Multifunctional treating agent for natural gas hydrate drilling fluid in sea area as well as preparation method and application of multifunctional treating agent

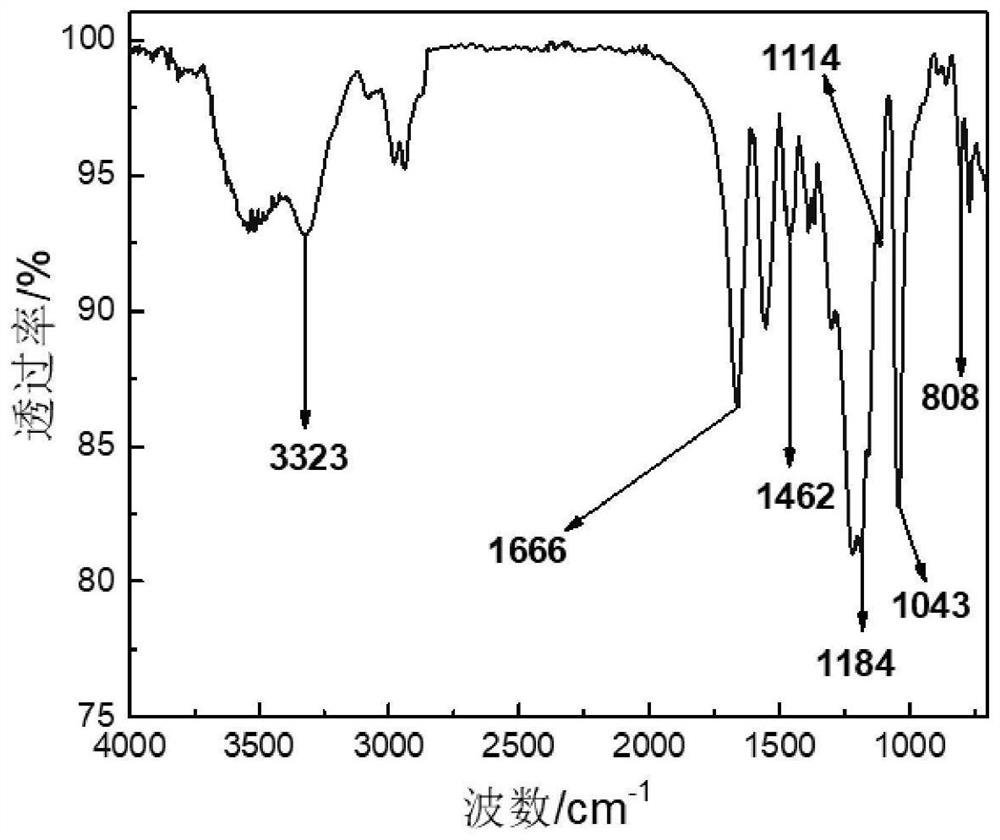

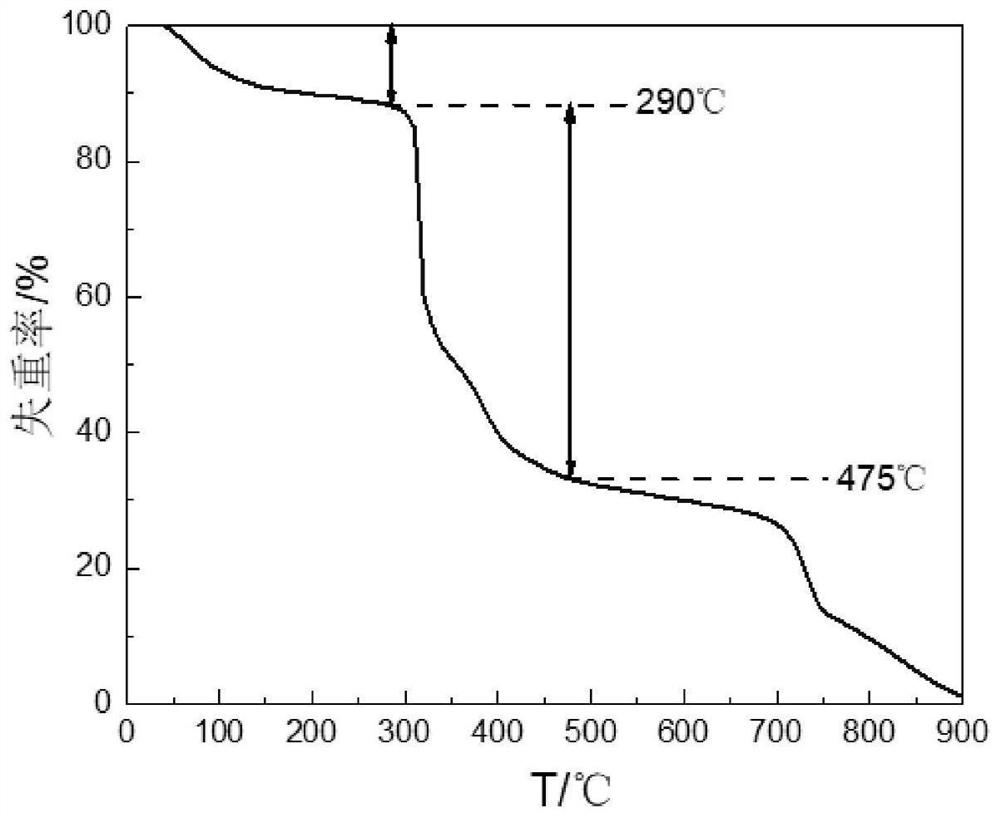

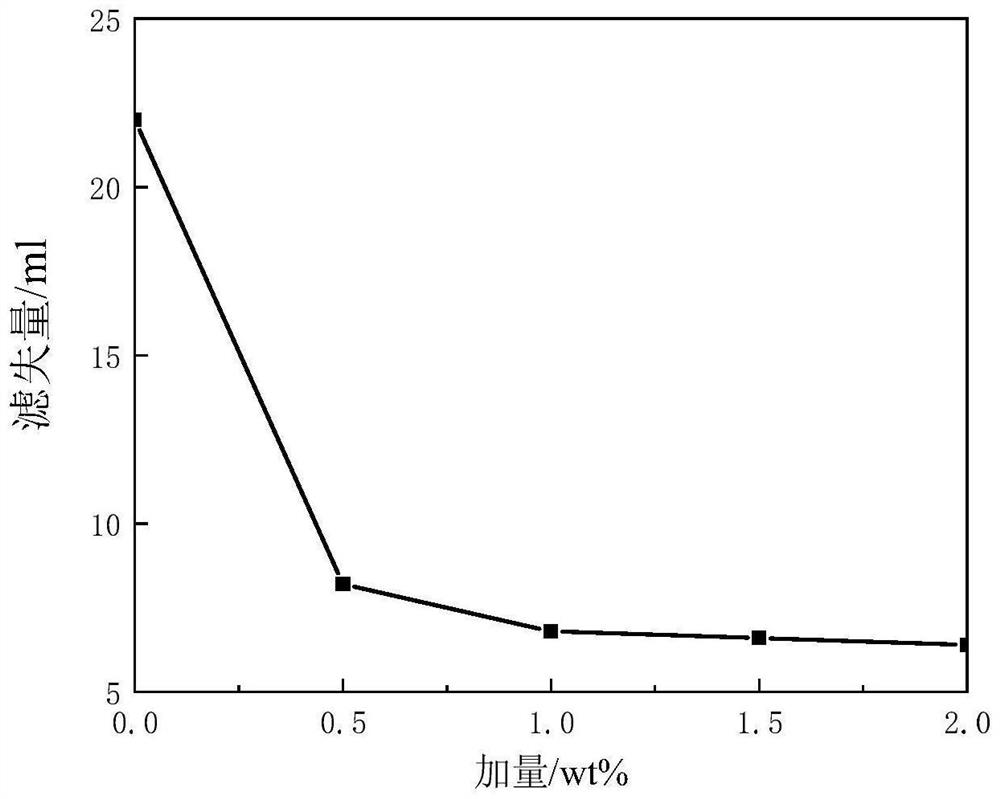

A technology for natural gas and drilling fluid, which is applied in the field of water-based drilling fluid organic additives for natural gas hydrate drilling in offshore areas, can solve the problems of poor filtration reduction and inhibition of natural gas hydrate decomposition, high toxicity of N-vinylpyrrolidone, and no environmental protection. requirements and other issues, to achieve the effect of excellent fluid loss reduction performance, excellent salt resistance performance, and improved hydrophilic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A multifunctional treatment agent for marine natural gas hydrate drilling fluid, prepared from the following raw materials: 1 g of modified cellulose, 3.10 g of dimethyl diallyl ammonium chloride (DMDAAC), 2-acrylamido-2- Methylpropanesulfonic acid (AMPS) 15.90g, initiator: ammonium persulfate 0.04g, sodium hydrogen sulfite 0.02g.

[0048] The preparation method of the modified cellulose comprises the steps:

[0049] (1) Mix 0.06 g of dimethoxymethyl vinyl silane with 6 g of distilled water uniformly, and hydrolyze for 1-2 min at room temperature to obtain a coupling agent solution. Then mix and disperse with an aqueous solution (mass concentration of 10 g / mL) containing 6 g of cellulose (weight-average molecular weight of 162.06 g / mol), and adjust pH to 4 with glacial acetic acid to obtain a synthetic solution;

[0050] (2) After placing the above synthetic solution in a three-necked flask equipped with a condenser and a mechanical stirring device, the modified cellul...

Embodiment 2

[0057] A multifunctional treatment agent for marine natural gas hydrate drilling fluid, prepared from the following raw materials: 3 g of modified cellulose, 4 g of dimethyl diallyl ammonium chloride (DMDAAC), 2-acrylamido-2-methyl 14 g of methyl propanesulfonic acid (AMPS), initiator: 0.02 g of ammonium persulfate, 0.02 g of sodium hydrogen sulfite.

[0058] The preparation method of the modified cellulose is the same as that in Example 1.

[0059] The preparation method of the above-mentioned multifunctional treatment agent for natural gas hydrate drilling fluid in the sea area comprises the following steps:

[0060] (1) Prepare 3 g of modified cellulose prepared as described above, 14 g of 2-acrylamido-2-methylpropanesulfonic acid and 4 g of dimethyldiallyl ammonium chloride and mix with 80 g of distilled water, magnetically at room temperature Stir evenly, and use a 30% NaOH aqueous solution to adjust the pH to 7 to obtain a mixed solution.

[0061] (2) A three-necked fl...

experiment example 3

[0063] A multifunctional treatment agent for marine natural gas hydrate drilling fluid, prepared from the following raw materials: 2 g of modified cellulose, 3.10 g of dimethyl diallyl ammonium chloride (DMDAAC), 2-acrylamido-2- Methylpropanesulfonic acid (AMPS) 15.90g, initiator: ammonium persulfate 0.02g, sodium hydrogen sulfite 0.02g.

[0064] The preparation method of the modified cellulose is the same as that in Example 1.

[0065] The preparation method of the above-mentioned multifunctional treatment agent for natural gas hydrate drilling fluid in the sea area comprises the following steps:

[0066] (1) Prepare 2 g of the modified cellulose prepared as described above, 15.90 g of 2-acrylamido-2-methylpropanesulfonic acid and 3.10 g of dimethyldiallyl ammonium chloride, mixed with 80 g of distilled water, at room temperature Under magnetic stirring, the pH was adjusted to 7 by using an aqueous NaOH solution with a mass concentration of 30% to obtain a mixed solution.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com