Clean polymer-free carrier fluid

A sand-carrying liquid and cleaning technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as difficult to meet high-temperature sand-carrying performance, damage to residue permeability, easy corruption of sand-carrying liquid, etc., and achieve good carrying capacity Sand ability, uniform dispersion reduction, and the effect of increasing sand concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

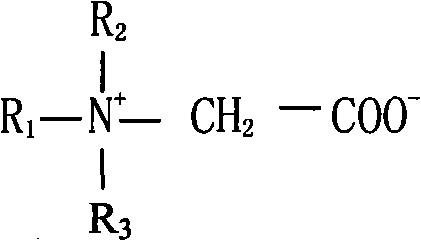

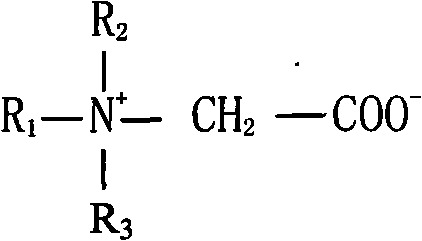

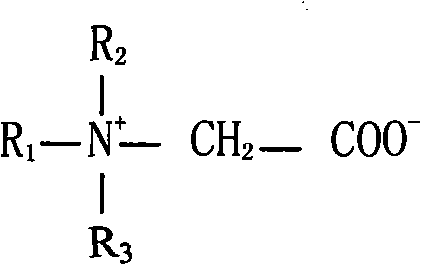

[0032] The invention discloses a novel surfactant for thickening, which belongs to the long-chain betaine surfactant,

[0033] It is a common amphoteric surfactant with the chemical formula:

[0034]

[0035] Among them, R 1 for C 16 -C 22 Hydrocarbyl, which can be linear or branched, stable or unstable; R 2 and R 3 for C 1 -C 4 Hydrocarbyl, can also be substituted by other groups, such as -OH. The following types of betaine-type surfactants can be used: cetyl dimethyl betaine, octadecyl dimethyl betaine, eicosyl dimethyl betaine, tallow diethyl betaine Wait. The basic dosage is 0.5%-15%. The specific dosage in field use depends on the performance requirements of the sand-carrying fluid. The optimized dosage is generally 2.0%-8%.

[0036] The introduction of the betaine group strengthens the biodegradability of the surfactant, has no toxic side effects on the environment, and reduces the adsorption amount of the formation, and the adsorption damage to the oil reser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com