Liquid crystal display panel and restoring method thereof

A liquid crystal display panel and repair method technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as easy breakdown, large graphics, poor display, etc., and achieve the effect of eliminating short circuits and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

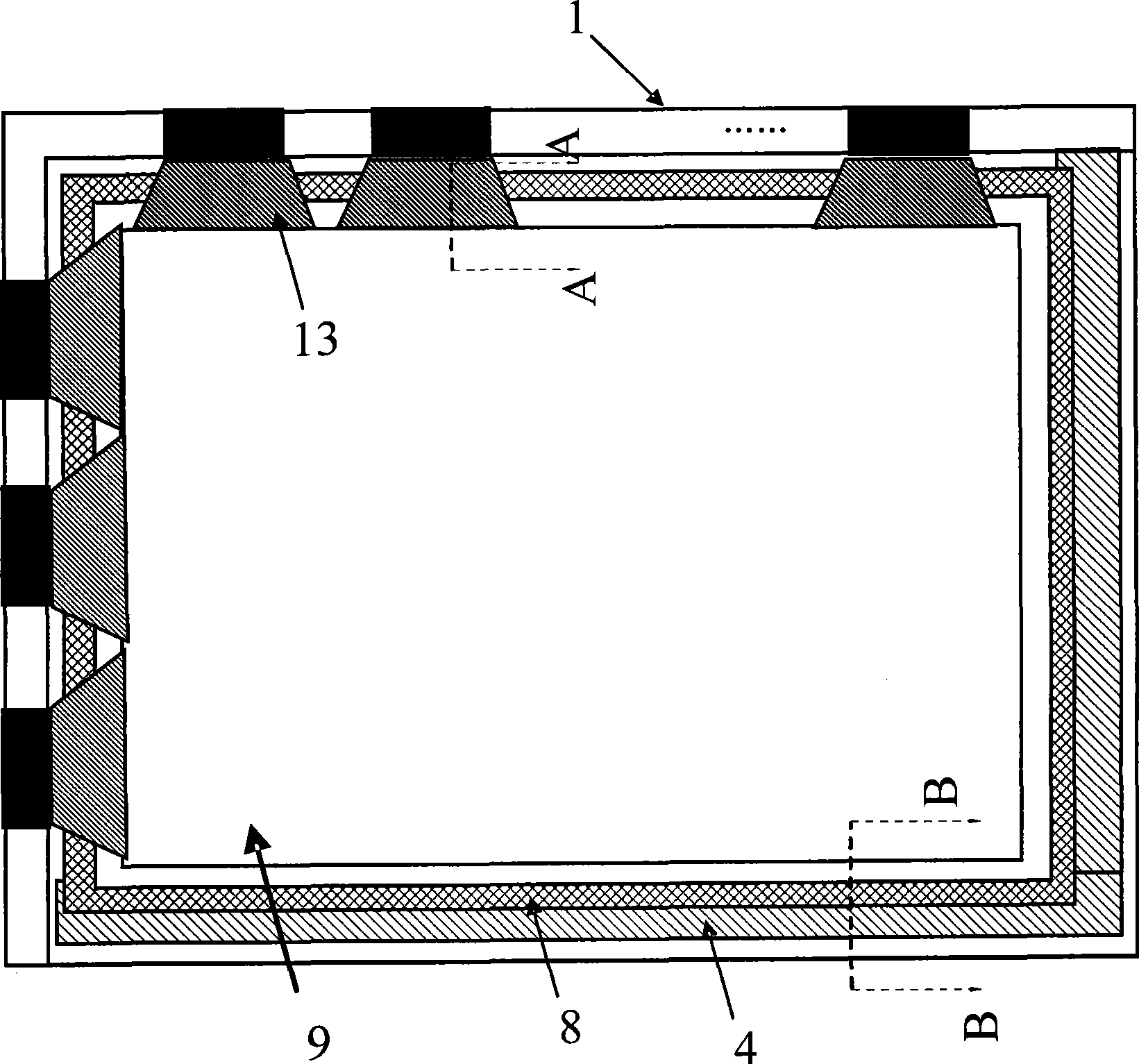

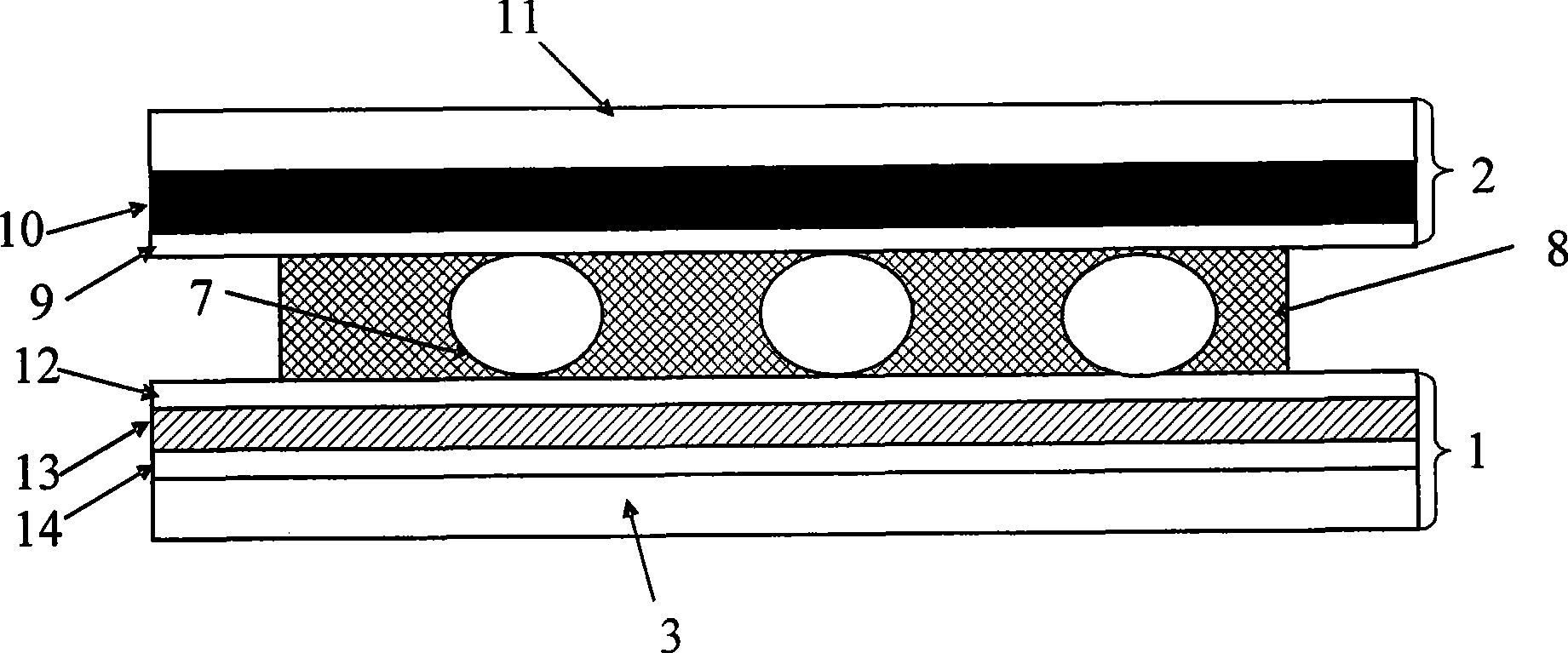

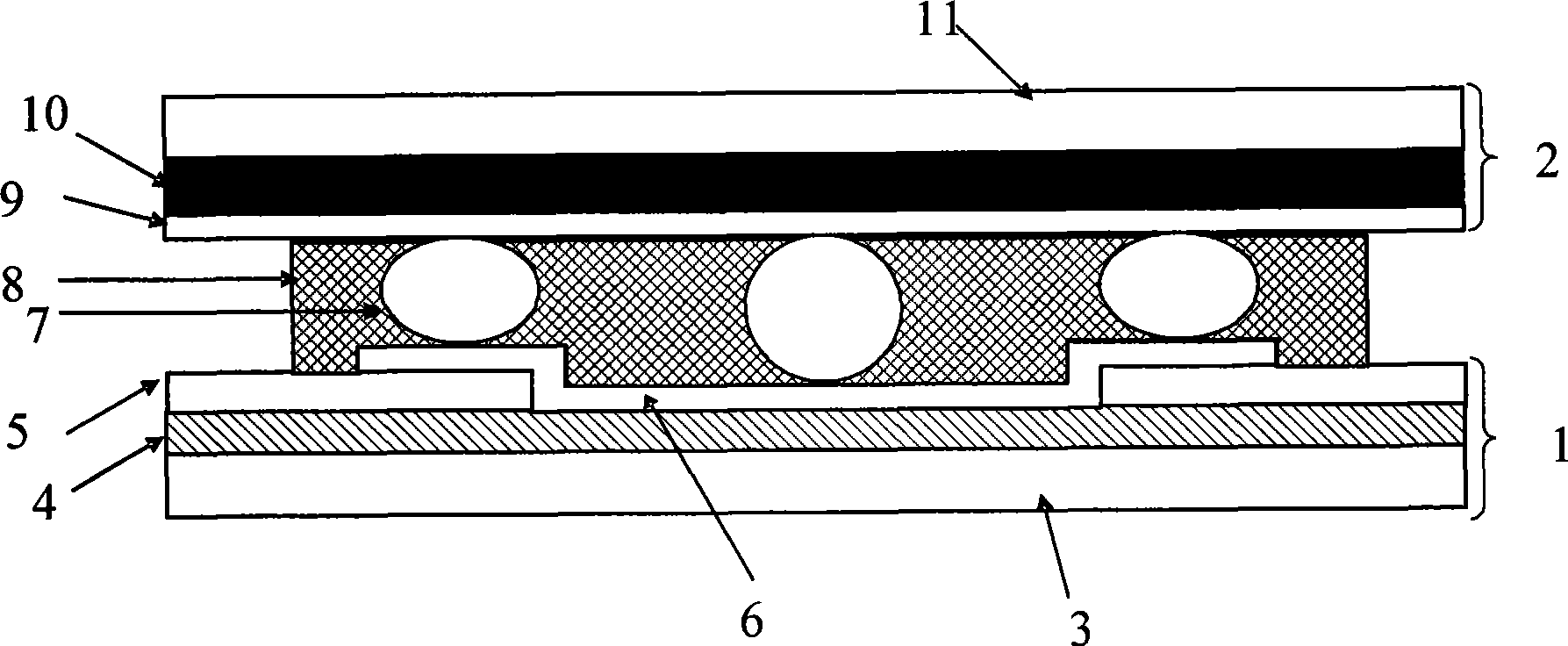

[0017] Hereinafter, the liquid crystal display panel and the repair method of the present invention will be described in further detail with reference to the accompanying drawings.

[0018] Figure 4 Is a schematic diagram of the structure of the first embodiment of the liquid crystal display panel of the present invention; Figure 5 for Figure 4 Sectional view along the C-C direction. Such as Figure 4 , Figure 5 As shown, the liquid crystal display panel of the present invention includes a plurality of signal terminals CO, signal leads 33 connected to the signal terminals CO transmit signals to the display area, and the indium-tin oxide (ITO) conductive layer on the side of the color film substrate 22 29 surrounds the signal lead 33 and has a frame sealant layer 28 near the signal terminal. The frame sealant layer 28 is arranged between the array substrate 21 and the color filter substrate 22 and is used to bond the array substrate 21 and the color filter substrate 22, The li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com