Salt and high temperature resistant filtrate loss reducer for seawater-based drilling fluid and preparation method thereof

A fluid loss control agent and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as the inability to improve the stability of drilling fluid, improve drilling efficiency, reduce comprehensive costs, and improve high temperature resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

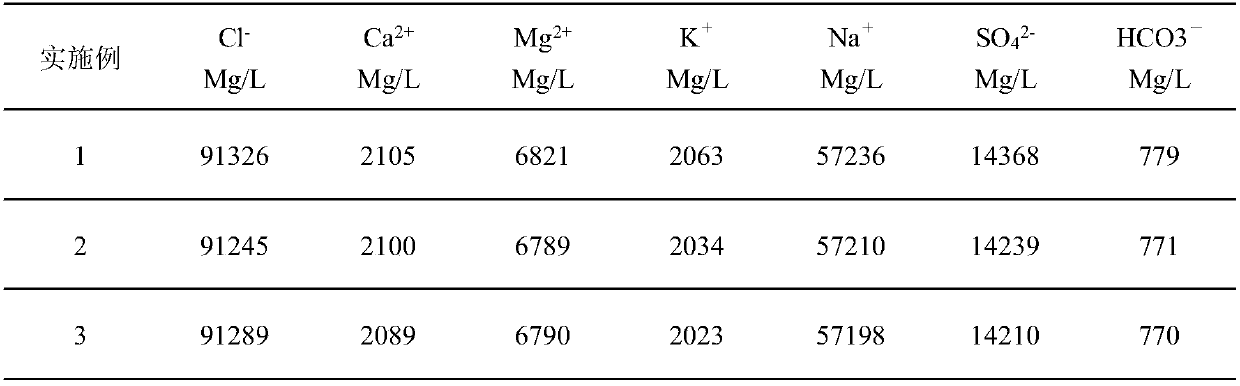

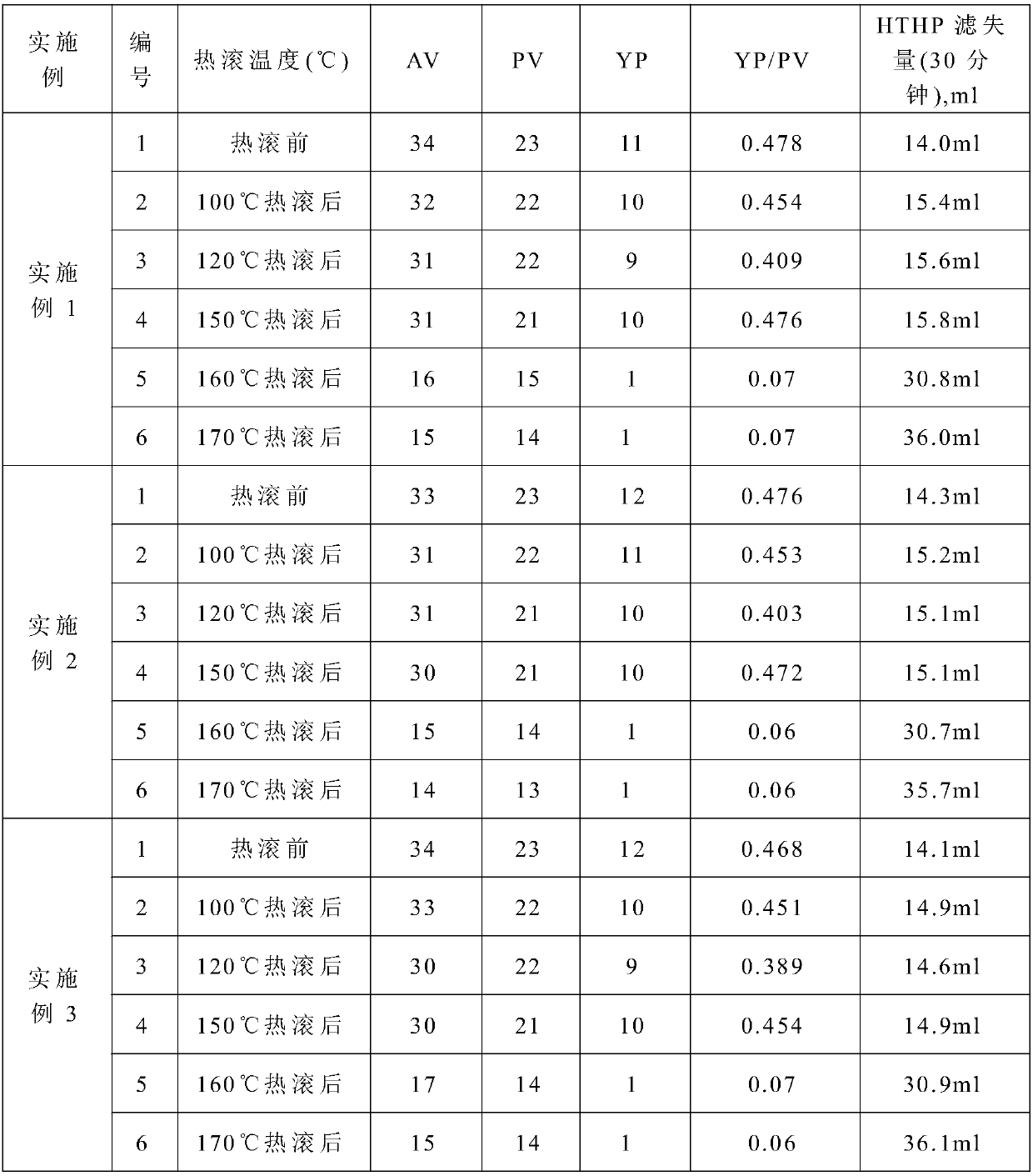

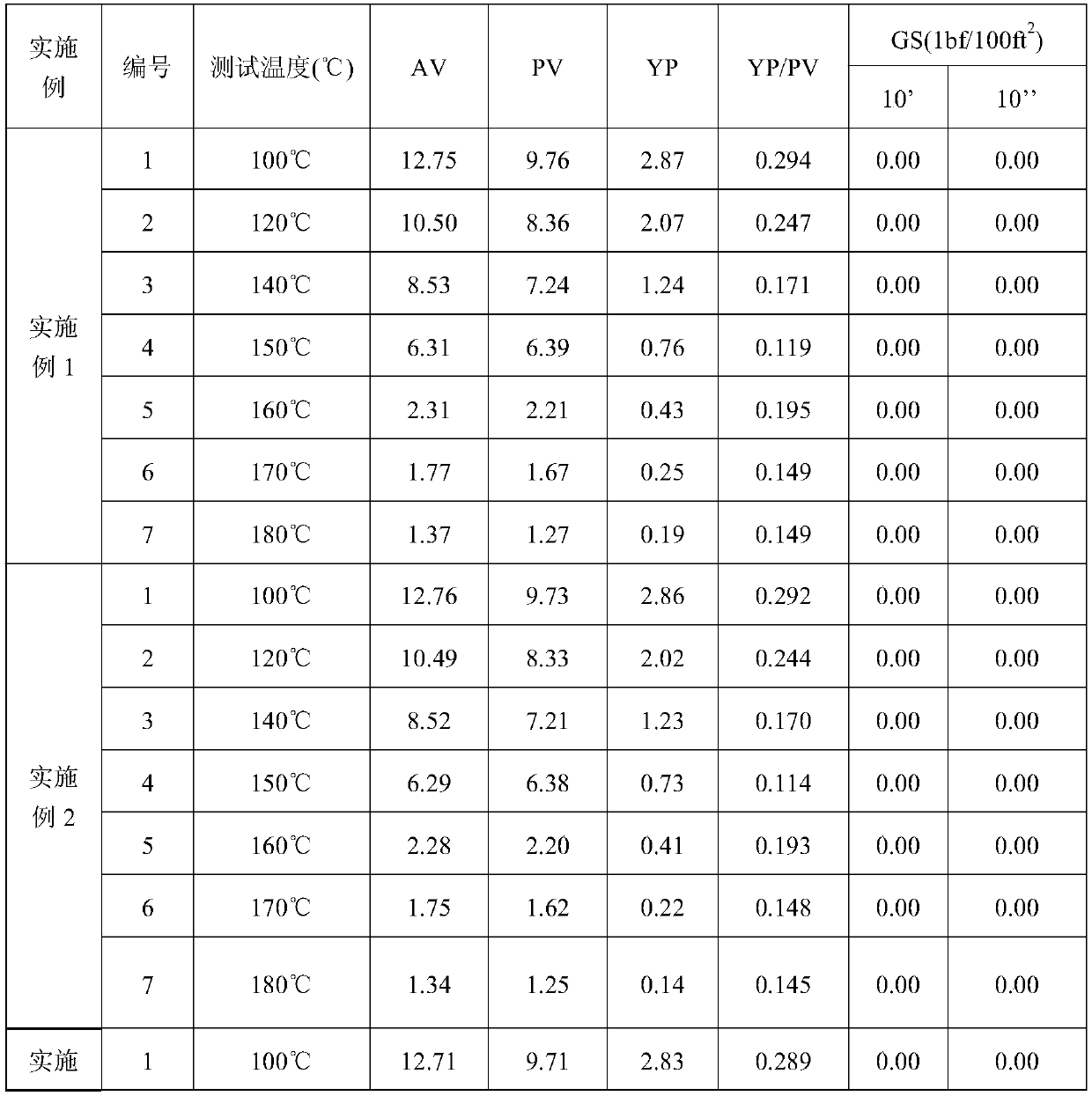

Embodiment 1

[0022] A kind of anti-salt and anti-high temperature fluid loss reducer for seawater-based drilling fluid, which is made of the following raw materials according to the following mass fraction: 50% of polymer monomer, 0.10% of the first initiator, 0.10% of the second initiator, and the balance for water.

[0023] The polymer monomer is made of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and hydrolyzed polyacrylonitrile ammonium salt, 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and The mass ratio of hydrolyzed polyacrylonitrile ammonium salt is 3:7:1.

[0024] The first initiator is ammonium peroxodisulfate with a mass concentration of 0.1%.

[0025] The second initiator is sodium metabisulfite with a mass concentration of 0.1%.

[0026] A method for preparing a salt-resistant and high-temperature fluid loss reducer for seawater-based drilling fluids, comprising the following steps:

[0027] 1) According to the formula quantity, first add 50% polymer mono...

Embodiment 2

[0036] A kind of anti-salt and anti-high temperature fluid loss reducer for seawater-based drilling fluid, which is made of the following raw materials according to the following mass fraction: 30% of polymer monomer, 0.05% of the first initiator, 0.05% of the second initiator, and the balance for water.

[0037] The polymer monomer is made of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and hydrolyzed polyacrylonitrile ammonium salt, 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and The mass ratio of hydrolyzed polyacrylonitrile ammonium salt is 1:5:2.

[0038] The first initiator is ammonium peroxodisulfate with a mass concentration of 0.1%.

[0039] The second initiator is sodium metabisulfite with a mass concentration of 0.1%.

[0040] A method for preparing a salt-resistant and high-temperature fluid loss reducer for seawater-based drilling fluids, comprising the following steps:

[0041] 1) First add 30% polymer monomers into water, stir well until co...

Embodiment 3

[0050] A kind of anti-salt and anti-high temperature fluid loss reducer for seawater-based drilling fluid, which is made of the following raw materials according to the following mass fraction: 60% of polymer monomer, 0.15% of the first initiator, 0.15% of the second initiator, and the balance for water.

[0051] The polymer monomer is made of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and hydrolyzed polyacrylonitrile ammonium salt, 2-acrylamido-2-methylpropanesulfonic acid, acrylamide and The mass ratio of hydrolyzed polyacrylonitrile ammonium salt is 5:9:0.5.

[0052] The first initiator is ammonium peroxodisulfate with a mass concentration of 0.1%.

[0053] The second initiator is sodium metabisulfite with a mass concentration of 0.1%.

[0054] A method for preparing a salt-resistant and high-temperature fluid loss reducer for seawater-based drilling fluids, comprising the following steps:

[0055] 1) Firstly add 60% of the polymer monomer into water, stir wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com