Water-based drilling fluid for loosening sandstones

A technology for water-based drilling fluid and sandstone, which is applied in the field of water-based drilling fluid, can solve the problems of difficult drilling fluids and the inability of conventional drilling fluids to meet the exploitation requirements of unconsolidated sandstone reservoirs, and achieves prevention of well wall collapse, good expansion, and strong inhibition. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The drilling fluid is prepared by water, sodium carbonate, bentonite, weighting agent, inhibitor, fluid loss reducer and viscosifier in parts by weight, and its specific mass fraction is: 84.3% water, 5% sodium carbonate, 4% bentonite, 0.2% PAC, 0.7% FLA1, 2% polyethylene glycol, 3% potassium silicate, 0.8% barium sulfate. The rheological properties, fluid loss control performance, inhibition performance and anti-pollution performance of unconsolidated sandstone drilling fluid are mainly evaluated.

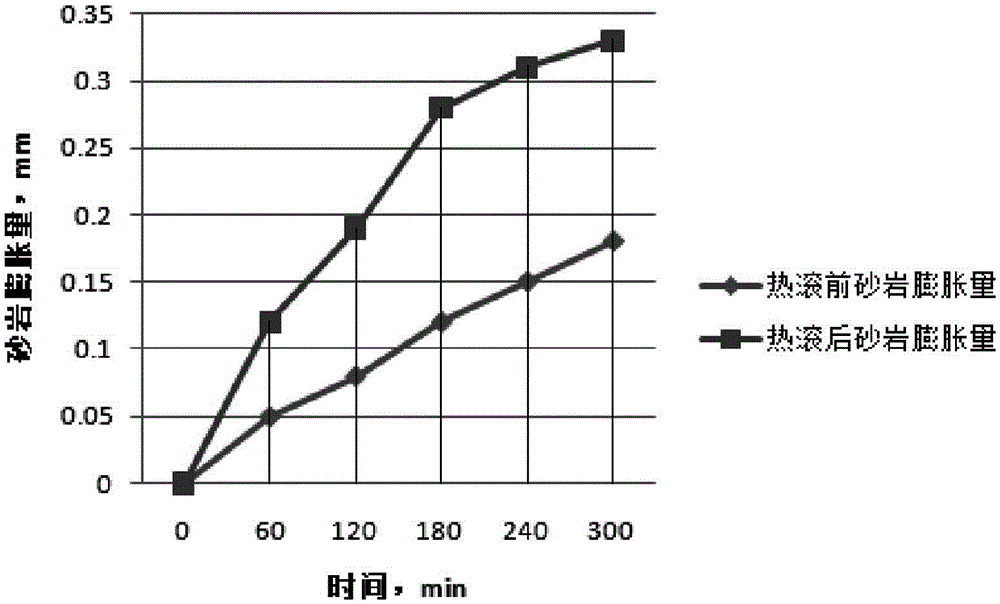

[0015] 1 Evaluation of rheological properties of drilling fluid

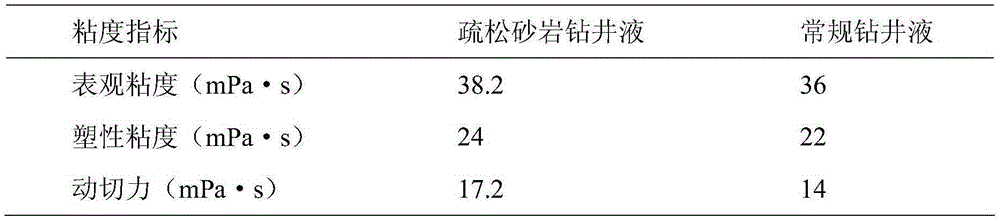

[0016] (1) Rheological property test of drilling fluid before aging

[0017] The rheological properties of the unconsolidated sandstone drilling fluid system were measured according to the drilling fluid experiment standards and compared with conventional drilling fluids, as shown in Table 1.

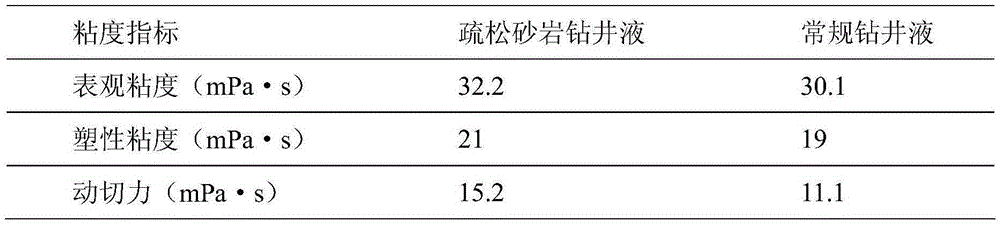

[0018] (2) Rheological property test of drilling fluid after aging

[0019] According to the drilling fluid exper...

Embodiment 2

[0030] The drilling fluid is prepared from water, sodium carbonate, bentonite, weighting agent, inhibitor, fluid loss reducer and viscosifier in parts by weight, water: sodium carbonate: bentonite: weighting agent: inhibitor: filter reducer Lost agent: thickener = 80:3:2:0.5:3:0.5:0.1.

[0031] The weighting agent is barium sulfate; the fluid loss control agent is hydrolyzed polyacrylonitrile monoammonium salt NH4-HPAN; the tackifier is vinyl monomer multiple copolymer PAC143.

[0032] The inhibitor is a mixture of polyethylene glycol and potassium silicate, and the weight ratio of polyethylene glycol and potassium silicate is: polyethylene glycol:potassium silicate=2:3.

Embodiment 3

[0034] The drilling fluid is prepared from water, sodium carbonate, bentonite, weighting agent, inhibitor, fluid loss reducer and viscosifier in parts by weight, water: sodium carbonate: bentonite: weighting agent: inhibitor: filter reducer Lost agent: thickener = 90:8:6:1:8:0.9:0.3.

[0035] The weighting agent is barium sulfate; the fluid loss control agent is hydrolyzed polyacrylonitrile monoammonium salt NH4-HPAN; the tackifier is vinyl monomer multiple copolymer PAC143.

[0036] The inhibitor is a mixture of polyethylene glycol and potassium silicate, and the weight ratio of polyethylene glycol and potassium silicate is: polyethylene glycol:potassium silicate=2:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com