Self-foaming flushing fluid tackifier, flushing fluid configuration reagent, and flushing fluid

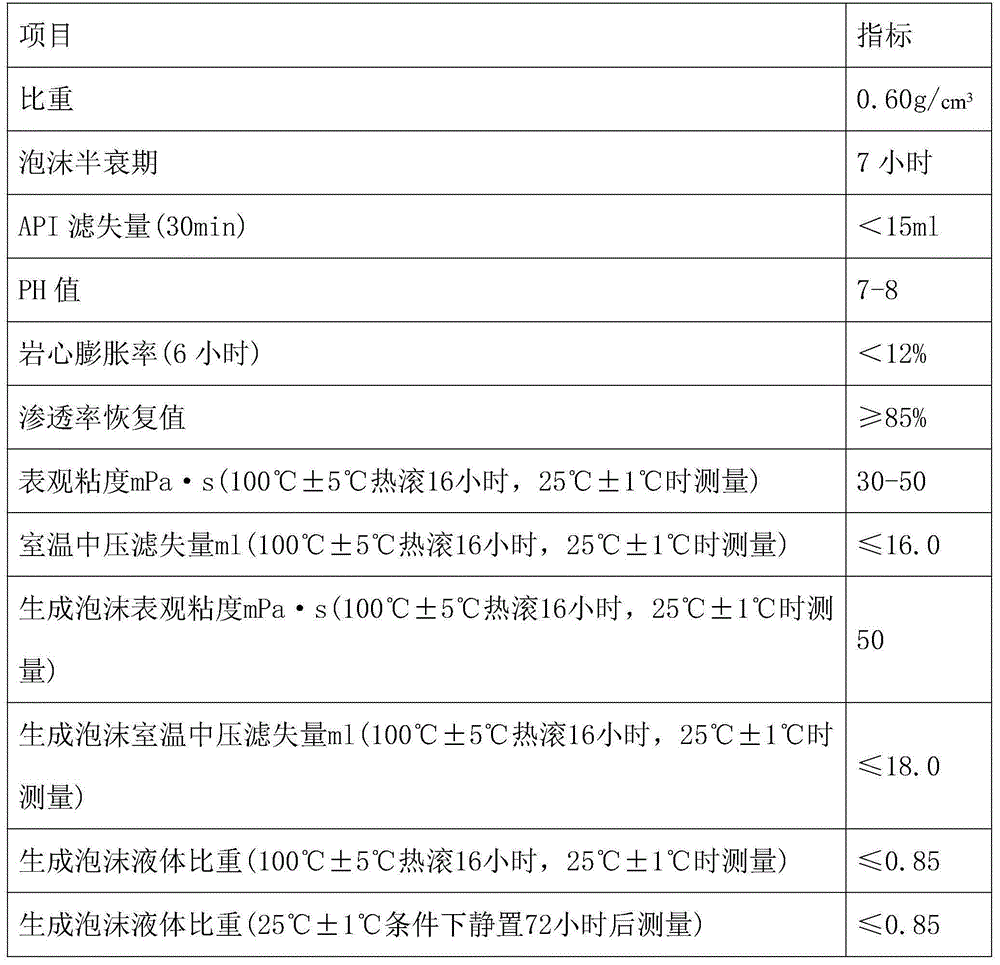

A well-flushing and self-foaming technology, applied in the field of oil and gas field drilling, can solve the problems of inability to continue production and sand production, and achieve the effects of excellent sand-carrying ability, good suspension and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A kind of flushing liquid and preparation method thereof

[0031] The well flushing fluid in this embodiment is prepared from a well flushing fluid preparation agent and water. The preparation agent for well flushing fluid consists of a viscosifier for self-foaming well flushing fluid, a maintenance agent, glacial acetic acid and a density regulator. The self-foaming well flushing fluid viscosifier is prepared by mixing and stirring the following raw materials in parts by weight for 30 minutes in a dry powder mixer: 7 parts of fracturing thickener, 18 parts of biopolymer, and 4.5 parts of polymer fluid loss reducer , 4.5 parts of polyvinyl alcohol, 30 parts of sodium bicarbonate and 36 parts of bentonite.

[0032] The preparation method of the well-flushing fluid of the present embodiment

[0033] The preparation method of the present embodiment is specifically made up of the following steps:

[0034] (1) Base fluid configuration: mix water and self-foa...

Embodiment 2

[0043] Preferred embodiment 2: 8 parts of fracturing thickener, 19 parts of biopolymer, 5 parts of polymer fluid loss control agent, 5 parts of polyvinyl alcohol, 31 parts of sodium bicarbonate and 37 parts of bentonite. In the preparation steps: (1) stirring in the middle for 50 minutes; (2) the use amount of the density regulator is 0.04 times the weight of the base liquid, and the density of the mixed liquid is 0.9 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com