Package For Power Storage Device

A technology for accumulators and exterior bodies, applied in the field of exterior bodies for electric storage devices, to achieve the effects of reducing connection space, eliminating short-circuits, and preventing short-circuit accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

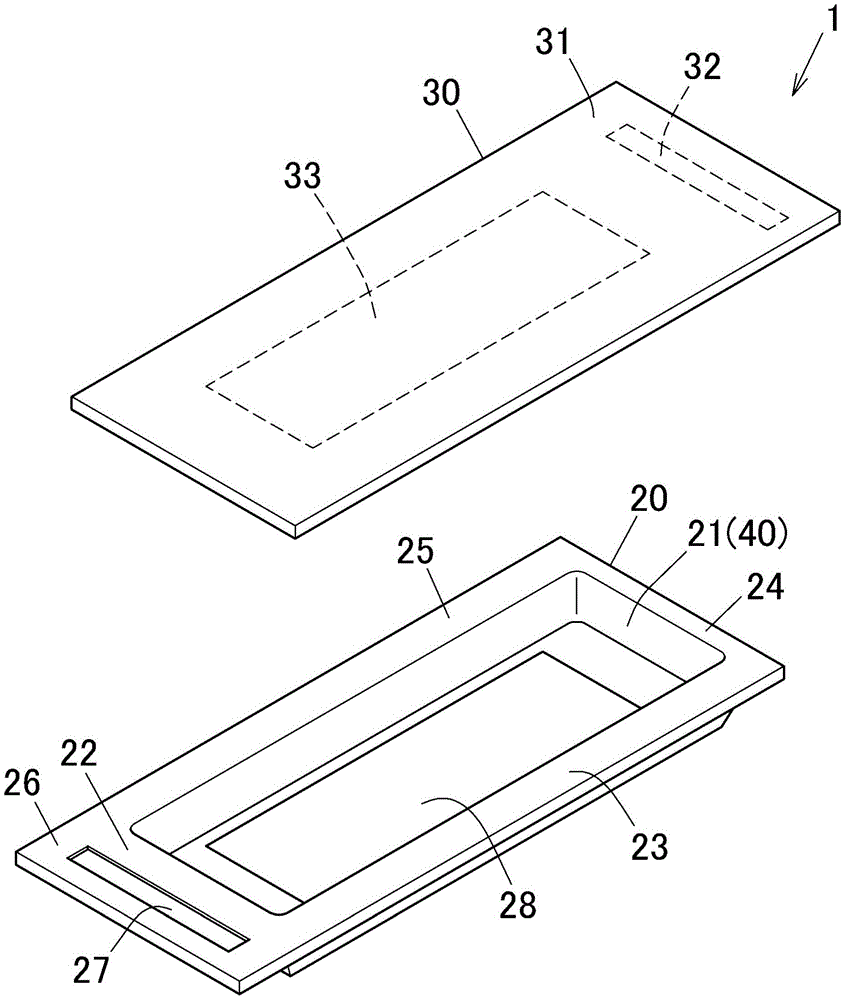

[0184] This example is referred to Figure 7A with Figure 7B The laminated exterior battery 101, refer to figure 1 , The exterior body 1 is composed of a main body 20 and a cover plate 30 .

[0185] The main body 20 is manufactured by the following method.

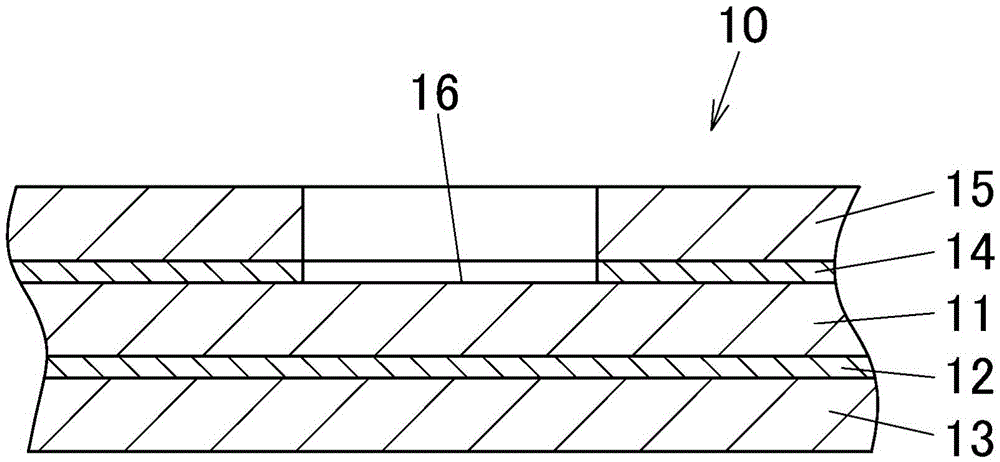

[0186] On one side of the metal foil layer 11 (aluminum foil) cut into A4 size, the coating amount after drying is 3g / m 2 Coating the adhesive 12 whose concentration was adjusted with a solvent, drying it at 100°C for 20 seconds, then laminating the heat-resistant resin layer 13, curing it in an aging oven at 40°C for three days to cure the adhesive 12 .

[0187] Such as Figure 12 As shown, after curing, stick an adhesive tape 80 of 80 mm × 80 mm on the center of the opposite surface of the metal foil layer 11 (predetermined position of the internal conductive part), and stick 80 mm at the predetermined position of the external conductive part 25 mm away from the pasting position. ×5mm tape 81( Figure 12 upper l...

Embodiment 2

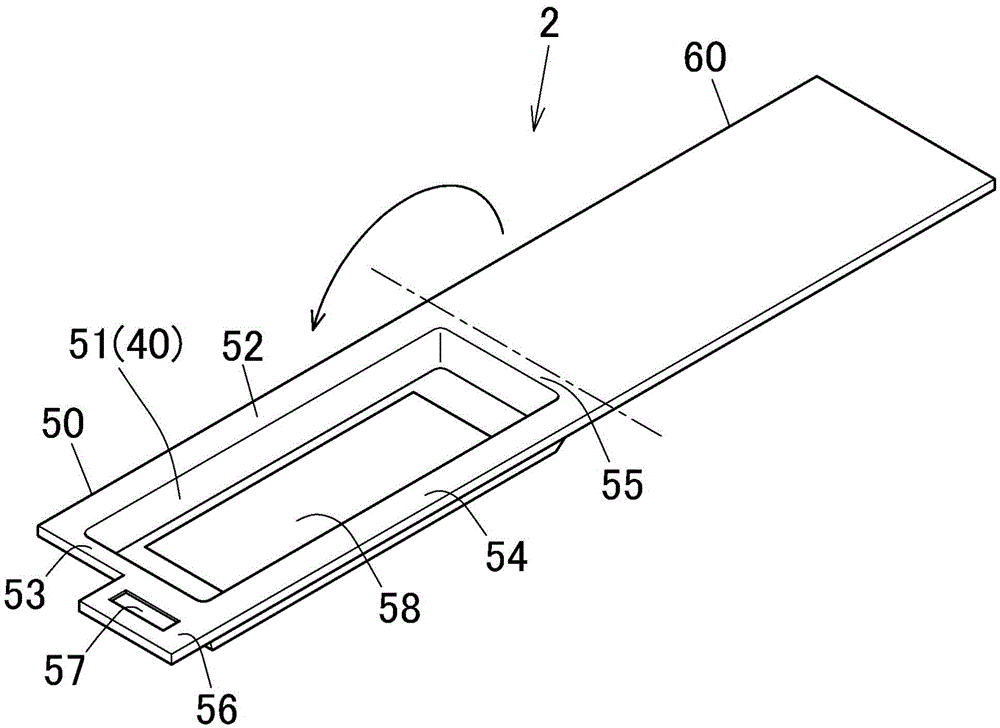

[0196] This example is referred to Figure 9A with Figure 9B of the laminated exterior battery 103, refer to Figure 4 , the exterior body 3 is composed of the main body 20 and the cover plate 35 .

[0197] The main body 20 is the same as the first embodiment.

[0198] The cover plate 35 is produced by the following method.

[0199] The laminated exterior for the cover plate 35 is performed in the same manner as the laminated exterior for the cover plate in Example 1, except that adhesive tapes 80 and 81 are attached to the surface of the metal foil layer 11 on the side of the heat-sealable resin layer 15. manufacture. This laminated exterior material was cut into 110 mm x 110 mm to obtain a cover panel 35 .

[0200] The negative electrode tab 75 was ultrasonically bonded to the negative electrode 71 of the battery body 70 and fixed.

[0201] The battery main body 70 is filled in the recess 21 of the main body 20, and the positive electrode 72 is bonded to the internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com