Nanocellulose-stabilized Pickering emulsion type drilling fluid and preparation method thereof

A nanocellulose and drilling fluid technology, applied in the field of drilling fluid, can solve the problems of low environmental protection and poor stability, achieve good rheological properties, reduce usage, improve rheology and fluid loss performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

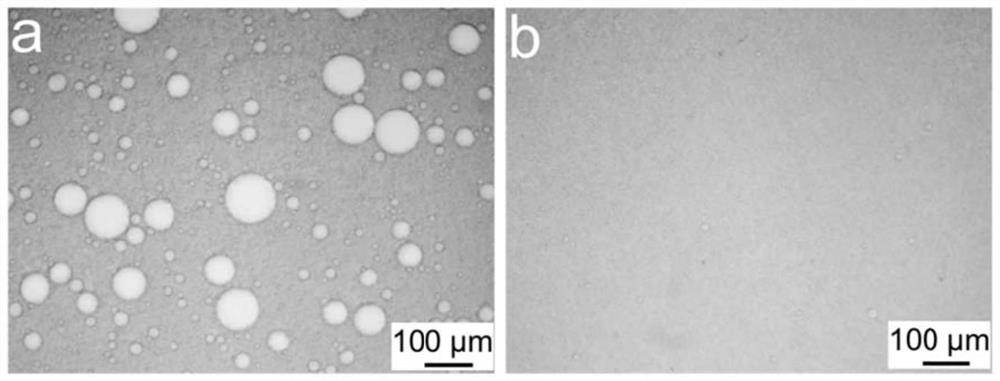

[0046] The present embodiment provides a kind of nanocellulose stable Pickering emulsion type drilling fluid, is made up of cellulose nanofibril (CNF) aqueous dispersion liquid and biodiesel, described cellulose nanofibril (CNF) aqueous dispersion liquid and The volume ratio of biodiesel is 3:1, and the mass percent concentration of the cellulose nanofibril (CNF) aqueous dispersion is 2 wt%.

[0047] The preparation method of the Pickering emulsion type drilling fluid that described nanocellulose is stable is as follows:

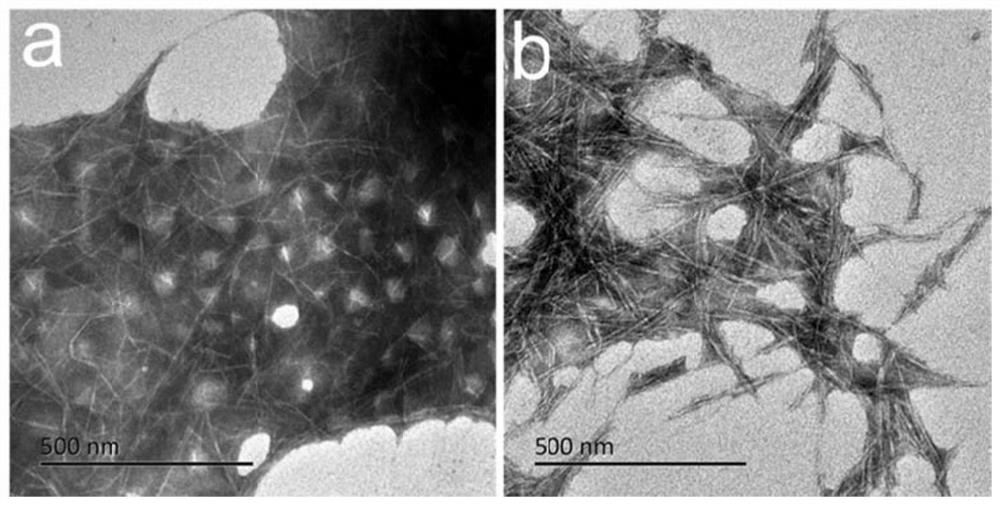

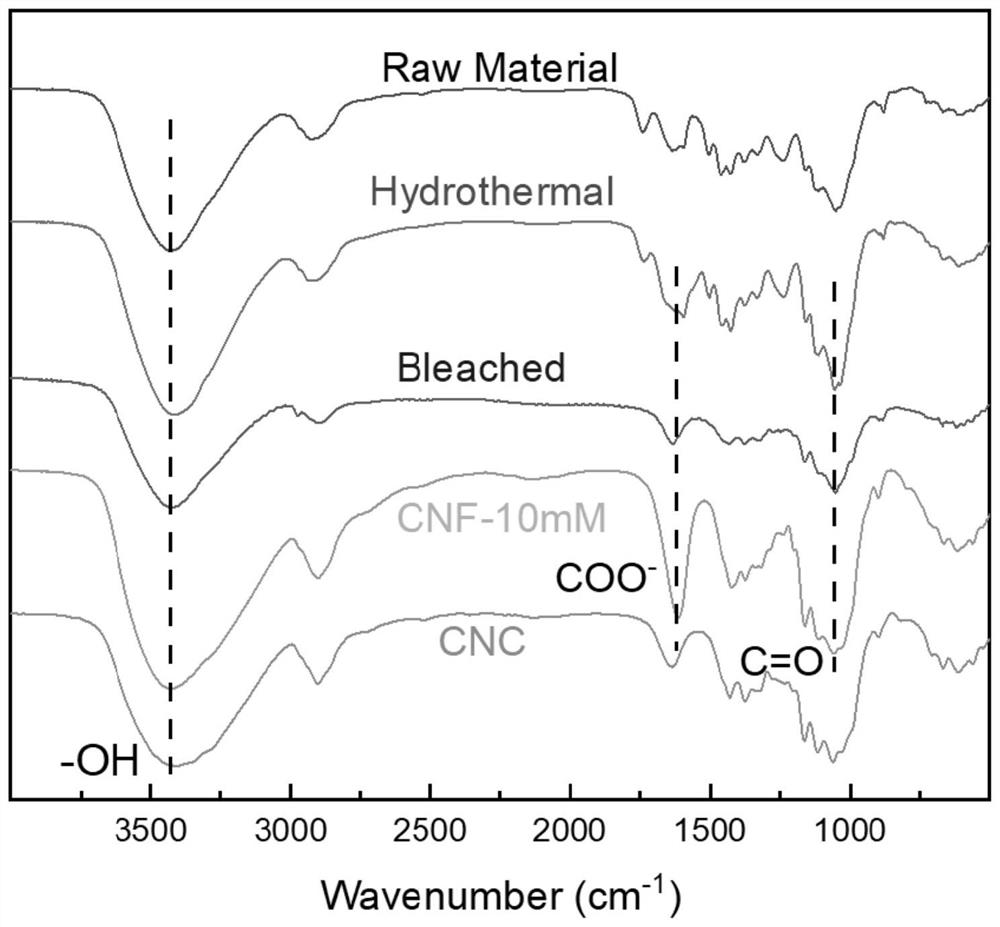

[0048] S1, preparation of cellulose nanofibril (CNF) aqueous dispersion; specifically include the following steps:

[0049] S1-1. Pretreatment of eucalyptus powder: hydrothermally treat eucalyptus powder <200 μm in a water bath at 90-100°C for 3-4 hours, centrifuge at a centrifugal speed of 3000rpm for 3min, and dry the precipitate at 60°C;

[0050] S1-2. Dehemicellulose removal of eucalyptus fibers: collect 20 g of dried eucalyptus fibers in step S1-1 and ...

Embodiment 2

[0058] The present embodiment provides a kind of nanocellulose stable Pickering emulsion type drilling fluid, is made up of cellulose nanocrystal (CNC) aqueous dispersion liquid and biodiesel, described cellulose nanocrystal (CNC) aqueous dispersion liquid and biodiesel The volume ratio of the cellulose nanocrystal (CNC) aqueous dispersion is 3:1, and the mass percent concentration of the cellulose nanocrystal (CNC) aqueous dispersion is 2wt%.

[0059] The preparation method of the Pickering emulsion type drilling fluid that described CNC is stable is as follows:

[0060] S1, preparing cellulose nanofibril (CNC) water dispersion liquid; Specifically comprise the following steps:

[0061] S1-1. Pretreatment of eucalyptus wood powder: hydrothermally treat eucalyptus wood powder with a particle size of <200 μm in a water bath at 90-100°C for 3-4 hours, centrifuge at a centrifugal speed of 3000rpm for 3 minutes, and dry the precipitate at 60°C;

[0062] S1-2. Dehemicellulose remo...

Embodiment 3

[0070] This embodiment provides a Pickering emulsion type drilling fluid stabilized by nanocellulose, which is composed of cellulose nanofibril (CNF) aqueous dispersion, bentonite and biodiesel, and the cellulose nanofibril (CNF) aqueous dispersion The volume ratio of biodiesel to biodiesel is 3:1, the mass percent concentration of the cellulose nanofibril (CNF) aqueous dispersion is 1 wt%, and the mass ratio of bentonite to CNF is 1:1.

[0071] The preparation method of the Pickering emulsion type drilling fluid that described nanocellulose is stable is as follows:

[0072] S1, preparation of cellulose nanofibril (CNF) aqueous dispersion; specifically include the following steps:

[0073] S1-1. Pretreatment of eucalyptus wood powder: hydrothermally treat eucalyptus wood powder with a particle size of <200 μm in a water bath at 90-100°C for 3-4 hours, centrifuge at a centrifugal speed of 3000rpm for 3 minutes, and dry the precipitate at 60°C;

[0074] S1-2. Dehemicellulose re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com