Complex frame positioning assembling jig

A technology for assembling fixtures and frames, which is applied in the field of fixtures, can solve the problems of difficult assembly and docking, complex and irregular main frame of the printer, and difficult operation, and achieve the effect of convenient positioning and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

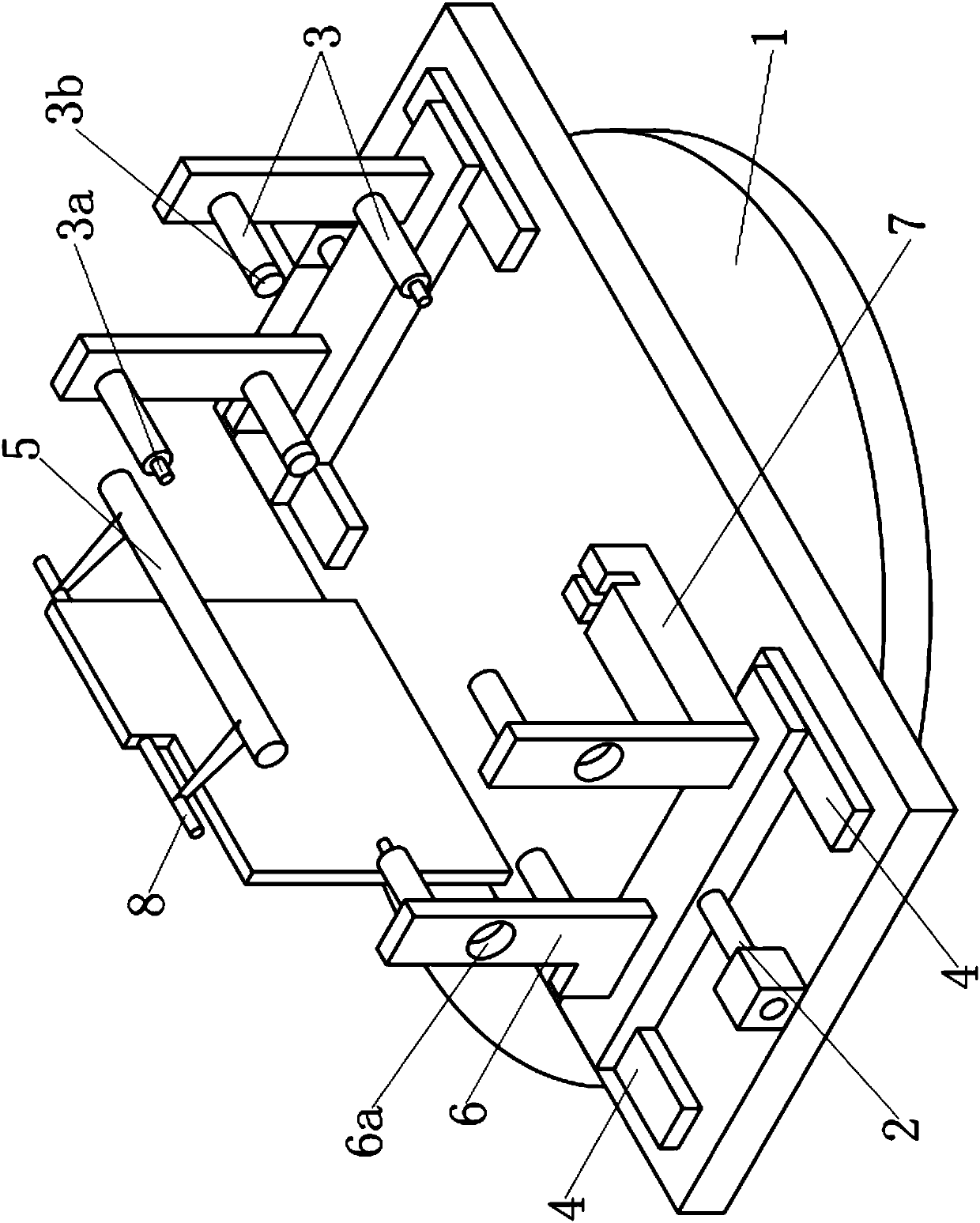

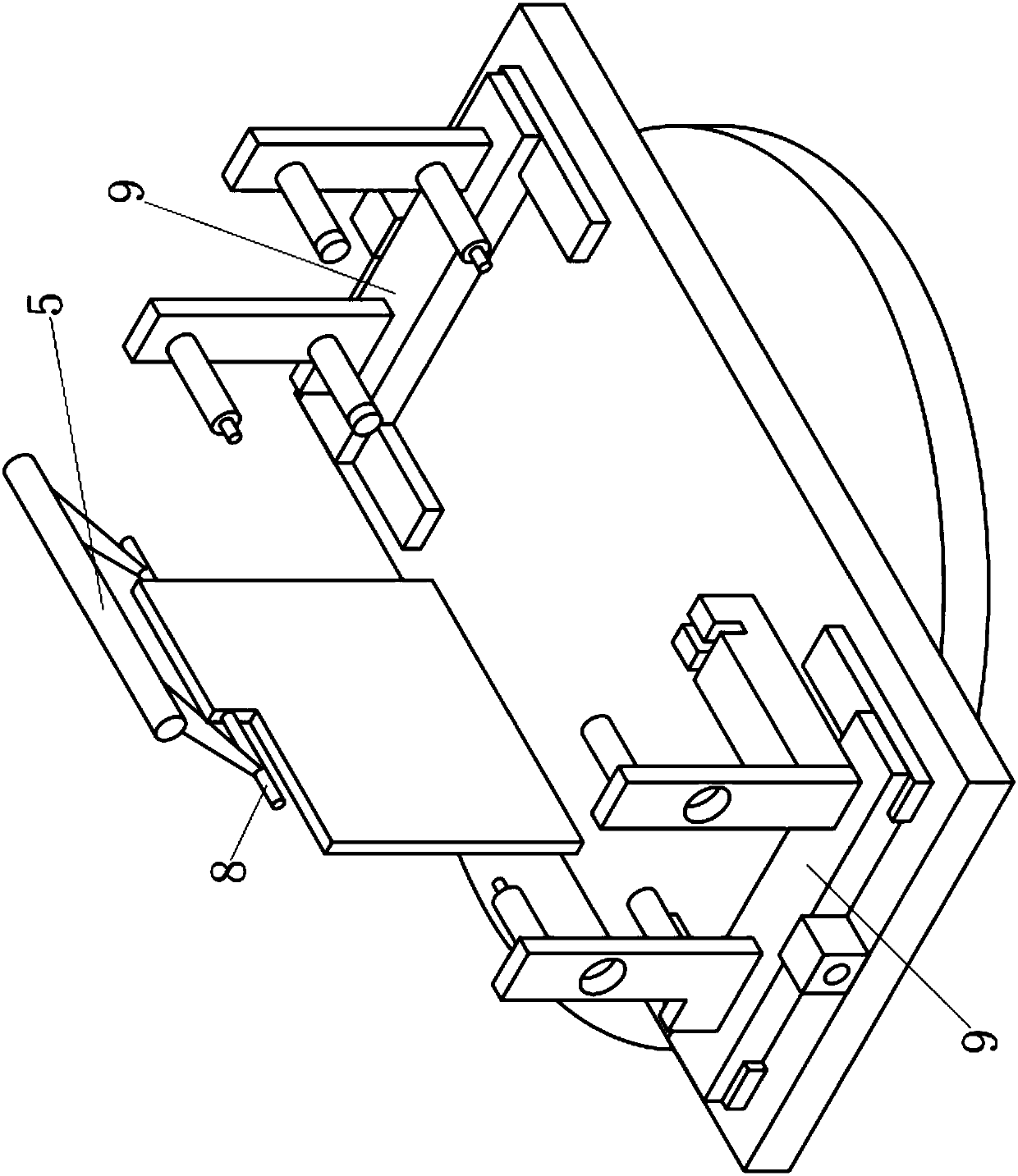

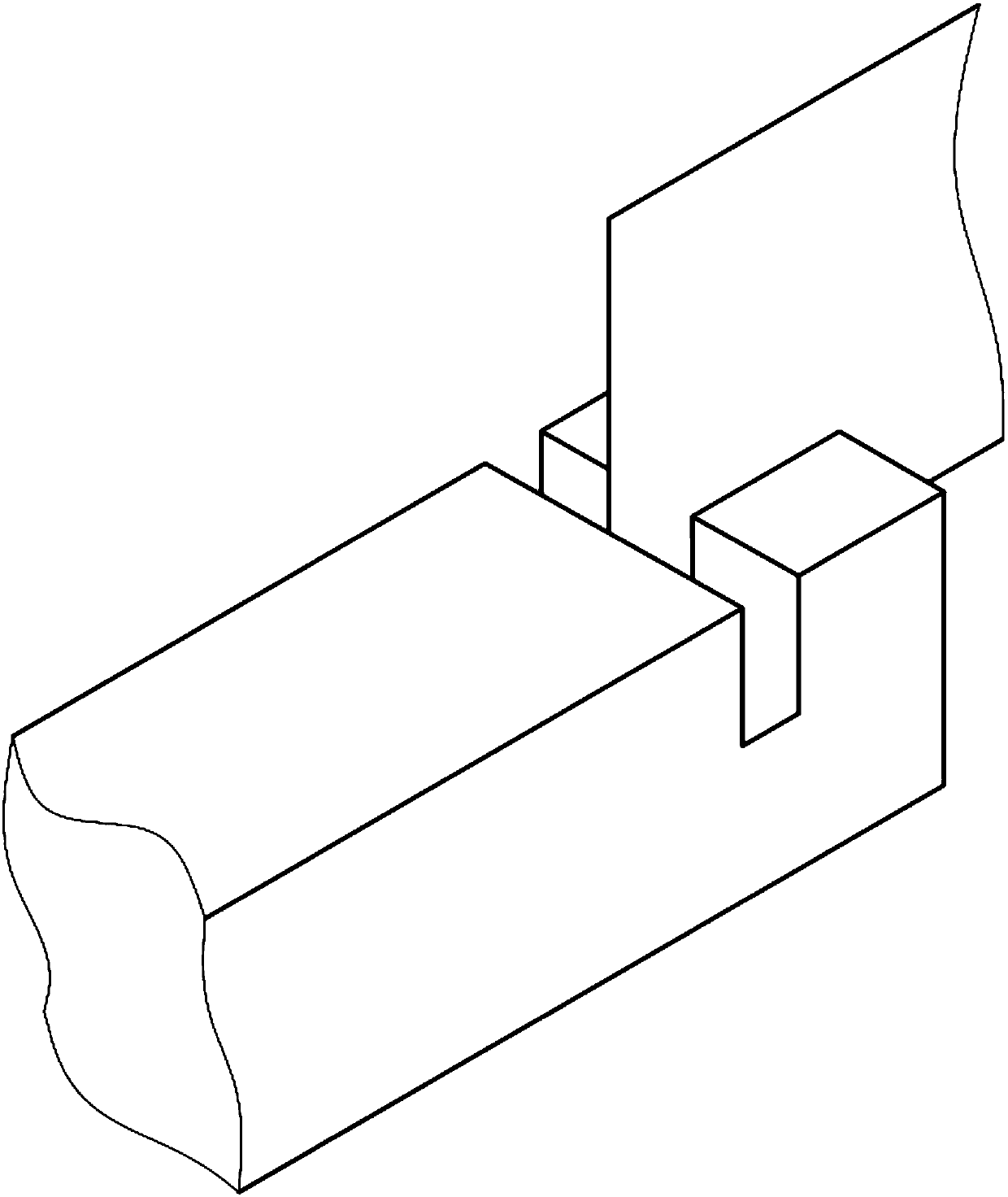

[0038] In order to achieve the purpose of the present invention, a complex frame positioning and assembly jig includes: several positioning columns 3 are arranged horizontally, and the positioning columns 3 approach each other along the axial direction of the positioning columns 3 to limit and fix the complex frame; slide rails 4 drive and position The columns 3 are close to or far away from each other; the movable rod 5 presses and limits the complex frame from top to bottom; the turntable 1 is set at the bottom of the complex frame positioning assembly jig, so that the complex frame positioning assembly jig has the freedom of rotation in the horizontal plane Spend.

[0039] The beneficial effect of adopting the above-mentioned technical solution is that the positioning column can fasten the complicated frame and at the same time precisely position it. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com