Patents

Literature

81results about How to "Strong ability to carry sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant polymer thickening agent for oil field fracturing fluid as well as preparation method and application of thickening agent

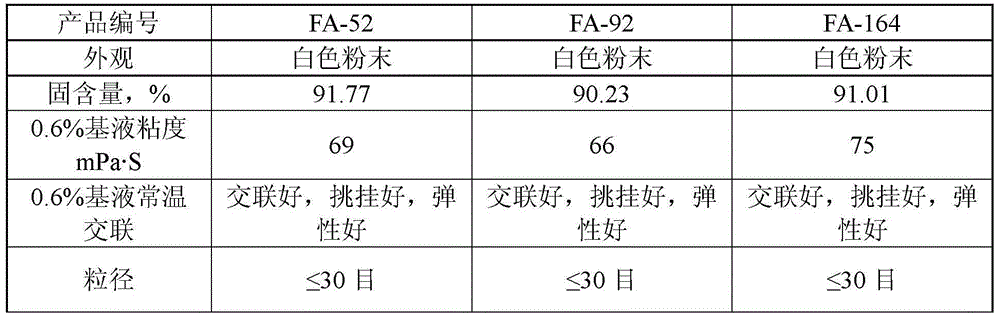

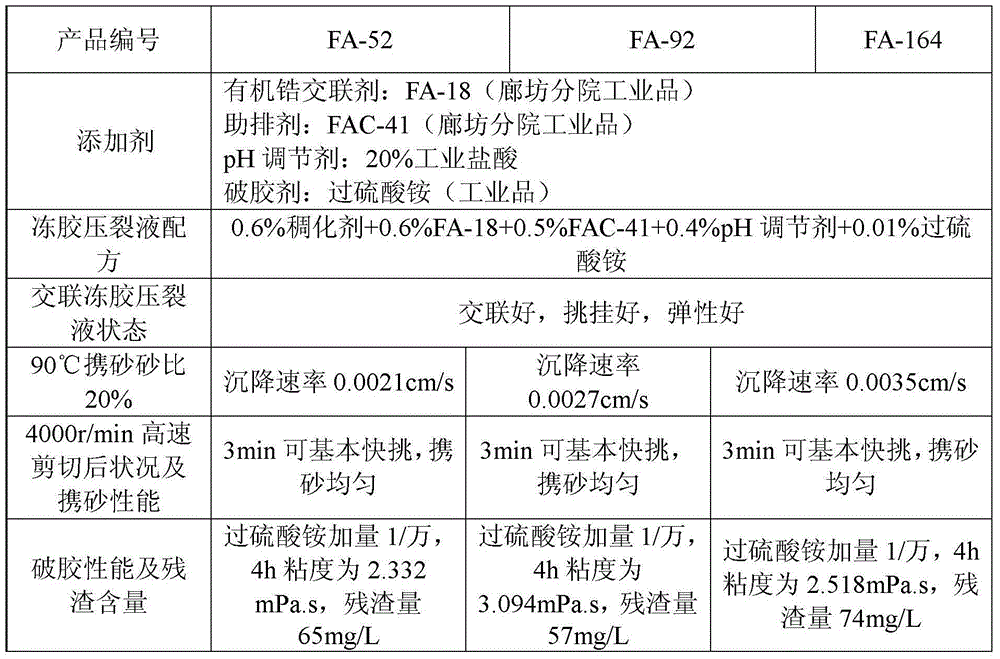

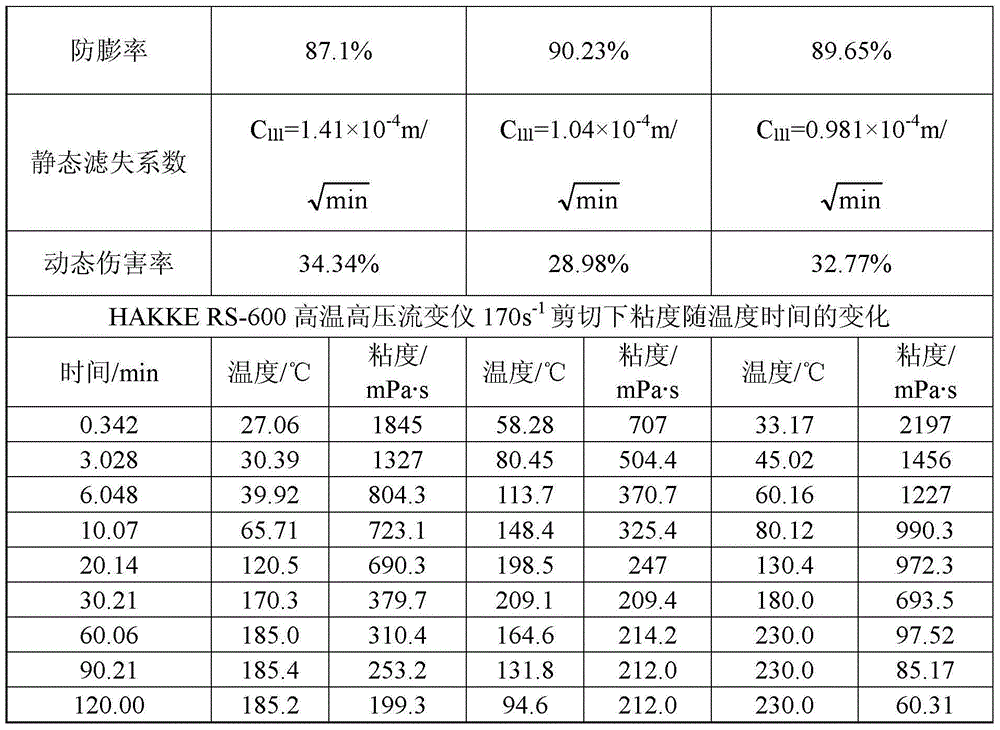

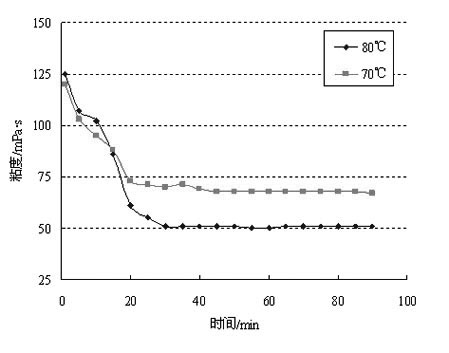

ActiveCN104449643AGood elasticityStrong ability to carry sandDrilling compositionSalt resistanceCarrying capacity

The invention discloses a high-temperature-resistant polymer thickening agent for an oil field fracturing fluid as well as a preparation method and application of the thickening agent. The preparation method of the thickening agent comprises the following step: polymerizing acrylamide, other olefin monomers, an initiating agent and a chain transfer agent in an aqueous solution by virtue of a solution process, wherein the weight ratio of acrylamide to the other olefin monomers to water is (10-20):(6-18):(62-84); and the other olefin monomers are selected from one or more, preferably two or three, of anionic olefin monomers, cationic olefin monomers or non-ionic olefin monomers. According to the high-temperature-resistant polymer thickening agent disclosed by the invention, free radicals are generated by using an aqueous solution catalyst process so as to ensure that the monomers are subjected to ternary polymerization or quaternary polymerization to form the anionic high molecular polyacrylamide polymer with the molecular weight of 4,000,000-8,500,000. After the thickening agent is crosslinked with a crosslinking agent, the thickening agent can be used for tolerating high temperature of more than 210 DEG C, and has the advantages of good crosslinked gel elasticity, strong sand carrying capacity, anti-shearing performance, salt resistance, no residues and the like.

Owner:PETROCHINA CO LTD

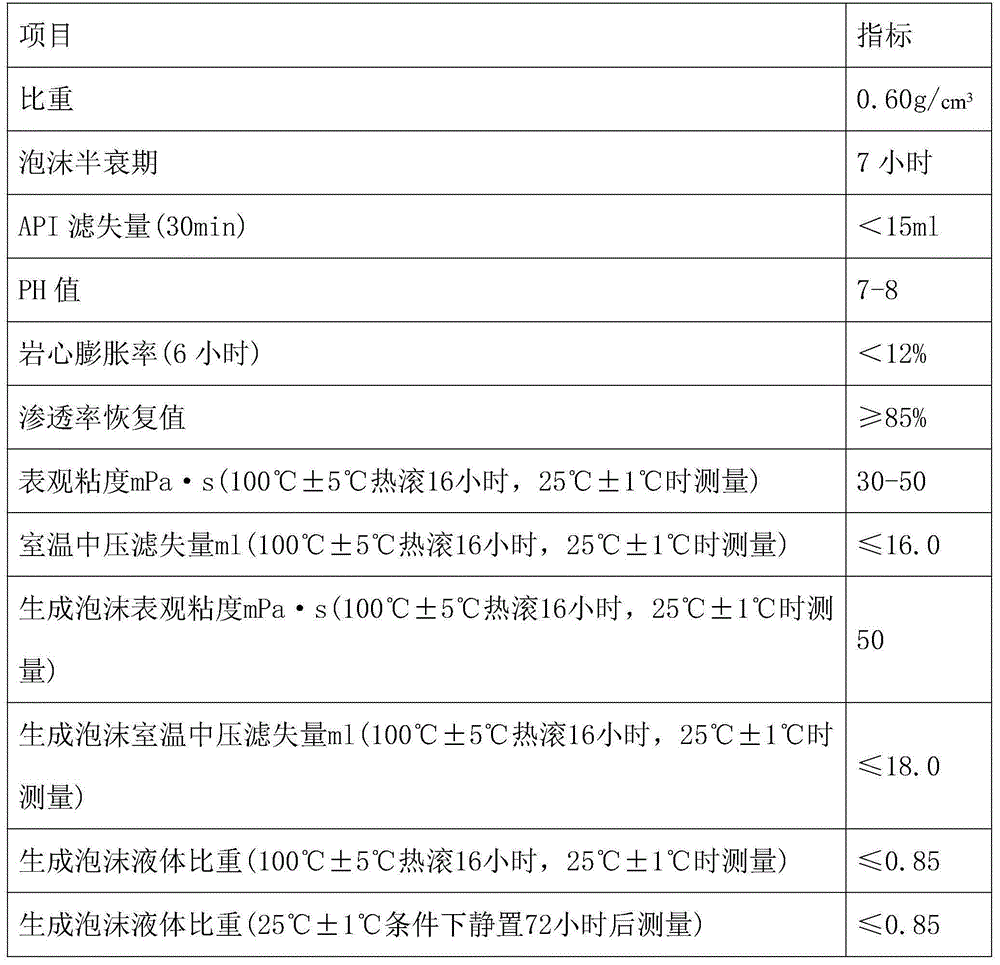

Fracturing fluid system of CO2 cleaning foam

The invention relates to a fracturing fluid system used in an oil and gas field, in particular to a fracturing fluid system of CO2 cleaning foam. The fracturing fluid system comprises the following components in percentage by weight: 0.3-0.8 percent of water-soluble hydrophobic association polymer, 0.25-0.55 percent of rheological auxiliary agent, 0.5-3.0 percent of clay stabilizer, 0.1-0.5 percent of foaming agent, 0.01-0.2 percent of gel breaker, 30.0-80.0 percent of liquid CO2 and the balance of water. Compared with the prior art, in the fracturing fluid system of the CO2 cleaning foam, a cross-linking agent is not needed, the foamability is good, the foam stability is high, the sand-carrying capability is strong, gel breaking is easy to control, no residue is generated after gel breaking, the superficial / interfacial tension of gel-breaking liquid is low, and the damage to the formation is less, and therefore, the fracturing fluid system can be used for fracturing modification of hypoisotonic, low-pressure and water-sensitive storage layers at the temperature of 60-140 DEG C.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

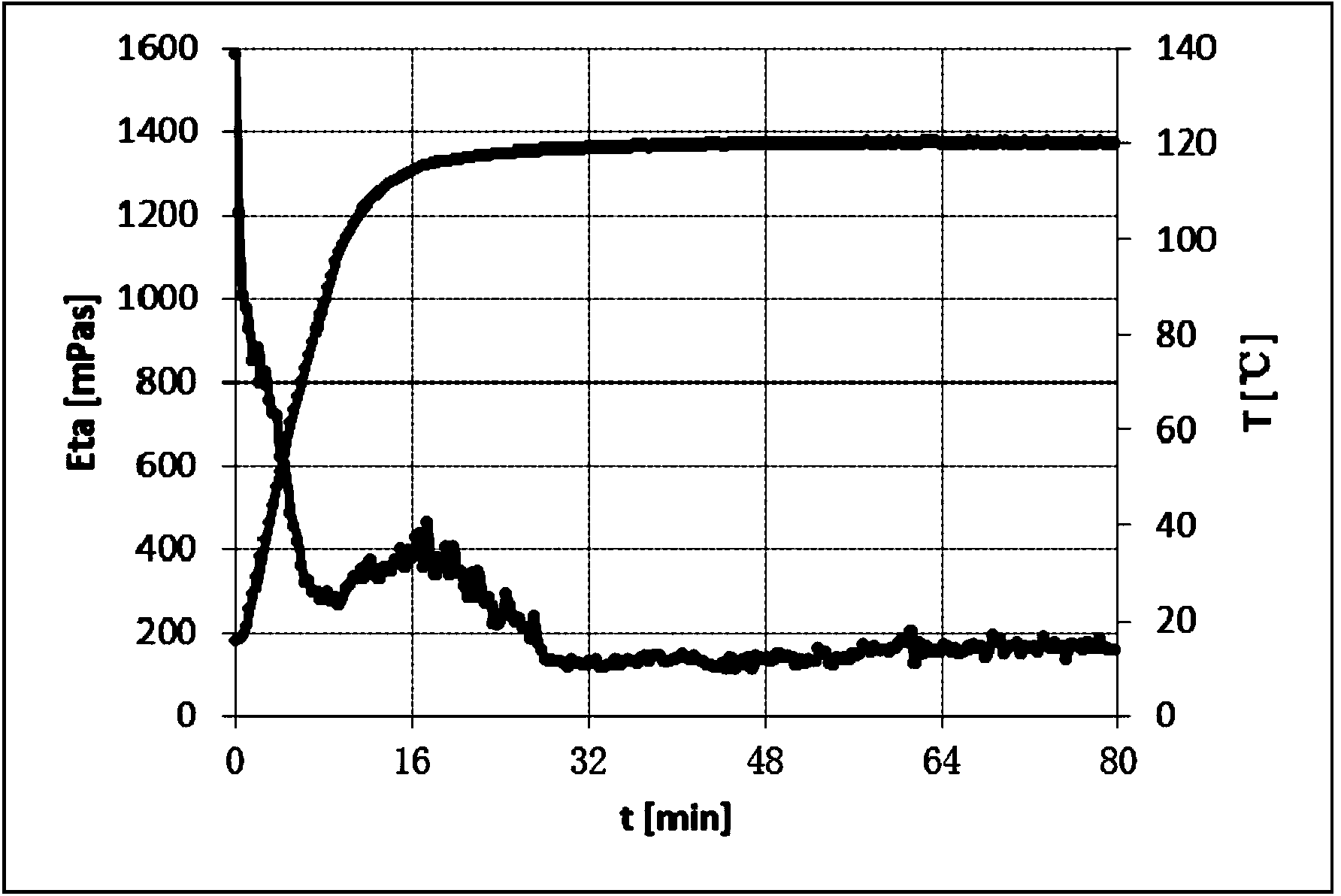

Novel cleaning fracturing fluid system and preparation method thereof

The present invention discloses a novel cleaning fracturing fluid system and a preparation method thereof. The system is characterized in that the fracturing fluid system comprises the following components in percentage by mass: 2%-6% of a cationic surfactant, 1%-5% of a cosurfactant, 0.5%-2% of an organic salt, 2%-7% of an inorganic salt and the balance of water. The preparation method for the cleaning fracturing fluid comprises the steps of: first mixing the cationic surfactant, the cosurfactant and water to obtain a uniform and transparent liquid; and sequentially adding an aqueous solution of the organic salt and the inorganic salt into the uniform and transparent liquid in the case of stirring, and stirring the system for uniform mixing. The preparation method for the cleaning fracturing fluid is simple, convenient in operation, good in viscoelasticity of the system and strong in sand-carrying capability without residues, breaks gels with water or oil automatically, and is easy to return and has small harm to strata.

Owner:CHINA PETROLEUM & CHEM CORP +1

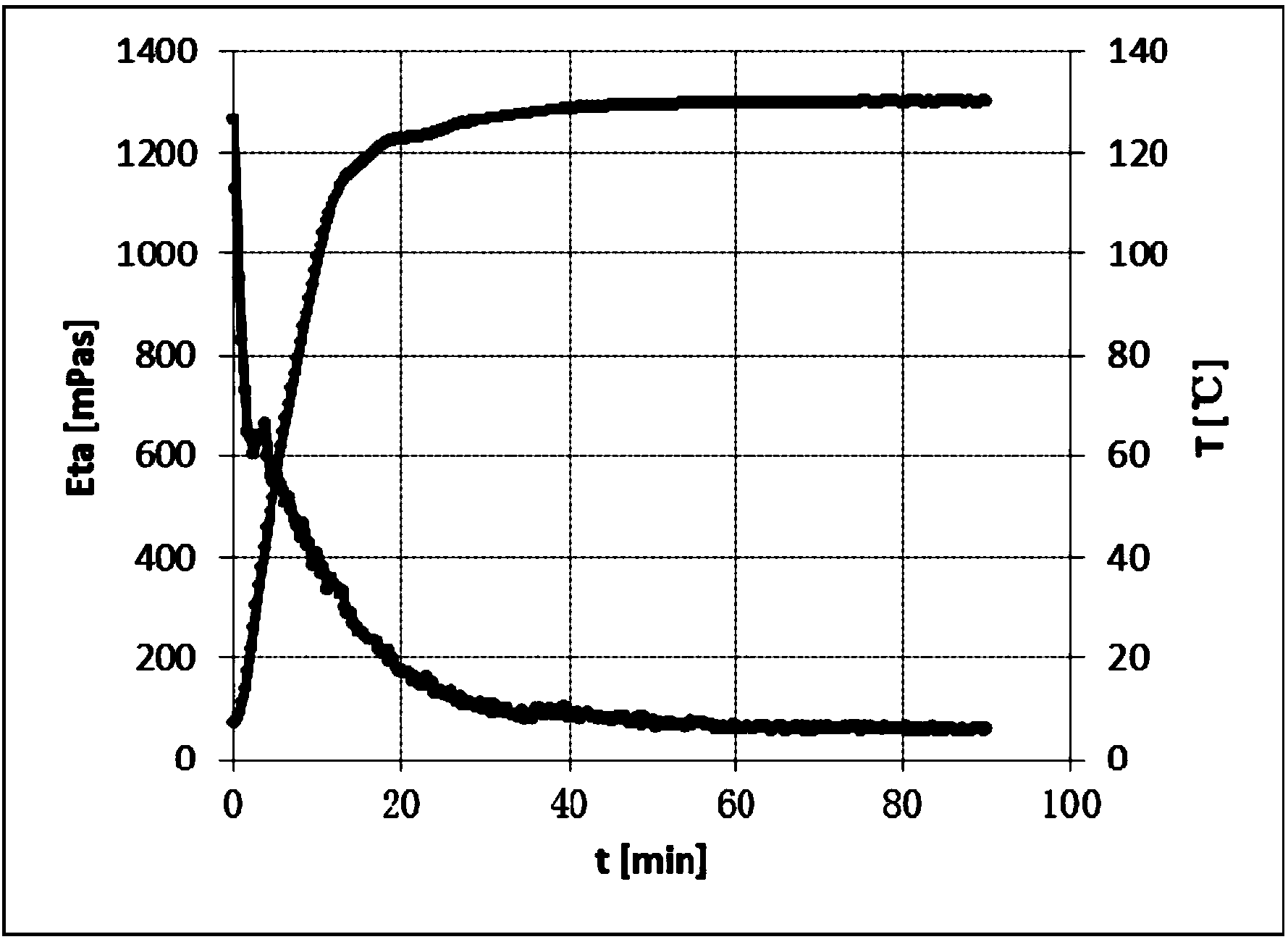

Clean fracturing fluid and preparation method thereof

InactiveCN105505370AEasy to prepareEasy to operateDrilling compositionFracturing fluidViscoelasticity

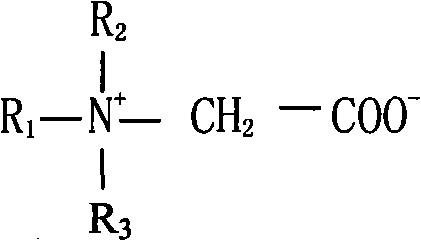

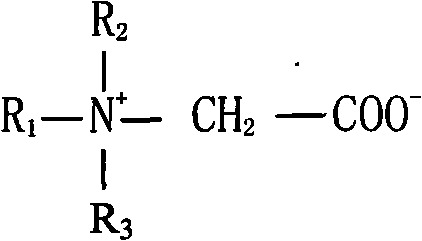

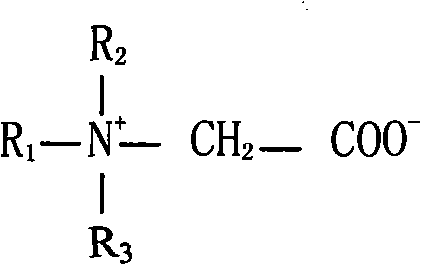

The present invention discloses a clean fracturing fluid system and a preparation method thereof, wherein the fracturing fluid system comprises, by mass, 3-6% of a cationic surfactant, 1-4% of a zwitterionic surfactant, 0.5-1.5% of counter ion, 2-5% of an electrolyte, and the balance of water. The clean fracturing fluid preparation method comprises: mixing a cationic surfactant, a zwitterionic surfactant and water to obtain a uniform transparent liquid, adding an aqueous solution of an electrolyte salt and counter ion to the uniform transparent liquid under stirring, and uniformly mixing to obtain the clean fracturing fluid. According to the present invention, the method has characteristics of simpleness and convenient operation, and the clean fracturing fluid system has characteristics of good viscoelasticity, strong sand-carrying ability, no residue, automatic gel breaking with water or oil, easy flowback, and low damage on stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cationic polymer densifier, fracturing fluid and preparation method thereof

ActiveCN104177534ANot easy to degradeIncrease polarityDrilling compositionPolymer scienceFracturing fluid

The invention discloses a cationic polymer densifier, a fracturing fluid and preparation methods of the cationic polymer densifier and the fracturing fluid. The cationic polymer densifier is prepared from the following components in percentage by weight: 30-35% of acrylamide monomer, 10-12% of dimethyl diallyl ammonium chloride monomer, 4-5% of anti-crosslinking agent, 4-5% of solubilizer, as well as redox initiator, 2, 2'-azo diisobutyl amidine dihydrochloride and the balance of water, wherein the redox initiator accounts for 0.05-0.06% of the total weight of the two monomers and 2,2'-azo diisobutyl amidine dihydrochloride accounts for 0.04-0.05% of the total weight of the two monomers. The fracturing fluid is prepared from the following components in percentage by weight: 0.8-1.0% of cationic polymer densifier, 0.3-0.4% of anionic association agent, 1.0-1.5% of antiswelling agent, 0.03-0.05% of gel breaker and the balance of water. The invention further discloses the preparation methods of the densifier and the fracturing fluid. The fracturing fluid disclosed by the invention has the characteristics of strong high-temperature resistance and anti-shear ability, low friction and less harm.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

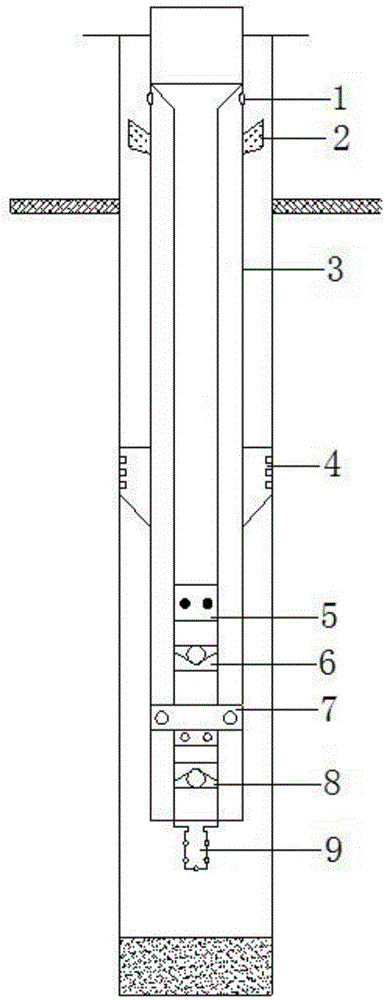

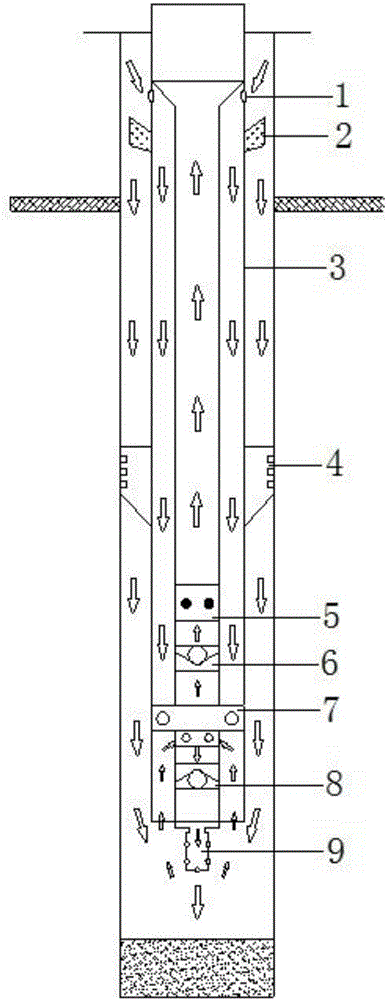

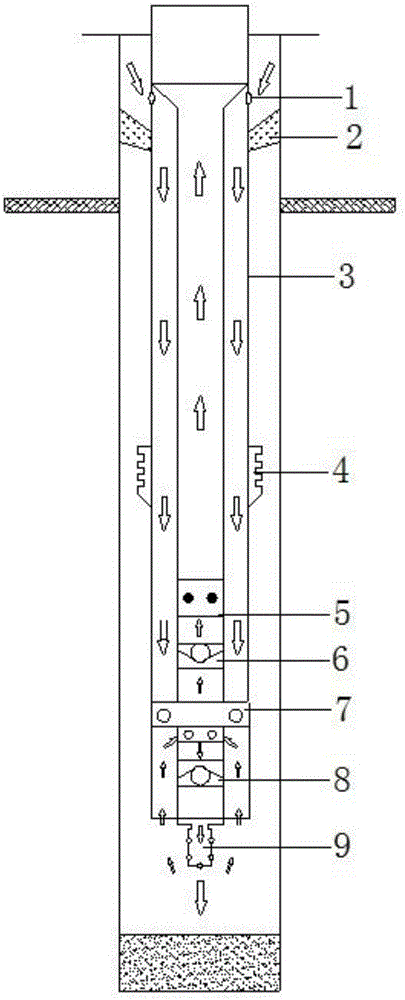

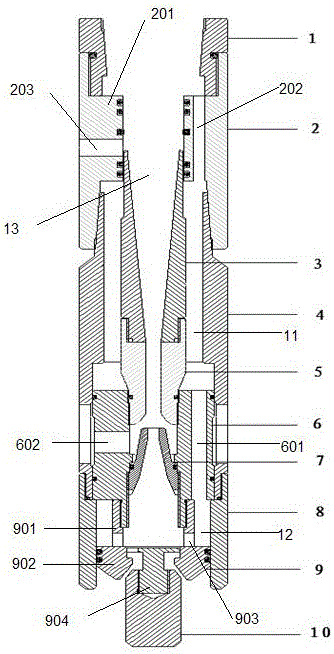

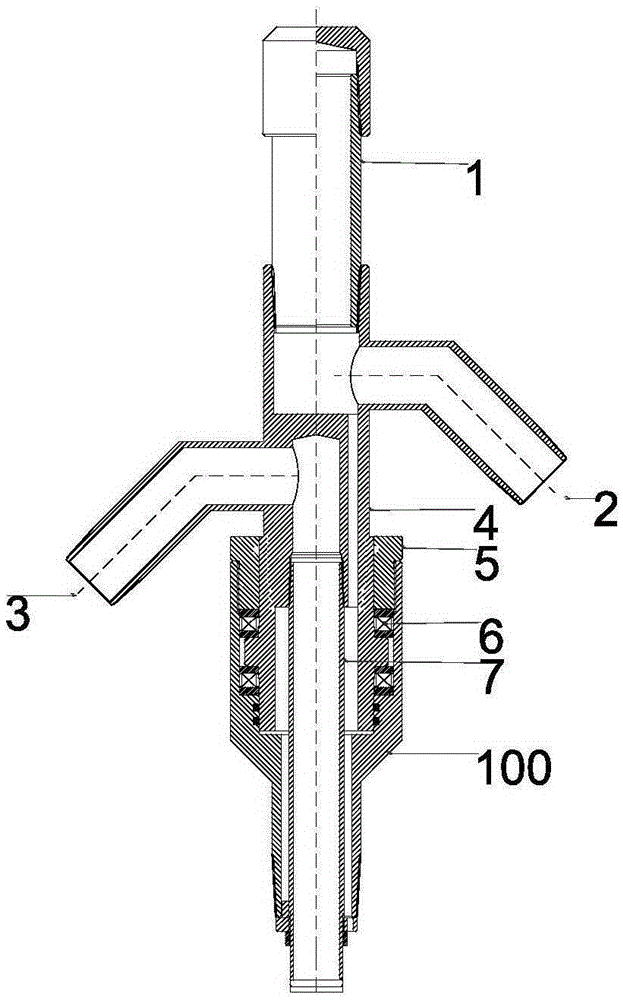

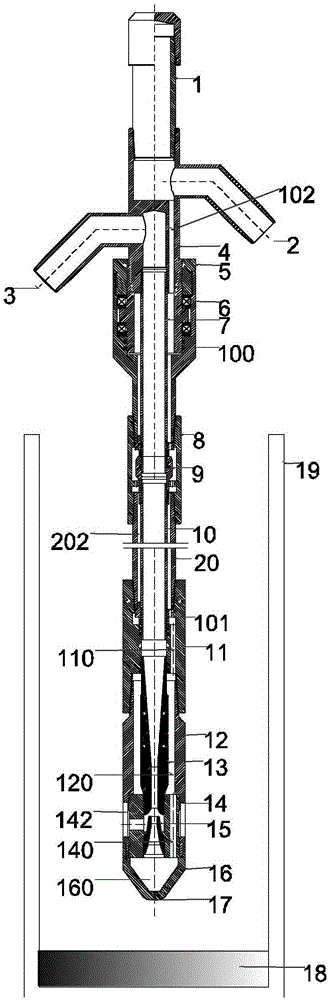

Oil well pipe cleaning and sand flushing integrated device and pipe cleaning and sand flushing method

ActiveCN106194112ARealize the technical requirements of scraper sand washing processReduced risk of stuck pipeDrilling rodsCleaning apparatusPositive pressureOil well

The invention discloses an oil well pipe cleaning and sand flushing integrated device. The device comprises a shunt nipple, a shunt packer, a double-layer pipe body, a pipe scraper and a sand flushing nipple which are mutually communicated and are each of a double-layer pipe structure; the pipe cleaning and sand flushing method comprises the steps that the pipe scraper is opened, the shunt packer is recovered, the device is placed down in an oil well casing, a well cleaning fluid is injected into casing annulus, and pipe cleaning and well cleaning are completed; after the sand surface position is determined, the pipe scraper is recovered, and the shunt packer is subjected to setting; a sand cleaning fluid is injected into the casing annulus, and the bottom of a well is flushed through positive pressure sand flushing or negative pressure sand flushing; finally, the shunt packer is upset, and pulling out of the hole is conducted. According to the oil well pipe cleaning and sand flushing integrated device, pipe cleaning and sand flushing operation can be achieved at a time, for formation leakage, both positive pressure sand flushing and negative pressure sand flushing can be conducted, the risk of sticking operation is reduced, the pipe cleaning and sand flushing operation efficiency is improved, the well-completion operation cycle is shortened, and the well-completion operation cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Formula of high-dispersion slurry for slurry shield

InactiveCN104177008AReduce water lossStrong ability to carry sandCarboxymethyl celluloseSodium Bentonite

The invention relates to a formula of high-dispersion slurry for a slurry shield. The high-dispersion slurry is composed of bentonite, water, sodium carbonate, sodium carboxymethyl cellulose (CMC) and a polycarboxylic acid superdispersant, wherein sodium carbonate accounts for 0.01-0.1% of the mass percent of bentonite, CMC accounts for 0.1-20% of the mass percent of bentonite, the polycarboxylic acid superdispersant accounts for 0.1-7% of the mass percent of bentonite, and total solids account for 1-5% of the mass percent of the water. The formula is characterized in that the polycarboxylic acid superdispersant is used. The slurry disclosed by the invention can be used for slurry balance shield construction, has a favorable stabilizing effect for excavation faces with different geologic structures and has better dispersibility, lower water loss as well as more excellent sand carrying capacity and stability as comparison with other kinds of common slurry.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

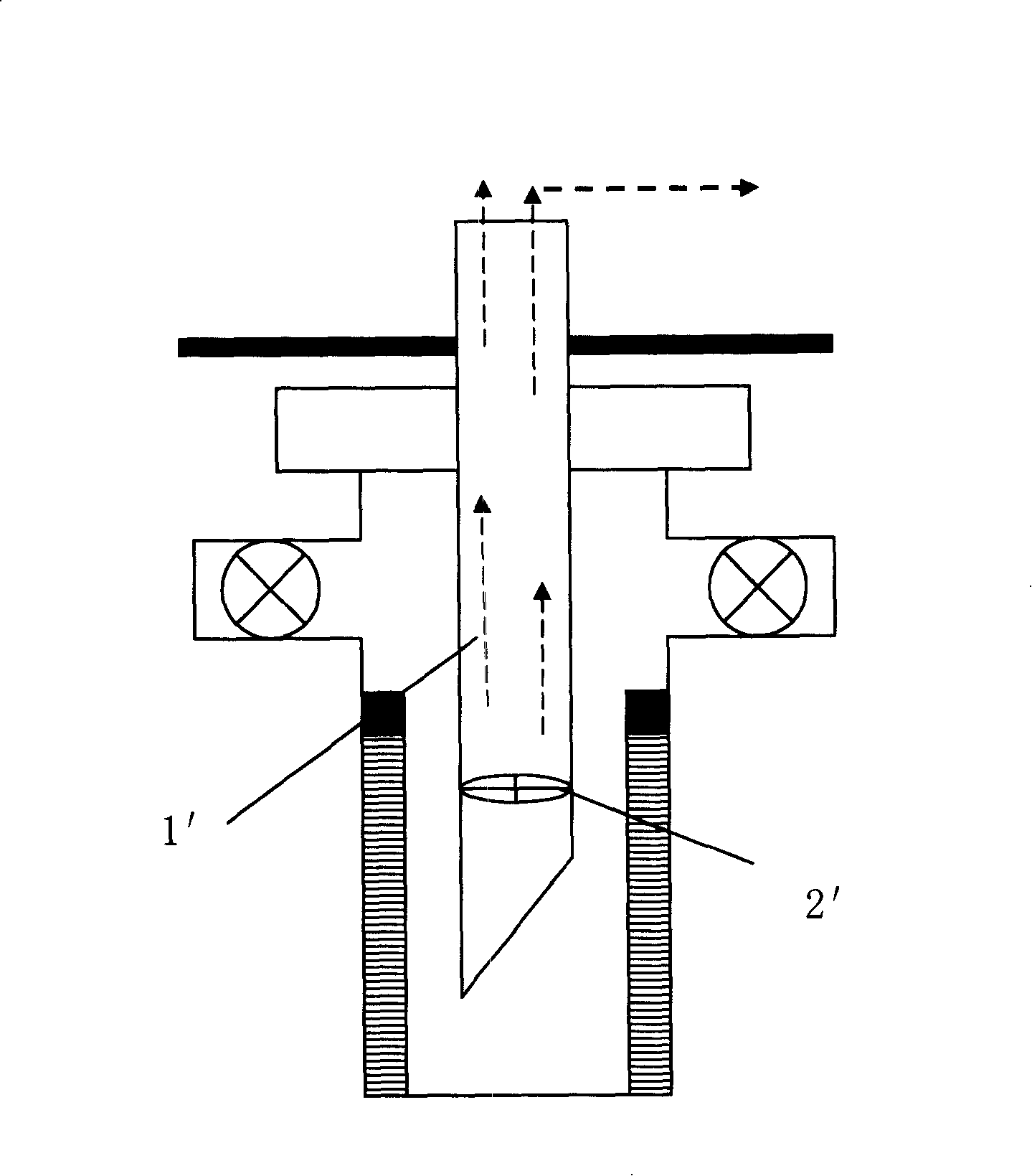

Continuous sand flushing technique and continuous sand flushing device thereof

The invention discloses a continuous sand-washing process and a continuous sand-washing device formed by, firstly, mounting control valves one by one on the upper port of a sand-washing pipe column and on the upper port of a single sand-washing pipe column. When the control valve is open, a regular sand-washing pipe column reaches down. When the sand-washing pipe column approaches or reaches the sand sediment or oil send at the bottom of a well, if extension is needed, single sand-washing pipe columns provided with control valves are connected one by one to establish sand-washing circulation channel, start a mud pump and carry out sand-washing operation; the control valve in open state allows double-way passage and offers such options as regular positive circulation operation and reverse circulation operation. Meanwhile, the control valve is started or closed manually to decouple from or couple with the single sand-washing pipe column. The invention is not subject to the restriction of sand medium and is particularly suitable for sand-washing operation by nitrogen foam under low-pressure well. The process saves the pressure-releasing time for connecting single sand-washing pipe column every time, realizes continuous sand washing, improves efficiency, prolongs the time of oil well production, and thus reduces cost and increases benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

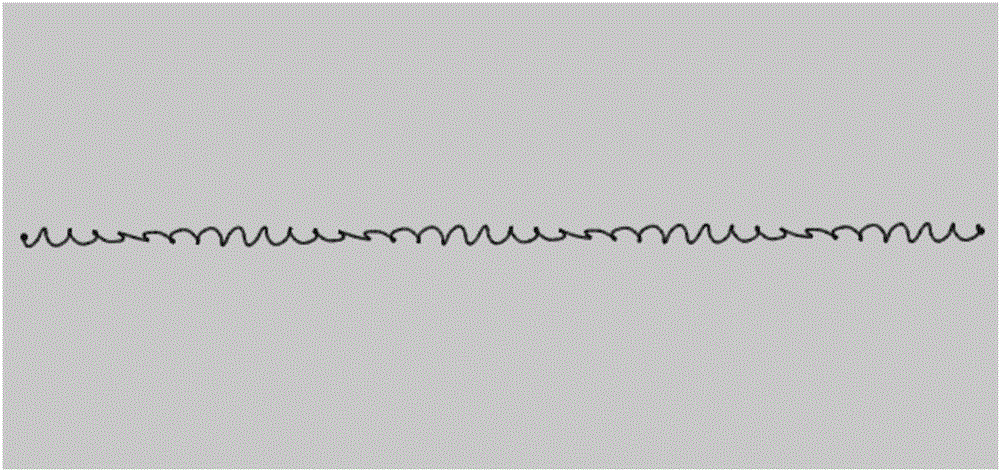

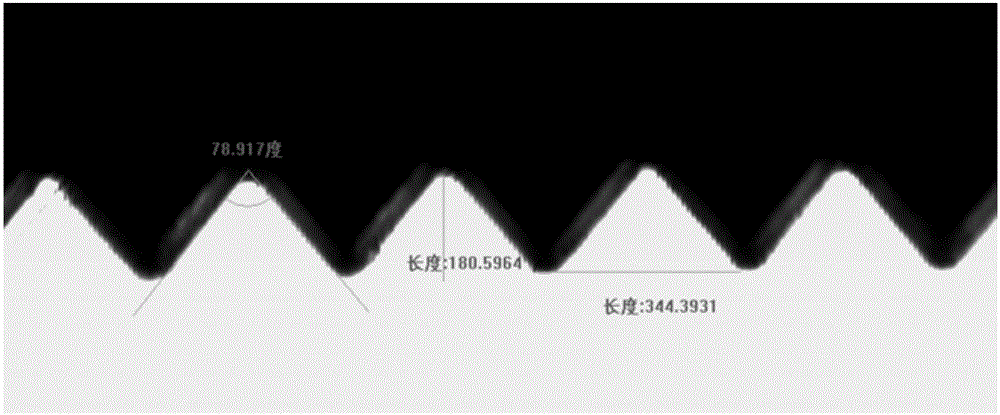

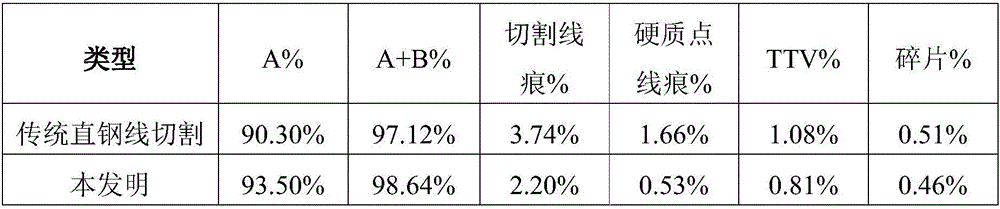

Wire-cutting method of crystalline silicon

InactiveCN106738395AReduce disconnectionStrong ability to carry sandFine working devicesWire cuttingCrystalline silicon

The invention relates to a wire-cutting method of crystalline silicon. The wire-cutting method adopts online mortar and a structure wire for cutting, cutting speed and cutting efficiency are improved effectively, yield is increased, cost of auxiliary materials like mortar is lowered, and slice profitability is improved.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

Organic aluminum-zirconium crosslinking agent and preparation method thereof, and low-molecular polymer fracturing fluid

InactiveCN104371699AImprove high temperature resistanceFacilitate cross-linkingDrilling compositionSolubilityFracturing fluid

The invention discloses an organic aluminum-zirconium crosslinking agent and a preparation method thereof, and a low-molecular polymer fracturing fluid. The crosslinking agent is prepared by reacting the following raw materials in parts by weight: 15-25 parts of zirconium salt, 15-25 parts of aluminum salt, 150-250 parts of polyalcohol, 75-85 parts of organic acid, 15-25 parts of gluconate and 55-65 parts of water. The organic aluminum-zirconium crosslinking agent has excellent high temperature resistance, and has favorable crosslinking effect under the conditions of high temperature and high salinity. The organic aluminum-zirconium crosslinking agent is stable under the condition of low pH value, can implement acid crosslinking, and ensures the normal proceeding of the acid fracturing. The organic aluminum-zirconium crosslinking agent has favorable compatibility with polymers and high crosslinking capacity; and the fracturing fluid formed by compounding the organic aluminum-zirconium crosslinking agent with polymers has the advantages of stable gel, excellent solid carrying capacity, excellent viscosity breaking performance and excellent shearing resistance under high-temperature conditions. The organic aluminum-zirconium crosslinking agent has the characteristics of high solubility, no pollution and low damage degree to the reservoir, and has wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water base guanidine gum fracturing fluid and preparation method thereof

The invention provides water base guanidine gum fracturing fluid, and belongs to the field of oil field fracturing technologies. The water base guanidine gum fracturing fluid comprises the following ingredients: guanidine gum derivative, cross-linking agents, gel breakers, thickening agents, PH value adjusting agents and water. The invention further provides a water base guanidine gum fracturing fluid preparation method. The method includes the following steps of (1) dissolving gelatinizing agents in the water, evenly mixing, and obtaining thickened water; (2) dissolving the cross-linking agents in the water, evenly mixing and obtaining cross-linking agent water solution; (3) adjusting the PH value of the thickened water to 9-10, then slowly adding the cross-linking agent water solution into the thickened water to obtain jelly solution; (4) and adding the thickening agents into the jelly solution, and finally adding the gel breakers to obtain the water base guanidine gum fracturing fluid. The water base guanidine gum fracturing fluid is low in sludge content after gel breaking, and meanwhile the cost of the water base guanidine gum fracturing fluid is greatly reduced.

Owner:BEIJING RECHSAND SCI & TECH GRP

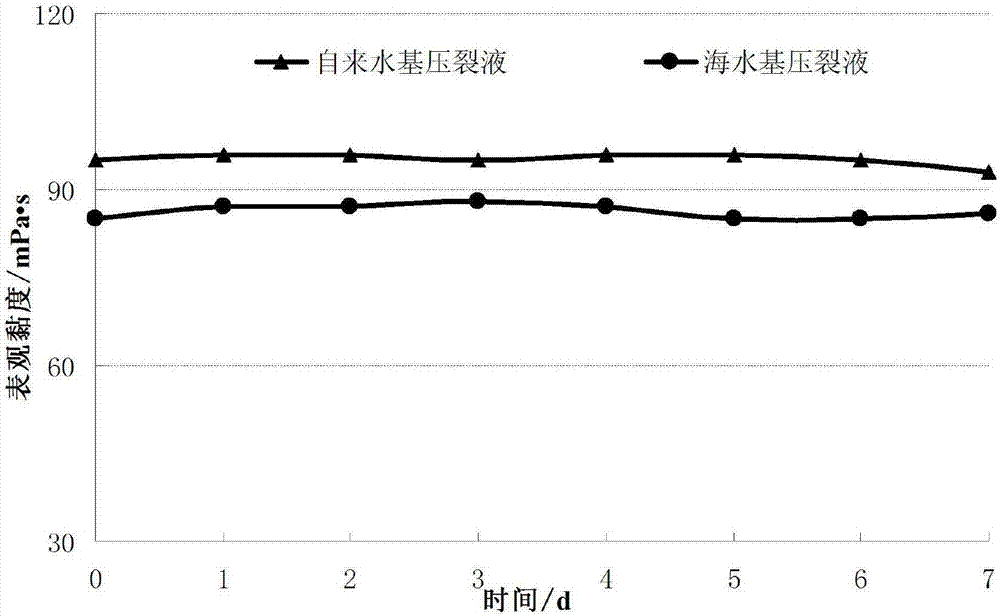

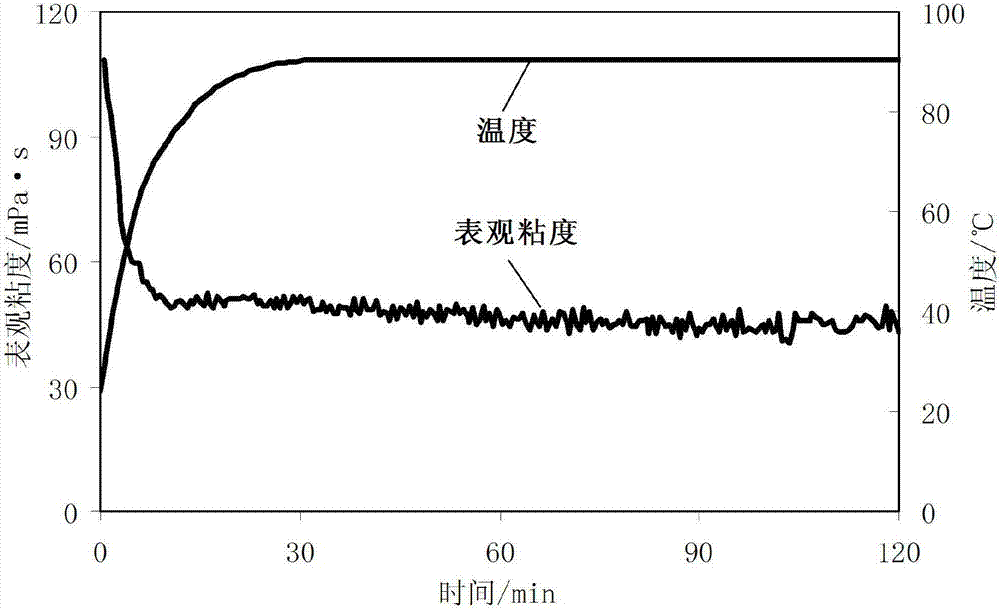

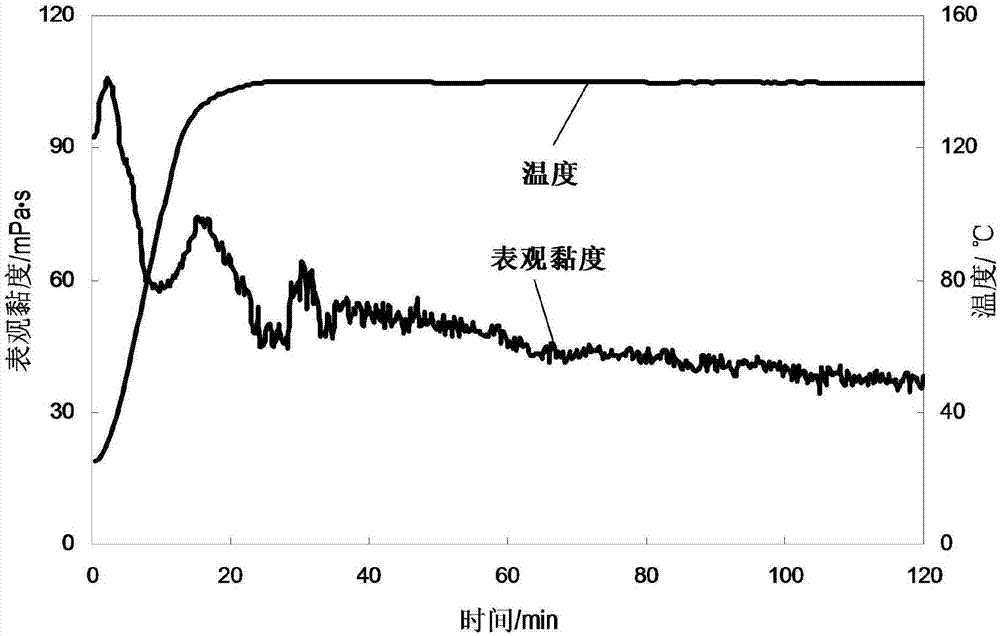

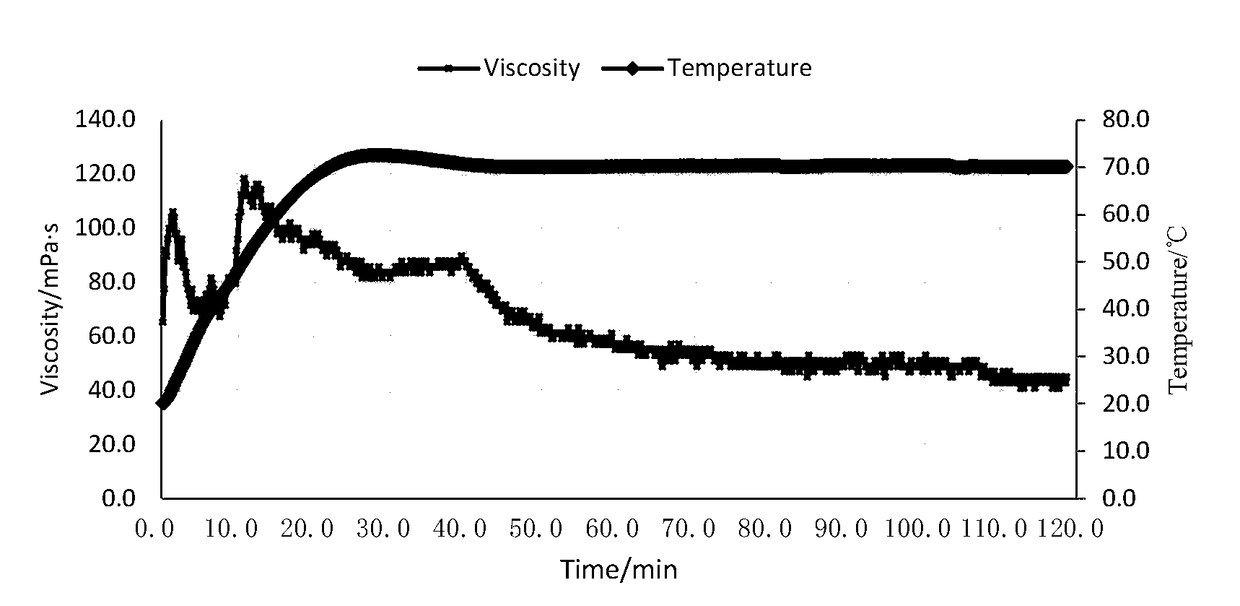

A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof

ActiveCN107474816AFast dissolutionImprove solubilityDrilling compositionPolymer scienceFracturing fluid

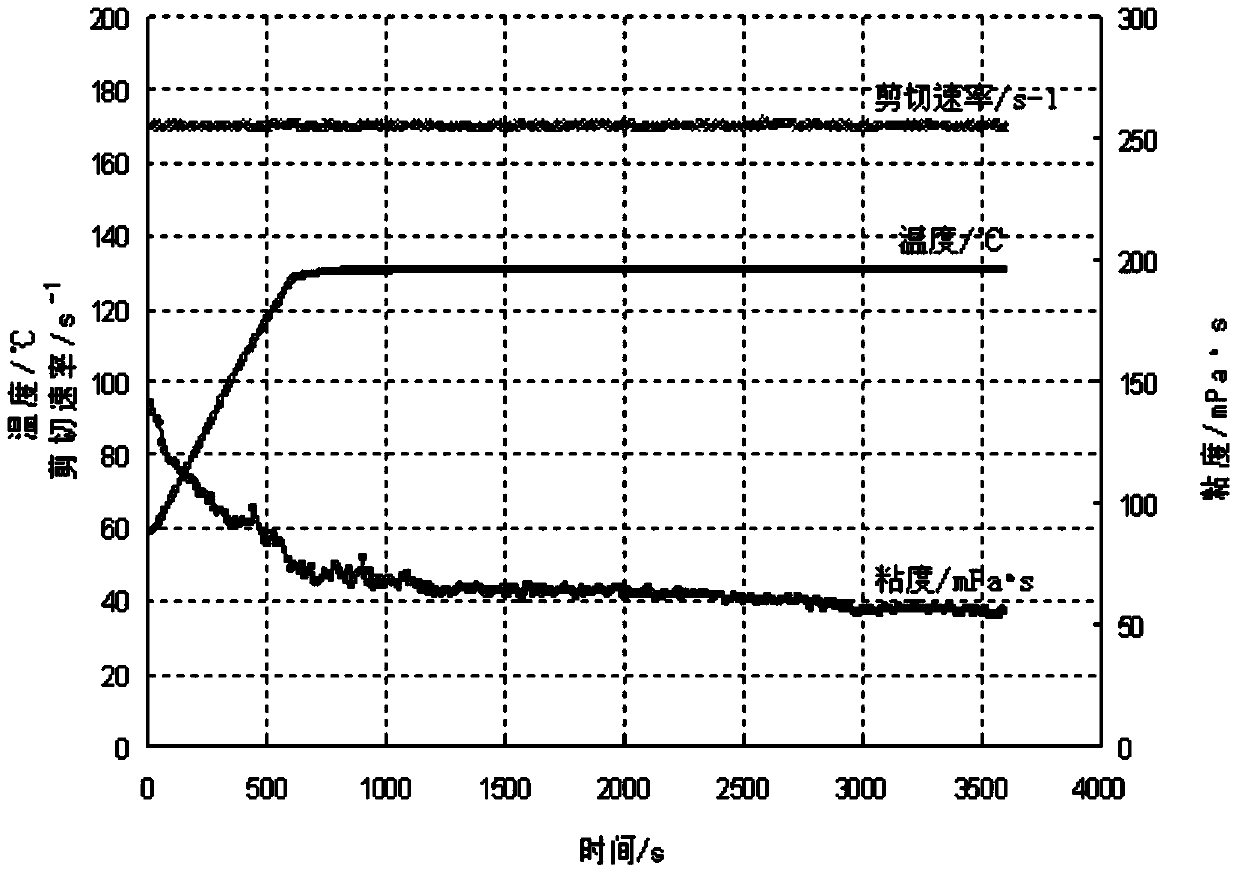

A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof are disclosed. The fracturing fluid includes 0.4-0.8 wt% of a thickening agent, 0.3-0.6 wt% of an auxiliary synergist, 0.2-0.4 wt% of an activating agent, 0.2-0.4 wt% of a metal ion stabilizer, and 0.3-0.4 wt% of a temperature stabilizer, with the balance being seawater. Beneficial effects of the fracturing fluid are that: a water-soluble multi-component copolymer is adopted as the thickening agent of the fracturing fluid system so that the fracturing fluid can rapidly swell in seawater having a high degree of mineralization; a low-viscosity high-elasticity fluid having a high space structure is formed through synergistic effects (non-crosslinking functions) with the auxiliary synergist; a sand-carrying property is good when the apparent viscosity is greater than 20 mPa.s; the prepared fracturing fluid is not eroded by bacteria, has characteristics of salt resistance, good temperature resistance and shearing resistance, low harm, no residue after cleaning, and the like, and can be prepared in batch or mixed continuously by adopting sea water; and the fracturing fluid can significantly reduce offshore fracturing construction costs and can increase fracturing construction efficiencies and reservoir yield-increasing effects.

Owner:SOUTHWEST PETROLEUM UNIV +1

Clean air foam cracking liquid

The invention provides a clean air foam cracking liquid. The clean air foam cracking liquid is prepared by mixing the following components in percentage by mass: 0.4% to 1.5% of zwitter-ion surfactant, 0.3% to 2.0% of composite cation ion surfactant, 0.0% to 0.5% of foam stabilizer, 0.5% to 3.0% of clay stabilizer, 0.6% to 2.05 of low-molecular alcohol, and the balance of water. The clean air foamcracking liquid has the advantages that the anion ion surfactant is not contained, so that the preparation is simple; after indoor evaluation, the foam quality can reach 55% to 80%, the foam qualityis high, the viscosity is high, and the sand carrying ability is excellent; by utilizing the surfactant beams to mutually wind and adhere, the crosslinking agent is not required, the adhesive breakingspeed is quick, and the permeability of the reservoir can be well protected because the anion ion surfactant is not contained after adhesive breaking and the adsorption with stratum dose not occur; under the condition of lower adding amount of surfactant, the better temperature-resistant property is obtained; the cost is low, and the preparation technology is simple.

Owner:河北中大永迪生物科技有限公司

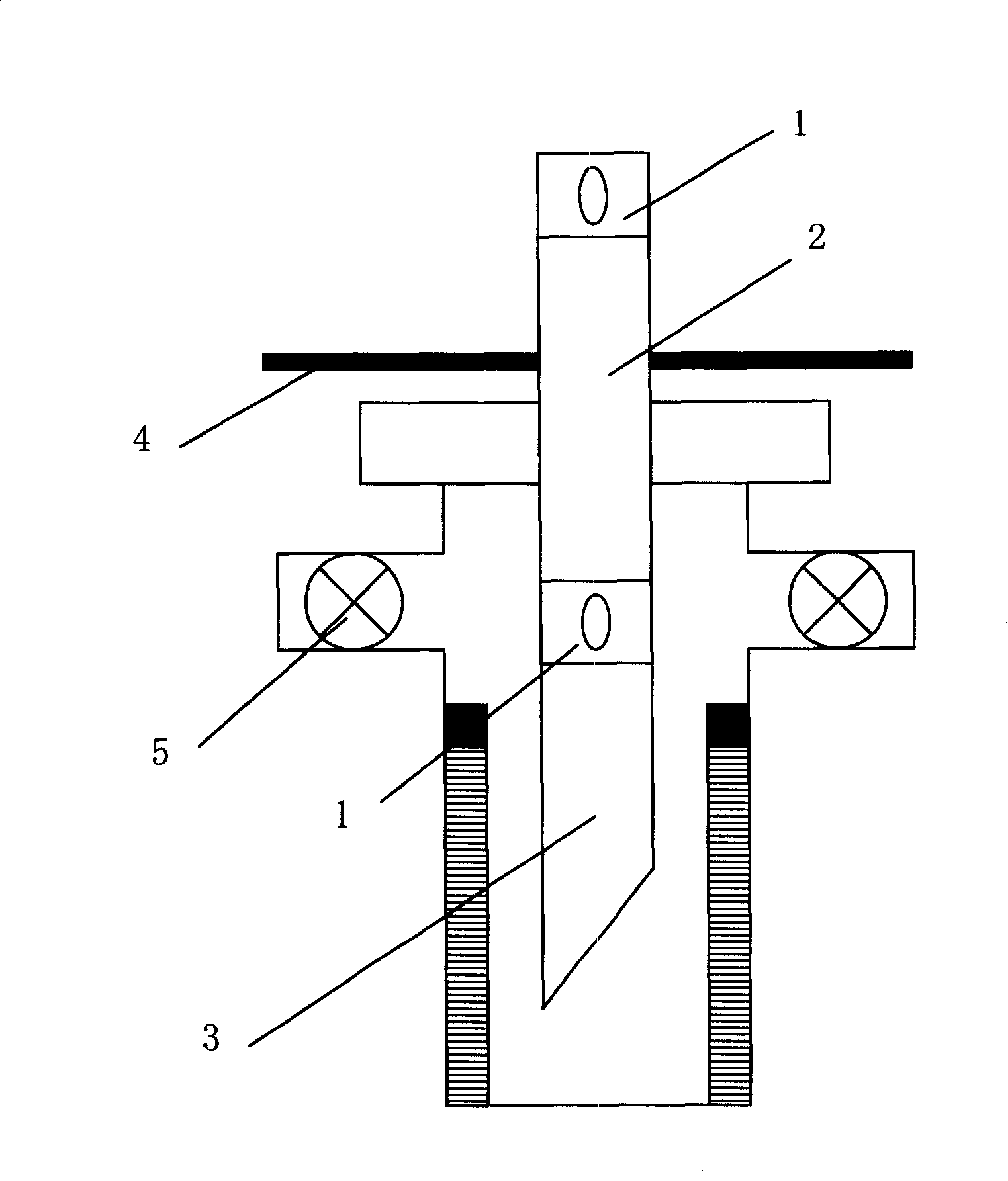

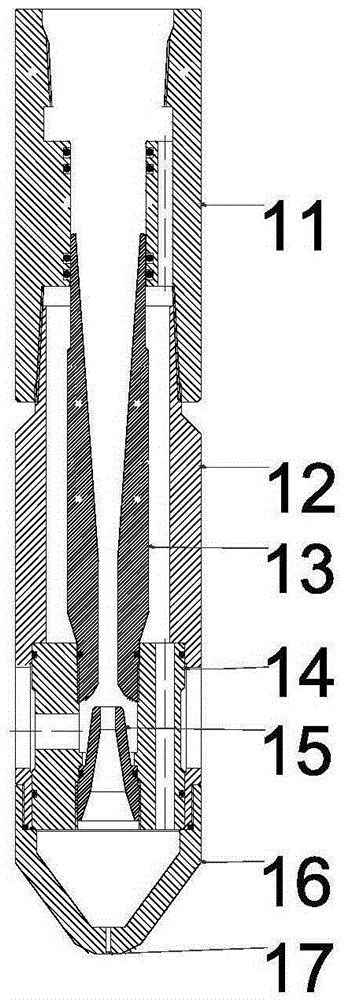

Concentric double-tube sand removal well-washing machine

The invention provides a concentric double-tube sand removal well-washing machine. The concentric double-tube sand removal well-washing machine comprises an upper joint, a backwashing bridge joint, a diffusion tube, a working cylinder, a choke, a jet flow bridge joint, a nozzle, a lower joint, a supporting seat and a supporting valve; backwashing is implemented by the concentric double-tube sand removal well-washing machine; during well washing, a flowing channel of the well-washing machine is small, an impacting force on a well bottom is strong, a concentric double-tube inner tube is small in diameter, flowing speed of well-washing liquid is high, and sand carrying capability of the well-washing liquid is also high; and moreover, when the sand removal well-washing machine reaches to the well bottom, a well-washing channel can be closed, high negative pressure can be generated through high-speed water flow of the nozzle, and flowback capability is improved.

Owner:PETROCHINA CO LTD

Clean polymer-free carrier fluid

InactiveCN101831284AStrong ability to carry sandReduce frictionDrilling compositionCross-linkOrganic acid

The invention provides clean polymer-free carrier fluid, which is characterized by mainly comprising the following components in percentage by weight: 0.5 to 15 percent of surfactant, 0.2 to 2 percent of cross-linking aid, 0.2 to 5 percent of stabilizing agent and the balance of solvent, wherein the surfactant is long-chain betaine surfactant, the cross-linking aid is organic acid salt, the stabilizing agent is long-chain alcohol, and the solvent is small molecular alcohol solution. The clean polymer-free carrier fluid effectively overcomes the defects of low effective content of primary agents and difficult liquid preparation, solves the problem of non-uniform dispersion of a propping agent, and has the characteristics of strong viscous elasticity, high suspension property, multiple functions, expanding prevention and difficult deterioration.

Owner:东营利丰化工新材料有限公司

Loose sand oil accumulation replacement sand prevention method

The invention provides a sand control technology for loose sandstone. Before sand control, by foam huff and negative-pressure mixed arrangement, the foam is used to discharge reservoir sand and clay particle fully, which are distributed unevenly near borehole zone; than high-pressure gravel is filled to sand control, even gravels are filled in the deficit stratum near borehole to improve the seepage behavior near borehole zone. The invention changes the seepage behavior of uneven stratum near borehole zone in basic, improves the well production rate, reduces the plugging near borehole zone by solid particles such as fine-silt sand, clay particle and so on in effect, and prolongs the valid period of sand control.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Recyclable fracturing fluid used for fracturing construction of sandstone gas reservoir

The invention discloses a recyclable fracturing fluid used for fracturing construction of a sandstone gas reservoir. A primary fracturing fluid comprises the following components in weight percent: 1% to 5% of chloridization stearic acid dimethylamino alcohol ester methyl ammonium, 1% to 5% of potassium chloride and the balance of water. The recyclable fracturing fluid has the advantages of leak-off of the fracturing fluid can be lowered, the pollution to the stratum can be reduced, and flowback liquid is reclaimed on the ground directly, so that earth surface pollution can be avoided; the flowback liquid is reclaimed, so that the water consumption can be lowered; the flowback liquid can be reused after being subjected to ground treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

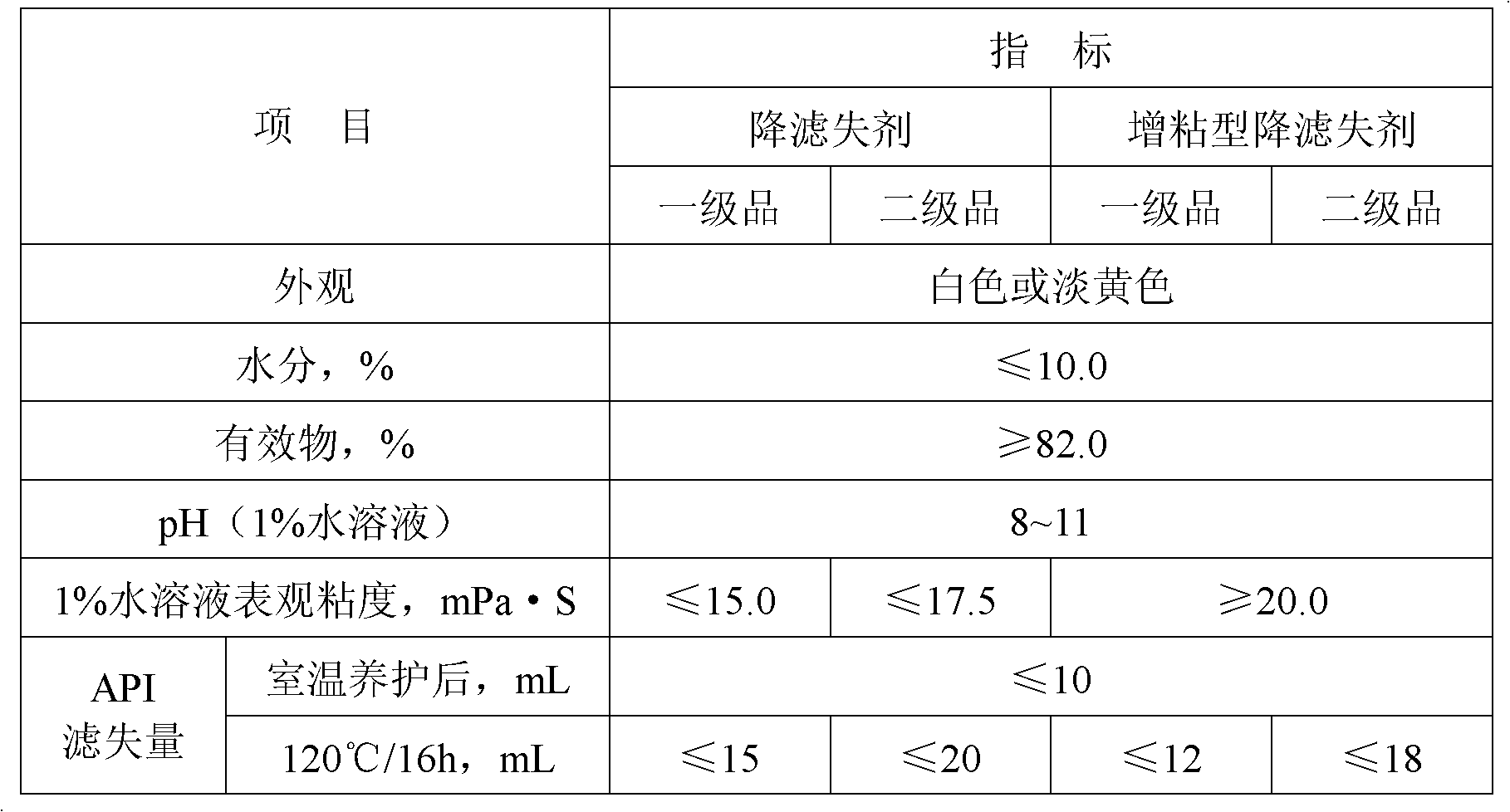

Drilling fluid for drilling horizontal well by filling nitrogen

InactiveCN103320102AEasy to adjustImprove performanceDrilling compositionWell drillingHorizontal wells

The invention discloses a drilling fluid system for drilling a horizontal well by filling nitrogen, and relates to the technical field of drilling fluid systems for drilling horizontal wells by filling nitrogen. The drilling fluid system disclosed by the invention comprises the following components in parts by weight: 0.29-0.41 parts of thickening agent, 0.17-0.23 parts of fluid loss agent, 4.3-4.7 parts of anti-collapse agent, 1.65-1.95 parts of temporary plugging agent, 0.50-0.70 parts of lubricating agent, 0.12-0.18 parts of defoaming agent, 0.08-0.12 part of pH adjustor and 91.71-92.89 parts of water. The drilling fluid system disclosed by the invention is used in the horizontal well under-balance drilling operation by filling nitrogen in the Changqing oilfield in the Ordos basin is used, therefore, the well can be effectively purified; the well wall is kept steady under negative pressure conditions; hydrocarbon reservoirs are protected; the mechanical drilling speed is increased; furthermore, the drilling fluid system is wide in material source and is easy to operate; the field drilling construction is convenient.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

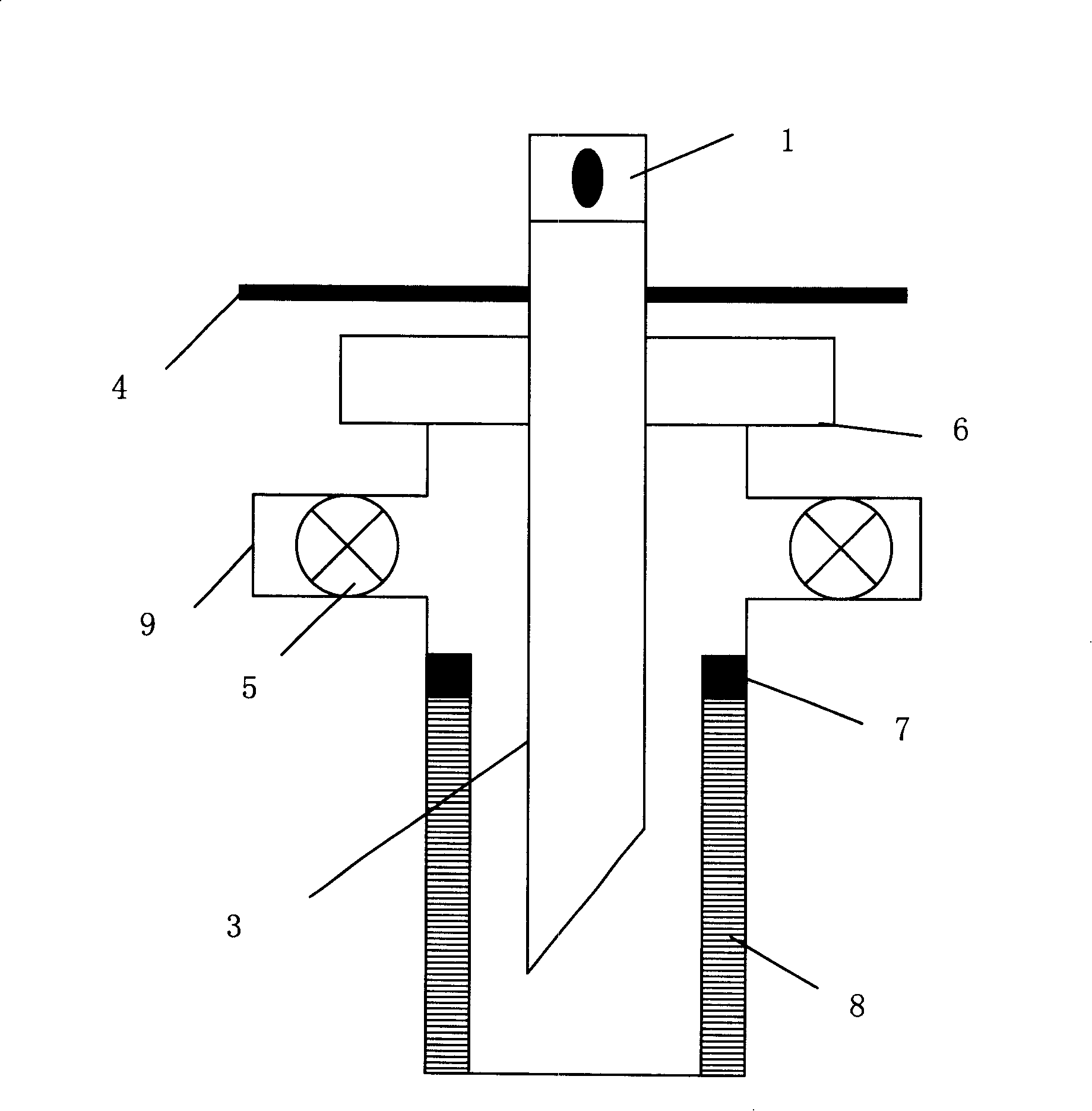

Well clean-up sand washing device and method

InactiveCN105332675AStrong sprintIncrease spitting speedCleaning apparatusFree rotationCarrying capacity

The invention discloses a well clean-up sand washing device and method. The well clean-up sand washing device comprises a faucet, a double-layer concentric oil pipe and a well clean-up device, wherein the faucet is provided with double flow channels and can rotate freely; the double-layer concentric oil pipe is connected with the faucet and is provided with a center channel and an annular flow channel; the well clean-up device is connected with the double-layer concentric oil pipe and can wash and jet flow for swabbing. By means of the well clean-up sand washing device and method, the technological requirements for being high in sprint force and sand-carrying capacity, capable of overcoming the defect of stratum low-pressure loss and the like can be met in the well clean-up sand washing process of a water well, and wellbore immediate vicinity blockage can be eliminated to a certain degree through the well clean-up device with the negative pressure swabbing function.

Owner:金湖县支点石油科技有限责任公司

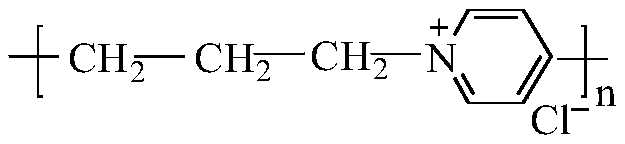

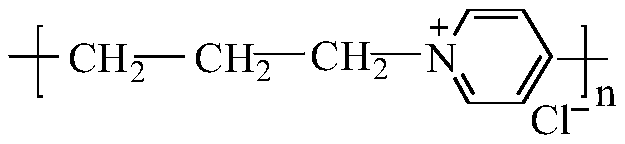

Sand-preventing method of artificial borehole wall, and material for sand prevention

ActiveCN107163926AImprove salt toleranceCalcium resistantFluid removalDrilling compositionAlkylphenolSURFACTANT BLEND

The invention discloses a sand-preventing method of an artificial borehole wall, and a material for sand prevention. The material for sand prevention comprises guide liquid, sand carrying liquid and promoting liquid which are prepared separately, wherein the guide liquid comprises the following components in percentage by weight: 0.5 to 20 percent of sodium chloride, 0.2 to 2 percent of calcium chloride, 0.1 to 1 percent of magnesium chloride, 0.2 to 4 percent of alkylphenol polyoxyethylene, 0.3 to 8 percent of an anionic surfactant capable of resisting calcium and magnesium ions and 0.01 to 6 percent of a dimethyl diallyl ammonium chloride-acrylamide-acrylic acid copolymer; the sand carrying liquid comprises the following components in percentage by weight: 0.01 to 5 percent of a dimethyl diallyl ammonium chloride-acrylamide copolymer and 0.5 to 20 percent of ammonium chloride; and the promoting liquid comprises the following components in percentage by weight: 8 to 22 percent of a penetrating agent and 18 to 35 percent of a dehydroxylation catalyst. The material for sand prevention performs sand prevention, can protect the stratum, has high sand carrying capability, reduces friction and enhances the consolidation strength, and the penetration ratio of the artificial borehole wall formed after sand prevention is more than 12 <mu>m<2>.

Owner:东营市科诺石油技术有限责任公司

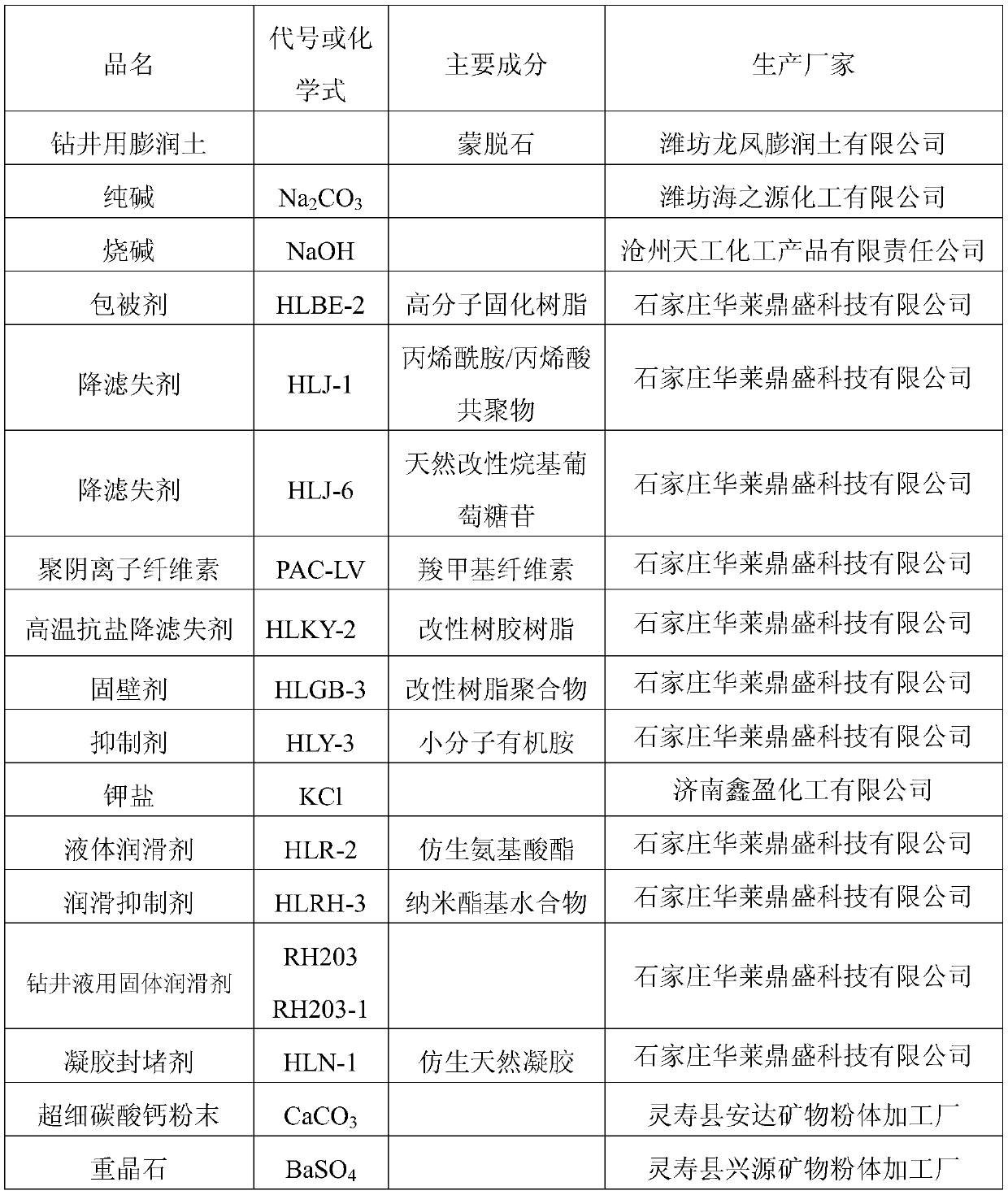

Three-protection-function water-base drilling fluid system

InactiveCN111574973AImprove performanceEasy to dehydrateDrilling compositionCellulosePhysical chemistry

The invention discloses a three-protection-function water-base drilling fluid system. Raw materials comprise 1000 parts of tap water, 40-50 parts of bentonite, 2-3 parts of sodium carbonate, 0.5-1 part of sodium hydroxide, 3-5 parts of coating agents HLBE-2, 6-8 parts of filtrate reducers HLJ-1, 15-20 parts of filtrate reducers HLJ-6, 5-7 parts of polyanionic cellulose PAC-LV, 5-10 parts of high-temperature salt-resistant filtrate reducer HLKY-2, 20-25 parts of wall-fixing agents HLGB-3, 20-25 parts of liquid lubricants HLR-2, 20-25 parts of lubrication inhibitors HLRH-3, 20-25 parts of drilling fluid solid lubricants, 5-10 parts of inhibitors HLY-3, 70-80 parts of KCl, 2-2. 5 parts of gel plugging agents HLN-1, 10-15 parts of superfine calcium carbonate powder, and a weighting agent. Thethree-water-retention-base drilling fluid system has good inhibition performance and good plugging performance, and is used for drilling of mud rock-siltstone inclined shaft sections and horizontal sections. Therefore, a problem that the well wall is prone to instability in the drilling process of water-based drilling fluid is solved, and the three-protection function of protecting the well wall,protecting an oil-gas layer and protecting the environment is achieved.

Owner:石家庄华莱鼎盛科技有限公司

Polymer-type acidic slickwater and preparation method thereof

InactiveCN106566523AImprove diversion capacityImprove fracturing effectFluid removalDrilling compositionHydrofluoric acidOrganic acid

The invention relates to the technical field of reconstruction of reservoirs of oil and gas fields, particularly to polymer-type acidic slickwater and a preparation method thereof. The polymer-type acidic slickwater comprises the following raw materials by mass percent: 0.1% to 7.5% of acid, 0.05% to 0.2% of an acid resistant resistance-reducing agent, 0.05% to 0.5% of a discharge aiding agent and 0.05% to 0.5% of a clay stabilizer, and the balance being water, wherein the acid is at least one in hydrochloric acid, organic acid and hydrofluoric acid. According to the polymer-type acidic slickwater, low-concentration hydrochloric acid is adopted to dissolve parts of carbonate minerals on the surfaces of cracks, non-uniform etchings are formed on the wall surfaces of the cracks, and flow conductivity of the cracks is strengthened; slickwater has certain viscosity, so that a propping agent can be effectively conveyed to far ends of the cracks, flow conductivity of the cracks is further strengthened, and the fracturing transformation effect on the reservoirs is improved; and the preparation method is simple, the preparation cost is low, the harm of the prepared polymer-type acidic slickwater to the reservoirs of the carbonate minerals is small, the polymer-type acidic slickwater easily flows back, prop-carrying capacity is high, and mining and yield increase of the reservoirs of the oil and gas fields are effectively achieved.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

Extended bentonite for drilling fluid and method for making same

InactiveCN1594491AHigh pulping rateFilter vector lowInorganic pigment treatmentCelluloseSodium Bentonite

The invention relates to extended bentonite for drilling fluid and method for making same, wherein the bentonite comprises alta-mud, sodium hydroxide, sodium salt, cellulose, starch, polypropylene ammonia, positive electricity adhesive, composite glue, and the preparing process comprises coarse crushing, finely crushing, screening, watering and stirring, squeezing, drying, and milling.

Owner:赵玉梅

Structural polymer foam stabilizer for foam fracturing and method for preparing structural polymer foam stabilizer

ActiveCN106928957AReduce drainageReduce gas diffusionDrilling compositionCarrying capacityPolymer science

The invention provides a structural polymer foam stabilizer for foam fracturing and a method for preparing the structural polymer foam stabilizer. The structural polymer foam stabilizer is characterized in that the foaming ratio of aqueous solution with 0.3 wt% of structural polymer foam stabilizer is higher than or equal to 600%, and the half life of the aqueous solution is longer than or equal to 12 h. The method includes steps of carrying out multilevel initiation polymerization on deionized water, solubilizers, water-soluble monomers with ethylene groups, structural monomers, anionic surface-active monomers, anionic surfactants, oxidation-reduction system initiators and azo-initiators to obtain polymerization products; heating the polymerization products until the temperatures of the polymerization products reach 80-95 DEG C and carrying out heat reaction for 8-24 h to allow the molecular weights of obtained polymers to be 2000-4000 thousands so as to obtain the structural polymer foam stabilizer. The structural polymer foam stabilizer and the method have the advantages that the structural polymer foam stabilizer is excellent in foam stabilization performance and efficient in foaming performance, high in sand carrying capacity and operability and low in cost and is temperature-resistant and shear-resistant, and excellent solubilization synergistic effects can be realized.

Owner:北京爱普聚合科技有限公司

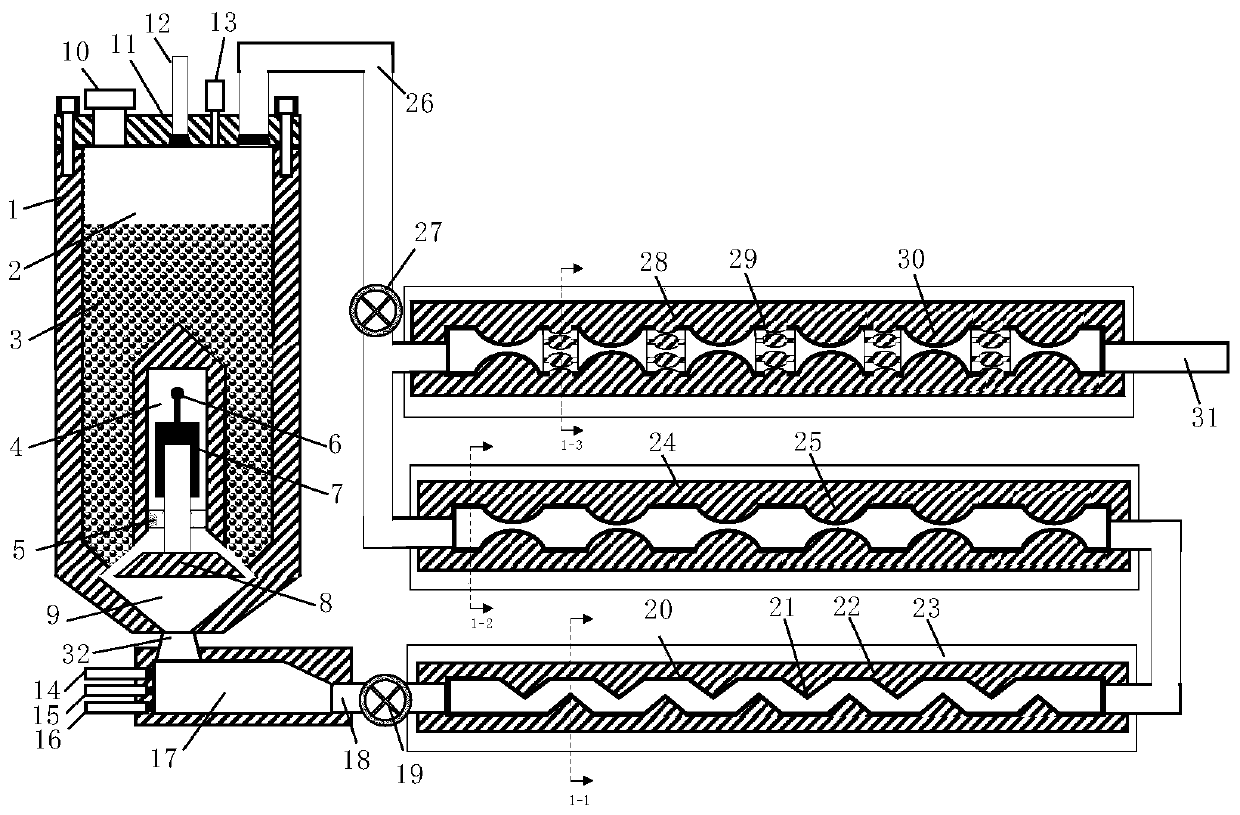

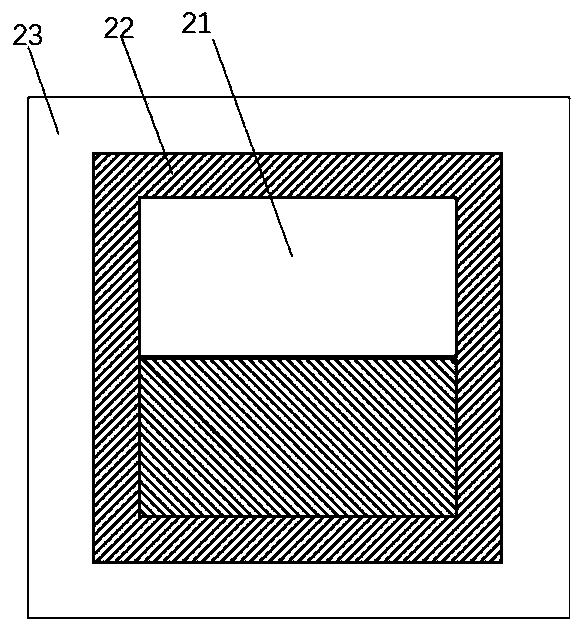

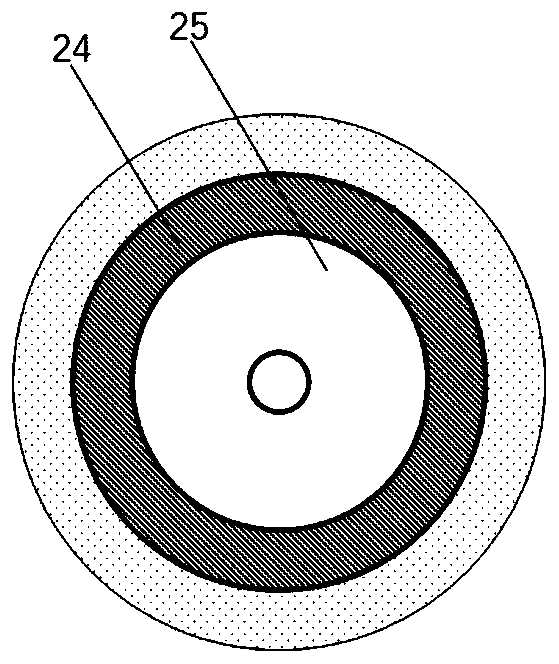

Anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof

The invention discloses an anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof. The anhydrous foam generator has the following structure: a sand adding port, a liquid CO2 second injection port and a safety valve are arranged at the top of a propping agent storage tank; the bottom of the propping agent storage tank communicates with a high-pressure gasand liquid mixer through a propping agent discharging pipe; the top of the propping agent storage tank communicates with a primary oscillator and a secondary oscillator through an exhaust pipe; a liquid CO2 first injection port, a N2 injection port and an anhydrous foam foaming agent injection port are formed in the side wall of the high-pressure gas and liquid mixer; and the side wall of the high-pressure gas and liquid mixer communicates with the primary oscillator through a liquid discharging pipe; and the primary oscillator, the secondary oscillator and a tertiary oscillator communicate with one another sequentially. According to the three tandem oscillation mode of the anhydrous foam generator, the anhydrous foam generator has the characteristic of efficient foaming, guarantees complete mixing of the liquid CO2, N2 and propping agent particles, enhances the foaming capability of the foaming agent for anhydrous foam fracturing, can generate uniform and compact anhydrous foam fracturing liquid, contributes to improving the fracturing efficacy and greatly reduces formation damage.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Self-foaming flushing fluid tackifier, flushing fluid configuration reagent, and flushing fluid

InactiveCN105131924APrevent leakageImprove stabilityDrilling compositionSodium bicarbonateSodium Bentonite

The invention belongs to the field of oil and gas field well drilling, and more specifically provides a self-foaming flushing fluid tackifier, a flushing fluid configuration reagent, a flushing fluid, and a preparation method of the flushing fluid. The self-foaming flushing fluid tackifier is mainly composed of a fracturing thickening agent, a biopolymer, a high molecular filtrate reducer, polyvinyl alcohol, sodium bicarbonate, and bentonite at a certain ratio; the flushing fluid configuration reagent is mainly composed of the self-foaming flushing fluid tackifier; and the flushing fluid is mainly prepared from the flushing fluid configuration reagent. The flushing fluid possesses following beneficial effects: safety guarantee is provided; inert gas cost is reduced; sand carrying capability is excellent; inhibitive ability is excellent; foam liquid water loss is relatively low; return permeability is excellent; compatibility is excellent; and the flushing fluid is convenient for construction, and is low in corrosivity.

Owner:任丘市奥源石油科技有限公司

Rectorite saturated brine drilling fluid for drilling under rock salt deep stratum

InactiveCN101914371ADeep Formation Drilling Work Goes SmoothlyDrilling work goes wellDrilling compositionRock coreCarrying capacity

The invention discloses a rectorite saturated brine drilling fluid for drilling under a rock salt deep stratum and belongs to the technical field of drilling and oil exploitation. The drilling fluid is prepared from an auxiliary agent, NaCl and water according to a certain proportion, wherein the auxiliary agent at least comprises 1 to 8 percent of sodium base rectorite, 0.2 to 14 percent of main fluid loss agent, 0.1 to 5 percent of auxiliary fluid loss agent, 0.1 to 1 percent of coating agent, 1 to 5 percent of wall protective agent, 1 to 5 percent of lubricant, 0.1 to 0.5 percent of antifoaming agent and 0.1 to 0.5 percent of NaOH, wherein the NaCl is in a saturated state in the drilling fluid. The drilling fluid of the invention can still keep good rheological property, prop-carrying capacity and filtration property resistance at the highest temperature of 200 DEG C, can quickly and safely drill in a salt layer, guarantees the smooth drilling operation under the deep stratum salt layer and is particularly suitable for drilling under the rock salt deep stratum and extracting rock cores.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

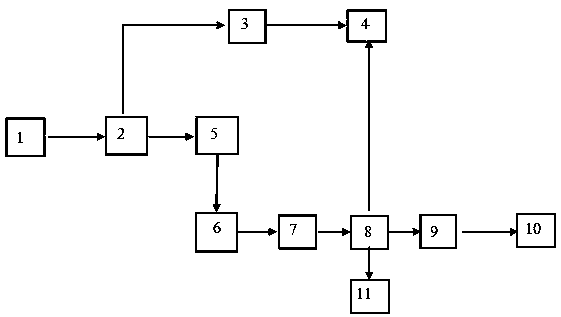

Fracturing flow-back fluid recycling treatment process

InactiveCN107840481ASatisfy the discharge requirementsStrong ability to carry sandWaste water treatment from quariesMultistage water/sewage treatmentLiquid storage tankTime-Consuming

The invention belongs to the technical field of waste water treatment and reuse in exploitation of oil and gas fields, and concretely relates to a fracturing flow-back fluid recycling treatment process. The fracturing flow-back fluid recycling treatment process is characterized by comprising a fracturing well head, a high-pressure gas-liquid separation device, a filtering cylinder filter, a gas combustion pot, a sterilization processing apparatus, a pH value adjusting and metal ion deposition apparatus, a flocculating settling apparatus, a low-pressure three-phase separator, a fine filter, a liquid storage tank, and a sand collection pot, the technical problem that fracturing flow-back fluid cannot be subjected to on-line recovery and re-utilization can be solved, and the problems that pollution environment and cost are high, the time consuming of the treatment process in the prior art for the fracturing flow-back fluid is long, and land occupation of processing equipment and the liquid storage tank is large can be solved. The treatment process realizes fine recycling of the fracturing flow-back fluid and on-line processing and recycling of the fracturing flow-back fluid, reliabledegree of the treatment process is high, operation is simple, on-site enforcement performance is strong, the processed flow-back fluid is used for fluid preparation construction, application propertyis stable, liquid sand-carrying capacity is strong, utilization rate of the flow-back fluid can achieve 98%, and on-site construction cycle is shortened.

Owner:PETROCHINA CO LTD

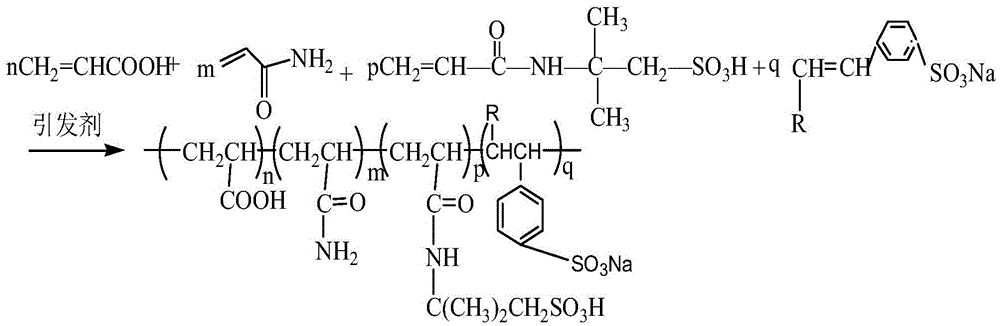

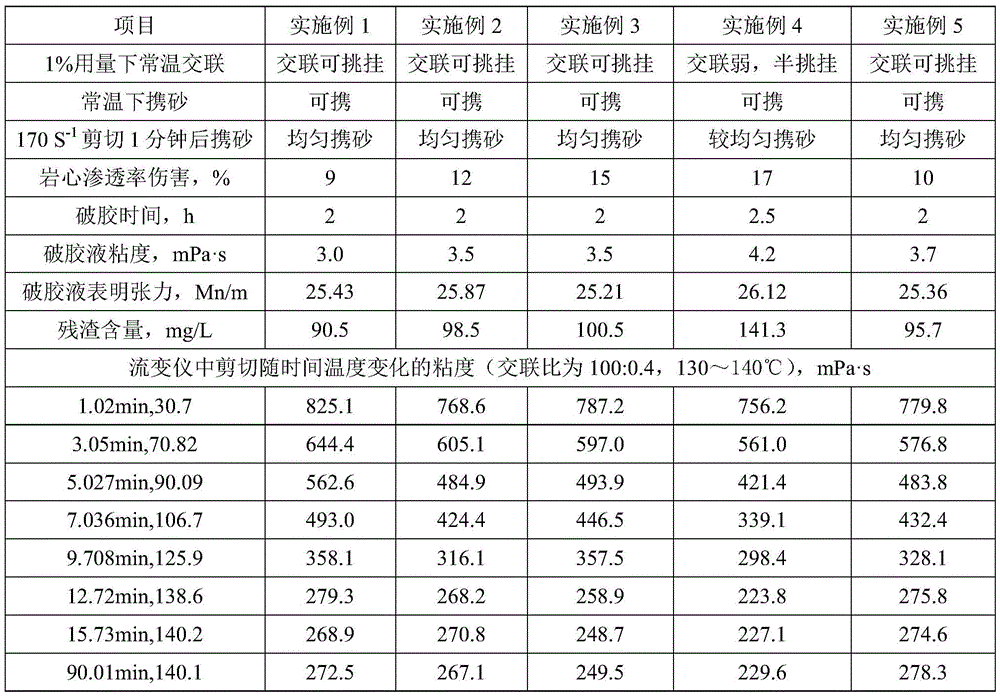

A kind of high temperature resistant thickener and its preparation method and application

ActiveCN104109219BImprove sand carrying capacityImprove shear resistanceDrilling compositionHigh resistancePolymer science

Owner:CHINA PETROLEUM & CHEM CORP +1

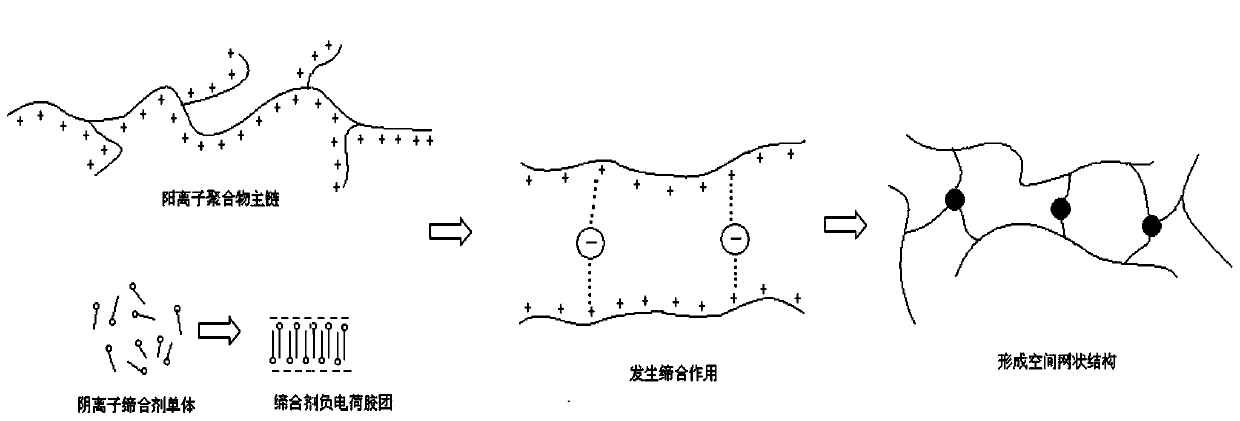

A kind of multi-component associative polymer cleaning fracturing fluid thickener and preparation method

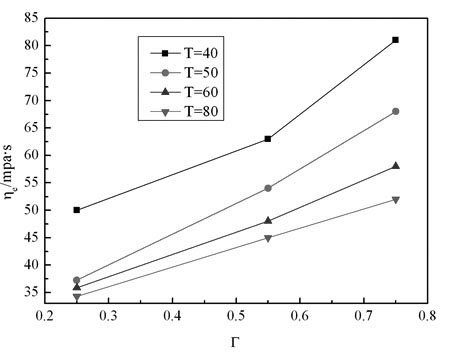

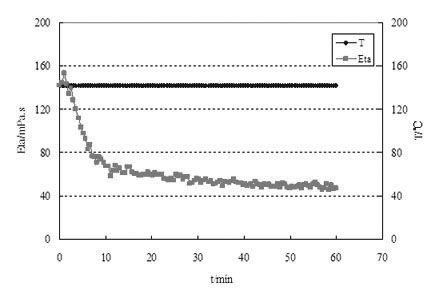

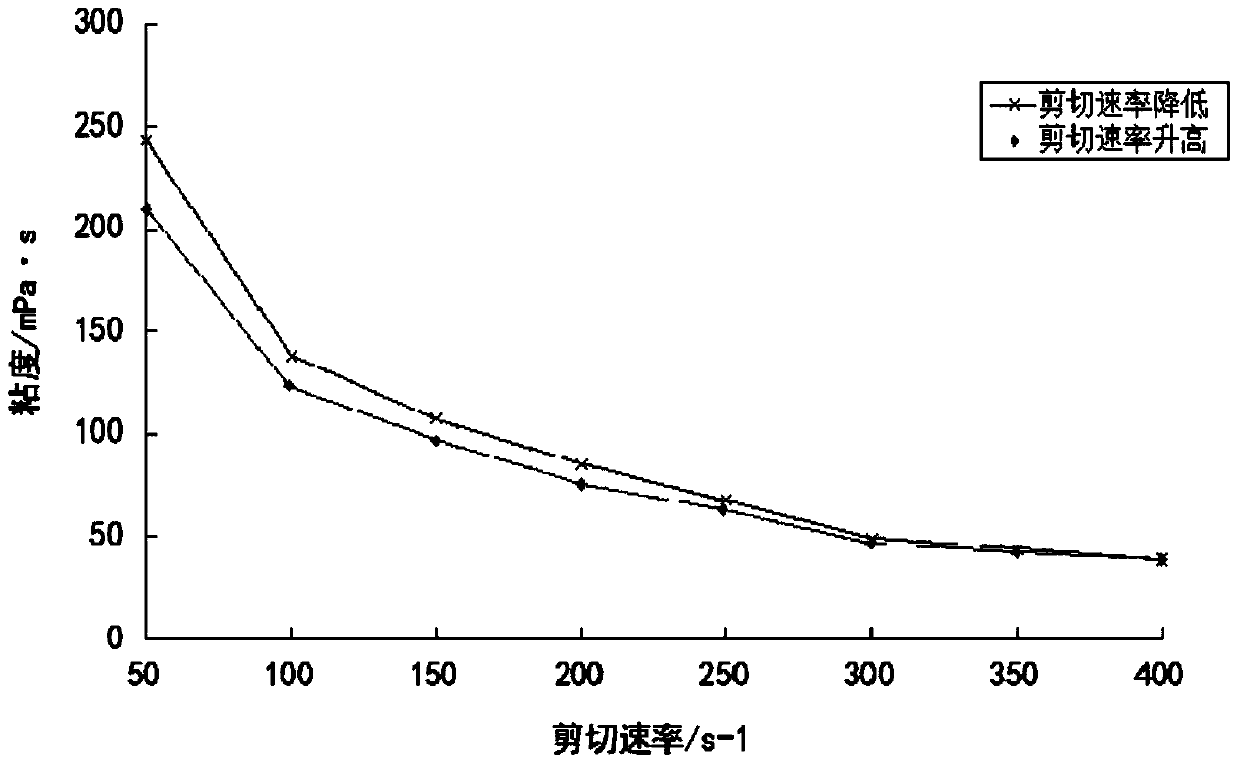

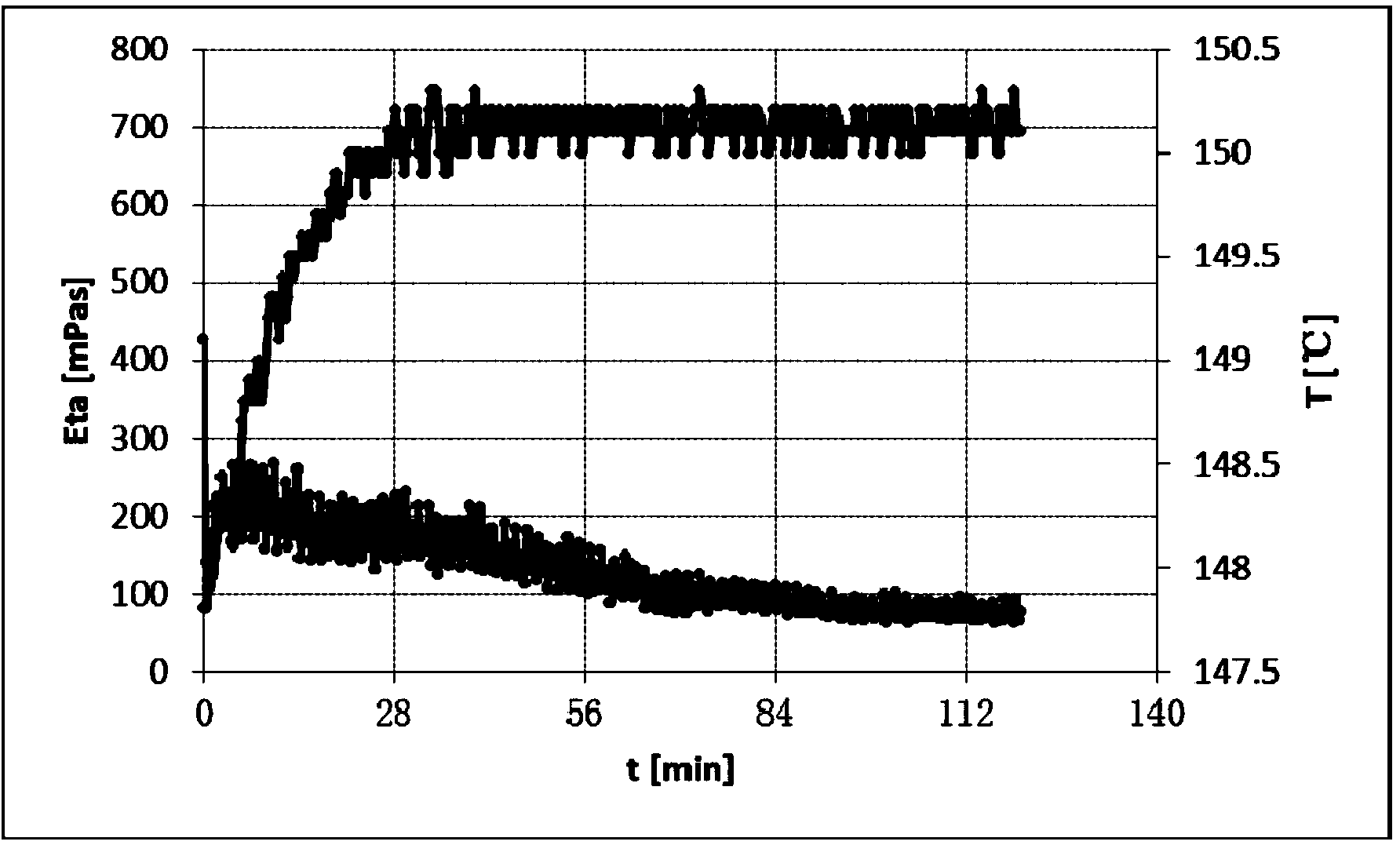

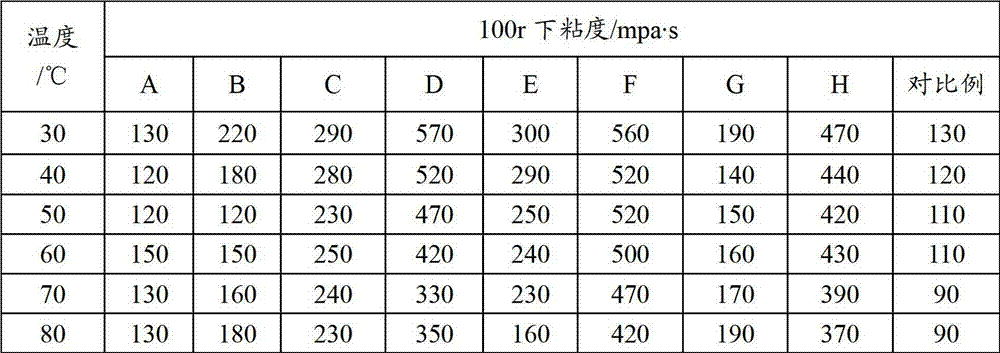

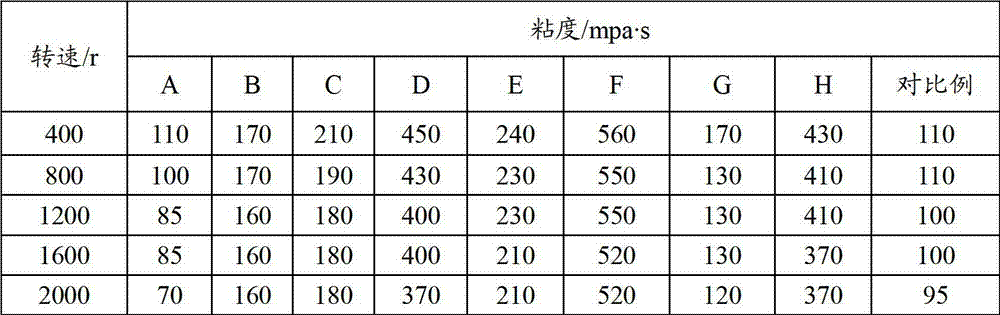

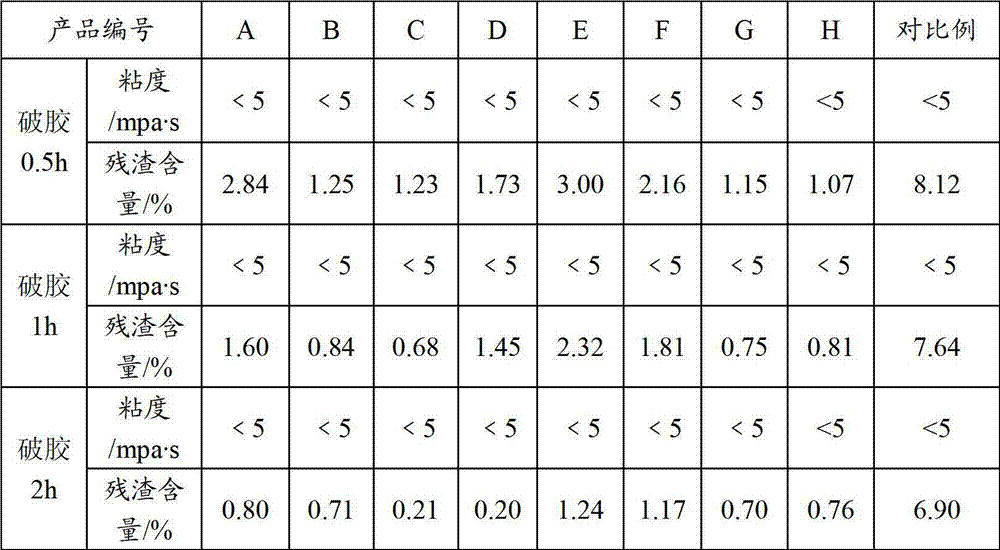

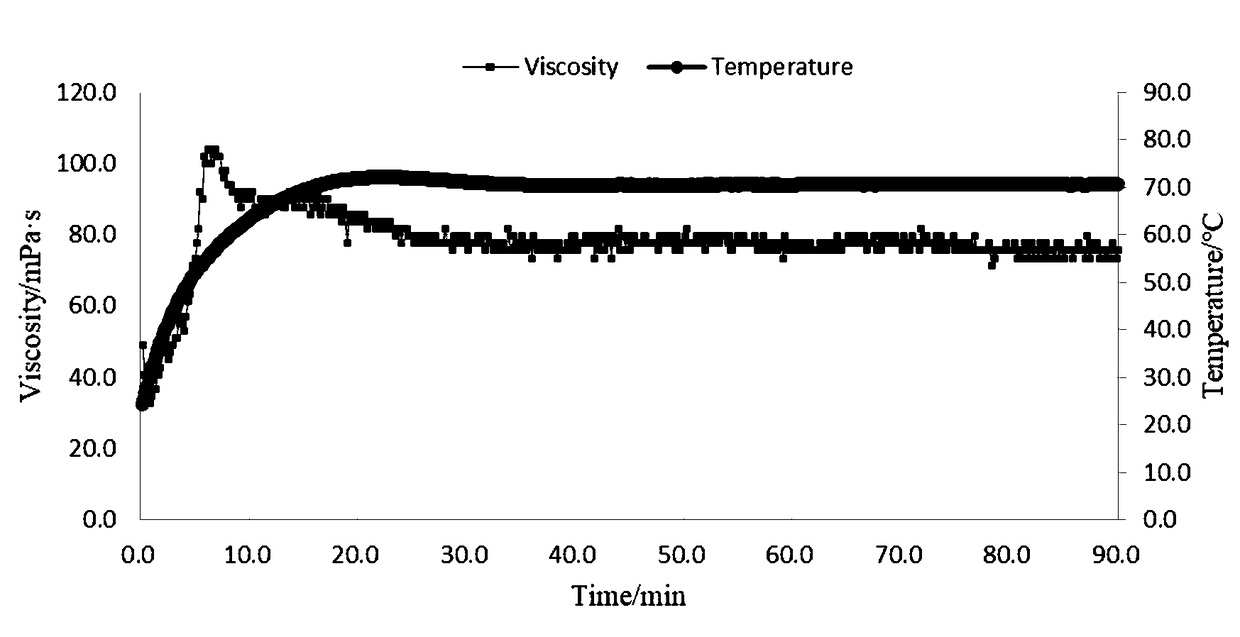

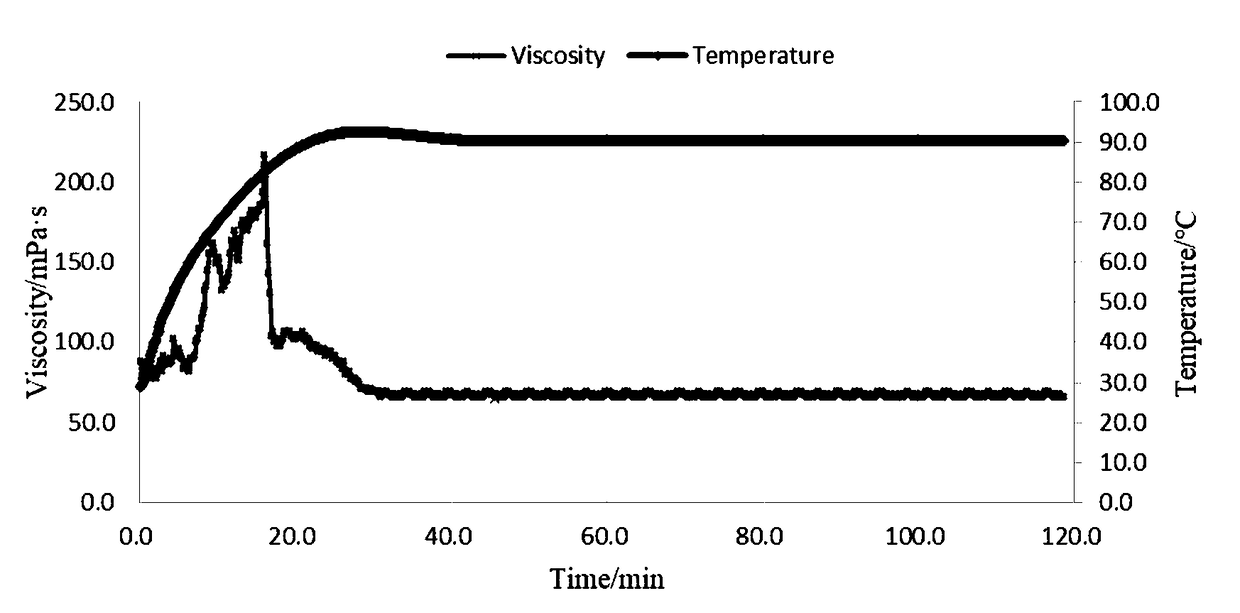

The invention relates to a multiple association type polymer cleaning fracturing fluid thickening agent, wherein evaluation indicators comprise that: 0.3% aqueous solution 20 DEG C viscosity is more than or equal to 30 mPa.s, solution viscosity after gel breaking is less than or equal to 5 mPa.s, and a static sand suspending time is more than or equal to 10 min. The invention further discloses a method for preparing the multiple association type polymer cleaning fracturing fluid thickening agent.

Owner:北京爱普聚合科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com