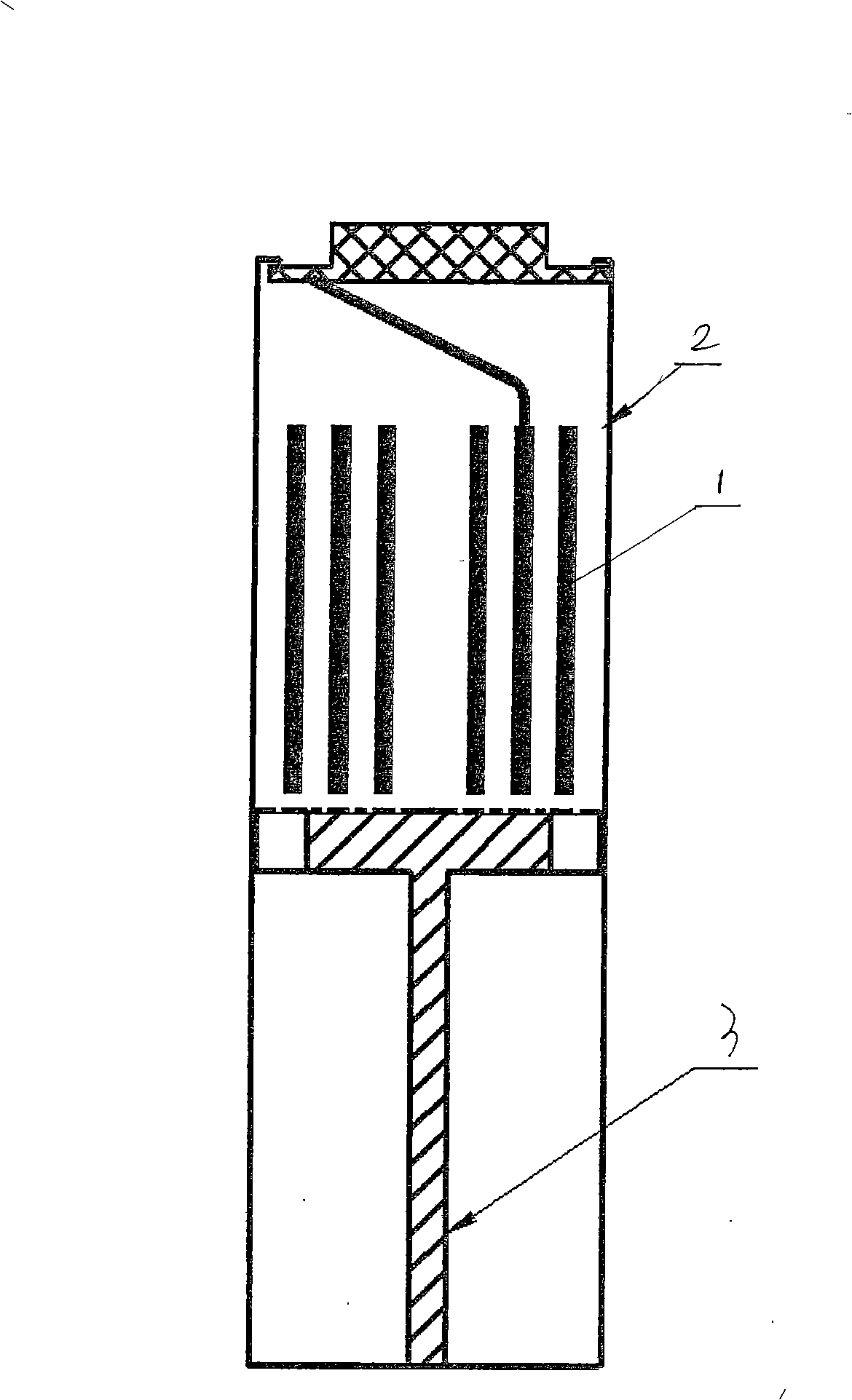

Low capacity nickel-hydrogen secondary battery and assembly method

A secondary battery and assembly method technology, which is applied in the manufacture of nickel storage batteries, alkaline storage batteries, alkaline storage batteries, etc., can solve problems such as volume deformation of the electrode group, impact of battery overcharge and overdischarge performance, battery short circuit, etc., to reduce ohms Internal resistance and polarization internal resistance, elimination of short-circuit and explosion hazards of batteries, and effects of improving discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Example: A battery with a model of AA600mAh is assembled according to the following steps:

[0014] 1. Install steel shell:

[0015] 1.1 First place the steel shell with a size of Φ13.9 / Φ13.5×49.0mm in the material box according to the rules, with the shell opening upward;

[0016] 1.2 Put a bottom lining with a size of Φ13.3×19mm in each battery case in turn, and push the bottom liner to the bottom of the steel case with a tool;

[0017] 2. Back-end assembly:

[0018] 2.1 Winding:

[0019] 2.1.1 The operator wears finger cots, and puts the positive electrode, negative electrode, separator, battery case and color box on the work table;

[0020] 2.1.2 Turn on the power switch of the winding machine, adjust the air pressure of the upper and lower clamps, the air pressure is 0.2 ~ 0.4MPa;

[0021] 2.1.3 Adjust the positioning of the diaphragm on the platform, fix it with a fixed block, and the diaphragm of the last ring is completely overlapped;

[0022] 2.1.4 Step on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com