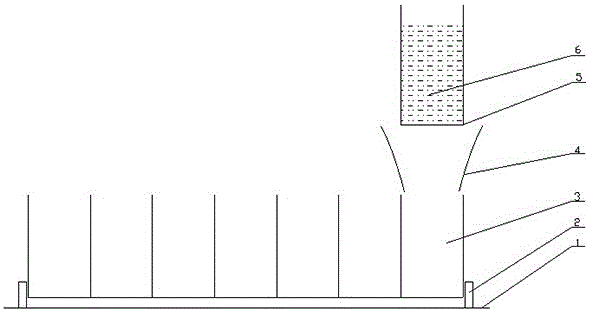

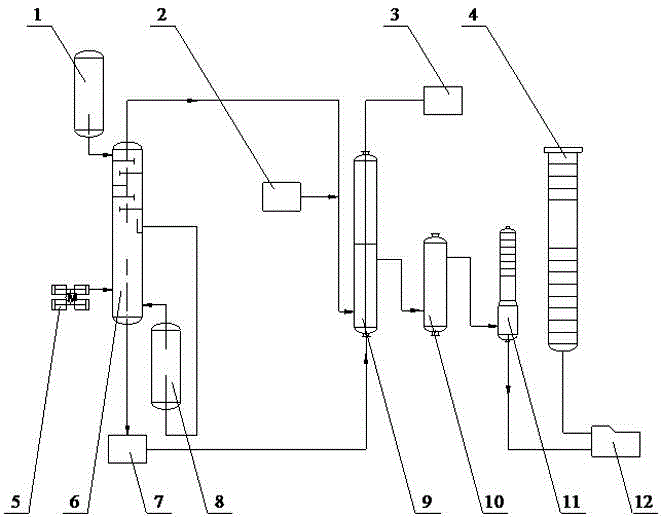

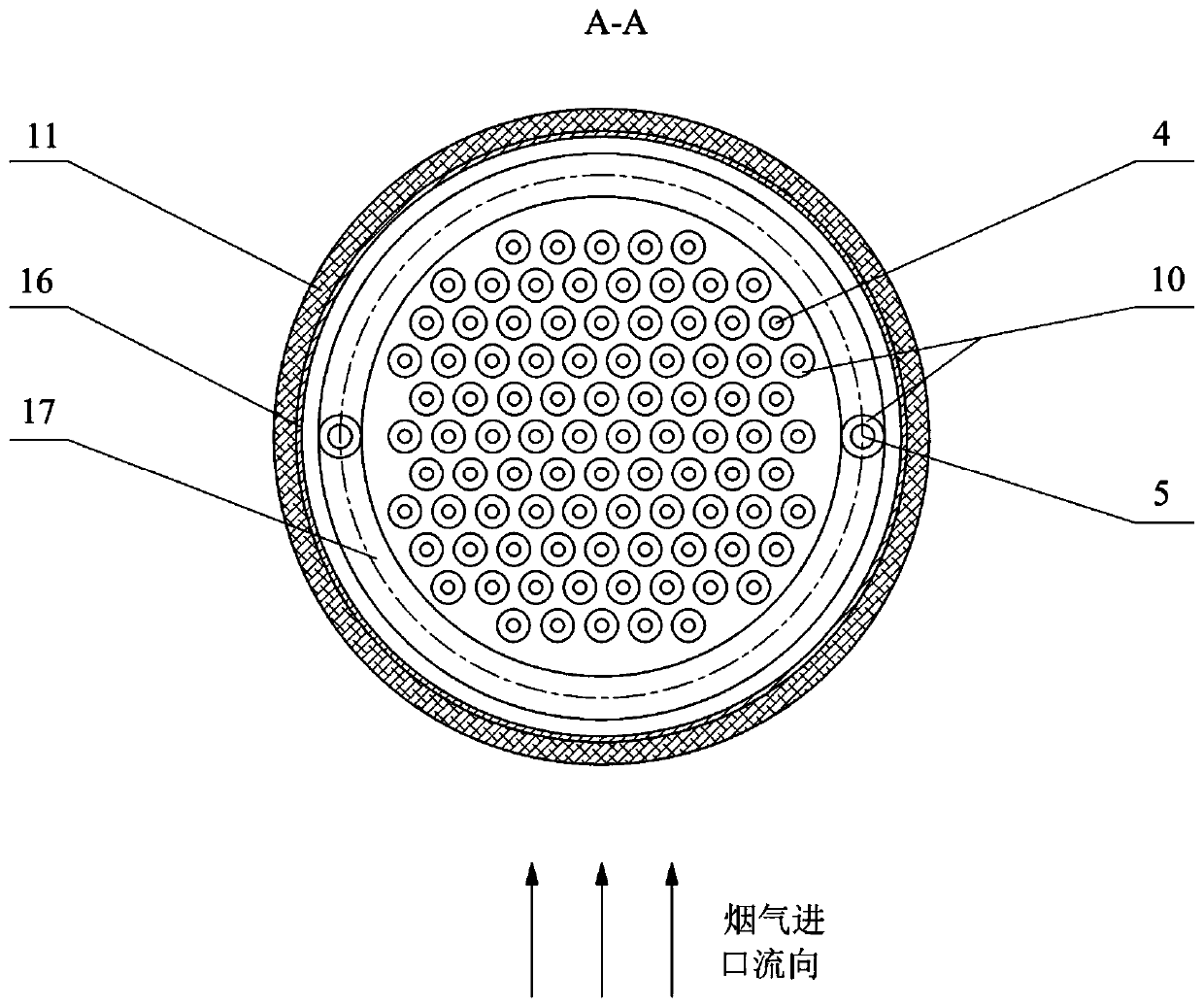

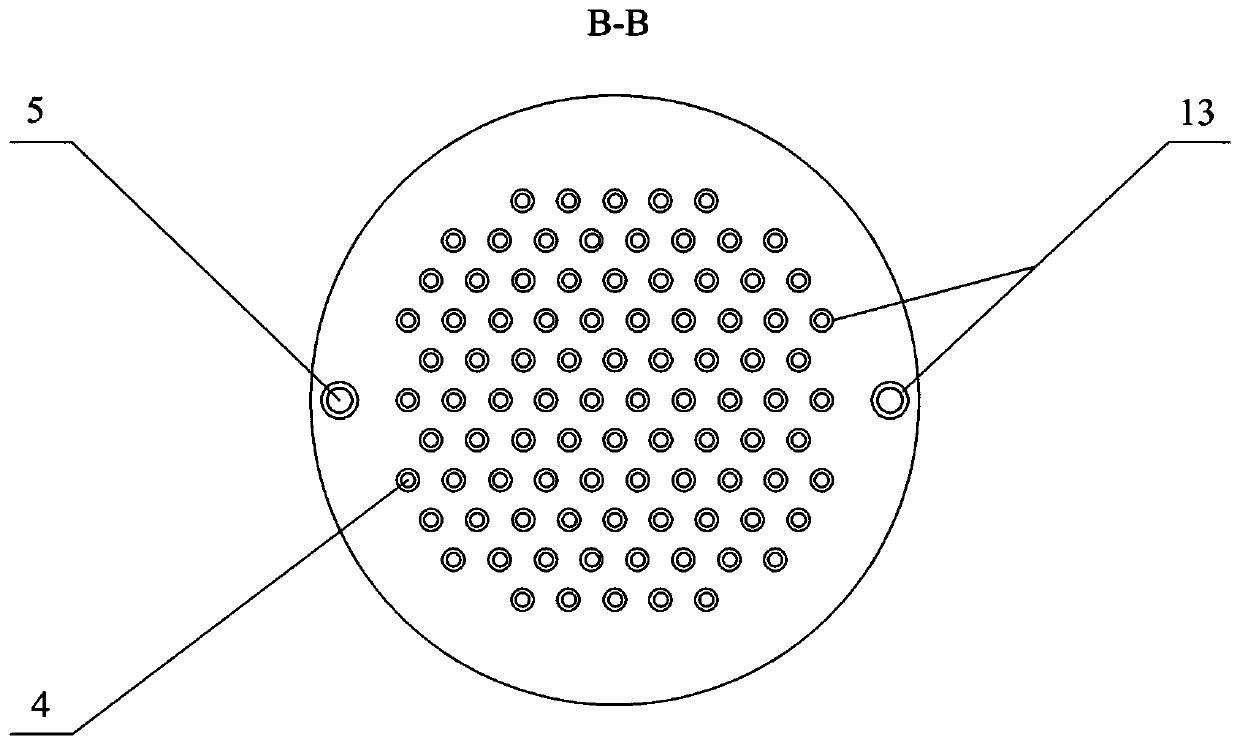

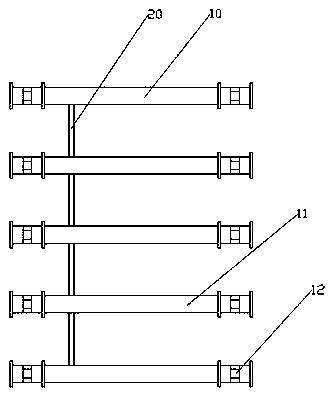

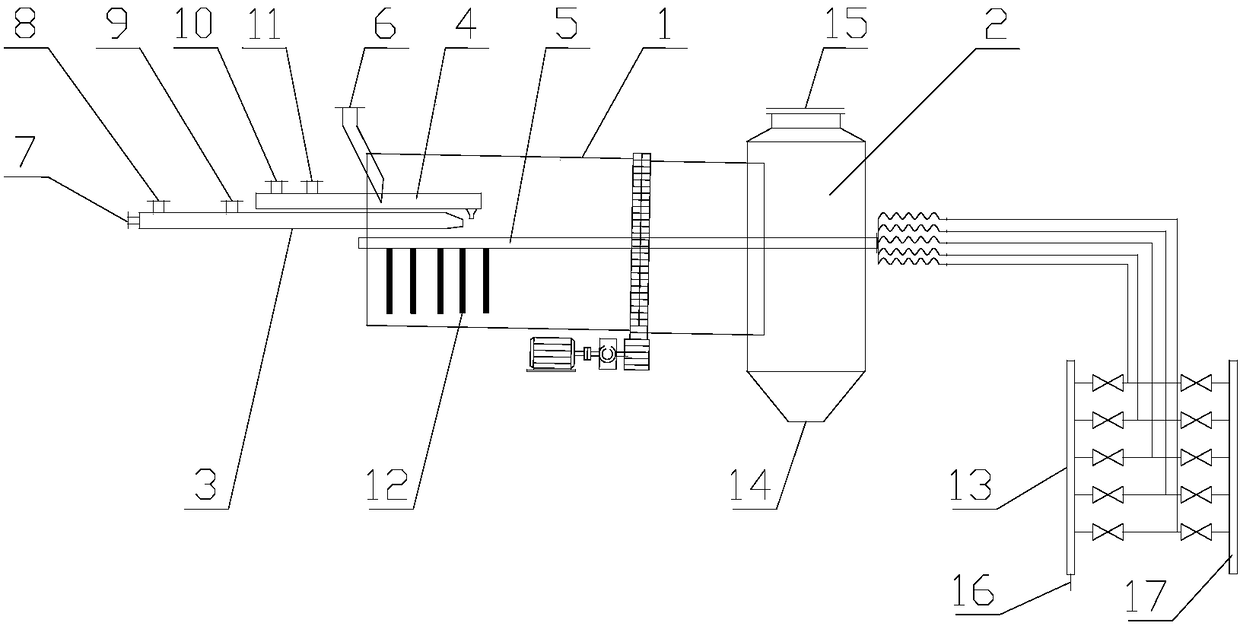

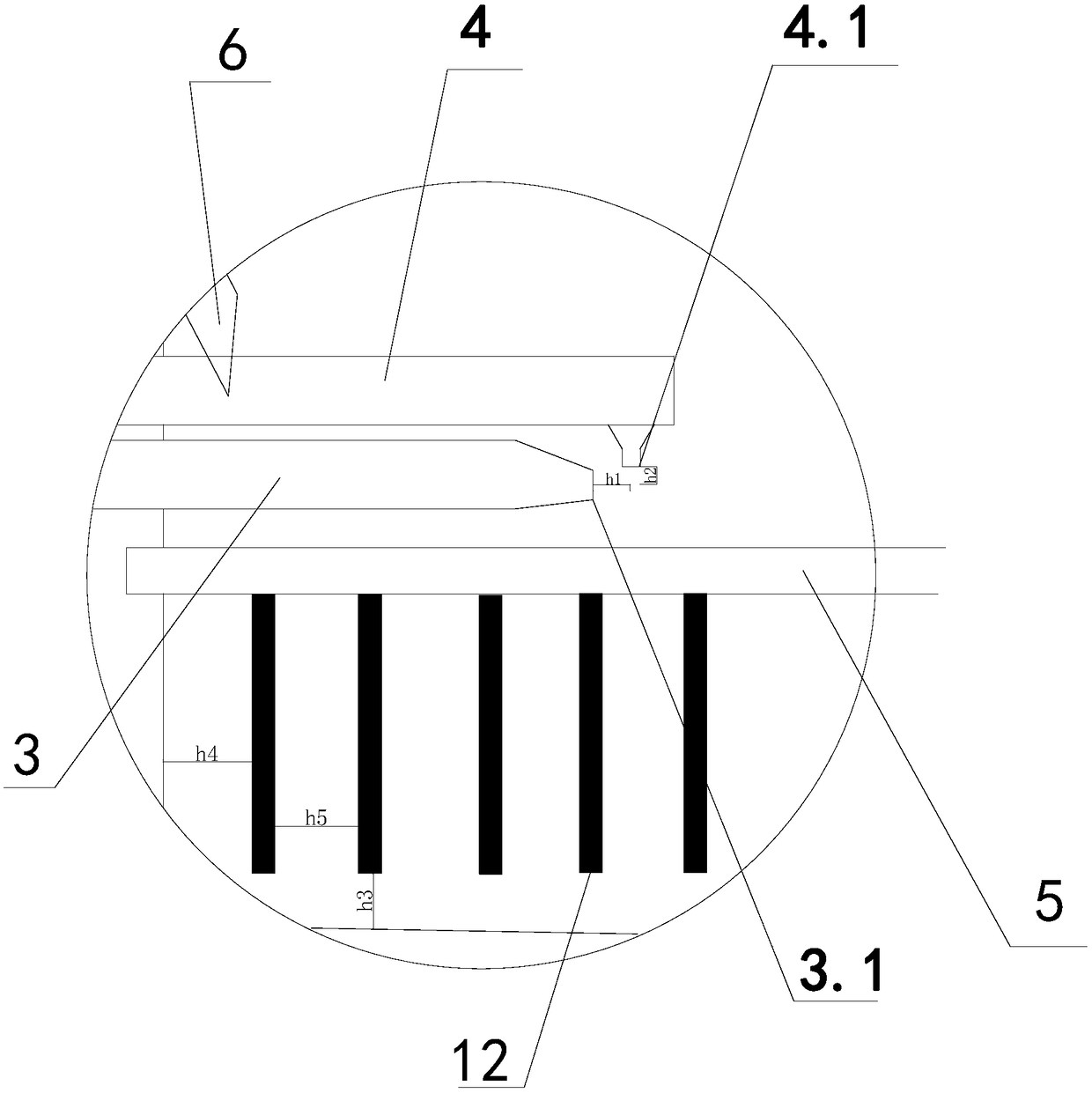

Parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat and preparation method thereof

ActiveCN110425510AImprove Primary UtilizationReduce heat pollutionIndirect heat exchangersCombustion technology mitigationExhaust gasProcess engineering

The invention relates to a parallel small diameter heat pipe enhanced heat exchange device for recovering medium and low temperature flue gas waste heat, aims to solve the problem of waste of medium and low temperature flue gas waste heat generated in small combustion equipment primarily, recovers the flue gas waste heat by means of parallel small diameter heat pipes to produce hot water or heat other substances, and is suitable for recovering waste heat of small flow flue gas or a discontinuous small flow heat source. The parallel small diameter heat pipe enhanced heat exchange device is primarily characterized in that the parallel small diameter heat pipe enhanced heat exchange device is good in heat transfer property, compact in structure, small in size, easy to process and low in cost,and can achieve self transfer of heat and efficient recovery of waste heat, so that the exhaust gas temperature is reduced greatly and the integral efficiency of the system is improved. The device isquite suitable for heat recovery of small capacity medium and low temperature flue gas waste heat and discontinuous waste heat resources, and a heating container is taken conveniently.

Owner:NANJING UNIV OF TECH +1

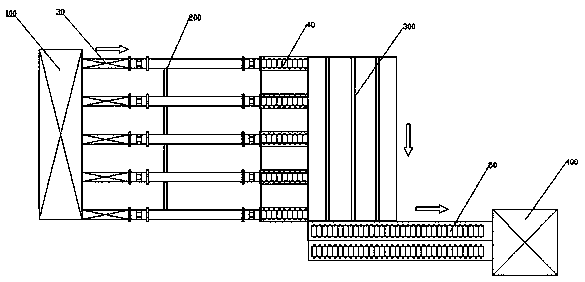

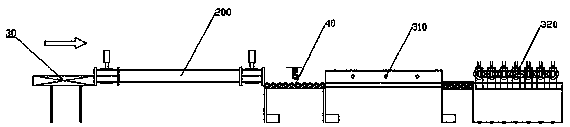

Continuous production system and production method for bamboo flattened plates

ActiveCN111409159AImprove Primary UtilizationSoften wellWood compressionBio-packagingControl systemProcess engineering

The invention discloses a continuous production system and production method for bamboo flattened plates. The continuous production system is characterized by being electrically connected with a control system and comprising a bamboo softening device for carrying out high-temperature and high-humidity softening treatment on bamboo chips, a bamboo pretreatment device, a planing and flattening all-in-one machine and a bamboo post-processing device, wherein the bamboo pretreatment device and the planing and flattening all-in-one machine are arranged at the feeding end and the discharging end of the bamboo softening device respectively, and the bamboo post-processing device is arranged at the discharging end of the planing and flattening all-in-one machine; and an automatic delivery device andan automatic conveying mechanism which are used for continuously and automatically conveying bamboo chips are arranged between the planing and flattening all-in-one machine and the bamboo softening device and between the planing and flattening all-in-one machine and the bamboo post-processing device respectively, and an automatic feeding device used for continuously and automatically feeding thebamboo chips is further arranged between the bamboo pre-processing device and the bamboo softening device. According to the continuous production system, intelligent control is achieved through the control system, the bamboo softening and flattening effect is good, the bamboo utilization rate is high, the yield of the bamboo flattened plates is remarkably increased, the manufacturing cost is low,continuous and efficient production of large-batch bamboo flattened plates can be achieved, the practicability is good, and the wide industrial application prospect is achieved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

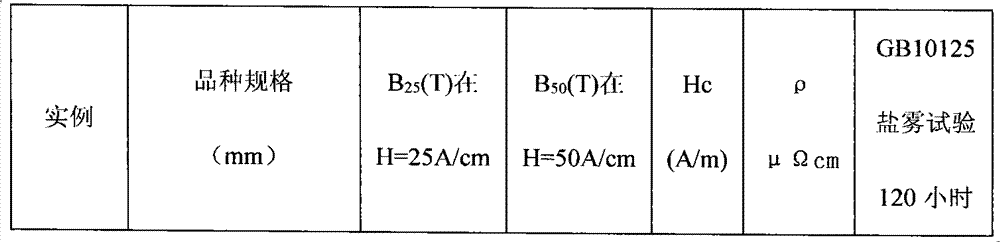

Smelting method of corrosion-resistant soft magnetic alloy material

ActiveCN103045943AReduce contentImprove Primary UtilizationIncreasing energy efficiencyMagnetic materialsCorrosion resistantHeat processing

The invention discloses a smelting method of a corrosion-resistant soft magnetic alloy material, and can solve the problems of low yield and low production efficiency of the produced corrosion-resistant soft magnetic alloy material and the like and also can improve the comprehensive performance of the material. The invention adopts the main scheme that a cast ingot for smelting an intermediate-frequency furnace or a vacuum induction furnace or other equipment is subjected to electroslag re-melting to obtain a high-quality heat processing blank. A formula for slag subjected to electroslag re-melting is calcium fluoride: calcium oxide: aluminum oxide=(65-80):(1-5):(15-25); and the filling ratio of 0.5-0.6 is adopted during re-melting. The smelting method has the following advantages that: the segregation is reduced, the organization is fined, the contents of P and S elements are reduced, the contents of inclusions are reduced, and the distribution of the inclusions is improved, so that the forming performance (the yield is improved by about 5-10 percent) and the use performance of materials are improved; and the produced blank has good surface quality and needs not to be peeled off, so that the material one-time utilization ratio (about 5-10 percent) and the production efficiency (about 5-10 percent) can be improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

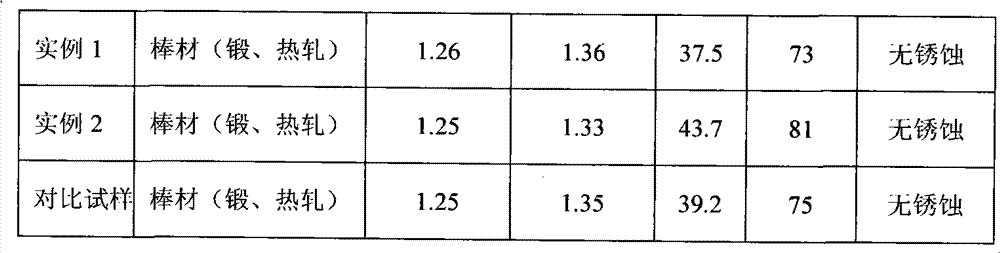

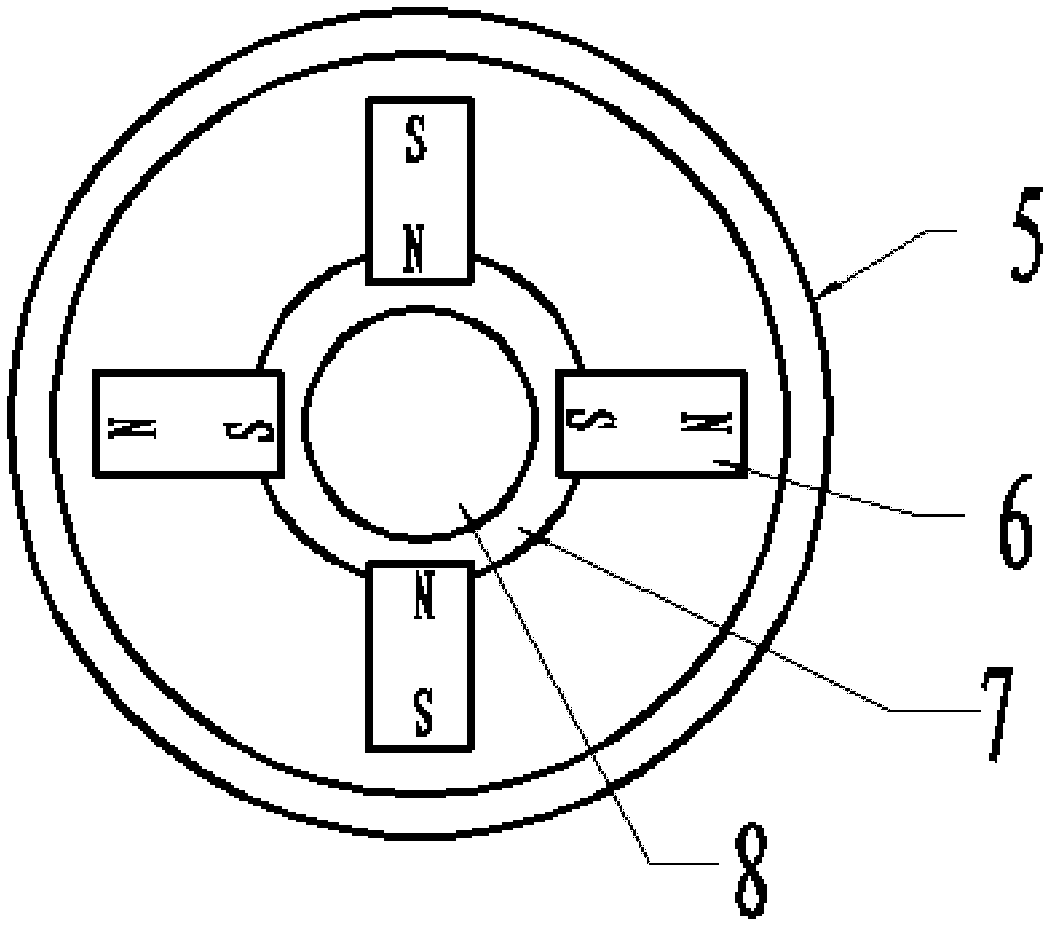

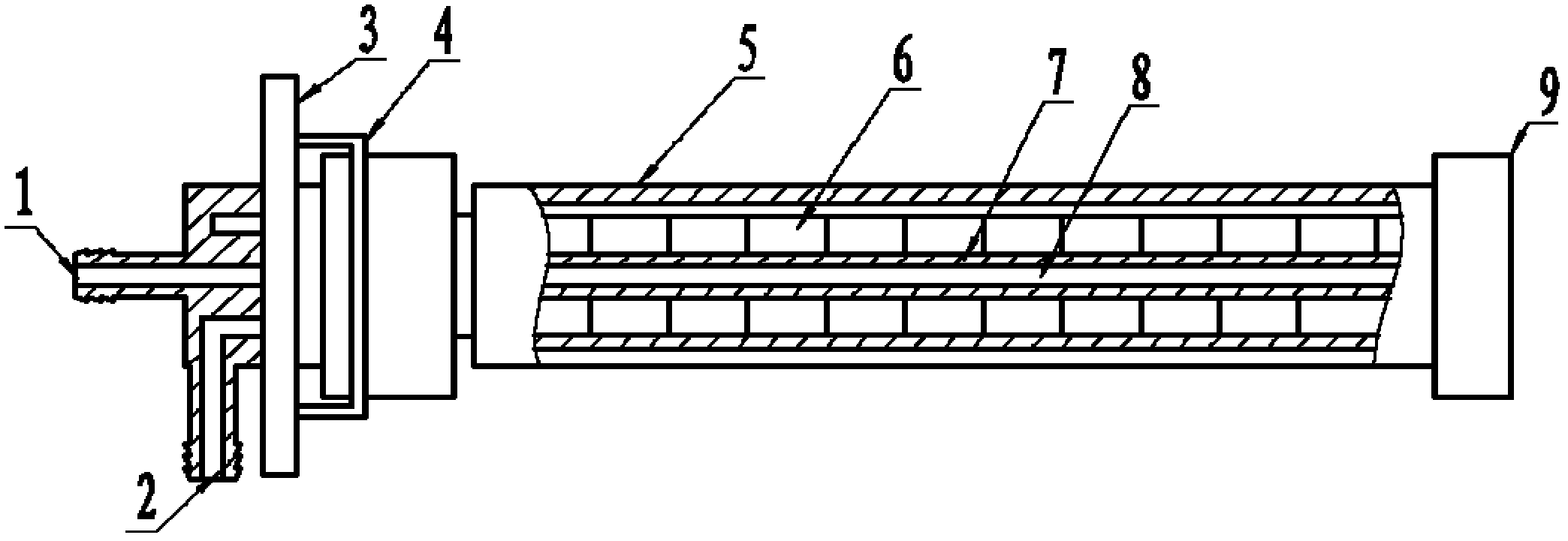

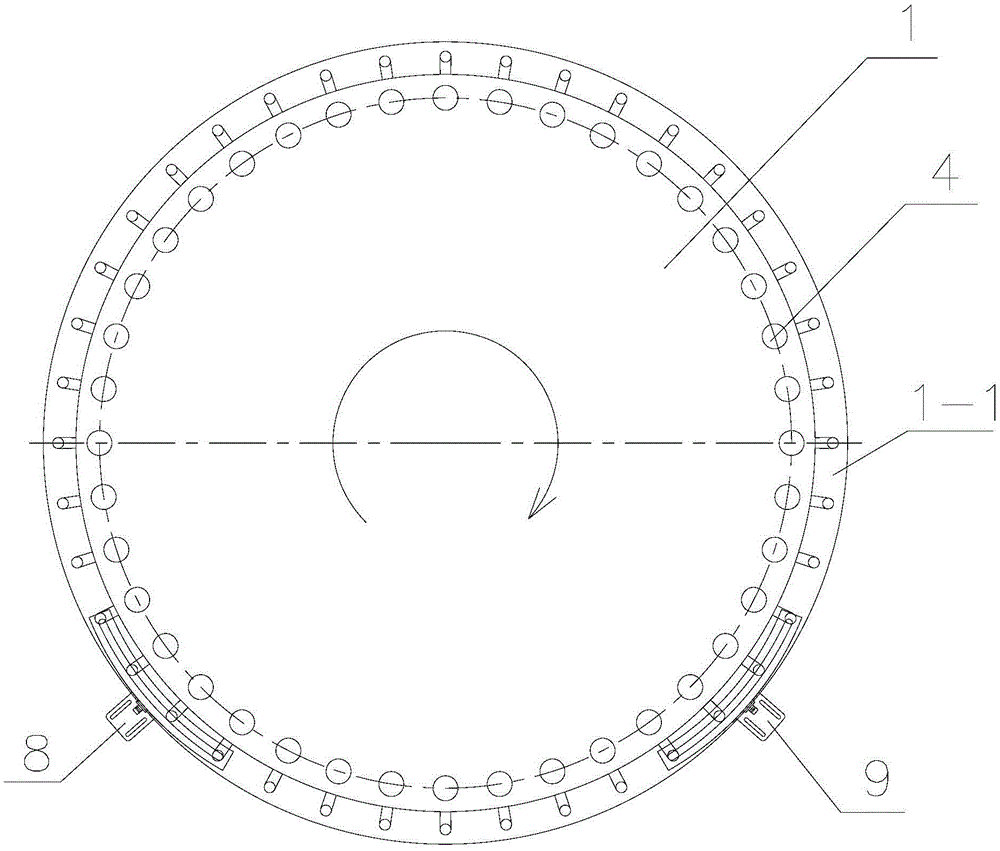

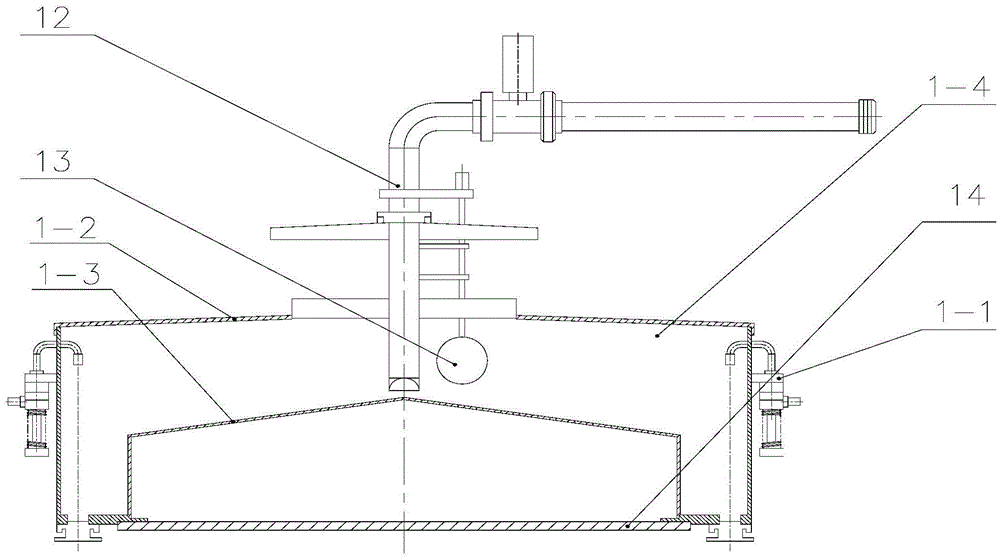

Rotating cathode mechanism

InactiveCN102560386AImprove Primary UtilizationReduce slaggingVacuum evaporation coatingSputtering coatingTarget surfaceEngineering

The invention relates to a rotating cathode mechanism which comprises a target rotating mechanism (4), a target bracket (3), a cooling water pipe (8), a pole boot (7), a plurality bar-shaped magnets (6) and a target material (5), wherein the pole boot (7), the plurality bar-shaped magnets (6) and the target material (5) are mounted outside the cooling water pipe (8) in sequence; an end cover (9) is mounted on one side of a sleeve; the target rotating mechanism (4) and the target bracket (3) are mounted at the other end of the sleeve; and a stainless steel tube is sleeved between the bar-shaped magnets (6) and the target material (5). The rotating cathode mechanism is a novel mechanism; the target material is rotated during a sputtering process, so that the consumption of the target material in the whole area is utilized to uniformly etch and the once use ratio of the target material is increased to above 80%; and the arcing and target surface residues are efficiently reduced and the stability of the technology is excellent.

Owner:WUXI KANGLI ELECTRONICS

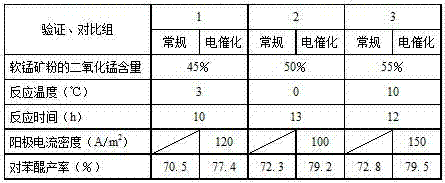

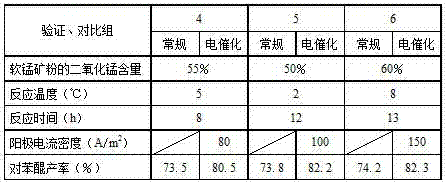

Method for preparing p-benzoquinone by electrocatalytic oxidation of phenylamine

InactiveCN102965688AImprove Primary UtilizationImprove primary yieldElectrolysis componentsElectrolytic organic productionAnilineBenzoquinone

Owner:CHONGQING YOUCUI SCI & TECH

Joint preparation method of potassium chloroplatinite and potassium chloroplatinate

ActiveCN102774894BIncrease profitSimple processRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPotassium tetrachloroplatinatePotassium

The invention relates to a joint preparation method of potassium chloroplatinite and potassium chloroplatinate. The joint preparation method comprises the steps of: completely dissolving metal platinum which is taken as a raw material by aqua regia, and adding hydrochloric acid to remove nitrogen compound to obtain chloroplatinic acid solution; neutralizing the chloroplatinic acid solution by using potassium hydroxide solution until the pH value is 5.5-7.5; adding potassium oxalate for reducing to obtain the potassium chloroplatinite; and separating out crystal, and adding hydrogen peroxide into the rest mother liquor to obtain the potassium chloroplatinate. The joint preparation method can be used for preparing two products by charging for once, is simple in technology and short in process flow, does not generate platinum-containing mother liquor, and is high in platinum utilization rate and good in product quality. The potassium chloroplatinite and the potassium chloroplatinate prepared by the invention are mainly used for manufacturing catalysts, chemically analyzing, preparing platinum-containing complexes and platinum-containing metallorganic compounds and the like, and are widely applied to industries such as military industry, electronic industry, medical industry, etc.

Owner:天津市风船化学试剂科技有限公司

A method for automatic weighing and assembling of cold-pressed recombined bamboo

ActiveCN106863506BFast growthBreeding is easyWood treatment detailsPlant material mechanical workingProcess engineeringIndustrial engineering

The present invention proposes a method for automatically weighing and assembling cold-pressed recombined bamboo, which includes the following process steps: (1) drying and sorting bamboo bundles soaked in glue; (2) alignment weighing and bundling of bamboo bundles; (3) Automatic stacking of bamboo bundles; (4) Moisture content balance and paving of bamboo bundles. Advantages: the present invention utilizes the existing drying and sorting line of dipped bamboo bundles to carry out on-line weighing, and bundles them, and after bundling, they are automatically stacked by a roller and a lifting device, and the moisture content is balanced, and then the two bundles are Or four bundles are sent into the billet trough, using this process to improve the existing cold-pressed recombined bamboo production technology, optimize its production process, improve the uniformity of cold-pressed recombined bamboo paving, reduce the labor intensity of employees, improve production efficiency and Quality guarantees the healthy development of cold-pressed bamboo recombined bamboo.

Owner:NANJING FORESTRY UNIV

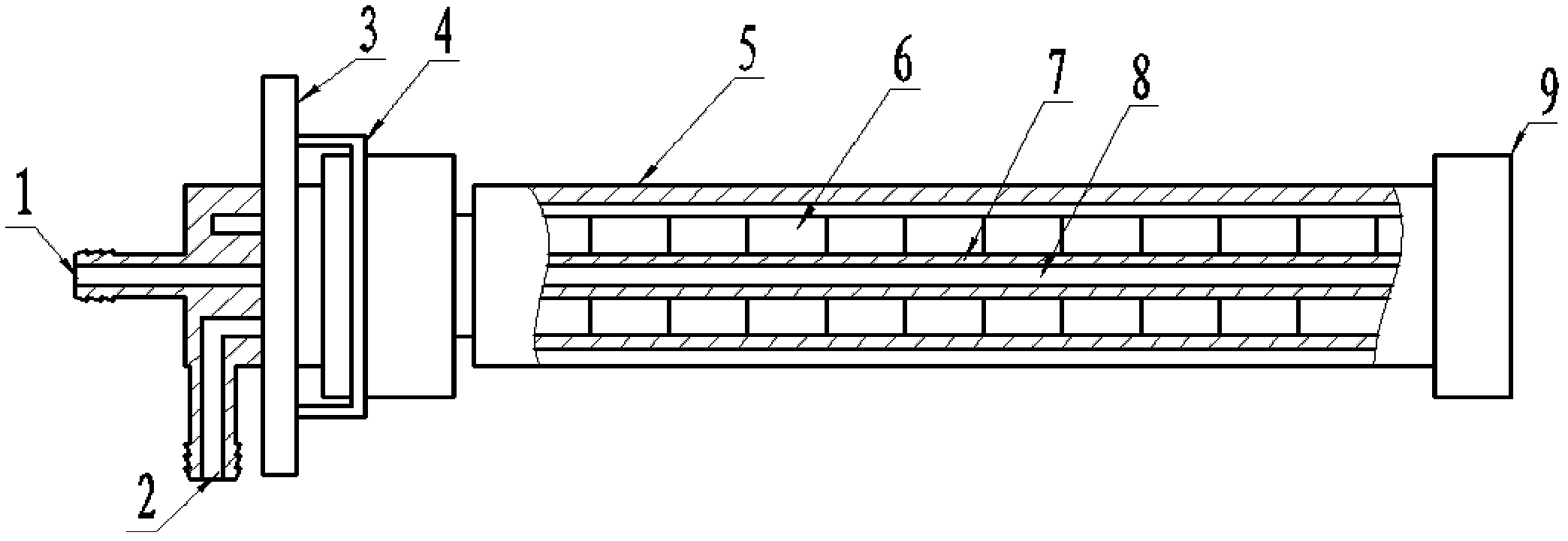

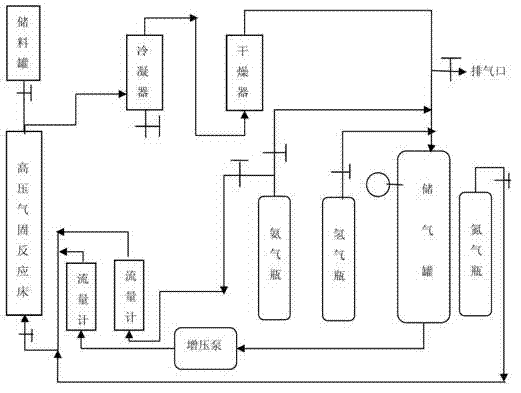

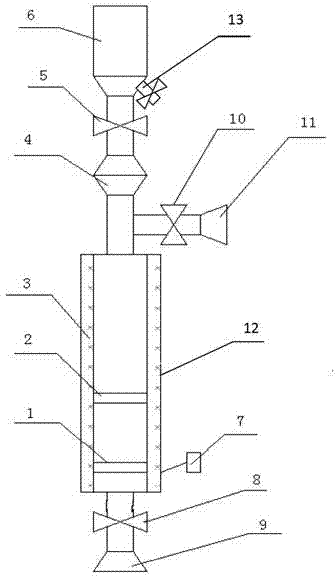

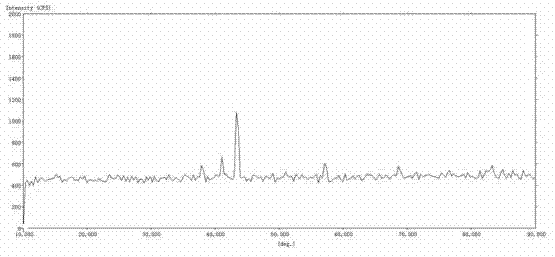

Preparation method of nitrided iron nano-powder and high-pressure gas-solid reaction bed thereof

InactiveCN103145106BIncreased pressure controlEliminate short circuitMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsFerric hydroxideInlet valve

The invention discloses a preparation method of nitrided iron nano-powder and a high-pressure gas-solid reaction bed of the nitrided iron nano-powder and effectively prepares the nitrided iron nano-powder in an energy-saving mode. The preparation method of the nitrided iron nano-powder comprises the following steps: ferric salt and alkali precipitator are quickly mixed in a reactor, and ferric hydroxide powder is obtained after the reaction; the ferric hydroxide powder is put into the high-pressure gas-solid reaction bed, and ammonia and gas storage tank gas are ventilated to conduct the reaction; under a sealing condition, reaction resultant is discharged into a material storage tank, and finally the required the crystal type nitrided iron nano-powder is obtained. The high-pressure gas-solid reaction bed of the nitrided iron nano-powder comprises a gas sparger, a powder supporting net, a heater, a quick connector, a material storage tank valve, a material storage tank, a heating power source, a thermocouple, a gas inlet valve, a gas inlet, a gas outlet valve, a gas outlet, a reaction bed side wall and a ventilation valve. The preparation method of the nitrided iron nano-powder and the high-pressure gas-solid reaction bed of the nitrided iron nano-powder are simple in operation and energy-saving, the rection equipment can be connected in parallel, and the batch production amount is big.

Owner:UNIV OF SCI & TECH LIAONING

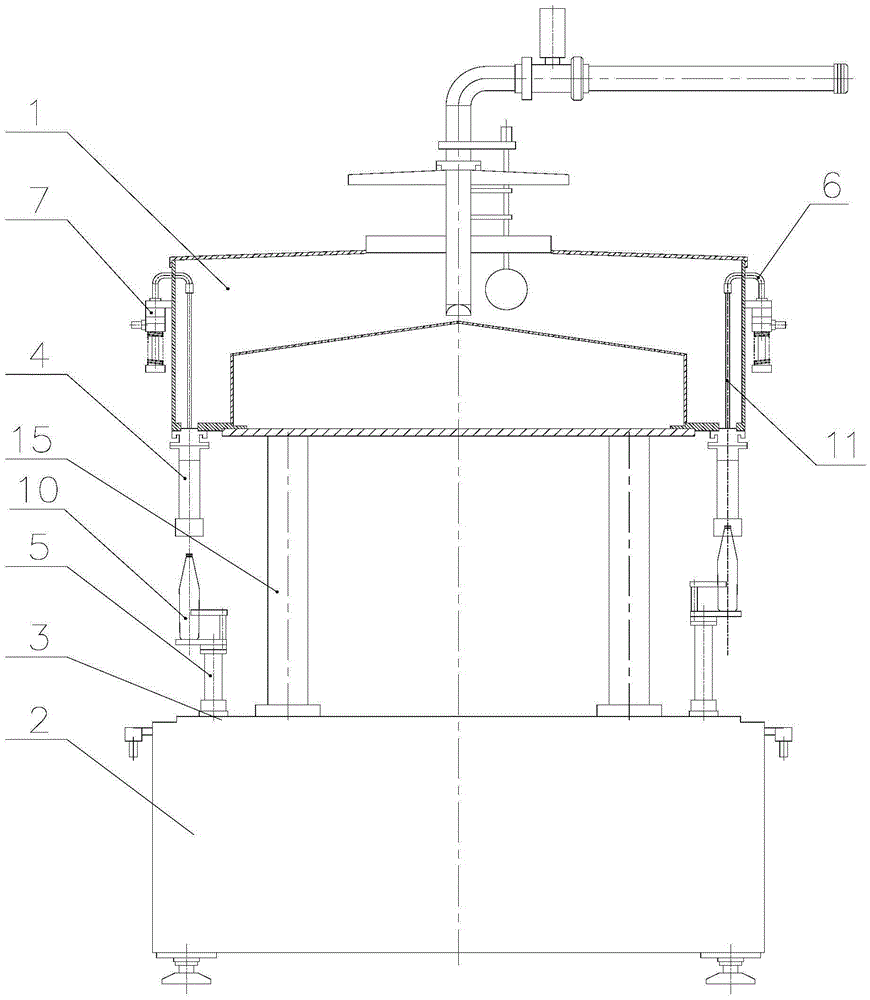

Micro-vacuum automatic balance filling machine and filling method

ActiveCN104528615BMeet filling requirementsConducive to large-scale improvementFilling using counterpressureBuffer tankEngineering

The invention discloses a micro-vacuum automatically-balanced filling machine and a filling method. A vacuumizing system is arranged on the filling machine; a plurality of vacuumizing silicone tubes are distributed on the side wall of a material cylinder of the filling machine, two ends of each vacuumizing silicone tube are respectively located on the inner and outer sides of the material cylinder, and the end parts, located on the inner side of the material cylinder, of the vacuumizing silicone tubes are connected with a central vacuumizing pipe of a filling valve; vacuumizing suction disc assemblies are respectively arranged at a bottle feeding workstation and a bottle discharging workstation on the material cylinder, the end parts, located on the outer side of the material cylinder, of the vacuumizing silicone tubes are communicated with the vacuumizing suction disc assemblies, and each vacuumizing suction disc assembly is connected with a negative pressure buffer tank and a vacuum pump through a vacuum tube. The filling method comprises the following steps that the whole vacuumizing system is in a negative pressure state; when the filling machine rotates, packaging bottles on the bottle feeding workstation are vacuumed by virtue of the vacuumizing system after packaging bottles are fed to the bottle feeding workstation, and then opening the filling valve is opened, and sauce is filled; after the packaging bottles are fed in and discharged out of the bottle discharging workstation, the filling valve is closed, and then residual sauce at bottlenecks of the packaging bottles is extracted by virtue of the vacuumizing system.

Owner:LEE KUM KEE XIN HUI FOOD

A kind of preparation technology of ultra-low viscosity dimethyl silicone oil

The invention discloses a preparation process of ultralow-viscosity dimethyl silicone oil. Low-molecule separation of dimethyl silicone oil is performed in a rectification manner, high-boiling-point components can be reserved to the greatest extent and low-boiling-point components can be separated to the greatest extent under the set rectification conditions, the content of octamethylcyclotetrasiloxane, decamethylcyclopentasiloxane and other molecules in the ultralow-viscosity dimethyl silicone oil with the higher boiling point can be further better controlled, application requirements in certain special high-end application fields such as the personal care industry can be met, besides, ultralow-viscosity linear dimethyl silicone oil with the lower boiling pointer can be captured from rectification fractions, and the one-time yield of a reaction is increased.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

A polysilicon production process and a production system for the process

ActiveCN102745694BAvoid it happening againReduce the temperatureSilicon compoundsMetallurgyCarburetor

The invention relates to a polysilicon production process and a production system used in the process. It includes mixing refined trichlorosilane with a concentration of more than 99.99% and hydrogen at a hydrogen:refined trichlorosilane molar ratio of 4 to 3:1 as a mixed gas feed into the CVD reduction furnace, and the mixed gas feed passes through the Bubble carburetor, heat exchanger for inlet and outlet, CVD reduction furnace main furnace and CVD reduction furnace auxiliary furnace connected in series; the final tail gas discharged from the CVD reduction furnace auxiliary furnace enters the CVD reduction furnace main furnace after heat exchange, and then enters the CVD reduction furnace main furnace. The surface of the silicon core in the furnace reacts to form polysilicon, and its by-product is intermediate tail gas; the intermediate tail gas is mixed with supplementary refined trichlorosilane gas and then enters the auxiliary furnace of the CVD reduction furnace, where the silicon core surface in the auxiliary furnace of the CVD reduction furnace generates The reaction produces polysilicon, and its by-product is the final tail gas; after the final tail gas comes out of the furnace, it exchanges heat with the mixed gas feed and then enters the reduction tail gas recovery system. The process and production system can produce high-quality electronic-grade polysilicon with high efficiency and low cost.

Owner:巴彦淖尔聚光硅业有限公司

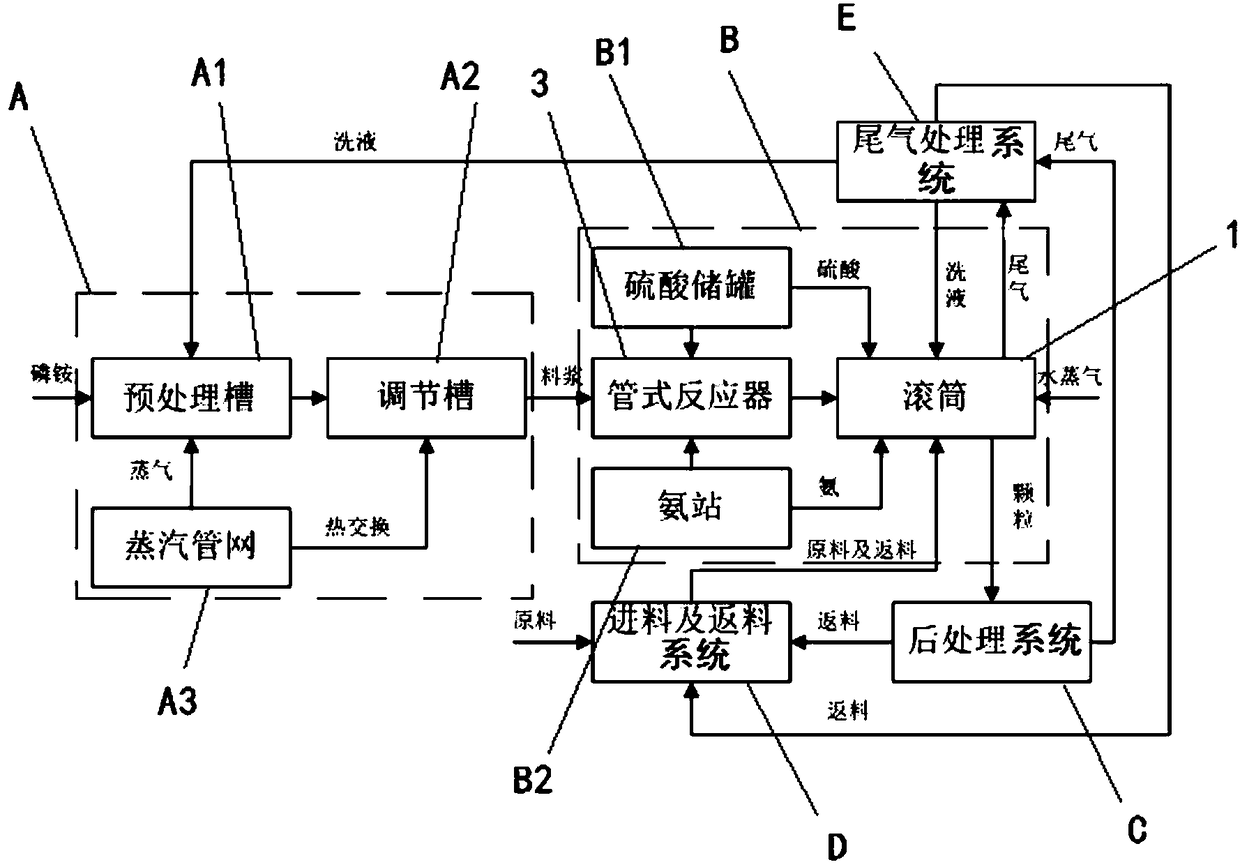

Compound fertilizer generation system

InactiveCN108440056AImprove Primary UtilizationUniform particle sizeFertilizer mixturesSolubilitySprayer

The invention discloses a compound fertilizer generation system, and solves the problems of uneven particle, high moisture content, more returning charge and the like in the production and granulationprocesses of the existing compound fertilizer. In the technical scheme, the compound fertilizer generation system comprises a pretreatment system, a granulation system, a posttreatment system and a charge and returning charge system which are sequentially connected, the granulation system comprises a roller provided with a drive device, a discharge structure is connected to the rear end of the roller, a charge tube, an acid mixing tube, a tubular reactor and an ammonia spraying tube bundle are sequentially arranged at the front section of the roller from top to bottom, the acid mixing tube, the tubular reactor and the ammonia spraying tube bundle are respectively provided with a sprayer; the charge tube is connected with the charge and returning charge system, the tubular reactor is connected with an ammonia station, the pretreatment system and a sulfuric acid storage tank respectively; the acid mixing tube is connected with a tail gas treatment system and the sulfuric acid storage tank respectively; and the ammonia spraying tube bundle is connected with the ammonia station. The system is simple, saves energy and reduces consumption, the product strength is high, the returning rate is low, the production efficiency is high, the water solubility is good, and the compound fertilizer generation system is environmentally friendly.

Owner:HUBEI UNIV OF TECH

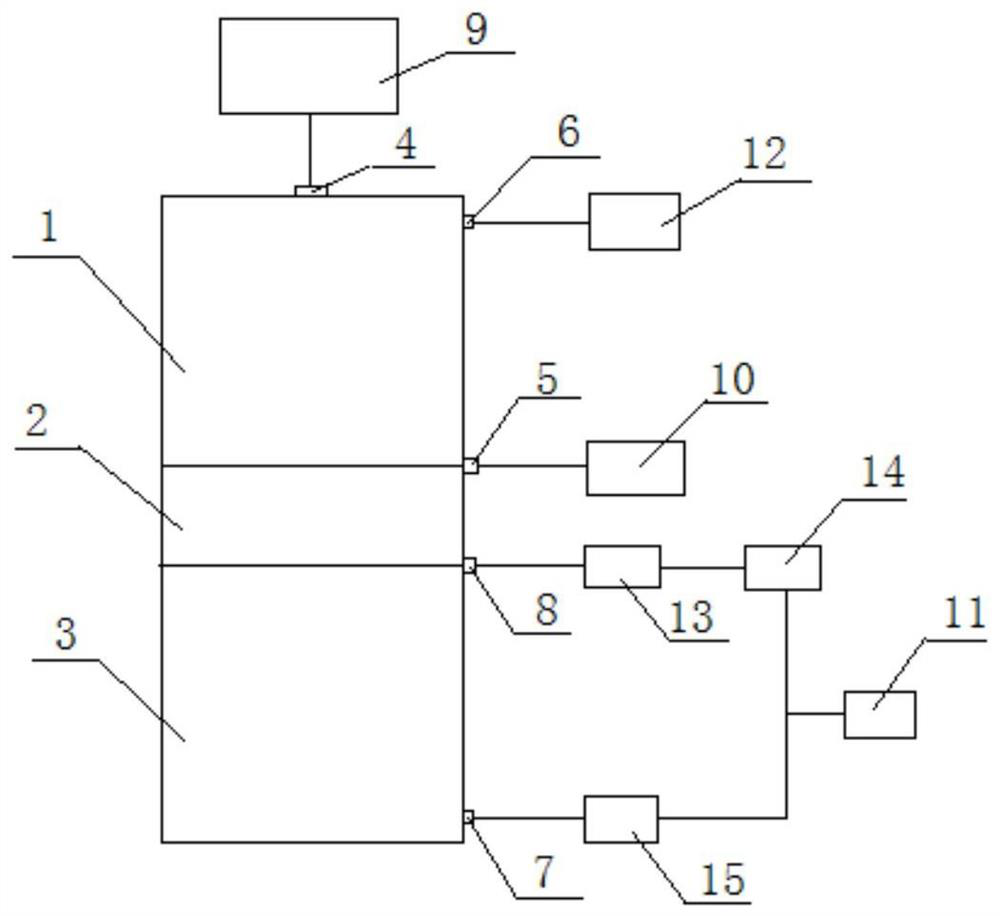

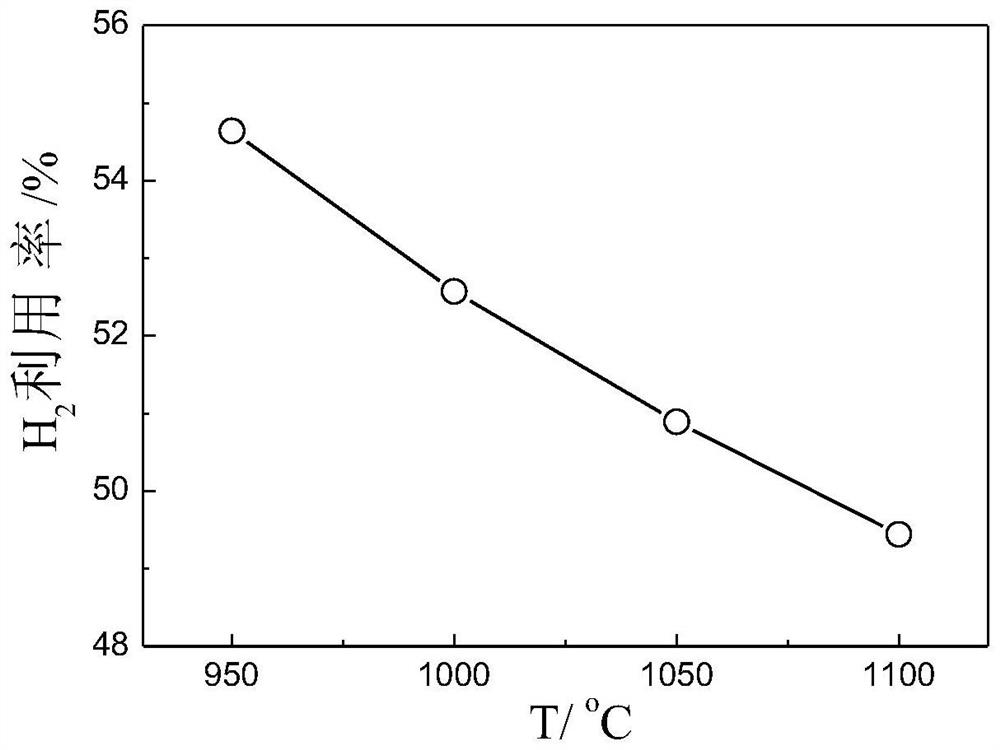

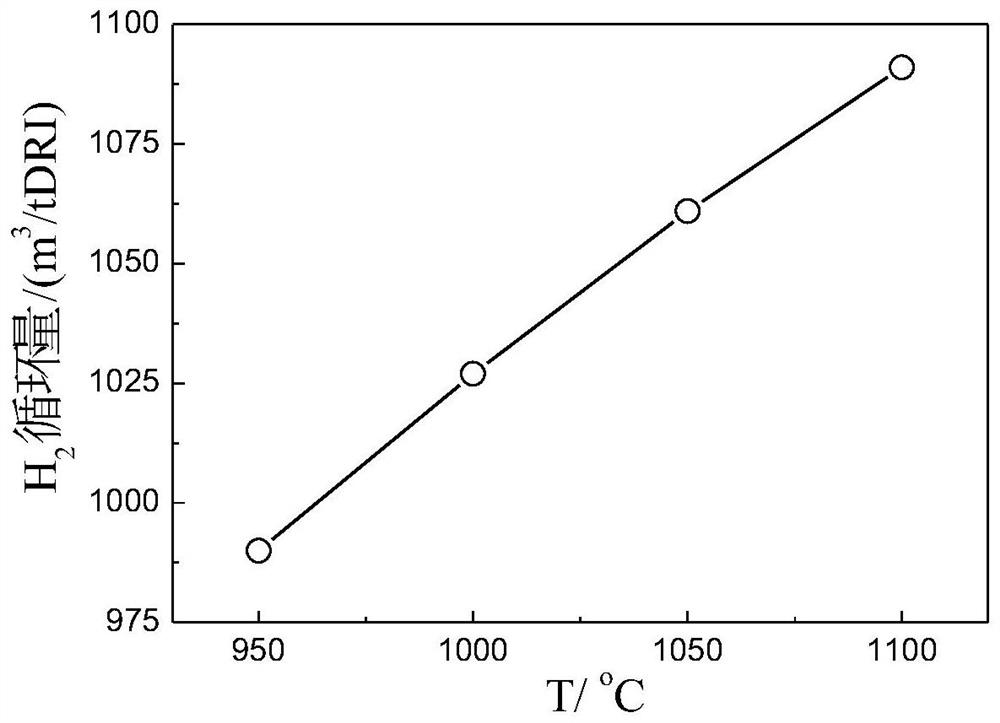

Heating-pure hydrogen reduction cooling system and method

The invention relates to a heating-pure hydrogen reduction cooling system and method, belongs to the technical field of shaft furnace reduction in the metallurgical process, and solves the problem of low hydrogen utilization rate in the prior art. The heating-pure hydrogen reduction cooling system comprises a heating section, an isobaric section and a reduction cooling section which are sequentially communicated from top to bottom; the heating section is provided with an oxidized pellet inlet, a hot flue gas inlet and a flue gas outlet, oxidized pellets from the oxidized pellet inlet are in contact with hot flue gas from the hot flue gas inlet in the heating section, the flue gas after contact is discharged from the flue gas outlet, and the oxidized pellets after contact enter the isobaric section; the reduction cooling section is provided with a hydrogen inlet and a gas outlet, oxidized pellets from the isobaric section and hydrogen from the hydrogen inlet are reduced and cooled in the reduction cooling section, and gas generated in the reduction and cooling process is discharged from the gas outlet. The hydrogen utilization rate is improved.

Owner:CENT IRON & STEEL RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com