Patents

Literature

68results about How to "Eliminate short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

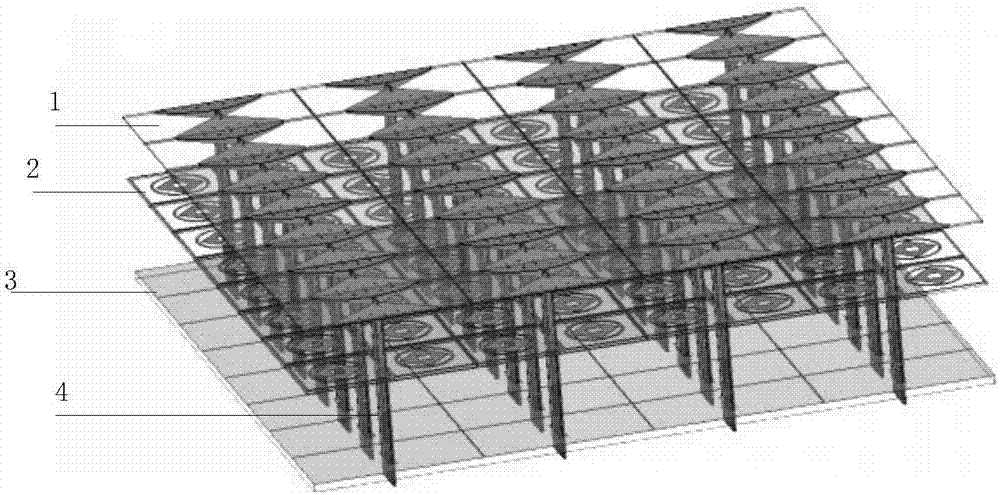

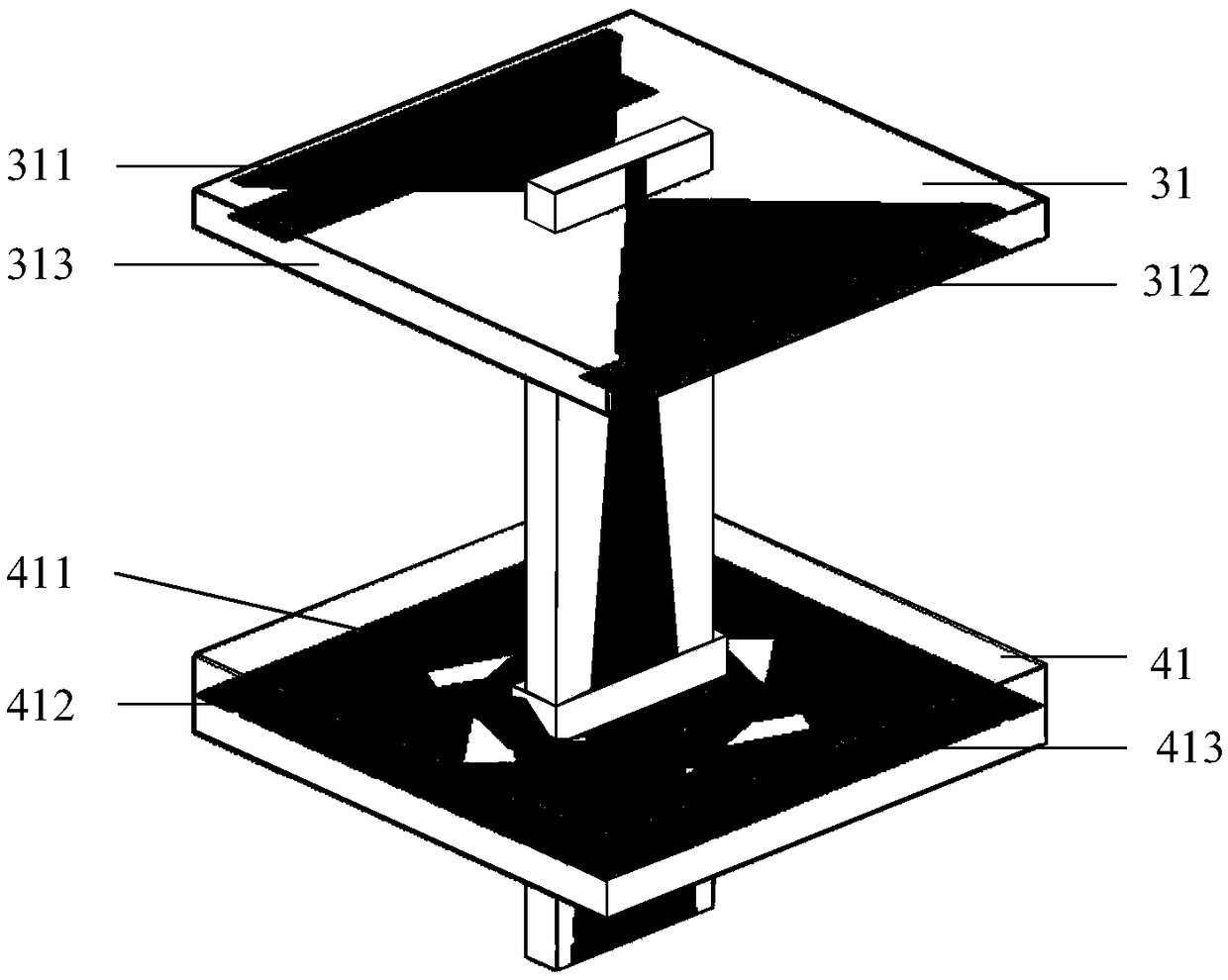

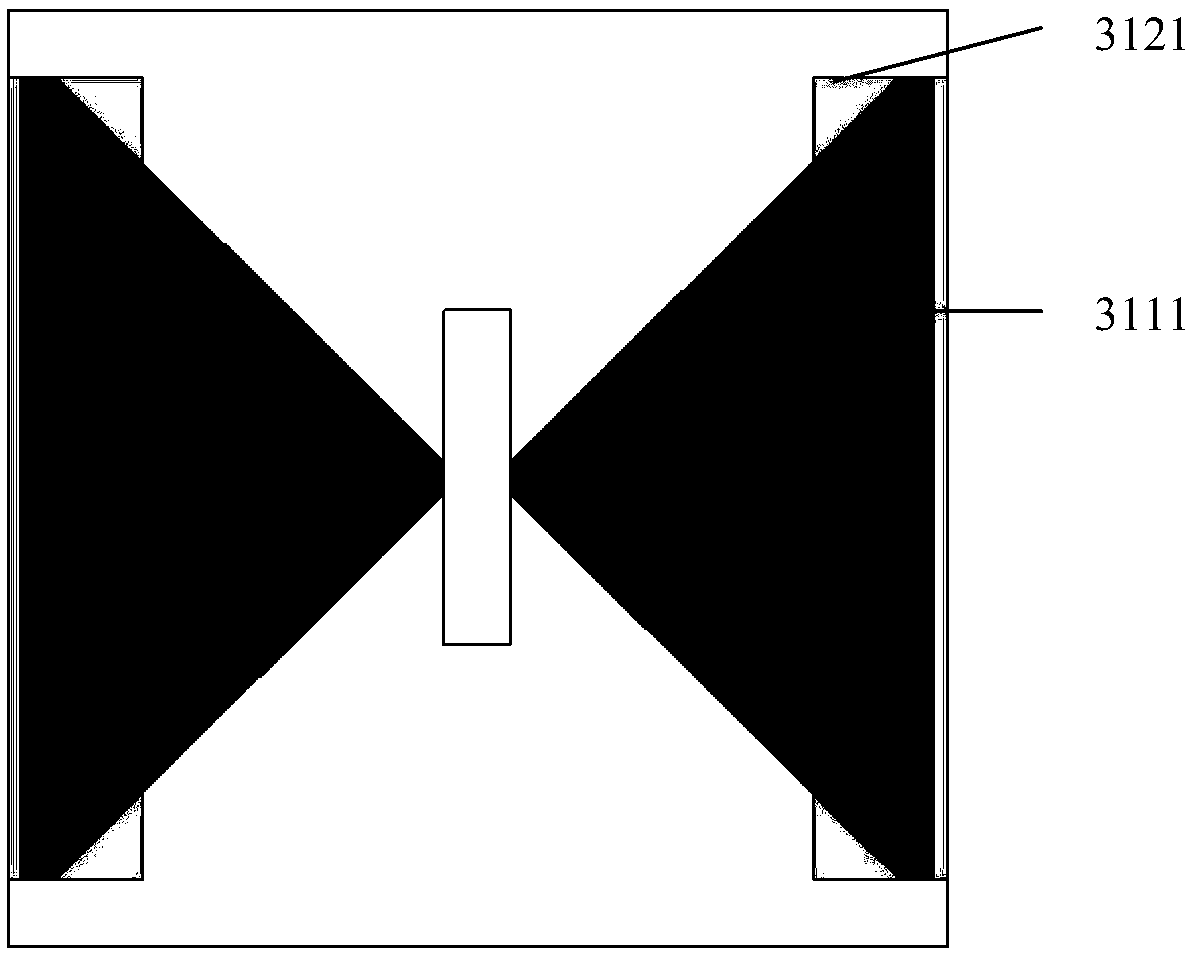

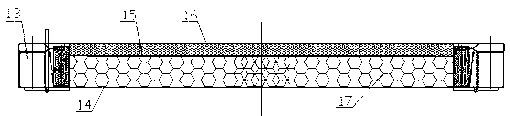

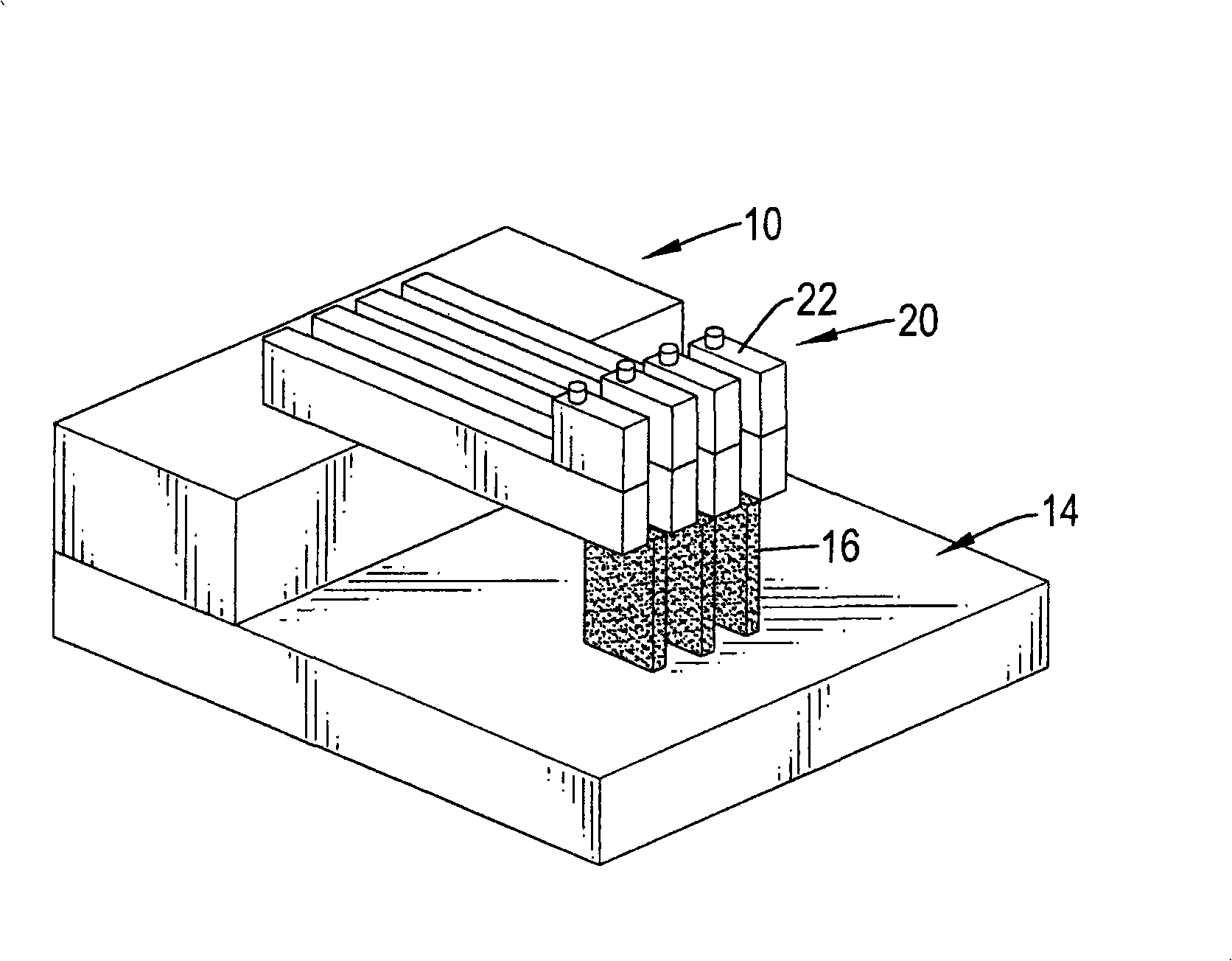

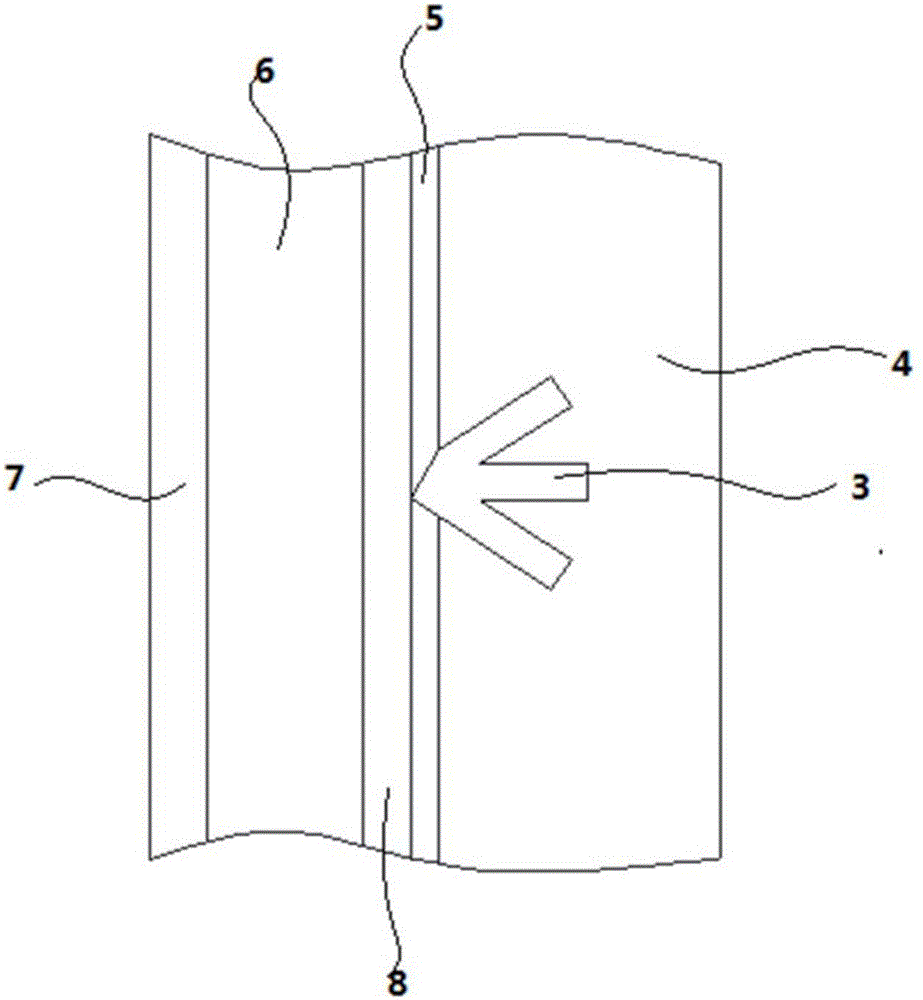

UWB (ultra wide band) array antenna

InactiveCN107275775AImprove the coupling effectHigh bandwidthParticular array feeding systemsRadiating elements structural formsClose couplingDipole antenna

The invention discloses a UWB (ultra wide band) array antenna, and mainly solves a problem that the bandwidth of a conventional array antenna is limited by the bandwidth of an antenna unit. The antenna comprises a dipole antenna array plate (1), a resistor-type frequency selection surface plate (2), a grounding plate (3) and a feed Balun (4). The antenna array plate consists of a plurality of dipole radiation periodic units, and each dipole radiation periodic unit comprises a dipole arm (111), a metal via hole (112) and a dielectric plate (113), wherein the dipole arms (111) are arranged on the upper and lower surfaces of the antenna array plate in a cross manner. The resistor-type frequency selection surface unit consists of a resistor paster and a dielectric plate, wherein the resistor paster consists of a square ring paster, a circular ring, and a rhombus paster. Through the close coupling between units, the reflection coefficient of the antenna at the band from 0.63GHz to 4.6GHz is less than or equal to -6dB, and the array bandwidth can be increased to 7.3 frequency multiplications. The antenna is used for FOPEN radars and through-the-wall imaging radars.

Owner:XIDIAN UNIV

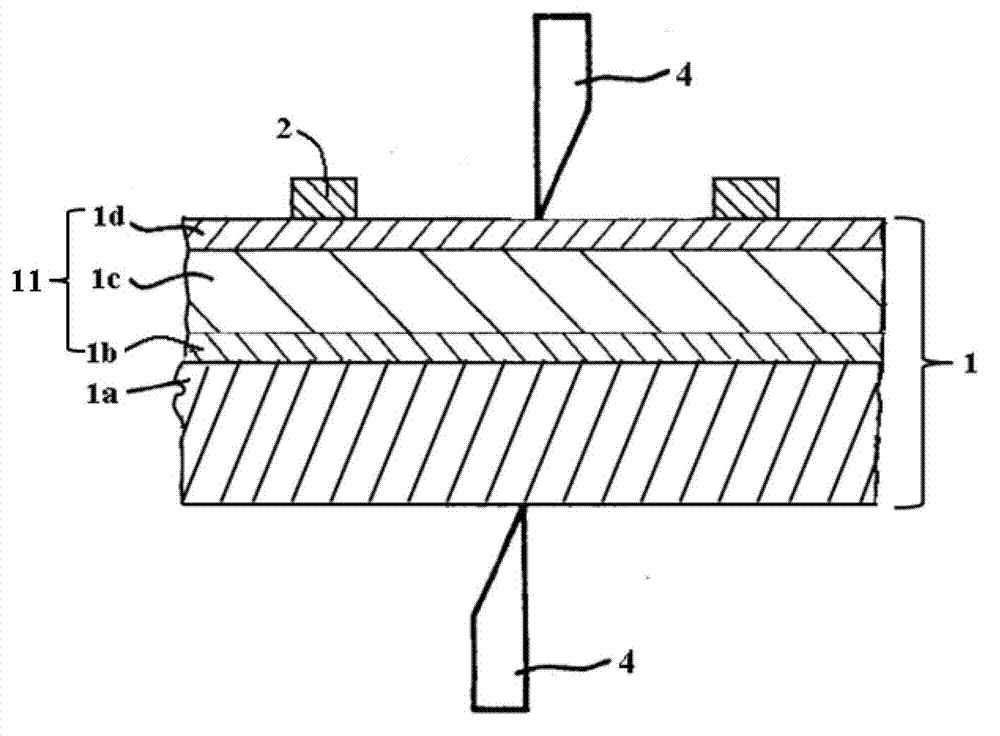

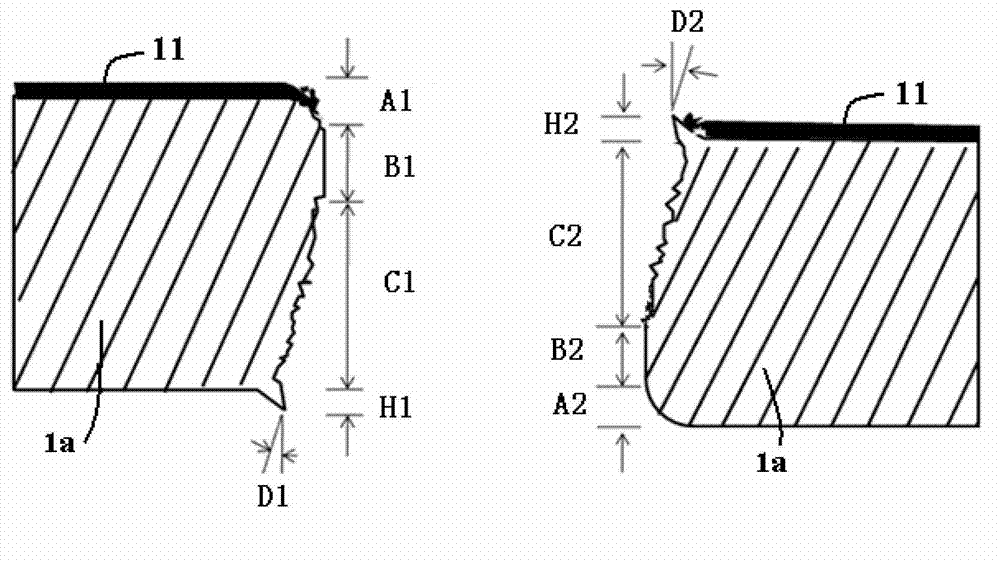

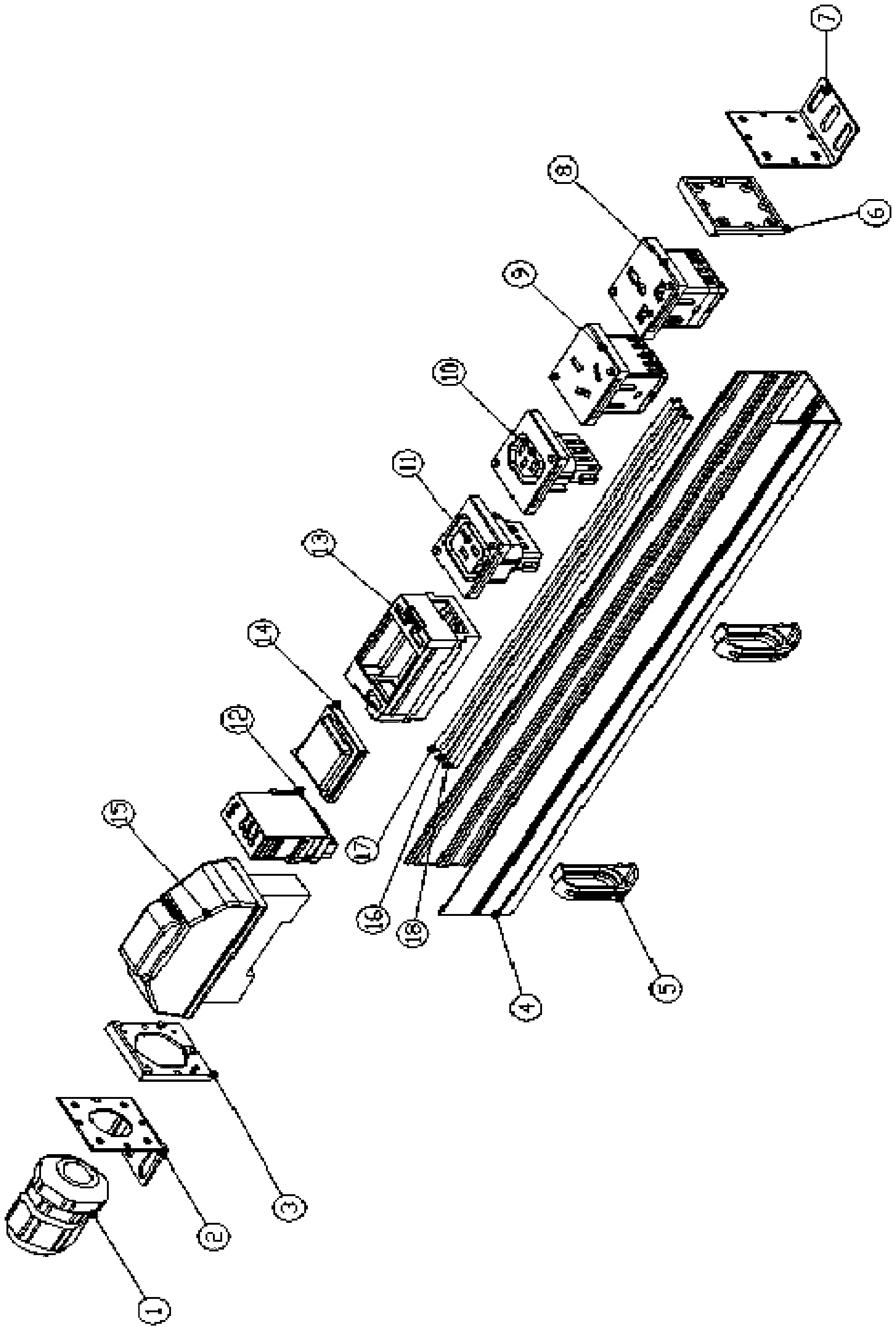

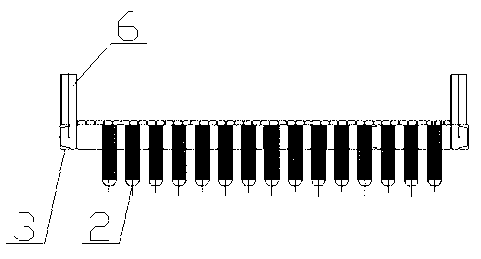

Cutting equipment and cutting method of flexible thin film solar cell

InactiveCN103050578AEliminate short circuitImprove compatibilityFinal product manufactureSemiconductor devicesControl systemMaterial consumption

The invention discloses cutting equipment of a flexible thin film solar cell. The cutting equipment comprises an uncoiling mechanism, a conveying mechanism, a scoring mechanism, a cutting mechanism, a finished product coiling mechanism, a leftover coiling mechanism and a control system, wherein the control system is used for controlling the respective work of the uncoiling mechanism, the conveying mechanism, the scoring mechanism, the cutting mechanism, the finished product coiling mechanism and the leftover coiling mechanism. The invention also discloses a method for cutting the flexible thin film solar cell by the cutting equipment. The method comprises the following steps of uncoiling a cell to be cut, receiving and conveying the cell to be cut by the conveying mechanism, sequentially scoring and cutting the cell to be cut, coiling the obtained finished product by the finished product coiling mechanism, and coiling the cut leftovers by the leftover coiling mechanism. The cutting equipment and the cutting method have the advantages that the short-circuiting of the thin film solar cell caused by cutting can be thoroughly avoided by the cutting method; the automation degree is high, and the qualified rate of the flexible thin film solar cell and the production efficiency are improved; the material consumption amount is little, and the production cost is low; and the splitting process is simple, the equipment is simple, and the operation is convenient.

Owner:普尼太阳能(杭州)有限公司

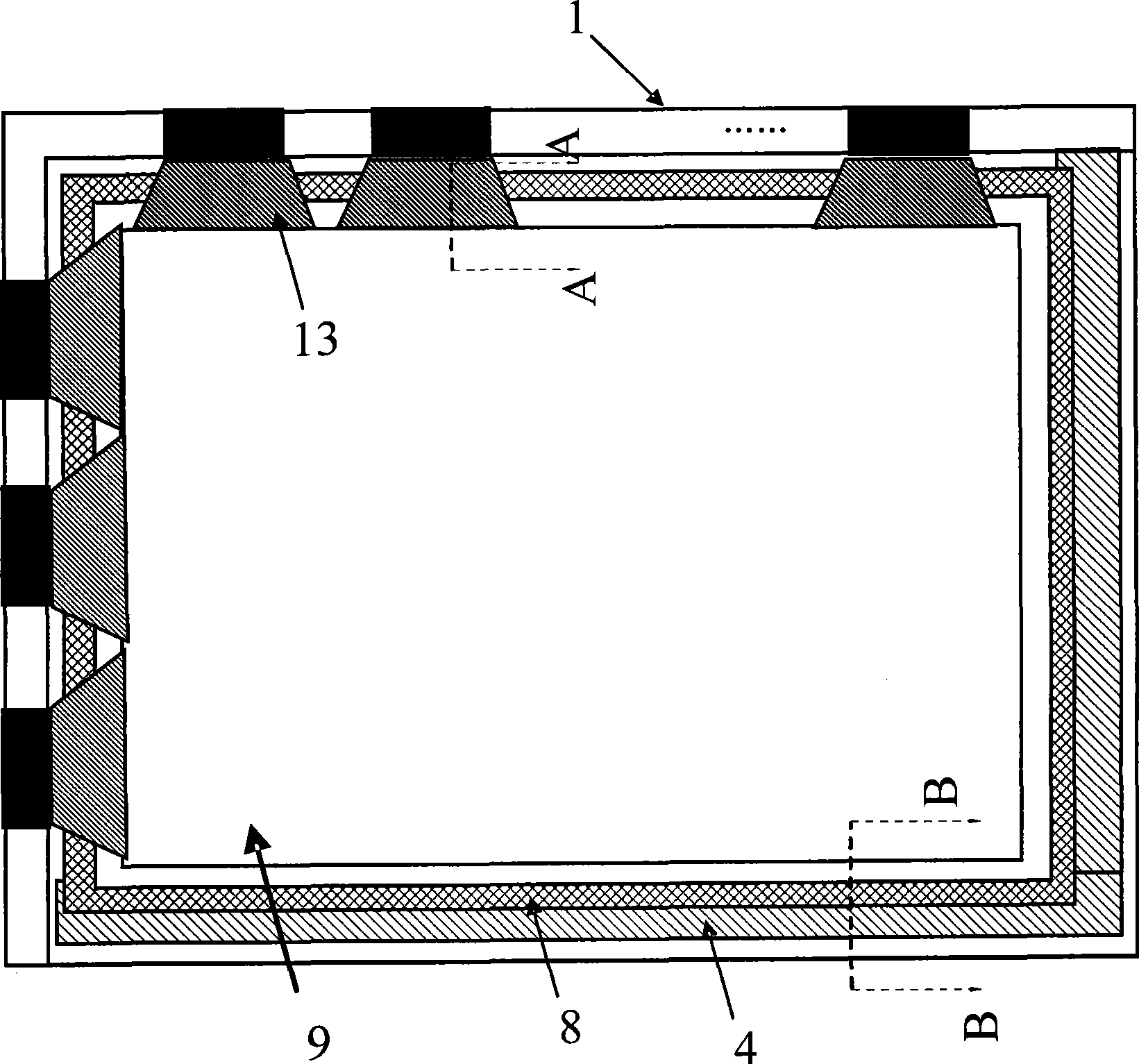

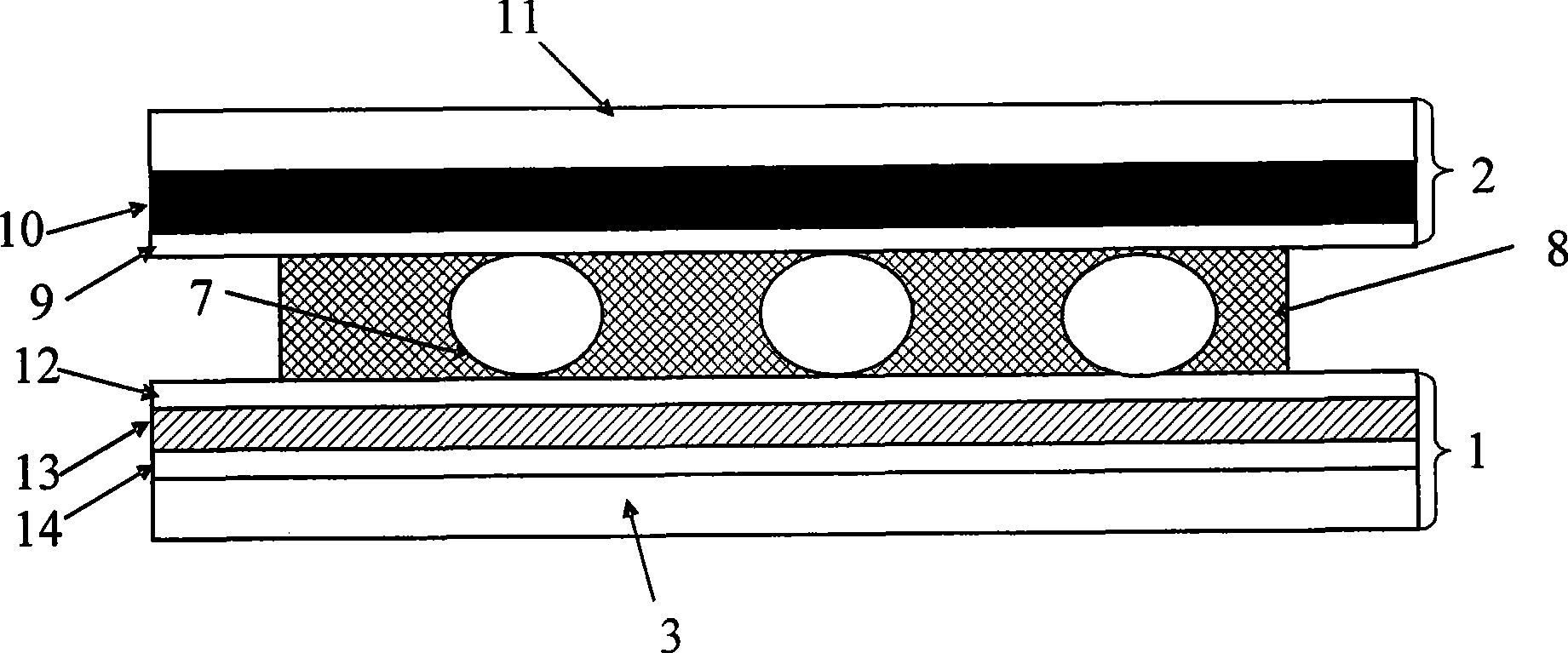

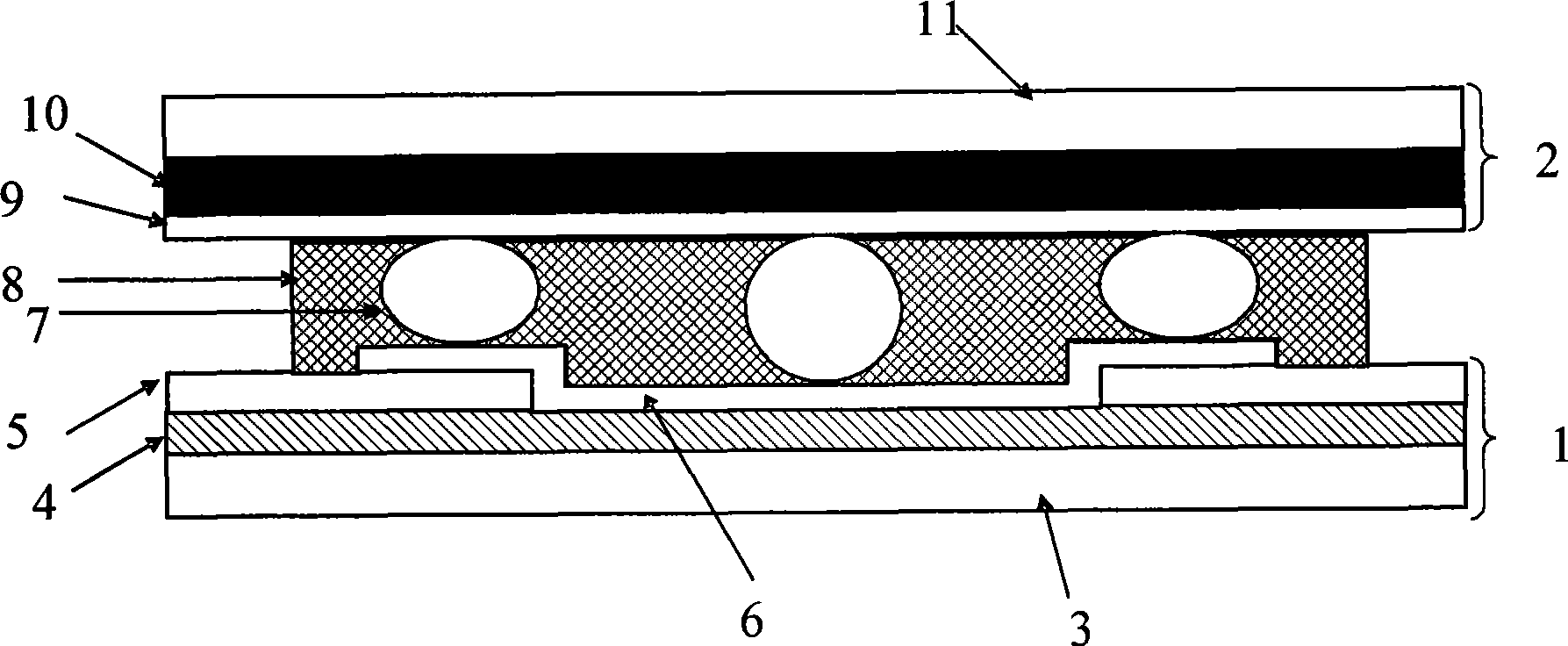

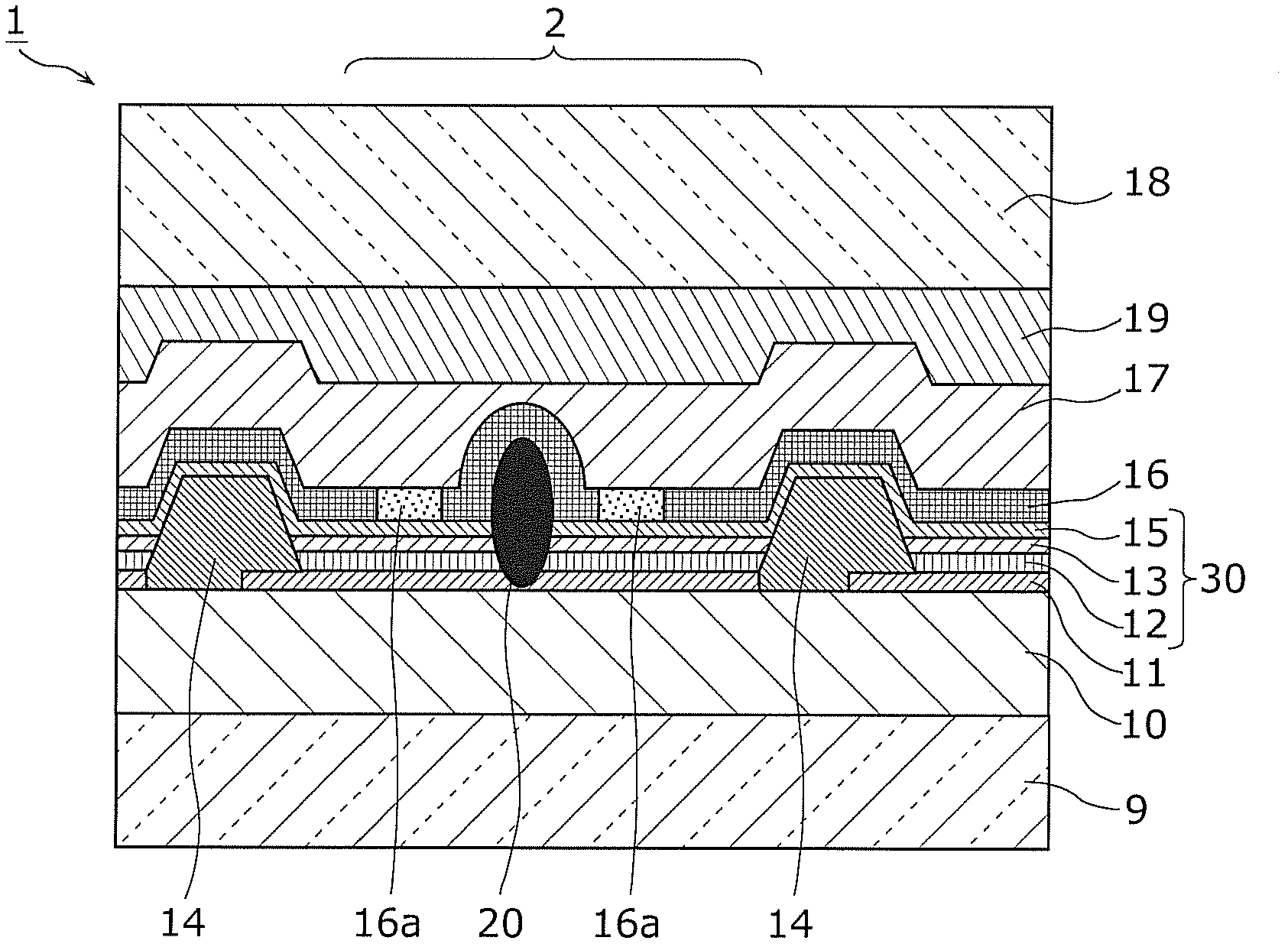

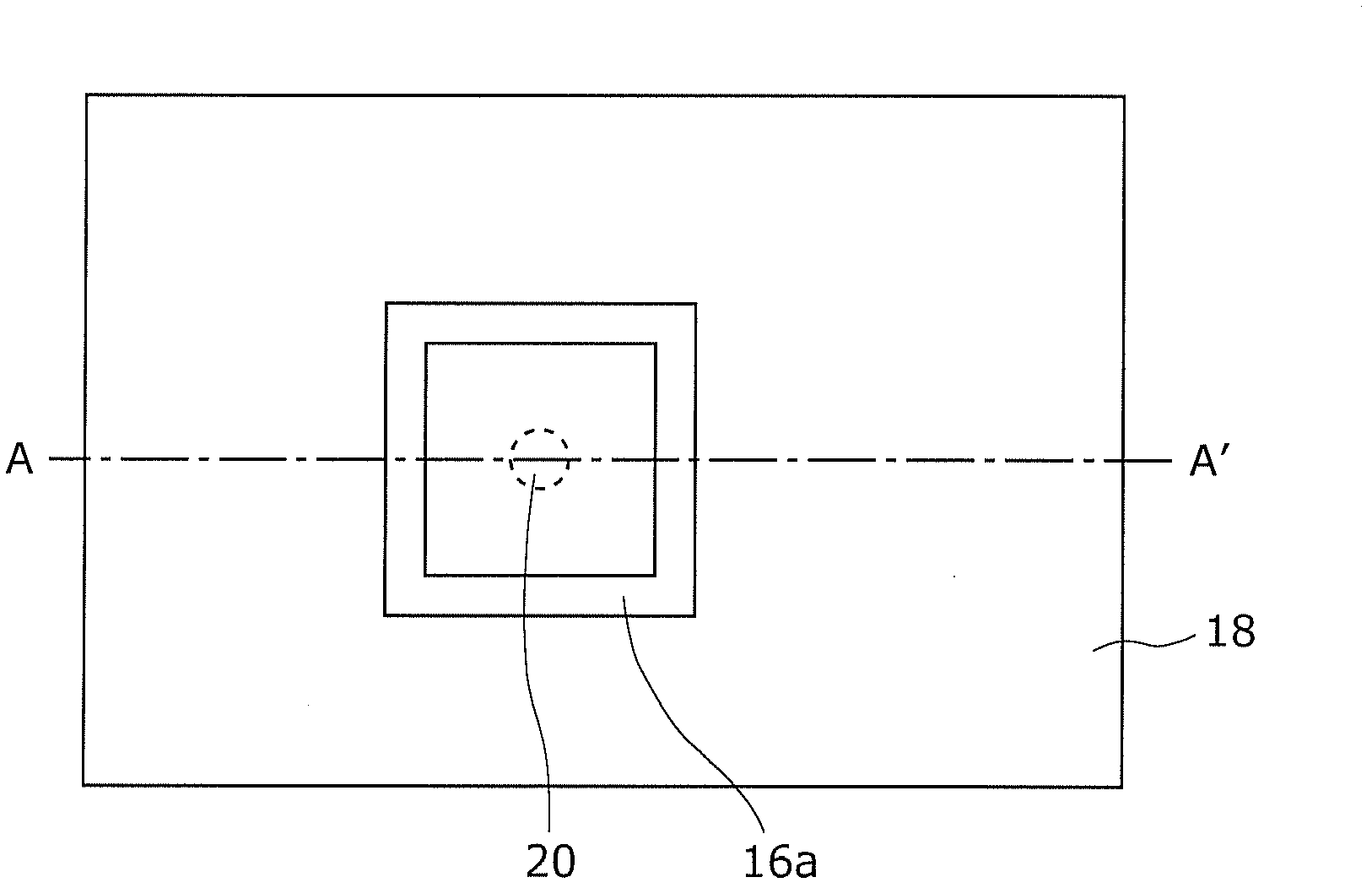

Liquid crystal display panel and restoring method thereof

InactiveCN101435923AEliminate short circuitImprove yield rateNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a liquid crystal display panel and a restoring method thereof. The liquid crystal display panel comprises an array substrate, a colored film substrate and signal leads on the array substrate, wherein restoring wires overlapped with the signal leads are arranged among the signal leads. The restoring method comprises: cutting off two ends of a shorted signal lead out of an applying range of a hermetical rim substratum by a laser beam, so as to ensure that two ends of the cut point are not communicated electrically; and then, dotting the overlapped area of the signal leads and the corresponding restoring wires by the laser beam, so as to puncture an insulating layer between each signal lead and each corresponding restoring wire, and melt and combine the signal lead and the corresponding restoring wire together, thereby communicating the signal lead and the corresponding restoring wire electrically. The liquid crystal display panel eliminates adverse display caused by short circuit between the signal lead and a gold ball particle through cutting off the shorted signal lead and utilizing the mode of continuing transferring signals by the restoring wire, thereby improving the yield of the liquid crystal display panel.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

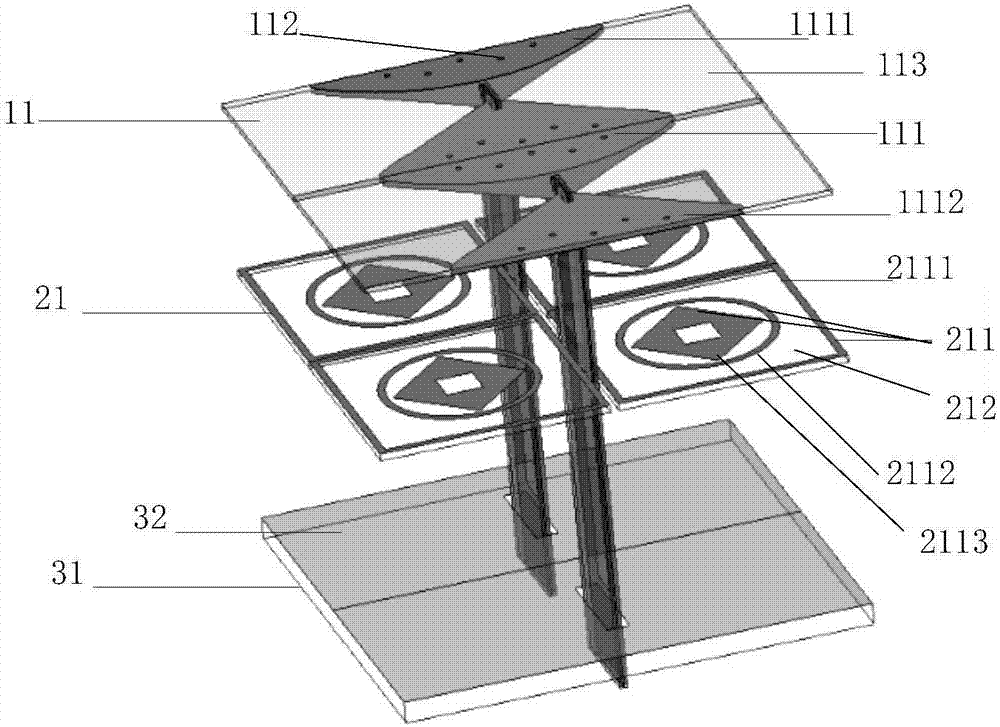

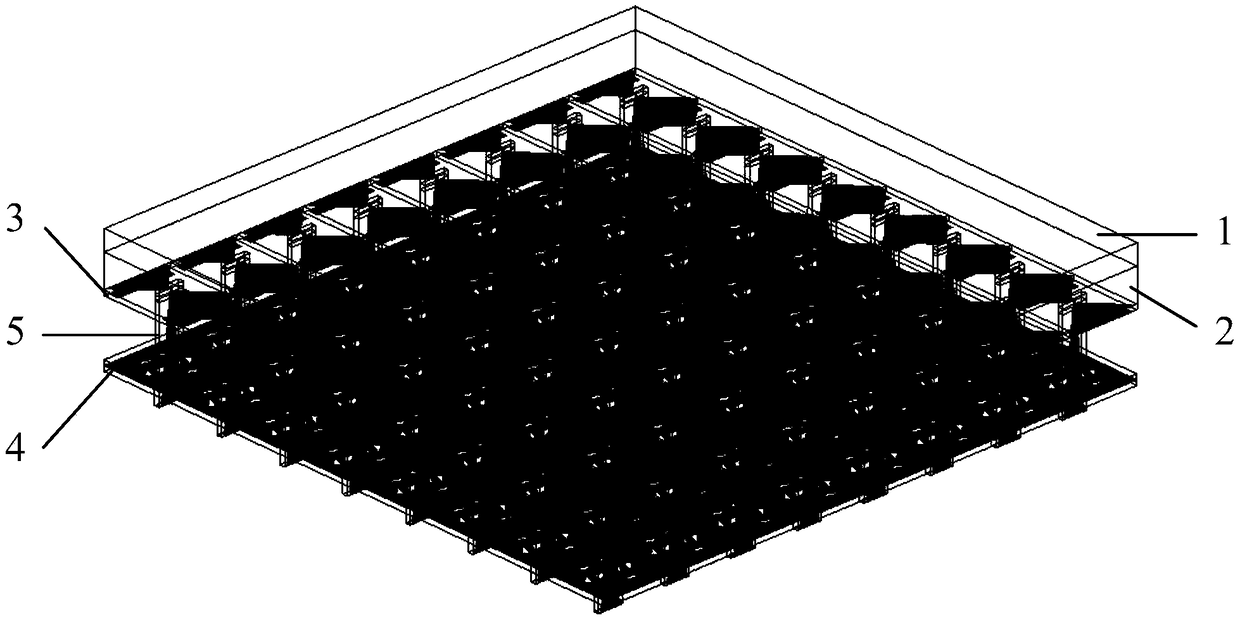

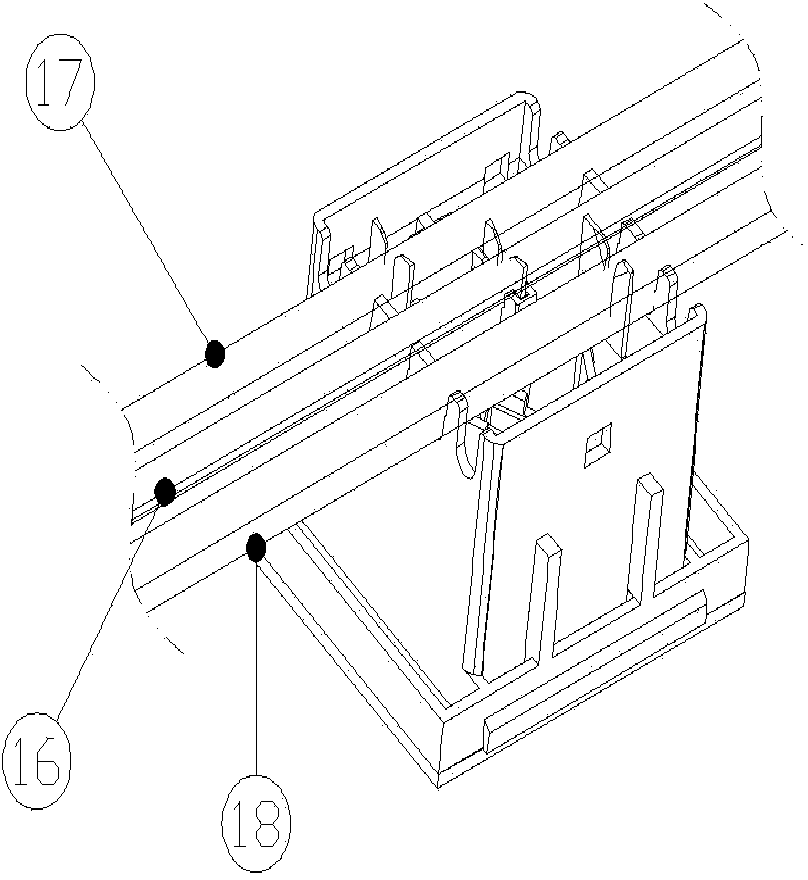

Ultra-wideband tightly coupled array antenna

ActiveCN109216940AWorking bandwidthHigh bandwidthParticular array feeding systemsRadiating elements structural formsUltra-widebandRadar systems

The invention provides a novel ultra-wideband tight coupling array, comprising a first matching layer, a second matching layer, an antenna array board, a frequency selection surface board and a feeding balun array. The antenna array board is positioned directly above the frequency selection surface board. The antenna array plate comprises a plurality of dipole radiation periodic units, each dipoleradiation periodic unit comprises a dipole arm, a coupling metal patch and an antenna dielectric plate; The frequency selective surface plate includes a plurality of frequency selective surface units, the dipole arm is composed of two first metal patches, the coupling metal patch includes two second metal patches, and each frequency selective surface unit is composed of two four-fold circular ring patches, a hexagonal star gap patch and two layers of frequency selective surface dielectric plates. A frequency selective surface is used to eliminate short-circuit points, the VSWR is less than 3in the frequency range of 1.14 GHz to 11.2 GHz, and the array bandwidth can be increased to 9.8 octaves, which can be used in communication and satellite tracking radar systems.

Owner:XIDIAN UNIV

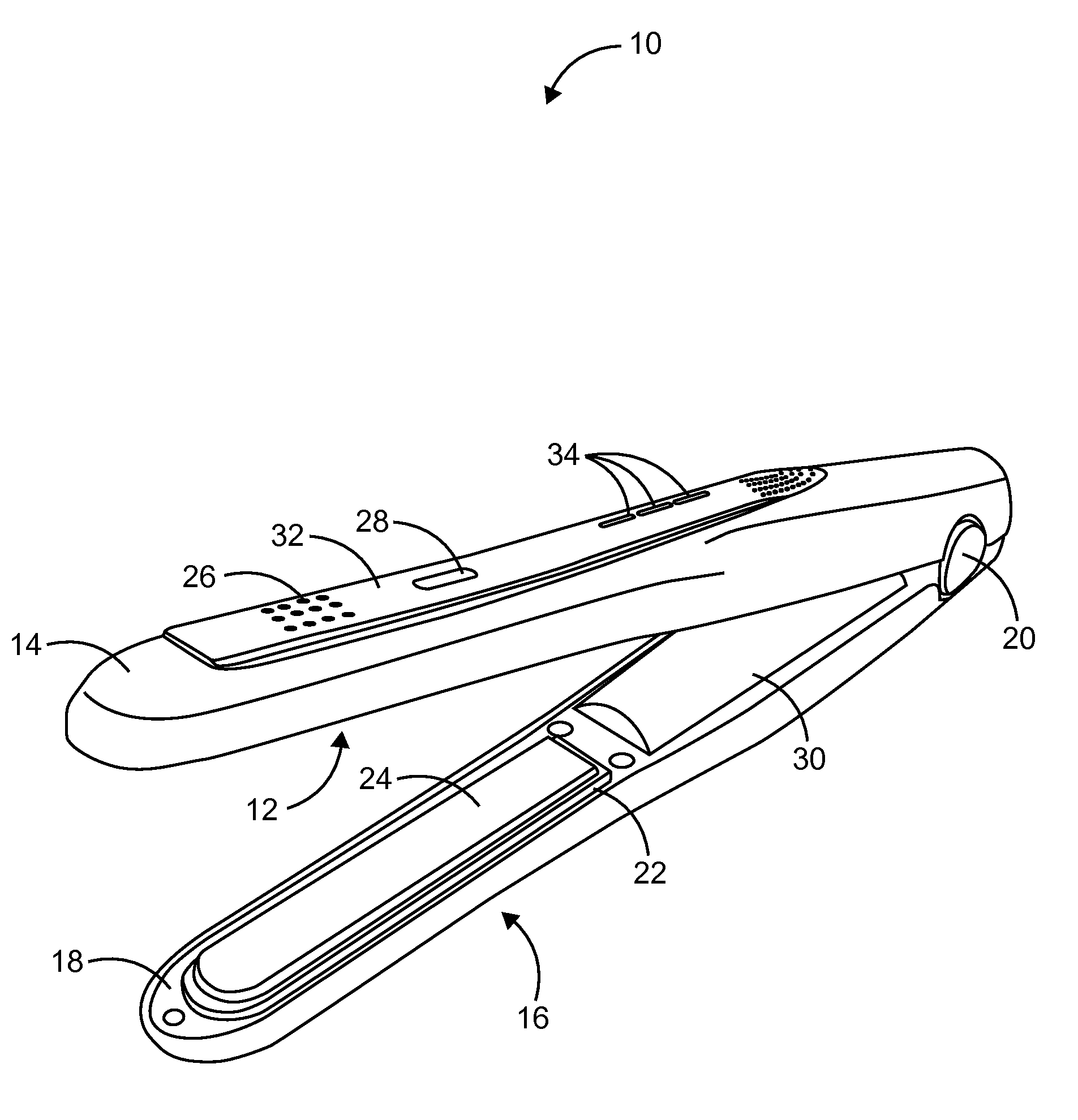

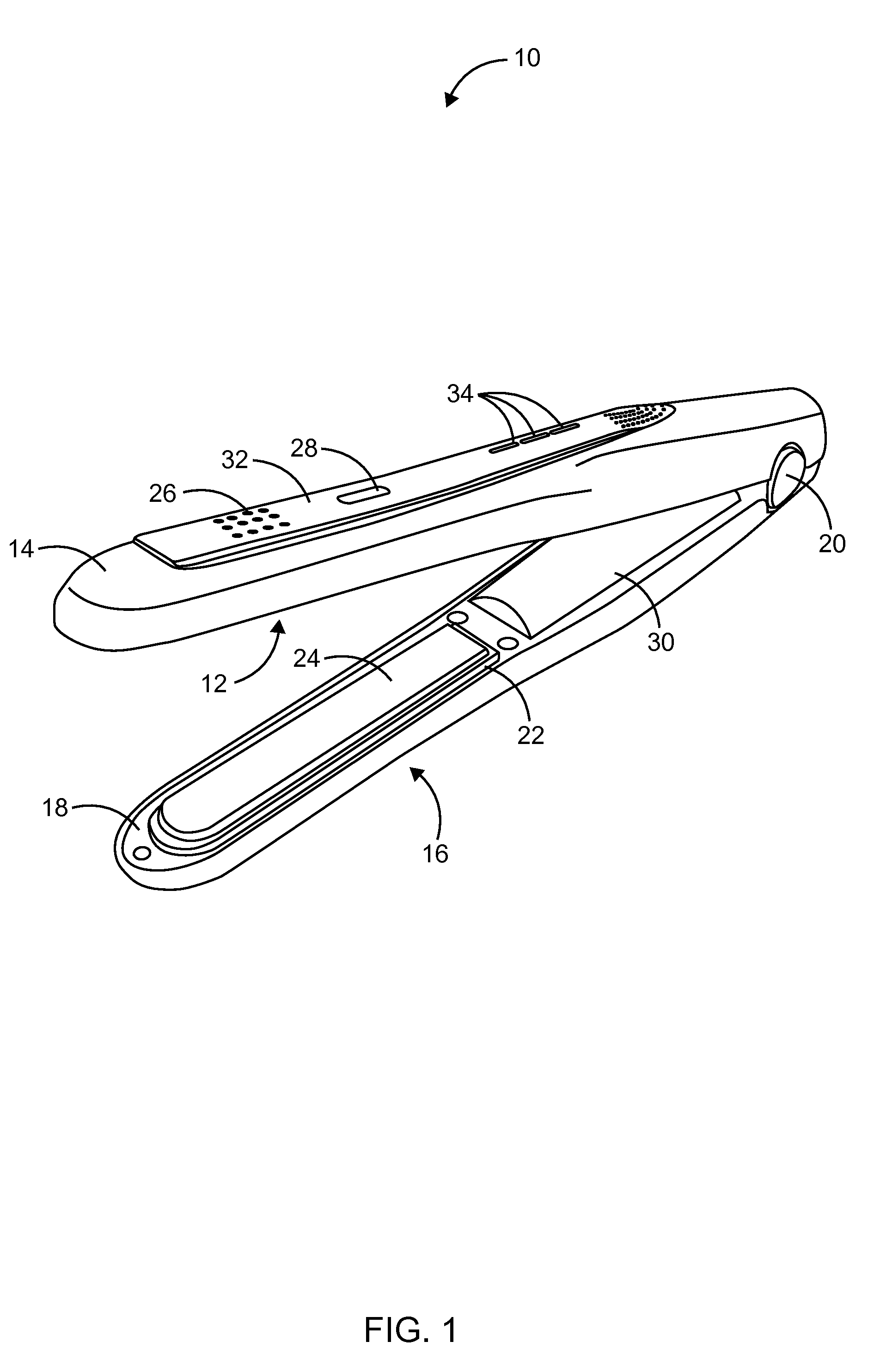

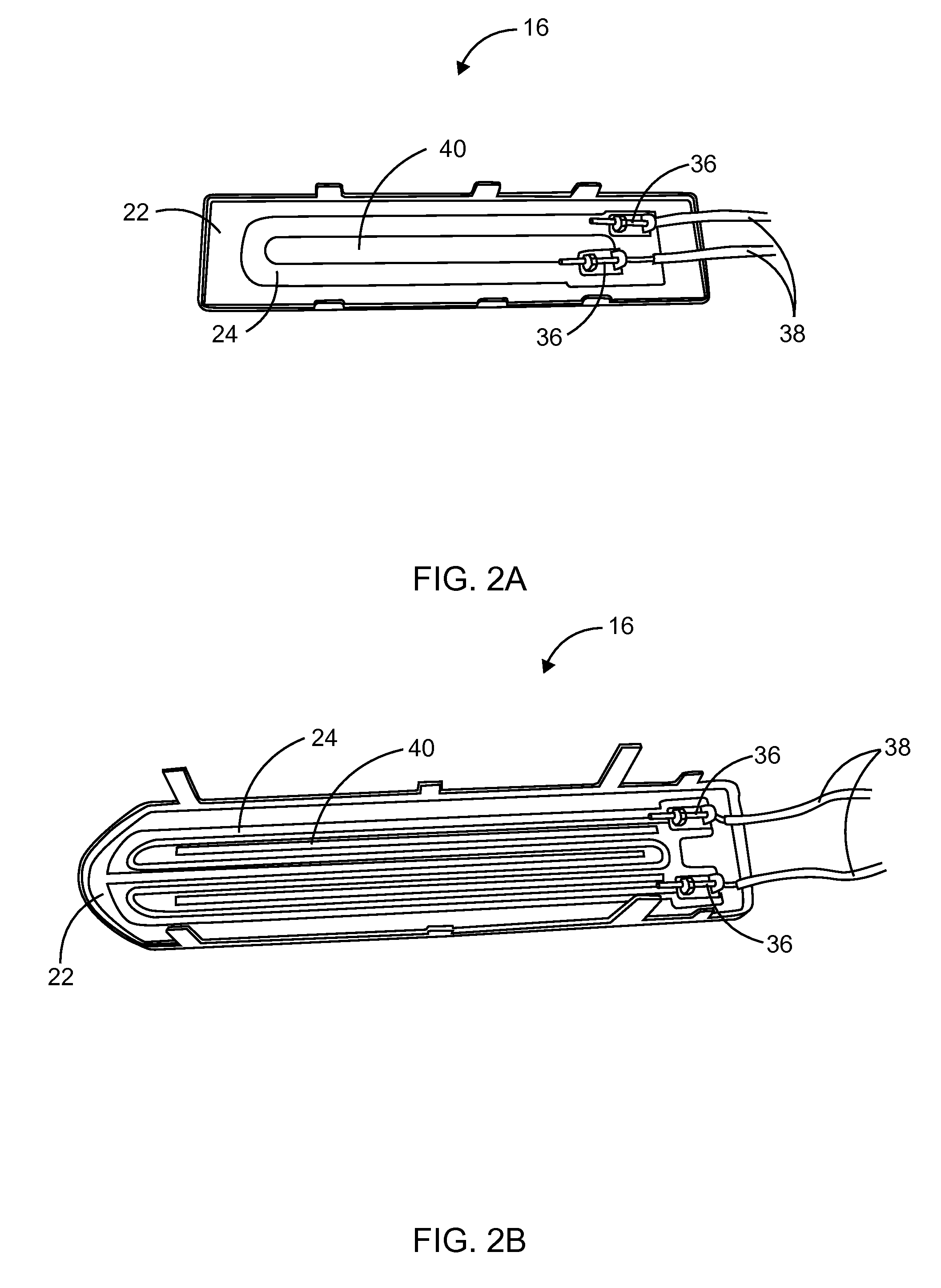

Low Voltage Hair Iron

InactiveUS20130098389A1Eliminate short circuitHigh temperatureLine/current collector detailsCurling-ironsElectrical batteryEngineering

A hair dressing device that utilizes low voltage from a pair of batteries to generate temperature needed for curling and straightening the hair comprises an upper body and a lower body, each having an outer side and an inner side. A heating plate is mounted on the inner side of the lower body facing the upper body. At least one heating element is mounted on the heating plate to generate heat utilizing high precision printing at high temperature. An insulating member is interposed between the at least one heating element and the heating plate to eliminate short circuit. The lower body is coupled to the upper body around a hinge section. A thermal sensor and a controller are incorporated in the hair dressing device to monitor and control the temperature of the heating plate. The hair dressing device can be connected and disconnected from power using an ON / OFF switch.

Owner:UWANO IZUMI

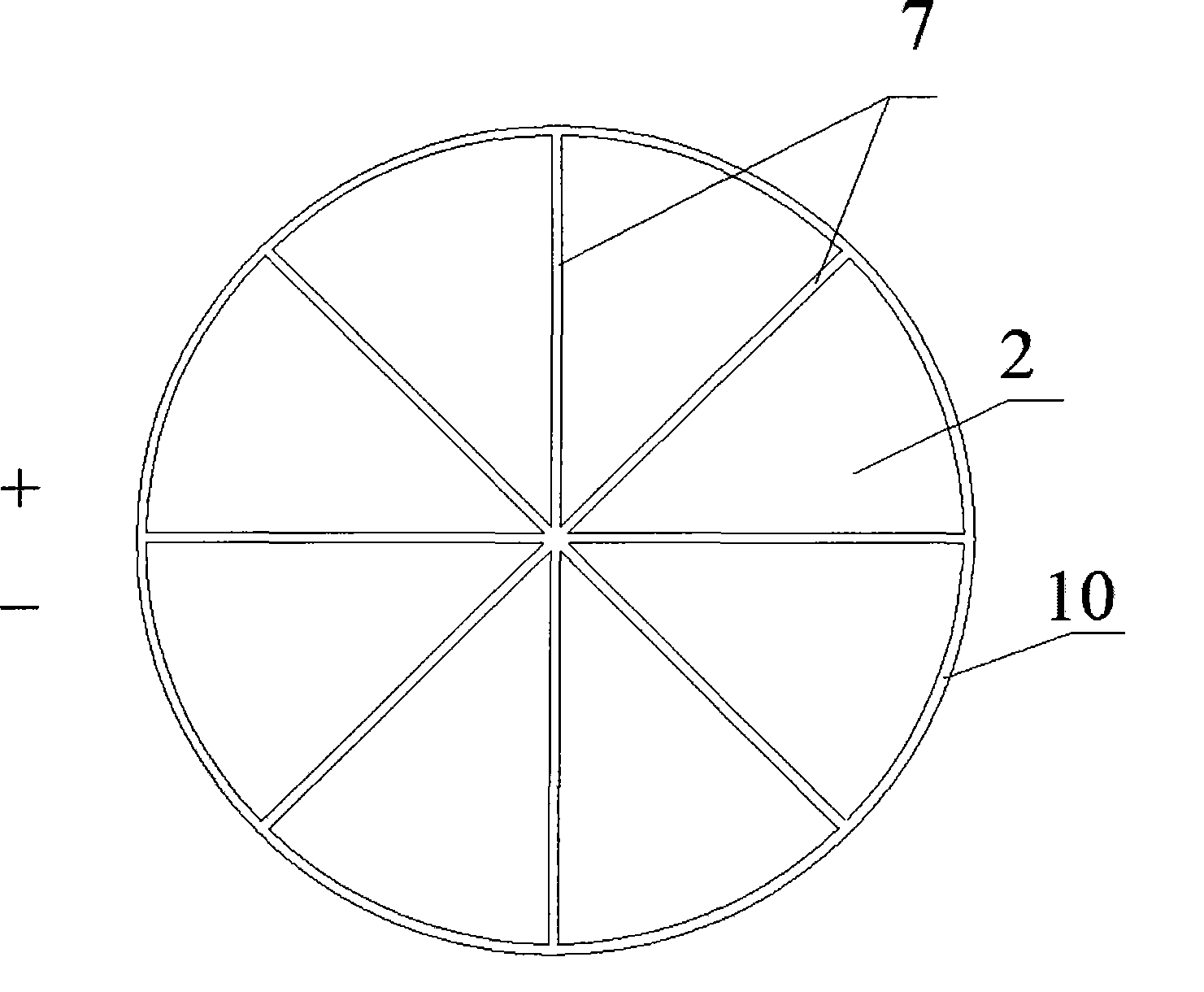

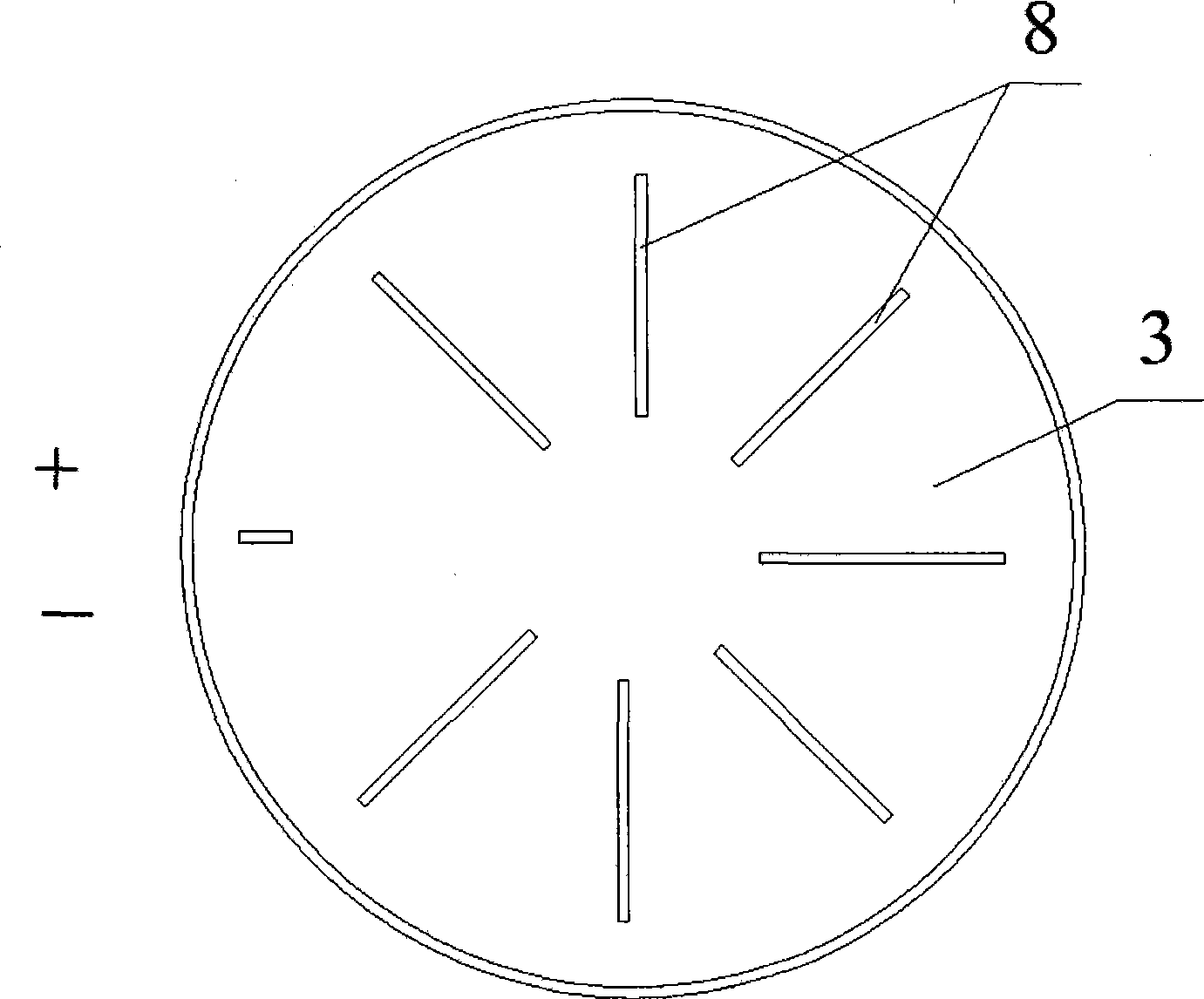

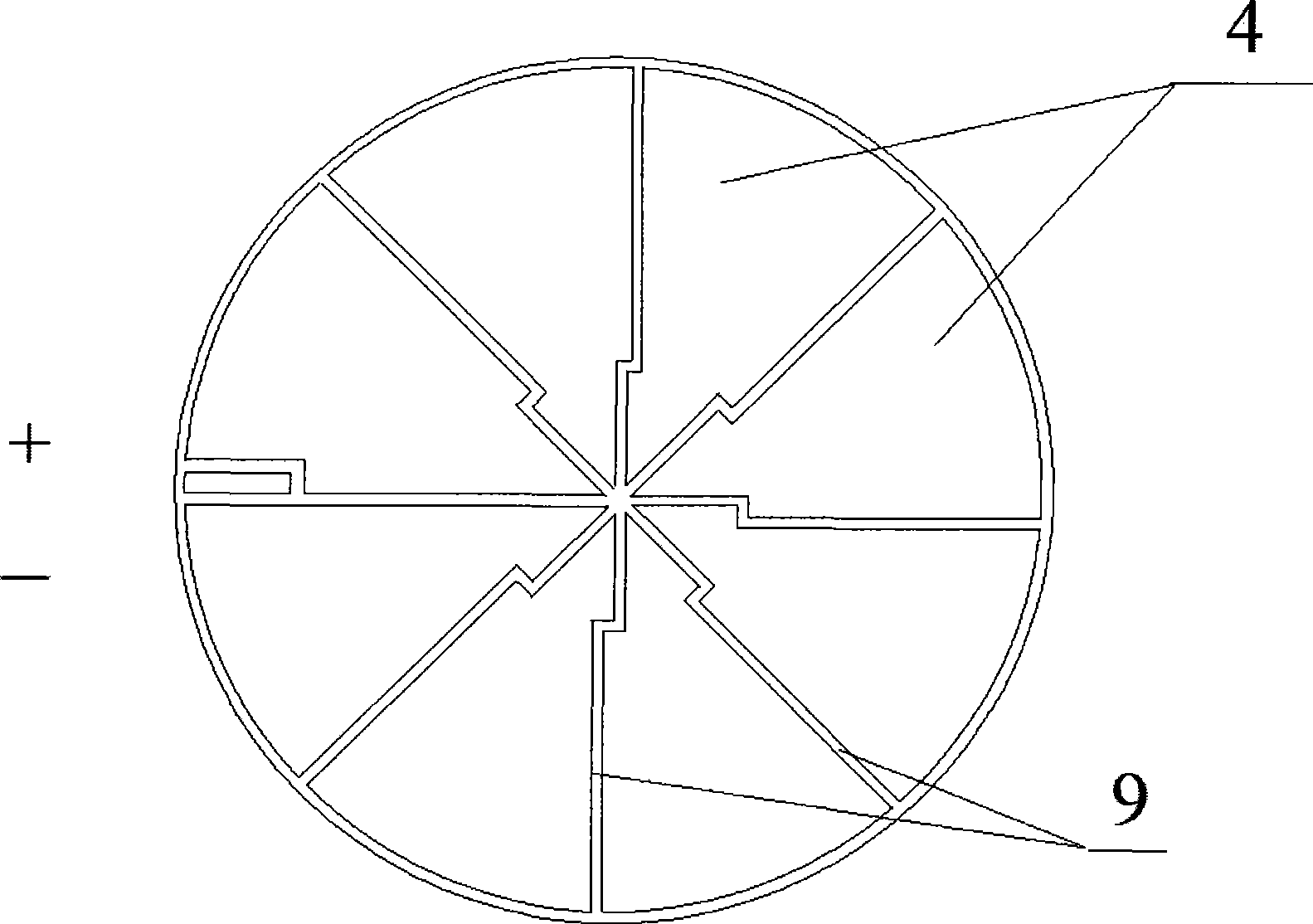

Circular silicon thin-film solar cell

ActiveCN101419989AIncrease the effective working areaGuaranteed electrical performancePhotovoltaic energy generationSemiconductor devicesLaser scribingSilicon thin film

The invention discloses a round silicon thin film solar cell and a fabrication method thereof. The cell is composed of cell units connected in series, and takes a transparent substrate as a substrate, comprises a front electrode layer, a silicon thin film layer, a back electrode layer and a back paint layer which are stacked up in sequence. The round silicon thin film solar cell is characterized in that working faces of the cell units are formed by laser scribing, an external envelope takes an arc shape, a working face inside the cell is composed of n serially connected cell units which have equal effective area, n is not less than 2, at least two shielding lines and a laser scribing line or a dot-and-dash line which connects a positive electrode and a negative electrode are arranged between the positive electrode and the negative electrode of the cell, and the width between the positive electrode and the negative electrode is 0.03-0.10mm. The fabrication method adopts advanced laser marking technology, can scribe the cell units with fan-shaped or irregular figures, has high precision, and causes the width of an invalid region inside the solar cell to decrease from 0.5-1.8mm to 0.03-0.20mm, thus enlarging the effective working area of the cell.

Owner:李毅

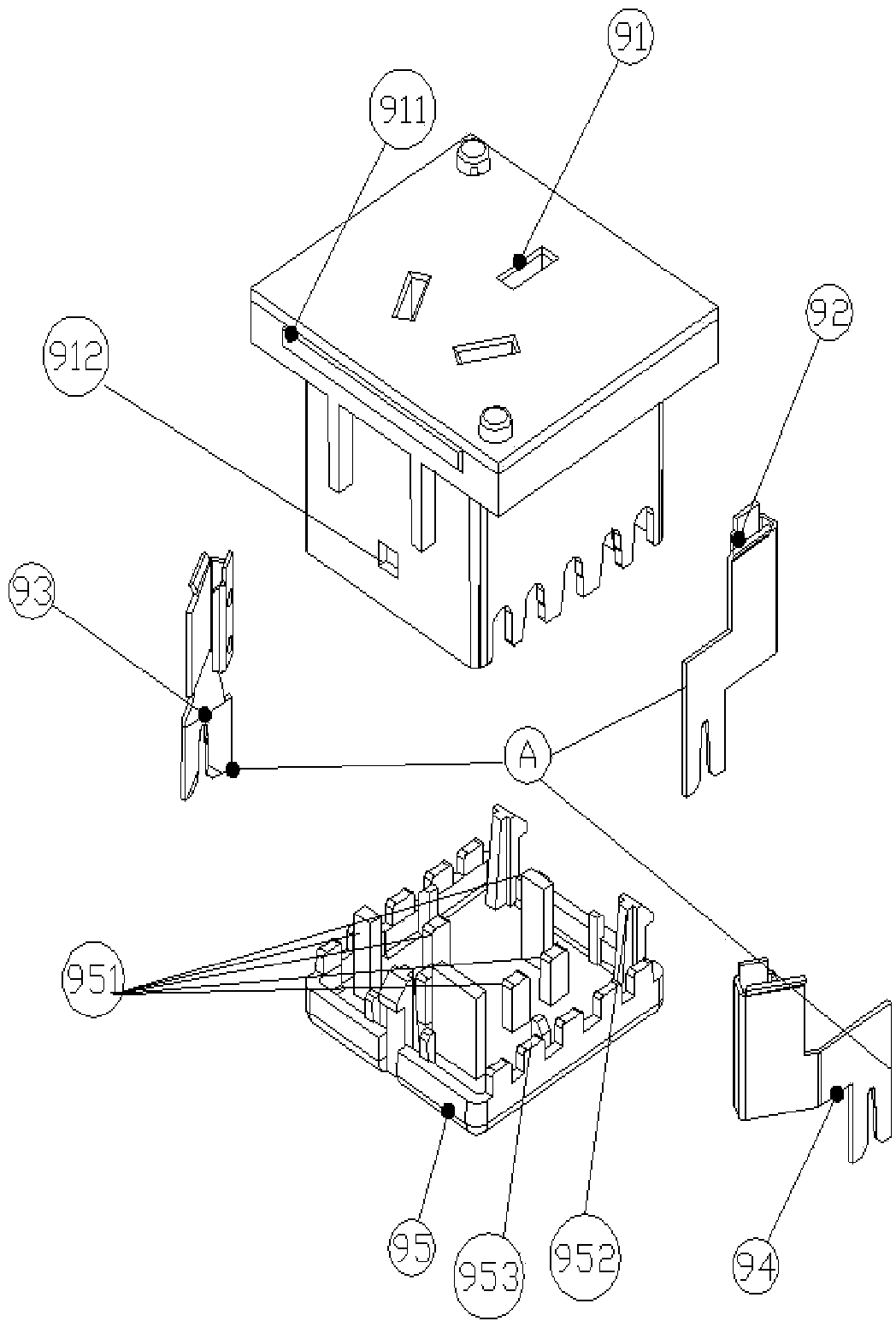

Socket module

InactiveCN104393436AFirmly connectedSave effective spaceCoupling contact membersContact members penetrating/cutting insulation/cable strandsPunchingFire risk

The invention discloses a socket module. The socket module comprises an upper cover and a lower cover, wherein the edge of the upper cover is provided with a convex clamping pin; the lower edge of the upper cover is provided with an annular wiring hole, an L wire clamping hole, a PE wire clamping hole and an N wire clamping hole. The socket module also comprises a PE elastic sheet, an N elastic sheet and an L elastic sheet; the PE elastic sheet, the N elastic sheet and the L elastic sheet are inserted in the corresponding positions inside the upper cover; the lower cover is internally provided with support pillars; and two opposite edges of the lower cover are respectively provided with buckles and wire clamping hole adjusting blocks. The quick punching clamping-type connection is low in resistance, reliable, durable, stable and small in temperature rise, and fire risks are eliminated; hidden electrical dangers such as short circuit and contact oxidation are eliminated; single-point power fault is eliminated, and the power-off range due to multi-point fault is reduced; no broken connection points exist in the whole bus, and connection is firm and nodes are clean; over high temperature rise is avoided, and fire risks do not exist; power distribution reliability is high; the appearance size is small, the height and the thickness of the shell can be controlled in the 1U standard and space can be effectively saved.

Owner:四川睿联安电气有限公司 +1

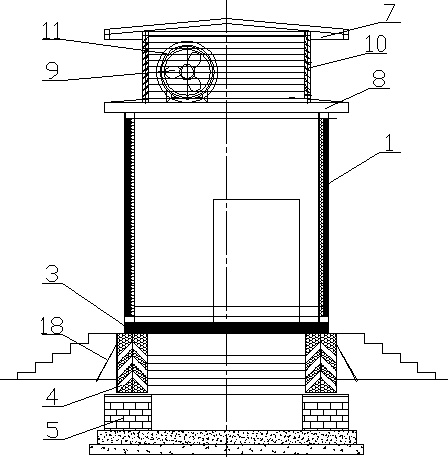

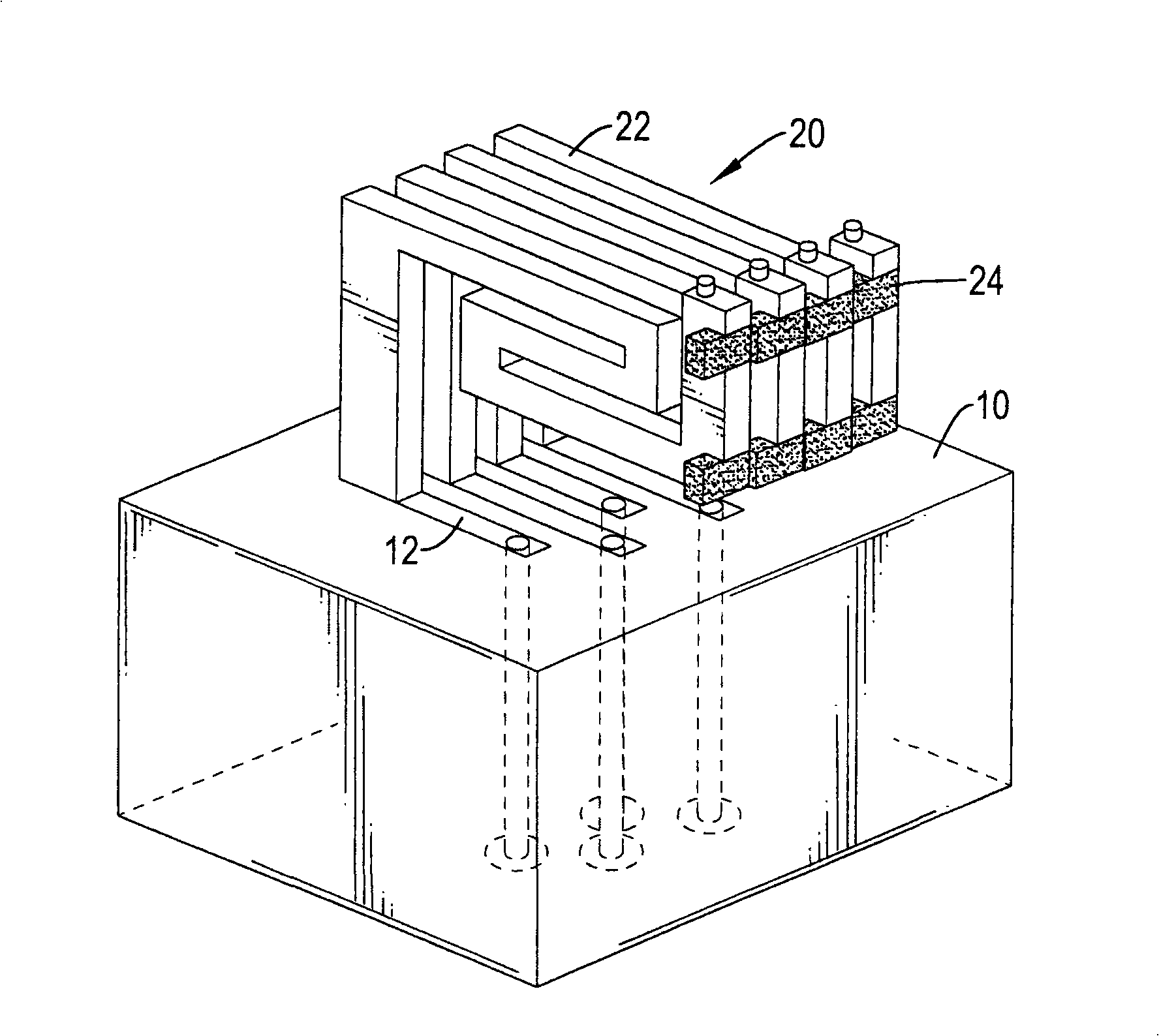

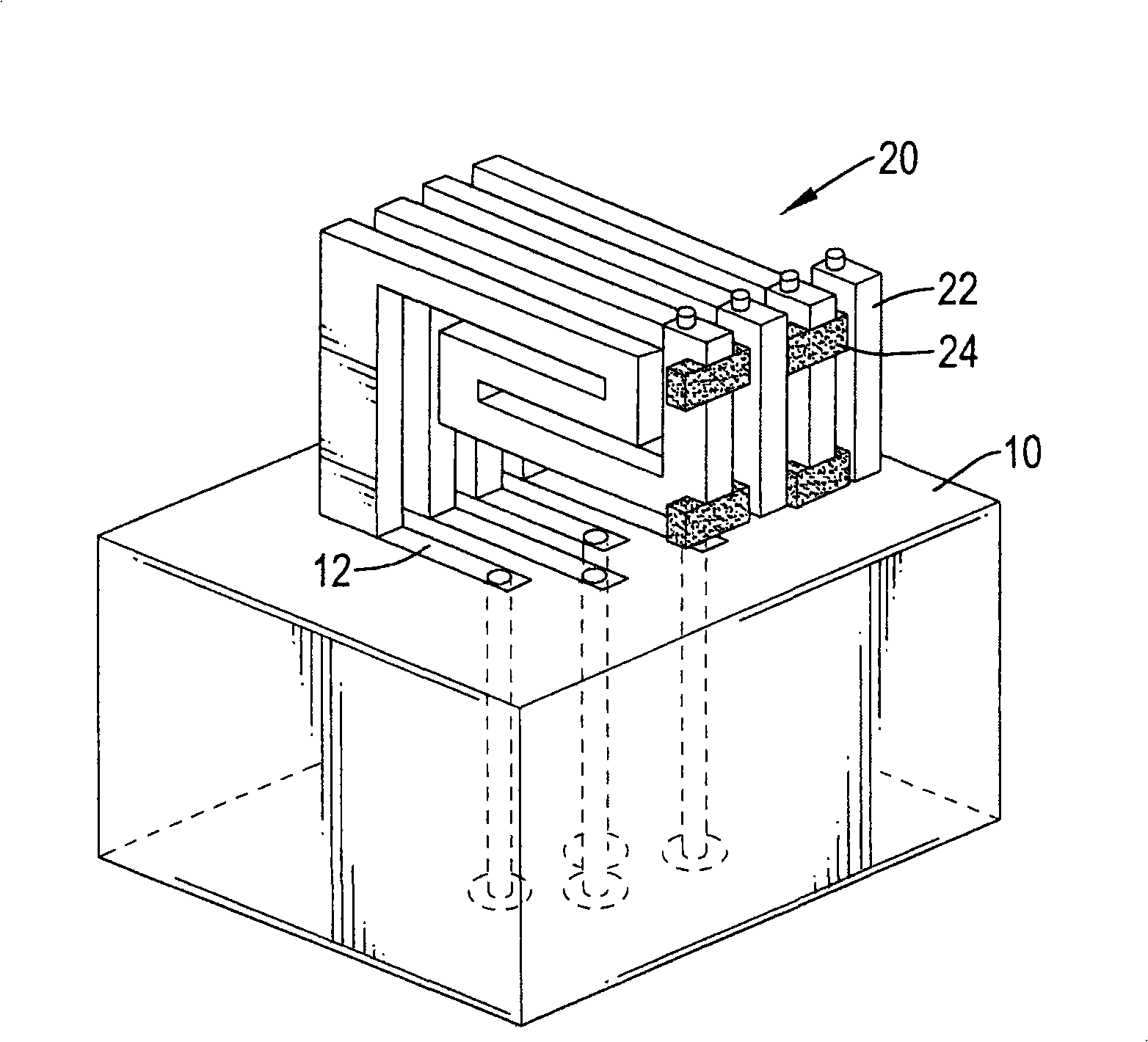

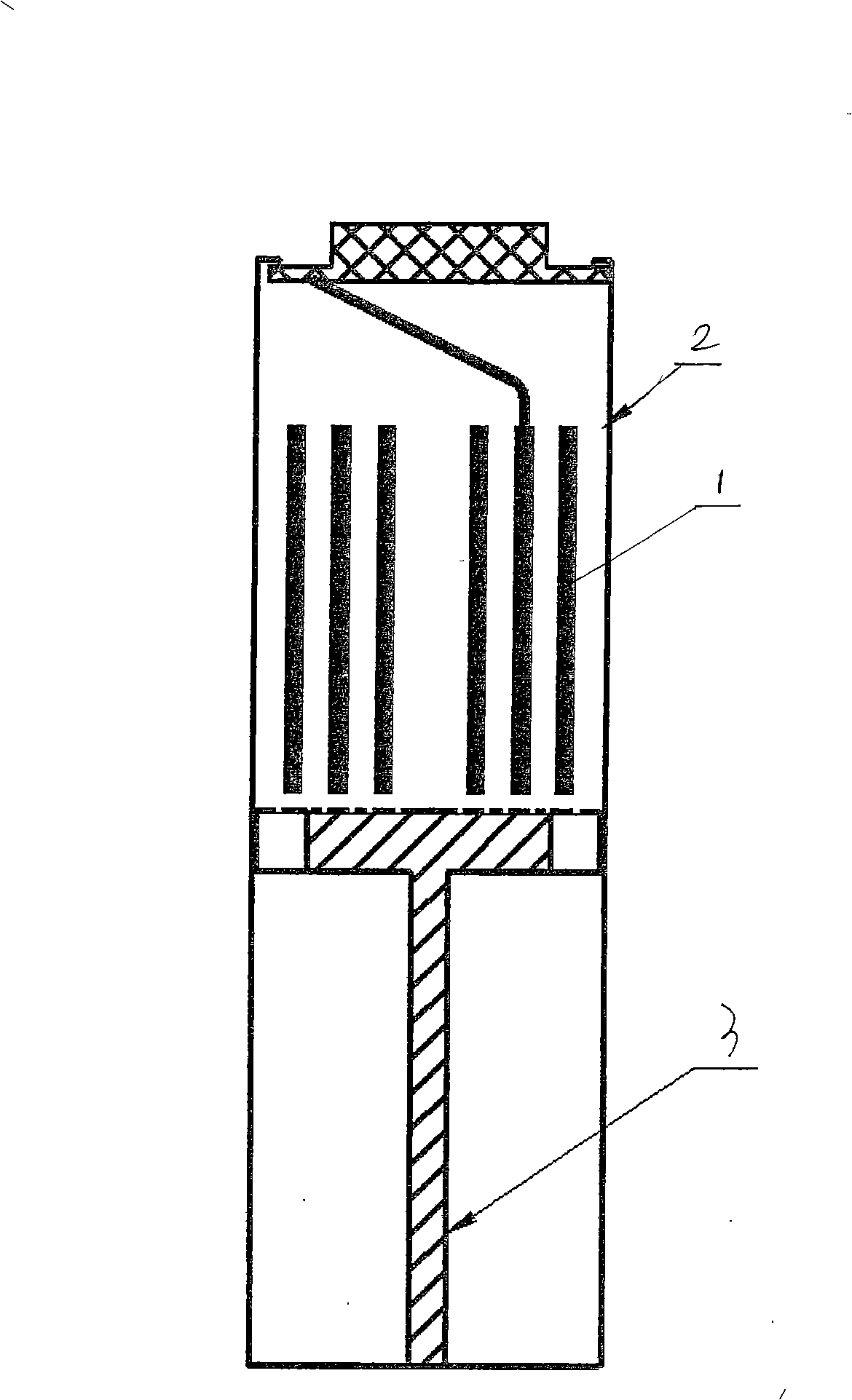

Silencing box body for box-type transformer with modular structure

InactiveCN103021629ARealize large-scale productionEasy to transportTransformers/inductances casingsTransformers/inductances noise dampingTransformerComputer module

The invention discloses a silencing box body for a box-type transformer with a modular structure. The silencing box body comprises a double-layer top cover module, a resonant sound absorbing wall body and a door connected below the double-layer top cover module, a silencing fence, a bottom beam, and a box body foundation provided with an inflow air silencer, wherein the bottom beam, the silencing fence and the box body foundation are fixed together through a positioning connecting rod; and the entire transformer box body is modularized, and comprises four parts. Due to the adoption of the silencing box body, large-scale production can be realized, and convenience is brought to transportation and field installation; meanwhile, convenience is brought to subsequent maintenance; and in particular, when the transformer is required to be overhauled, only a top cover is required to be detached, and the transformer is hoisted out of the box body, so that the cost is lowered.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +2

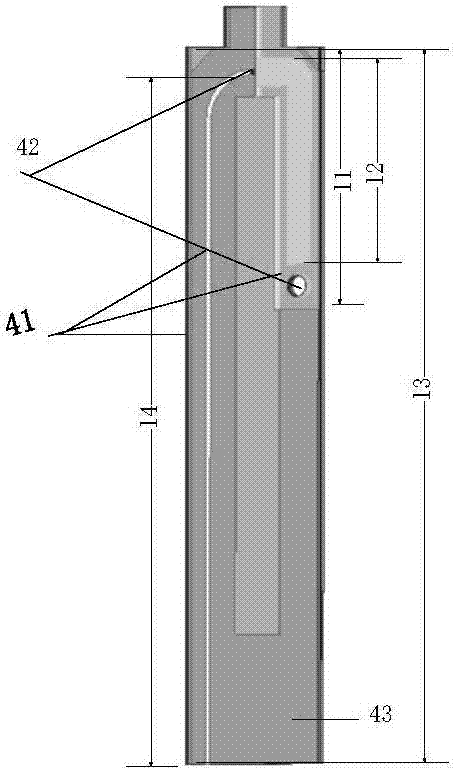

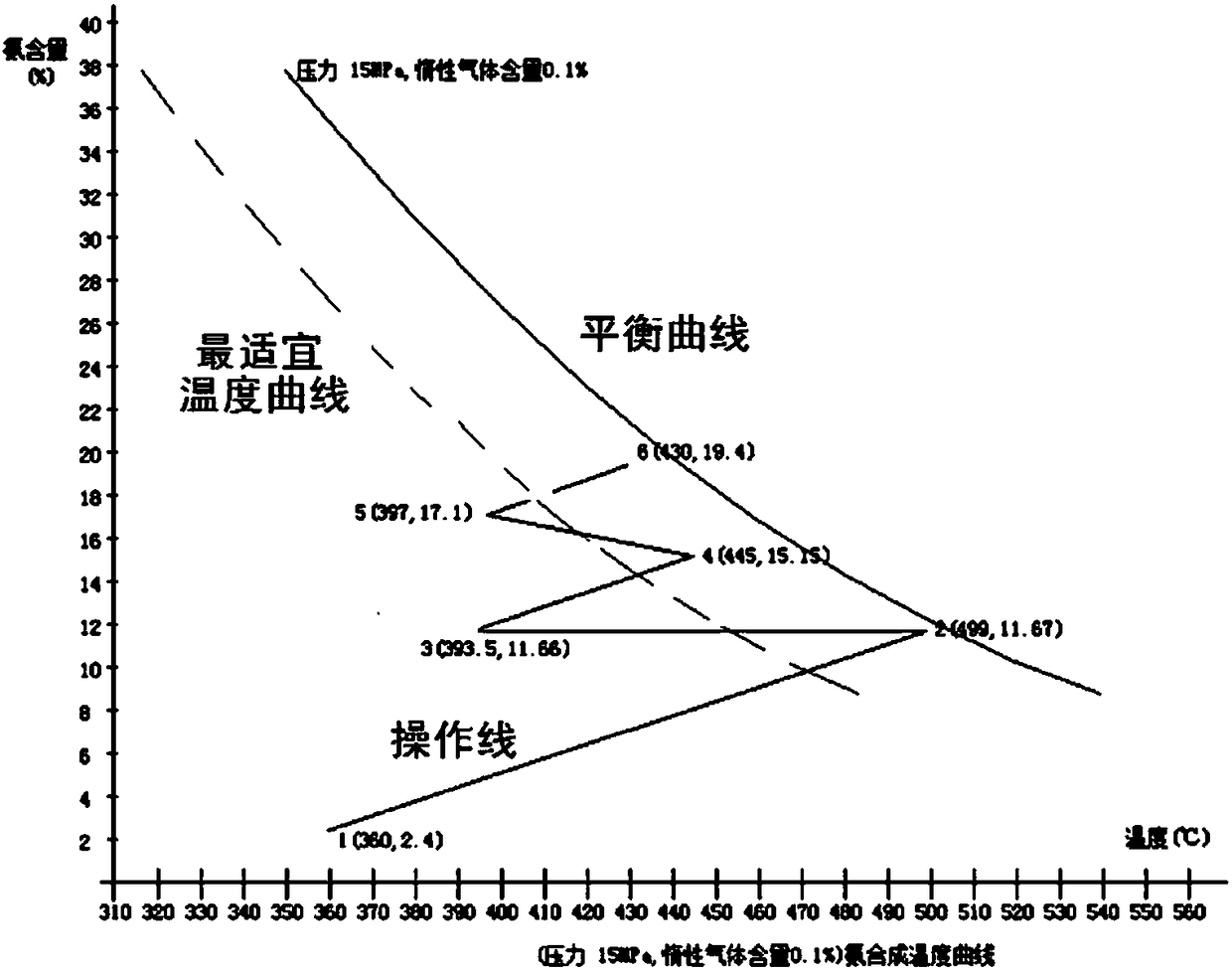

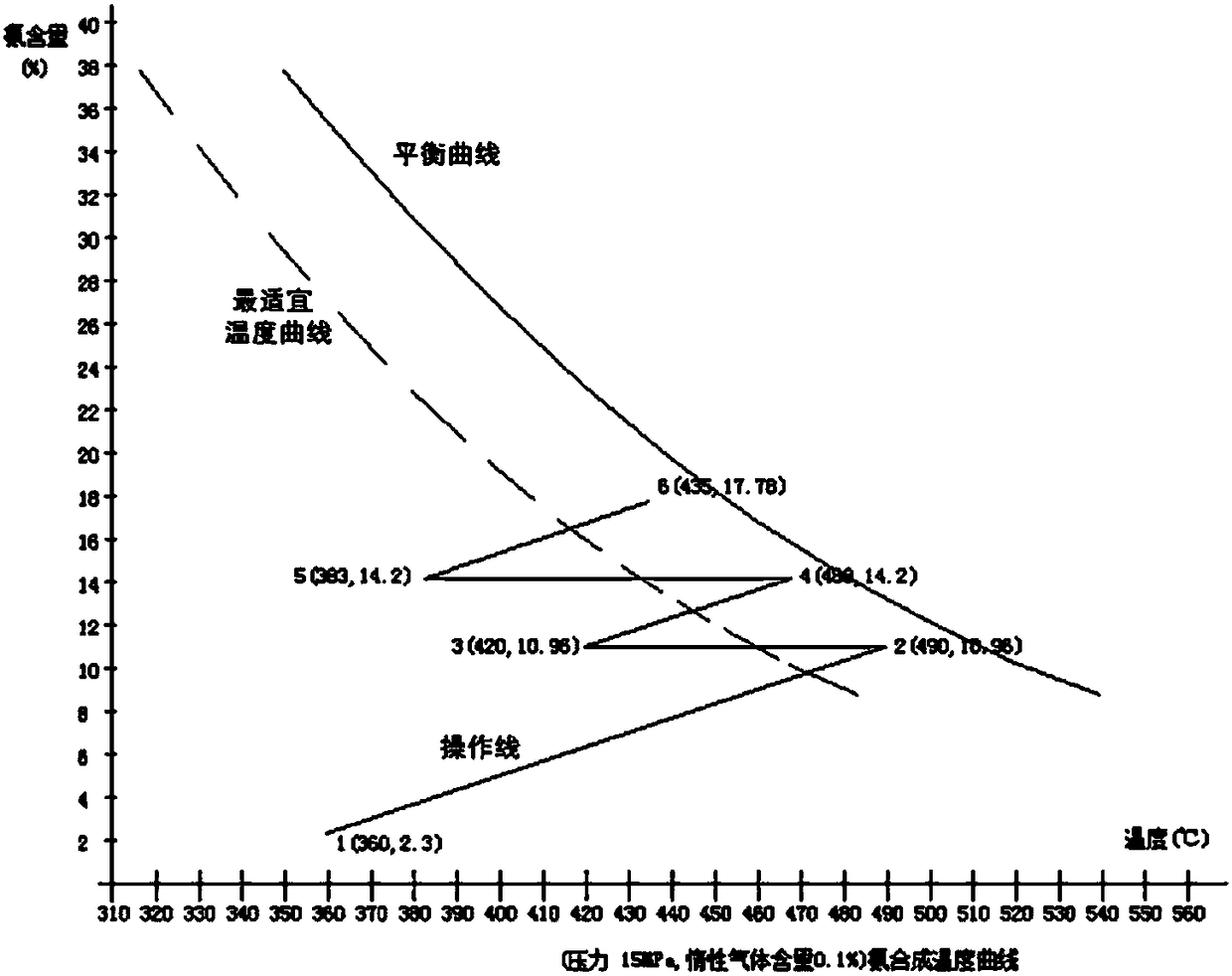

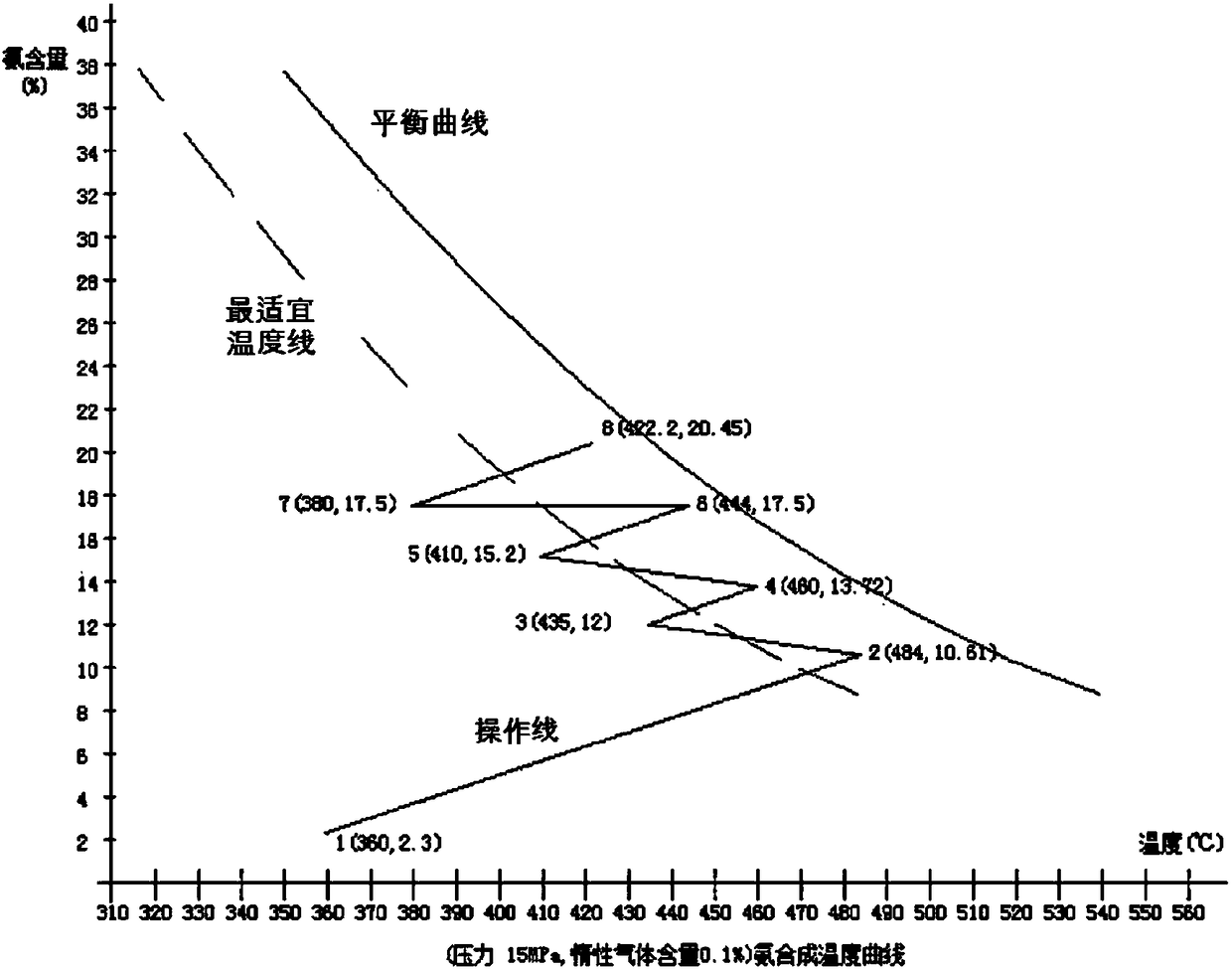

Ammonia synthesis reactor and ammonia synthesis technology

PendingCN108057399ASimple structureQuick responseEnergy inputChemical/physical processesAmmoniaNH3 compound

The invention discloses an ammonia synthesis reactor and an ammonia synthesis technology. The ammonia synthesis reactor comprises an outer barrel and an inner barrel, wherein the inner barrel is separated into a plurality of sections of regions through sealing heads in the height direction; each section of region is internally correspondingly provided with a catalyst basket; heat exchange devicesare arranged in the catalyst basket in part of the regions; unreacted gas is heated so that reaction gas is cooled; a condition that a catalyst is deactivated is effectively avoided and the utilization period of the catalyst is long.

Owner:HUNAN ANCHUN ADVANCED TECH

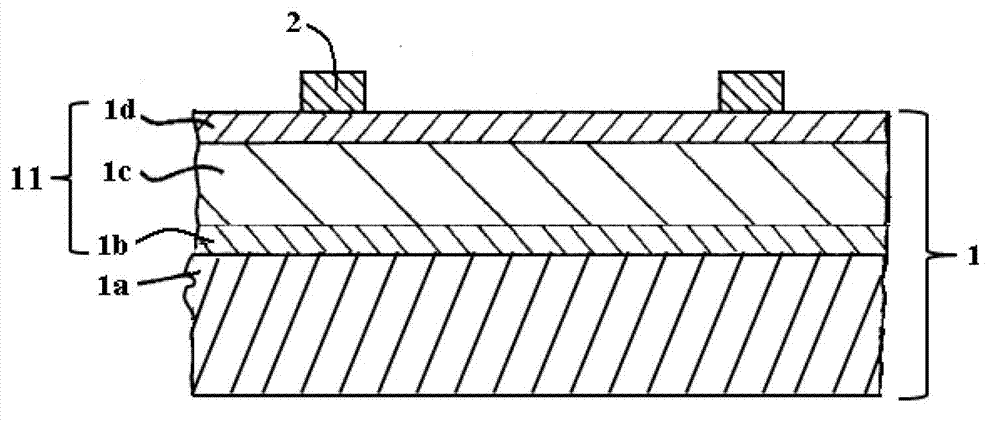

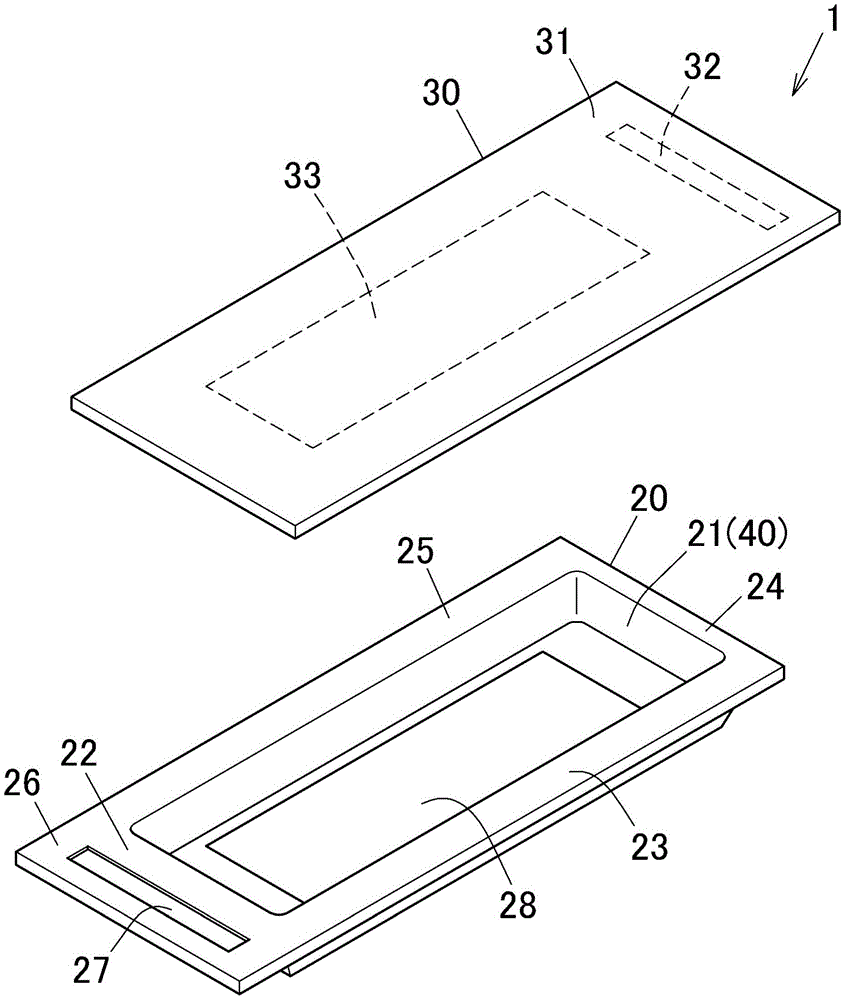

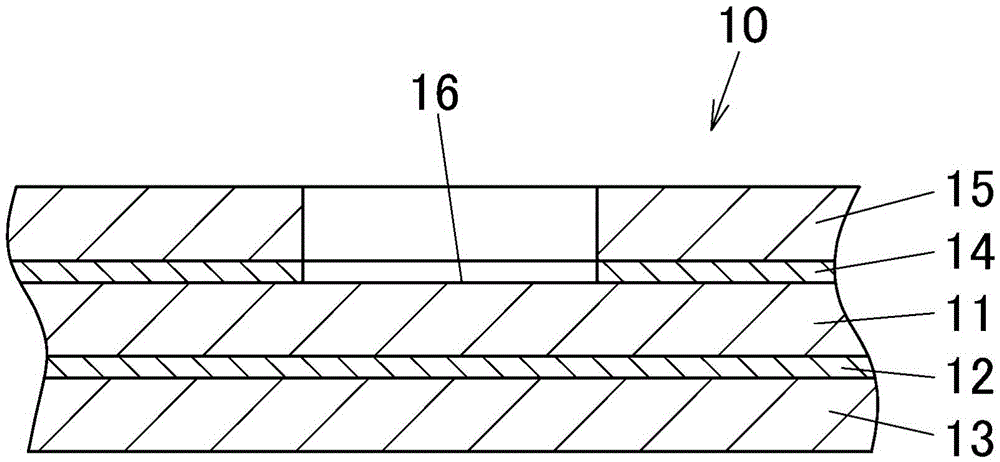

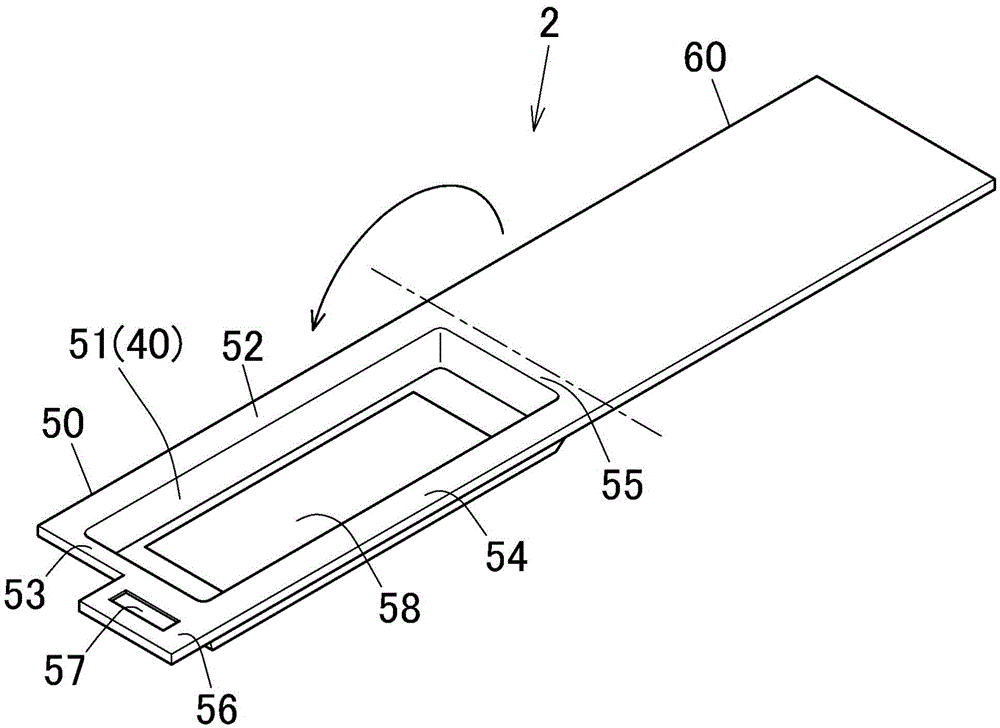

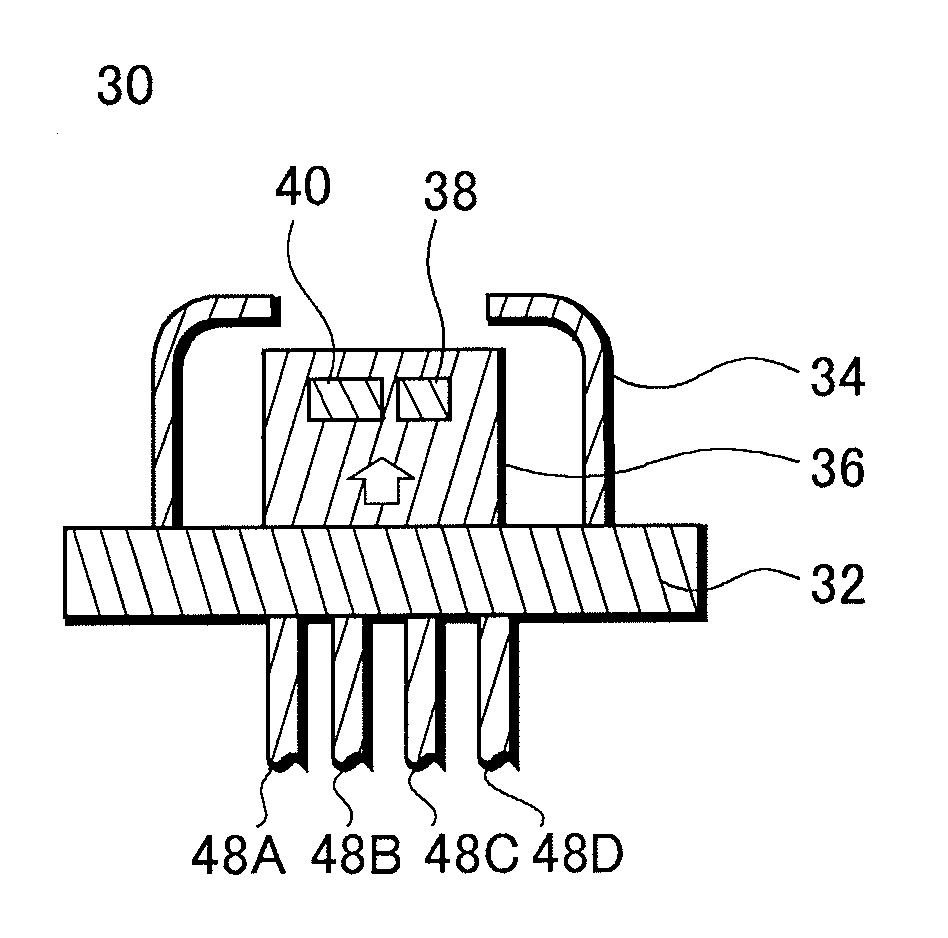

Package For Power Storage Device

InactiveCN105789508ALow costSave connection spaceCurrent conducting connectionsFinal product manufactureMetallic foilEngineering

A package for a power storage device includes at least one laminated packaging material 1 having first and second sections. The packaging material includes a metallic foil layer, a heat-resistant resin layer, and a heat-fusible resin layer. In a state in which the heat-fusible resin layers of the first and second sections are faced, peripheral edges thereof are heat-sealed to form a storage chamber 40 for accommodating a device main body. One of the sections is extended outside the storage chamber 40 to form a conductive flange 26, 31 having an exposed heat-fusible resin layer. The conductive flange is provided with an external conductive section in which the heat-fusible resin layer is partially removed to expose the metallic foil layer. The packaging material having the external conductive section 27,32 is provided with an internal conductive section 28,33 in the storage chamber in which the heat-fusible resin layer is partially removed to expose the metallic foil layer.

Owner:SHOWA DENKO PACKAGING CO LTD

Probe short circuit preventing structure

InactiveCN101329366AEliminate short circuitShort circuit will notElectrical measurement instrument detailsElectrical testingPhysicsShort circuit

The invention provides a probe short-circuit prevention structure which is an insulated separation structure; each separation structure can be embedded in a probe body or a corresponding position of a probe seat, which is at the interval of the probes, thus causing each probe to have the efficacy of mutual separation when in use.

Owner:MICROELECTRONICS TECH INC

Electrode plate of lithium ion cell and lithium ion cell with the same

InactiveCN1805188AEliminate short circuits inside the batteryImprove securityElectrode carriers/collectorsSecondary cellsEngineeringAnode

The invention relates to an electrode plate of battery and the lithium battery with said electrode plate. Wherein, the four angles of said electrode plate all are smooth curve angles. With said inventive electrode plate, when coiling or layering the anode plate, baffle film and the cathode plate to form the electrode core, the short circuit or micro short circuit of battery caused by breaking the baffle film with four shape angles can be avoided, to improve the safety of battery.

Owner:BYD CO LTD

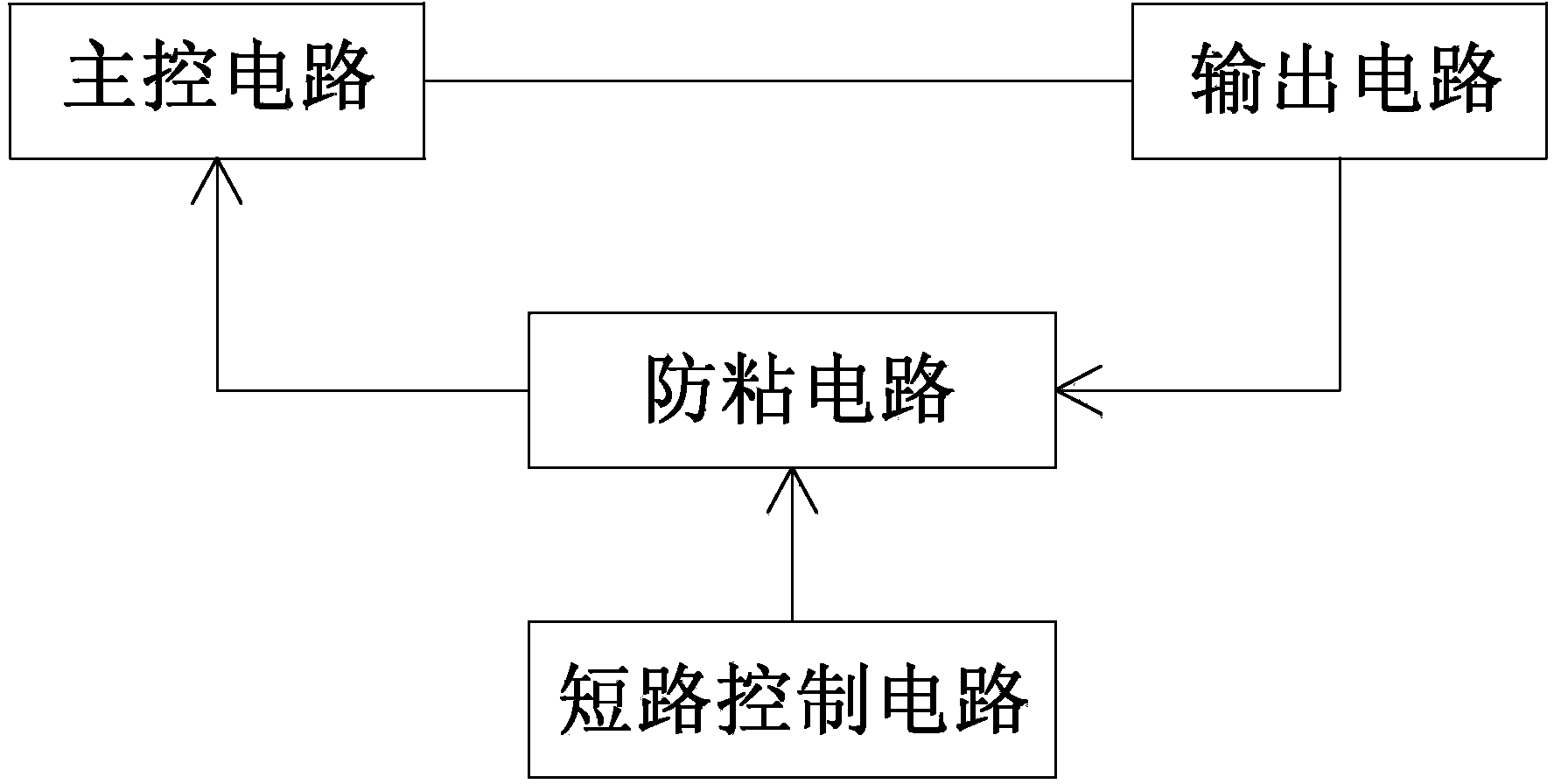

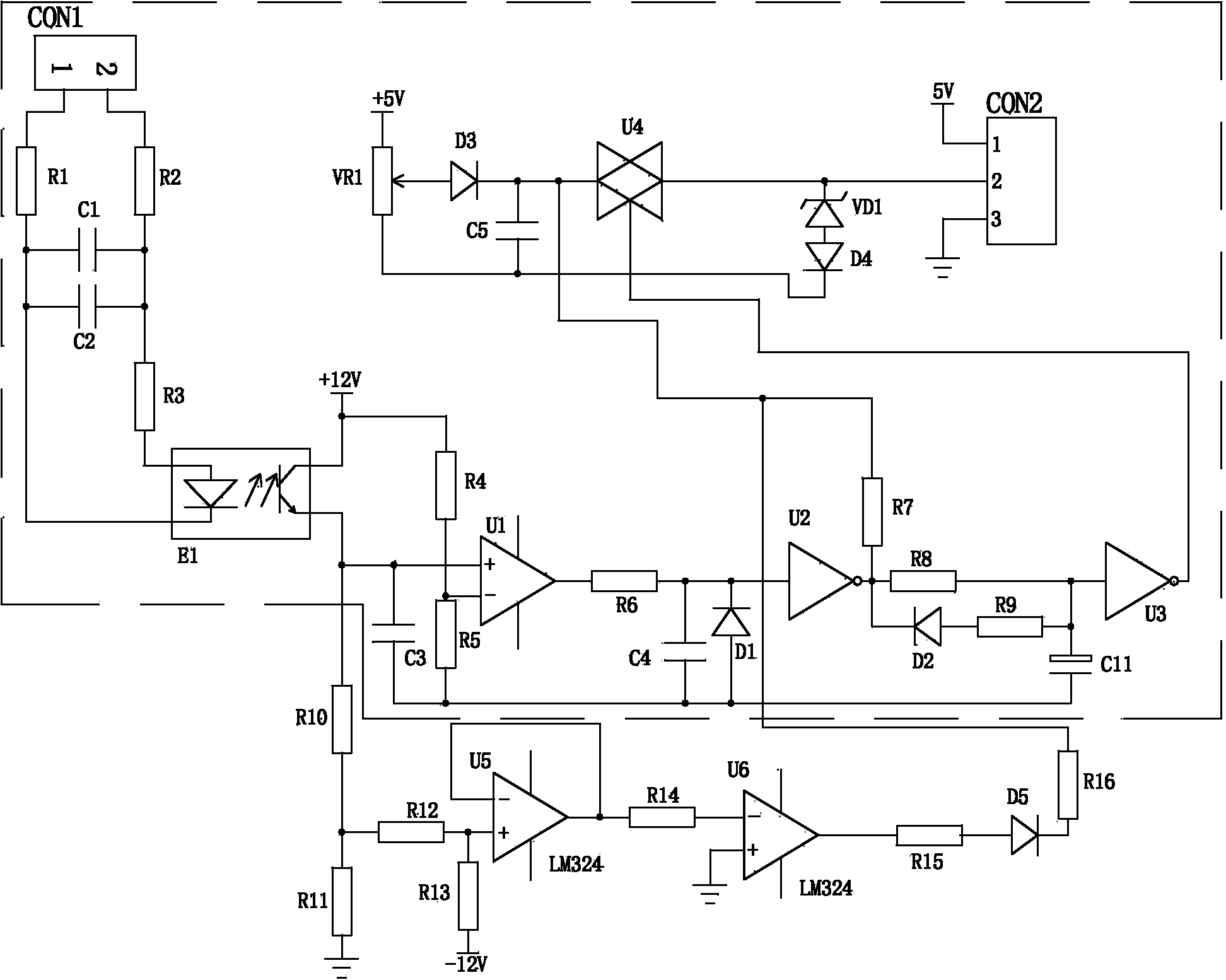

Control circuit of inverter welding machine

ActiveCN104028876AAvoid short circuitProtection against brief short circuitsArc welding apparatusControl circuitComputer engineering

The invention discloses a control circuit of an inverter welding machine. The control circuit comprises a master control circuit and an output circuit, and the master control circuit and the output circuit are connected. The control circuit of the inverter welding machine further comprises an adhesion preventing circuit used for preventing adhesion between a welding rod and a workpiece. The control circuit of the inverter welding machine has the advantage that the welding rod can be avoided from being adhered with the workpiece.

Owner:NINGBO EUROPA WELDING & CUTTING TECH

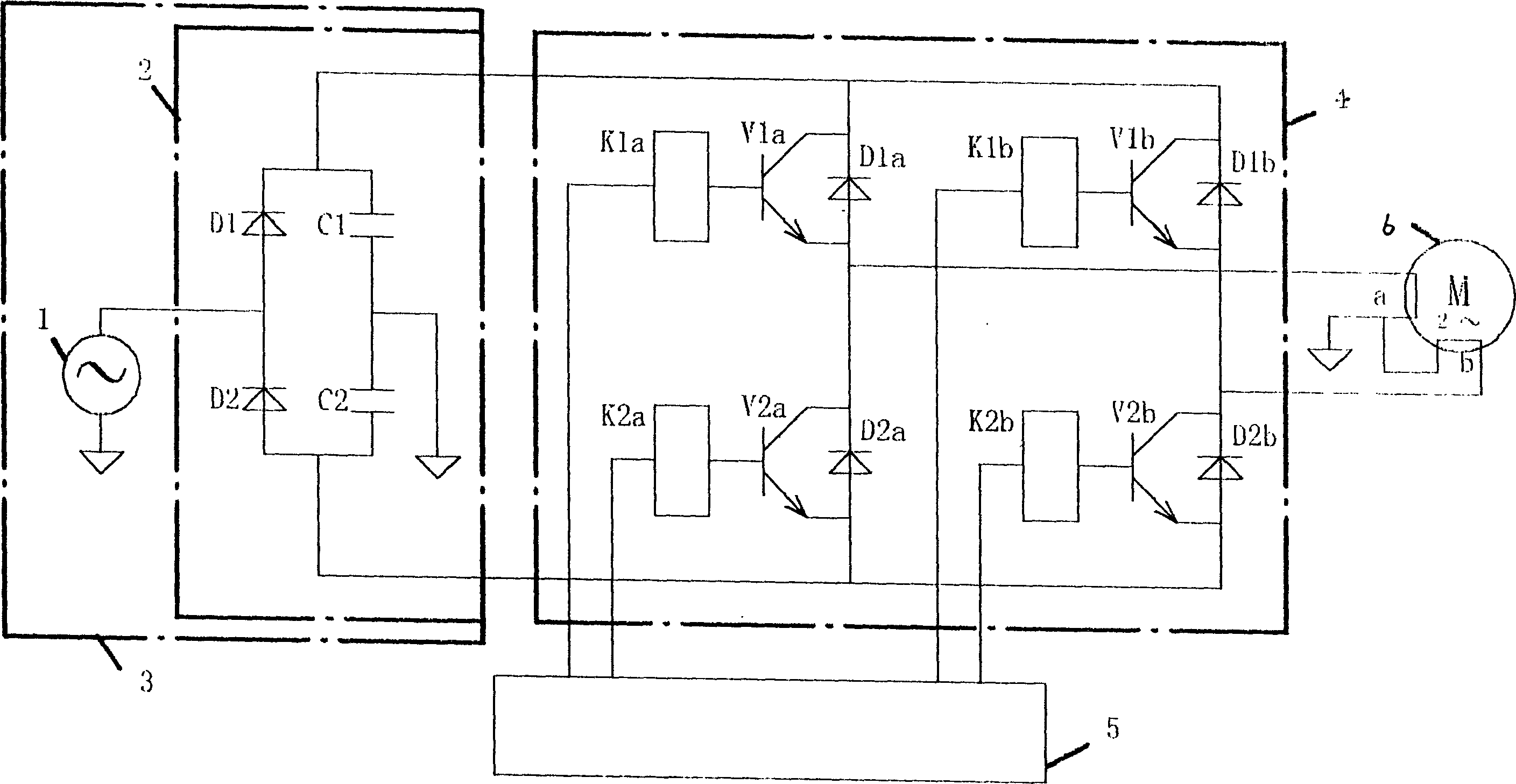

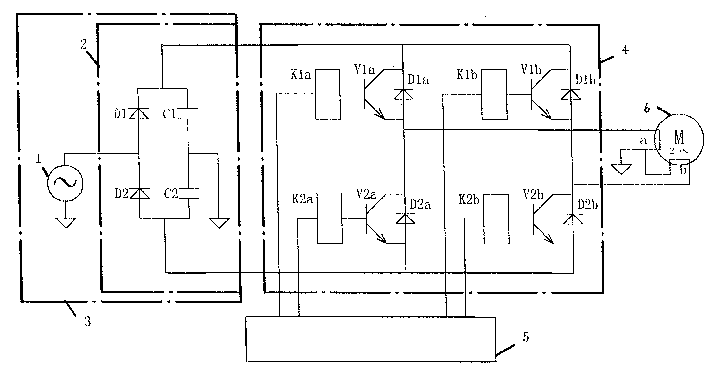

Frequency varying driven washer

InactiveCN1184735CEliminate short circuitEliminate impedanceDC motor speed/torque controlAc-ac conversionPhase differencePower grid

The present invention relates to a frequency-variable driven washing machine, which is characterized by that in said washing machine the electric network power supply is converted into variable frequency and two-phase power source whose time lag is equal to 1 / 4 cycle to drive two-phase symmetrical winding motor of space phase difference Pi / 2 electric angle. Its one technical scheme is as follows: electric network power source is converted into variable frequency power source by means of rectifying-filtering circuit and inversion circuit, its rectifying-filtering circuit is formed from positive half-wave rectification filtering circuit and negative half-wave rectification filtering circuit and has a common end with power supply circuit of electric network, and its inversion icrcuit is double half wave 4 unit, and its uses existent washing machine motor. It possesses the excellent performance of symmetrical motor, and its structure is simplified and cost is reduced.

Owner:JINLING ELECTRICAL CO LTD

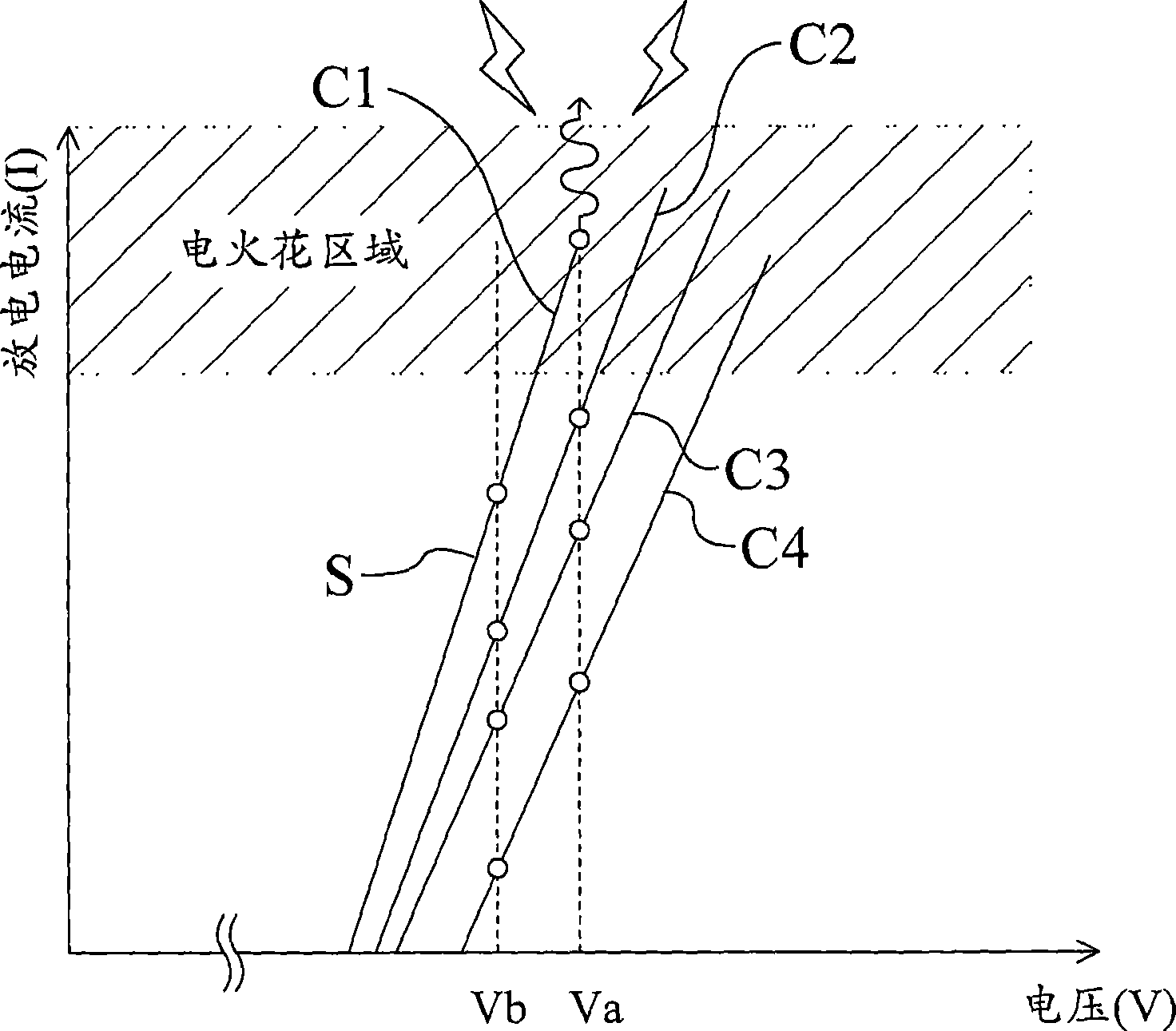

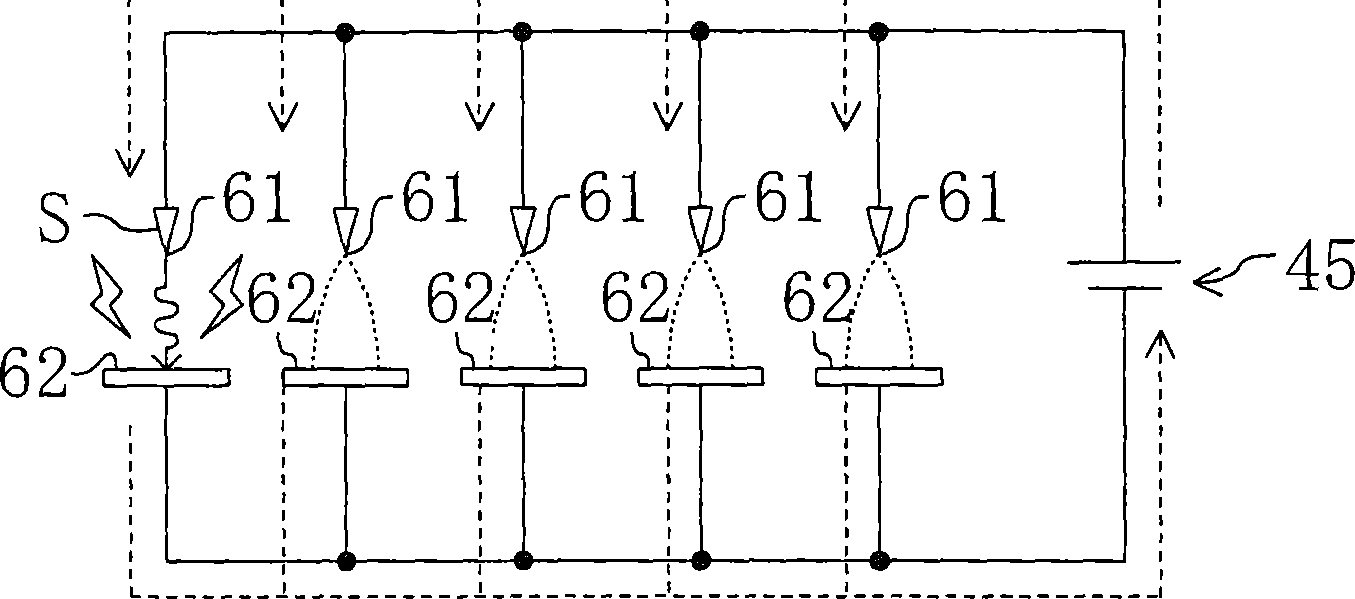

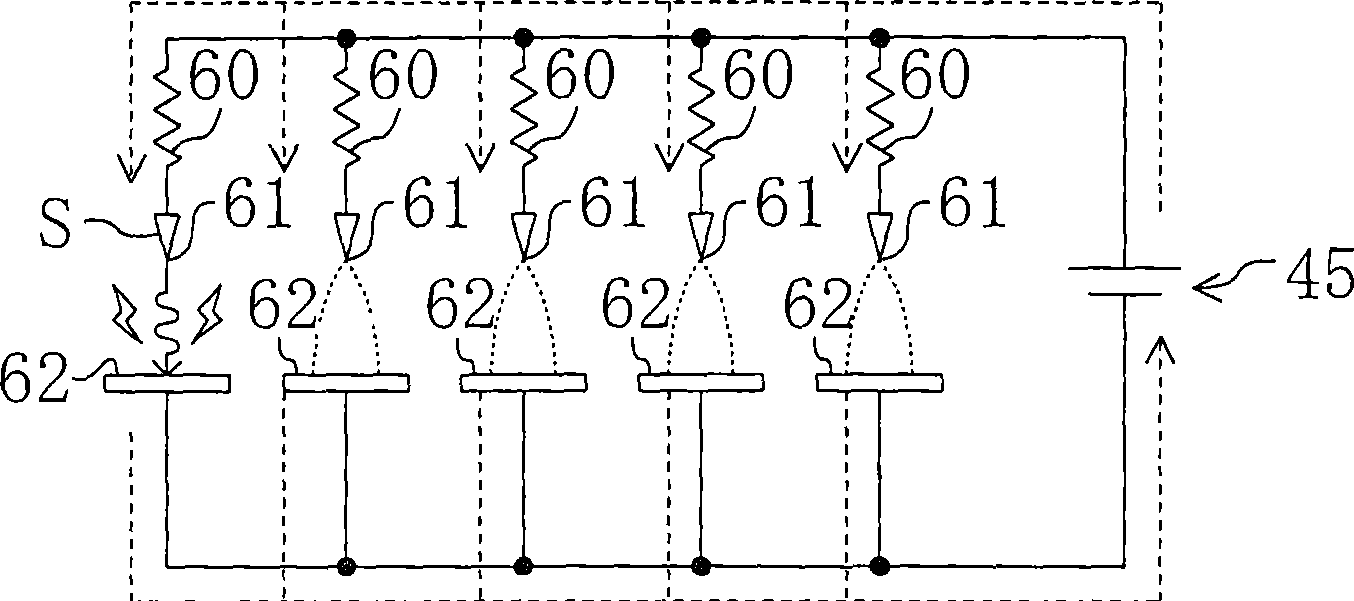

Discharge device and air cleaning device

InactiveCN1910799AReduce productionReduce noiseSpark gap detailsGas treatmentAir cleaningEngineering

In a discharge device for performing streamer discharge between a discharge electrode (41) including a plurality of discharge parts (61) and a counter electrode (42) including a plurality of counter parts (62) confronting the discharge parts (61), a resistor (60) is provided in a current carrying path between power source means (45) and the discharge parts (61).

Owner:DAIKIN IND LTD

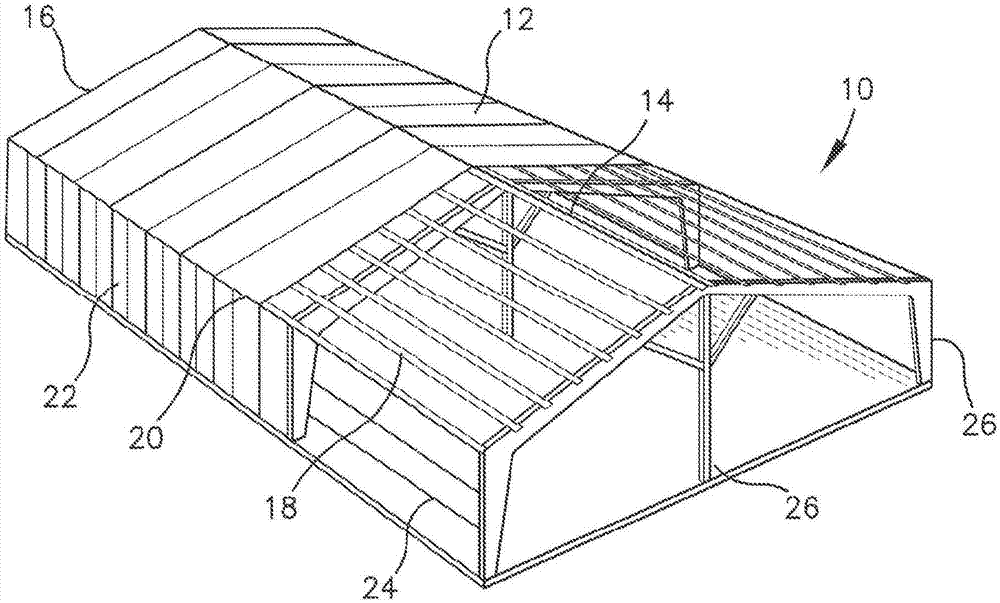

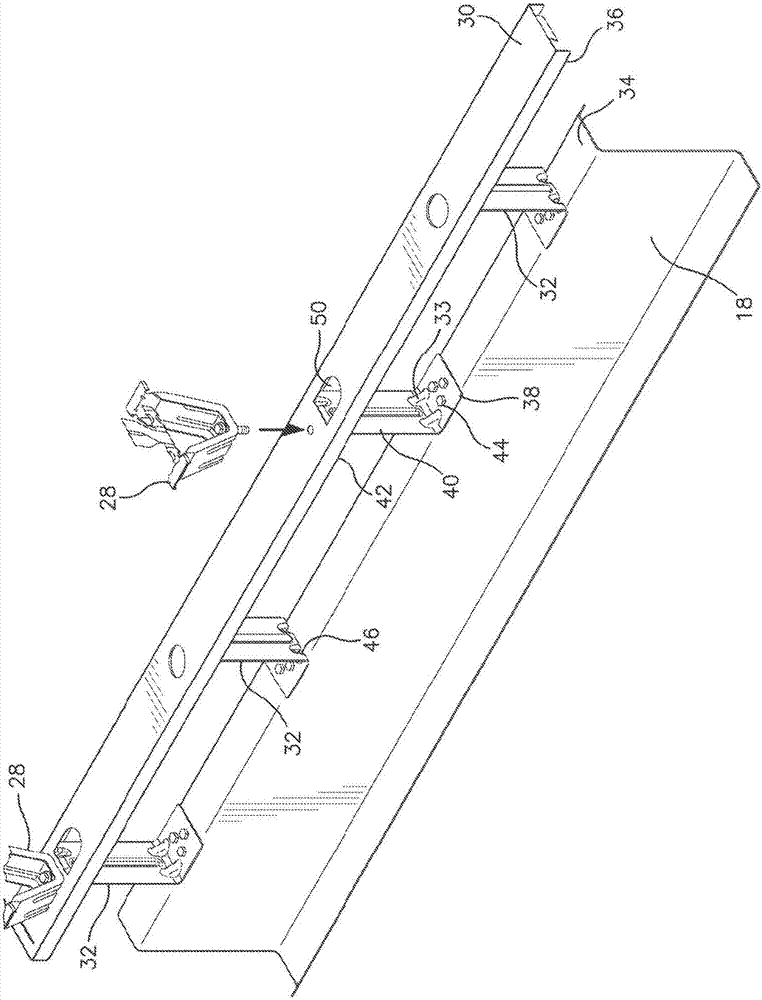

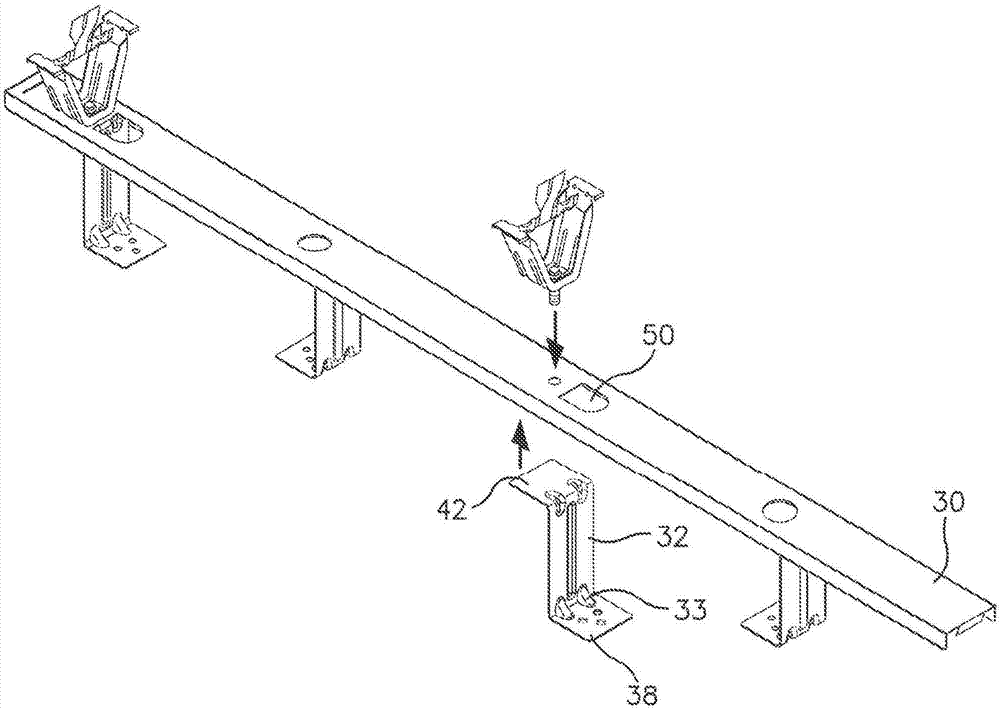

System for enhancing the thermal resistance of roofs and walls of buildings

InactiveCN107407092AEliminate heat transfer shortsEliminate short circuitRoof covering using slabs/sheetsRoof covering insulationsPurlinInsulation layer

A system for insulating a building comprising a first layer of rolled insulation disposed atop a longitudinally extending upper chord of a roof truss, a purlin or a girt of a wall. Discrete insulating spacer members are intermittently disposed atop the first insulation layer and along the longitudinally extending chord, purlin or girt. A three sided bridge with a plurality of tab elements overlaying and contiguous with the insulating spacer members. A second layer of rolled insulation disposed atop the bridge and panel clips secured with a fastener extending through each of the second layer of insulation, bridge, insulating spacer member, first layer of insulation and upper chord.

Owner:BLUESCOPE BUILDINGS NORTH AMERICA

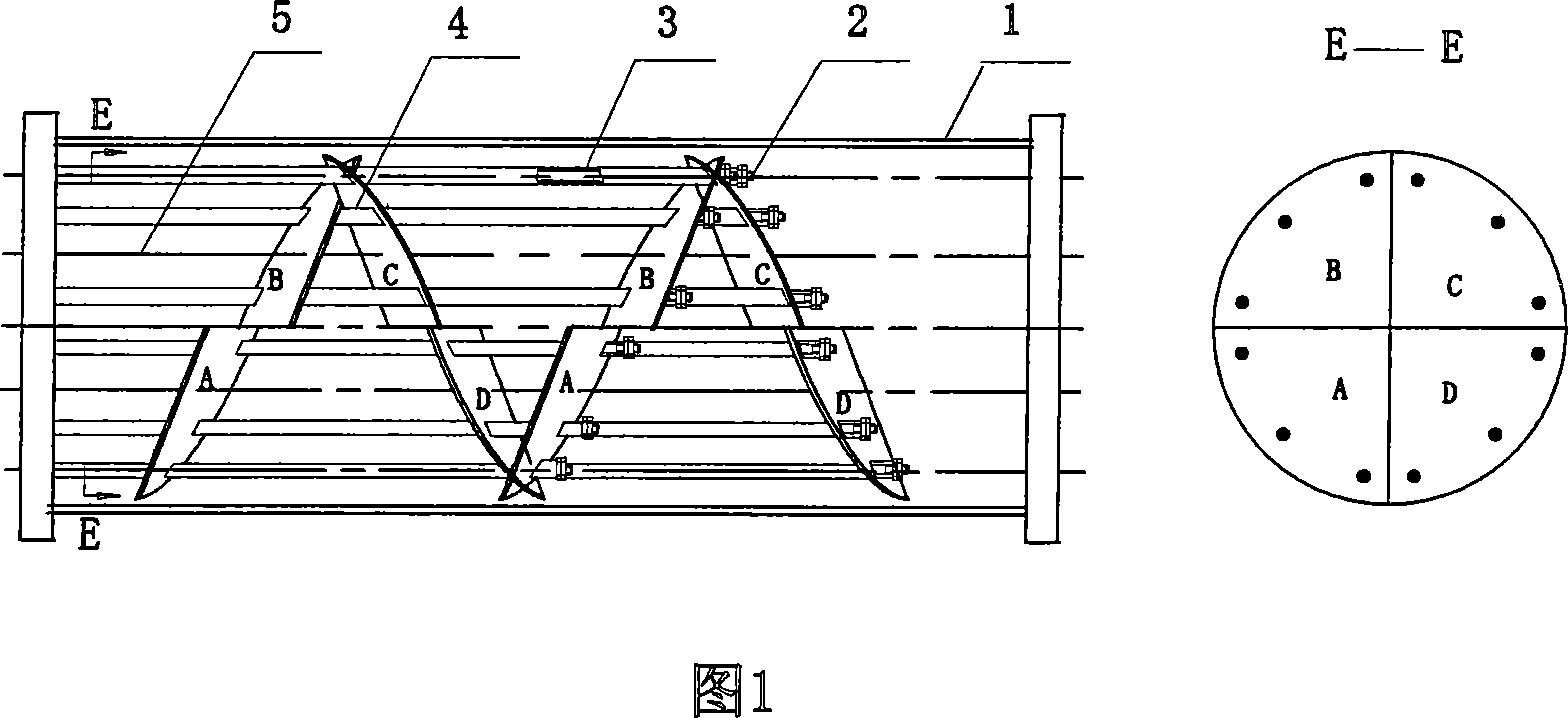

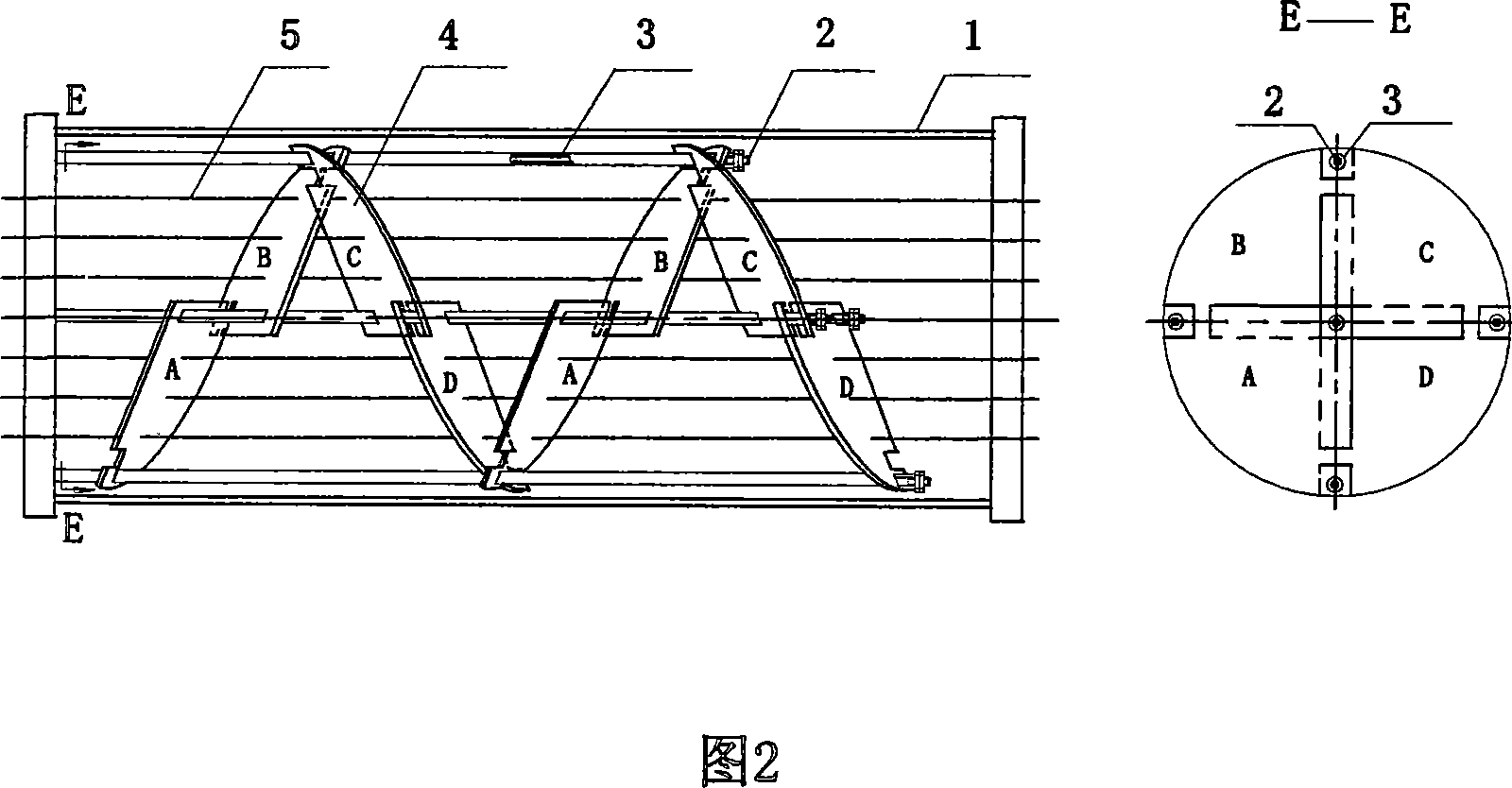

Setups modus of short-circuit-proof spiral baffle plate shell-and-tube heat exchanger draw rod

InactiveCN101042289AImprove weaknessesFirmly connectedChemical industryHeat exchanger casingsShell and tube heat exchangerEngineering

It aims to solve the low heat exchange issue of common tubular shell spiral folding plate, and it features in each projection being 360degree / 4 fan baffle plate with two straight lines extended to 10mm to 100 mm, with the pulling pole going through the central axial line of the shell and two vertical line through the overlapping part of the baffle plate, using pipe spacer to position the baffle plate.

Owner:宋小平 +1

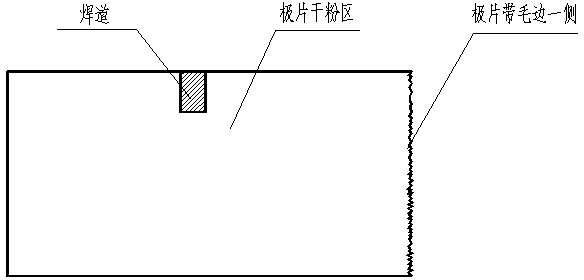

Treatment process for edge of coated-type alkaline accumulator pole piece and auxiliary edge-covering equipment

ActiveCN102779982AEliminate short circuitEliminate Low Pressure ProblemsAlkaline accumulator electrodesLow voltagePole piece

The invention relates to a treatment process for the edge of a coated-type alkaline accumulator pole piece and auxiliary edge-covering equipment. The process comprises the following steps of: covering an alkali-resistant insulating material having a width of 2-10 mm on the edge of foamed nickel by an automatic edge-covering machine before filling active substances in a cell pole piece preparing raw material namely foamed nickel; and compressing the part of the foamed nickel covered by the alkali-resistant insulating material until the thickness of the part is less than 1.5 mm; and finally filling the active substances in the edge-covered foamed nickel. After the process method is adopted, because the burred edge of the foamed nickel is covered by the smooth insulating material, the edge has no need to be trimmed during the subsequent machining; and because the burred edge of the foamed nickel is covered by the smooth insulating material, the edge cannot be damaged during the subsequent machining for the pole piece, and a powder in the pole piece cannot fall off, so that the problems of short circuit and low voltage caused by the burrs on the edge of the pole piece and the powder falling-off of the edge during the use process of the accumulator are eliminated.

Owner:LIAONING JIUYI ENERGY TECH

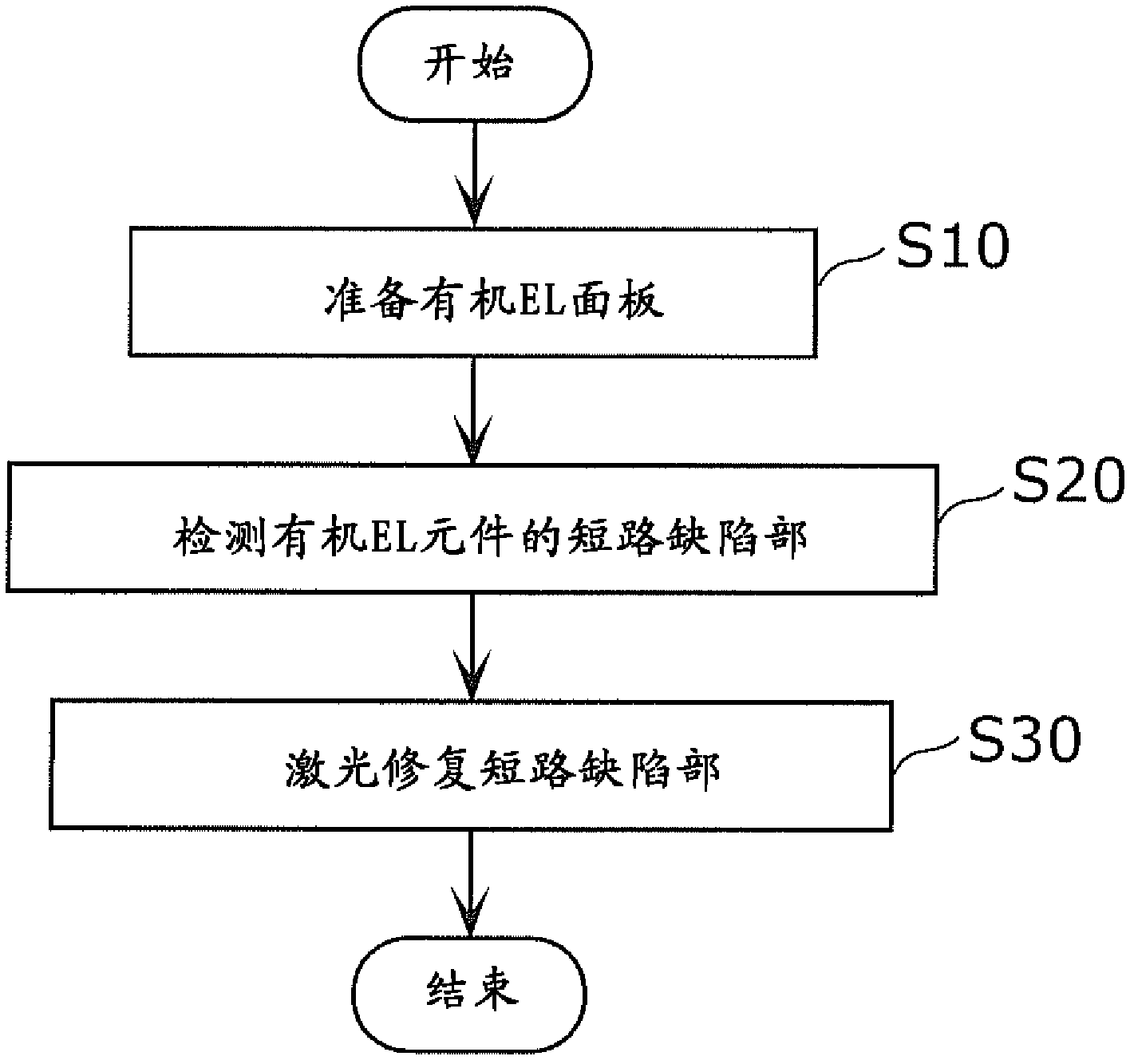

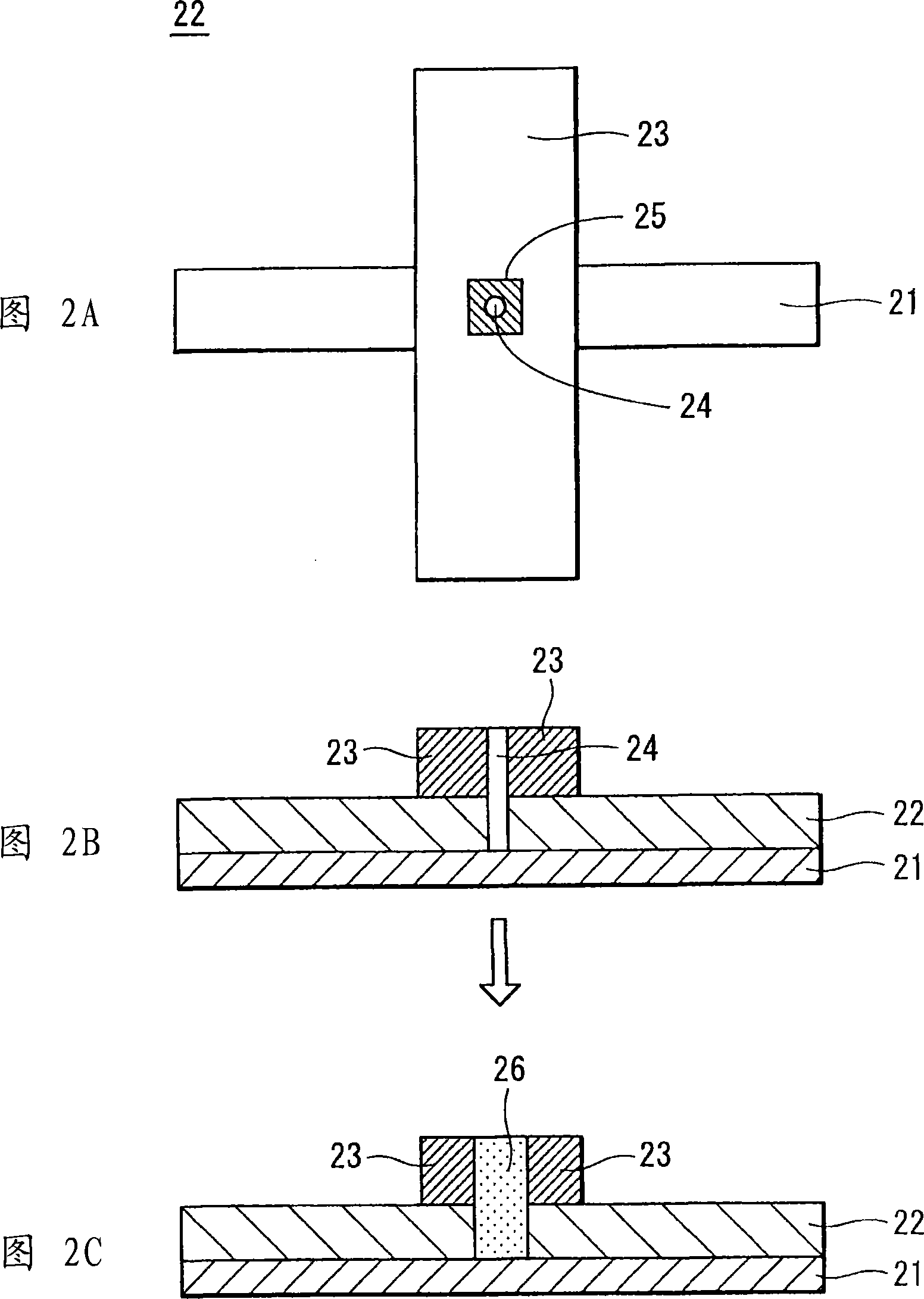

Method for manufacturing organic el element and method for setting focal point of laser

ActiveCN102845132AEliminate short circuitIncrease profitElectroluminescent light sourcesSolid-state devicesOrganic layerOptoelectronics

Owner:JAPAN DISPLAY DESIGN & DEV CONTRACT CO LTD

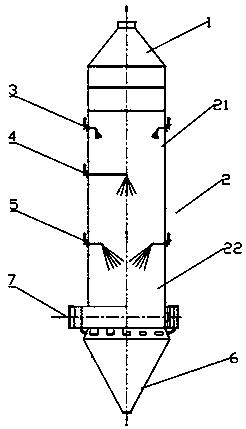

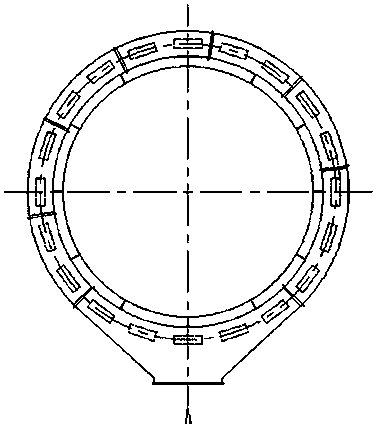

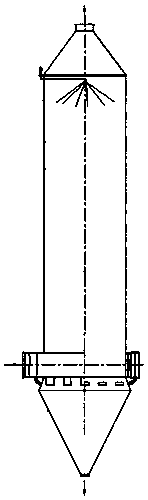

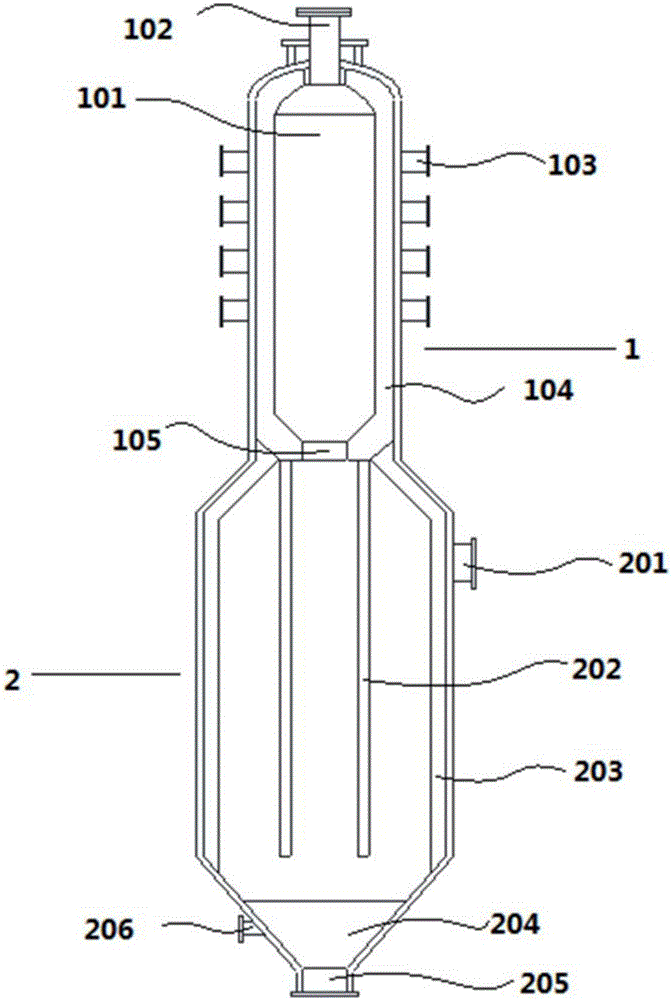

Spray drying tower

PendingCN110841316AReduce energy consumptionLow costEvaporator accessoriesEvaporation by sprayingSpray driedTower

The invention discloses a spray drying tower. A hot gas enters from the bottom of the drying tower and is output from the top, to-be-dried materials entering the drying tower from the side face in a spraying mode are dried and then are output from the bottom of the drying tower in a powdery mode, and the drying tower comprises an upper tower body, a straight cylinder section and a lower tower body. The upper tower body is a conical barrel body which is provided with an outlet in the top and is reduced in diameter upwards, and the dried gas is discharged from the outlet in the top of the uppertower body; the straight cylinder section extends vertically downwards from the lower end of the upper tower body, the straight cylinder section comprises a first straight cylinder section and a second straight cylinder section which are equal in axial length from top to bottom, a circle of short spray guns are annularly arranged on the inner wall of the first straight cylinder section, and a circle of long spray guns are annularly arranged on the inner wall of the second straight cylinder section; a central spray gun is arranged on the inner wall of the middle of the straight cylinder section, the lower tower body is in a cone shape with the diameter shrunk downwards, and a hot gas distributor is arranged on the cross section of the top of the lower tower body.

Owner:浙江美宝工业科技股份有限公司

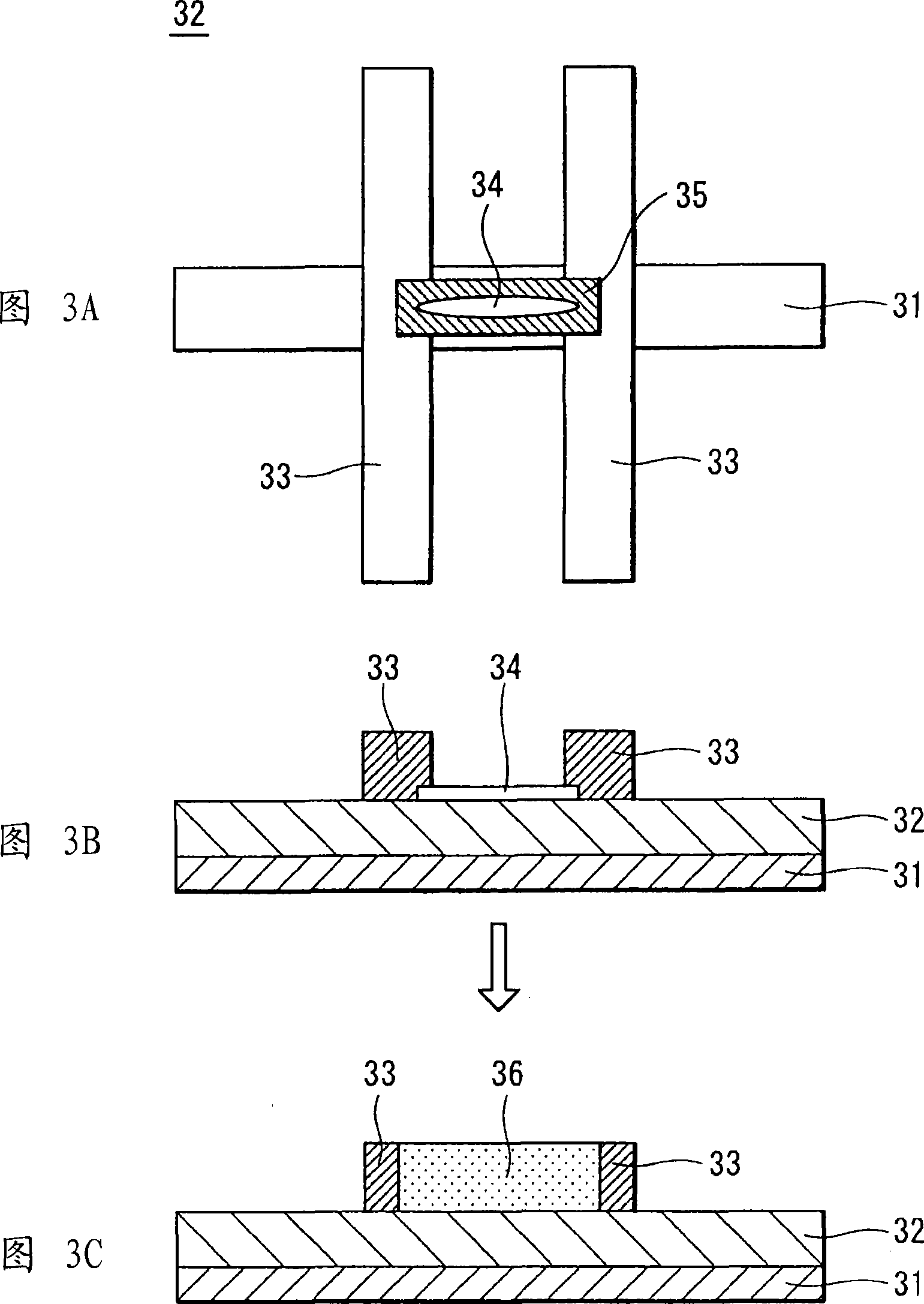

Laser processing apparatus, laser processing method, manufacturing method of wiring substrate, manufacturing method of display apparatus and wiring substrate

InactiveCN101195193ALaser processing is simple and reliableImprove manufacturing yieldSemiconductor/solid-state device manufacturingChemical vapor deposition coatingLaser processingLifting gas

The invention discloses a laser processing apparatus, laser processing method, manufacturing method of wiring substrate, manufacturing method of display apparatus. A laser processing apparatus includes a support table, a local exhaust device, and a laser light source unit. The support table supports a processing object. The local exhaust device directs laser light into a local exhaust unit in which pressure is locally adjusted over the support table. The laser light source unit outputs the laser light. The local exhaust device is capable of relatively being lifted from the support table by injecting a lift gas to the support table. The processing object includes a multilayer film formed of two or more layers with different materials. An input unit into which reflectance of the processing object is inputted is connected to the laser light source unit.

Owner:SONY CORP

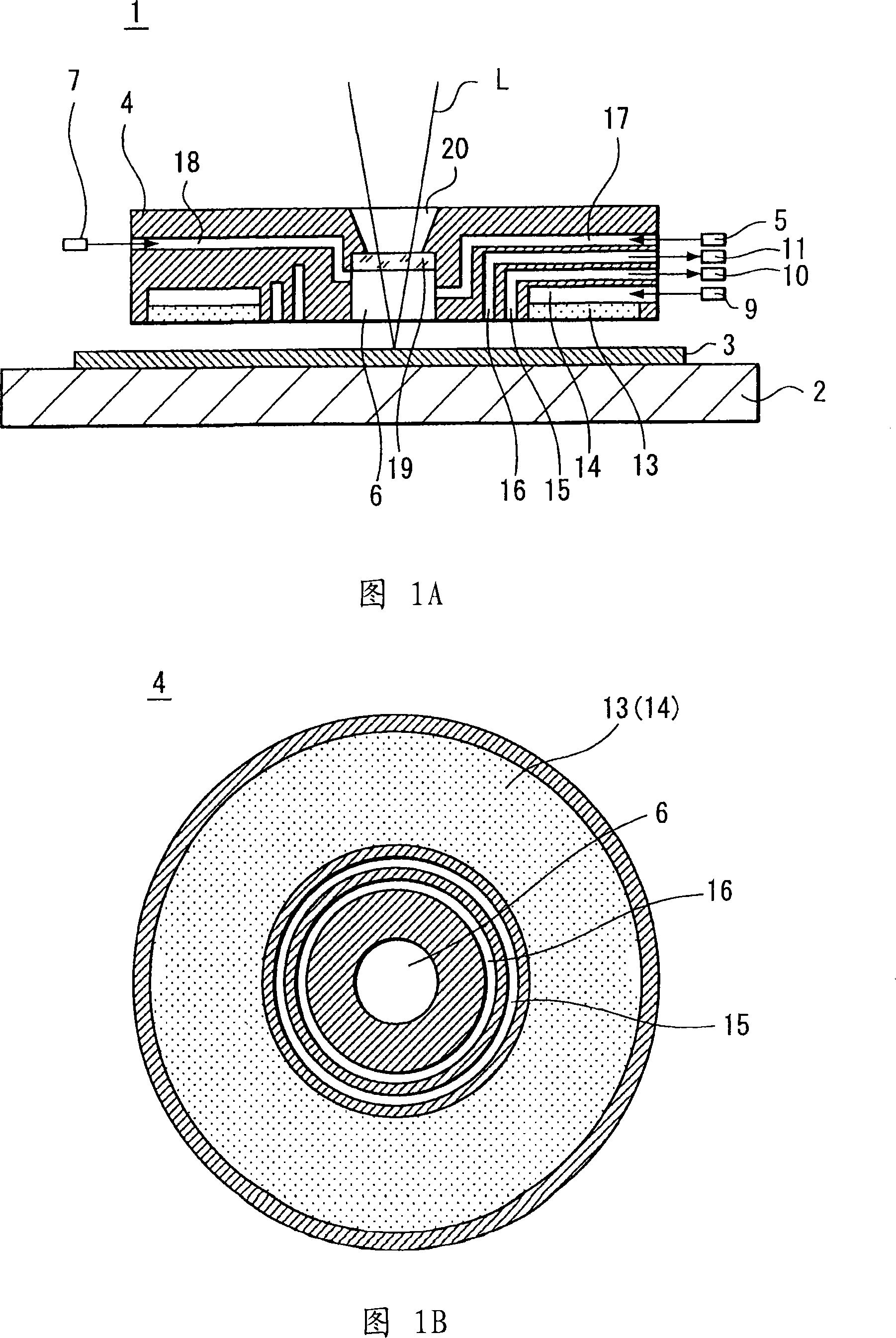

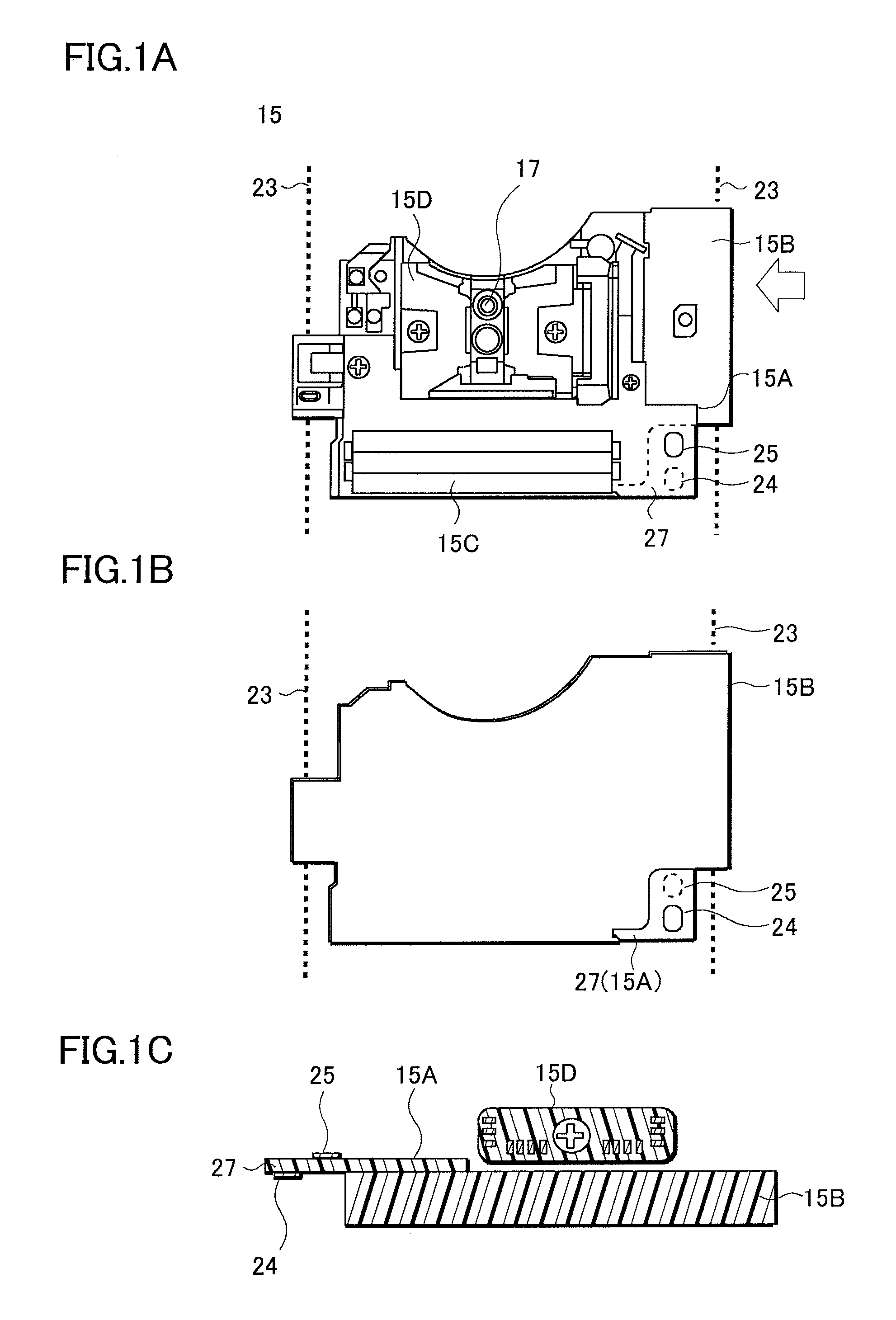

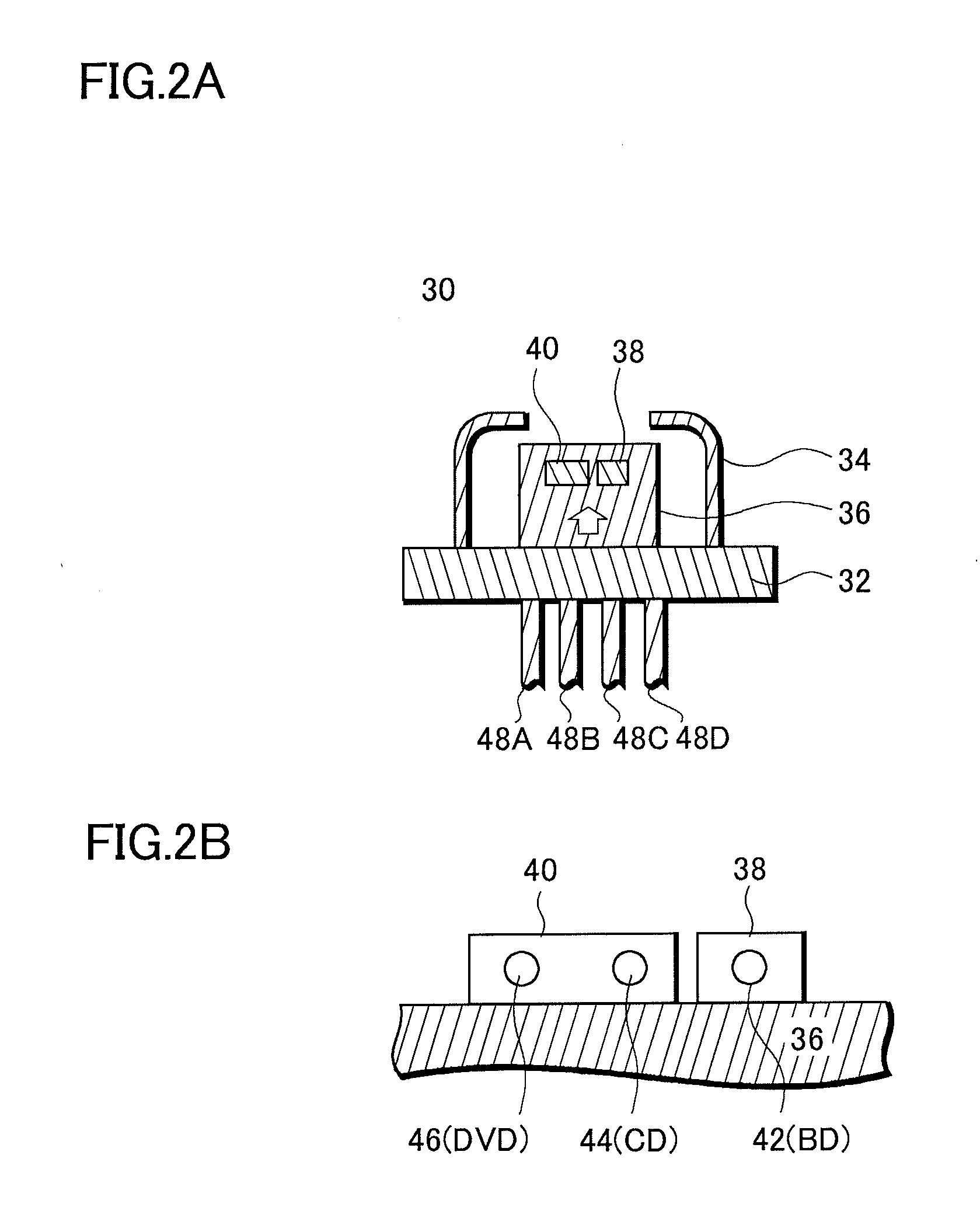

Optical pickup device, optical disk device, and manufacturing method for the same

InactiveUS20120199761A1Eliminate short circuitCost reductionMaterial analysis by optical meansSemiconductor/solid-state device manufacturingElectrostatic dischargeOptical pickup

Provided is an optical pickup device with which a short-circuit can be released from above and below. The optical pickup device (15) is provided with: a housing (15B) formed by ejecting a resin material in a prescribed shape; an actuator (15D) that is positioned on the top surface of the housing (15B) so as to hold an objective lens (17); a circuit board (15A) that is fixed to the main surface of the housing (15B); and a connector (15C) that is attached to the top surface of the circuit board (15A). A second short-circuit part (25) and a first short-circuit part (24) are disposed on the top surface and the bottom surface of the circuit board (15A), and a built-in light-emitting chip is protected from electrostatic discharge damage by shorting either one of the short-circuit parts.

Owner:SANYO ELECTRIC CO LTD +1

Insulation processing process for high-voltage motor group braided wire

InactiveCN101651386AImprove insulation performanceHigh mechanical strengthManufacturing dynamo-electric machinesYarnBreakdown strength

The invention relates to an insulation processing method for a high-voltage motor group braided wire, belonging to the technical field of motors. The insulation processing method for the high-voltagemotor group braided wire sequentially comprises an insulation working procedure jointing with the working procedures of wiring, bending, wire transposition and intrabundle gelling. The insulation processing method for the high-voltage motor group braided wire is characterized by adopting a transposition way of 360 degrees from a motor stator wire rod line to the end part, and a stator wire rod copper lead braided wire adopts a structure of double-terylene glass yarn pocket covering and sintering a sintered copper flat wire structure for insulation. The invention has the advantages of simple process, small insulation thickness, high puncture strength and low manufacture cost of the braided wire, favorable machine unit running effect, and the like and can prevent a wire rod intrabundle shortcircuit and improve the insulation quality of the stator wire rod braided wire.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

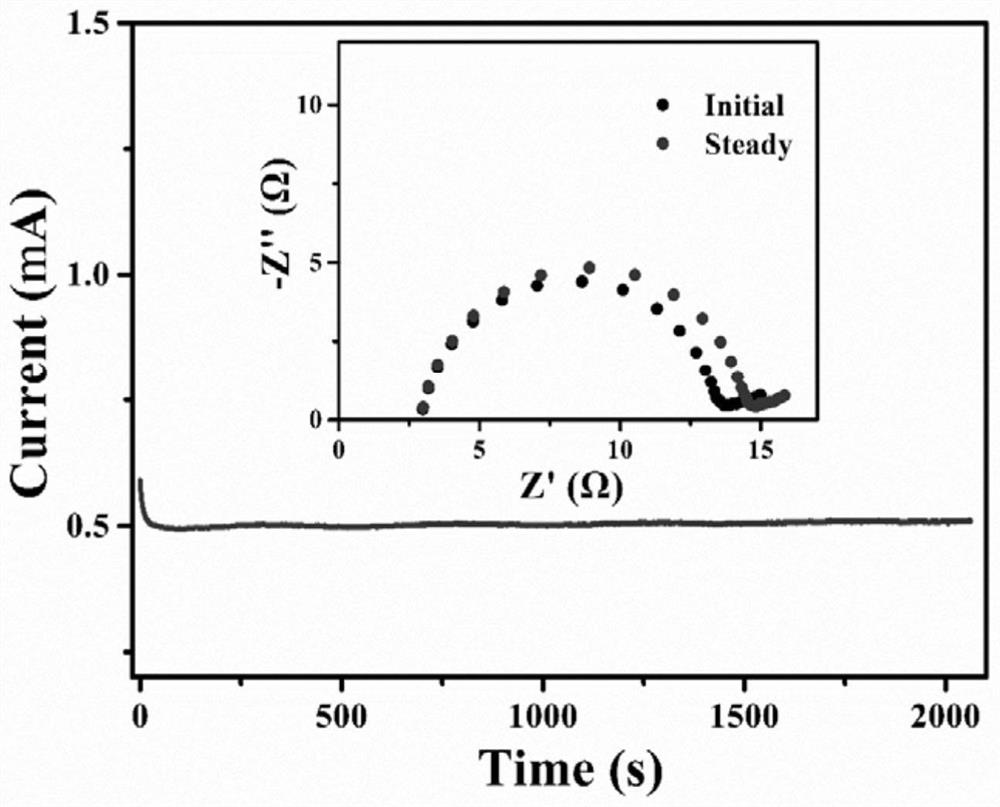

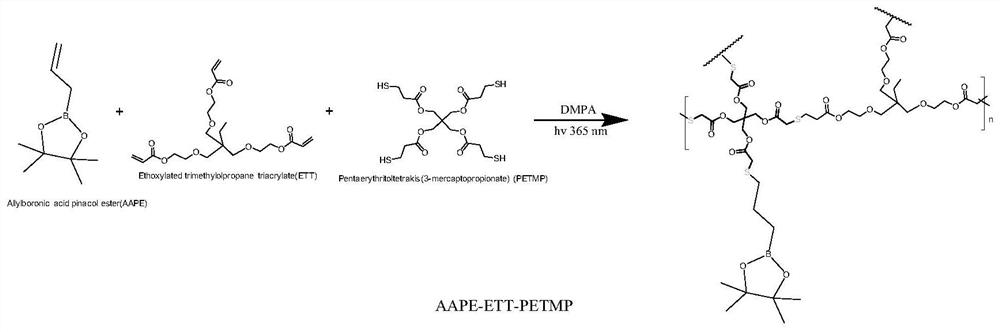

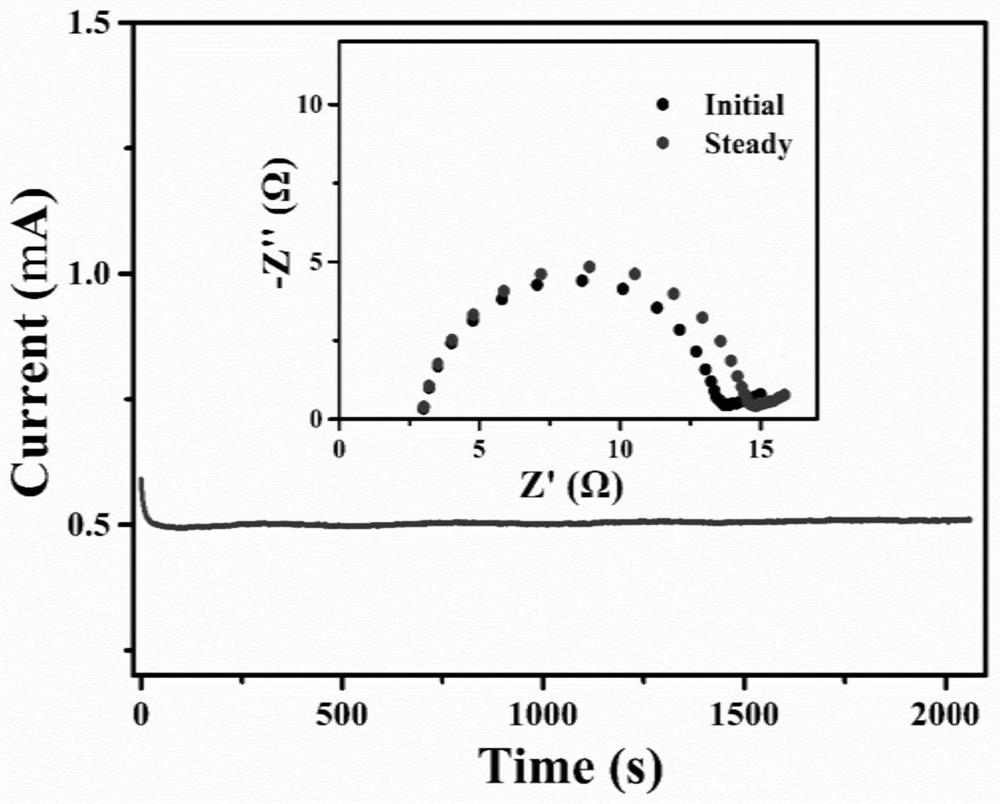

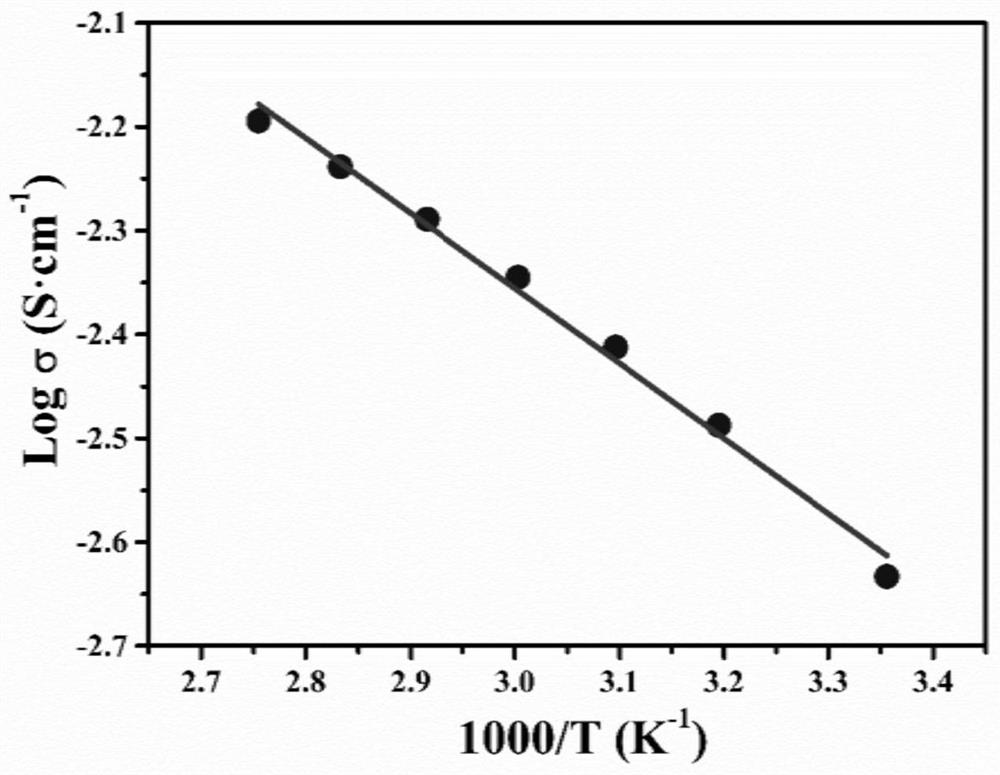

Anion acceptor type single-ion conductor flame-retardant gel polymer electrolyte and preparation method thereof

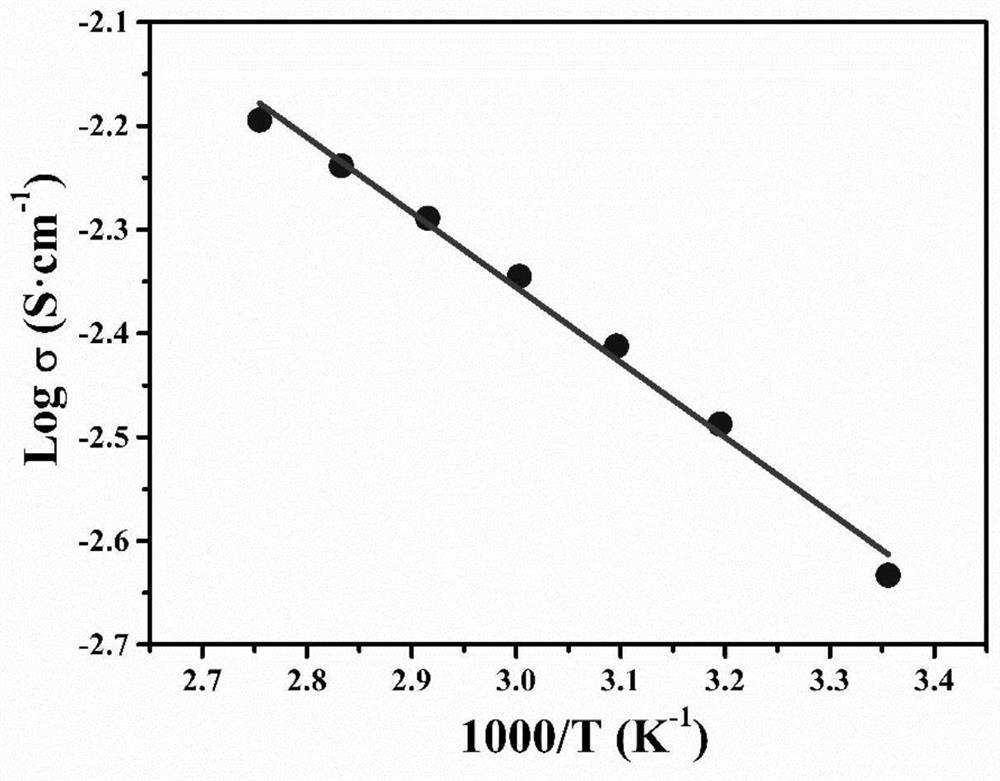

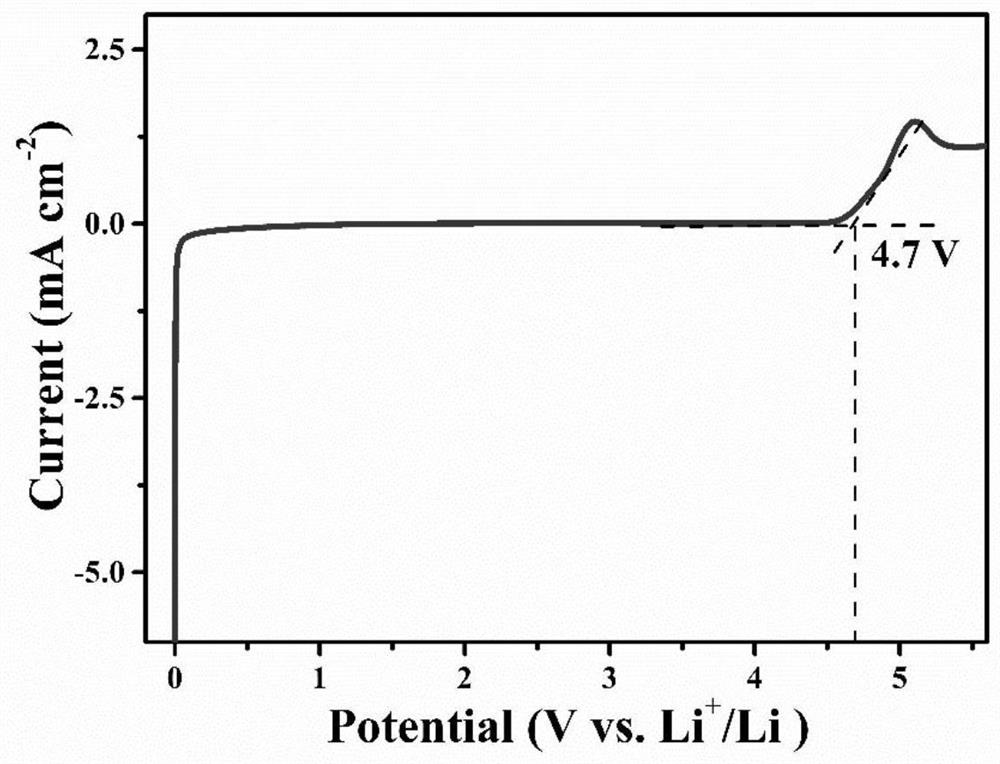

ActiveCN112164824ARestricted freedom of movementIncrease the number of transfersSolid electrolytesFibre typesPolymer scienceUltraviolet lights

The invention discloses a preparation method of an anion acceptor type single-ion conductor flame-retardant gel polymer electrolyte, which comprises the following steps: (1) uniformly stirring and mixing allyl boronic acid pinacol ester, trimethylolpropane triacrylate, pentaerythritol tetramercaptoacetate, propylene carbonate and benzoin dimethyl ether until the components are completely dissolvedto obtain a solution A; (2) dripping the solution A obtained in the step (1) on an electrostatic spinning PVDF (Polyvinylidene Fluoride) membrane, uniformly infiltrating, transferring to ultravioletlight, and carrying out ultraviolet light polymerization reaction, so as to obtain an anion acceptor type single ion conductor flame-retardant gel polymer membrane; and (3) completely soaking the anion receptor type single ion conductor flame-retardant gel polymer membrane obtained in the step (2) in an electrolyte mixed solution to obtain the anion receptor type single ion conductor flame-retardant gel polymer electrolyte. The invention also provides the anion acceptor type single-ion conductor flame-retardant gel polymer electrolyte prepared by adopting the preparation method.

Owner:WUYI UNIV

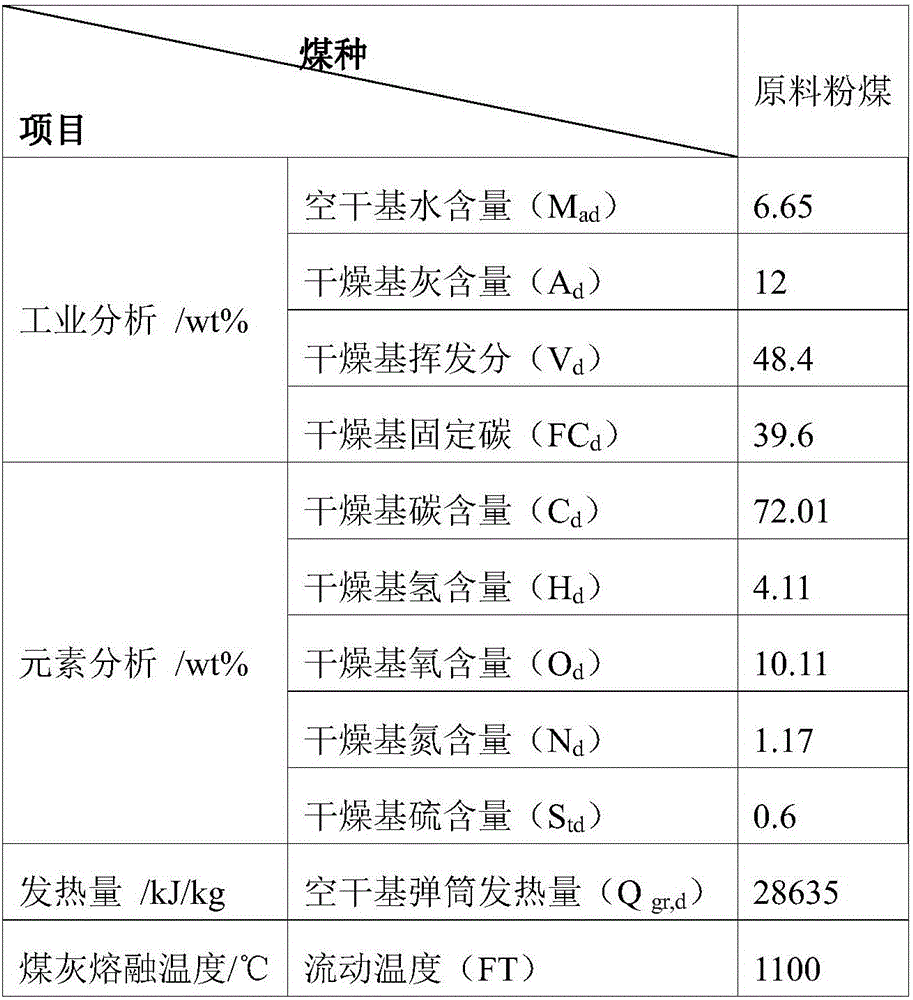

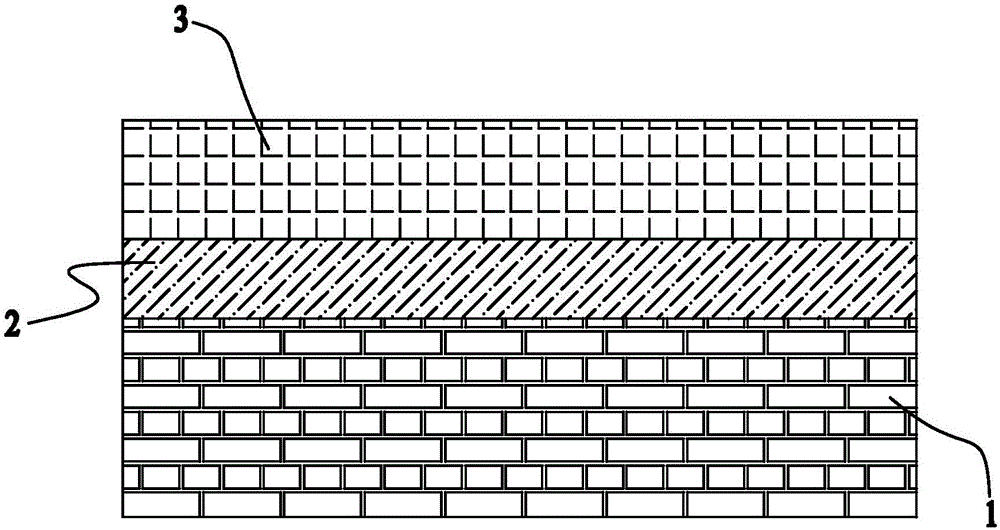

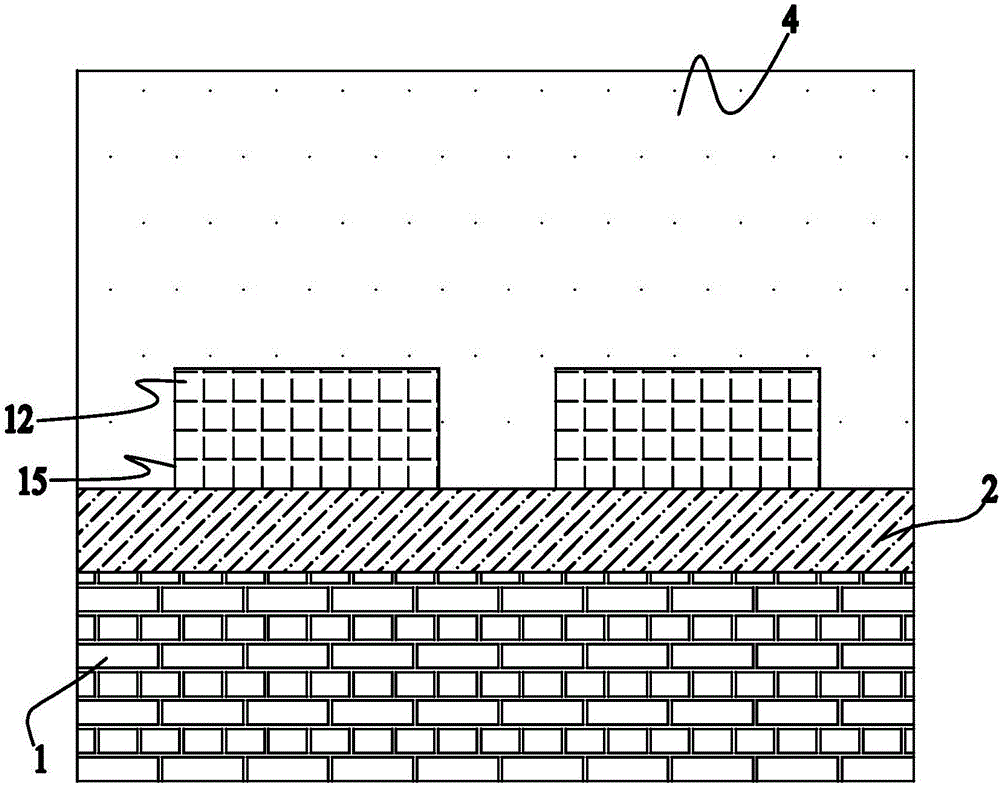

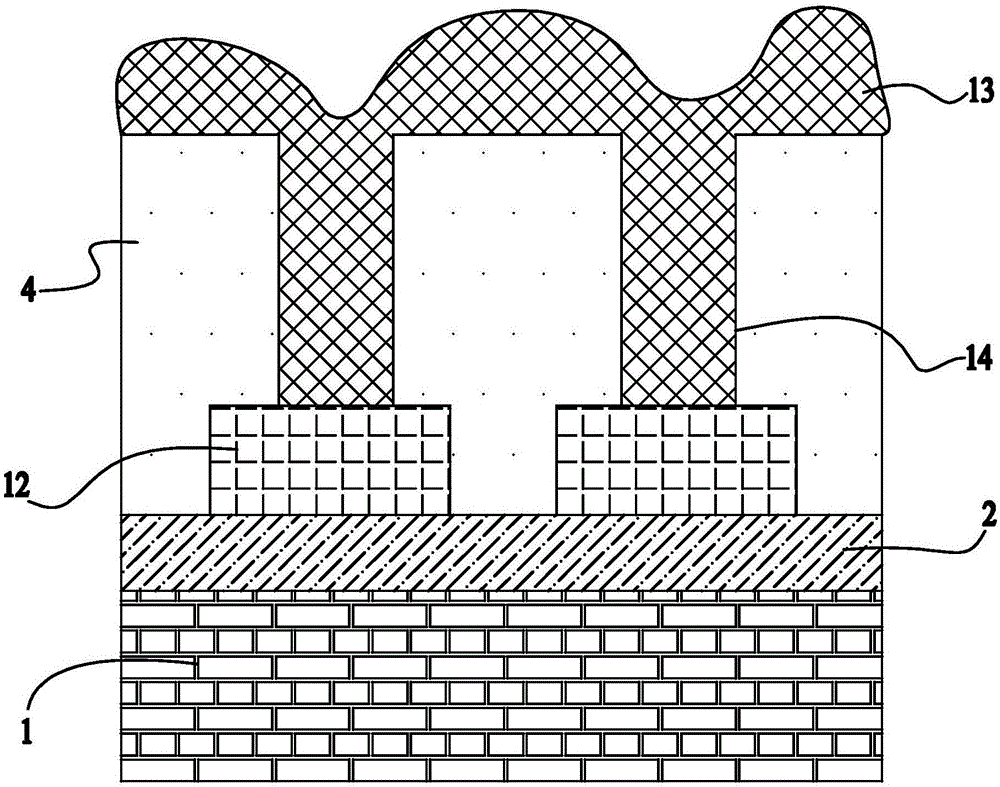

Entrained-flow bed gasifier

InactiveCN106753574AImprove volumetric efficiencyWell mixedGasifier feeding meansGranular/pulverulent flues gasificationSyngasInter layer

The invention discloses an entrained-flow bed gasifier comprising a gasification chamber and a radiant syngas cooler which can be connected with the bottom of the gasification chamber in a detachable manner, wherein a main process burner is arranged at the top of the gasification chamber; the gasification chamber is provided with a furnace body; a plurality of rows of sub-process burners are arranged on the outer wall of the furnace body; a hearth is arranged in the furnace body; a gasification chamber cooling wall is arranged between the furnace body and the hearth; an outer-layer cooling wall and an inter-layer cooling wall are arranged on the outer wall and at the center axis of the radiant syngas cooler respectively; and a slag pool is arranged at the bottom of the radiant syngas cooler and communicates with a circulating water pipeline for supplementing slag pool circulation water into the slag pool. The entrained-flow bed gasifier provided by the invention has the advantages of high in gasification effectiveness, high in safety, clean, environmentally friendly, easy and convenient to operate and fast to start and stop.

Owner:SHANGHAI YINENG GAS TECH

MTM anti-fuse structure on through hole and preparation process thereof

InactiveCN106601718AImprove process toleranceImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesLithographic artistEngineering

The invention relates to an MTM anti-fuse structure on a through hole and a preparation process thereof. The structure comprises a substrate and a device layer on the substrate. The device layer is pressed and covered by a fuse sealing body which is internally provided with a fuse lower electrode. A fuse upper electrode is arranged outside the fuse sealing body and is just above the fuse lower electrode. An anti-fuse dielectric structure and an anti-fuse bottom layer blocking body are arranged between the fuse upper electrode and the fuse lower electrode. The anti-fuse bottom layer blocking body coats the top end of the fuse lower electrode in the fuse sealing body. The anti-fuse dielectric structure is supported on the anti-fuse bottom layer blocking body, and the fuse upper electrode is supported on the anti-fuse dielectric structure. The structure of the MTM anti-fuse structure is compact, the times of lithography can be reduced, the process operation is simple, the process cost is reduced, the integration degree is raised, and the reliability of anti-fuse is improved.

Owner:58TH RES INST OF CETC

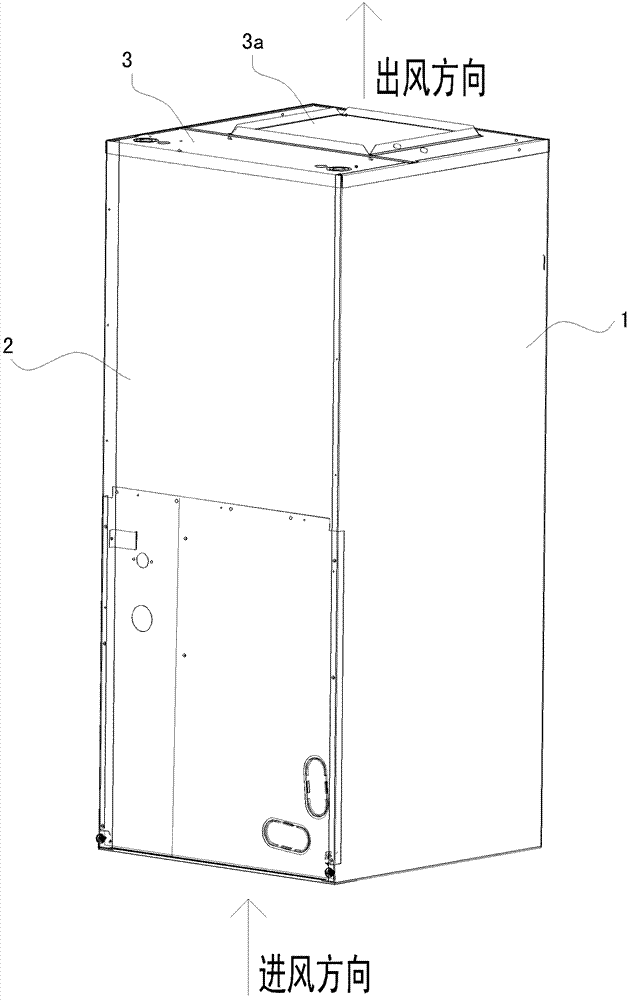

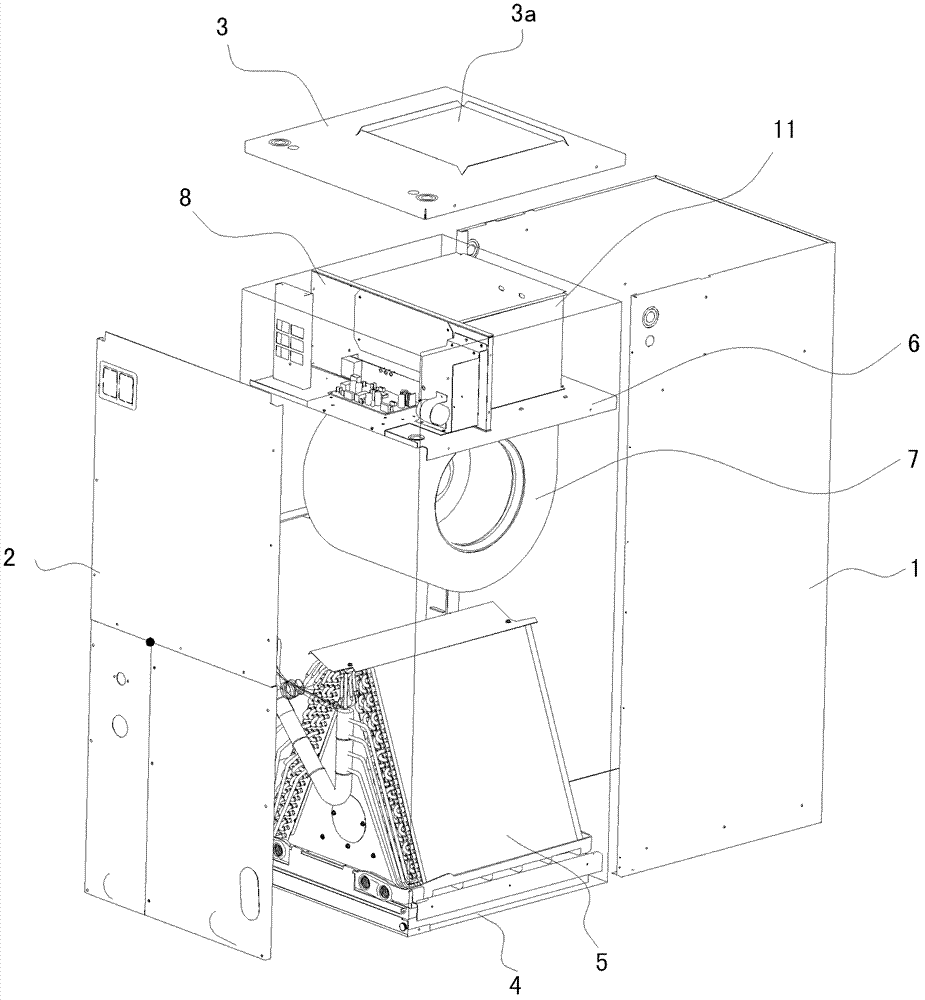

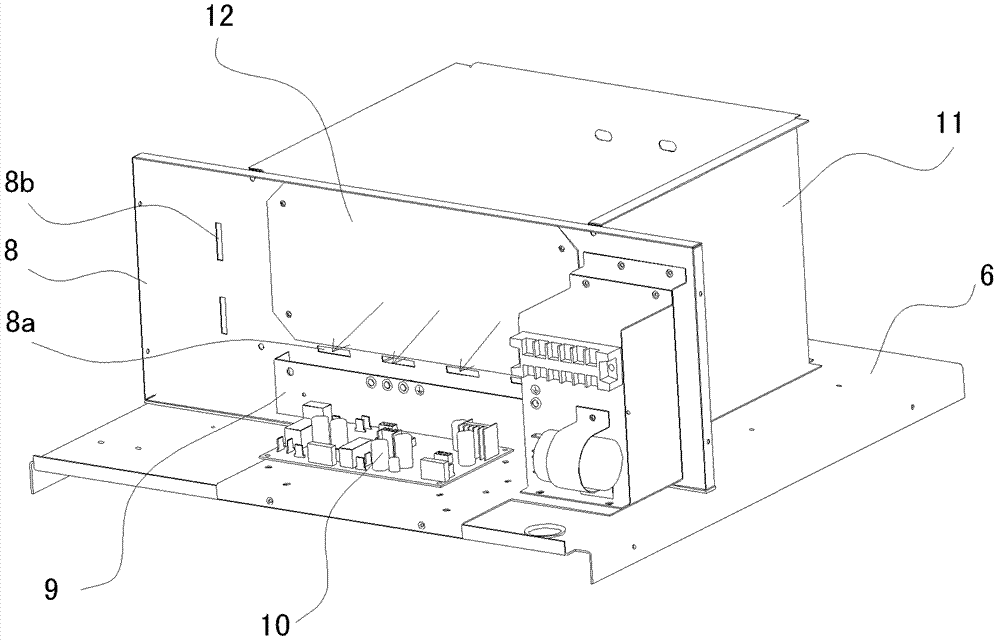

Inner machine of air conditioner

ActiveCN103196180ASolve condensationEliminate short circuitLighting and heating apparatusAir conditioning systemsEngineeringElectric control

The invention discloses an inner machine of an air conditioner, which comprises a housing, an evaporator, a draught fan, and an electric control box, wherein an air inlet and an air outlet are formed in the housing; an air passage communicated with the air inlet and the air outlet are arranged inside the housing; the electric control box is positioned at the outer part, next to the air outlet, of the air passage; and more than one air holes are formed in a baffle between the electric control box and the air passage. According to the inner machine of the air conditioner provided by the invention, the air holes, communicated with the air passage, are formed in the baffle of the electric control box to well solve the condensation problem of the electric control box and avoid the serious humidity environment for electric components, and therefore, the reliability is greatly improved; potential safety hazards, such as short circuit of the electric components, water seepage inside the electric control box and the like are eliminated; and the processing process that the air holes are formed in the baffle is simple.

Owner:GREE ELECTRIC APPLIANCES INC

Low capacity nickel-hydrogen secondary battery and assembly method

InactiveCN101340008ALower ohmic resistanceLower polarization internal resistanceFinal product manufactureAlkaline accumulators manufactureHydrogenEngineering

The invention discloses a low-capacity nickel-hydrogen secondary battery and an assembly method thereof. The low-capacity nickel-hydrogen secondary battery comprises a steel case and a polar group, wherein, the polar group consists of a positive electrode, a negative electrode and a membrane, and is characterized in that: a substrate is arranged at the bottom of the steel casing; the assembly method of the low-capacity battery comprises the following steps: (1). assembling the steel casing: the steel case is well placed in a material case regularly with the mouth upwards, the substrate is arranged on the steel casing and then the substrate is pushed to the bottom of the steel case by a tool; (2). assembling the rear end: a wound polar group is put into the steel casing where the substrate is placed in the step (1), and then groove rolling, glue coating, spot welding, alkali injection, and sealing and assembly procedures are performed; (3) high-temperature laying: the assembled battery in the step (2) is laid with the head part of the battery downwards at high temperature; (4) formation: the formation is performed after high-temperature laying in the step (3) for 48 hours. The assembly method is simple and convenient, and the low-capacity nickel-hydrogen secondary battery obtained by adopting the assembly method is characterized by low cost and good battery performance.

Owner:江苏赛尔电池有限公司

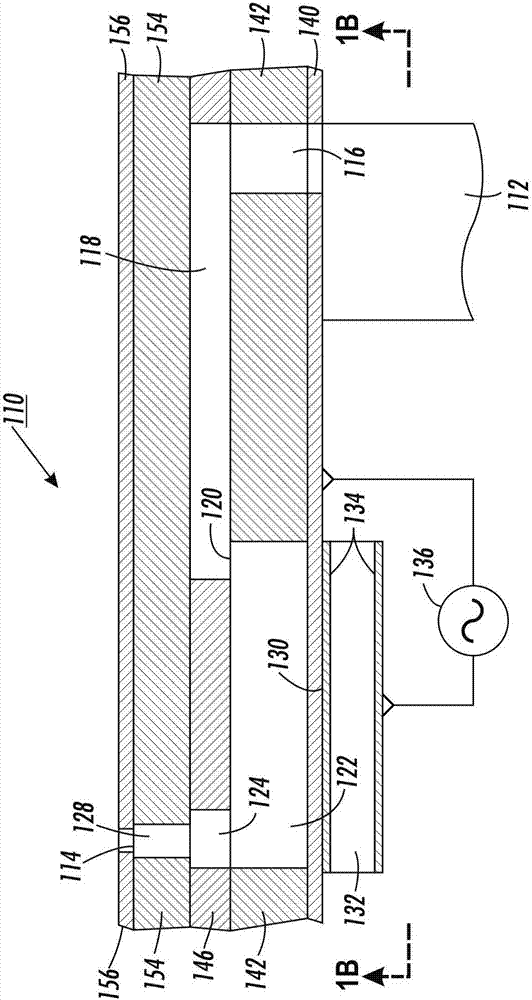

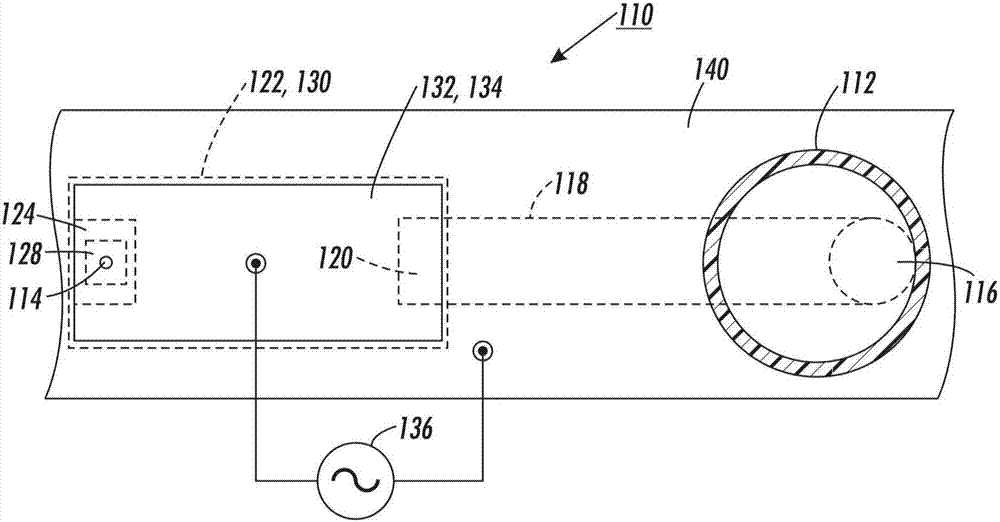

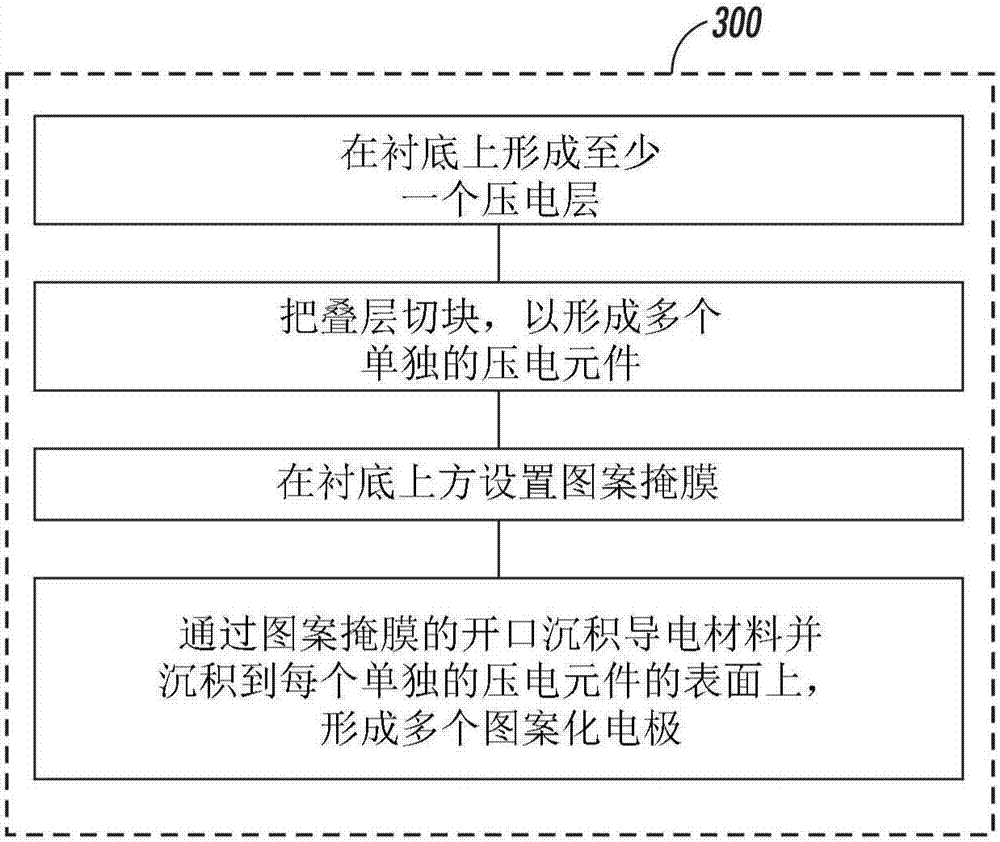

Method of forming piezo driver electrodes

A method for forming piezoelectric transducers for inkjet printheads includes: forming at least one piezoelectric layer on a substrate; forming at least one electrode pattern by depositing a conductive material on an exposed surface of the at least one piezoelectric layer; and forming a plurality of individual piezoelectric elements from the at least one piezoelectric layer before or after the forming of the at least one electrode pattern.

Owner:XEROX CORP

Anion acceptor type single ion conductor flame retardant gel polymer electrolyte and preparation method thereof

ActiveCN112164824BRestricted freedom of movementIncrease the number of transfersSolid electrolytesFibre typesUltraviolet lightsMercaptoacetic acid

The invention discloses a preparation method of an anion acceptor type single ion conductor flame-retardant gel polymer electrolyte, which comprises the following steps: (1) allyl borate pinacol, trimethylolpropane triacrylate, Pentaerythritol tetramercaptoacetate, propylene carbonate and benzoin dimethyl ether were stirred and mixed evenly until completely dissolved to obtain solution A; (2) solution A obtained in step (1) was dropped onto the electrospun PVDF membrane to infiltrate evenly, and transferred Under ultraviolet light, an ultraviolet photopolymerization reaction occurs to obtain an anion acceptor type single ion conductor flame retardant gel polymer film; (3) the anion acceptor type single ion conductor flame retardant gel polymer film obtained in step (2) is placed After soaking completely in the electrolyte mixture, the anion acceptor type single ion conductor flame retardant gel polymer electrolyte is obtained. The invention also provides the anion acceptor type single ion conductor flame retardant gel polymer electrolyte prepared by the preparation method.

Owner:WUYI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com