Filtrate reducer and preparation method thereof, and water-based drilling fluid and application thereof

A technology for water-based drilling fluid and fluid loss control agent, which is applied in earth-moving drilling, chemical instruments and methods, and wellbore flushing, etc., can solve the problem that the temperature and salt resistance of fluid loss control agent cannot be balanced with environmental friendliness, etc. To achieve the effect of good filtration performance, high synthesis efficiency and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

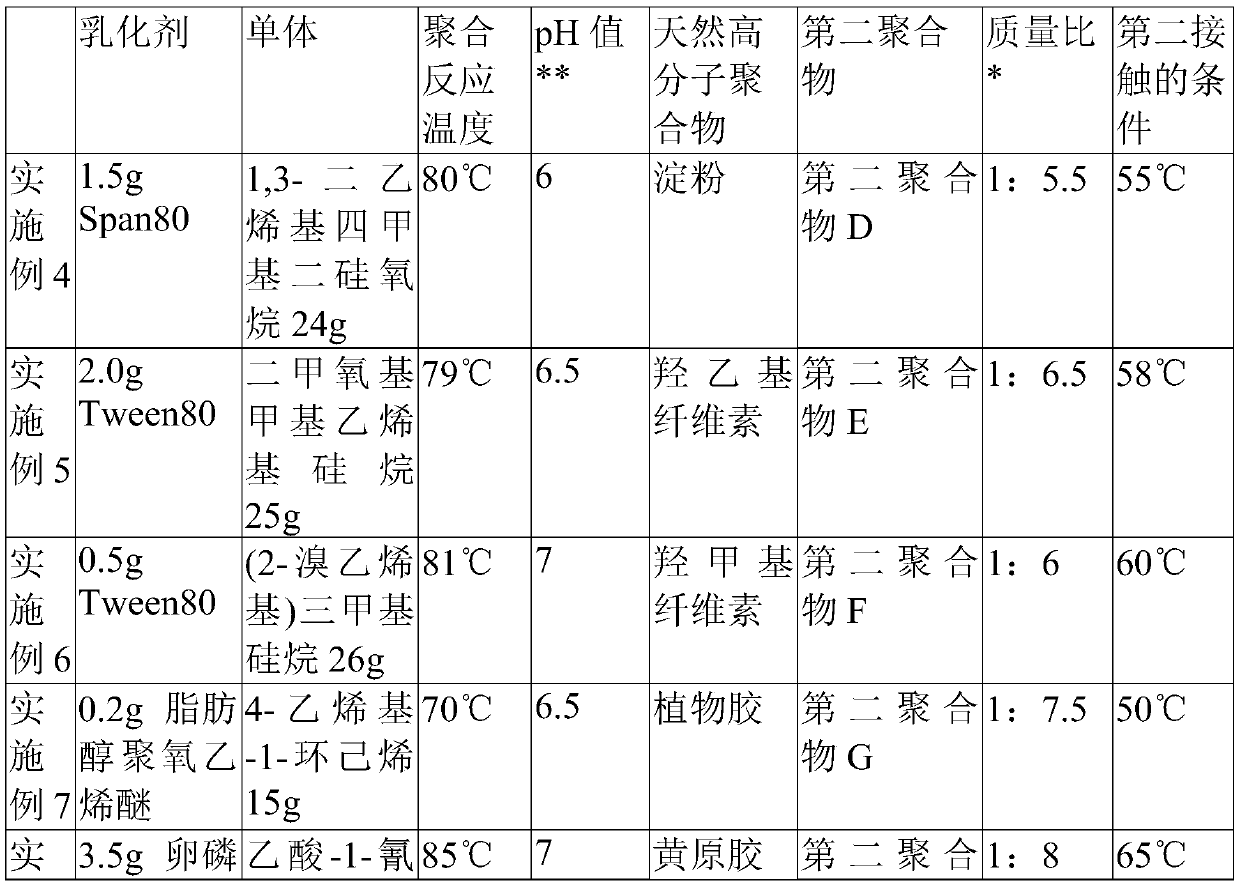

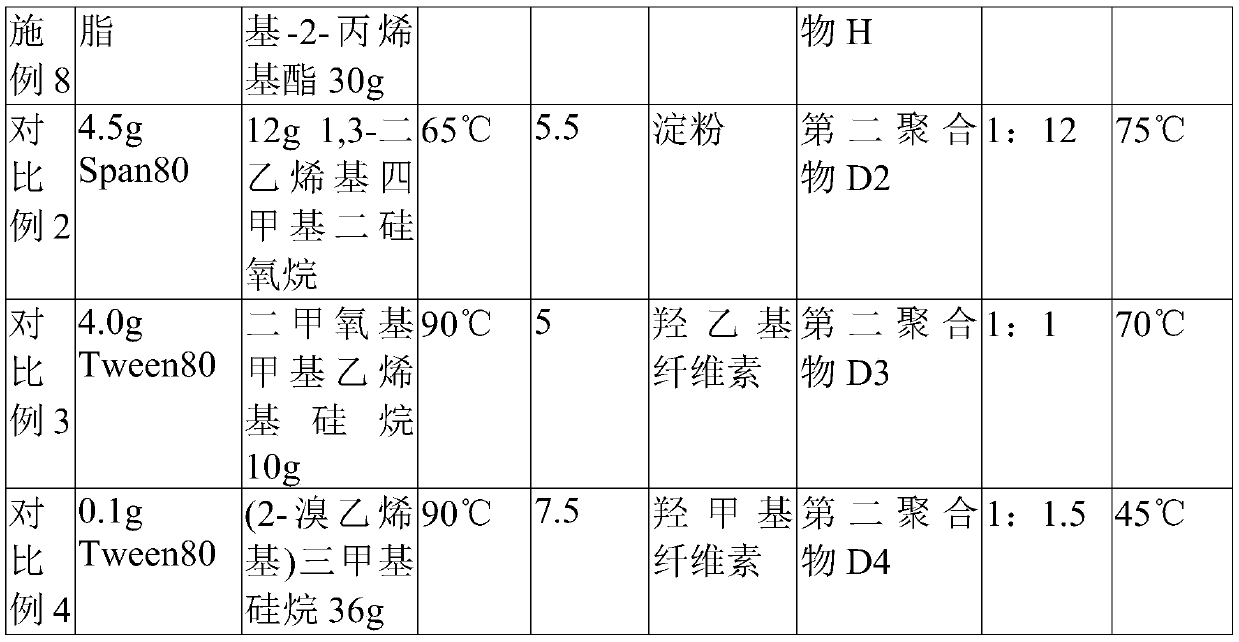

[0032] The second aspect of the present invention provides a method for preparing a fluid loss control agent, wherein the method includes:

[0033] (1) Carry out first contact with emulsifier and water, make the first mixed solution;

[0034] (2) In the presence of an initiator, the first mixed solution and the monomer are polymerized to obtain an emulsion solution; and the emulsion solution is purified and extracted, and the obtained extract is subjected to shear granulation and drying dried and comminuted to produce a second polymer;

[0035] (3) performing a second contact with the first polymer, water and the second polymer to obtain a second mixed solution;

[0036] (4) Centrifuging, washing, drying and grinding the second mixed solution to obtain the fluid loss control agent;

[0037]Wherein, the first polymer is a natural polymer;

[0038] Wherein, the monomer is selected from methyl-4-vinylbenzoate, dimethoxymethylvinylsilane, 1,3-divinyltetramethyldisiloxane, (2-br...

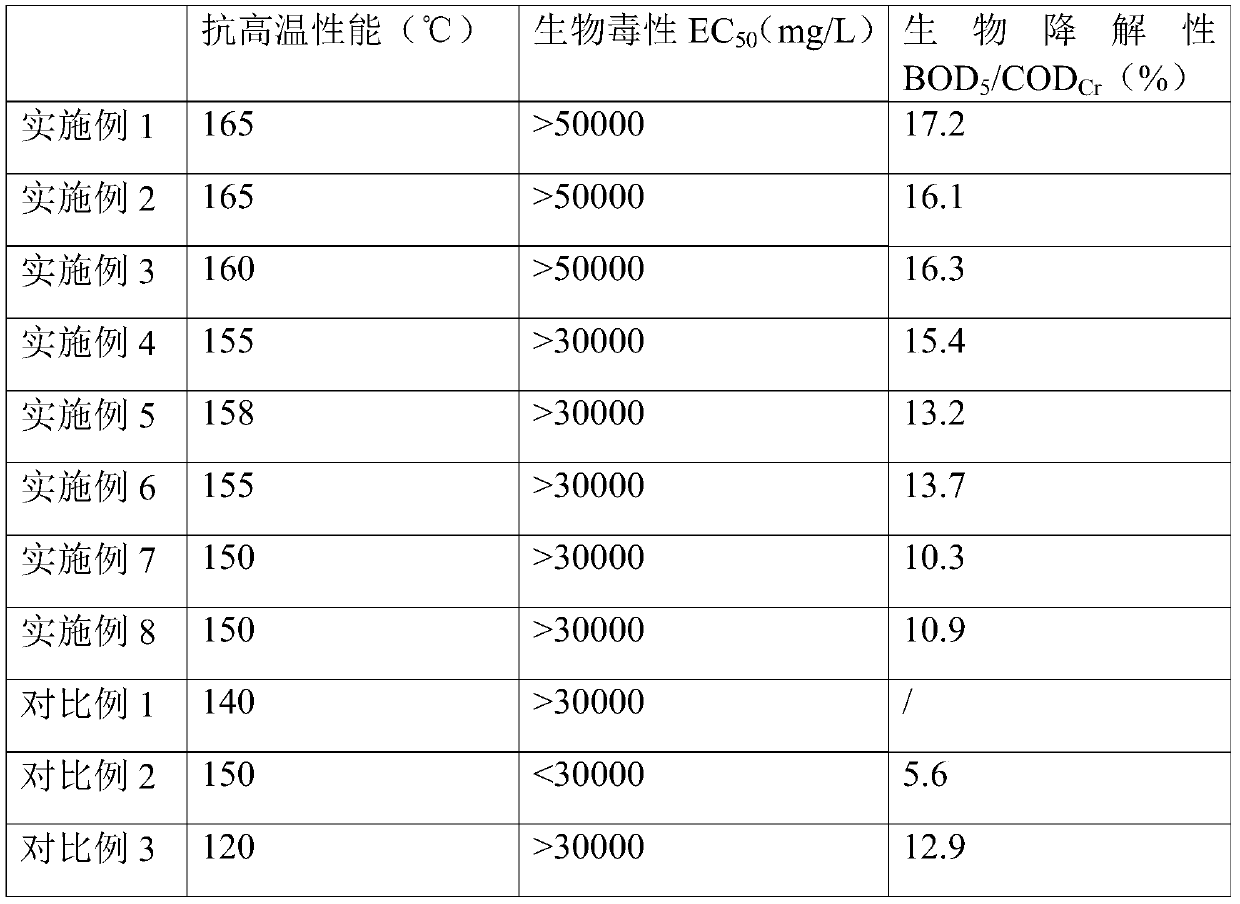

Embodiment 1

[0080] This example is to illustrate the fluid loss control agent prepared by the method of the present invention.

[0081] (1) Synthesis of the second polymer A

[0082] Add 80mL of deionized water and 1.2g of emulsifier Tween80 into a 250mL three-necked flask equipped with a reflux device, control the stirring speed at 1000r / min, stir for 30min to mix evenly, during which the temperature is controlled at 60°C, and 10% sodium hydroxide solution is used to Adjust the pH value to 6, then dissolve 0.5g of ammonium persulfate in 20g of 1,3-divinyltetramethyldisiloxane monomer and add it dropwise to the aqueous solution through a constant pressure funnel, and the stirring speed is 2000r / min, The dropping time of 1,3-divinyltetramethyldisiloxane monomer is controlled at 30min (with the dropping rate of 20g / 30min), and the monomer is added and then stirred for 30min, and high-purity nitrogen is introduced Oxygen is driven away, the temperature is gradually raised to the reaction te...

Embodiment 2

[0087] This example is to illustrate the fluid loss control agent prepared by the method of the present invention.

[0088] (1) Synthesis of the second polymer B

[0089] Add 100mL of deionized water and 1.2g of emulsifier OP-10 into a 250mL three-necked flask equipped with a reflux device, control the stirring speed at 950r / min, stir for 35min to mix evenly, during which the temperature is controlled at 50°C, and oxidized with 10% hydrogen The sodium solution adjusts the pH value to be 6.5, and then the methyl-4-vinyl benzoate monomer dissolved in 24g of 0.5g potassium persulfate is added dropwise in the aqueous solution through a constant pressure funnel, and the stirring speed is 2000r / min. Base-4-vinyl benzoate monomer was added dropwise at a rate of 0.5g / min. After the monomer was added dropwise, continue stirring for 30 minutes, and high-purity nitrogen was introduced to drive oxygen, and the temperature was gradually raised to the reaction temperature. 78°C, polymerize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com