Patents

Literature

79results about How to "Improve filtration loss reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of synthetic base drilling fluid

The invention discloses a preparation method of a synthetic base drilling fluid. The preparation method comprises the steps of a. adding 2.0%-4.0% of organic soil, 3.0%-5.0% of main emulsifier, 2.0%-4.0% of auxiliary emulsifier, 0.1%-0.2% of wetting agent, 0.5%-2.0% of flow pattern conditioning agent and 2.0%-3.0% of CaO to 60-70% of synthetic base in percent by weight under a stirring condition, and stirring for 30min; b. preparing a CaCl2 solution with the mass concentration of 20%, and enabling CaCl2 to completely dissolve; c. slowly adding 10%-15% of CaCl2 aqueous solution in percent by weight to the synthetic base under a stirring condition; and d. adding 4.0%-6.0% of filtrate-loss reducer and 2.0%-3.0% of anti-sloughing blocking agent in percent by weight to the synthetic base under a stirring condition to form the synthetic base drilling fluid. The preparation method is simple in processing steps and easy in operation. The synthetic base drilling fluid prepared by the method has the characteristics of strong anti-sloughing inhibition capability, good salt and calcium erosion resistance performance and obvious lubrication performance.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

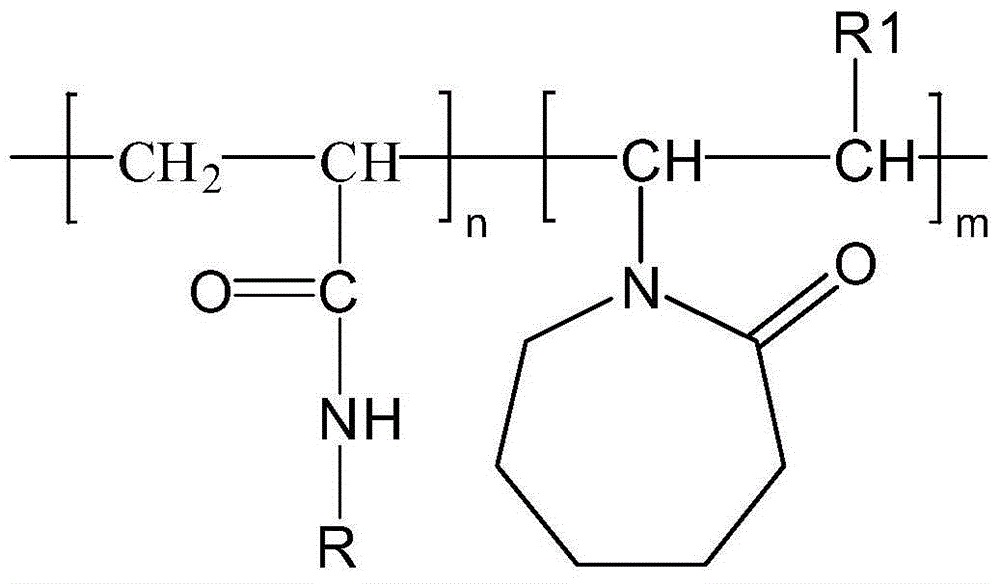

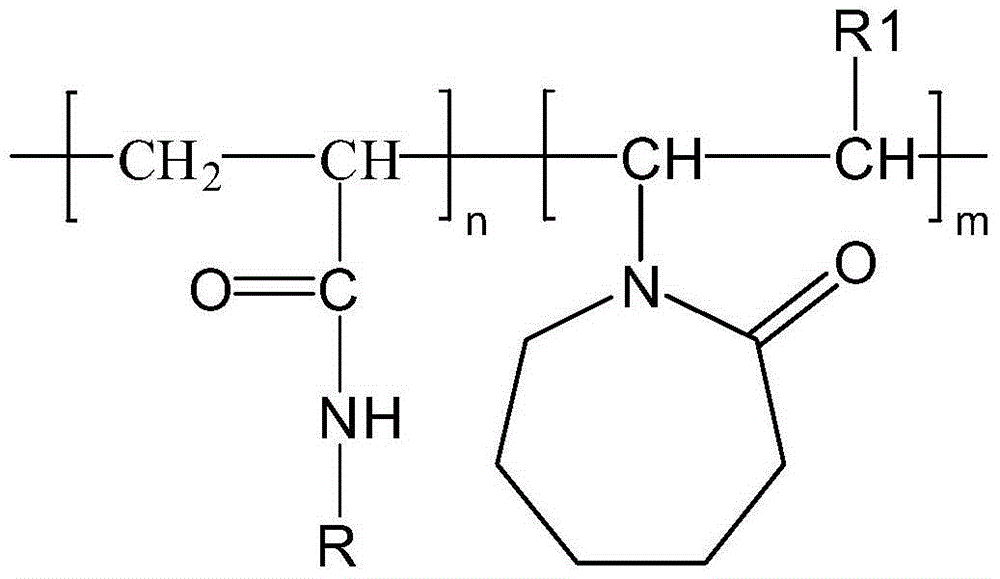

Drilling fluid filtrate reducer with natural gas hydrate inhibiting effect

InactiveCN104449600AEnhanced inhibitory effectImprove filtration loss reduction effectDrilling compositionReducerInhibitory effect

The invention relates to a copolymer of N-substituted acrylamide and N-vinyl caprolactam serving as a drilling fluid filtrate reducer with hydrate inhibition performance. The copolymer is made from vinyl acrylamide and N-alkyl caprolactam and is applied to a hydrate inhibitor and a filtrate reducer in the drilling fluid. The copolymer has the average molecular weight of 10000-2000000, the polymerization unit ratio is 0.1-10, the use mass concentration is 0.5-3 percent, and the use pressure is between 1MPa and 30MPa. According to the novel treatment agent disclosed by the invention, a natural gas hydrate inhibitor is combined with a filtrate reducer in a drilling fluid treatment agent, two functions are realized by virtue of one treatment agent, the cost of the drilling fluid is reduced, and the stability of the drilling fluid is guaranteed under the condition that the hydrate inhibition performance and filtrate loss reduction performance are improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

White asphalt for drilling fluid and method for preparing white asphalt for drilling fluid

ActiveCN103013461AGood sealing of cracksEasy to reverseDrilling compositionAlkylphenolPolyacrylamide

The invention discloses white asphalt for drilling fluid and a method for preparing the white asphalt for drilling fluid. The white asphalt is prepared from the following raw materials in parts by weight: 40 parts-50 parts of paraffin, 1 part-2 parts of alkylphenol polyoxyethylene ether, 4 parts-5 parts of polyethylene glycol, 4 parts-5 parts of polyacrylamide, 20 parts-30 parts of stearic acid and 20 parts-30 parts of light calcium carbonate. The method for preparing the white asphalt comprises the following steps: adding the paraffin, alkylphenol polyoxyethylene ether, polyethylene glycol and stearic acid into a reactor proportionally; raising the temperature of the reactor to 70 DEG C-100 DEG C, and then stirring for 20-40 minutes at constant temperature; adding polyacrylamide to be stirred for 30 minutes at constant temperature; and finally, uniformly adding light calcium carbonate to be stirred for 0.5-2 hours at constant temperature and then discharging, and carrying out spray granulation to obtain the white asphalt. The white asphalt does not damage a hydrocarbon reservoir, has good lubricating performance and prevents collapse and blockage, filtration can be effectively reduced, the capacity of oil-gas wells is improved, and the technical problems of easily generated loss, collapse and the like during a drilling process when stratums with complicated conditions are drilled are solved.

Owner:河北华运鸿业化工有限公司

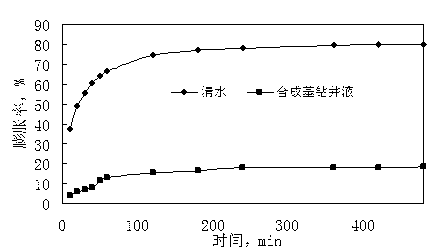

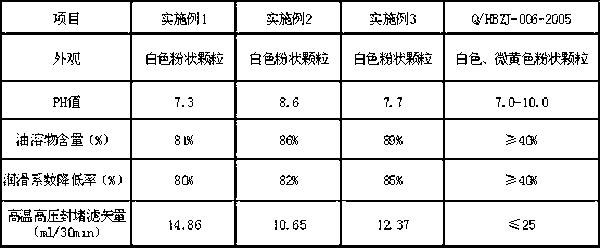

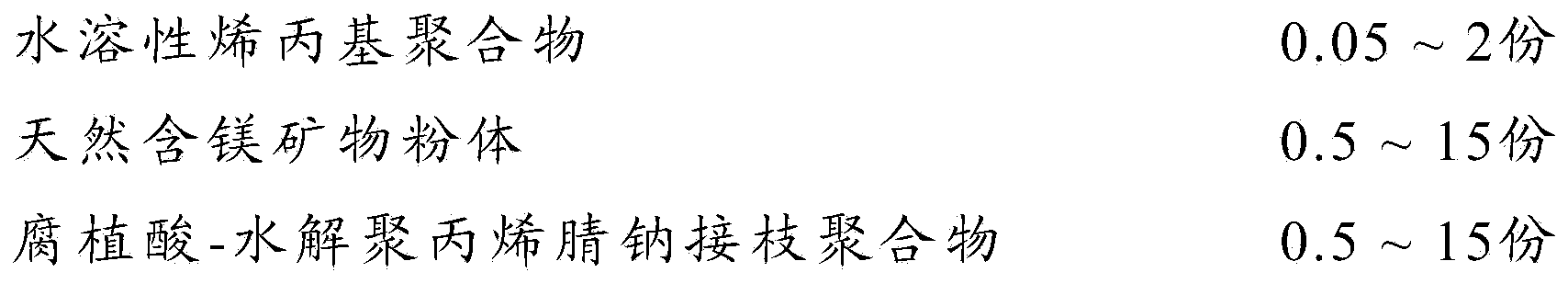

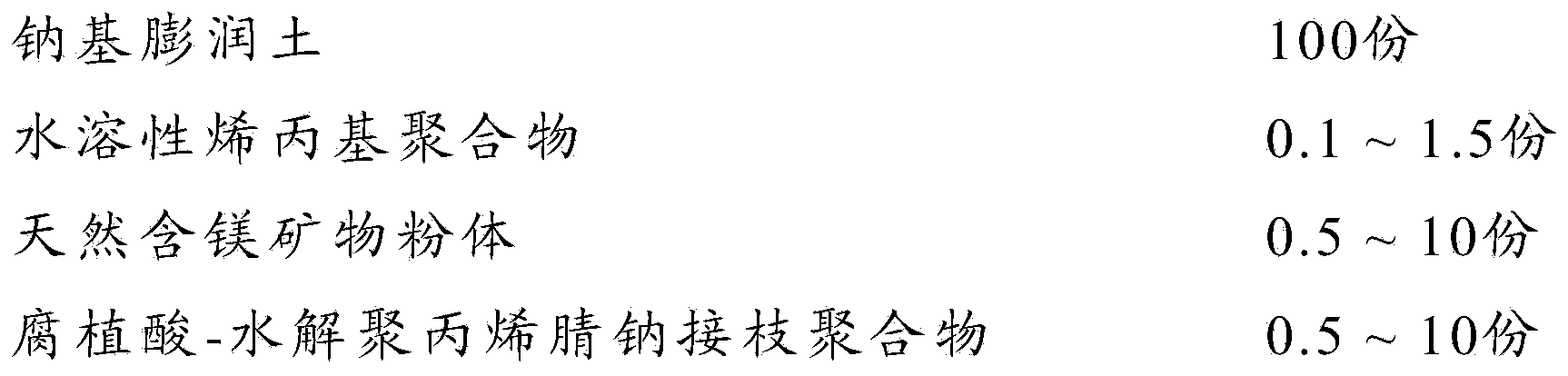

Thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and preparation method thereof

ActiveCN103525384AHigh pulping rateViscosity increase efficiencyDrilling compositionFiltrationWell drilling

The invention discloses thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and a preparation method of the thixotropy bentonite slurry. The thixotropy bentonite slurry is modified by a modifying agent comprising a water-soluble allyl polymer, natural magnesium containing mineral powder and a humid acid-hydrolysis sodium polyacrylonitrile graft polymer. The preparation method of the thixotropy bentonite slurry comprises the following steps: preparing sodium bentonite, preparing bentonite-based slurry, preparing the modifying agent and finally preparing the modified bentonite. The mud-making rate, the viscosity increasing efficiency and the de-filtration effect of the bentonite prepared by the method provided by the invention are greatly improved, and the modifying effect of the bentonite is far superior to that of bentonite modified by using a single modifying agent.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

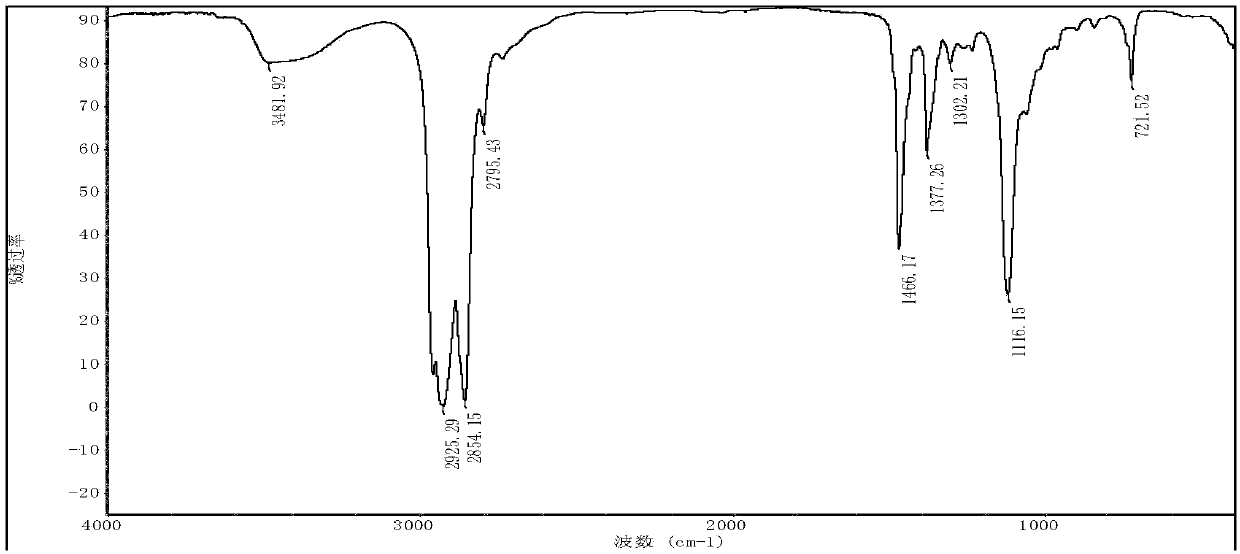

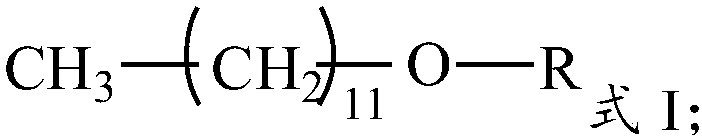

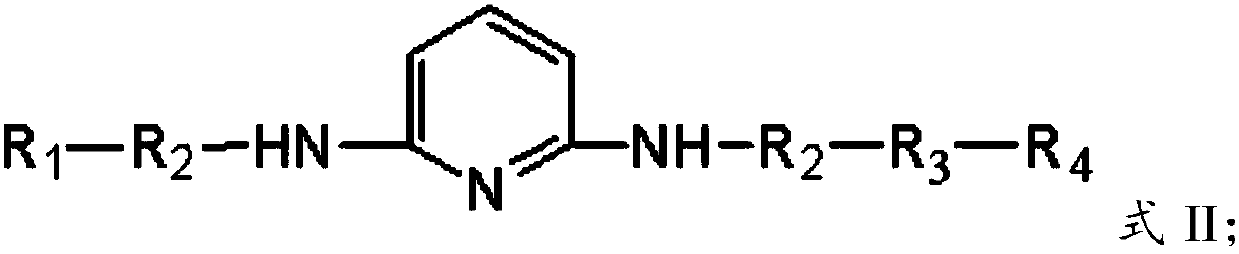

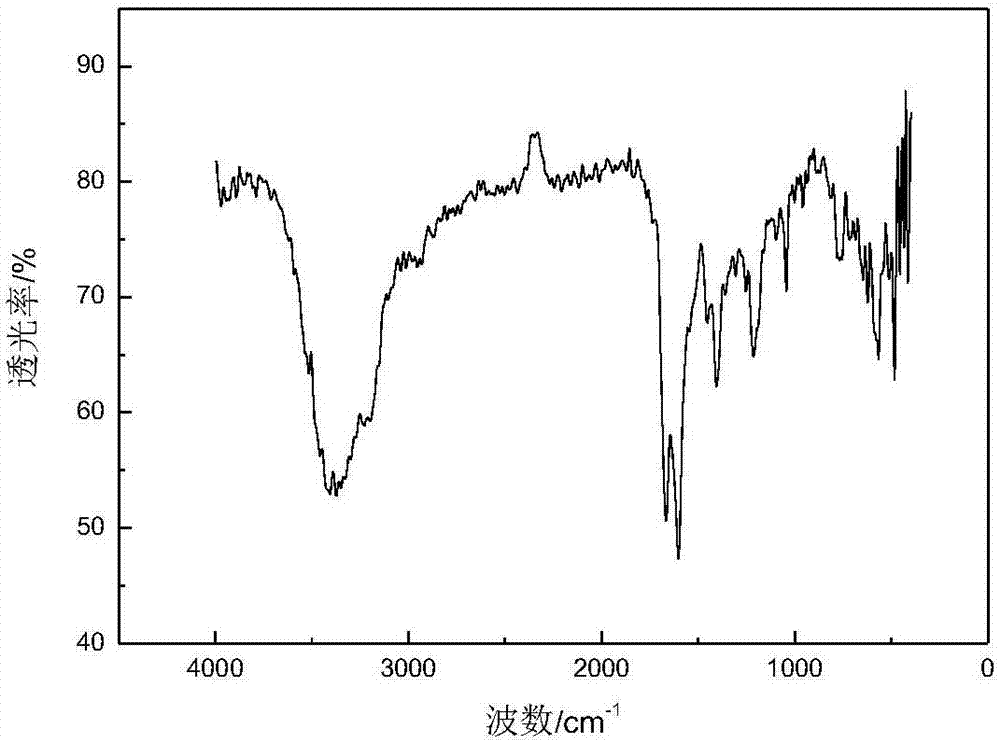

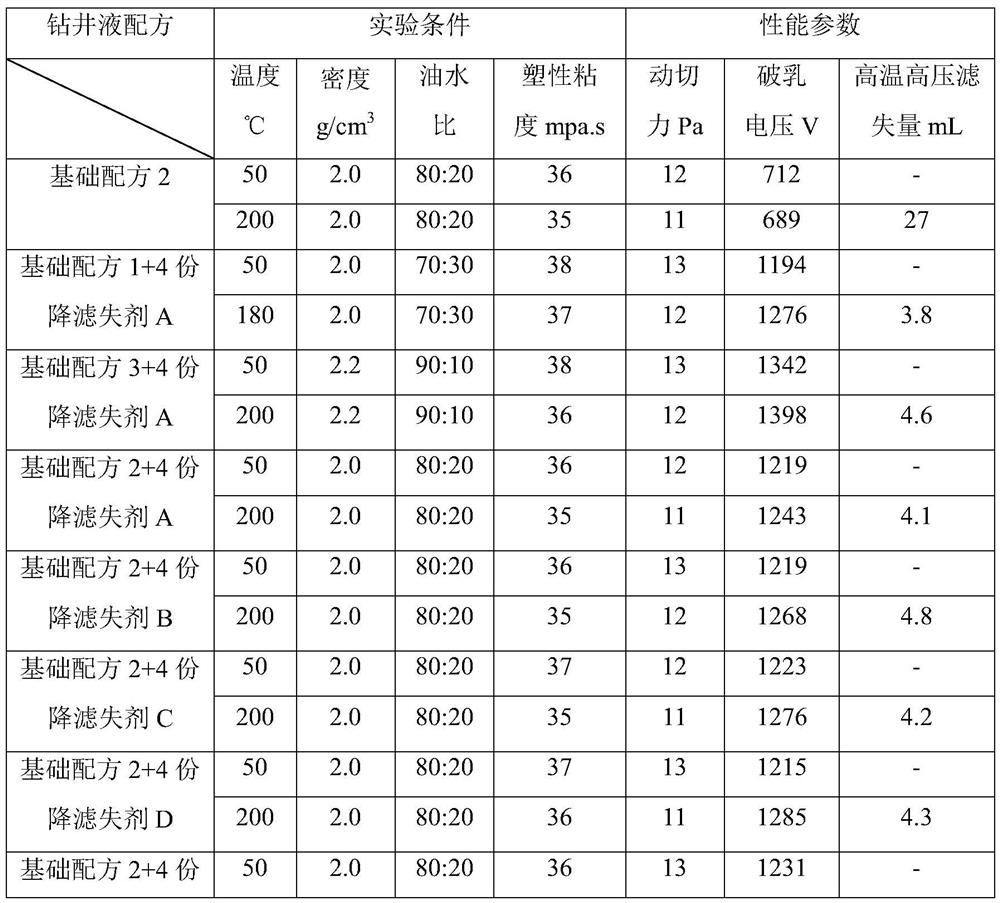

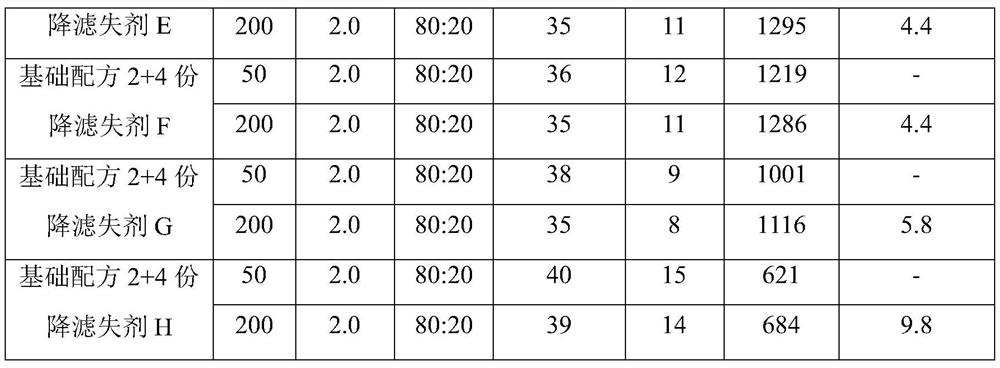

Oil-based drilling fluid filtrate reducer containing cross-linked structure, and preparation method

ActiveCN103184036AEnhanced plugging and wall building performanceImprove filtration loss reduction effectDrilling compositionOrganic acidChemistry

The invention provides an oil-based drilling fluid filtrate reducer containing a cross-linked structure, and a preparation method. the method is carried out according to the following steps: (1) adding 0.1-30 parts by mass of a long-chain alkyl fatty acid and 1 part by mass of a polyene polyamine into a reaction vessel, stirring uniformly, driving oxygen for 20-30 min with nitrogen, heating to a temperature of 80-160 DEG C and reacting for 15 min-8 h; (2) cooling a temperature of the system to 75-85 DEG C, adding 0.5-25 parts by mass of a humic acid, stirring uniformly, driving the oxygen for 20-30 min with the nitrogen, heating to a temperature of 90-180 DEG C and reacting for 15 min-10 h; (3) adding 0.005-5 parts by mass of a binary or multiple organic acid, stirring uniformly and reacting for 15 min-16 h at a temperature of 100-200 DEG C; and (4) cooling a product obtained by the step (3) to a room temperature, smashing the product, and screening with a 50-100 mesh sieve to obtain the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling fluid filtrate reducer and preparation method thereof

InactiveCN106634875AImprove filtration loss reduction effectImprove densification performanceDrilling compositionLow speedNanoparticle

The present invention provides a drilling fluid filtrate reducer, which contains, by weight, 30-70 parts of an oil phase, 10-30 parts of a nonionic surfactant, and 20-50 parts of a nanometer silica and nanometer calcium carbonate water dispersion. The invention further provides a preparation method of the drilling fluid filtrate reducer, wherein the preparation method comprises: mixing a nonionic surfactant and an oil phase according to a certain ratio, carrying out high speed stirring for 10-30 min at a temperature of 20-40 DEG C with a magnetic stirrer, gradually adding a nanometer silica and nanometer calcium carbonate water dispersion under low speed stirring, and carrying out high speed stirring for 10-30 min to obtain the drilling fluid filtrate reducer. According to the present invention, the pore and the micro-crack are blocked by using the nanoparticles, the formed filter cake is relatively compact, the quality of the filter cake can be improved, the filtrate reducing of the drilling fluid can be reduced, the stability of the borehole wall can be improved, and the good oil and gas layer protection effect is provided.

Owner:中石化石油工程技术服务有限公司 +2

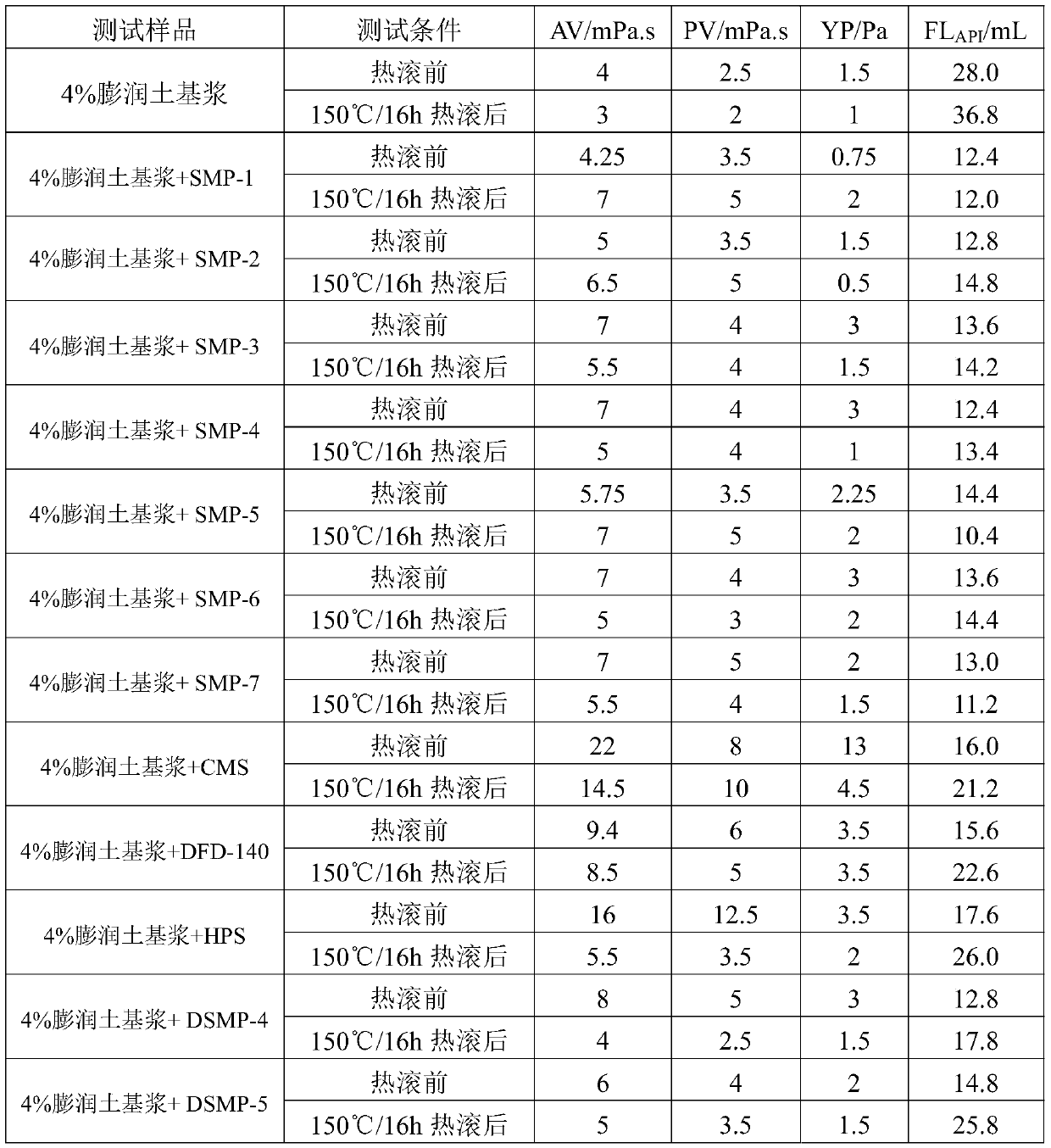

Filtrate reducer and preparation method thereof, and water-based drilling fluid and application thereof

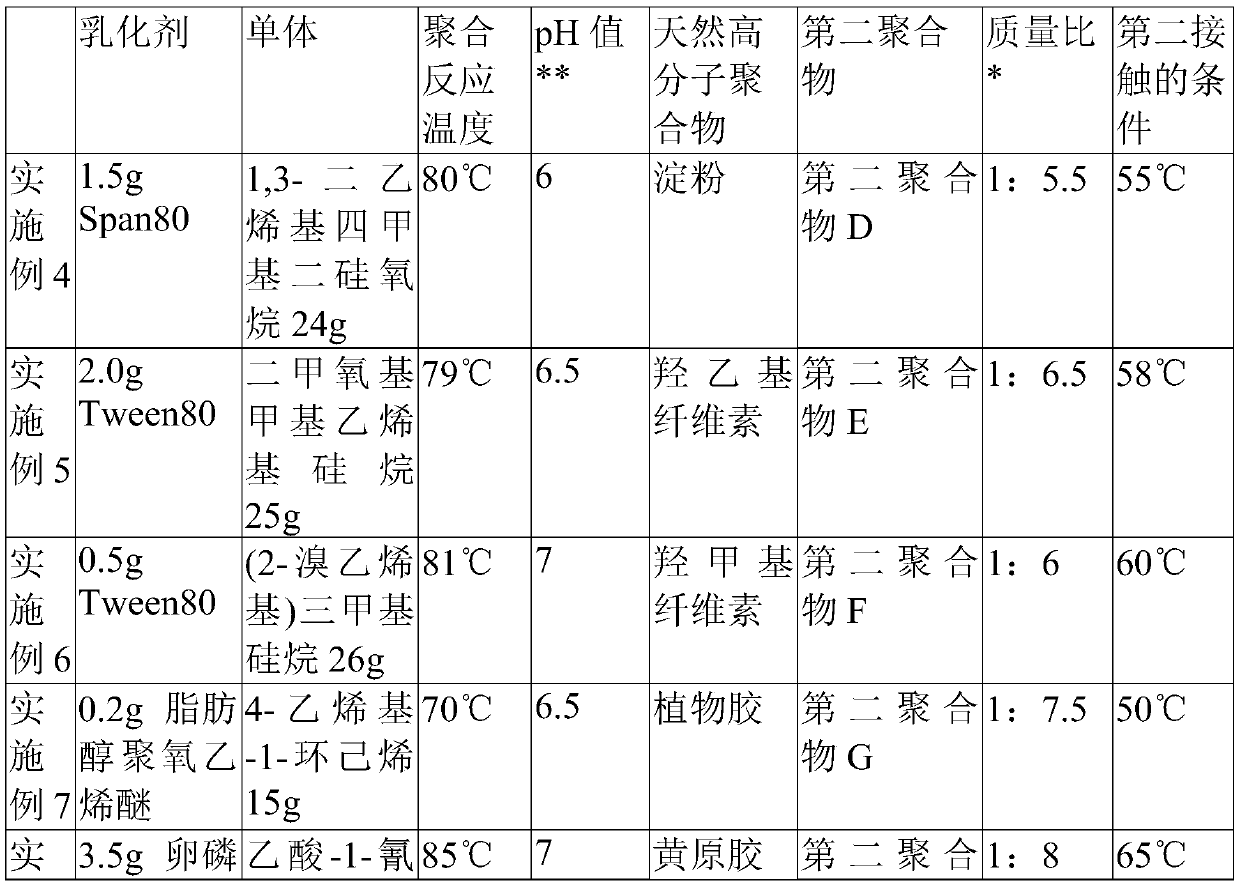

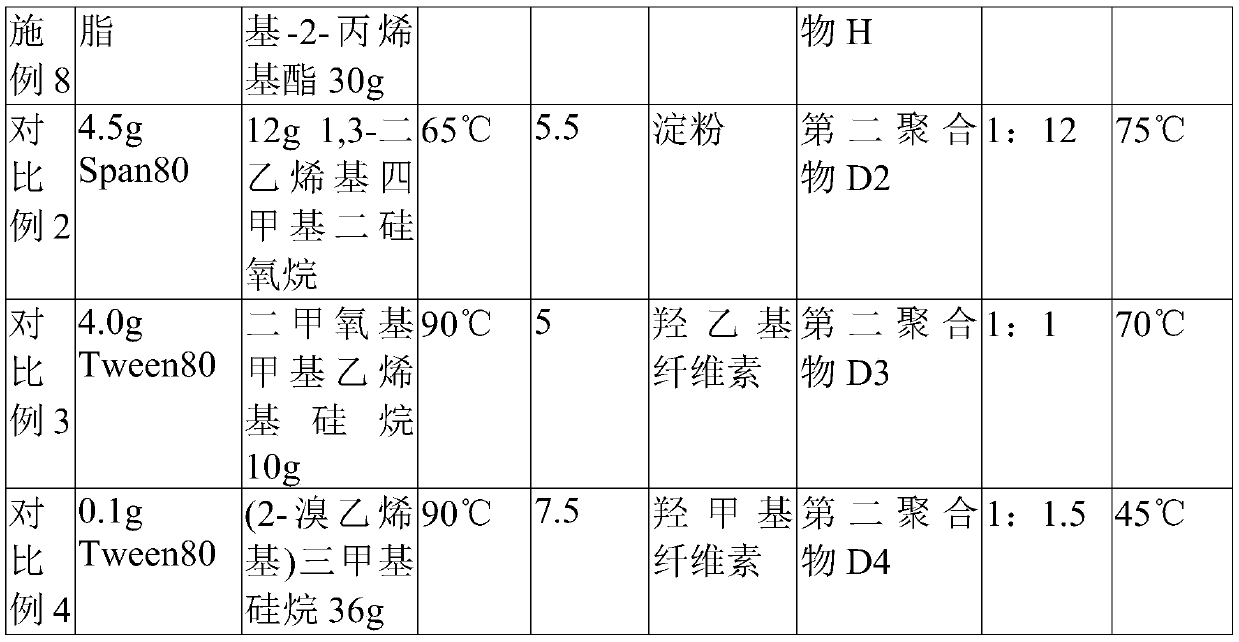

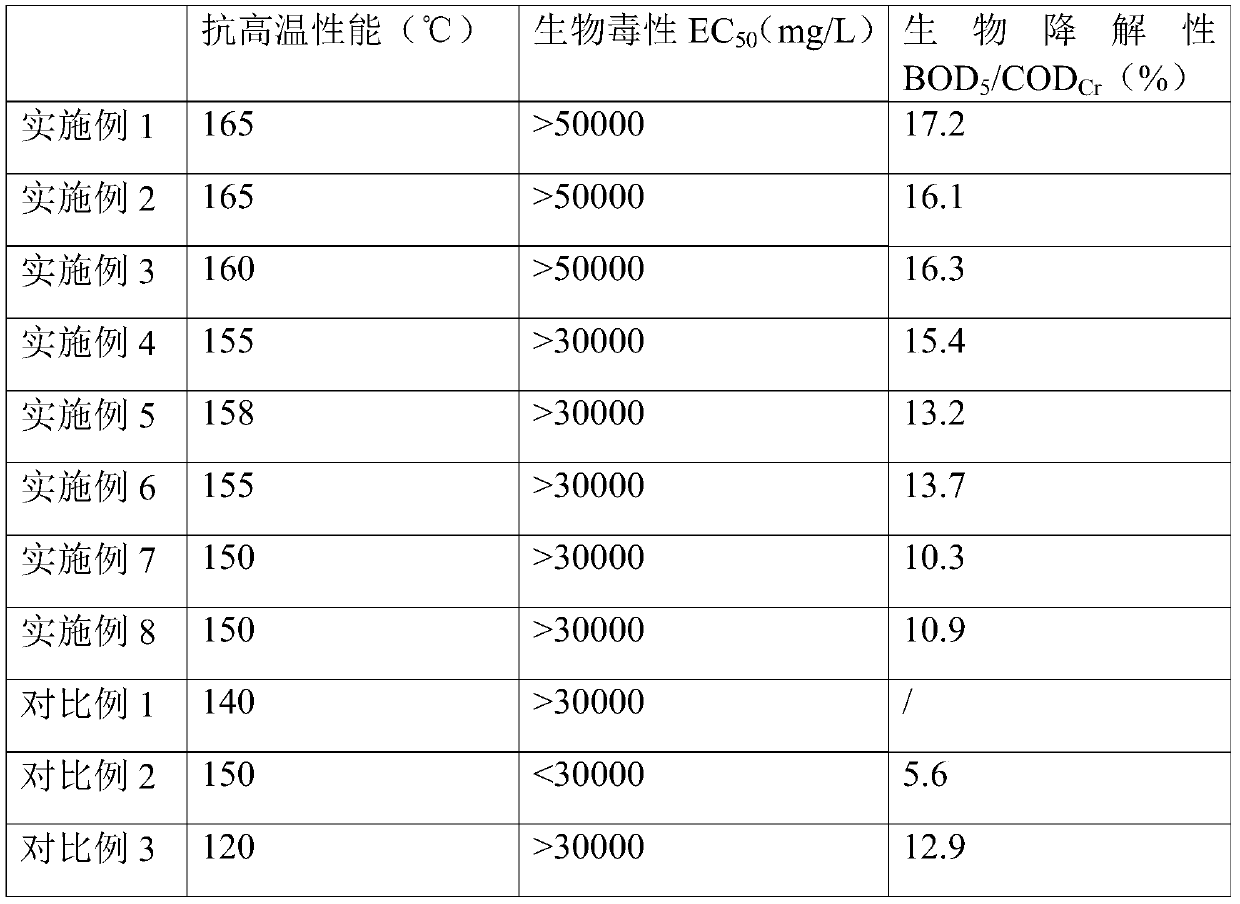

The invention relates to the technical field of oil exploitation, and discloses a filtrate reducer and a preparation method thereof, and a water-based drilling fluid and application thereof. The filtrate reducer comprises a first polymer and a second polymer, wherein the first polymer is a natural high-molecular polymer; the second polymer is prepared by carrying out a polymerization reaction on an emulsifier and a monomer in the presence of an initiator; and the monomer is one or more selected from a group consisting of methyl-4-vinylbenzoate, dimethoxymethylvinylsilane, 1,3-divinyltetramethyldisiloxane, (2-bromovinyl)trimethylsilane, 4-vinyl-1-cyclohexene and acetic acid-1-cyano-2-propenyl ester. The water-based drilling fluid containing the filtrate reducer has salt resistance and high-temperature resistance, meets the requirement for the environmental protection properties of no toxicity and easy degradation, and also has tackifying and shear strength improving properties.

Owner:CHINA PETROCHEMICAL CORP +3

Nanometer starch microsphere filtrate reducer for water-based drilling fluid, preparation method thereof and water-based drilling fluid

ActiveCN109880602AImprove the blocking effectBiodegradableDrilling compositionWater basedStarch Microspheres

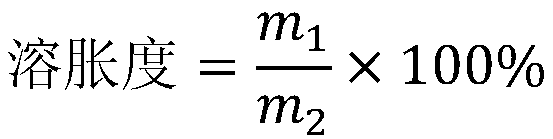

The invention relates to the field of petroleum engineering oilfield chemistry and discloses a nanometer starch microsphere filtrate reducer for a water-based drilling fluid, a preparation method thereof and the water-based drilling fluid. The nanometer starch microsphere filtrate reducer is prepared by dropwise adding a starch-containing alkaline solution into a continuous phase containing continuous phase oil and emulgator under the existence of cross-linking agent and initiator, reacting and centrifugally separating. The nanometer starch microsphere filtrate reducer is characterized by average grain diameter of 50-1000nm, swelling degree of 200-600%, total pore space volume of 0.5-4mL / g and capacity of resisting against temperature at 150 DEG C or above. According to the invention, thenanometer starch microsphere is used as a filtrate reducer, so that the leak-off of drilling fluid can be more effectively controlled, and meanwhile, temperature resistance can be obviously promoted,influence on viscosity of drilling fluid is smaller, and an excellent blocking effect to micropores and cracks on floor can be achieved. The nanometer starch microsphere has the advantages of biodegradability, environment-friendly property, extensive source and simple preparation process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

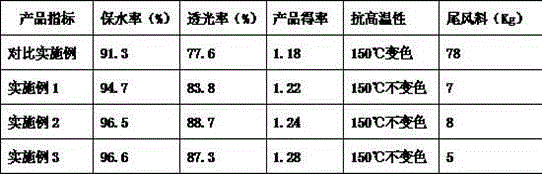

Preparation method of cellulose ether and cellulose ether obtained in same

ActiveCN105111317AHigh light transmittanceImprove water retentionPotassium persulfatePhysical chemistry

The invention provides a preparation method capable of improving various performances and especially a water retention rate and light transmittance of cellulose ether. The method comprises an alkalization step, an etherification step, a desolvation step, an acid regulation step and a posttreatment step of cellulose powder, wherein the acid regulation step is as follows: adding an acrylic acid / acrylamide mixed solution accounting for 1.0 to 3.5 percent by weight of the cellulose powder and initiator accounting for 0.1 to 0.13 percent by weight of the mixed solution, stirring for 10 to 40 minutes under the condition that the temperature is not lower than 90 DEG C, determining the pH value to be 5.5 to 8.5, and then discharging the material, wherein the acrylic acid / acrylamide mixed solution consists of acrylic acid and acrylamide in a mass ratio of (3 to 9): 1, and the initiator is potassium persulfate or ammonium persulfate. The preparation method is simple and easy, the problem of poor reaction at the etherification period can be overcome by utilizing the step for systematically adjusting the pH value, the cellulose ether obtained in the method hardly contains fibers and semi-cellulose ether, so that the light transmittance, water retention property and filtration reduction effect are obviously improved. The invention also provides cellulose ether obtained by the preparation method.

Owner:广东龙湖科技股份有限公司

Filtration reducing agent for drilling fluid and preparation method thereof

ActiveCN104031621AEnhanced fluid loss control performanceGood filter loss reduction effectDrilling compositionChemistrySodium metabisulfite

The invention discloses a filtration reducing agent for a drilling fluid and a preparation method thereof. The filtration reducing agent comprises the components in parts by weight: 200-250 parts of phenol, 50-60 parts of sodium chloroacetate, 50-60 parts of epoxy chloropropane, 380-430 parts of formaldehyde, 80-100 parts of sodium metabisulfite, 80-90 parts of anhydrous sodium sulfate, 65-78 parts of sodium hydroxide, 60-70 parts of trimethylamine, 36-45 of sodium 2-chloroethanesulfonate, 25-35 parts of carboxymethyl cellulose, 30-40 parts of acrylic amine, 28-40 parts of vinyl acetate, 30-36 parts of dimethyl diallyl ammonium chloride, and 800-1000 parts of water. The preparation method comprises the steps of firstly dissolving sodium hydroxide in water, adding phenol and sodium chloroacetate, carrying out a reaction, then adding epoxy chloropropane and trimethylamine, continuing to carry out a reaction, after the reaction, adding other components, successively carrying out reactions, and carrying out spray drying on the finally-obtained mixture to obtain the filtration reducing agent product.

Owner:新疆中经宏泰石油技术服务有限公司

Drilling fluid for drilling horizontal well by filling nitrogen

InactiveCN103320102AEasy to adjustImprove performanceDrilling compositionWell drillingHorizontal wells

The invention discloses a drilling fluid system for drilling a horizontal well by filling nitrogen, and relates to the technical field of drilling fluid systems for drilling horizontal wells by filling nitrogen. The drilling fluid system disclosed by the invention comprises the following components in parts by weight: 0.29-0.41 parts of thickening agent, 0.17-0.23 parts of fluid loss agent, 4.3-4.7 parts of anti-collapse agent, 1.65-1.95 parts of temporary plugging agent, 0.50-0.70 parts of lubricating agent, 0.12-0.18 parts of defoaming agent, 0.08-0.12 part of pH adjustor and 91.71-92.89 parts of water. The drilling fluid system disclosed by the invention is used in the horizontal well under-balance drilling operation by filling nitrogen in the Changqing oilfield in the Ordos basin is used, therefore, the well can be effectively purified; the well wall is kept steady under negative pressure conditions; hydrocarbon reservoirs are protected; the mechanical drilling speed is increased; furthermore, the drilling fluid system is wide in material source and is easy to operate; the field drilling construction is convenient.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Brown coal resin for drilling fluid and production technology of brown coal resin

InactiveCN108018028AImprove salt resistanceImprove high temperature resistanceDrilling compositionFiltrationSlurry

The invention discloses brown coal resin for a drilling fluid and a production technology of the brown coal resin. Brown coal and sulfonated phenolic resin are used as main materials, sulfonated phenol humic acid with excellent salt resistance and high-temperature resistance is introduced, and the brown coal resin has remarkable high-temperature-resistant, filtration loss reduction and salt-resistant performance after being modified with a basifier and a sulfonating agent and has anti-collapse and viscosity control effects. A small amount of carboxymethyl cellulose is added, and the carboxymethyl cellulose has excellent stability and still has significant performance at 150 DEG C or above; meanwhile, trimethylamine and sulfomethyl sodium humate with excellent temperature resistance, salt resistance and calcium and magnesium ion resistance are introduced, the adsorption capacity of sulfonated phenolic resin and clay is enhanced, the temperature resistance and the salt resistance of theproduct are effectively improved, the value of the product is increased, the addition amount is small, the filtration loss reduction effect is significant, and excellent filtration loss reduction performance can be produced after only 1.0% of base slurry is added.

Owner:YUMEN OIL FIELD KEDA CHEM

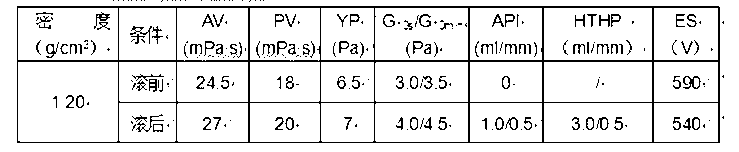

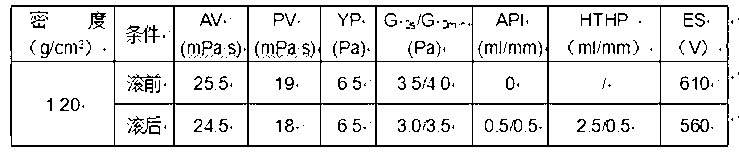

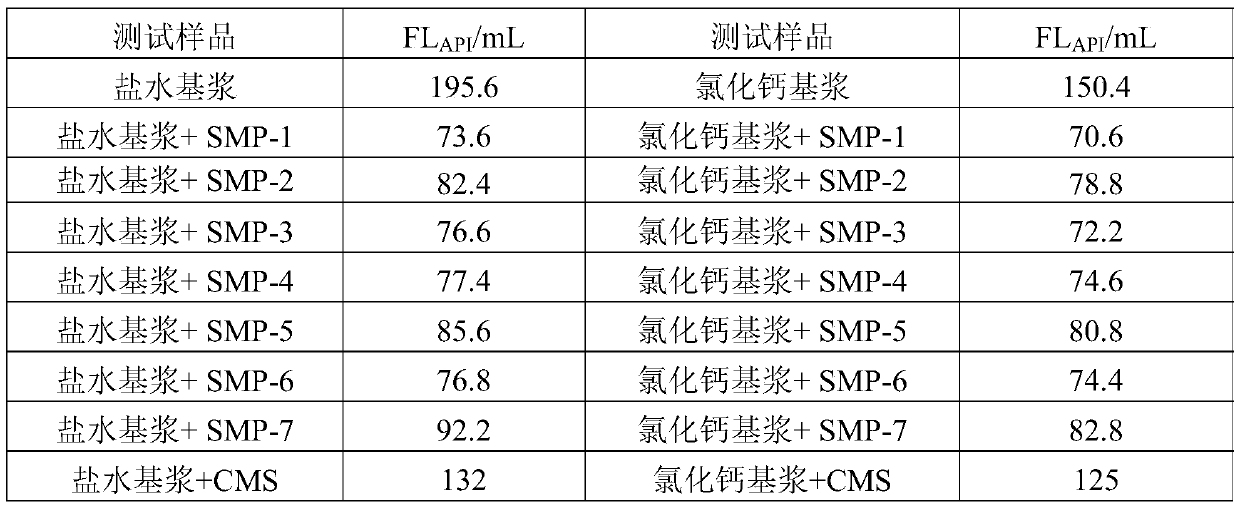

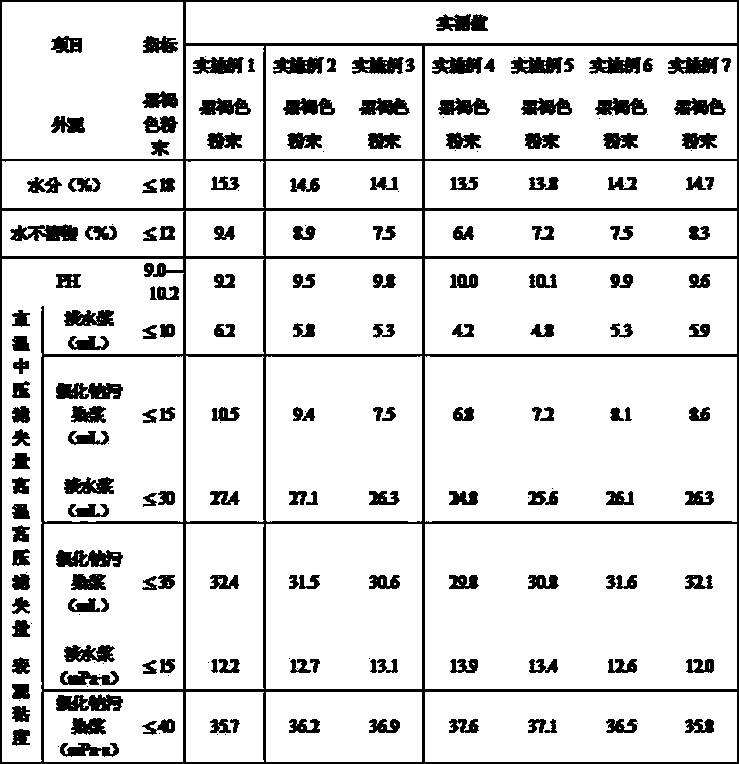

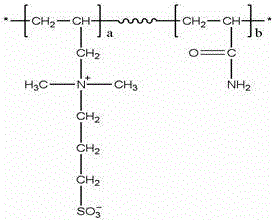

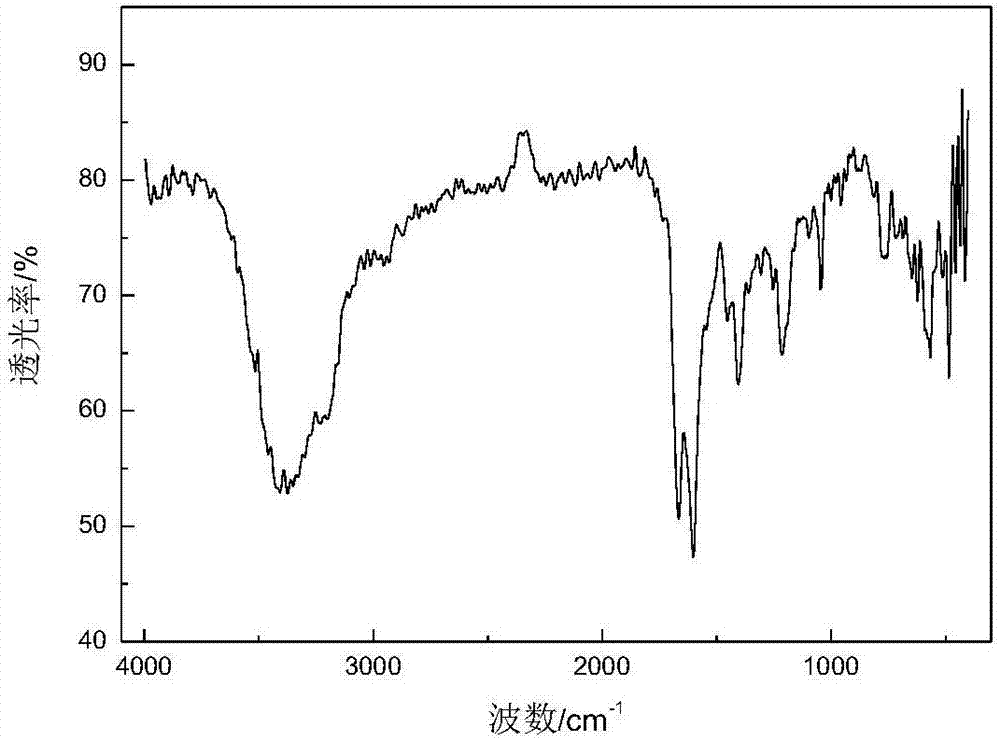

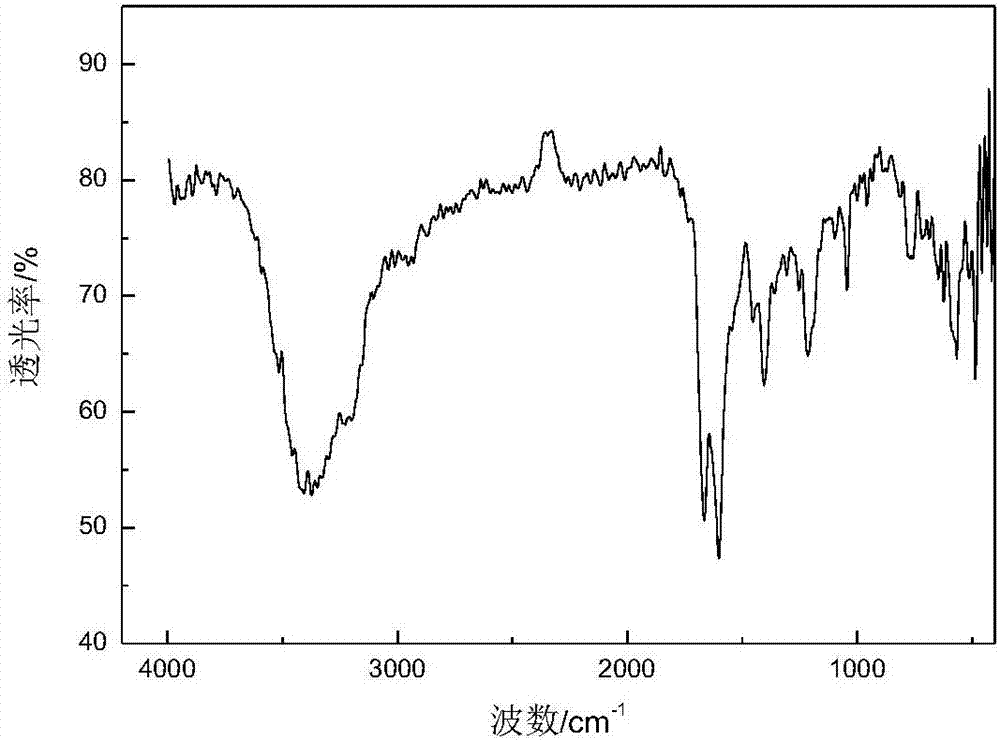

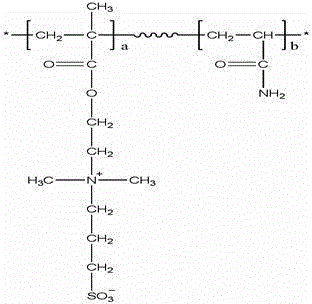

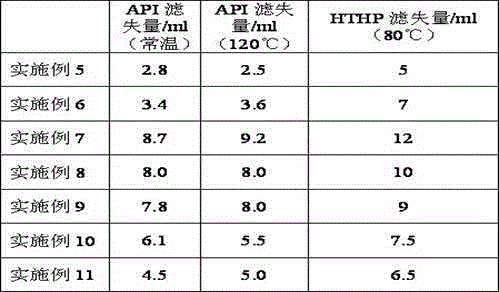

Strongly inhibitory water-based drilling fluid, preparation method therefor and application thereof

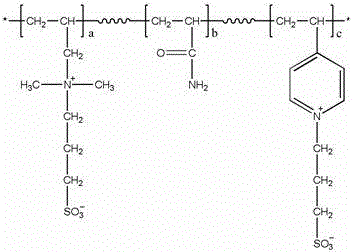

ActiveCN105086959AImprove the lubrication effectEnhanced inhibitory effectDrilling compositionWater basedFiltration

The invention provides a strongly inhibitory water-based drilling fluid, a preparation method therefor and application thereof. The drilling fluid comprises water, an amphoteric ionic polymer, anhydrous calcium chloride, a soil phase and a flow pattern modifier, wherein based on the water weight, the amphoteric ionic polymer accounts for 0.5-5 wt%, the anhydrous calcium chloride accounts for 20-70 wt%, the soil phase accounts for 0-6 wt% and the flow pattern modifier accounts for 0.1-0.4 wt%. The invention further provides a synthesis method for the water-based drilling fluid and application thereof. According to the drilling liquid provided by the invention, by virtue of a synergistic effect of the calcium chloride and the amphoteric ionic polymer, the drilling fluid has good rheological performance, filtration control performance, inhibition performance, sealing performance and lubricating performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Filtrate reducer preparation method

InactiveCN107418528AStrong filtration capacityImprove temperature resistanceDrilling compositionPetroleumAcrylic acid

The invention relates to a filtrate reducer preparation method and belongs to the field of petrochemical engineering. The filtrate reducer preparation method disclosed by the invention comprises the steps: firstly mixing, reacting and evaporating tannin and a sodium hydroxide solution to obtain dry matter; then mixing and heating substances of acrylic acid, sodium p-styrene sulfonate and the like, adding substances of the prepared dry matter and the like to react to obtain jelly and drying and smashing to obtain reactant; then mixing substances of aluminum potassium sulfate dodecahydrate, palmitic acid and the like to obtain a mixed solution and mixing and heating the mixed solution and the obtained reactant; dropwise adding an initiator to react, adding an obtained product into absolute ethyl alcohol to be separated out, filtering and drying and smashing filter residues to obtain a filtrate reducer. The temperature-resistance and salt-tolerance filtrate reducer prepared by the preparation method disclosed by the invention still has higher filtrate reduction performance under high-salinity environment and further has better temperature resistance.

Owner:石磊

Biomass synthetic base drilling fluid and preparation method thereof

InactiveCN109517587AImprove the lubrication effectGood compatibilityDrilling compositionBiomassChemistry

The invention provides biomass synthetic base drilling fluid and a preparation method thereof and belongs to the technical field of expansion of petroleum natural gas environment-friendly type synthetic base drilling fluid. The biomass synthetic base drilling fluid provided by the invention comprises biomass base fluid, a CaCl2 water solution, organic soil, an emulsifier, a wetting agent, a fluidloss agent, CaO and barite. The biomass base fluid, the emulsifier and the wetting agent have a cooperative agent; under the cooperative effect of all components in the drilling fluid, the biomass synthetic base drilling fluid provided by the invention has relatively good performance; and all the raw materials are green and environmentally friendly and have a relatively low price and good biodegradability, and the biomass synthetic base drilling fluid is novel green synthetic base drilling fluid.

Owner:SINOPEC SSC +1

Drilling fluid additive, preparation method thereof and drilling fluid

ActiveCN107987182AEnhanced inhibitory effectImprove cutting effectDrilling compositionAlcoholCarboxylic acid

The invention provides a drilling fluid additive. The drilling fluid additive comprises a structure shown as formula I, wherein in the formula I, a is 1200-3100, q is 1-10, p is 2-10, m is 1-16, n is1-5, o is 0-4, and M is an alkali metal element. The invention further provides a preparation method of the drilling fluid additive in the technical scheme. The preparation method comprises the following steps: (1) preparing a first intermediate product from chitosan, an alkali compound and an alcohol compound through a reaction; (2) preparing a second intermediate product from the first intermediate product and chlorocarboxylic acid through a reaction; (3) preparing a third intermediate product from the second intermediate product, a chloro monobasic alcohol compound, a chloro dibasic alcoholcompound and a chloroalkyl epoxide through a reaction; (4) preparing the drilling fluid additive from the third intermediate product and organic amine through a reaction. The drilling fluid additivehas good inhibition performance, shearing increasing performance and filter loss reducing performance.

Owner:SINOPEC SSC +1

Highly efficient water-based drilling fluid and synthesizing method and application therefor

ActiveCN105086961AEnhanced fluid loss control capacityStrong inhibitoryDrilling compositionChemistryDrilling fluid

The present invention provides a highly efficient water-based drilling fluid and a synthesizing method and application therefor. The drilling fluid comprises water, a zwitterion polymer, anhydrous calcium chloride, a soil phase and a flow pattern regulator, wherein, with the weight of the water as a reference, the weight of the zwitterion polymer is 0.5-5% of that of the water, the weight of the anhydrous calcium chloride is 20-70% of that of the water, the weight of the soil phase is 0-6% of that of the water and the weight of the flow pattern regulator is 0.1-0.4% of that of the water. The present invention further provides a synthesizing method and application for the water-based drilling fluid. According to the drilling water provided by the present invention, synergy between the calcium chloride and the zwitterion polymer enables the drilling fluid to have the excellent rheological property, filtration control property and inhibiting property, plugging property and lubricating property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water base drilling fluid, and preparation method and application thereof

ActiveCN105086958AImprove the lubrication effectEnhanced inhibitory effectDrilling compositionWater basedFiltration

The invention provides a water base drilling fluid, and a preparation method and application thereof. The drilling fluid comprises water, a zwitterionic polymer, anhydrous calcium chloride, a soil phase, and a flow pattern regulator, wherein, based on the weight of water, the usage amount of the zwitterionic polymer is 0.5 to 5 wt% of the usage amount of the water; the usage amount of the anhydrous calcium chloride is 20 to 70 wt% of the usage amount of the water; the usage amount of the soil phase is 0 to 6 wt% of the usage amount of the water; and the usage amount of the flow pattern regulator is 0.1 to 0.4 wt% of the usage amount of the water. The invention also provides a preparation method and application for the water base drilling fluid. According to the invention, through synergistic effects of the calcium chloride and the zwitterionic polymer, the water base drilling fluid in the invention has excellent rheological performance, filtration loss control performance, inhibition performance, sealing performance and lubrication performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

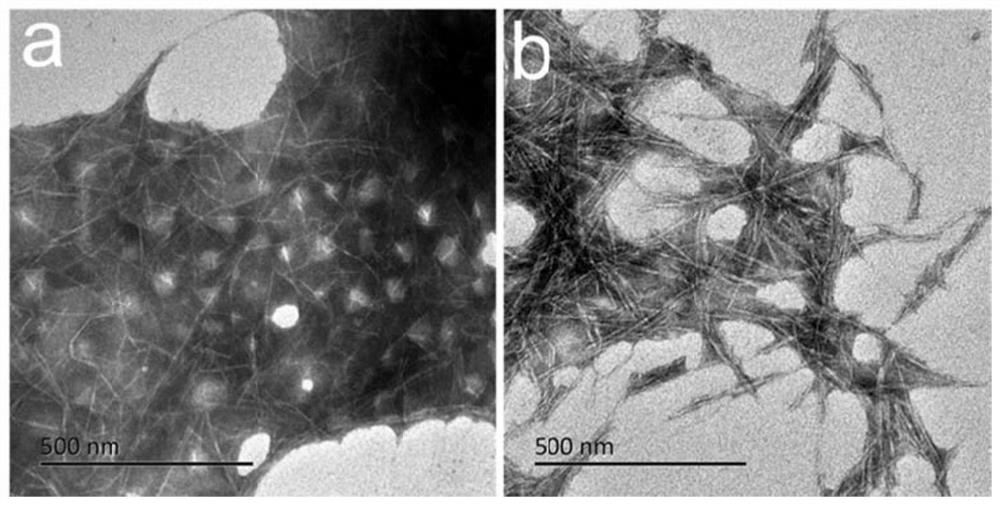

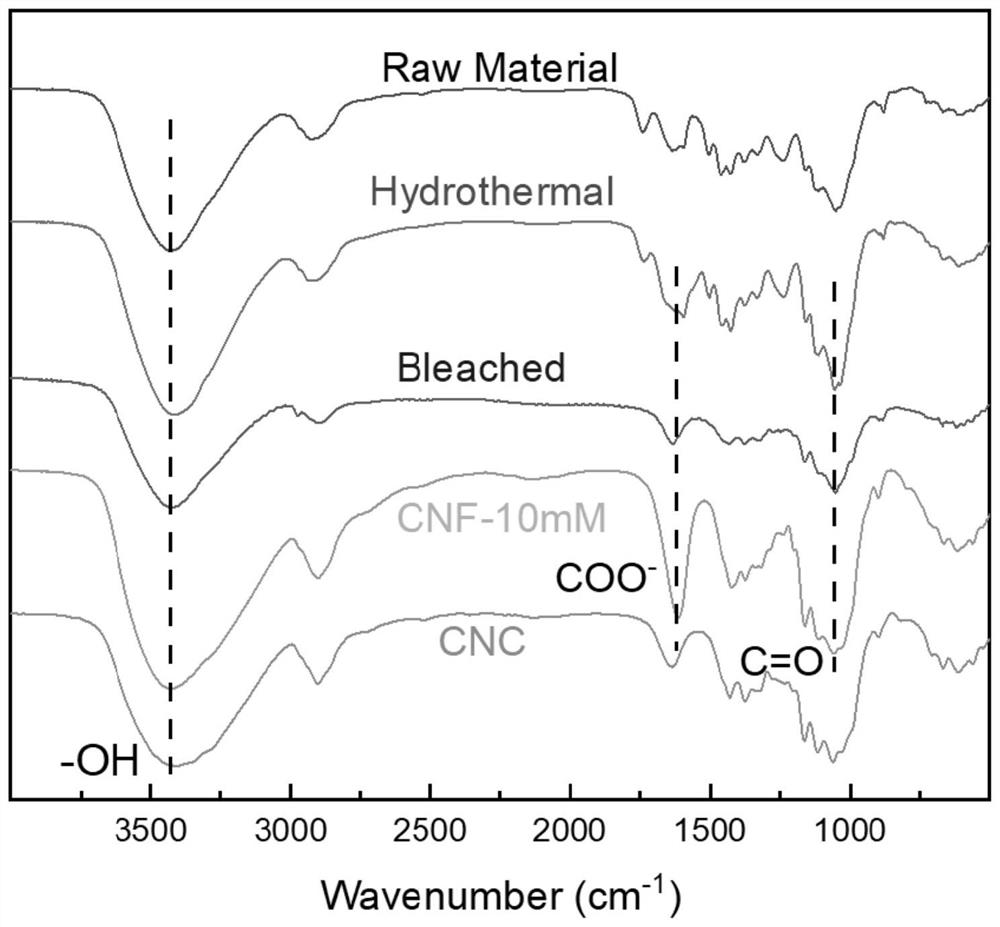

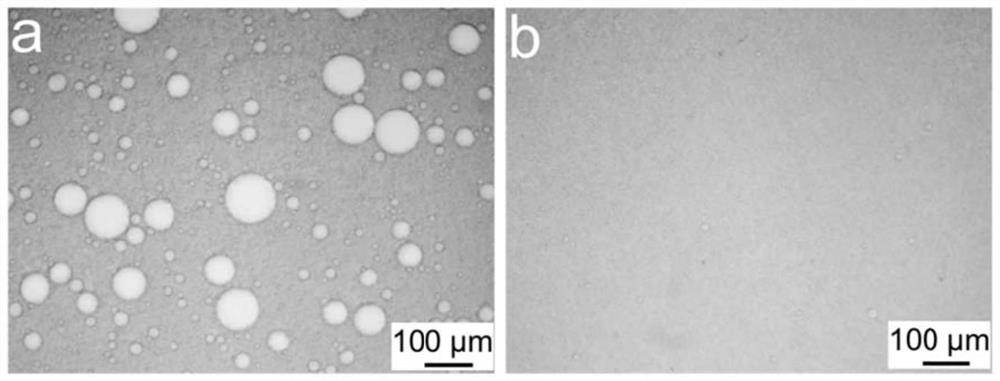

Nanocellulose-stabilized Pickering emulsion type drilling fluid and preparation method thereof

ActiveCN113980660AImprove rheologyReduce fluid lossDrilling compositionBiodieselUltrasonic emulsification

The invention provides a nanocellulose-stabilized pickering emulsion type drilling fluid and a preparation method thereof. According to the nanocellulose-stabilized Pickering emulsion type drilling fluid, nanocellulose (cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC)) is used as a green and environment-friendly emulsion stabilizing, rheology and filtration modifier, a nanocellulose aqueous dispersion is in the concentration range of 0.5-2.5 wt%, the nanocellulose aqueous dispersion and biodiesel are mixed according to the volume ratio of 2: 1-4: 1, and ultrasonic emulsification is carried out to form the Pickering emulsion type drilling fluid. Or a proper amount of bentonite is added to reduce the use amount of the nanocellulose, and the rheological property and filtrate loss reduction property of the drilling fluid are further improved. The Pickering emulsion type drilling fluid with stable nanocellulose, which is prepared by the method disclosed by the invention, has the characteristics of greenness and environmental protection and excellent rheology and filtrate loss reduction performance.

Owner:NANJING FORESTRY UNIV

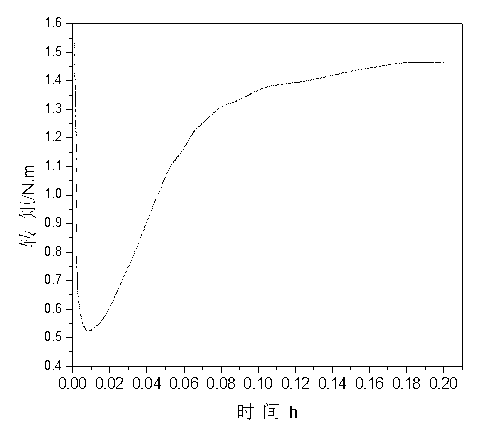

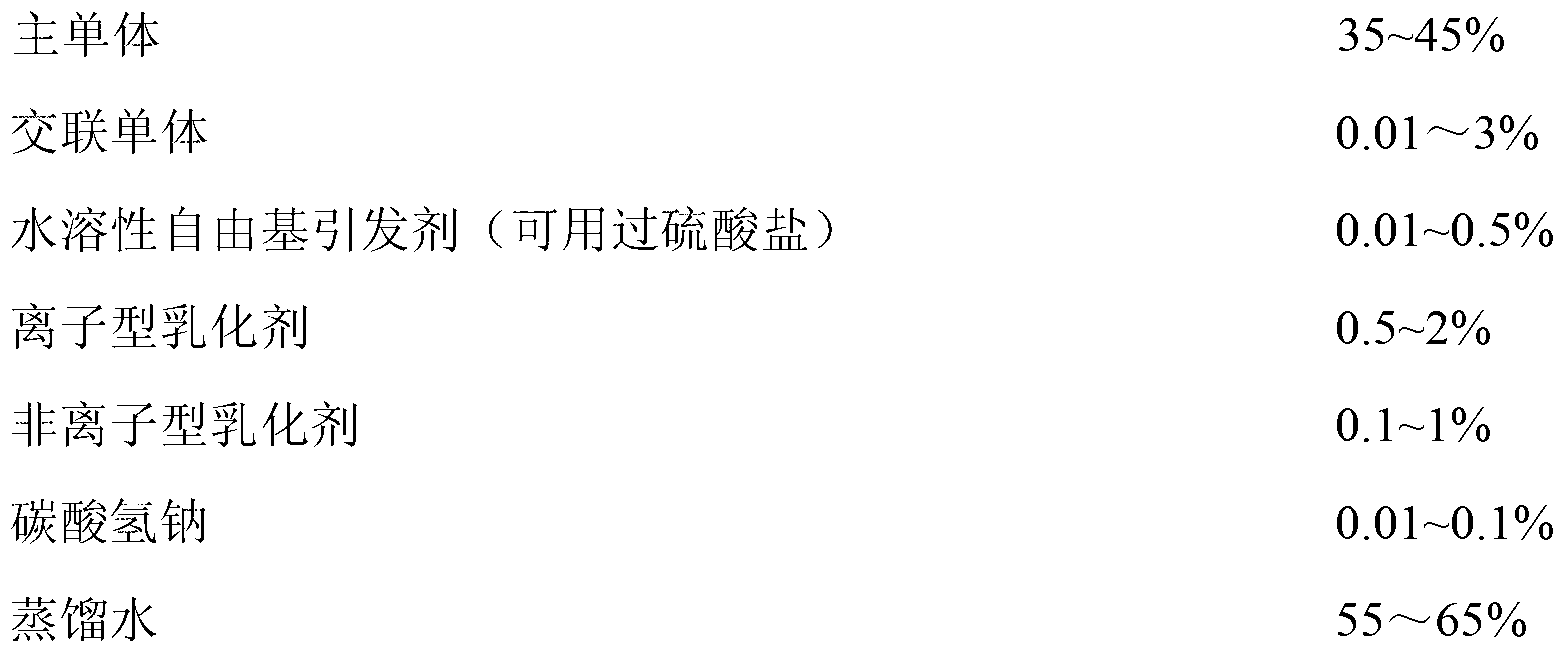

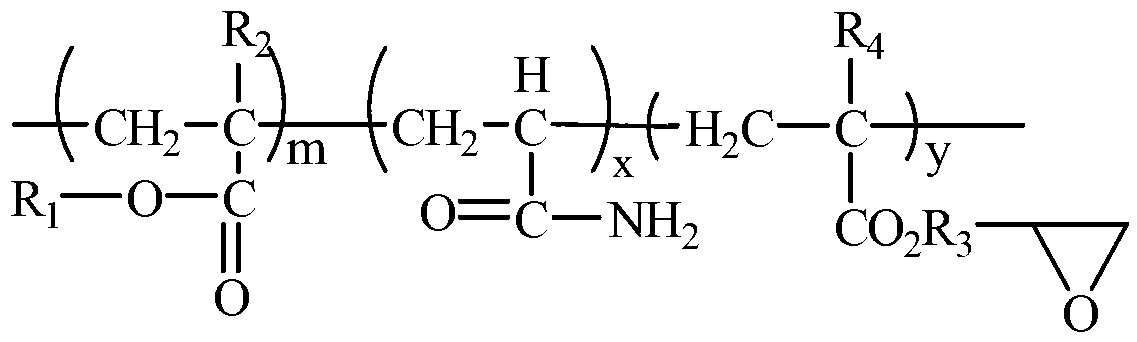

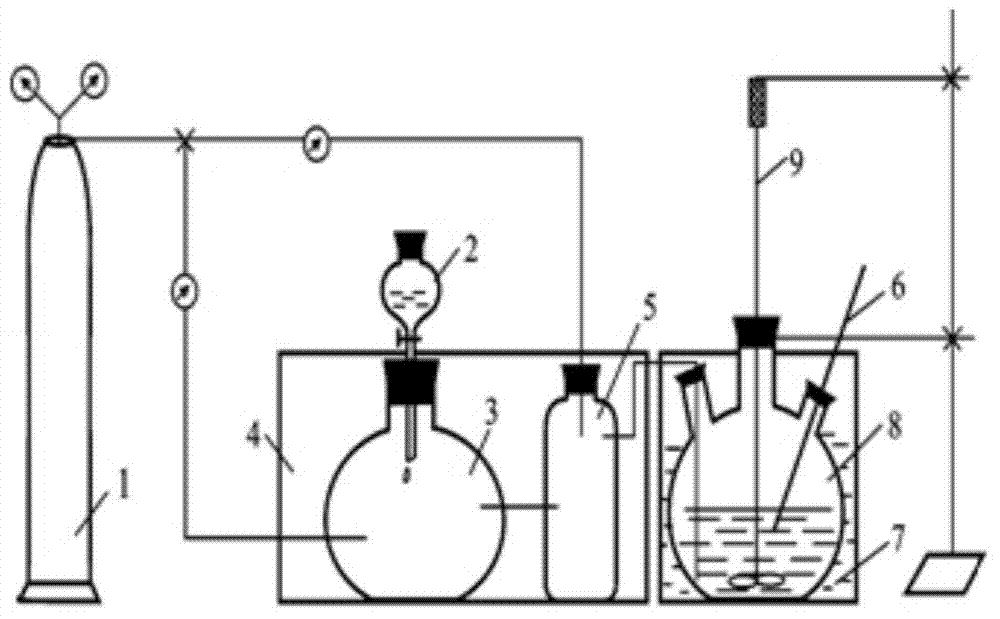

Crosslinking fluid loss agent preparation method

InactiveCN103265662AImprove viscoelastic properties and temperature resistanceStrong adsorption capacityDrilling compositionChemistryWater soluble

The invention discloses a crosslinking fluid loss agent preparation method. The method comprises steps of: adopting acrylic ester and acrylamide as main monomers of the crosslinking fluid loss agent and glycidyl acrylate as a crosslinking monomer of the crosslinking fluid loss agent, selecting a water-soluble radical initiator, and synthesizing a copolymer in the presence of nitrogen through adopting an emulsion polymerization method. The polymerization reaction time takes 2 hours, the insulation time costs 2 hours, the pH value is set to be 6-7, and the polymerization experimental reaction temperature is 70 DEG C. The copolymer prepared by the method can crosslink at the temperature of above 130 DEG C so as to form a proper crosslinking network structure, so that the viscoelasticity and temperature resistance of cement slurry can be improved, a problem of the poor temperature resistance of an acrylamide polymer which is served as a fluid loss agent can be solved, and the fluid loss reduction performance of the fluid loss agent in deep wells and ultradeep wells is improved. The crosslinking fluid loss agent mainly serves as the fluid loss agent for the well cementation cement slurry of oil-gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing amphoteric ion polymer fluid loss additive

InactiveCN100595254CStrong salt resistanceIncreased chance of clogged poresDrilling compositionWater bathsIce water

The invention relates to a process for preparing amphoteric ion polymer fluid loss additive, which is characterized in that the process for preparation comprises the following steps: firstly, dissolving acrylamide and 2- acryloylamino-2-methylpropanesulfonic acid into water according to the mass ratio which is 10:1-3:1, getting mixed solution A, secondly, leading the mixed solution A to react 3-6hunder the temperature which is 35 DEG C to 70 DEF C, and pH value which is 3-10 and under the condition of adding with initiating agent, and getting mixed solution B, thirdly, cooling the mixed solution B with ice-water bath, adding NaClO which is -10 DEG C-5 DEG C and contains NaOH according to the substance ratio which is -CONH2:NaClO: NaOH=1:0.1:10-1:1:10, reacting 5-10h in ice-water bath, getting mixed solution C, fourthly, adding HCl solution, and getting viscous products, fifthly, stirring and washing viscous products in carbinol to get white sediment, and then taking out sediment, granulating, drying, disintegrating, and then getting products. The process for preparation has the advantages of high-temperature resistance, salinity tolerance and low production cost, and the conditionof the process is moderate and controllable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

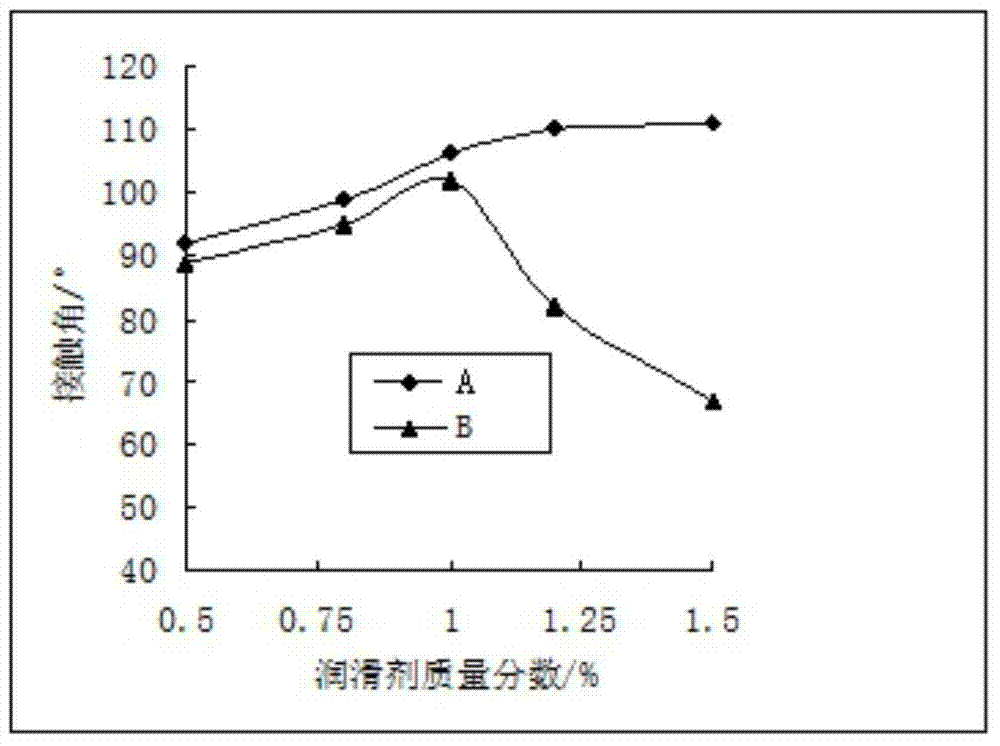

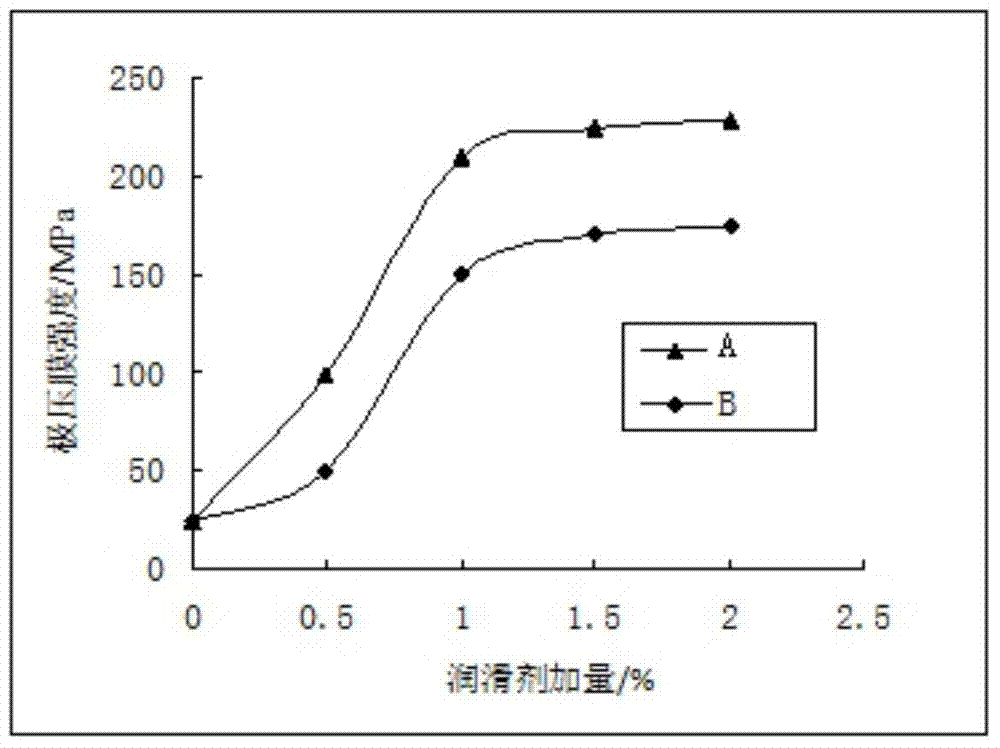

Method for preparing multifunctional lubricant of drilling fluid by using waste oil

The invention discloses a method for preparing a multifunctional lubricant of drilling fluid by using waste oil. The method comprises the following steps: (1) firstly, weighing the waste oil and putting into a reactor, and putting the reactor into an electrothermal constant-temperature water bath kettle; (2) then weighing liquid SO3 and putting into a dropping funnel, in order to change the liquid SO3 dripping from the dropping funnel into a gas SO3, and keeping a gas generator connected with the dropping funnel at 50-70 DEG C by a thermal cycling effect of a jacket water bath; (3) mixing with N2 before the gas SO3 enters a reactor; and (4) controlling the reaction temperature at 50 DEG C, enabling the gas SO3 to react with the waste oil for 2-4 hours, and then adding an organic alkali to the reactor, adjusting the pH to 8-9, and then adding a composite surfactant to the reactor, so as to obtain the lubricant after agitating for 3-10 minutes. Compared with the similar lubricant, the lubricant prepared by the method disclosed by the invention is simple in production technology, and low in cost, has good high-temperature extreme pressure lubricity, also has good fluid loss effect and anti-collapse performance, and is applicable to horizontal well and complicated stratum drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

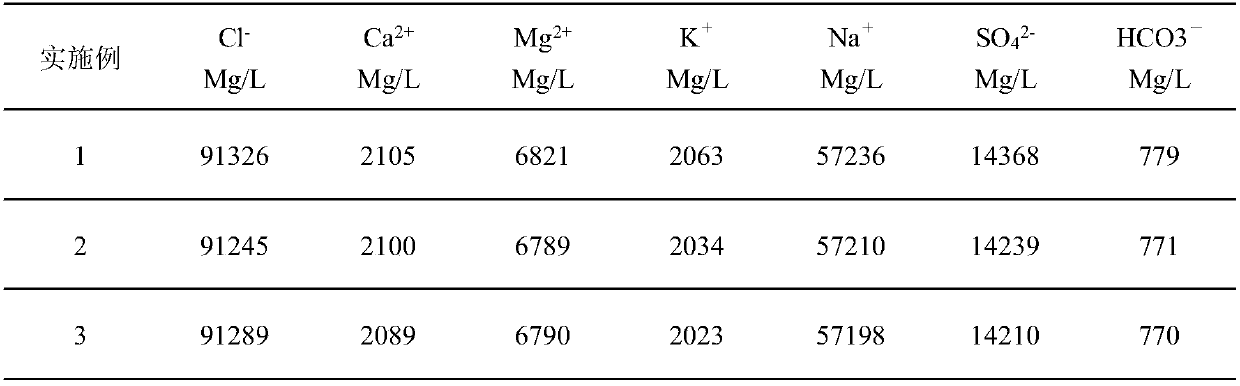

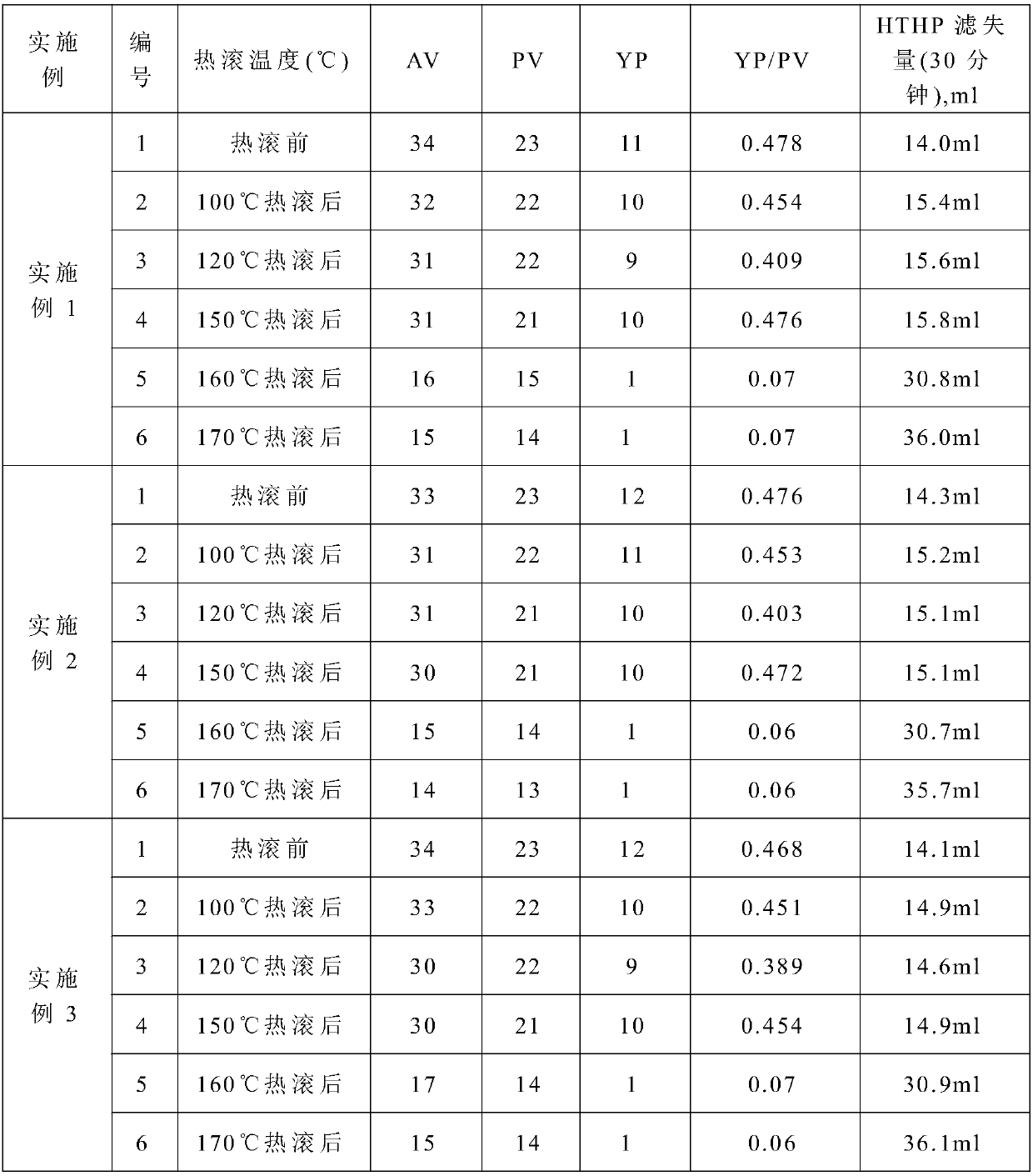

Salt and high temperature resistant filtrate loss reducer for seawater-based drilling fluid and preparation method thereof

InactiveCN109652029AStrong fluid loss reductionImprove filtration loss reduction effectDrilling compositionChemical industryTemperature resistance

Belonging to the technical field of chemical industry, the invention relates to a salt and high temperature resistant filtrate loss reducer for seawater-based drilling fluid and a preparation method thereof. The filtrate loss reducer is prepared from the following raw materials by mass fraction: 30%-60% of a polymer monomer, 0.05%-0.15% of a first initiator, 0.05%-0.15% of a second initiator, andthe balance water. The invention solves the problems that existing filtrate loss reducers cannot meet the requirement of maintaining good temperature resistance in an environment containing salt and calcium and the temperature and salt resistant filtrate loss reducer that can stabilize borehole walls and inhibit shale expansion and meet the drilling requirements of shallow sea areas in Peru is notdeveloped yet. The filtrate loss reducer provided by the invention has strong filtrate loss reducing properties, is suitable for various density conditions, especially for the filtrate loss reductionof high density drilling fluid, also has strong hardness resistance and strong inhibition properties, and can effectively control the filtrate loss reducing properties of drilling fluid under a hightemperature condition, improve the high temperature resistance and drilling efficiency of drilling fluid, and reduce the comprehensive cost of drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Petroleum drilling auxiliary agent and preparation method thereof

PendingCN111500267AImproved heat and salt resistanceImprove heat and salt resistanceDrilling compositionMicrocrystalline waxDioxyethylene Ether

The invention discloses a petroleum drilling auxiliary agent and a preparation method thereof, and belongs to the technical field of petroleum auxiliary agent preparation. The petroleum drilling auxiliary agent is prepared from the following raw materials: modified humic acid, 4-hydroxy-6-acetamido-2-naphthalene sulfonic acid, maleic anhydride acylated chitosan, modified potassium hexatitanate whiskers, nonylphenol polyoxyethylene ether, linear polysiloxane, microcrystalline wax, hydroxyl aluminum and water. The petroleum drilling auxiliary agent is prepared through high-speed dispersion. By improving the prior art of the petroleum drilling auxiliary agent, the high-temperature and low-temperature filtration losses are remarkably reduced, and the application requirements are met.

Owner:粤久久食品科技(江门)有限公司

High-temperature-resistant and high-salt-resistant hydrophobic blocking agent and preparation method thereof

PendingCN114685736AImprove densification performancePrevent intrusionDrilling compositionMethacrylateMeth-

The invention relates to the technical field of well drilling, in particular to a high-temperature-resistant and high-salt-resistant hydrophobic blocking agent and a preparation method thereof. The high-temperature-resistant and high-salt-resistant hydrophobic blocking agent is prepared from 5 to 10 parts by mass of modified SiO2, 2 to 5 parts by mass of lauryl sodium sulfate, 10 to 20 parts by mass of acrylamide, 10 to 20 parts by mass of methacryloyloxyethyl trimethyl ammonium chloride, 2 to 6 parts by mass of octadecyl methacrylate, 0.2 to 0.5 part by mass of an initiator and a proper amount of acetone and water. According to the SiO2 graft polymer prepared through polymerization, the blocking effect is achieved through SiO2, the surface of SiO2 is hydrophobic through a long-chain alkyl chain and an ester group, and then the surface of a mud cake or a stratum pore is hydrophobic while tiny pores in the mud cake and pores in the stratum are blocked, so that invasion of water molecules is more effectively prevented, the compactness of the mud cake is improved, and the water permeability of the mud cake is improved. The filtrate loss is reduced, the filtrate loss reduction performance of the drilling fluid at high temperature and high salt is enhanced, formation pores and cracks are blocked, and the effect of efficiently stabilizing a well wall is achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

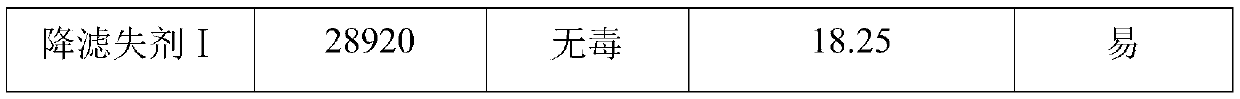

Nanofiber-hydrophobic starch compound-based filtrate reducer for drilling fluid and preparation method thereof

The invention relates to a nanofiber-hydrophobic starch compound-based filtrate reducer for a drilling fluid. The nanofiber-hydrophobic starch compound-based filtrate reducer comprises the following components in percentage by mass: 33-41% of cationic nano cellulose, 4.5-6.0% of a dispersing agent, 34-43% of hydrophobic modified starch, 11-13% of nano silicon dioxide and 6.5-7.1% of nano graphite.Sugarcane residues are dried, crushed, purified, dialyzed and cationized and are combined with hydrophobic modified starch on the basis to form a nanofiber-hydrophobic modified starch compound, and meanwhile, nano silicon dioxide is used as an auxiliary material, so that the temperature resistance and the nano pore filling capacity of the nanofiber-hydrophobic modified starch compound are enhanced, and the filtrate loss reduction effect of the nanofiber-hydrophobic modified starch compound is improved. The treating agent has strong filtration loss reduction and temperature resistance, is non-toxic, and has no adverse effect on the environment.

Owner:中石化石油工程技术服务有限公司 +2

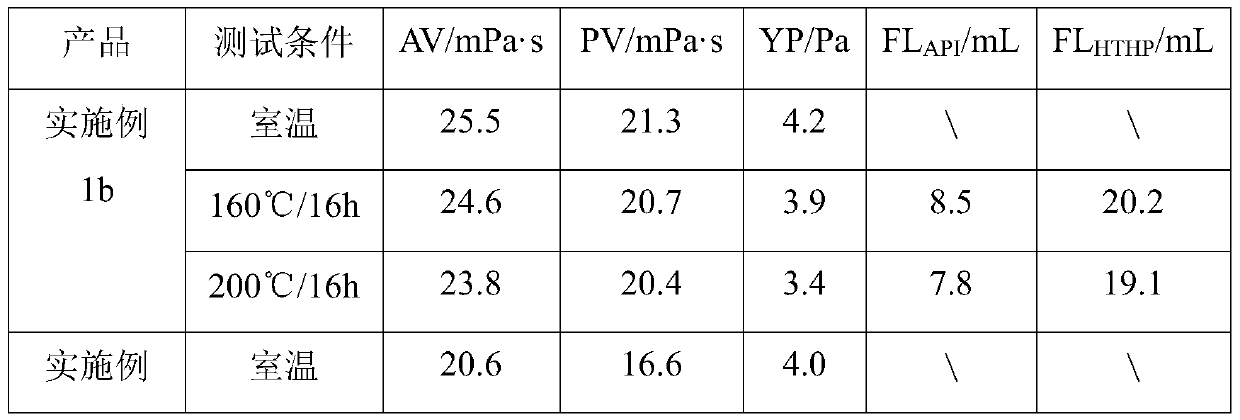

High-temperature water-based drilling fluid and preparation method thereof

ActiveCN110846004BGood resistance to salt and pollutionAppropriate viscosityDrilling compositionPolyethylene glycolPhysical chemistry

The invention discloses a high-temperature water-based drilling fluid. The high-temperature water-based drilling fluid comprises, by weight, 103 to 104 parts of base slurry, 1 to 1.5 parts of a filtrate reducer I, 1.5 to 2 parts of a filtrate reducer II, 2 to 2.5 parts of a filtrate reducer III, 2 parts of polyethylene glycol, 1 to 1.5 parts of aminosilanol, 3 to 5 parts of potassium chloride, 2 to 2.5 parts of a lubricant, 0.6 to 1 part of calcium carbonate powder with a size of 600 to 800 meshes, 1.2 to 1.5 parts of modified diatomite with a size of 400 to 500 meshes and barite with an addition amount that allows the high-temperature water-based drilling fluid to be weighted to 1.4-1.7 g / cm<3>. The invention also discloses a preparation method of the high-temperature water-based drillingfluid. The drilling fluid has the beneficial effects of resisting high temperature and reducing the permeability and the filter loss of the drilling fluid.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

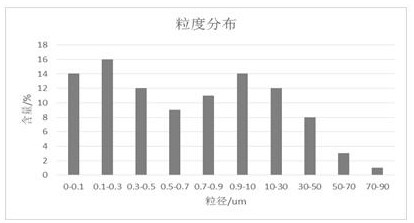

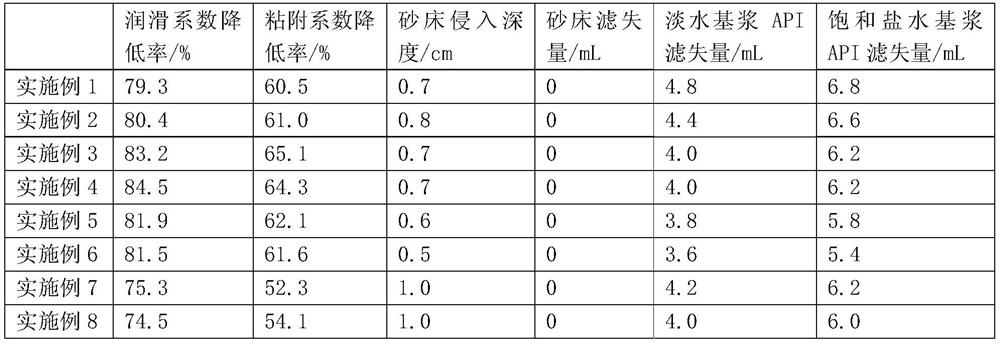

Lubricating and plugging filtrate reducer for drilling fluid and preparation method of lubricating and plugging filtrate reducer

PendingCN114686183AWide particle size rangeStrong deformabilityDrilling compositionFunctional monomerAmmonium sulfate

The invention relates to the field of treating agents for drilling fluids, in particular to a lubricating and plugging filtrate reducer for a drilling fluid and a preparation method of the lubricating and plugging filtrate reducer. Comprising 31 to 35 parts of a functional monomer, 0.6 to 0.8 part of graphene oxide, 80 to 100 parts of water, 70 to 80 parts of an oil phase dispersion medium, 20 to 30 parts of paraffin, 15 to 20 parts of a composite emulsifier and 1.0 to 1.5 parts of an initiator. The functional monomers comprise acrylic acid, acrylamide, 2-acrylamido-2-methylpropanesulfonic acid and styrene. The compound emulsifier is formed by mixing Span80 and Tween 80; the weight ratio of the Span80 to the Tween 80 is 1: 1. And the oil phase medium is white oil or diesel oil. The initiator is a composition of ammonium persulfate and sodium hydrogen sulfite. The preparation method of the lubricating plugging filtrate reducer for the drilling fluid is a reverse emulsion polymerization method. The lubricating plugging agent has a wide particle size distribution range, can effectively plug microcracks with different sizes to form a high-lubricity isolating membrane, has lubricating performance, plugging performance and filtrate loss reduction performance, can resist the temperature of 220 DEG C, can resist NaCl to be saturated, and has a wide application prospect.

Owner:SINOPEC SSC +2

Recyclable anti-collapse type polymer mud and preparation method thereof

PendingCN110591665ASolve shrinkageSolve the problem of collapsed holesChemical/physical/physico-chemical stationary reactorsDrilling compositionFiberSodium Bentonite

The invention discloses recyclable anti-collapse type polymer mud and a preparation method thereof. The recyclable anti-collapse type polymer mud is prepared from the following raw materials in partsby weight: 2.5-5 parts of a tackifier, 4-11 parts of a filtrate reducer, 70-80 parts of a solid phase film formation agent, 0.05-0.1 part of a dispersant, 0.1-0.2 part of a lubricant, 30-60 parts of sodium carbonate and 70-110 parts of water. The anti-collapse type polymer mud which comprises vegetable gum as a main tackifying component, a sulfonate copolymer as the filtrate reducer and plant fiber powder as a main solid phase film formation component has a filter loss less than 15mL within 30 minutes, a viscosity of 18-30s, a mud film thickness of 2-4mm and a sand content smaller than 5%, a mud film can be uniform and dense, and compared with common polymer mud and conventional bentonite mud, the mud solves the problems of hole shrinkage and hole collapse in water-sensitive geological hole drilling construction.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Filtrate loss reduction composition, filtrate loss reducer, and preparation method and application of filtrate loss reducer

PendingCN113801338AImprove stabilityPrevent slidingDrilling compositionDiethylenetriamineOleic Acid Triglyceride

The invention provides a filtrate loss reduction composition, a filtrate loss reducer and a preparation method and application of the filtrate loss reducer. The filtrate loss reduction composition is prepared from the following components in parts by weight: 160-320 parts of oleic acid, 50-80 parts of diethylenetriamine and 100-170 parts of humic acid. When the filtrate loss reducer formed by the high-molecular polymer is applied to drilling fluid, the filtrate loss of the drilling fluid can be controlled, and the stability of a well wall can be improved. The probability that the performance of a drilling fluid system becomes poor due to the fact that the filtrate loss reducer is decomposed in the using process of the high-temperature drilling fluid is reduced. Especially for a high-temperature-resistant gas-to-oil synthetic base drilling fluid system with relatively high requirement on the environmental protection property of a treating agent, the filtrate loss reducer is beneficial for improving the high-temperature emulsion stability and filtrate loss reduction performance of the high-temperature-resistant gas-to-oil synthetic base drilling fluid system. Therefore, the problems that the performance of a high-temperature-resistant gas-to-oil synthetic base drilling fluid system is reduced and the filtrate loss is increased are solved. The formula is simple, the raw materials are cheap and easy to obtain, and the production cost is low.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com