High-temperature-resistant and high-salt-resistant hydrophobic blocking agent and preparation method thereof

A technology of high temperature resistance and plugging agent, applied in the field of drilling, can solve the problem of not considering salt resistance and other problems, and achieve the effects of efficiently stabilizing wellbore, reducing filtration loss and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

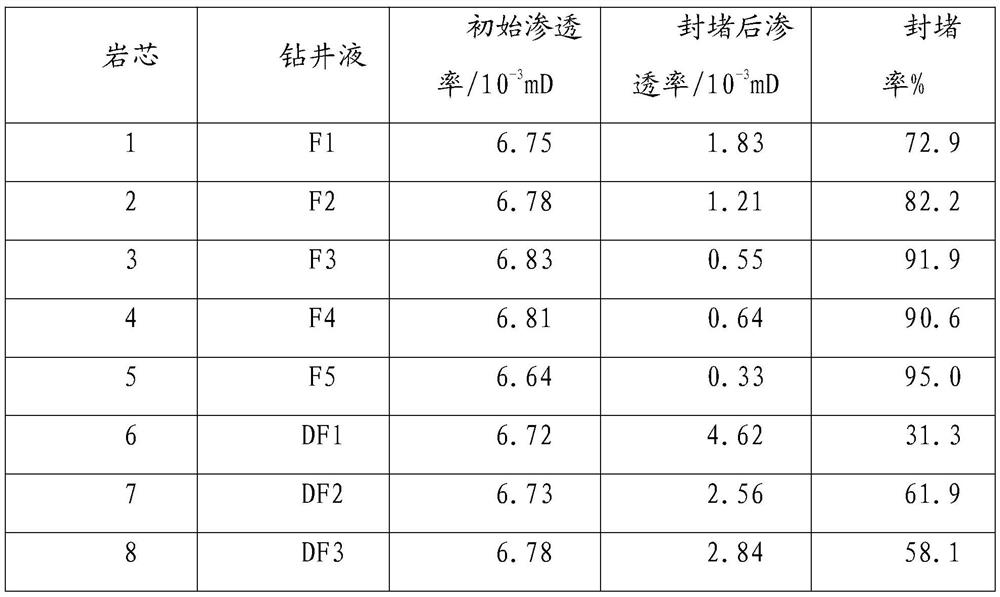

Examples

Embodiment 1

[0027] In this embodiment, the high temperature and high salt hydrophobic blocking agent is modified by 10 parts by mass of SiO 2 , 5 parts of sodium lauryl sulfate, 20 parts of acrylamide, 15 parts of methacryloyloxyethyltrimethyl ammonium chloride, 2 parts of octadecyl methacrylate, 0.25 parts of initiator benzyl peroxide It is prepared from acyl and appropriate amounts of acetone and water.

[0028] In this embodiment, the modified SiO 2 40 parts by mass of SiO 2 , 5 parts of KH570, 1 part of initiator benzoyl peroxide (BPO), an appropriate amount of anhydrous ethanol, an appropriate amount of pH regulator triethylamine and an appropriate amount of water.

[0029] In this example, the modified SiO 2 The preparation method is:

[0030] 1) Weigh 40 parts by mass of SiO 2 , added to 100 parts of absolute ethanol, magnetic stirring to make it fully dispersed;

[0031] 2) Weigh 5 parts of KH570 in mass fraction and add it to 100 parts of water / absolute ethanol system, magn...

Embodiment 2

[0041] In this embodiment, the high temperature and high salt hydrophobic blocking agent is modified by 5 parts by mass of SiO 2 , 5 parts of sodium lauryl sulfate, 20 parts of acrylamide, 15 parts of methacryloyloxyethyltrimethyl ammonium chloride, 2 parts of octadecyl methacrylate, 0.25 parts of initiator benzyl peroxide It is prepared from acyl and appropriate amounts of acetone and water.

[0042] In this embodiment, the modified SiO 2 40 parts by mass of SiO 2 , 5 parts of KH570, 1 part of initiator benzoyl peroxide (BPO), an appropriate amount of anhydrous ethanol, an appropriate amount of pH regulator triethylamine and an appropriate amount of water.

[0043] In this example, the modified SiO 2 The preparation method is:

[0044] 1) Weigh 40 parts by mass of SiO 2 , added to 100 parts of absolute ethanol, magnetic stirring to make it fully dispersed;

[0045]2) Weigh 5 parts of KH570 by mass fraction and add it to 100 parts of water / absolute ethanol system, magnet...

Embodiment 3

[0055] In this embodiment, the high temperature and high salt hydrophobic blocking agent is modified by 10 parts by mass of SiO 2 , 5 parts of sodium lauryl sulfate, 15 parts of acrylamide, 20 parts of methacryloyloxyethyl trimethyl ammonium chloride, 3 parts of octadecyl methacrylate, 0.5 parts of initiator benzyl peroxide It is prepared from acyl and appropriate amounts of acetone and water.

[0056] In this embodiment, the modified SiO 2 70 parts by mass of SiO 2 , 7 parts of KH570, 1.5 parts of initiator benzoyl peroxide (BPO), an appropriate amount of absolute ethanol, an appropriate amount of pH regulator triethylamine and an appropriate amount of water.

[0057] In this example, the modified SiO 2 The preparation method is:

[0058] 1) Weigh 70 parts by mass of SiO 2 , added to 100 parts of absolute ethanol, magnetic stirring to make it fully dispersed;

[0059] 2) Weigh 7 parts of KH570 in mass fraction and add it to 100 parts of water / absolute ethanol system, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com