Fracturing flow-back fluid recycling treatment process

A technology for recovery and treatment of fracturing flowback fluid, which is applied in the fields of mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Issues such as online recycling, processing equipment and large storage tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

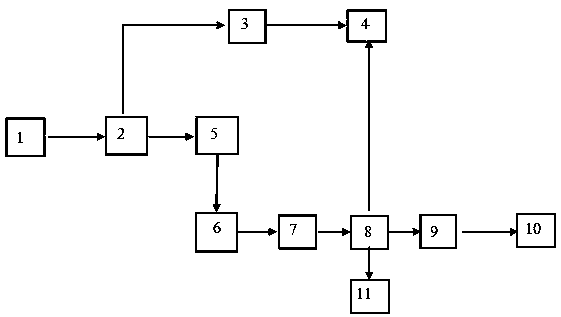

[0021] Such as figure 1 As shown, a fracturing flowback fluid recovery treatment process includes a fracturing wellhead 1, and is characterized in that it also includes a high-pressure gas-liquid separator 2, a cartridge filter 3, a gas combustion tank 4, a sterilization treatment device 5, and a pH Value adjustment and metal ion precipitation device 6, flocculation and sedimentation device 7, low-pressure three-phase separator 8, fine filter 9, liquid storage tank 10 and sand collection tank 11, the outlet of the fracturing wellhead 1 is connected to high-pressure gas-liquid separation The inlet of device 2, the outlet of high-pressure gas-liquid separator 2 connect the inlet of filter cartridge filter 3 and the inlet of sterilizing treatment device 5 respectively, the outlet of filter cartridge filter 3 connects the inlet of gas combustion tank 4, and the inlet of sterilizing treatment device 5 The outlet is sequentially connected to the pH value adjustment and metal ion pre...

Embodiment 2

[0023] Such as figure 1 As shown, on the basis of Example 1, the high-pressure gas-liquid separator 2 is provided with a cyclone separation element and a grit chamber. The high-pressure gas-liquid separator has the function of cyclone sand removal, and is provided with a cyclone separation element and a grit chamber. When the high-pressure fluid passes through the cyclone separation element, under the action of centrifugal force and gravity, the liquid and solid sand enter the settling In the tank, the gas enters the gas combustion tank from the upper pipeline, and the structure is simple; when the gas separated by the high-pressure gas-liquid separator 2 contains less solids, it can be directly connected to the gas combustion tank 4 instead of passing through the cartridge filter 3 for sand removal.

[0024] Further, the cartridge filter 3 includes a two-stage filter device, the first-stage filter device is a sand removal bucket and the gas enters the sand removal bucket alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com