Patents

Literature

76results about How to "Restricted freedom of movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

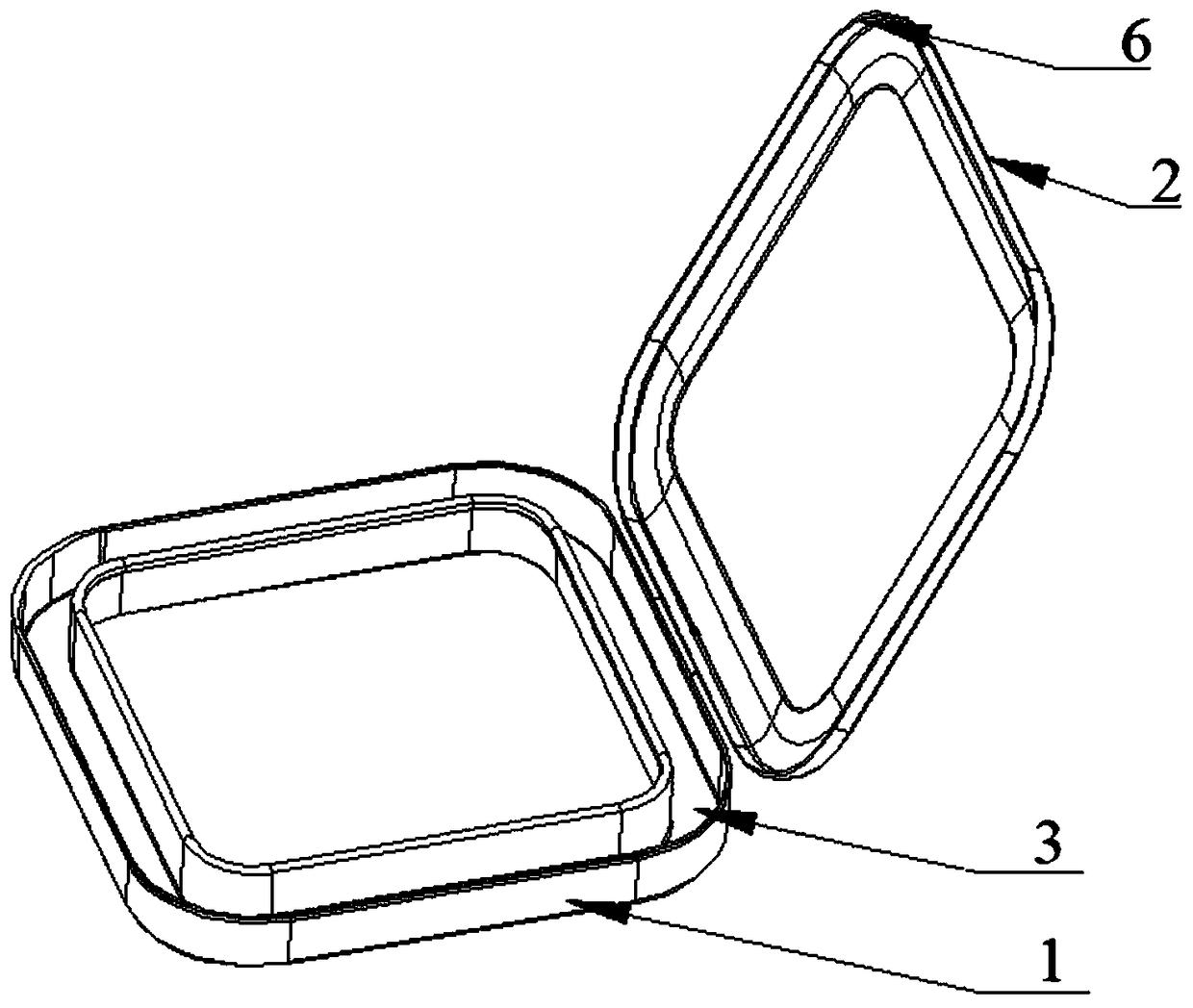

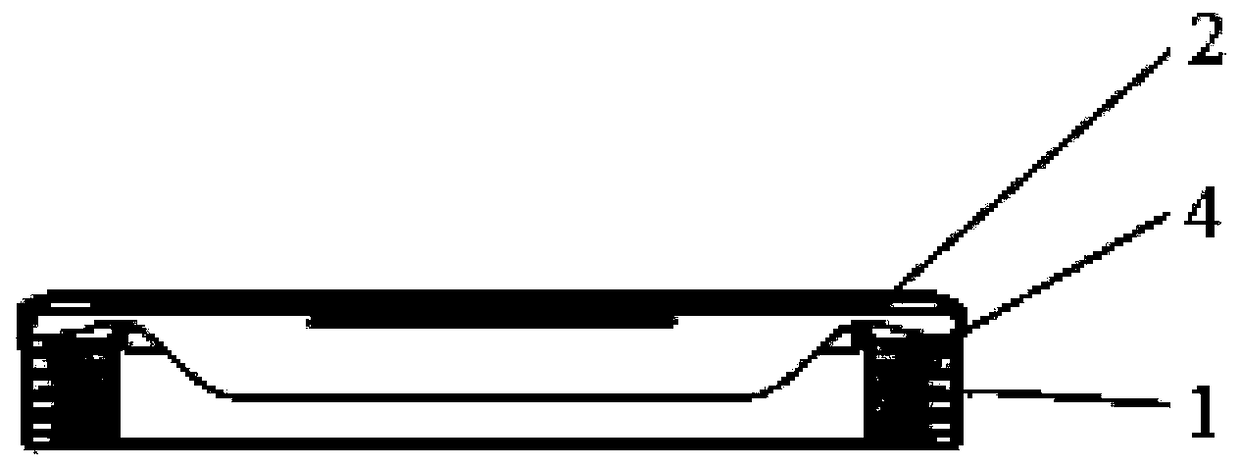

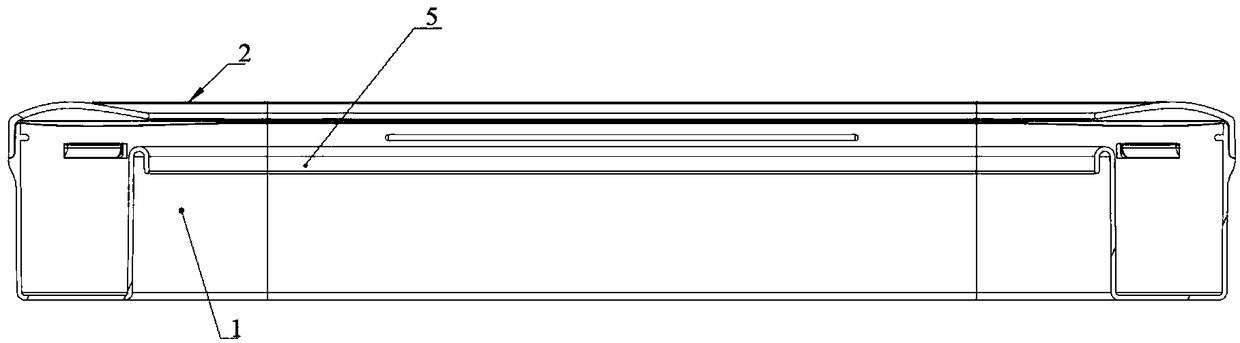

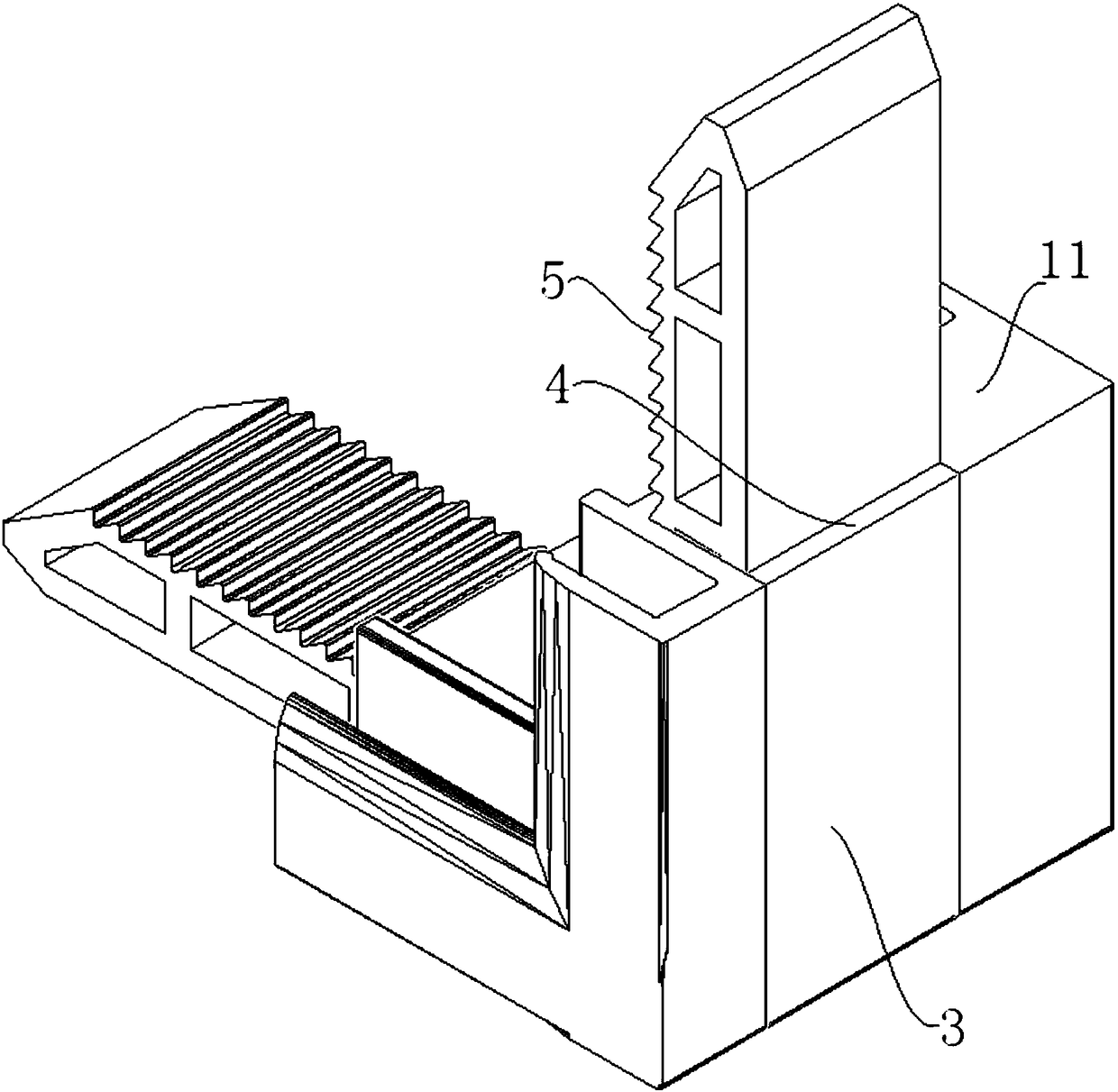

Trash bag component and intelligent trash bin

PendingCN108974704AImprove automationImprove the level of intelligenceRefuse receptaclesEngineeringAutomation

The application relates to the technical field of intelligent trash bins, in particular to a trash bag component and an intelligent trash bin. The trash bag component includes a storage body and a cover; the storage body is provided with a first through hole and a circular channel arranged around the first through hole and used for storing a trash bag; the cover is provided with a second through hole corresponding to the first through hole; an opening of the circular channel is covered; a gap is provided between the cover and one sidewall of the circular channel so as to form a trash bag outlet. The trash bag component with these settings has the advantages that the trash bag component can be applied to intelligent trash bins so as to conveniently implement the function of full-automatic laying and packing of trash bags, thereby further increasing trash bin automation level and intelligence level; damage to trash bags during production, storage and transport of the trash bags is effectively avoided; trash bag changing is simple so that efficiency can be improved; the trash bag component is of integrate structure, is convenient to assemble and helps reduce production and mounting costs.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

Acrylic acid emulsion with nuclear shell structure and high thixotropy and preparation method and application of acrylic acid emulsion

The invention relates to an acrylic acid emulsion with a nuclear shell structure and high thixotropy and a preparation method and application of the acrylic acid emulsion. The preparation method comprises the following steps that firstly, a nuclear layer part is prepared through emulsion polymerization, an adopted monomer does not contain carboxyl monomers and contains a small number of crosslinking monomers; and secondly, a shell layer is prepared through emulsion polymerization, a mixture of the monomers in the second step and an initiator is dropwise added into a reaction mixing system of the first step, the monomers in the second step comprise monomers with carboxyl and crosslinking monomers, after a reaction is completed, the temperature is decreased to the specific temperature, a certain amount of amine is added to adjust PH of the emulsion, and thus the acrylic acid emulsion with the nuclear shell structure and the high thixotropy can be obtained. The acrylic acid emulsion prepared through the preparation method can be used in silver powder baking varnish coating, using of a silver powder directional agent and a thickener can be reduced when a coating formula is designed, gloss and resistance of a paint film are improved, the coating cost is lowered, and the applicability and construction tolerance of the coating formula are improved.

Owner:CHANGZHOU HUAKE POLYMERS

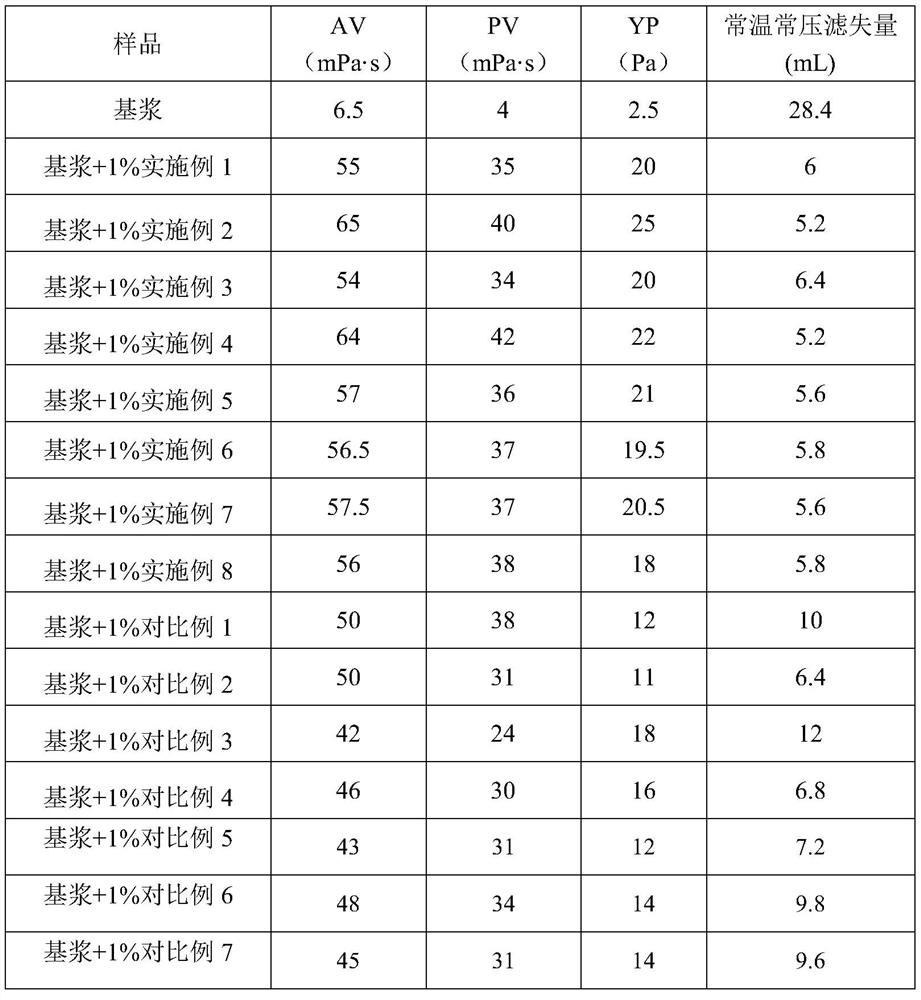

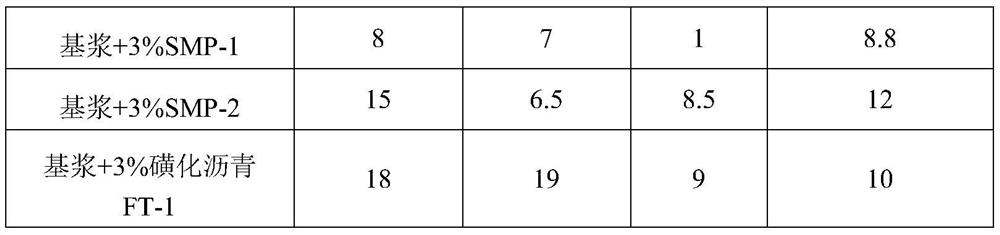

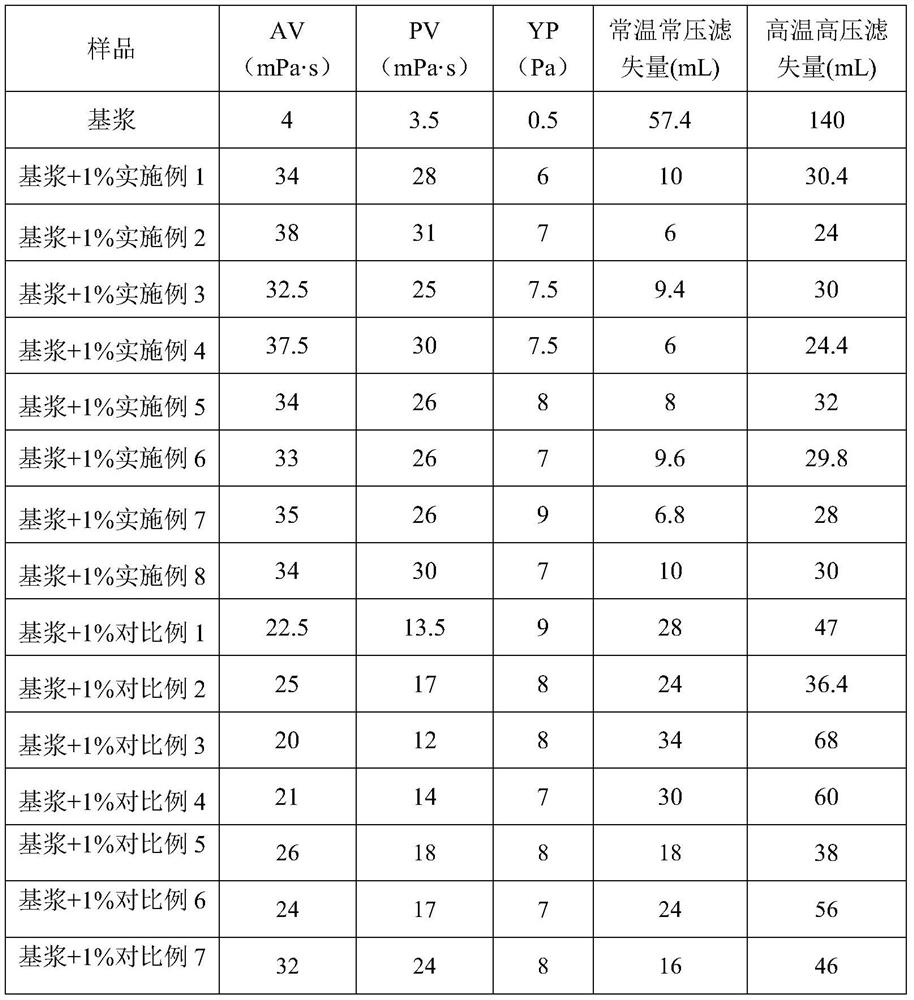

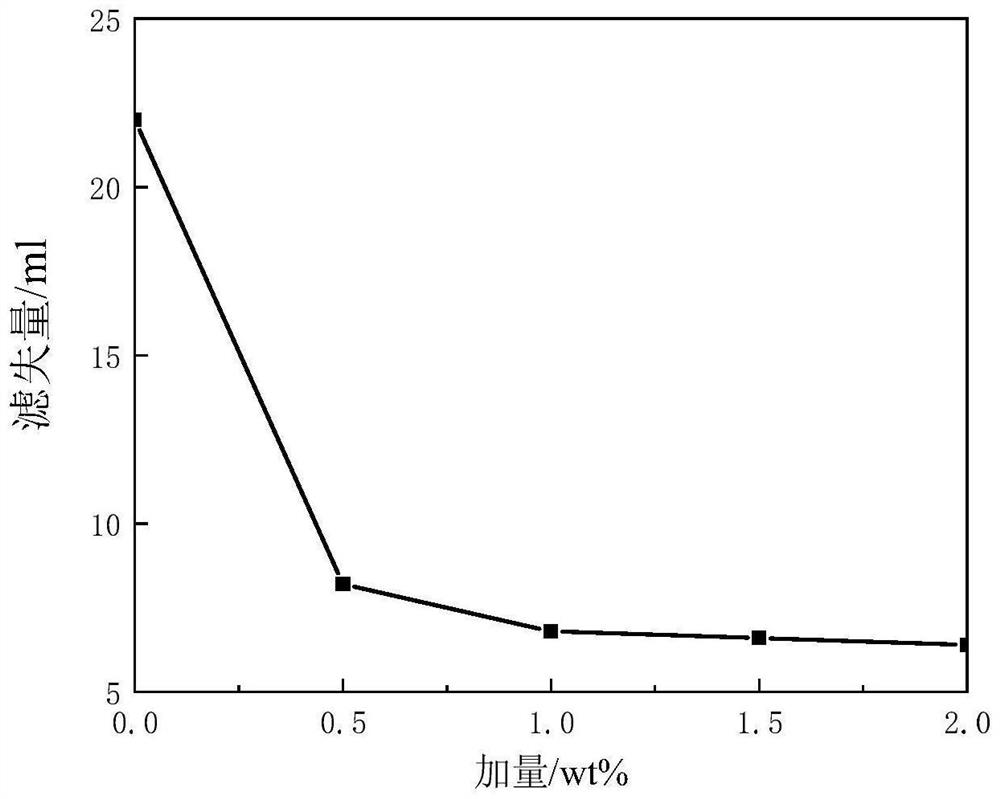

Preparation method of environment-friendly ultrahigh-temperature-resistant filtrate reducer for water-based drilling fluid

ActiveCN111875758AImprove temperature resistanceImprove hydrolysis resistanceDrilling compositionPhysical chemistryCross linker

The invention provides a preparation method of an environment-friendly ultrahigh-temperature-resistant filtrate reducer for a water-based drilling fluid, which comprises the following steps: reactingnano hectorite with a silane coupling agent to obtain a nano cross-linking agent; and in the presence of a nano cross-linking agent and an initiator, carrying out polymerization reaction on an amide monomer, a high-temperature-resistant monomer, a cationic monomer and a polyene monomer by using an inverse emulsion polymerization method to obtain the environment-friendly ultrahigh-temperature-resistant filtrate reducer. The filtrate reducer prepared by the preparation method disclosed by the invention can resist high temperature and has an excellent filtrate reduction effect and good environmental protection performance. The filtrate reducer disclosed by the invention is not only suitable for deep and ultra-deep oil and gas drilling, but also suitable for drilling of geothermal wells and environment-sensitive areas.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

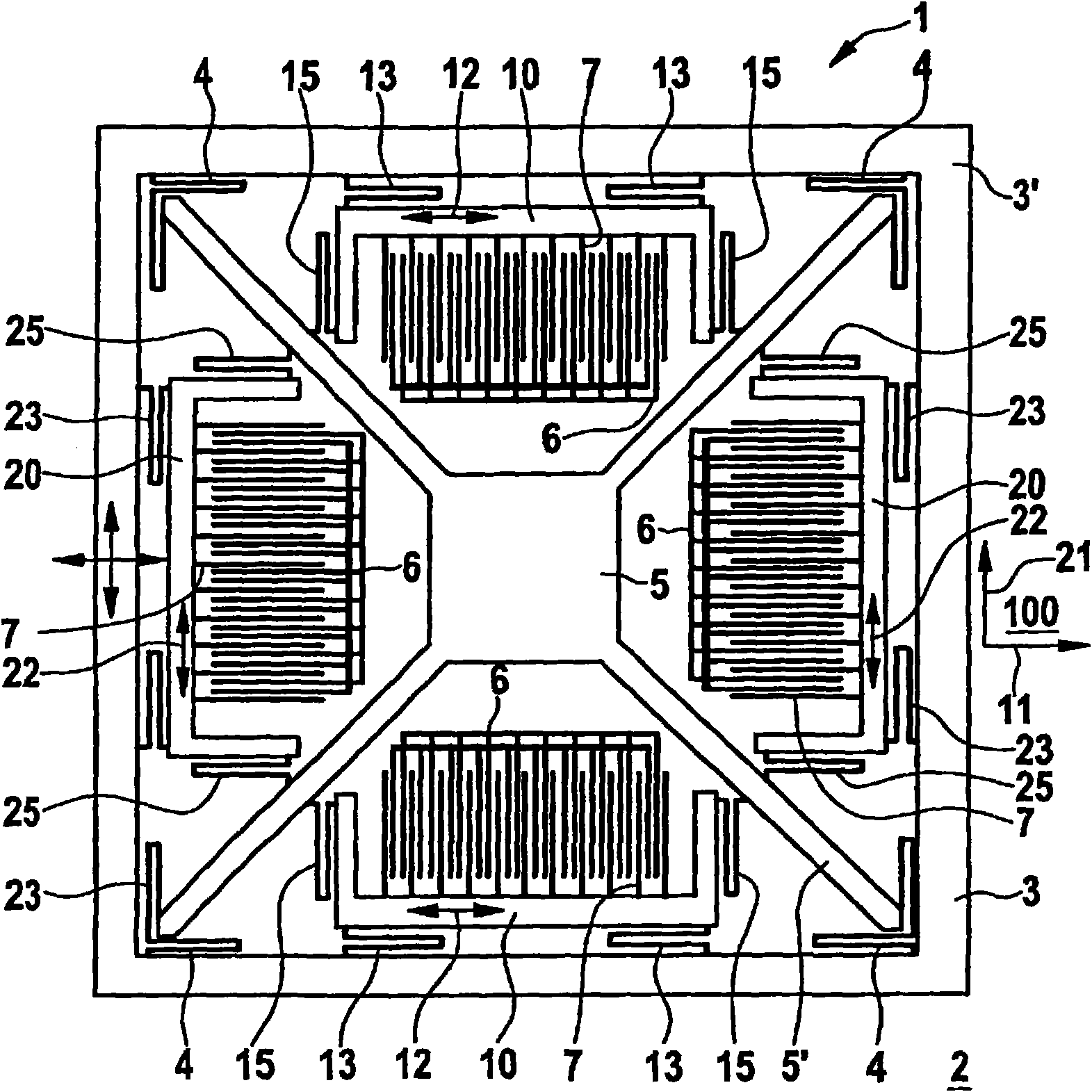

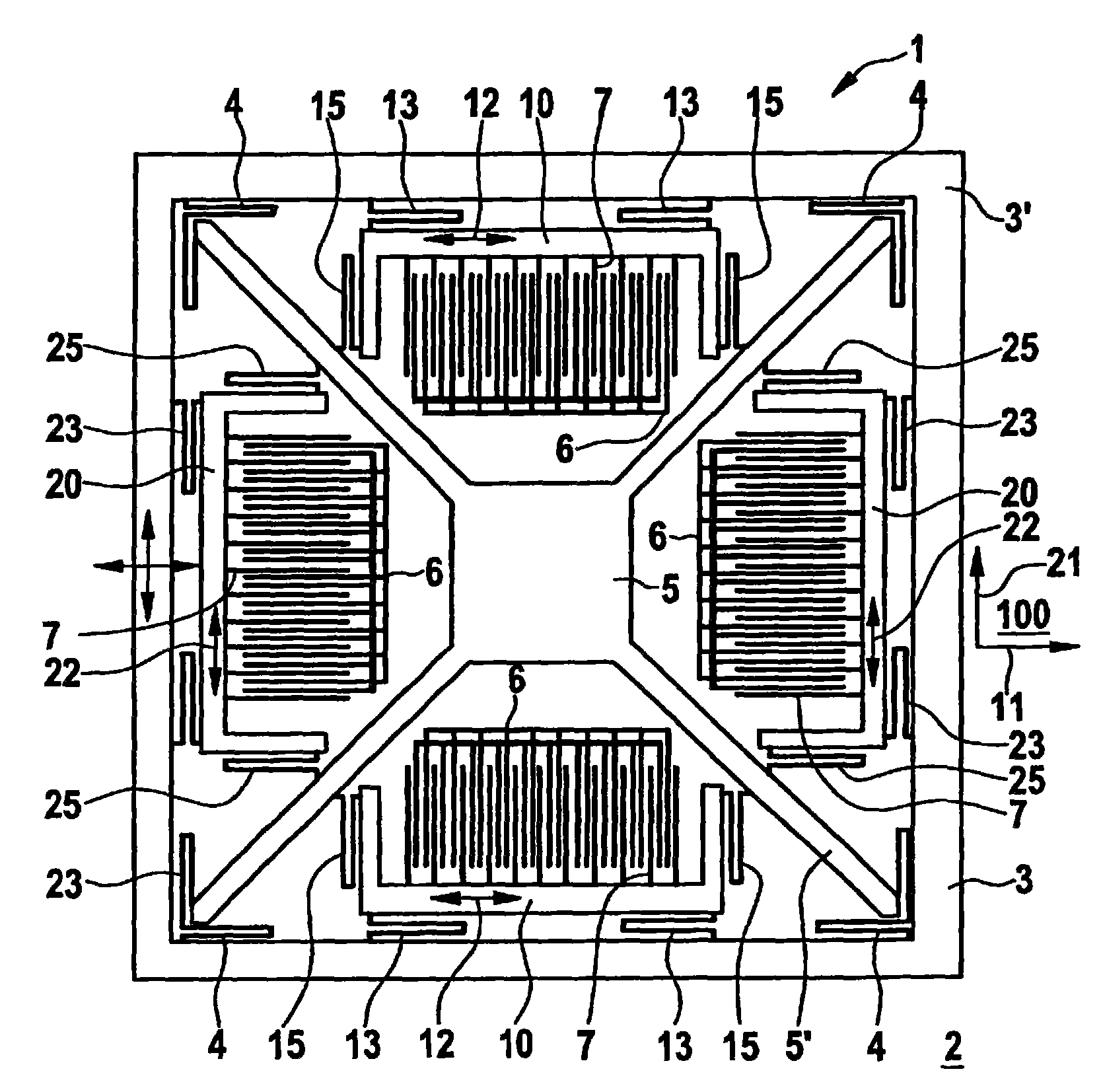

Sensor device

ActiveCN101799480ASave spaceAchieve couplingAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsClassical mechanicsAcceleration Unit

The invention provides a sensor device, in particular to an acceleration sensor device; the sensor device is provided with a base having a main extending plane and an oscillator mass capable of movably hanging in relative to the base, wherein the sensor device comprises a first detecting element used for detecting the first movement of the oscillator mass along with the first direction parallel to the main extending plane, and the sensor device comprises a second detecting element used for detecting the second movement of the oscillator mass along the second direction parallel to the main extending plane and vertical to the first direction, wherein both the first detecting element and the second detecting element are respectively capable of being fixed on the oscillator mass movably in relative to the oscillator mass.

Owner:ROBERT BOSCH GMBH

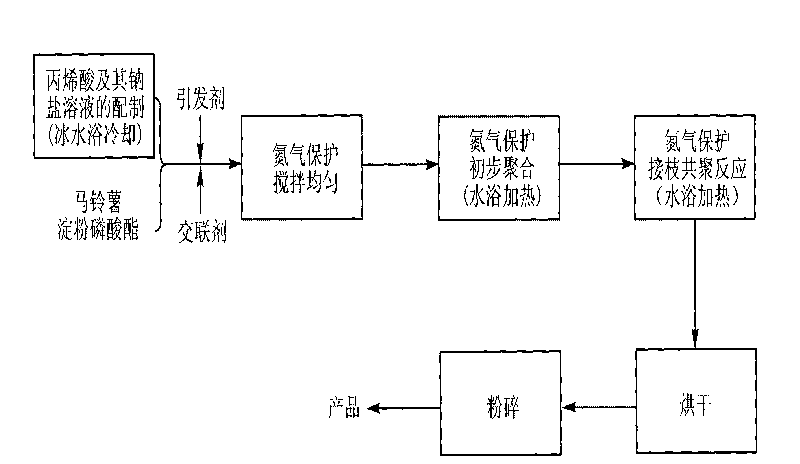

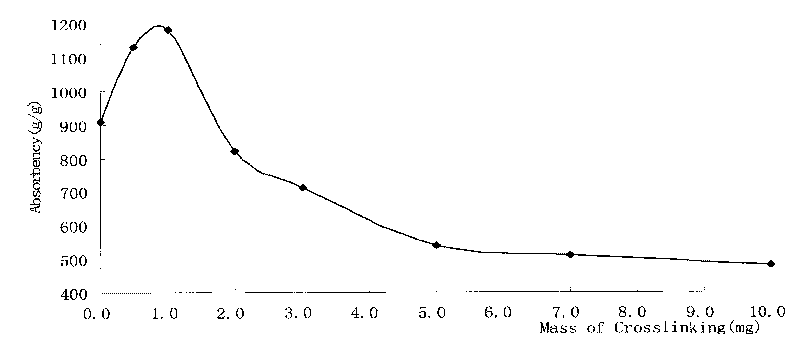

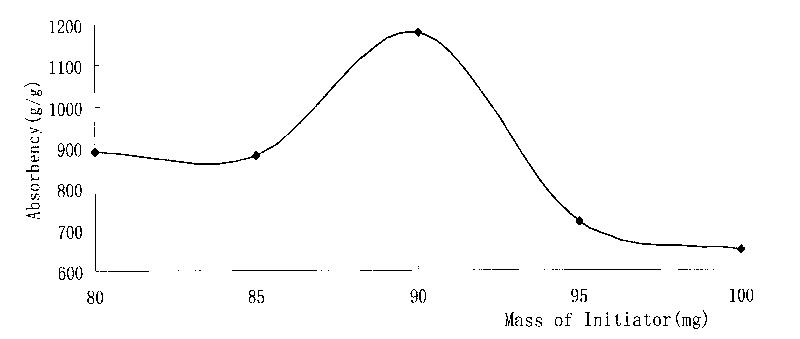

Method for preparing super absorbent resin with cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and sodium salt thereof

The invention discloses a method for preparing super absorbent resin with a cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and a sodium salt thereof. The method comprises the following main technological processes of: under ice water bath cooling, performing neutralization reaction between a sodium hydroxide solution and acrylic acid used for removing a polymerization inhibitor so as to prepare the acrylic acid and a sodium salt solution of the acrylic acid; mixing the prepared acrylic acid and the sodium salt solution of the acrylic acid with potato starch phosphate; adding an initiator of persulfate, a crosslinking agent of N,N'-methylene bi-acrylamide so that the mixture is mixed evenly under stirring; then under the protection of nitrogen gas, heating the mixture in a water bath and stirring the mixture so that the potato starch phosphate performs graft copolymerization with the acrylic acid and the sodium salt solution of the acrylic acid; stopping stirring after reaching a certain temperature, performing heat preservation reactions, and then stopping introducing the nitrogen gas; and taking out a product, cutting the product into small pieces, drying the small pieces in a drying oven to have constant weights, and crushing the small pieces to obtain the super absorbent resin.

Owner:INNER MONGOLIA UNIVERSITY

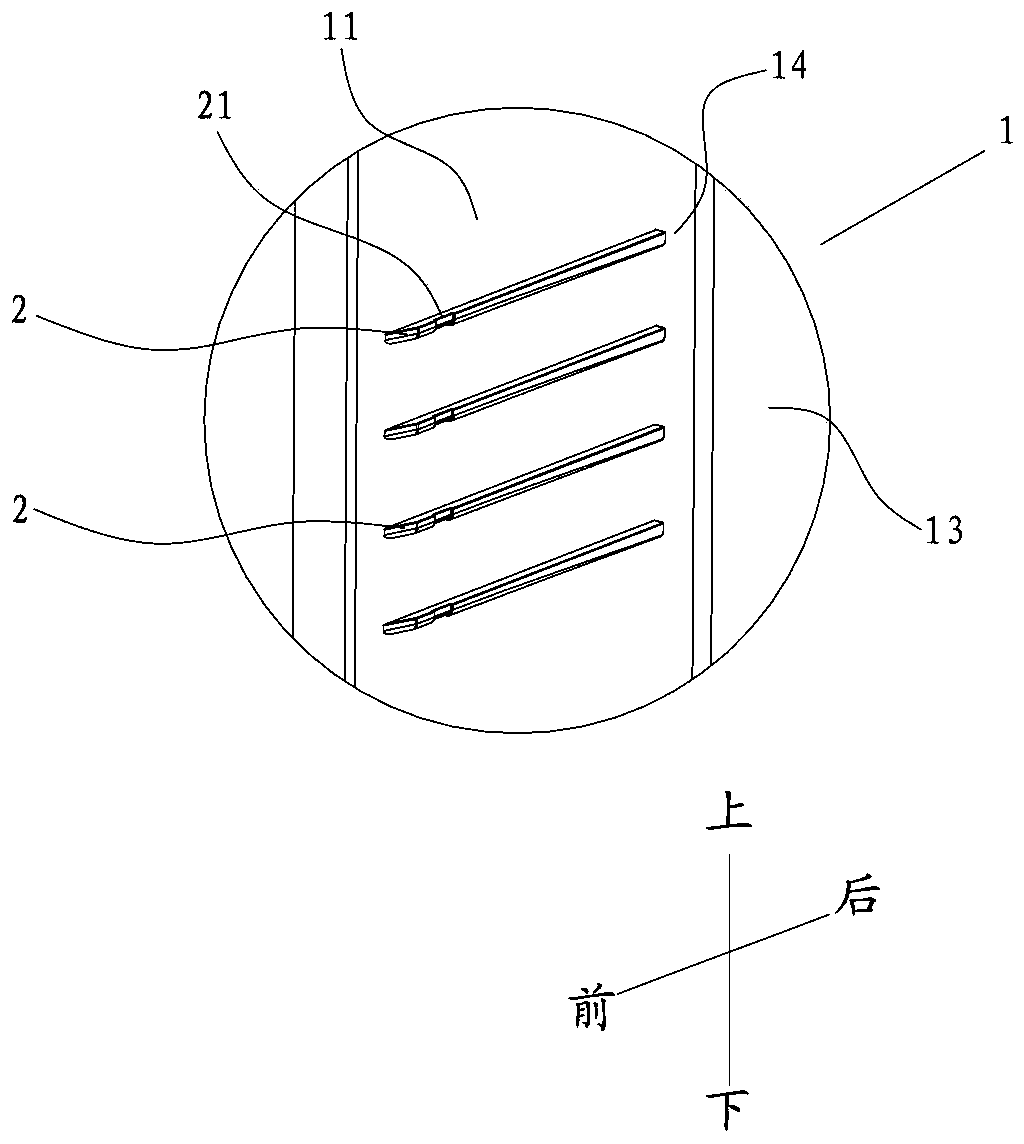

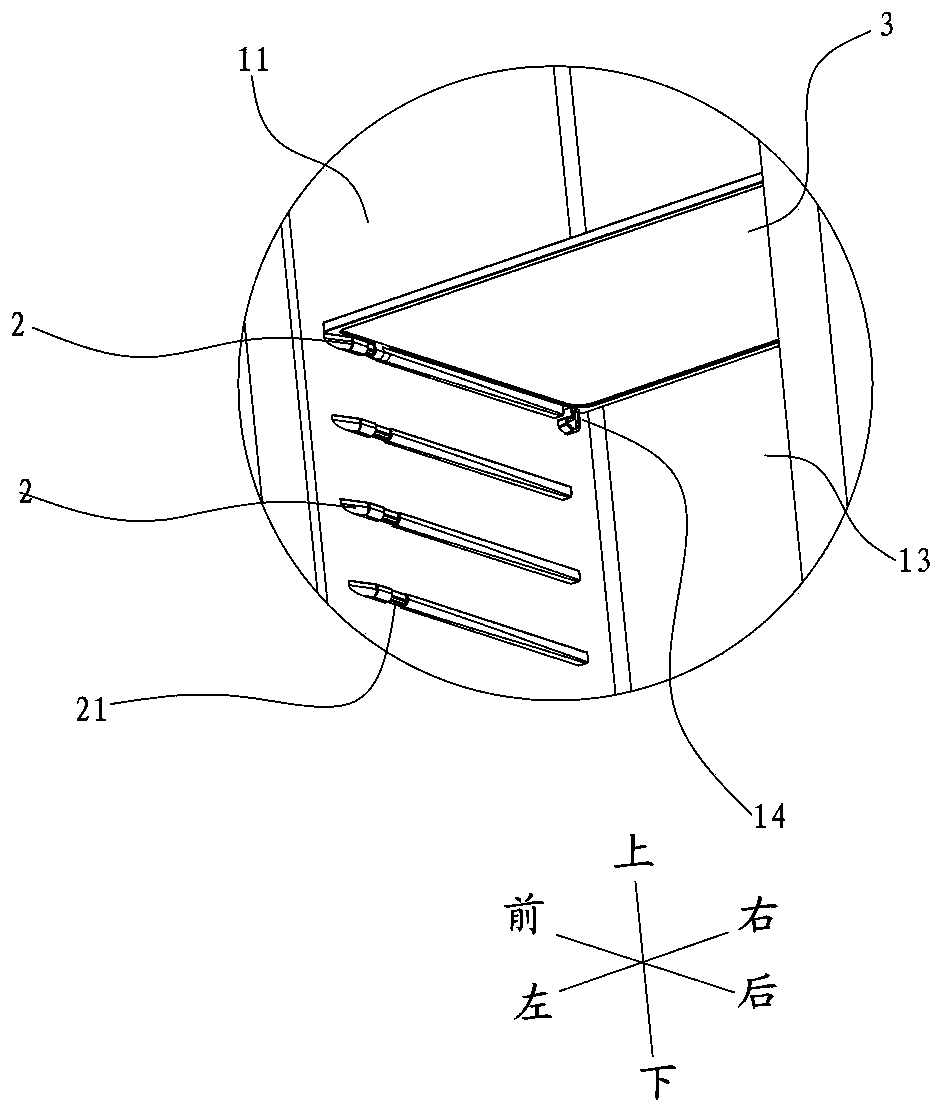

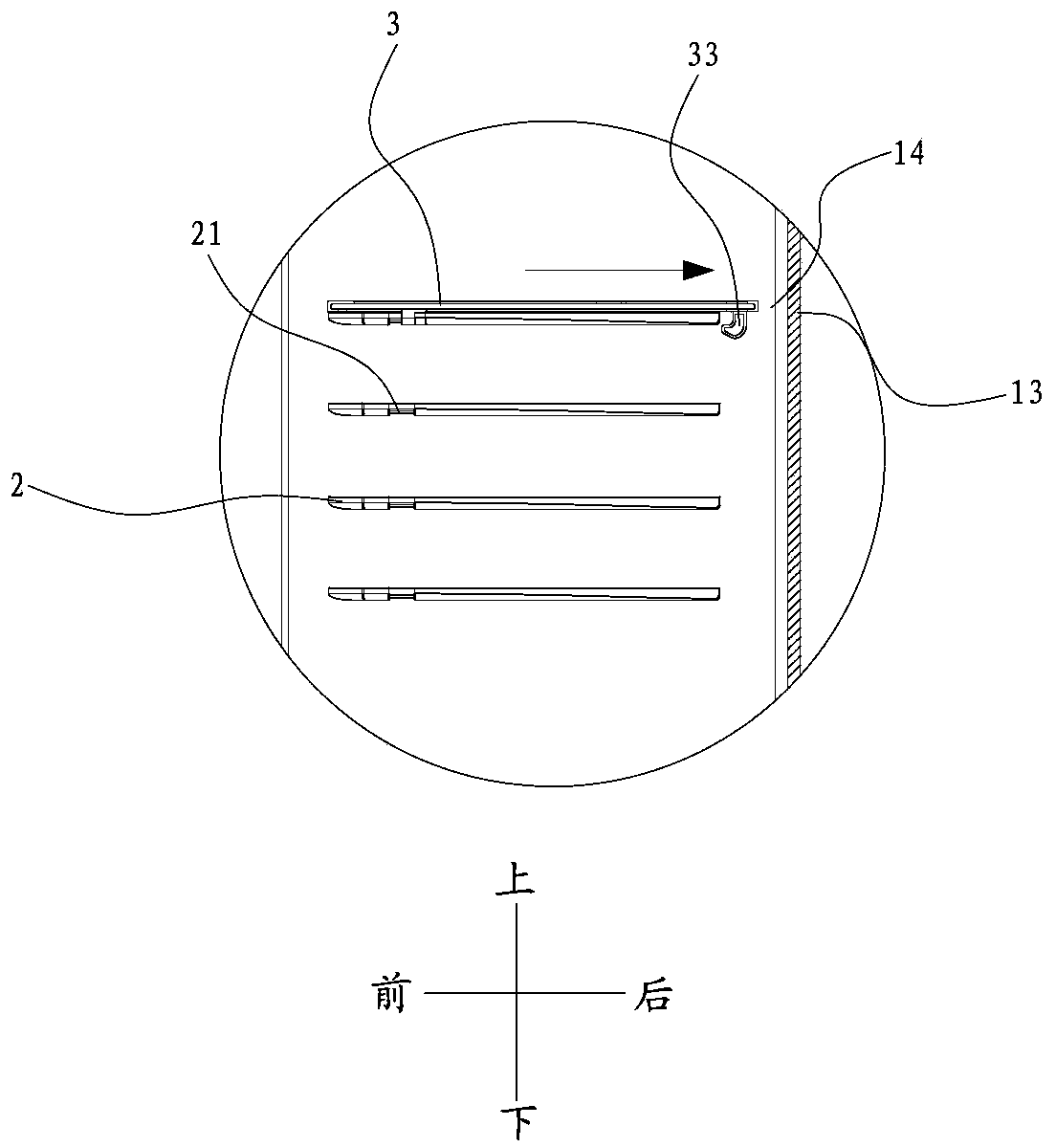

Refrigerator

ActiveCN103363754APrevent up and down movementGood practicalityLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention discloses a refrigerator, which comprises a box, rib bars and a glass shelf assembly, wherein a compartment is arranged in the box; the rib bars are respectively arranged on the left side wall and the right side wall of the compartment and extend along the forward and backward direction; the rear ends of the rib bars are separated from the rear side wall of the compartment; a first positioning structure is arranged on each rib bar; the glass shelf assembly is horizontally supported on the rib bars; a second positioning structure and a third structure are arranged on the glass shelf assembly; the second positioning structure is matched with the rear ends of the rib bars for blocking so as to limit the forward and upward movement of the glass shelf assembly relative to the rib bars; and the third positioning structure is matched with the first positioning structure so as to limit the forward and backward movement of the glass shelf assembly relative to the rib bars. According to the refrigerator, the freedom of motion of the glass shelf assembly can be well limited, the glass shelf assembly can be prevented from moving upwards and downwards as well as leftwards and rightwards, and the practicability is good.

Owner:HEFEI HUALING CO LTD

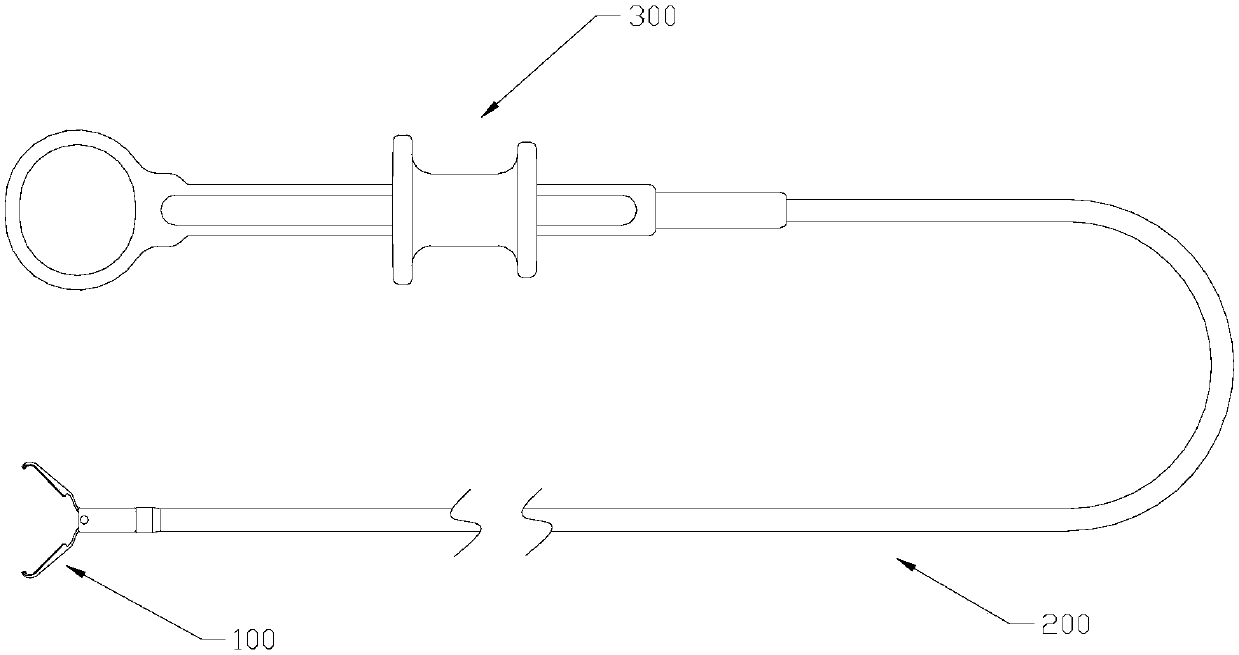

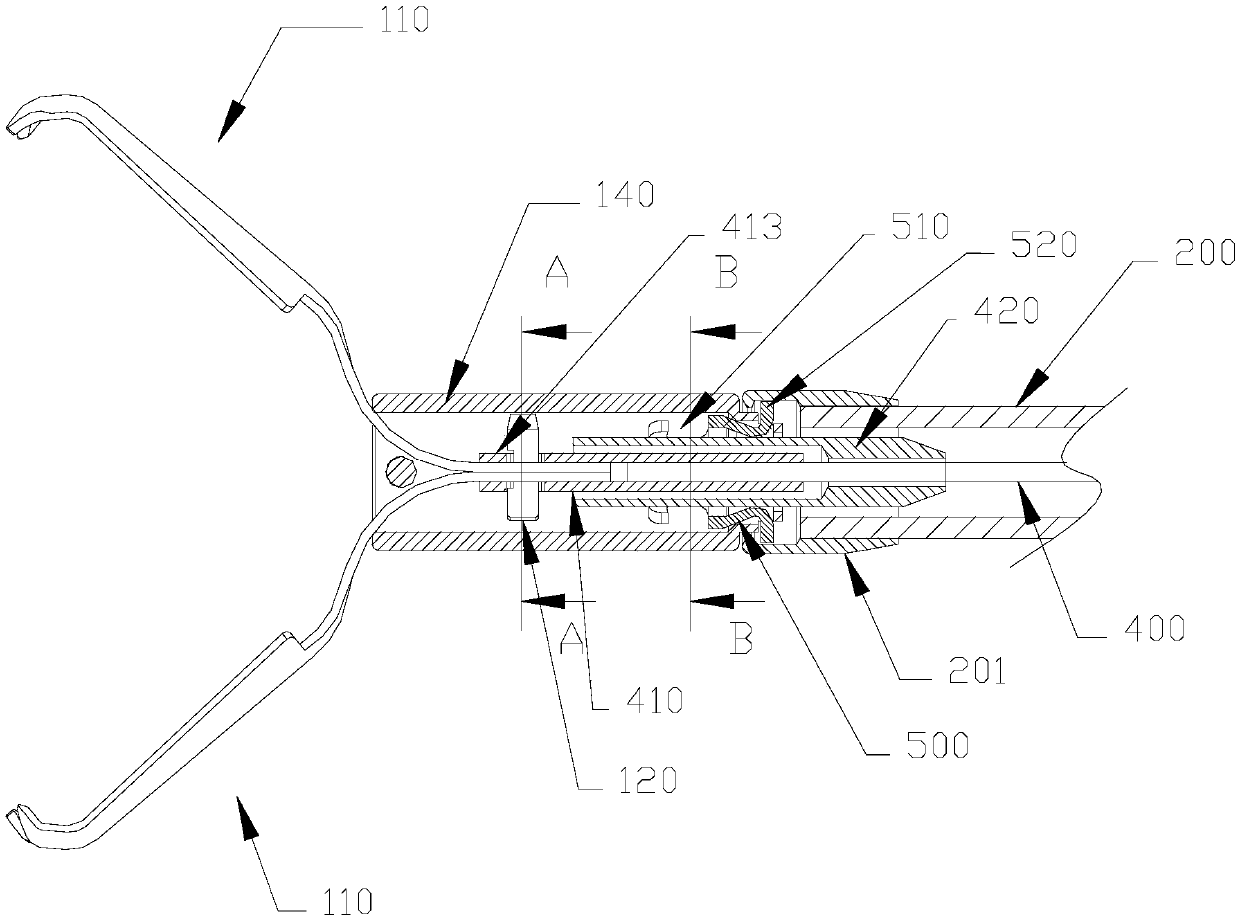

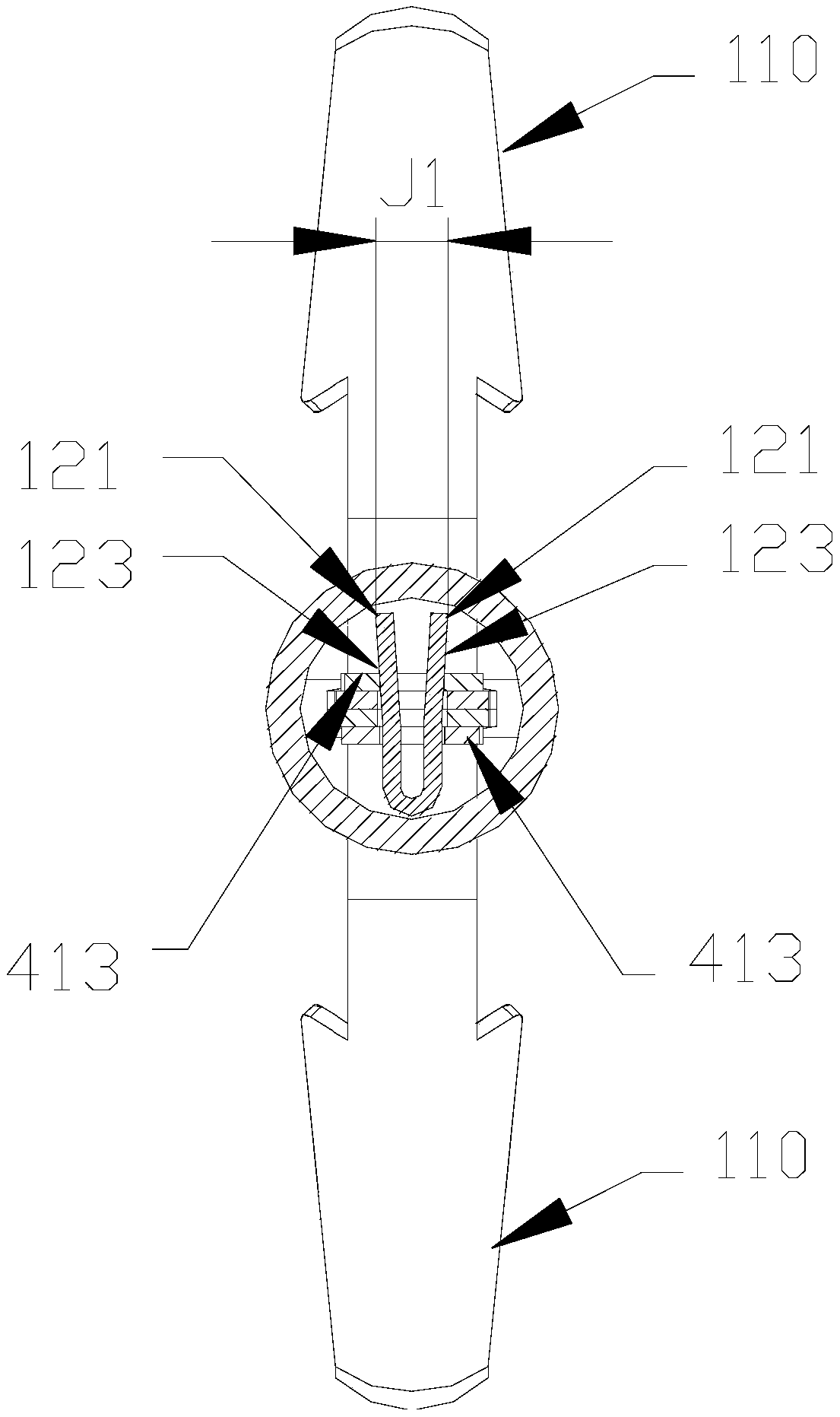

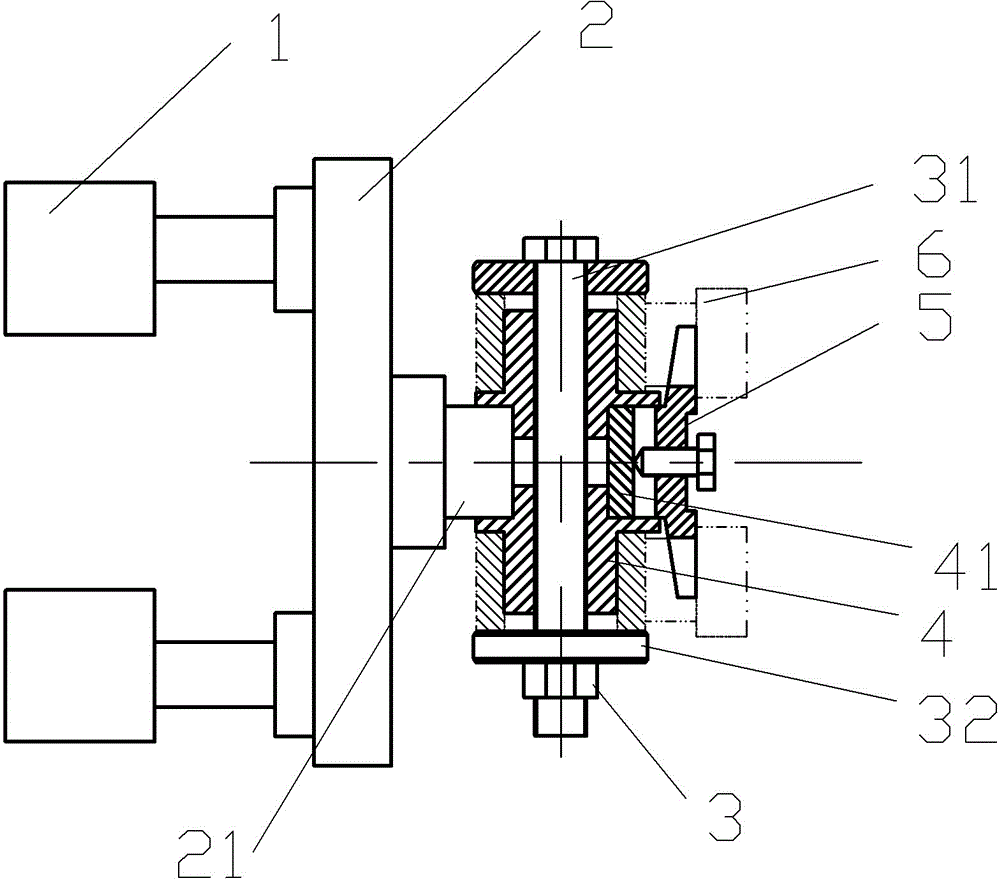

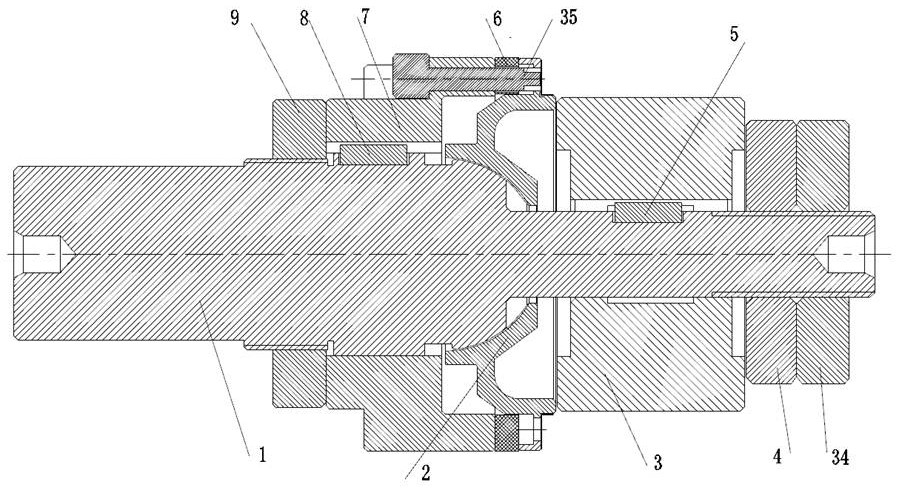

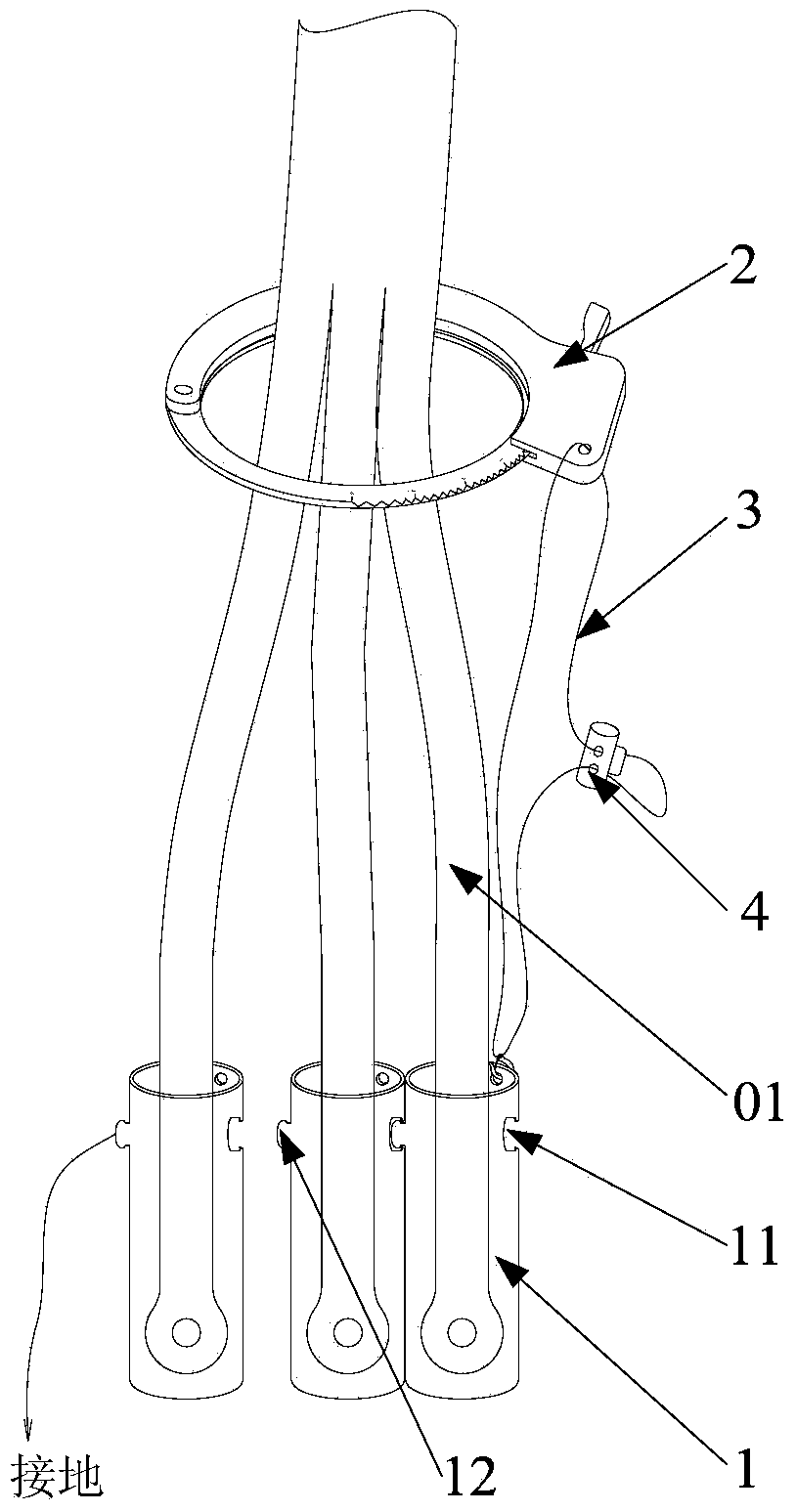

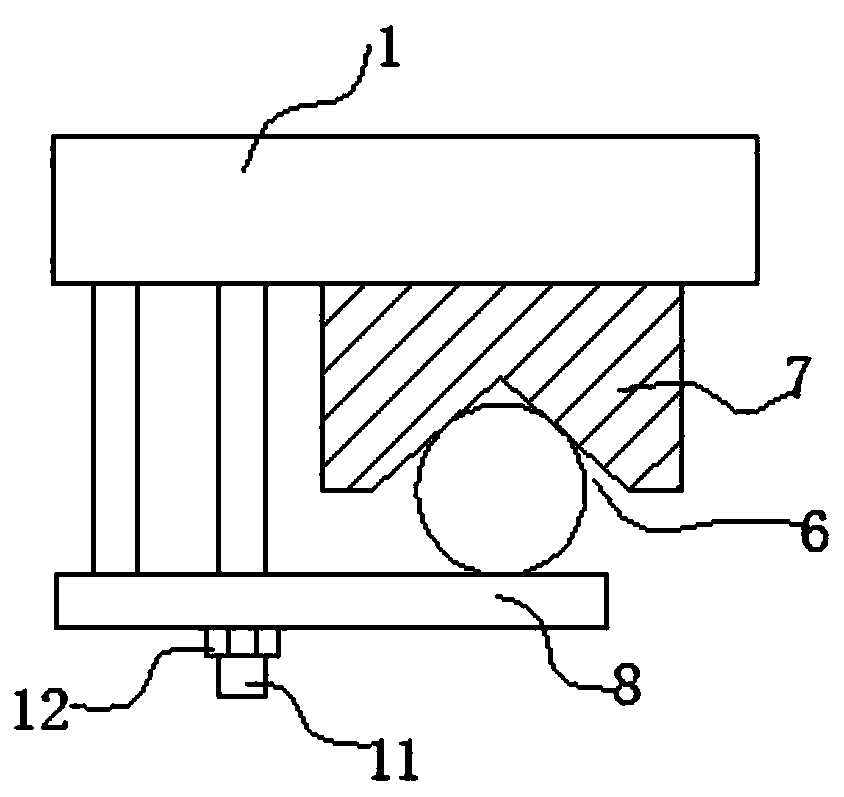

Clamping device

The invention relates to a clamping device. The clamping device comprises clamps, a locking pin, a tightening pipe and a core shaft, wherein a connecting hole is formed in the clamps; the locking pinpenetrates through the connecting hole, and comprises an elastic part and a locking part connected with the elastic part; the core shaft penetrates through the tightening pipe to be connected with theclamps; a releasing part is arranged at the far end of the core shaft, and is connected with the locking pin; the tightening pipe is provided with a locking position; when the clamps are located at the first position, the releasing part is used for restricting the locking pin and compressing the elastic part to enable the locking part to be separated from the locking position; and when the clampsare located at the second position, the releasing part releases restriction to the locking pin, the elastic part is sprung back, and the locking part extends into the locking position for locking. After being closed, the clamps are locked, firm locking is realized, and the situation that the clamps are opened once again can be avoided.

Owner:HANGZHOU AGS MEDTECH CO LTD

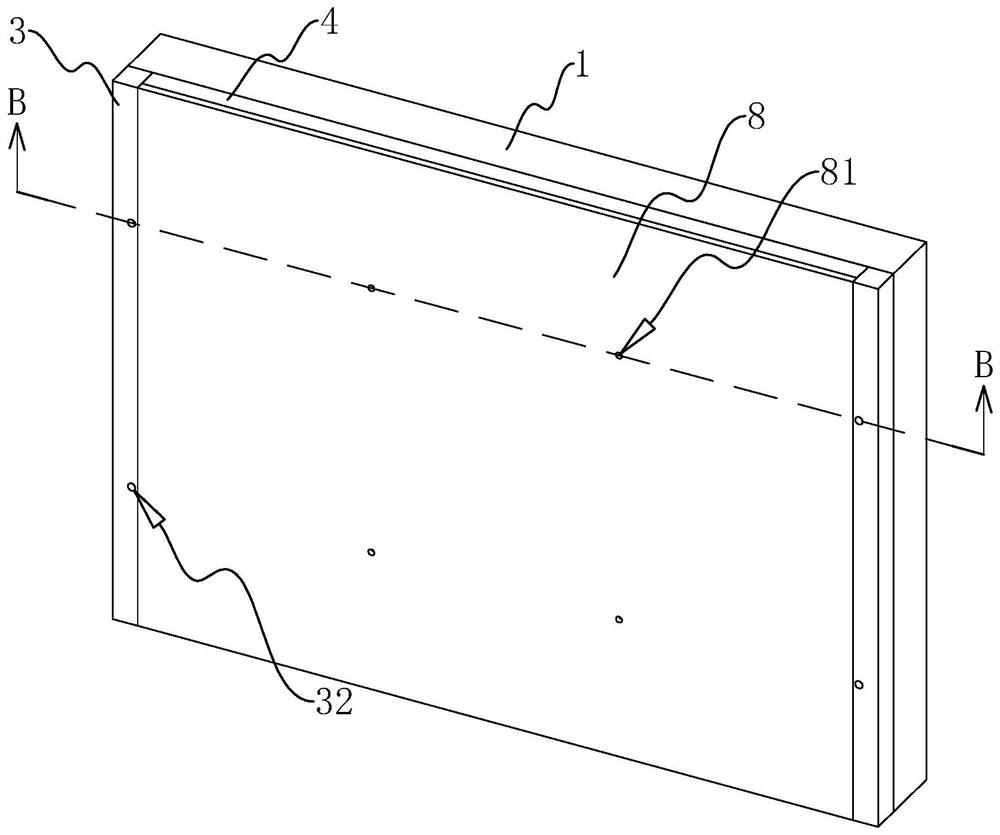

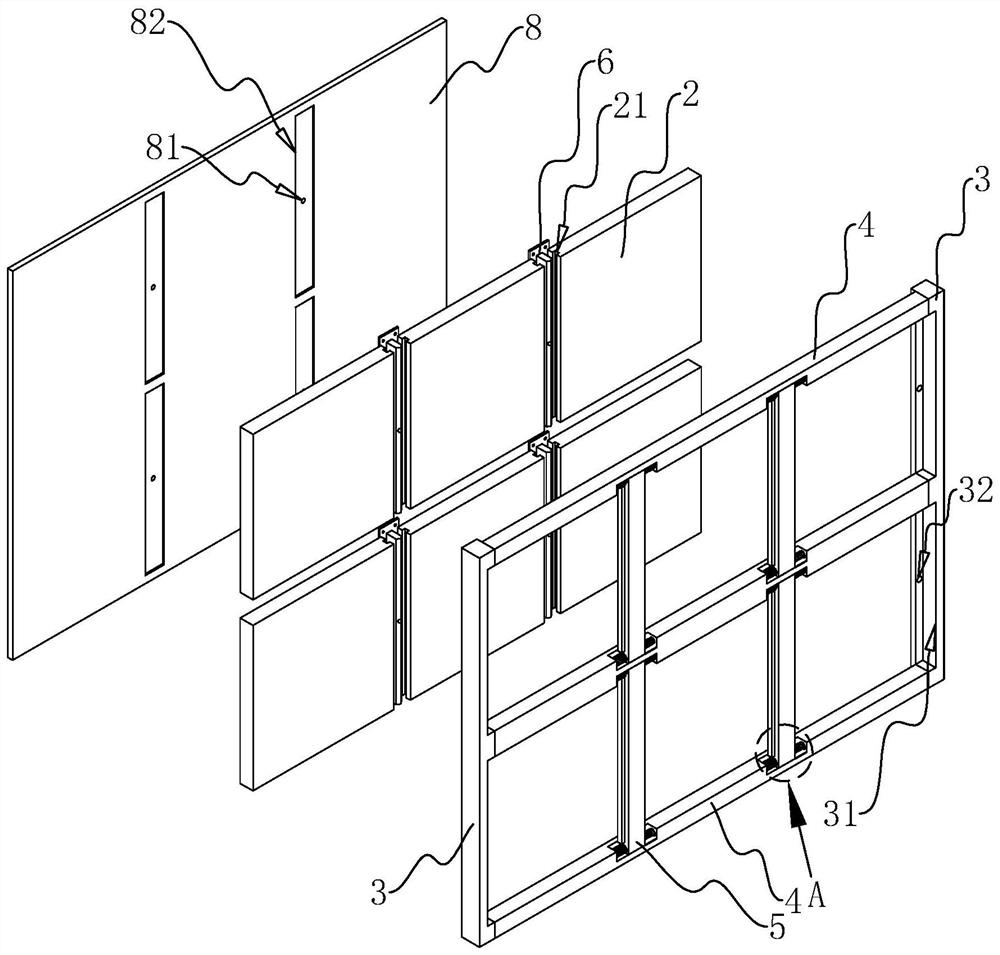

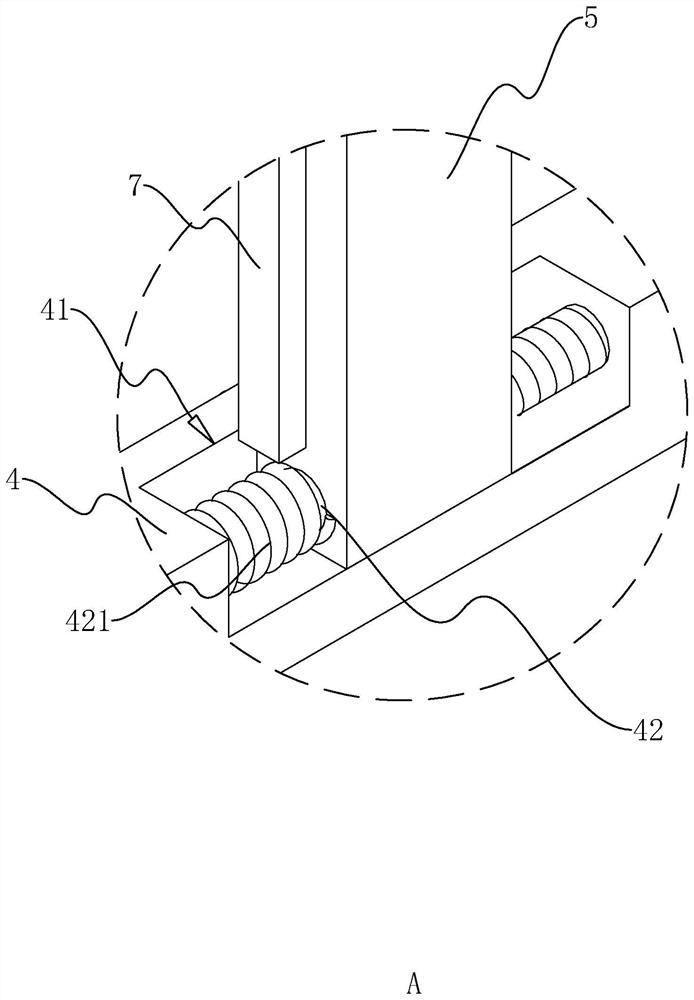

Energy-saving and environment-friendly thermal insulation wall and construction method thereof

ActiveCN113684945ANot prone to offset effectsEnsure connection stabilityCovering/liningsWallsInsulation layerThermal insulation

The invention discloses an energy-saving and environment-friendly thermal insulation wall and a construction method thereof. The energy-saving and environment-friendly thermal insulation wall comprises a wall body and a plurality of prefabricated insulation boards, two vertical main keels are symmetrically arranged on the wall body, mounting grooves are formed in the opposite side walls of the two vertical main keels, a plurality of horizontal keels are arranged between the two vertical main keels, and a plurality of vertical auxiliary keels are movably arranged between every two adjacent horizontal keels; the two ends, in the vertical direction, of each prefabricated insulation board are matched with the every two adjacent horizontal keels in an abutting mode correspondingly, and the ends, in the horizontal direction, of the prefabricated insulation boards are matched with the vertical auxiliary keels in an abutting mode or are matched with the mounting grooves in an inserted mode; and a plurality of buckle plates corresponding to the vertical auxiliary keels in a one-to-one mode are fixed between the two horizontal keels, and the buckle plates are matched with the prefabricated insulation boards on the two sides in an abutting mode. The energy-saving and environment-friendly thermal insulation wall has the effect that the splicing position between the every two adjacent prefabricated insulation boards is not prone to deviation, the connection stability of the splicing position between the every two adjacent prefabricated insulation boards can be kept, and the risk of cracking of an insulation layer can be reduced.

Owner:湖北金漳水利水电工程有限公司

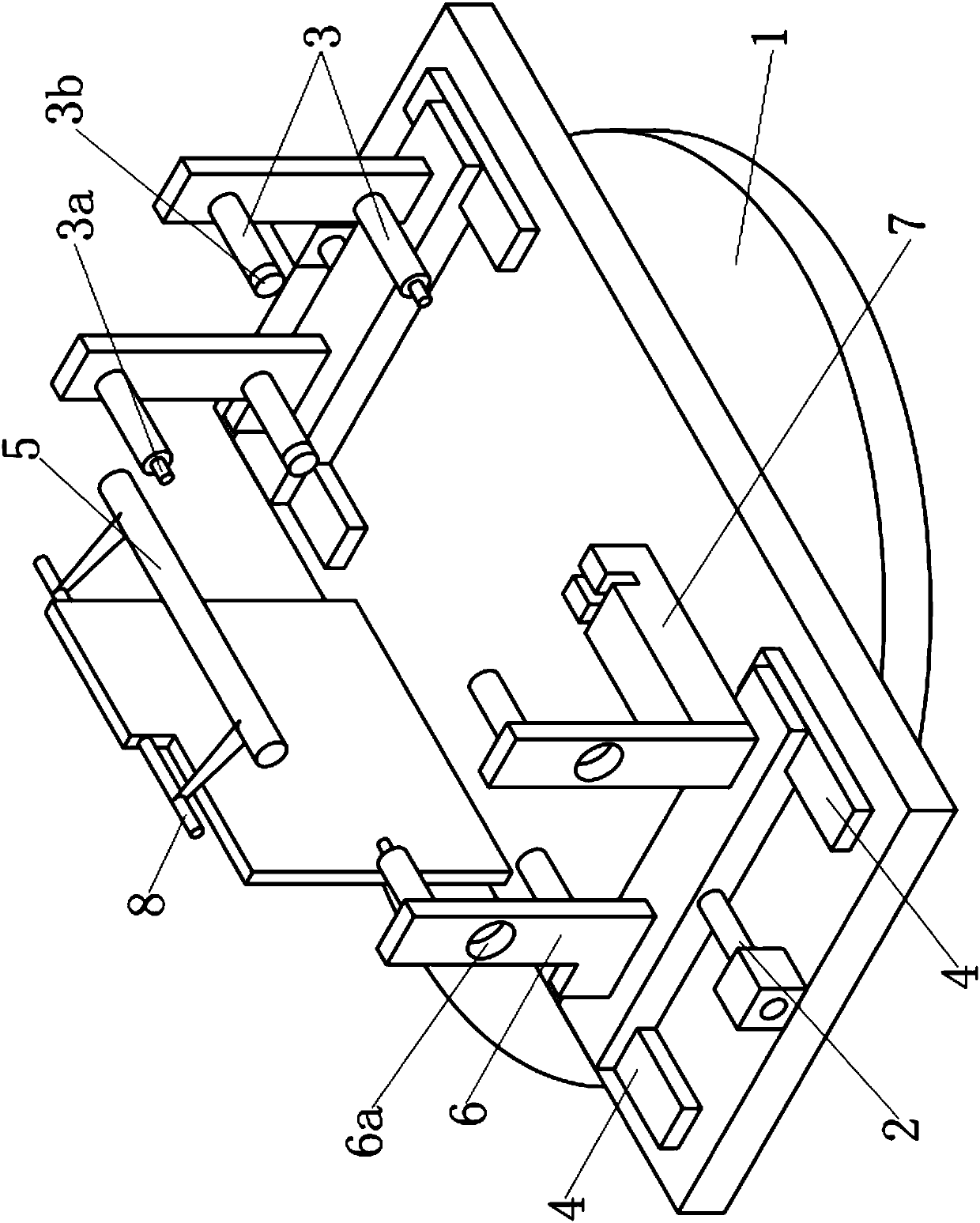

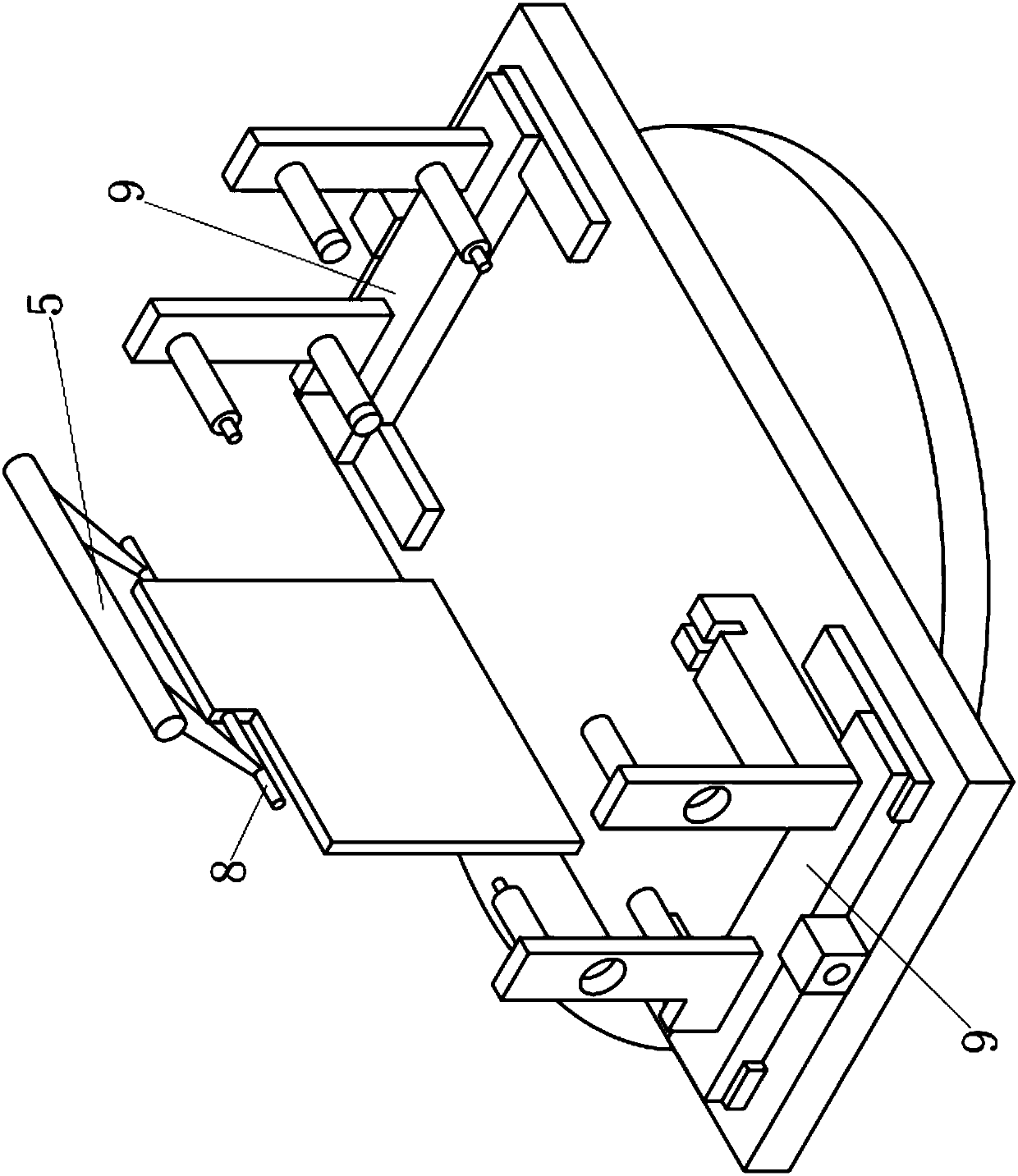

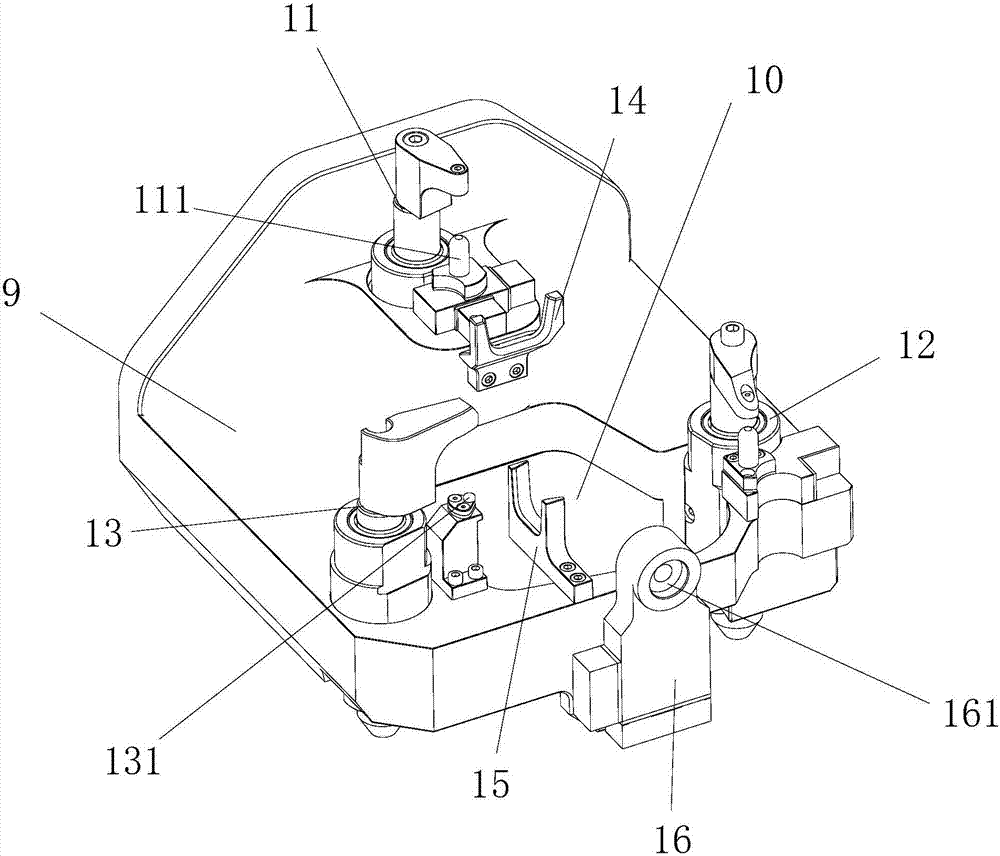

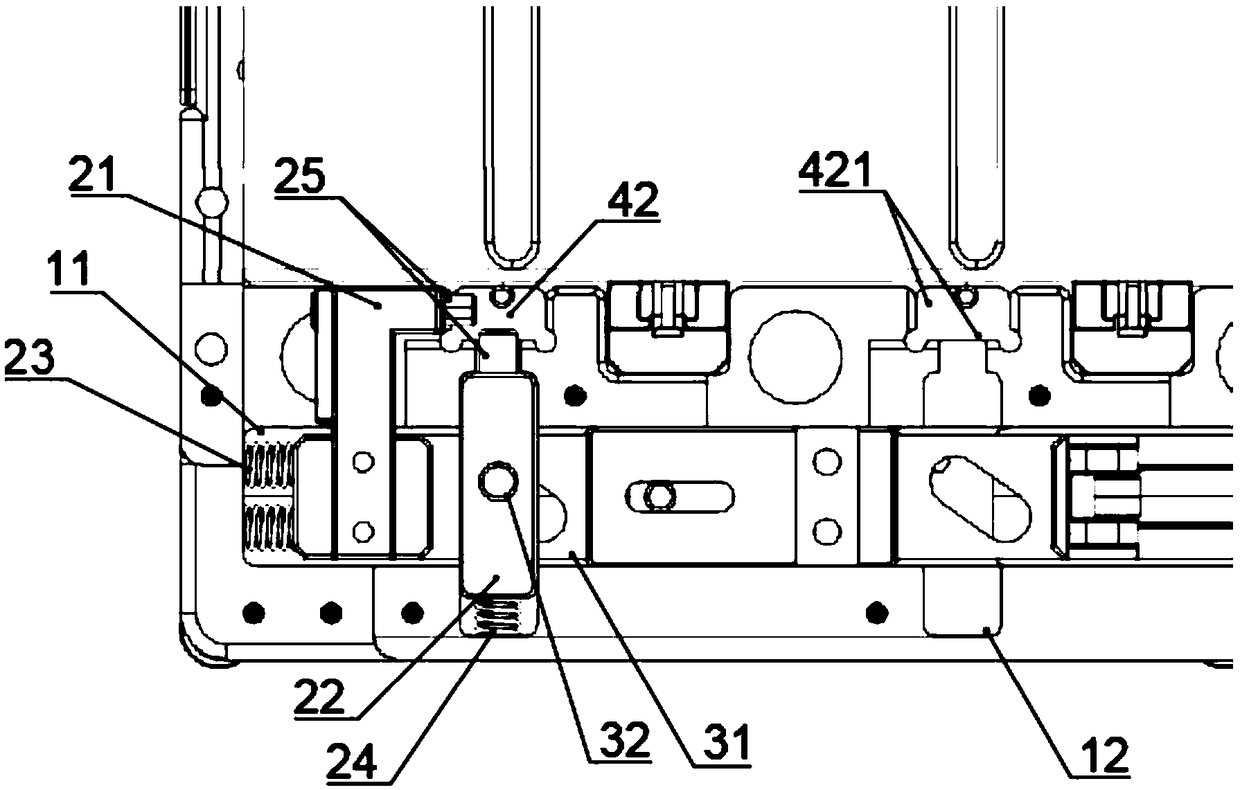

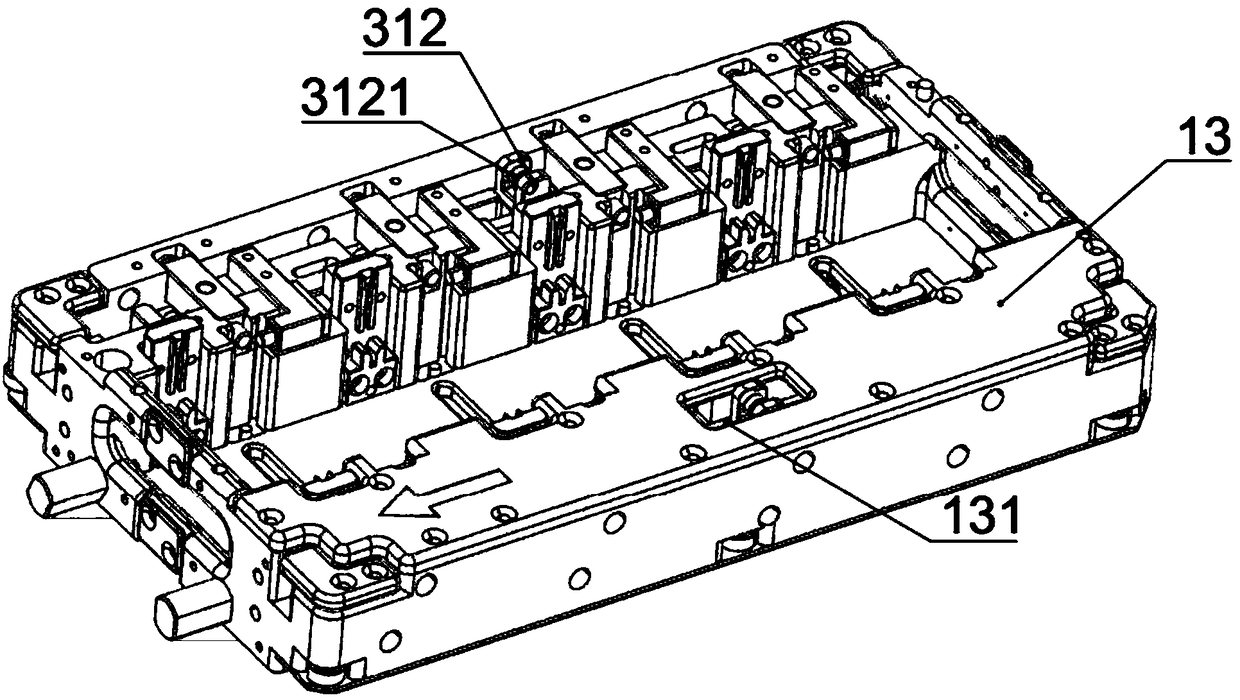

Complex frame positioning assembling jig

PendingCN107695924AEasy to locate and disassembleConvenient screw fixingWork holdersMagnetEngineering

The invention discloses a complex frame positioning assembling jig. The complex frame positioning assembling jig comprises positioning columns, sliding rails, a movable rod and a rotary plate, whereinthe multiple positioning columns are horizontally arranged; the positioning columns opposite approach to limit and fix a complex frame in the axial direction of the positioning columns; the sliding rails drive the positioning columns to oppositely approach or move away; the movable rod presses downwards to limit the complex frame from top to bottom; and the rotary plate is arranged at the bottomend of a complex frame positioning assembling jig body, so that the complex frame positioning assembling jig has the rotation degree of freedom in the horizontal plane; the bottoms of the positioningcolumns are fixed to a plurality of vertical stand columns; the stand columns on the same side are fixed to stand column bases arranged horizontally; the stand column bases are matched with the sliding rails; the sliding rails are matched with a bottom plate and the rotary plate from top to bottom; toggle clamps are connected between the stand column bases and the bottom plate; and magnets are arranged at the heads of the positioning columns. Through the complex frame positioning assembling jig, the complex frame of a printing machine is accurately butt-jointed and limited, convenience is provided for staff to achieve the screw fastening effect on the complex frame, and meanwhile, the fastening process efficiency is improved.

Owner:YIHE PRECISION IND SUZHOU

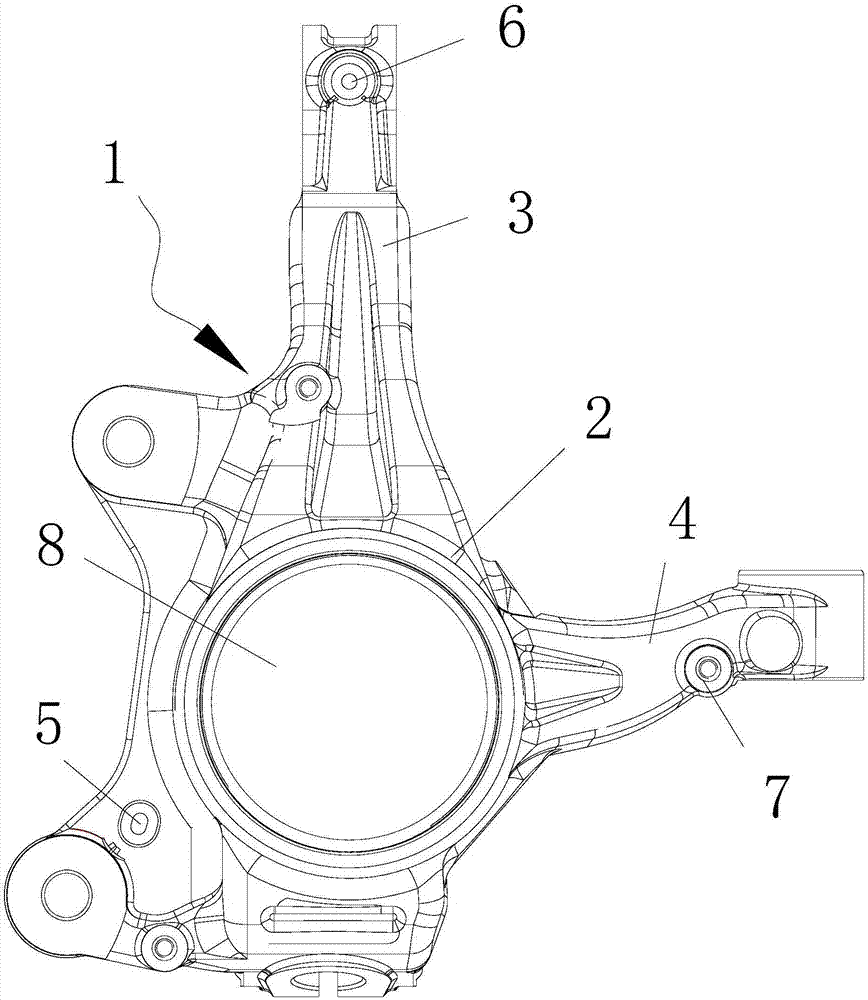

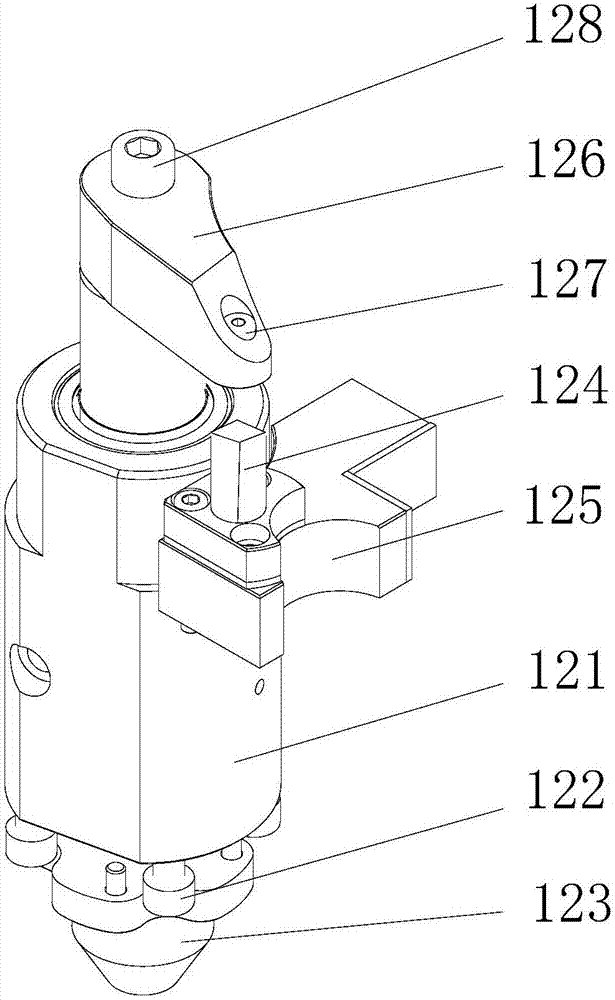

Automobile steering knuckle as well as steering knuckle positioning and fastening device

ActiveCN107235076AFirm positioning and clampingLimited rotational freedomSteering linkagesPositioning apparatusMarine engineering

The invention provides an automobile steering knuckle as well as a steering knuckle positioning and fastening device. The automobile steering knuckle comprises a steering knuckle body in which a steering shaft hole is formed, wherein a first positioning part, a second positioning part and a third positioning part which are arranged in a triangular shape are formed on the steering knuckle body; the first positioning part and the second positioning part are clamping and fixing parts which are formed on the steering knuckle body and can be connected with an external mechanism in a clamping manner; one of the clamping and fixing parts is in a strip shape; and the third positioning part can be abutted and connected with the external mechanism. The invention also provides a steering knuckle positioning and fastening device for positioning and fastening the automobile steering knuckle. According to the automobile steering knuckle disclosed by the invention, complete positioning of the steering knuckle can be achieved by the arrangement of the first positioning part, the second positioning part and the third positioning part to guarantee stable positioning and fastening of the steering knuckle; and besides, the structure of a steering knuckle positioning and fastening fixture can be simplified, so that the problems that the design is difficult and collision accidents are easy to occur caused by complicated structure of the fixture can be solved, and the automobile steering knuckle is good in practicability.

Owner:GREAT WALL MOTOR CO LTD

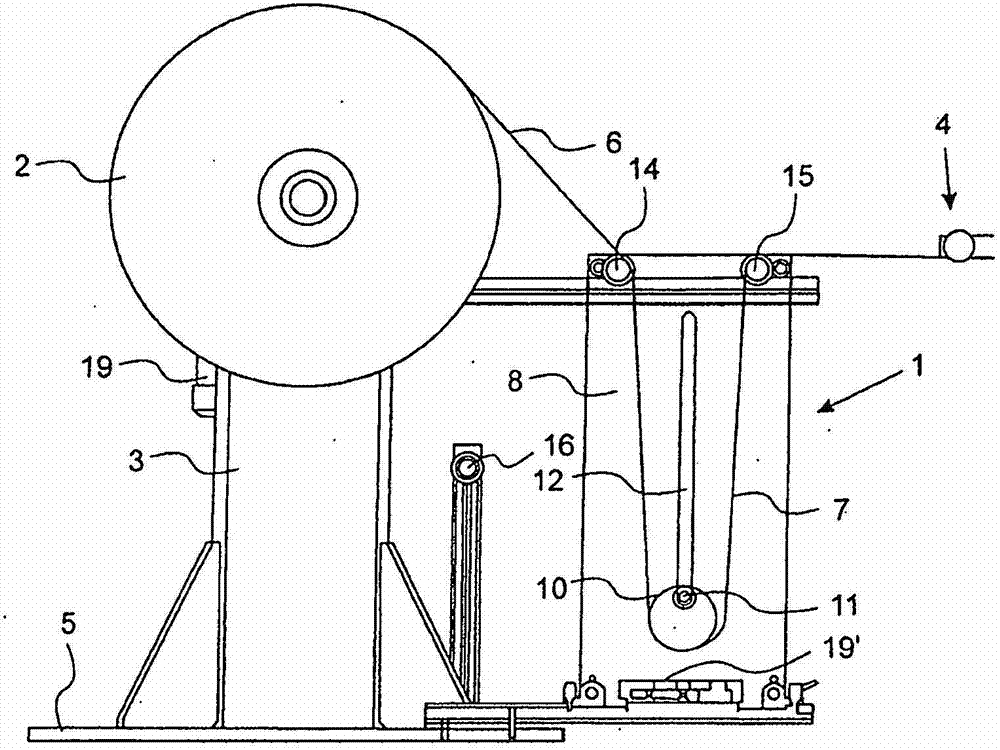

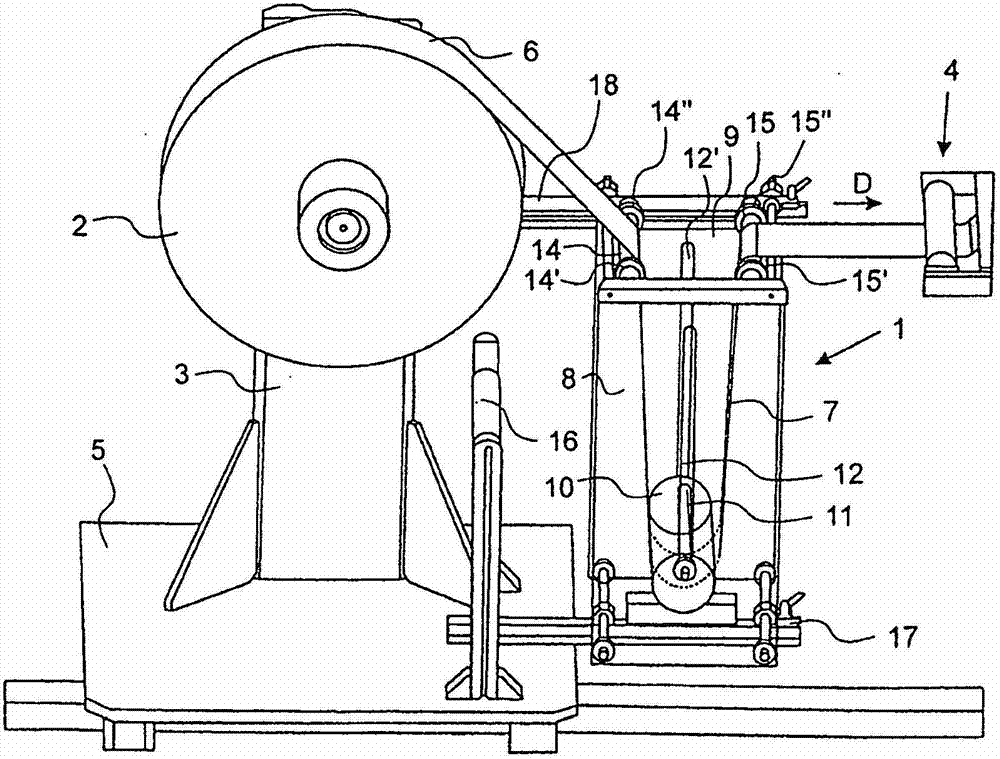

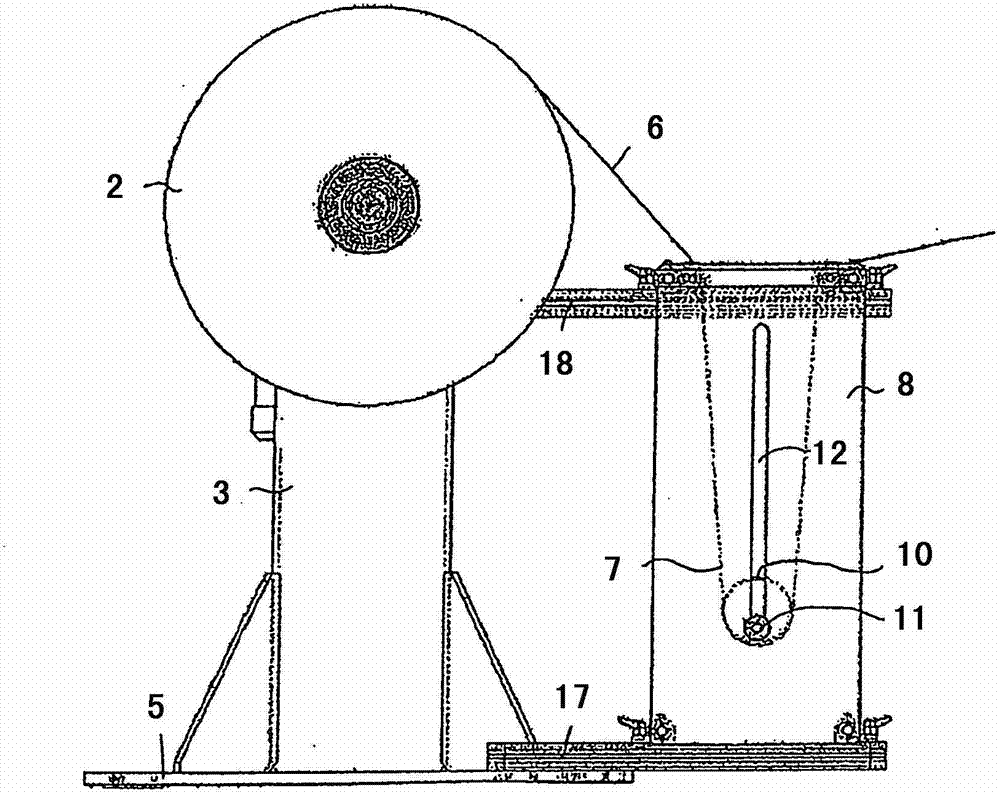

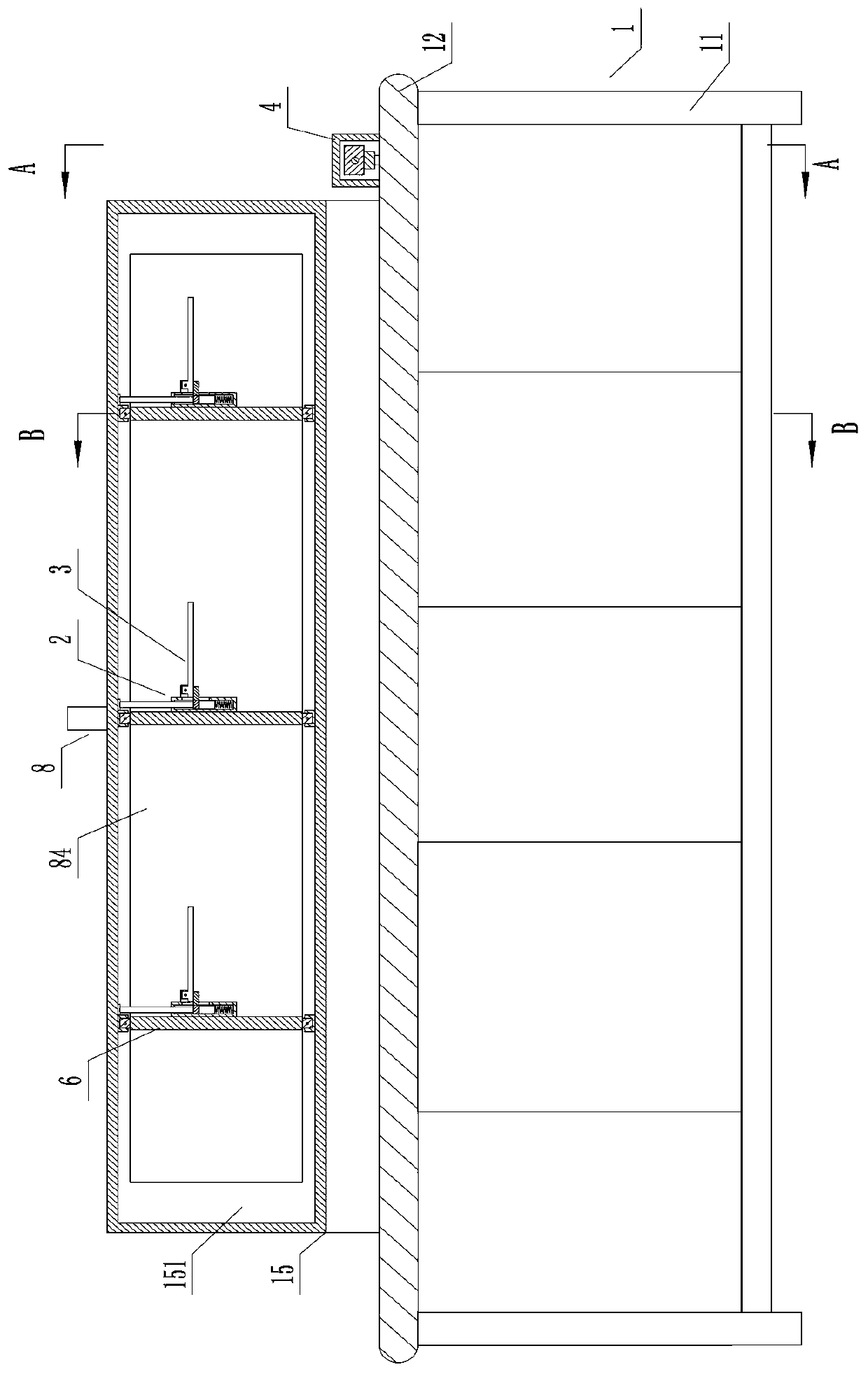

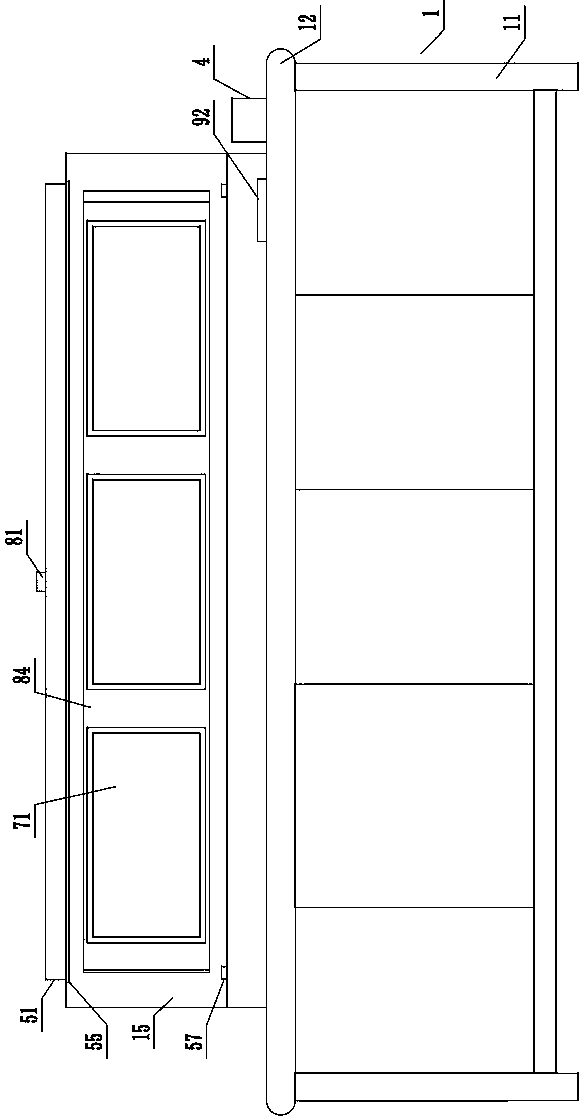

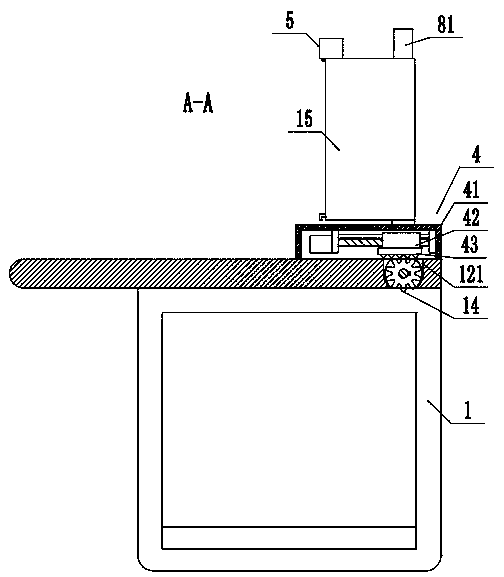

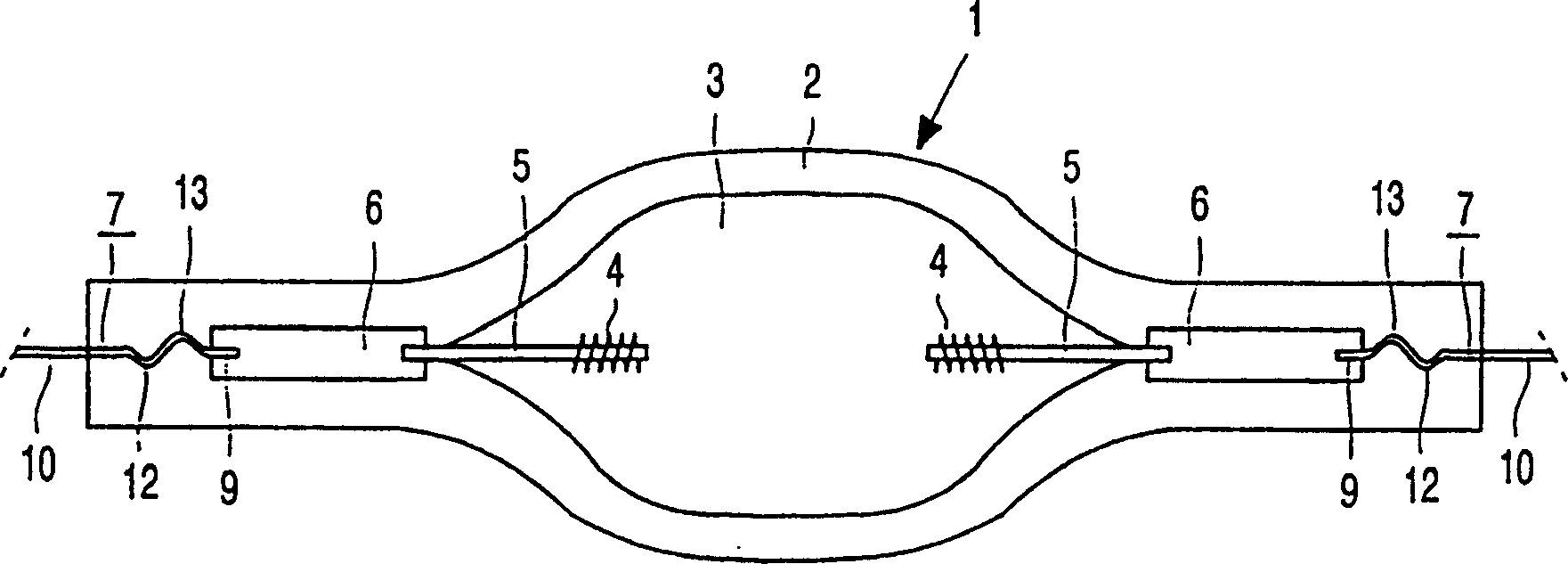

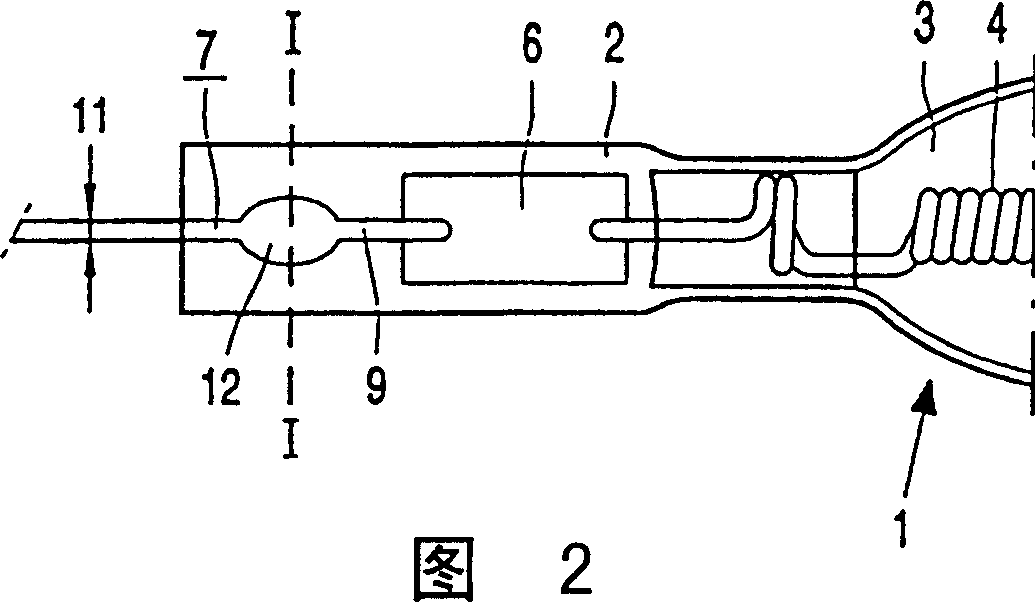

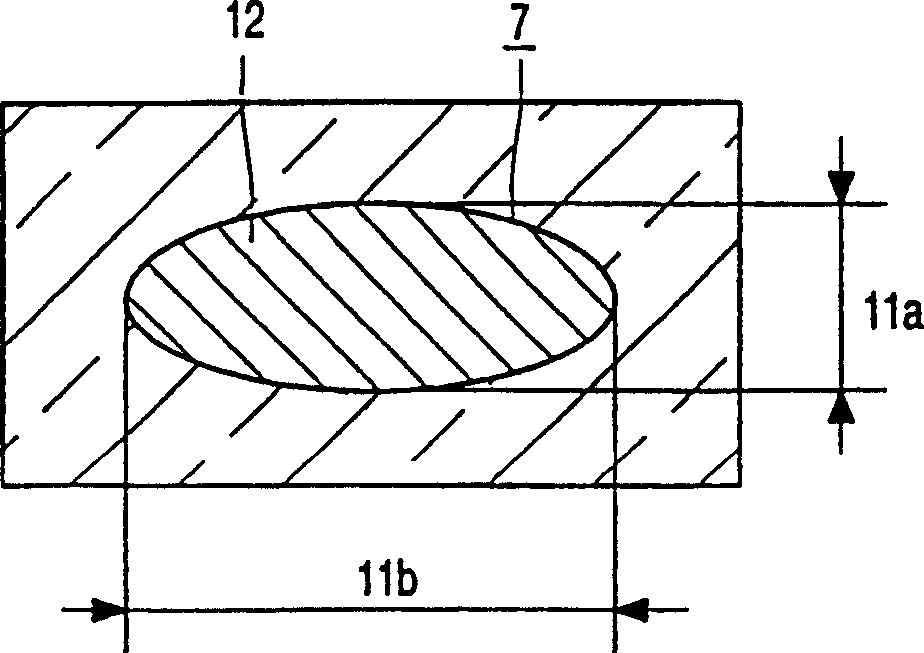

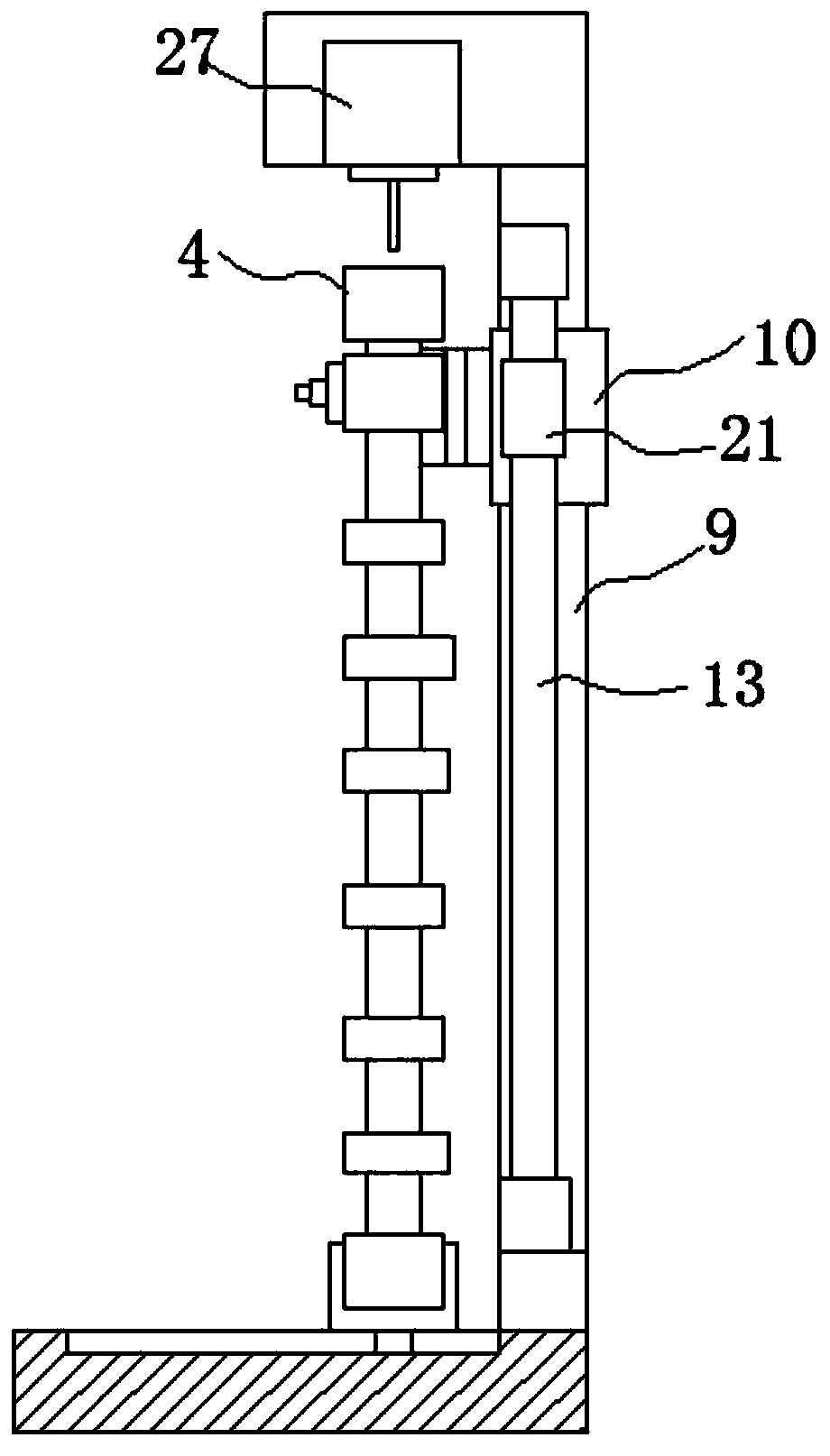

Arrangement for forming band loop and process and apparatus for producing tear-open lids

ActiveCN102958625AEasy to operateRestricted freedom of movementMetal-working feeding devicesPositioning devicesMechanical engineeringHollow cylinder

When handling a foil band (6) which is to be uncoiled from a delivery spool (2) and is drawn in gradually by a drawing-in device (4), a foil band loop (7) is produced. In order that this can take place without any errors with high production cadences, provision is made of an arrangement (1) in which a hollow cylinder (10) rests loosely on the band with a limited freedom of movement so as to form the band loop. Such an arrangement is preferably provided for the production of tear-open lids, in which a foil band is uncoiled from a band delivery spool and fed to a stamping and sealing station.

Owner:SOUDRONIC

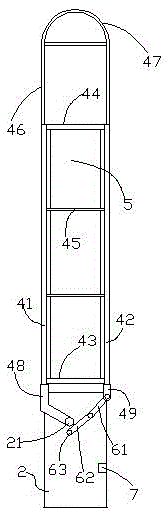

Console with multi-screen unified adjustment and dustproof functions

PendingCN111419006AFast adjustmentConvenience to workFouling preventionStands/trestlesEngineeringClassical mechanics

The invention discloses a console with multi-screen unified adjustment and dust prevention functions, which comprises a console body, and is characterized in that the console body comprises a bracketand a tabletop fixed on the bracket, and further comprises a rotating roller rotationally mounted in a first opening formed in the tabletop by taking a use direction as a reference; a pitching adjusting mechanism driving the rotating roller to rotate; a rotating cover fixedly mounted on the rotating roller; a front-back transverse moving mechanism mounted in the rotating cover; a left-right swinging mechanism mounted on the front-back transverse moving mechanism; a transverse moving driving mechanism driving the front-back transverse moving mechanism to move; and a control module, a locking mechanism, an unlocking mechanism and a dustproof mechanism. The pitching angle of the rotating cover and the pitching angles of the multiple displays can be adjusted in a unified mode through the pitching adjusting mechanism, the front-back distance of each display is adjusted in a unified mode through the transverse moving driving mechanism, and after the locking mechanism is unlocked through theunlocking mechanism, the displays are also adjusted independently; the rotating cover is closed through the dustproof mechanism, and therefore dust prevention is conducted on the displayer.

Owner:BEIJING BXHD MACHINE ROOM EQUIP CO LTD

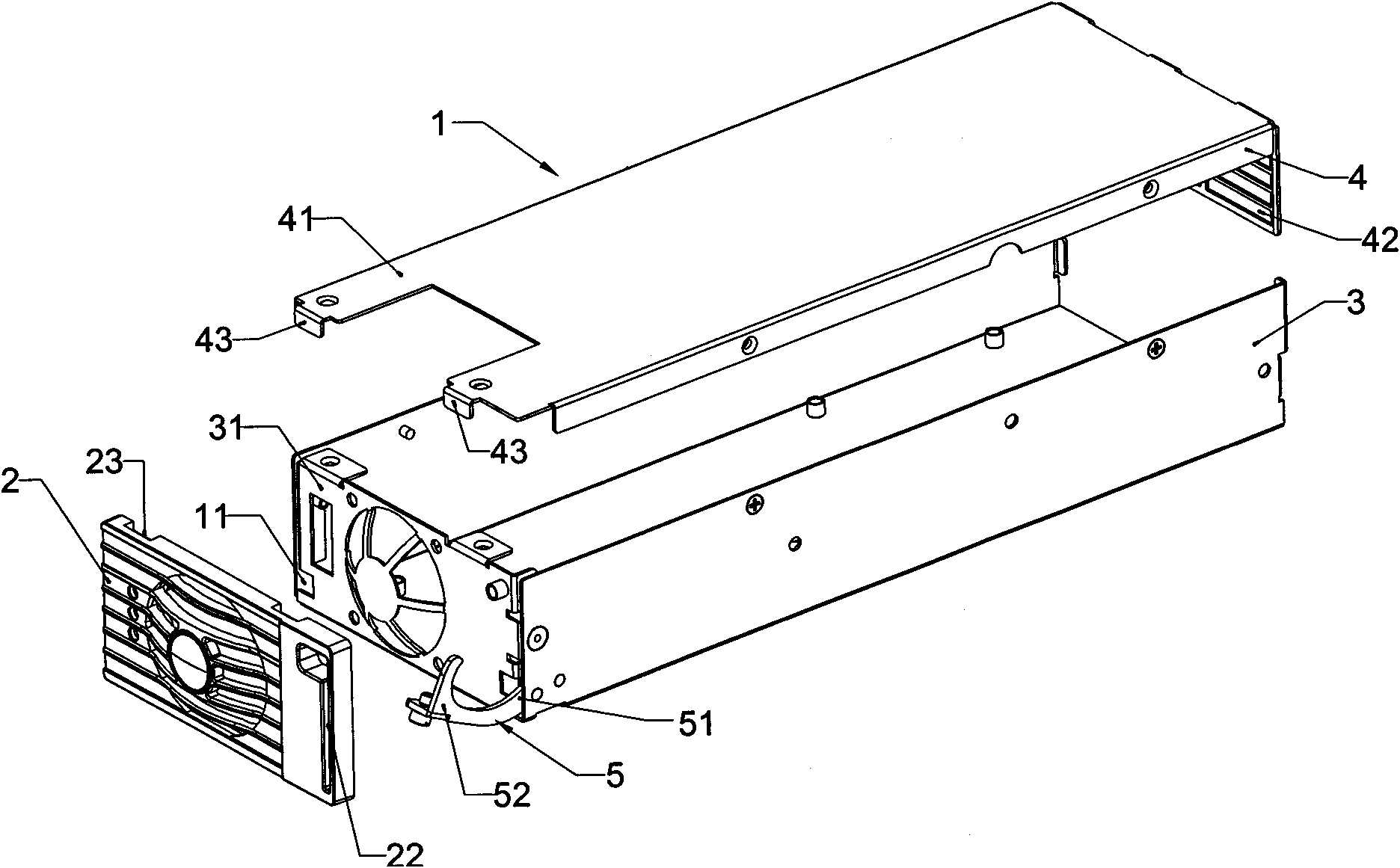

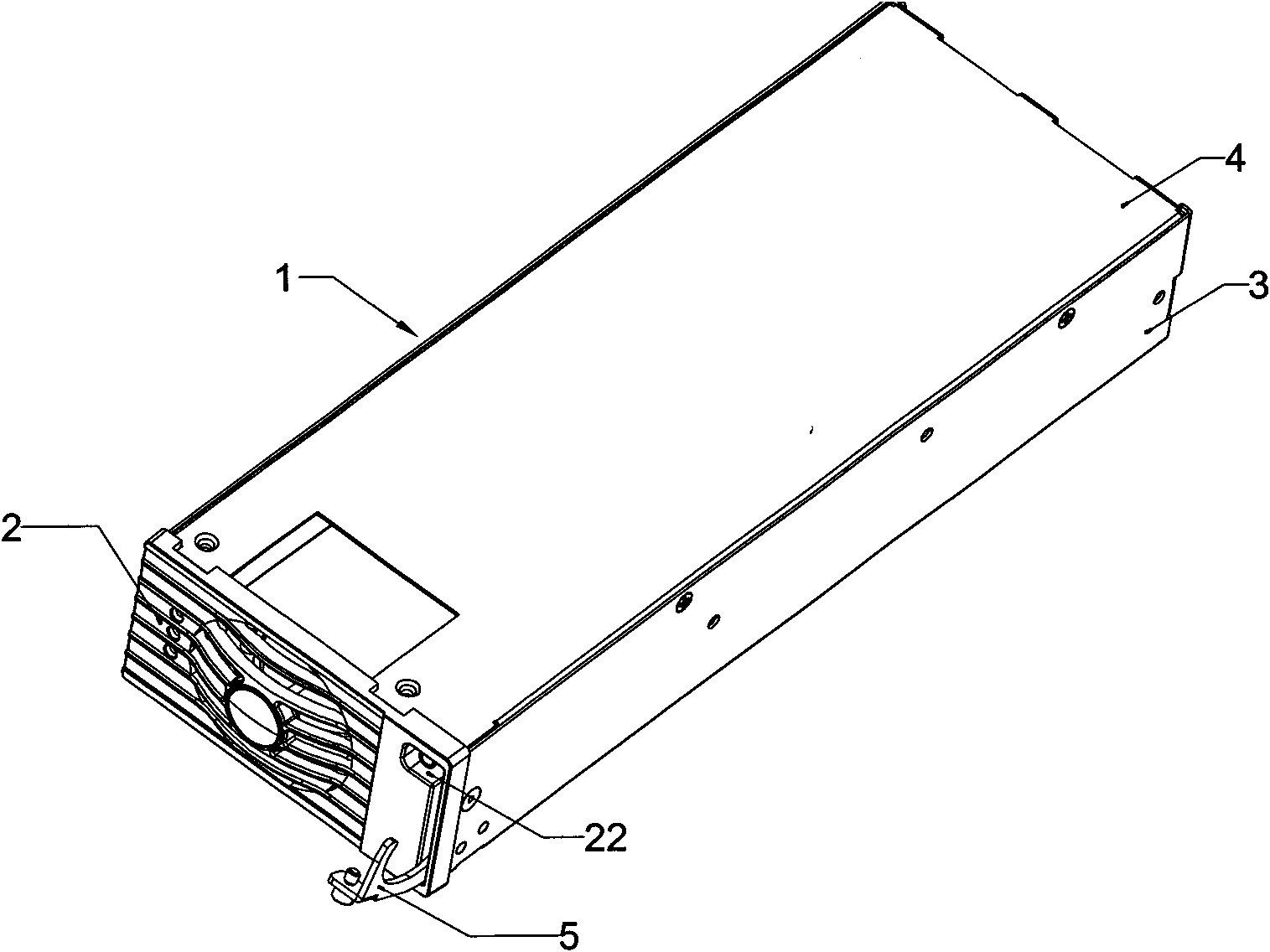

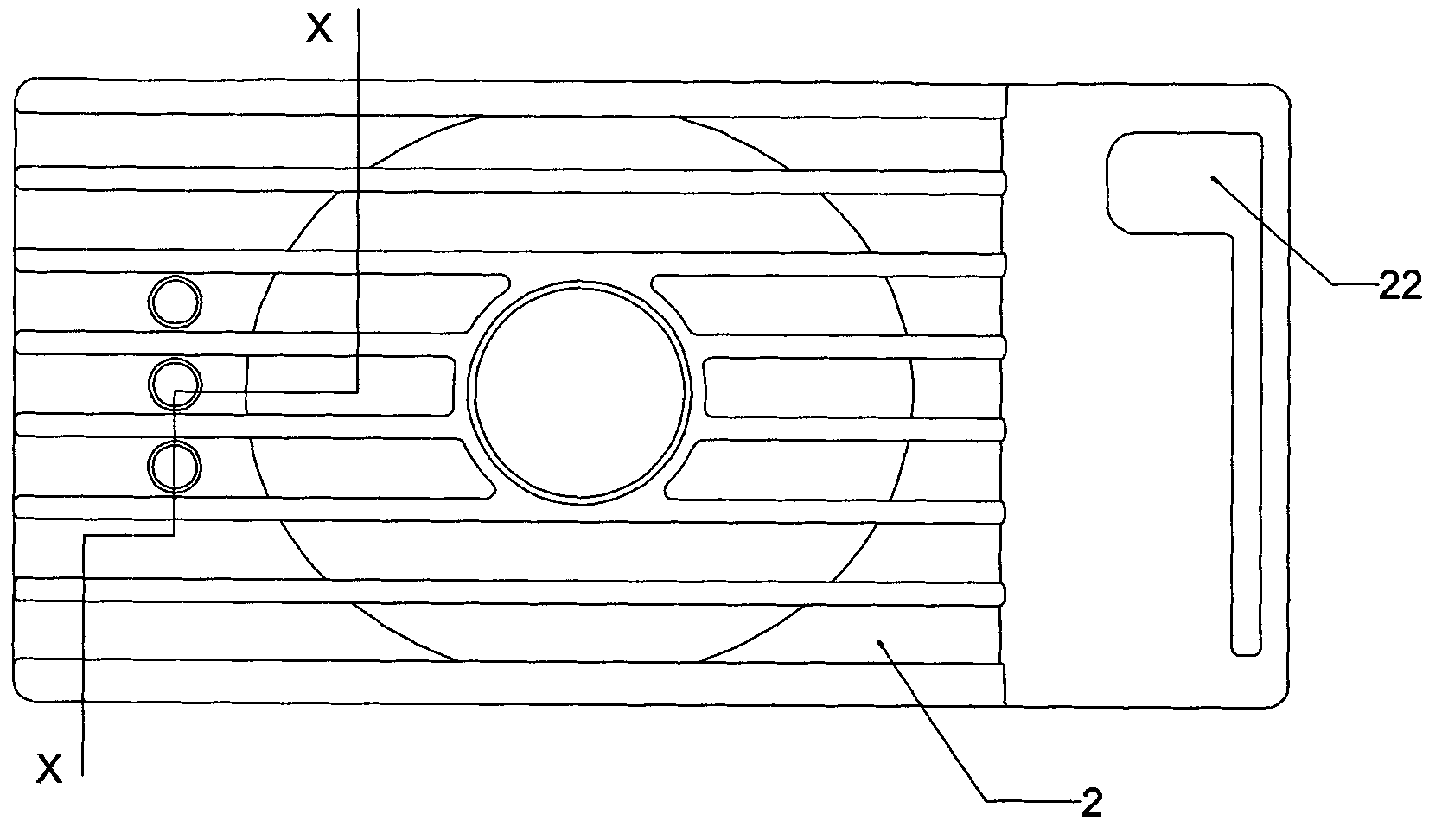

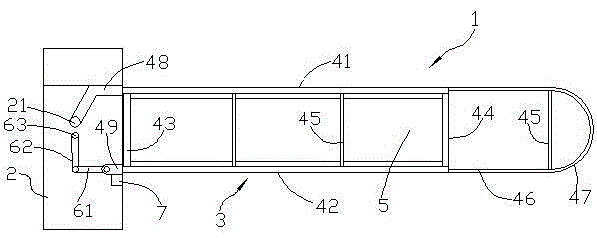

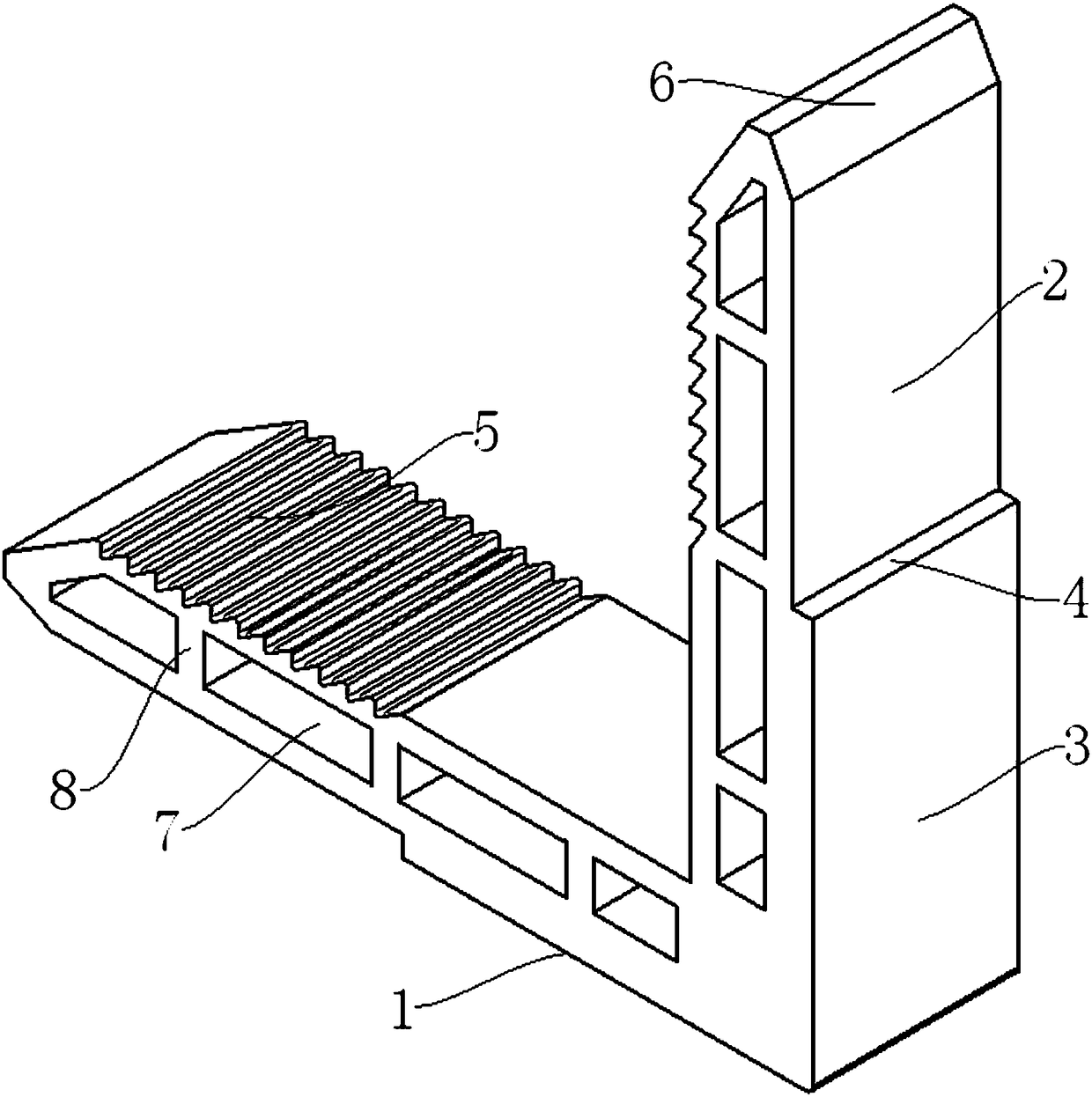

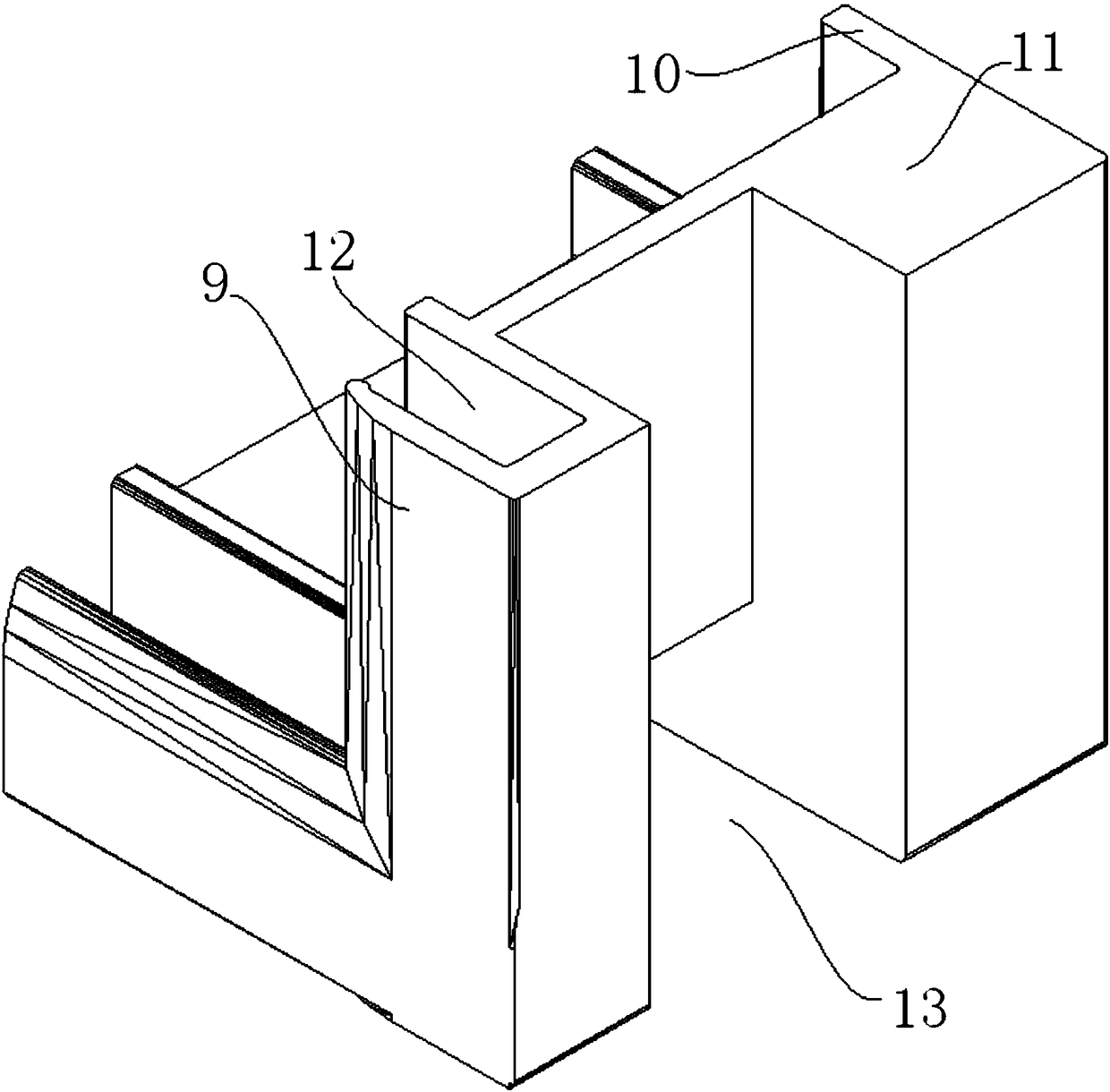

Cabinet and electrical and electronic equipment

InactiveCN101951742AReduce in quantityLow costCasings/cabinets/drawers detailsBiomedical engineeringElectronic equipment

The invention relates to a cabinet and electrical and electronic equipment. The cabinet comprises a body (1) and a faceplate (2) arranged on the body (1); the inner side of the faceplate (2) is provided with a hook (21), the body (1) is correspondingly provided with a hang hole (11), and the faceplate (2) matched with the hook of the hang hole (11) through the hook (21) is arranged on the body (1). The body (1) comprises a lower cover (3), an upper cover (4) and a handle (5). The upper cover (4) comprises a bending edge (43) extending downward, the top of the faceplate (2) is correspondingly provided with a jack (23), the bending edge (43) is inserted in the jack (23), and the faceplate (2) shadows the bending edge (43). Adopting the cabinet and the electrical and electronic equipment of the invention, the appearance of the faceplate can not be influenced by assembly, the number of assembly fasteners can be reduced, and the cost can be lowered.

Owner:EMERSON NETWORK POWER CO LTD

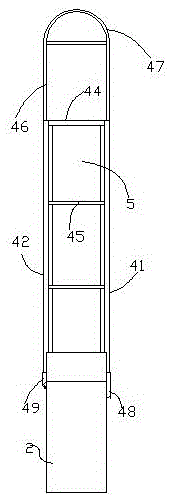

Advertisement gateway

ActiveCN105469726ARestricted freedom of movementNot easy to shakeArticle advertisingIlluminated signsEngineeringPower output

The invention relates to an advertisement gateway and belongs to the technical field of gateways. The advertisement gateway comprises a gate and an upper rod. The upper rod is connected with a power output shaft of the gate. The advertisement gateway further comprises a lower rod opposite to the upper rod. The lower rod is hinged to the gate through a connecting rod assembly. An advertisement board assembly is fixedly connected between the upper rod and the lower rod. Compared with the prior art, the advertisement gateway has the advantages that due to the fact that the upper end and the lower end of the advertisement board assembly are fixedly connected with the upper rod and the lower rod, and the upper rod and the lower rod are connected with the gate, the freedom of motion of the advertisement board assembly in the front-back direction is limited, the advertisement gateway is not likely to be blown by wind or shake, the stability is good, meanwhile, the advertisement board assembly with the larger area can be installed, and the advertisement release area is increased; in addition, the advertisement gateway with the two-rod assembly is more attractive in appearance.

Owner:JIANGXI BAISHENG GATE & DOOR AUTOMATION

Drilling fixture for wooden door processing

InactiveCN104400840ARestricted freedom of movementLimit the automatic degree of rotationDrilling machinesFeeding apparatusWhole bodyNeck parts

The invention discloses a drilling fixture for wooden door processing. The drilling fixture comprises a base and a clamping seat, wherein two fixing sleeves are respectively arranged on the upper side and the lower side of the base; inner holes of connecting pieces are formed in excircles of the fixing sleeves in a sleeving way; the two fixing sleeves are connected together through a stud, one end of the stud is fixed by a nut, the left ends of the two fixing sleeves prop against the clamping seat, the two fixing sleeves, and the two connecting pieces and the clamping seat form a firm whole body through the stud, so that the movement freedom of the connecting pieces is limited; anti-rotating blocks are clamped at the right ends of the two fixing sleeves, the two ends of the anti-rotating blocks are U-shaped openings, and the U-shaped openings are formed in the neck parts of the connecting pieces in a clamping way and firmly clamp and fix the connecting pieces on the fixture, so that the rotation freedom of the connecting pieces is limited, and accordingly, the connecting pieces are firmly fixed to realize accurate drilling of the connecting pieces.

Owner:CHONGQING ZHUOMA FURNITURE

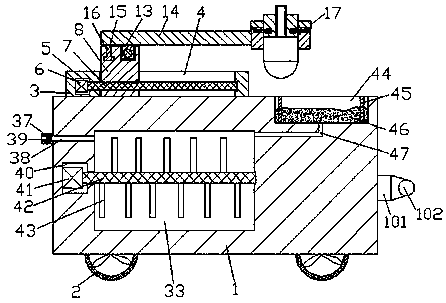

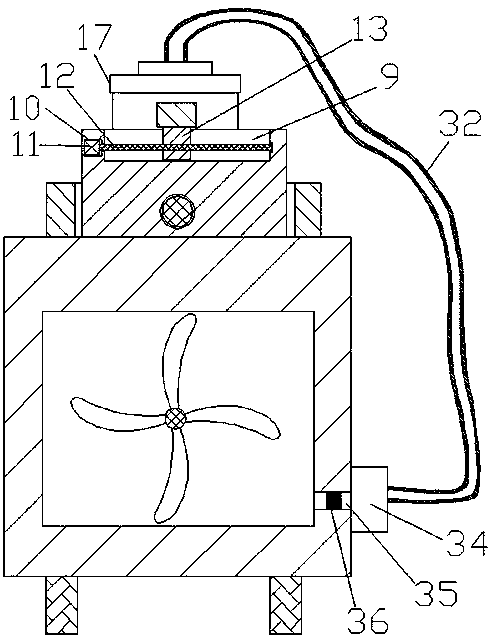

Improved type water cutting robot device

InactiveCN108453629AAvoid power dropReduce torqueAbrasive feedersAbrasive machine appurtenancesWater pipeEngineering

The invention discloses an improved type water cutting robot device which comprises a movable box body. The improved type water cutting robot device is characterized in that movable rollers are arranged at the lower end of the movable box body, wherein a disassembly device is arranged on the right end surface of a supporting rod; the lower end of a locking block is fixedly connected with a strong-pressure water sprayer; a water pumping tube is arranged on the center position of the upper end of the strong-pressure water sprayer; a water pumping pump is fixedly connected with the lower end of the rear end surface of the movable box body; a water filling space is formed inside the movable box body; a water adding tube is arranged at the upper end of the left end surface of the movable box body; a plurality of stirring blades are uniformly distributed on the shaft body of a rotary shaft; and a water-flow buffer slot with an upward opening is formed in the right side of the upper end surface of the movable box body. In work, water which penetrates through an object is injected into the water-flow buffer slot, so that cyclic utilization of water resources is guaranteed, working strengthof water cutting can be strengthened by steel grit, connection is stable, dismounting and replacing are convenient, and handheld use under a special condition is met.

Owner:黄剑青

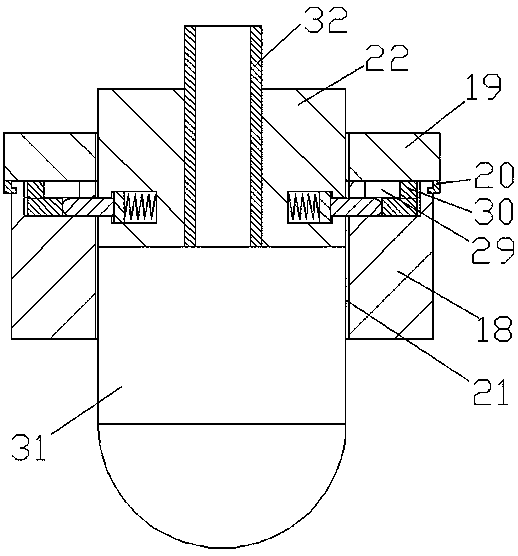

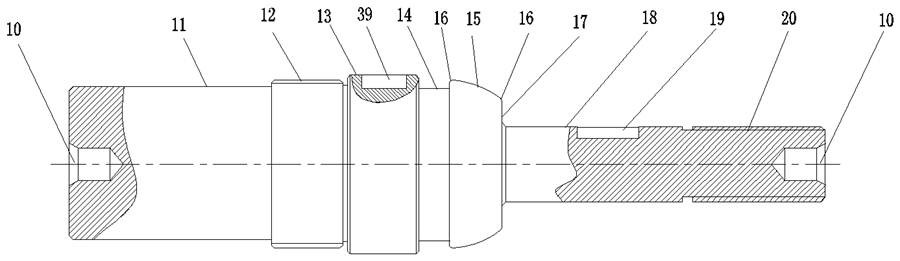

Positioning clamp and machining method for rotor cover of dynamic pressure air bearing of gyro motor

ActiveCN114589520APrecise positioningRestricted freedom of movementWork clamping meansPositioning apparatusAir bearingGyroscope

The invention relates to a thin-wall part precision turning machining method and a positioning clamp, in particular to a positioning clamp and a machining method of a gyroscope motor dynamic pressure air bearing rotor cover. The positioning clamp comprises a spherical surface positioning mandrel, a positioning lantern ring, an anti-vibration pad and a back supporting seat. The spherical positioning mandrel is a step shaft with center holes formed in the two end faces, and comprises a clamping section, a large thread section, a second guide cylindrical section, a spherical positioning section, a spherical table end face, a first guide cylindrical section and a small thread section from left to right in sequence. The machining method comprises the steps of first-step machining of the rotor cover, machining of a series of spherical positioning mandrels, machining of a positioning lantern ring and a back supporting seat, selection of a proper spherical positioning mandrel, turning of the rotor cover and the like. The problems that an existing machining method is poor in positioning precision and low in machining efficiency, and the concave spherical surface is crushed are solved, damage to the concave spherical surface is avoided by limiting six degrees of freedom, and the machining precision of the rotor cover is guaranteed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

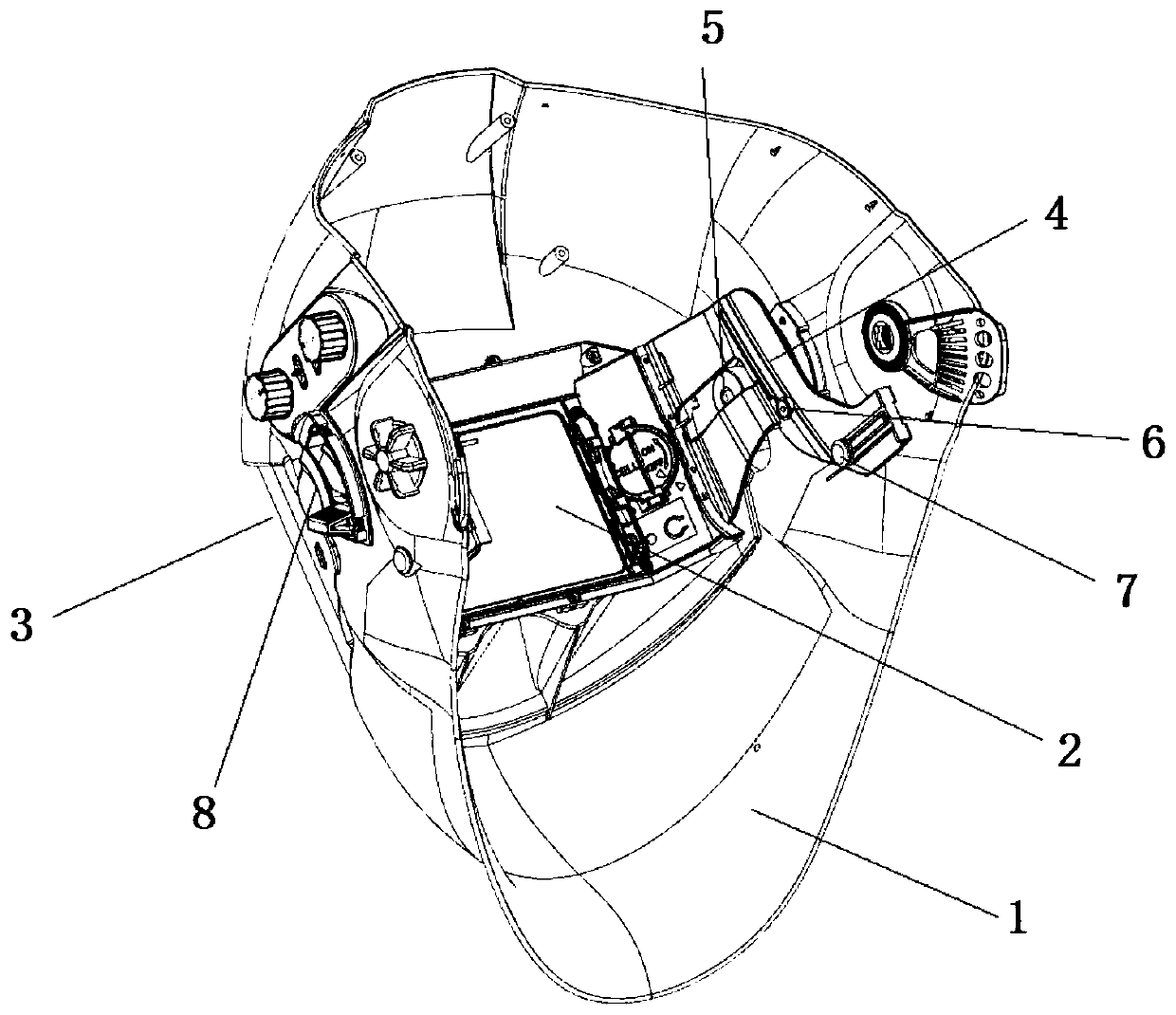

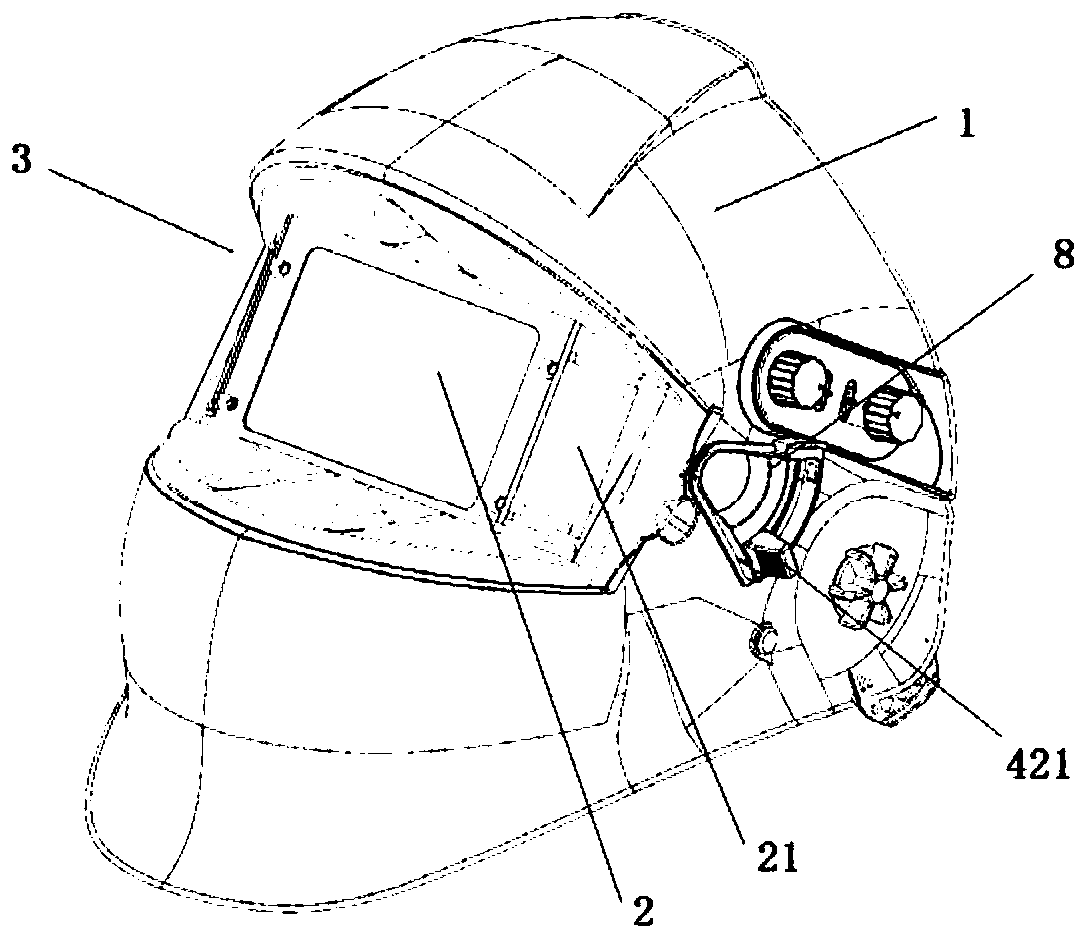

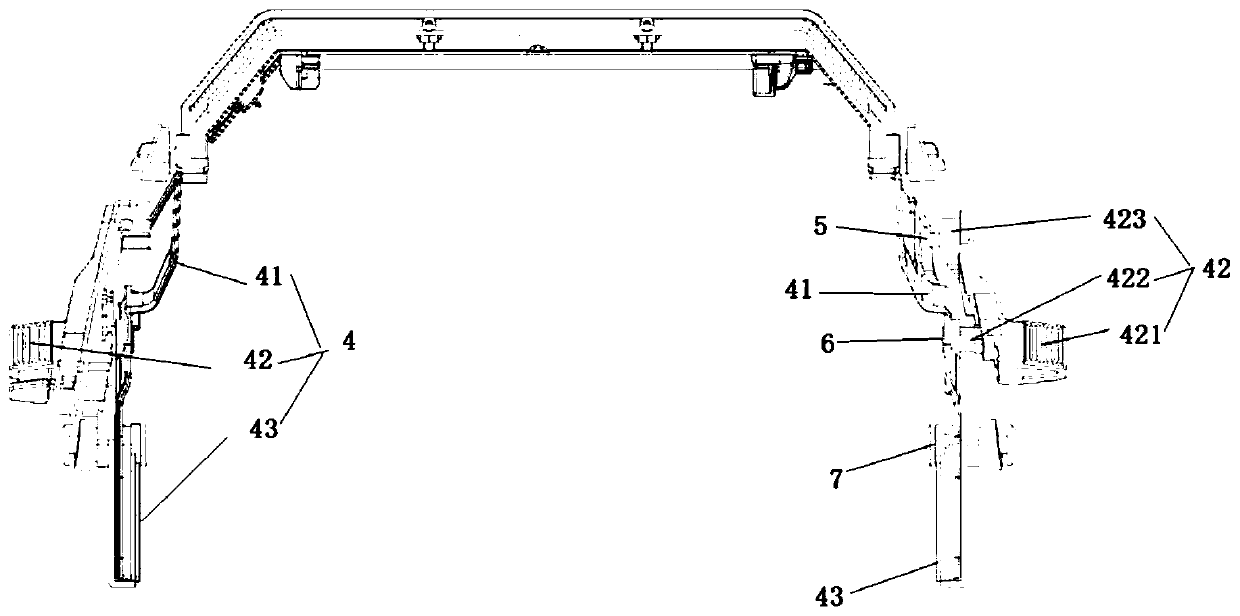

Goggle inner lifting-type face mask

PendingCN109718007AAvoid Weld SpatterAvoid Sanding SplashGogglesEngineering safety devicesProtective glassesGravity center

The invention discloses a goggle inner lifting-type face mask. The face mask comprises a face mask body, a goggle, a front protective glass and connecting rod mechanisms; and the front protective glass is fixed on the front side of the face mask body, the goggle is fixed on the connecting rod mechanisms, the connecting rod mechanisms can adjust the goggle to move up and down and rotate and are rotationally connected to the two sides of the face mask body, and the goggle is positioned in the face mask body. The face mask has the beneficial effects that: the goggle inner lifting mode is adoptedto prevent the goggle from being easily polluted by welding spatter, polishing spatter and dust when the goggle is lifted outside; the defects that the gravity center of the whole face mask moves forwards and the face mask is too heavy are avoided; and the goggle can be lifted up inside the face mask, so that the sight is still not influenced in the situation that the face mask is not taken off, and the face mask is wider and more flexible to adapt to occasions, and is more convenient to operate.

Owner:ANHUI HENGYU OPTICAL ELECTRONICS CO LTD

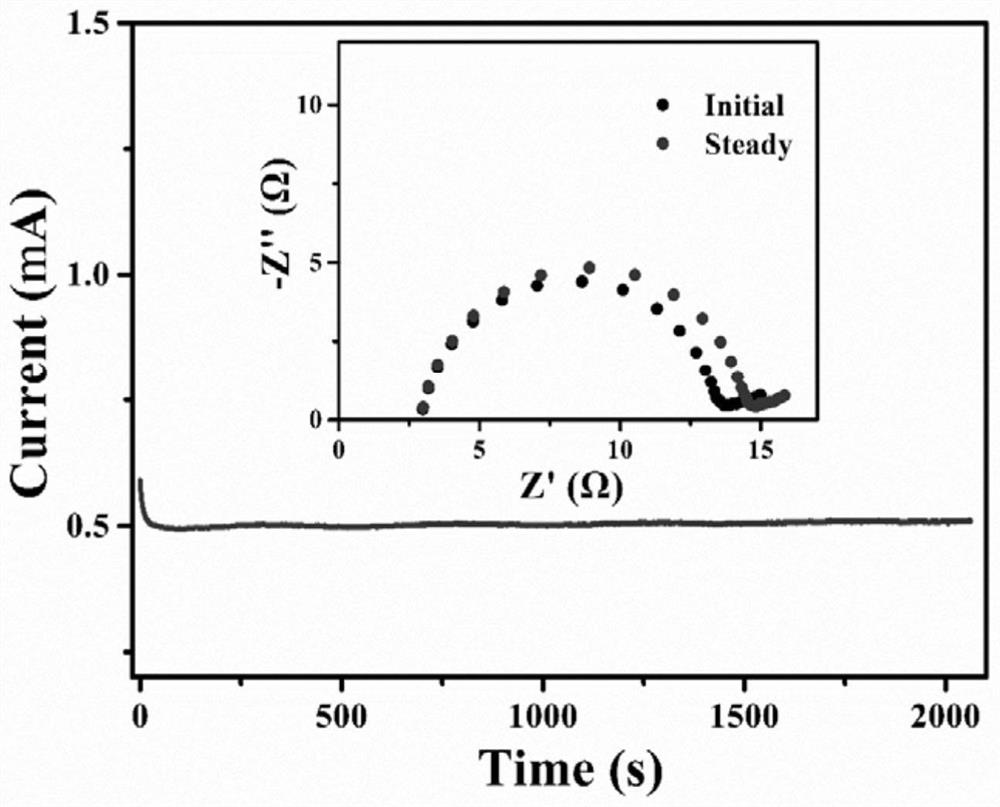

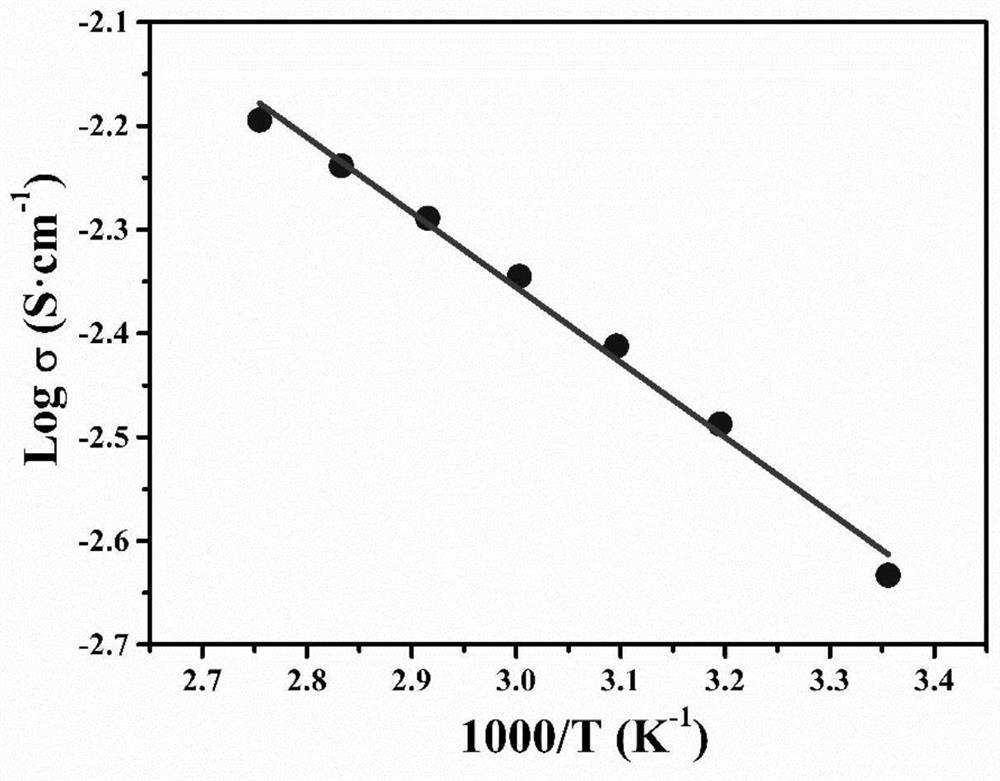

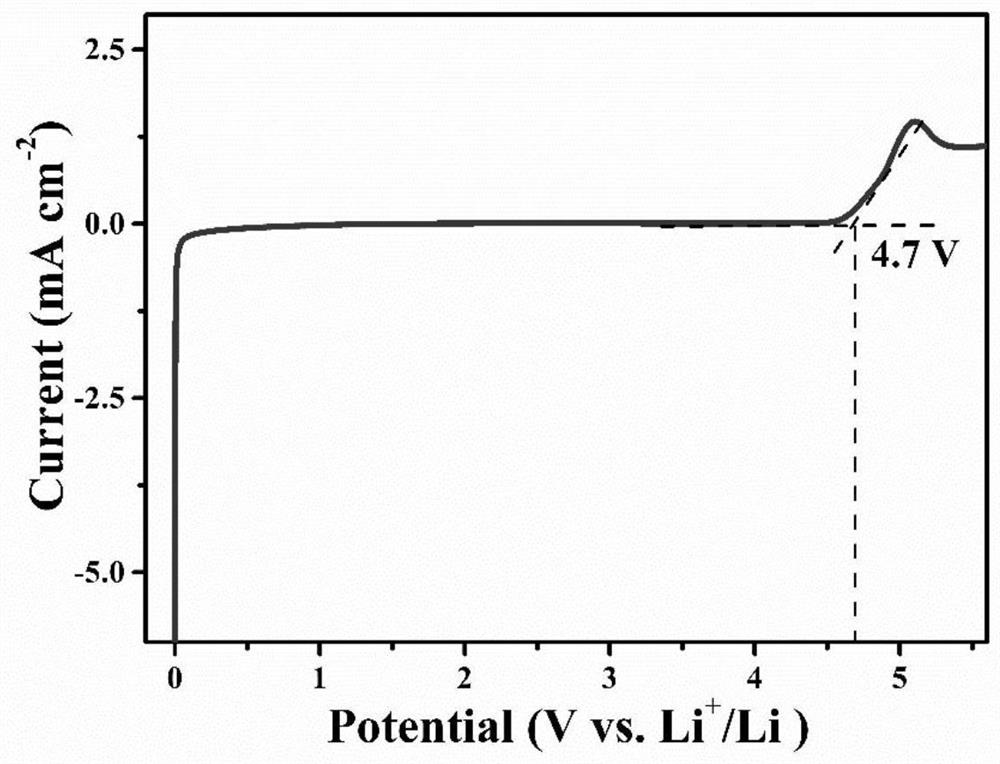

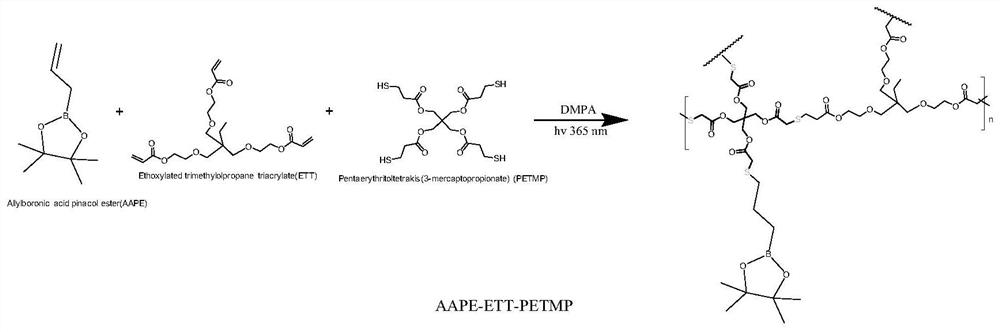

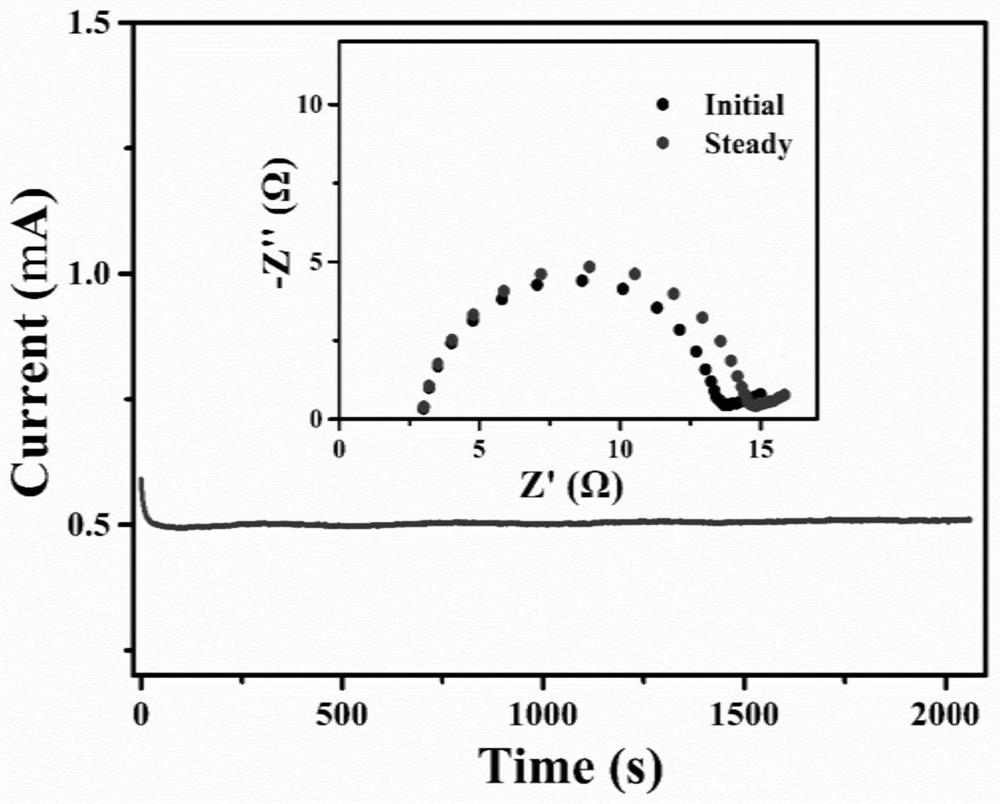

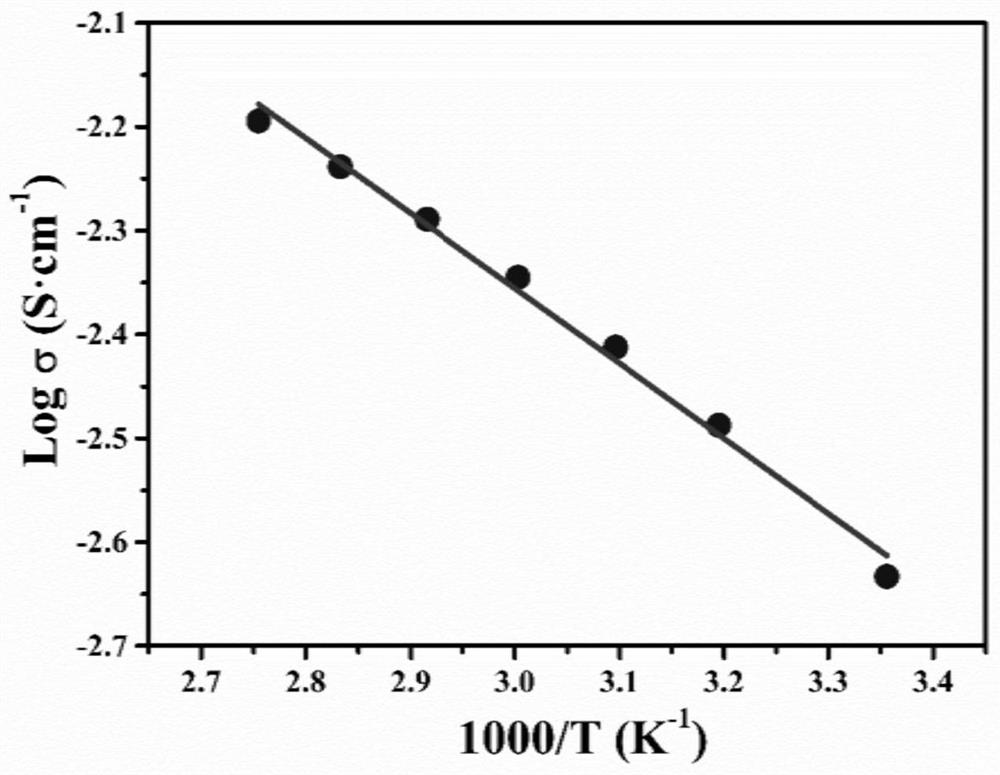

Anion acceptor type single-ion conductor flame-retardant gel polymer electrolyte and preparation method thereof

ActiveCN112164824ARestricted freedom of movementIncrease the number of transfersSolid electrolytesFibre typesPolymer scienceUltraviolet lights

The invention discloses a preparation method of an anion acceptor type single-ion conductor flame-retardant gel polymer electrolyte, which comprises the following steps: (1) uniformly stirring and mixing allyl boronic acid pinacol ester, trimethylolpropane triacrylate, pentaerythritol tetramercaptoacetate, propylene carbonate and benzoin dimethyl ether until the components are completely dissolvedto obtain a solution A; (2) dripping the solution A obtained in the step (1) on an electrostatic spinning PVDF (Polyvinylidene Fluoride) membrane, uniformly infiltrating, transferring to ultravioletlight, and carrying out ultraviolet light polymerization reaction, so as to obtain an anion acceptor type single ion conductor flame-retardant gel polymer membrane; and (3) completely soaking the anion receptor type single ion conductor flame-retardant gel polymer membrane obtained in the step (2) in an electrolyte mixed solution to obtain the anion receptor type single ion conductor flame-retardant gel polymer electrolyte. The invention also provides the anion acceptor type single-ion conductor flame-retardant gel polymer electrolyte prepared by adopting the preparation method.

Owner:WUYI UNIV

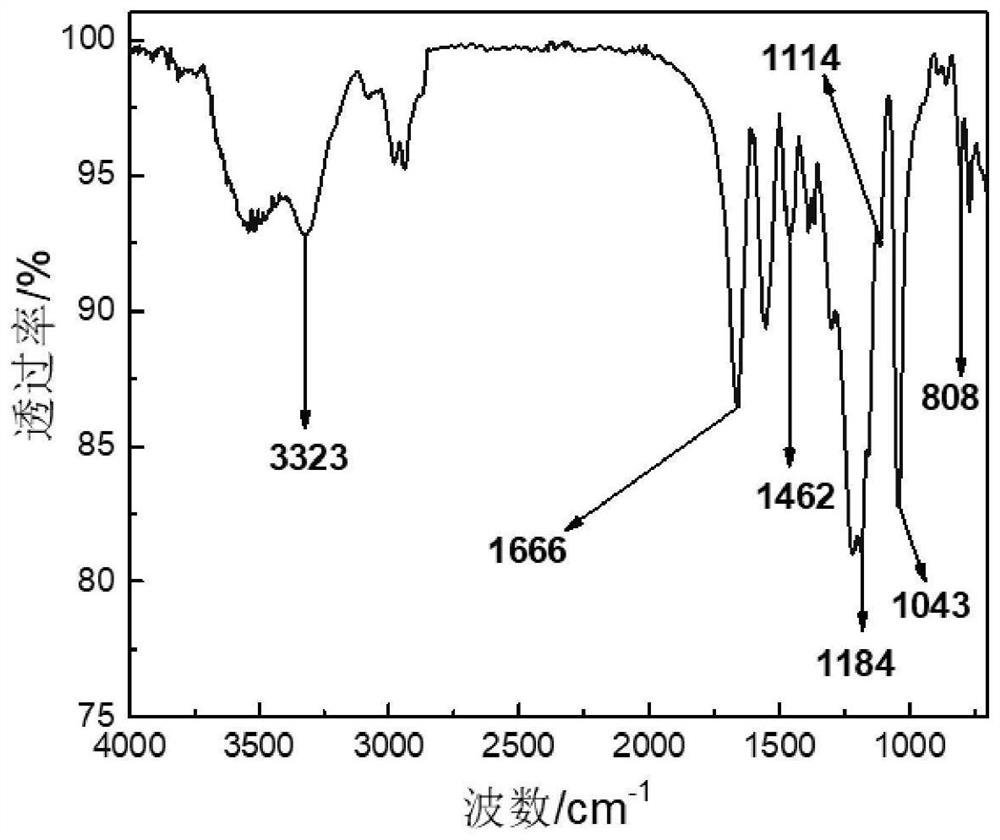

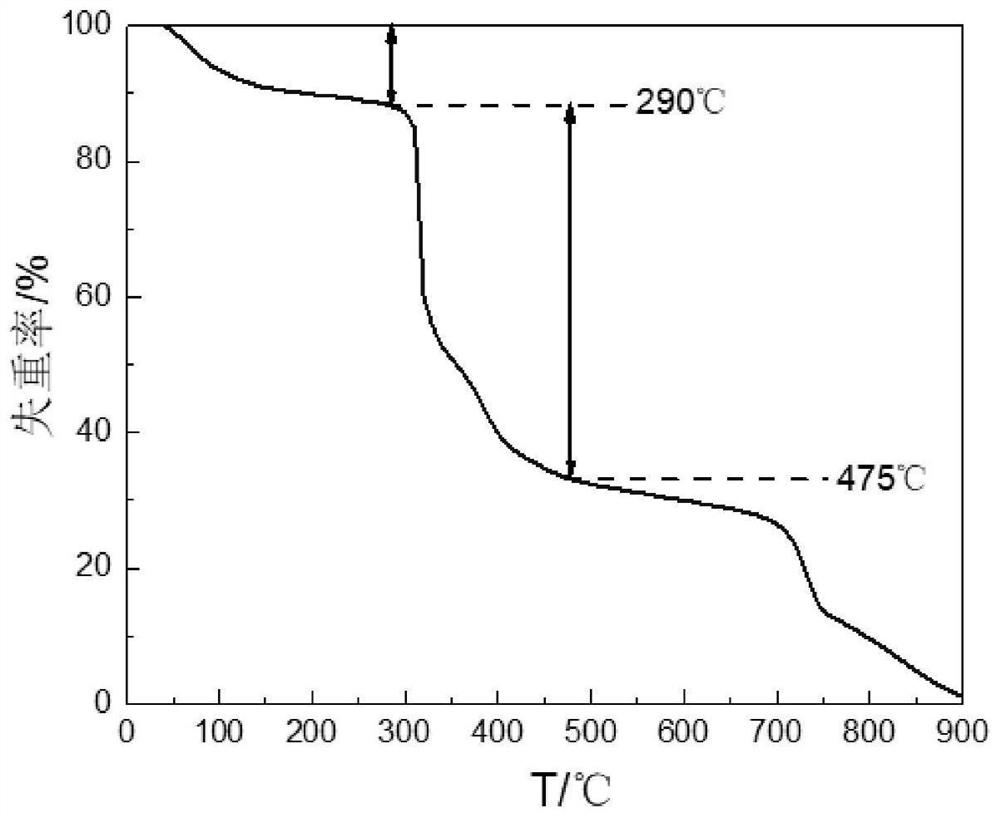

Black matte polyimide film comprising titanium dioxide and preparation method thereof

The invention relates to a black matte polyimide film comprising nano titanium dioxide. The black matte polyimide film comprises a polyimide polymer and inorganic filler, wherein the inorganic filleris added into the polyimide in a form of filler dispersion, and the filler dispersion comprises the following components in parts by weight: 1.0 part of low-conductivity carbon black, 0.4 to 2.0 partsof matting powder, 0.1 to 1.2 parts of nano titanium dioxide, 0.5 to 3.6 parts of anti-settling agent, and 18.0 to 53.2 parts of polarity organic solvent. Due to the existence of Ti-O-Ti structure, the nano titanium dioxide is added into the polyimide and has strong interaction force with polyimide molecules, so that not only is the thermal decomposition temperature relatively high, but also theactivity of the polyimide molecule can be inhibited, the rigidness can be improved, and the size stability is good.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

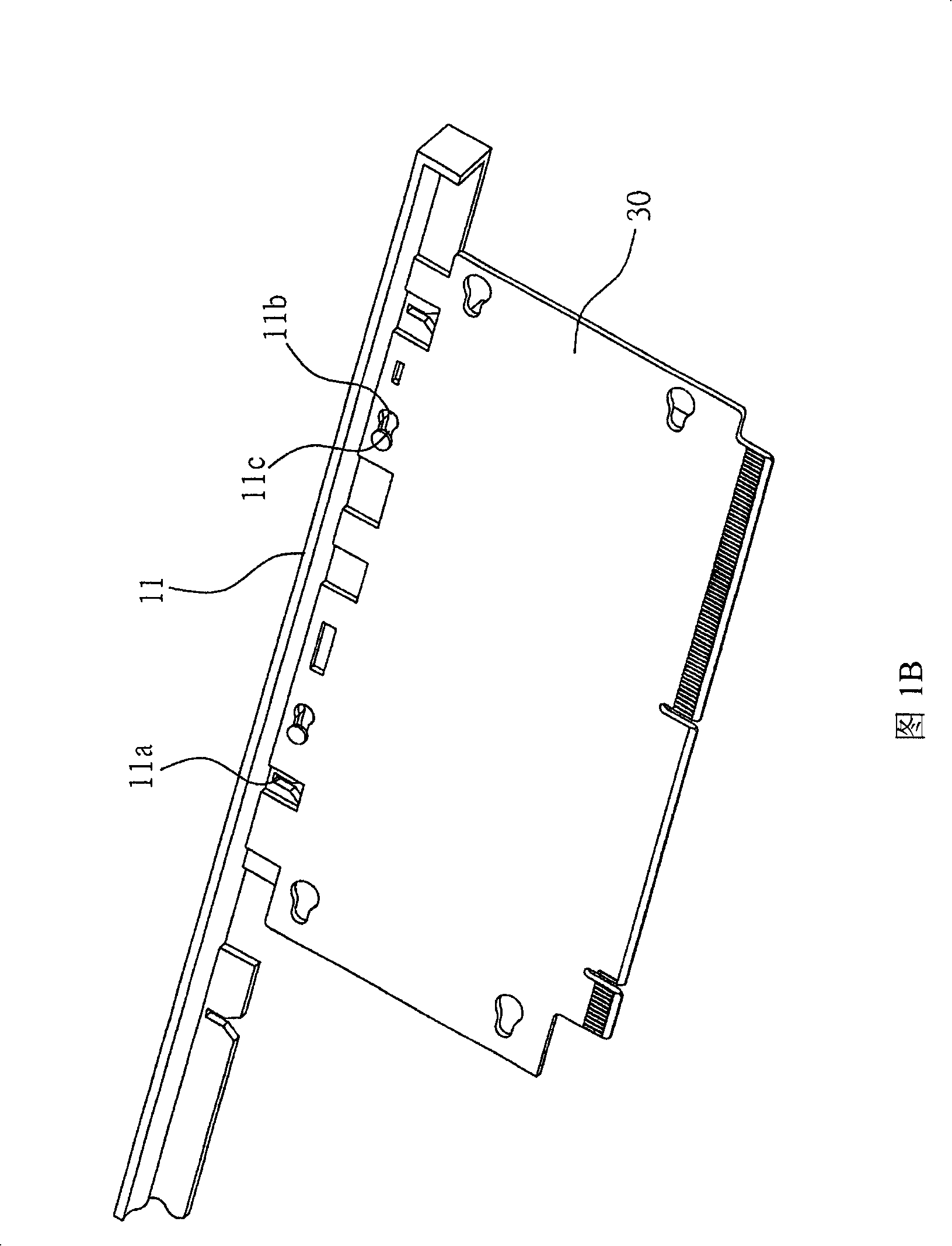

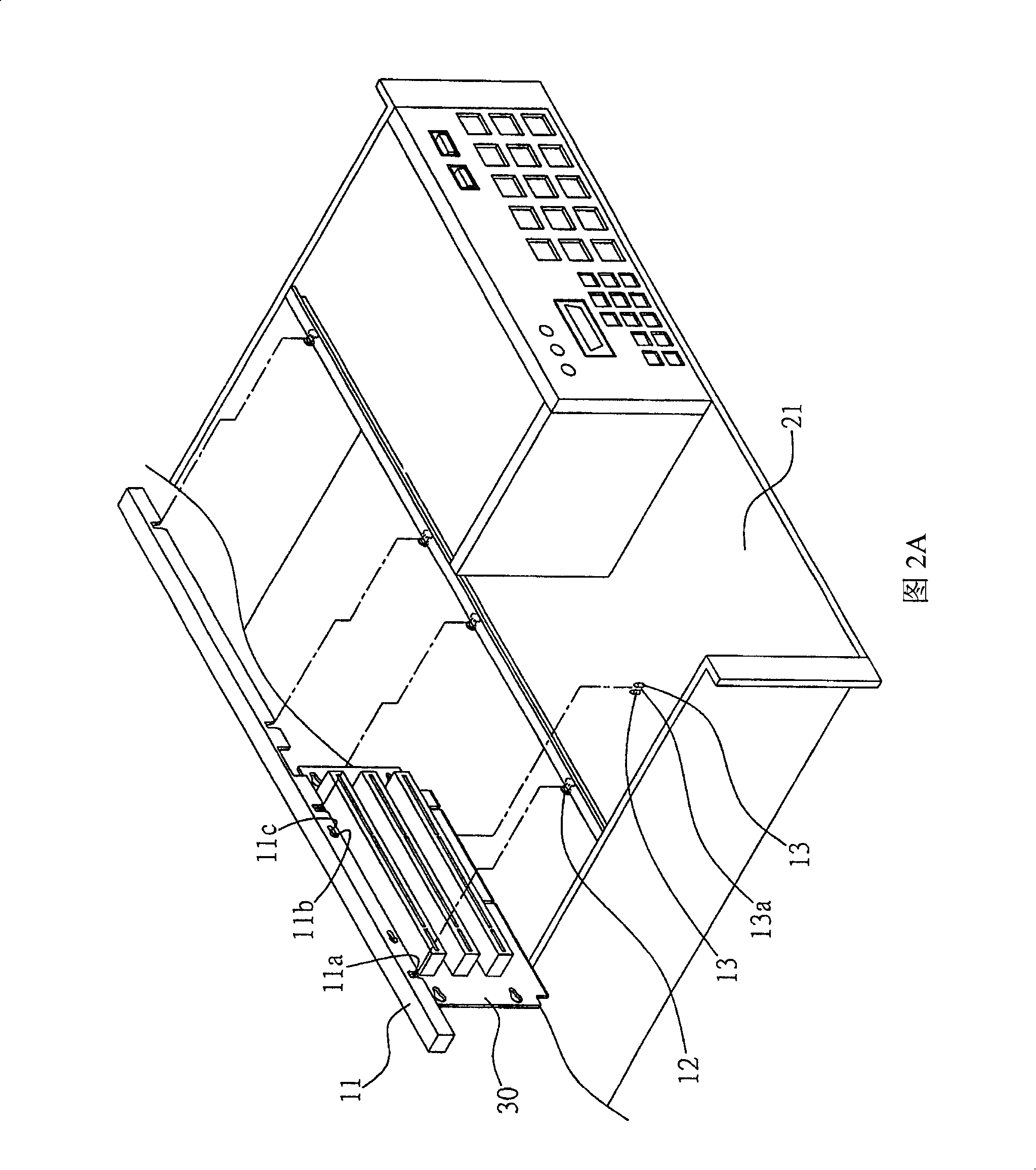

Fixed structure

ActiveCN101201675ARestricted freedom of movementEasy to operateDigital processing power distributionSupport structure mountingEngineeringHuman power

The invention provides a fixed structure which is arranged on a casing. When a fixed bracket provided with a switching circuit board is fixed on the casing, a first fixing part which is arranged on the fixed bracket is block and fixed with a second fixing part which is arranged on the casing. At the same time, a plurality of capacity spaces formed by locating parts are arranged on the base of the casing, so the switching circuit board can be fixed in the capacity space and is further fixed on the casing. The invention is easy to be operated and can reduce the waste of manpower and man-hour when the present in assemble and disassemble. So the problems in the prior art that the assembly must be executed with tools and the problems of disassemble are avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

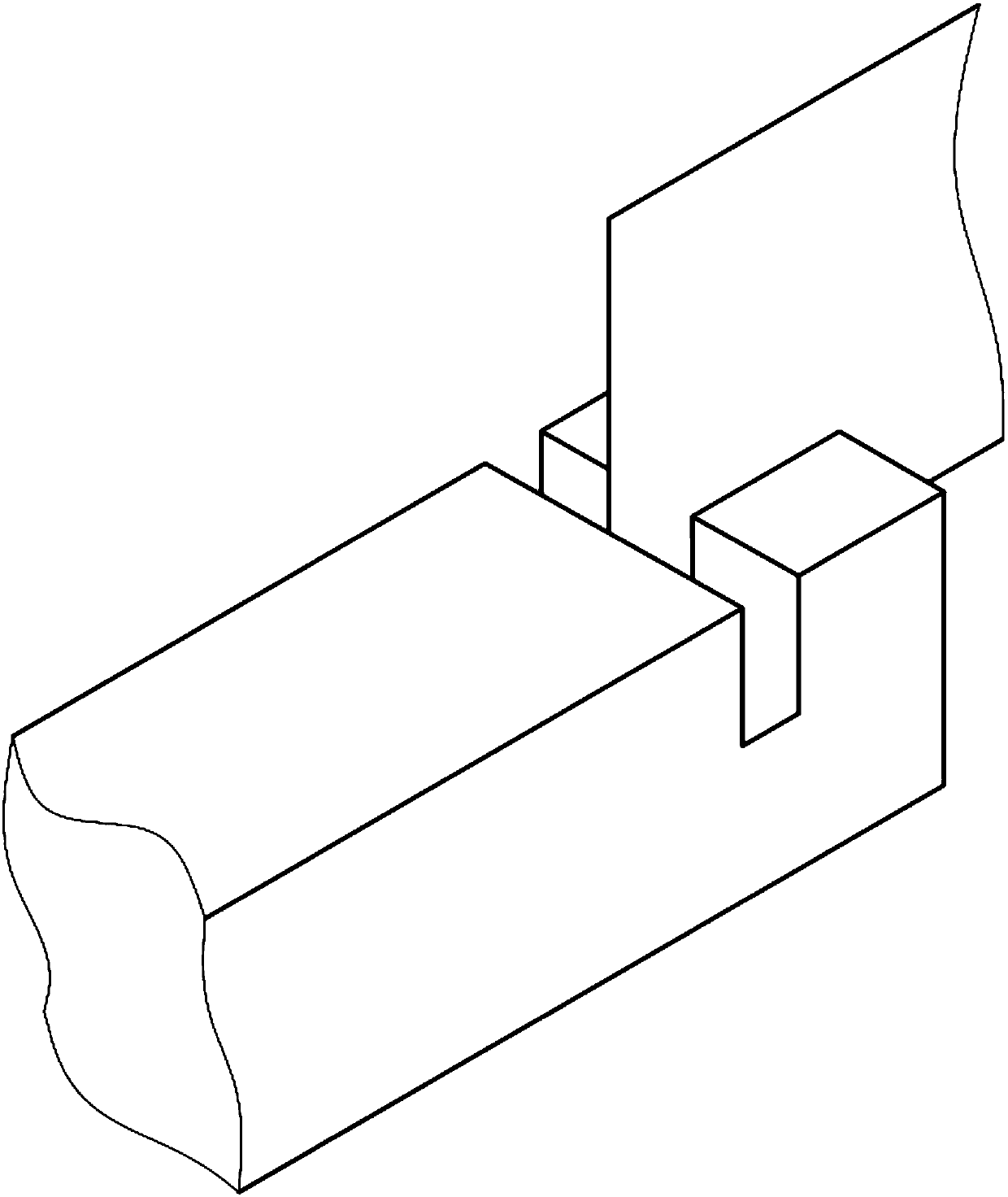

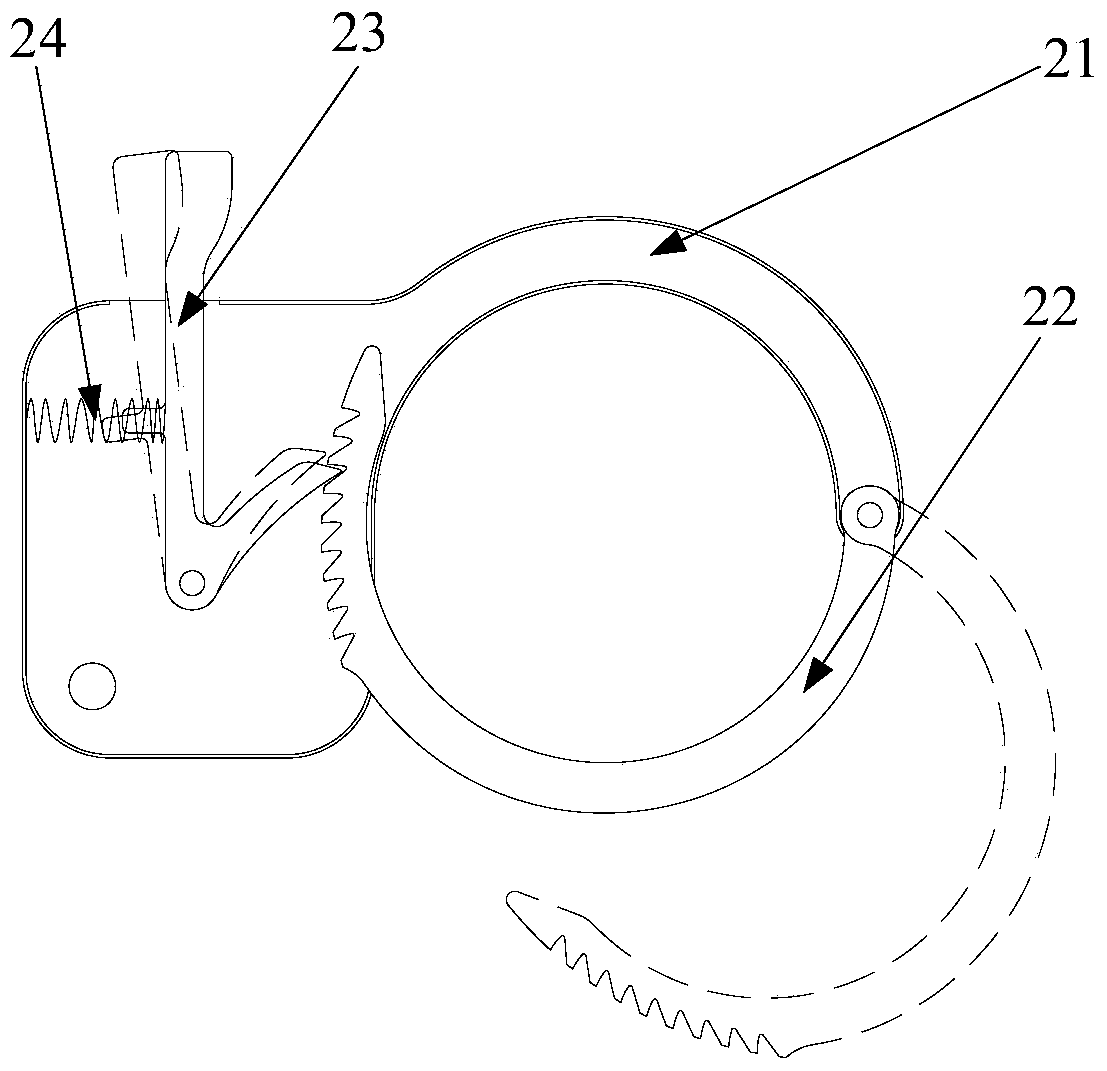

Vertical connection structure of photovoltaic module and photovoltaic module thereof

PendingCN108512501AReduce lossAvoid damagePhotovoltaicsPhotovoltaic energy generationEngineeringCross section.transverse

The invention discloses a vertical connection structure of a photovoltaic module and a photovoltaic module thereof. The vertical connection structure comprises a corner, which is provided with connecting arms, sawtooth surfaces and stop surfaces; the two connecting arms are vertically connected in an L shape, and each connecting arm is divided into an insertion section and a connection section along the length direction; the sawtooth surfaces are located on the insertion sections; the stop surfaces are located at the boundaries of the insertion sections and the connection sections, and are perpendicular to the length directions of the insertion sections and the connection sections; the insertion sections are in contact connection with the inner cavity of a profile, and the stop surfaces are in contact with the ends of the profile; and the corner guard is provided with a groove having an L-shaped length, the groove is in contact with the inner sides of the connection sections, and whenthe corner guard is assembled with the corner, the cross-sectional contours of the corner guard at the groove and the corner are the same as the cross-sectional contour of the profile. The corner clamps the periphery of the corner guard, the profile clamps the two ends of the corner guard, and the three are fixed tightly, so that the sharpness of the corner of the profile is eliminated, the repairof the profile is avoided and the assembly work of the personnel is reduced.

Owner:PERLIGHT SOLAR

Cable sheath

ActiveCN103762528AReduced freedom of movementReduce bending and dispersionApparatus for joining/termination cablesEngineeringElectric cables

Owner:NINGBO TRANSMISSION & DISTRIBUTION CONSTR

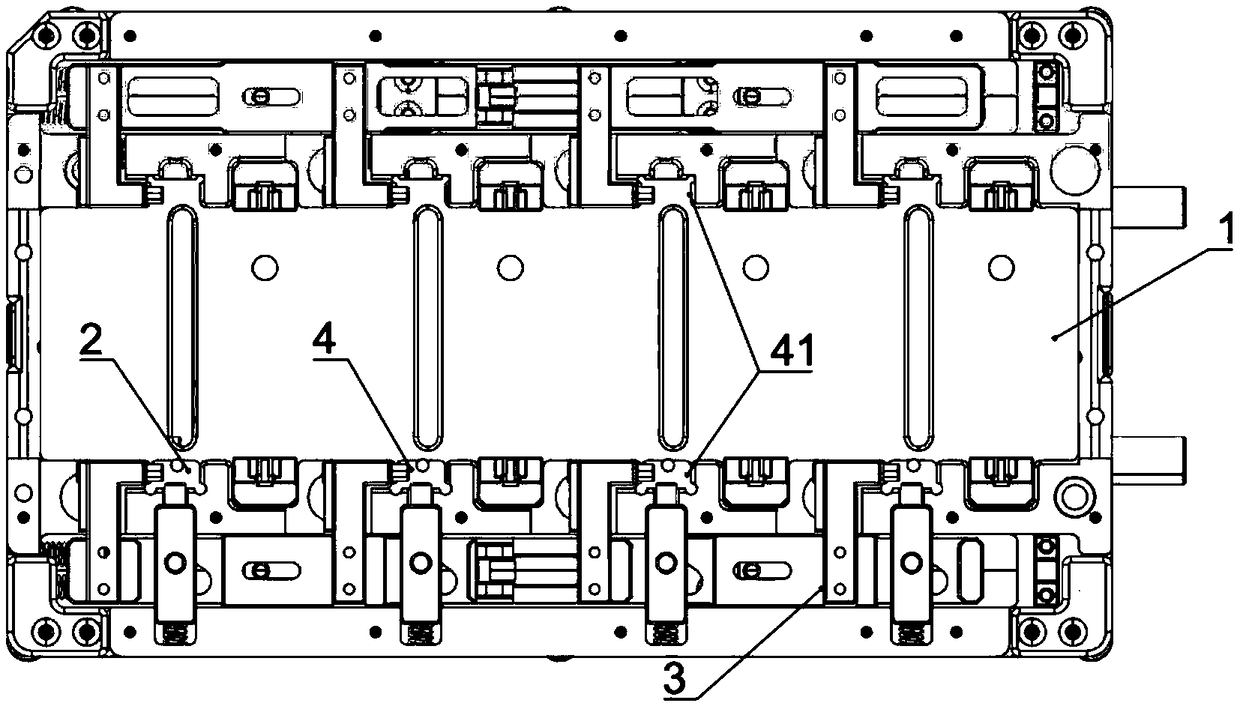

Production line assembly jig

PendingCN108705275APrecise positioningAccurate locationMetal working apparatusProduction lineLocking mechanism

The invention provides a production line assembly jig. The production line assembly jig comprises a plurality of positioning mechanisms and locking mechanisms, wherein the positioning mechanisms are arranged in a part placing region of a base for initially positioning workpieces. The locking mechanisms are provided with locking positions for locking and fixing the workpieces in the positioning mechanisms and unlocking positions for unlocking the workpieces. The locking mechanisms included draft gears and first locking devices connected to the draft gears, and the draft gears are acted upon byexternal force and drive the first locking devices to move to the unlocking positions or the locking positions; and the locking mechanisms further comprise second locking devices arranged on the draftgears with the first locking devices in a linkage mode. The second locking devices lock the workpieces in a different direction from the first locking devices, and the draft gears are acted upon by the external force and simultaneously drive the first locking devices and the second locking devices to move to the unlocking positions or the locking positions. The production line assembly jig can perform bidirectional positioning on the workpieces and can perform bidirectional locking or unlocking operation at the same time, and is suitable for operation of the workpieces in the production lineoperation.

Owner:SUZHOU RS TECH

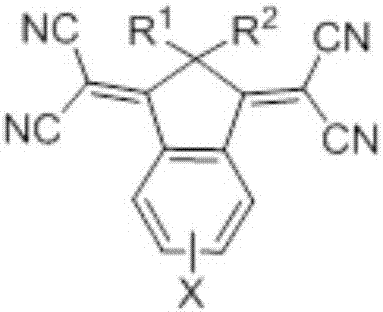

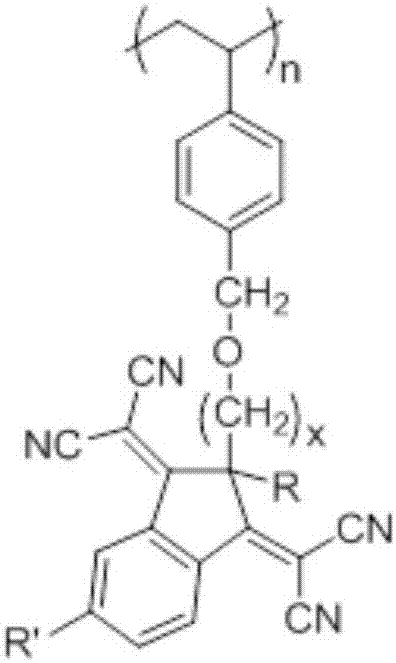

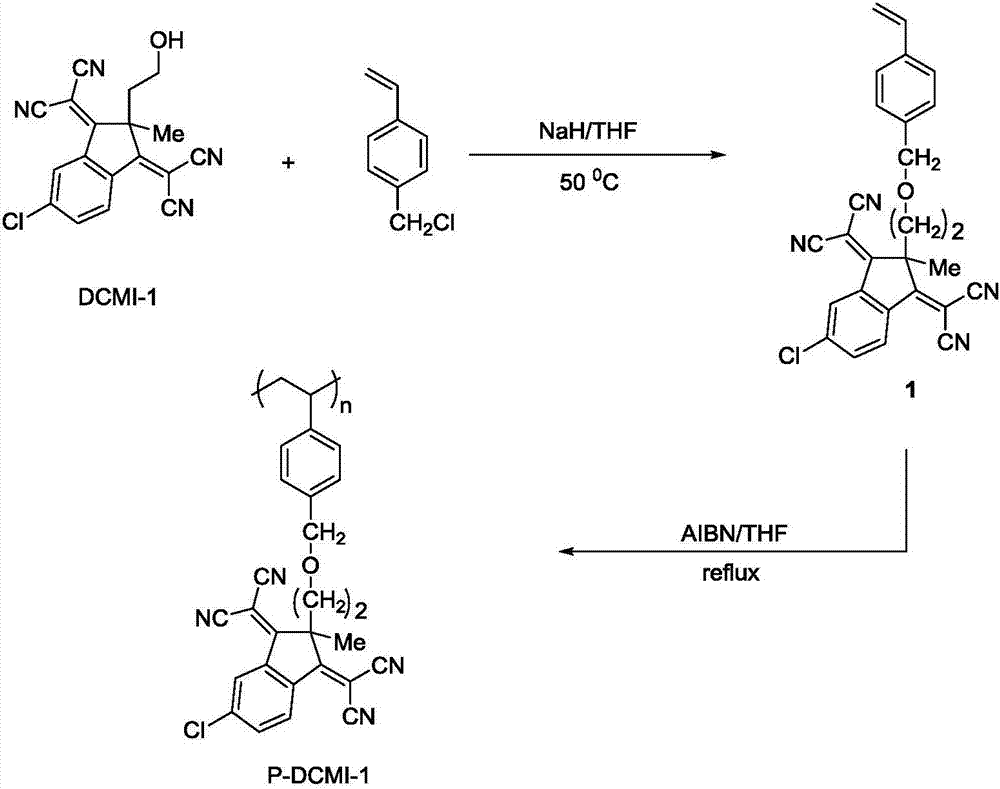

Polymer electron transport materials containing DCMI functional groups and application thereof

InactiveCN107417834AGood electron transport propertiesRestricted freedom of movementElectrography/magnetographyAlkaneSolubility

The invention relates to a class of polymer electron transport materials containing DCMI functional groups and applications thereof, belonging to the technical field of organic photoconductive drums. The polymer electron transport material described in the present invention has a polystyrene structure as the main chain and a DCMI structure as the side chain, and the side chains are grafted on the main chain through ether bonds, which not only maintains the excellent electron transport ability of the DCMI structure, but also The compatibility and crystallization resistance of this type of material with the film-forming resin are greatly improved; at the same time, due to the existence of a longer alkane main chain, the solubility of this type of material in organic solvents is increased. The polymer electron transport material described in the present invention is suitable for the preparation of positively charged organic photoconductive drums of laser printers, and effectively overcomes the disadvantages of poor processability and easy separation from resin film layers of DCMI small molecule materials. Positively charged organic photoconductive drums have excellent photoelectric properties.

Owner:中船汉光科技股份有限公司

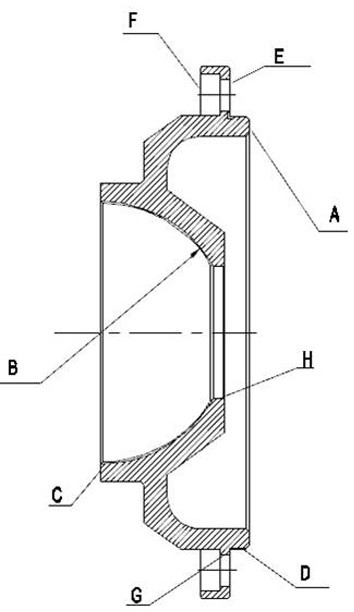

Electric lamp

An electric lamp, comprising: a light-permeable lamp chamber (1) sealed in a vacuum-tight manner, a space (3) for accommodating an electric element (4) sealed by a quartz glass wall (2), the electric element (4 ) is connected to a metal foil (6) completely embedded in the wall (2) via an inner current conductor (5) protruding from the wall (2) of the lamp vessel (1) into the space (3); and at least one outer current conductor (7) having a first end (9), a second end (10) and a diameter (11), said first end (9) being connected to the metal foil (6) and completely sealed in the lamp housing (1) In the wall (2), said second end (10) protrudes from the wall (2) to the outside; the fixed part includes the first end ( 9) Deformation region, characterized in that the deformation region of the fixing part comprises a bending region (12) at the first end (9), so that the lifetime of the current feed of the lamp is increased in terms of resistance to mechanical loads.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Preparation method and sealing process of sealing glass for high-temperature vibration acceleration sensor

ActiveCN114230181AGood seal matchingGood chemical stabilityGlass productionThermal dilatationVibration acceleration

The invention discloses a preparation method and a sealing process of sealing glass for a high-temperature vibration acceleration sensor, a SiO2-Al2O3-BaO-CaO system is selected, and the matching property of glass-metal sealing is changed by adding a metal oxide, carrying out controllable adjustment on glass components and improving the thermal expansion coefficient of the glass, so that the sealing performance of the glass-metal sealing is improved. Further, the high-temperature insulating property of the sealing glass is improved by adjusting the concentration of the components. According to the invention, the appearance of the sealing product is improved, the sealing process is simplified, and the consistency of the sealing product is high.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Anion acceptor type single ion conductor flame retardant gel polymer electrolyte and preparation method thereof

ActiveCN112164824BRestricted freedom of movementIncrease the number of transfersSolid electrolytesFibre typesUltraviolet lightsMercaptoacetic acid

The invention discloses a preparation method of an anion acceptor type single ion conductor flame-retardant gel polymer electrolyte, which comprises the following steps: (1) allyl borate pinacol, trimethylolpropane triacrylate, Pentaerythritol tetramercaptoacetate, propylene carbonate and benzoin dimethyl ether were stirred and mixed evenly until completely dissolved to obtain solution A; (2) solution A obtained in step (1) was dropped onto the electrospun PVDF membrane to infiltrate evenly, and transferred Under ultraviolet light, an ultraviolet photopolymerization reaction occurs to obtain an anion acceptor type single ion conductor flame retardant gel polymer film; (3) the anion acceptor type single ion conductor flame retardant gel polymer film obtained in step (2) is placed After soaking completely in the electrolyte mixture, the anion acceptor type single ion conductor flame retardant gel polymer electrolyte is obtained. The invention also provides the anion acceptor type single ion conductor flame retardant gel polymer electrolyte prepared by the preparation method.

Owner:WUYI UNIV

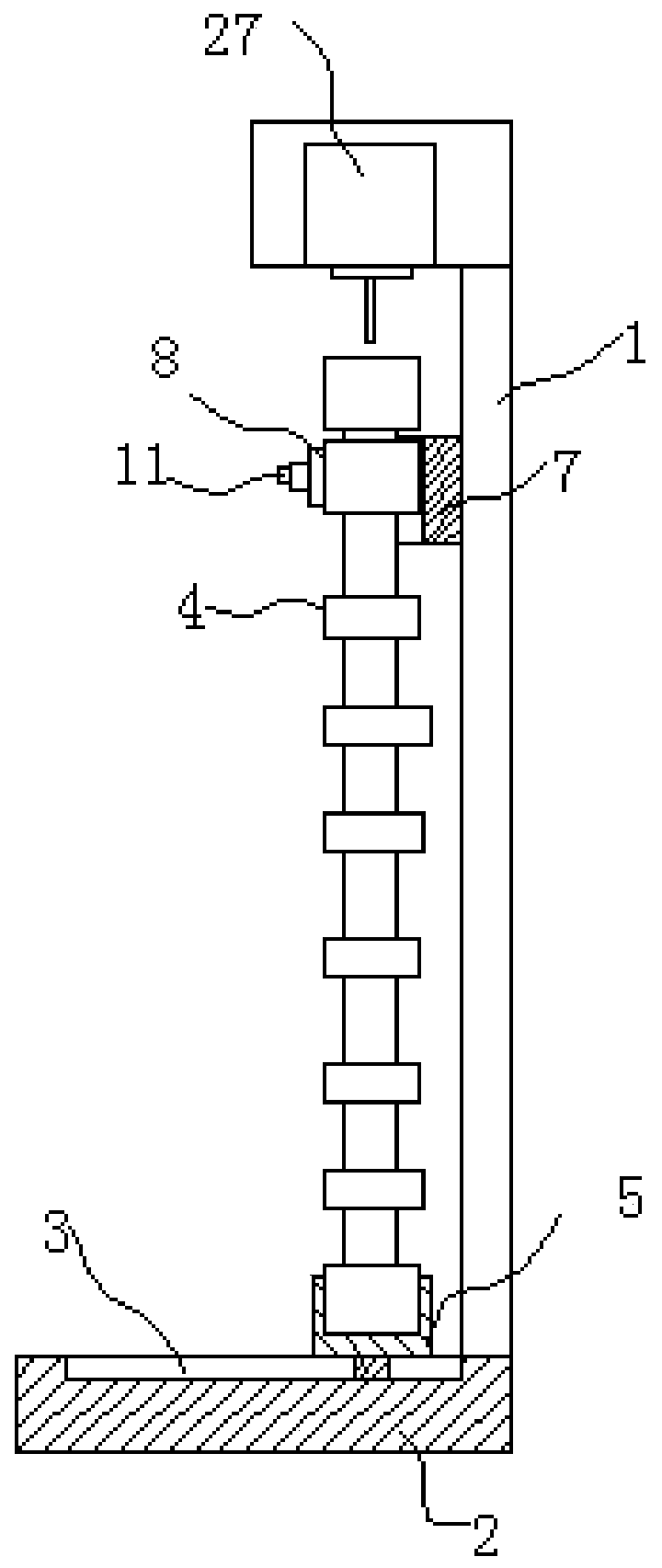

Camshaft drilling device

PendingCN109732121ARestricted freedom of movementAvoid positioning interferencePositioning apparatusMetal-working holdersCamEngineering

The invention discloses a camshaft drilling device. The camshaft drilling device comprises a rack, wherein a base is fixedly installed at the lower end of the rack, a guide groove which extends transversely or longitudinally is formed in the upper surface of the base, a positioning sleeve which sleeves the lower end of the cam shaft is movably installed in the guide groove, and the inner peripheral surface of the positioning sleeve is close to the outer peripheral surface of a camshaft and is in clearance fit with the lower end of the camshaft; a cam shaft positioning device located above thepositioning sleeve is further arranged on the rack, and a drilling device which is positioned above the upper end of the cam shaft is further arranged on the rack; the camshaft positioning device is located above the positioning sleeve to fix the camshaft and the rack together, the lower end of the cam shaft is inserted into the positioning sleeve, the positioning sleeve can move along the guide groove, the position of the positioning sleeve can be adjusted relative to the guide groove so that free movement of the lower end of the cam shaft can be limited; and meanwhile, positioning interference is avoided.

Owner:SHENGRUI TRANSMISSION

Multifunctional treating agent for natural gas hydrate drilling fluid in sea area as well as preparation method and application of multifunctional treating agent

The invention provides a multifunctional treating agent for natural gas hydrate drilling fluid in sea areas as well as a preparation method and application of the multifunctional treating agent. The multifunctional treating agent disclosed by the invention is prepared from the following raw materials in parts by mass: 0.1 to 10 parts of modified cellulose, 2 to 8 parts of dimethyl diallyl ammonium chloride (DMDAAC), 10 to 20 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 0.02 to 0.08 part of an initiator, the modified cellulose is cellulose modified by dimethoxy methyl vinyl silane. The multifunctional treating agent for the natural gas hydrate drilling fluid can effectively inhibit hydrate decomposition, improve the low-temperature filtration property of the drilling fluid, improve the stability of a hydrate reservoir and a wellbore and guarantee safe and smooth proceeding of hydrate drilling engineering; and the paint has salt resistance, and is environment-friendly and safe.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com